Page 1

V l*i-^ii-^ ' «-rf-f

OPERATORS IN

The UIHITE FUp-Top

i

Page 2

[. FEATURES AND PARTS

Principle Parts................................................................................................................4—5

II. ACCESSORIES.................................................................................................................. 6

Contents of Accessory Set..................................................................................................6

III. YOUR SEWING MACHINE AND CASE..........................................................................7-8

Portable Case..................................................................................................................... 7

Setting the Extension Flaps for Sewing on Flat Sewing Surface

Setting Flaps for Free-Arm Sewing.................................................................................... 7

Electrical Connections.........................................................................................................8

Sewing Light...................................................................................................................... 8

IV. PREPARING THE MACHINE TO SEW...................................................................... 9-11

Winding the Bobbin.

Lower Threading.............................................................................................................. 10

Threading the Bobbin Case..................................................................................... 10

Placing Bobbin Case in Shuttle................................................................................. 10

Upper Threading............................................................................................................ 11

V. CHOOSING THE RIGHT NEEDLE..............................................................................12-14

Types of Needles................................................................................................... 12—13

Needie-Thread-Fabric Chart................................................................................... . 12—13

Changing the Needle...................................................................................................... 14

Changing the Needle Plate.............................................................................................. 14

VI. GETTING TO KNOW YOUR SEWING MACHINE.....................................................15-21

Adjusting the Stitch................................................................................................... 15—17

Stitch Length Dial...................................................................................................... 15

Reverse Lever....................................................................................................... 15

Stitch VA/idth Dial.................................................................................................... 15

Relating Stitch Length to Stitch Width

Pattern Selector Dial......................................................................................... 16—17

Pattern Selector Release Button........................................................................16—17

Pattern indicator Window

One Step Buttonhole Control Dial............................................................................. 18

Stitch Density Control................................................................................................ 18

Needle Position..................................................................................................... 19

Adjusting for the Fabric.................................................................................................... 19

Feed Dog Control...................................................................................................... 19

Pressure Control , ................................................................................................. 19

Tension........................................................................................................................... 20

Adjusting the Thread Tensions................................................................................ 20

The Proper Presser Foot

Changing the Foot................................................................................................... 21

The AH Purpose Foot................................................................................................21

The Straight Stitch Foot

The Buttonhole Foot................................................................................................ 21

The Embroidery Foot............................................................................................. 21

The Cording and Zipper Foot....................................................................................21

VII. HOW TO SEW............................................................................................................22-23

Pinning......................................................................................................................... 22

Placement of Fabric/Starting a Seam..............................................................................22

Guiding the Fabric......................................................................................................... . 22

Etched Seam Guide............................................................................................... 22

Cloth Guide.......................................................................................................... 22

Presser Foot as a Guide.......................................................................................... 22

..............................................................................................

.......................................

...

.................................................................................................... 9

....................................................................

.................................................................................

.............................................................................................

........................................................................................... 21

16—17

4-5

7

15

21

Page 3

Holding the Fabric...................................................................................................... 23

Turning Corners..........................................................................................................23

Curved Seams........................................................................................................... 23

Sewing Across Heavy Seams.................................................................................... 23

Ending Seam/Removai of Fabric................................................................................23

Vm. APPLICATIONS OF THE STRAIGHT STITCH

Seams

Basting/Topstitching. . . ¿T4T . 24

Darning........................................................................................................................ - ■ 24

Elastic Thread Shirring......................................................................................................24

IX. APPLICATIONS OF THE ZIGZAG STITCH.........................................................25-29

Overcasting................................................................................................................... 25

Seaming Knits...................................................................................................................25

Sewing on Buttons

Satin Stitching. ................................................................................................................ 26

Tapering/Creative Embroidery......................................................................................... 26

Freehand Monogramming................................................................................................27

Applique.................................................................................-

Gathering Over a Cord.................................................................................................... 28

Lace Applications........................................................................................................... 29

Flutter Hems. .................................................................................................................. 29

X. BUTTONHOLES.....................................................................

Preparation ................................................................................................................... 30

Built-in One Step Buttonholer......................................................................................... 31

Turn-Around Buttonholes............................................................................................... 32

Corded Buttonholes....................................................................................................... 33

Stretch Buttonholes

XI. APPLICATIONS OF THE BLIND HEM STITCH

Hemming..................................................................................................................... 35

Decorative Effects........................................................................................................... 36

Topstitch Effects............................................................................................................... 36

Decorative Stitch Combinations..................................................................................... 36

XII. APPLICATIONS OF THE STRETCH BLIND HEM

Hemming..........................................................................................................................37

Edging.......................................................................................................................... 37

Eyelash Buttonholes....................................................................................................... 37

XIII. APPLICATIONS OF THE MULTIPLE STITCH ZIGZAG

Overcasting.................................................................................................................... 38

Patching........................................................................................................................ 38

Mending a Tear or Instant Darning................................................................................. 38

Elastic Application........................................................................................................ 39

Understitching Facings............................................................................................ ..39

Decorative Effects.......................................................................................................... 39

XIV. APPLICATIONS OF THE SCALLOP STITCH...........................................................40

Hemming. ........................................................................................................................40

Decorative Effects............................................................................................................40

XV. APPLICATIONS OF THE REVERSE BLIND HEM STITCH

Shell Tuck ........................................................................................................................40

XVI. APPLICATIONS OF THE INTERLOCK

Shell Tuck........................................................................................................................41

........................................................................................................................... ‘

...

...................................................................................................... 25

Forming a Thread Shank.......................................................................................... 26

Manual Embroidery Designs................................................................................... 27

........................................................... -............................................34

...................

Lingerie Seam..................................................................................................................41

Inserting Lace.............................................................................................................. 41

.........................................................

........................................

...

............................

..................................................

...................................................

....................................

.....

...........................40

..............................................

30-34

35-36

38-39

24

28

37

41

Page 4

XVI!.

XVII!.

XIX.

XX.

XXI.

XXM.

XXIII.

XXIV.

XXV.

XXVI.

XXVII.

XXVII!.

XXIX.

XXX.

XXXI.

APPLICATIONS OF THE CHECKER STITCH

AND THE DOMINO STITCH........................................................................................... 42

Decorative Effects........................................................................................................... 42

Corded Decorative Effects............................................................................................. 42

APPLICATIONS OF THE REVERSE STITCH PATTERNS

Decorative Effects .......................................................................................................... 43

APPLICATIONS OF THE CROWN STITCH ....................................................................44

Decorative Effects.......................................................................................................... .44

APPLICATIONS OF THE CROSS STITCH.................................................................... 44

Decorative Effects. ,

APPLICATIONS OF THE OVERLOOK STITCH....................................................... 45-47

Seams........................................................................................................................... 45

Nylon Tricot Seams...........................................................................................................46

Applying Elastic.................................................................................................................46

Ladder Stitch................................................................................................................... 46

Hemstitching................................................................................................................... 47

Topstitching...................................................................................................................... 47

APPLICATIONS OF THE STITCH AND OVERCAST......................................................48

Seams........................................................................................................................... 48

Applying Ribbing............................................................................................................. 48

APPLICATIONS OF THE FAGOTING STITCH................................................................48

Decorative Effects.............................................................................................................48

APPLICATIONS OF THE SMOCKING STITCH...............................................................49

Seams............................................................................................................................... 49

Elastic Shirring.............................................................................................................. 49

Decorative Effects — Baseball.........................................................................................49

APPLICATIONS OF THE ELASTIC EDGING STITCH

Topstitching.......................................................................................................................50

Edging...............................................................................................................................50

APPLICATIONS OF THE STRETCH OVERLOOK

APPLICATIONS OF THE STRAIGHT STRETCH STITCH

Seams...............................................................................................................................51

Topstitching..................................................................................................,. . ..............

APPLICATIONS OF THE RICK-RACK STITCH...............................................................52

Topstitching..................................................................................................................... 52

Tapering............................................................................................................................52

TWIN NEEDLE SEWING......................................................................................... 53-54

Twin Needle Sewing Effects............................................................................................ 53

Pin Tucks.................................................................................................................... 54

Decorative Tucks or Designs............................................................................................54

FREE ARM SEWING....................................................................................................... 55

USE OF ACCESSORIES............................................................................................... 56

Cording and Zipper...........................................................................................................56

...

......................................................................................................44

.........................................................

............................................

....................................................

.............................................

43

50

51

51

51

XXXII.

xxxm.

XXXIV.

ADDITIONAL SPECIAL ACCESSORIES........................................................................ 57

Roller Foot........................................................................................................................57

Overcast Foot...................................................................................................................57

Blind Hem Foot................................................................................................................ 57

Roller Hem Foot............................................................................................................ 57

Fringe Foot..................................................................................................................... 57

CARE AND MAINTENANCE OF YOUR SEWING MACHINE

Changing Needle............................................................................................................ 58

Cleaning

Oiling ....

Changing the light bulb.....................................................................................................59

MINOR PROBLEMS AND THEIR SOLUTIONS

...........................................

........................................................................................................................ 59

....

................................................................ 58

....................................................

............................

58-59

60-61

Page 5

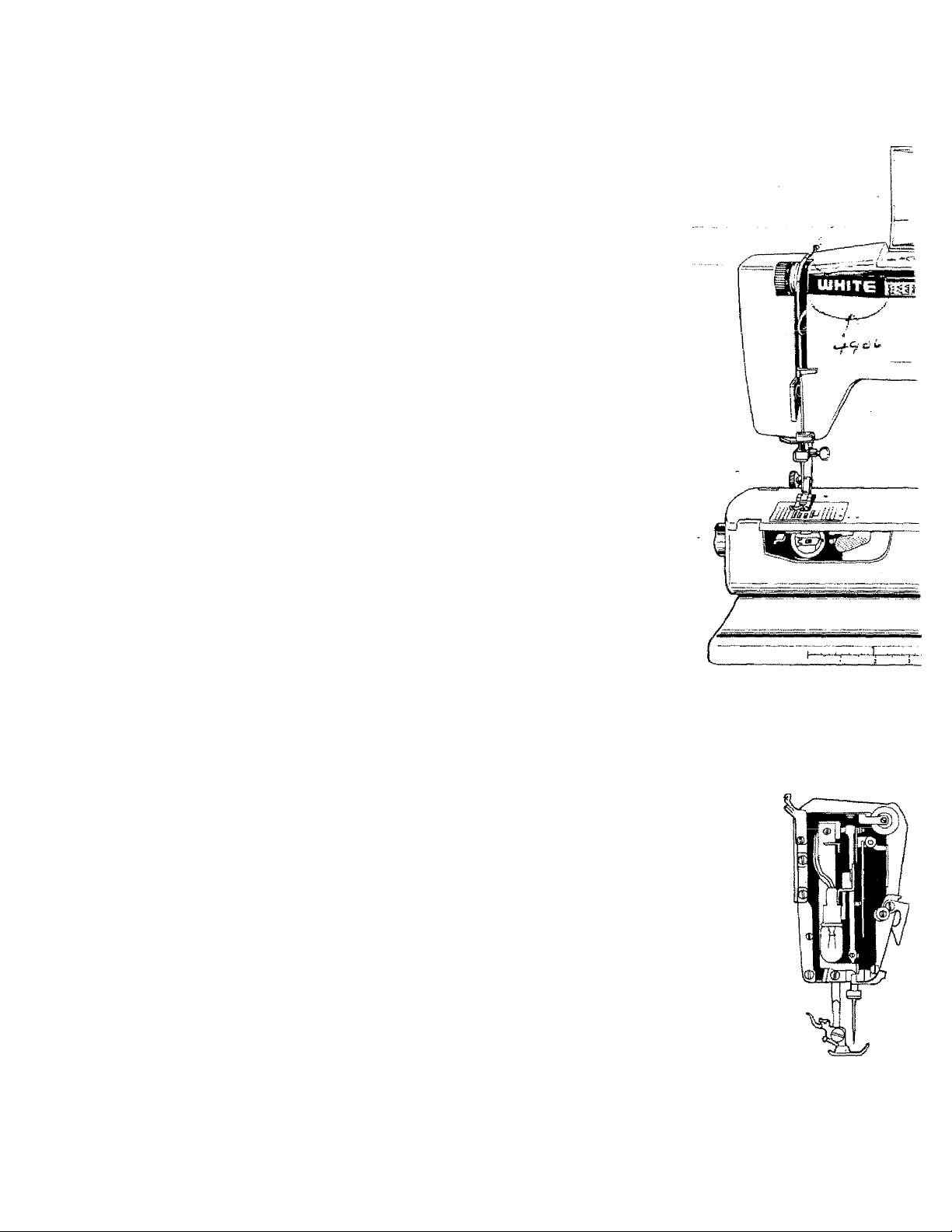

PRINCIPLE PARTS

Controi Panel Cover ,. ^

covers pattern selector dial, release button, one-step buttonhole

control dial, stitch density controi, bobbin winder and bobbin

winder guide.

Pattern Selector Dial

selects pattern desired. May be turned in any direction.

Pattern Selector Release Button

is pushed down to release pattern selector dial.

<■" Pattern indicator Window

shows all the stitch patterns available. Relative stitch length

setting is color coded for each stitch pattern. Yellow indicator

shows the stitch chosen.

Tension Dial

has two discs which regulate the amount of tension on the

needle thread.

Take-up Lever

regulates the flow of thread through the needle. It has an

open eyelet to simplify threading. The take-up lever should

always be in the highest position when beginning or ending

sewing.

Face Plate

opens to the left to allow for easy changing of the light bulb.

Check Spring

helps control the flow of thread through the needle.

t-'t-C ,■ t 'i -

releases flaps for flat sewing surface,

holds the presser foot in place,

holds the needle in place.

holds the fabric in place for sewing. Snap-on feet are provided

with the sewing machine. Various interchangeable soles are

included in the accessory box. The front of the presser foot

shank is white to make needle threading easier.

Needle Plate Release Lever

pushes the needle plate up for easy removal.

moves the fabric after each stitch is formed, The diamond

points give a gentle feed for delicate fabrics as well as an

accurate feed for heavy fabrics.

has guide lines on the left and right for greater sewing

accuracy. It snaps off for easy cleaning.

Flat Sewing Surface Brace

holds flaps up for flat sewing airface.

Flat Sewing Surface Flaps

are released and braced whenever a flat sewing surface is

desired or access to the bobbin is needed.

controls the amount of pressure on the fabric. The illustrated

plate indicates the proper position for various fabrics.

Flap Release Knob

Thumb Screw

Needle Clamp Screw

Presser Foot

Diamond Point Feed Dog

Needle Plate

Pressure Control

Page 6

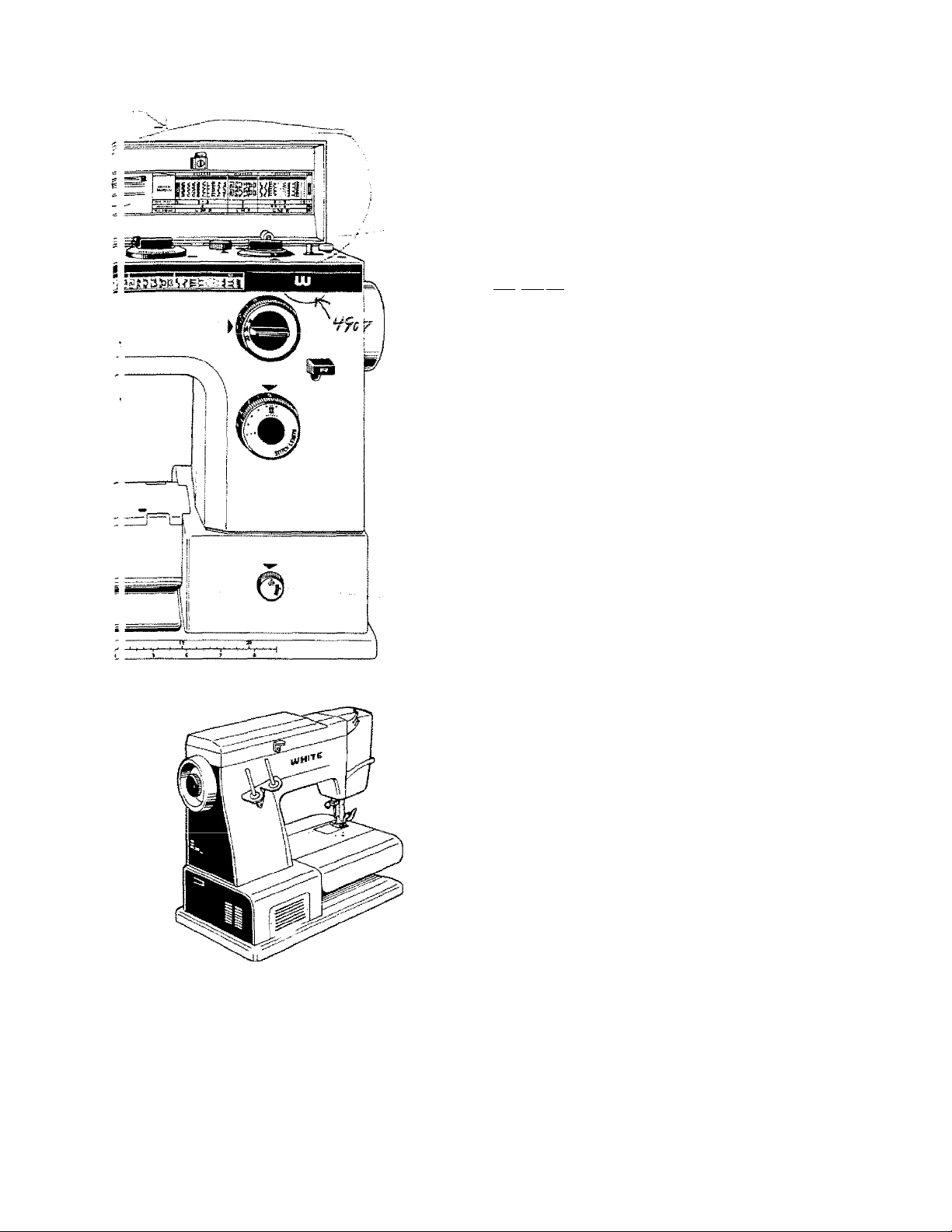

Bobbin Winder Tension Discs

controls the tension on the thread as the bobbin is being

wound.

Stitch Density Control

regulates the closeness or openness of the buttonhole side

and stretch stitches,

One Step Buttonhole Control Dial

Selects buttonhole length for automatic one-step buttonholes.

"^Bobbin Winder

□ lui'naL'iitafly'^topswindTnf~ii^en the bobbin is filled,

Hand Wheel

controls the up and down movemertt of the needle bar.

Always turn it toward you.

Stitch Width Dial

allows for precise adjustment of zigzag stitch width as well as

tapering.

Needle Position Dial

Is turned for needle position change.

Reverse Lever

allows for easy back-tacking to lock thread ends.

Stitch Length Dial

allows for precise adjustment of stitch length from very fine to

very long.

Feed Dog Control

adjusts the height of the feed dog for special sewing

applications.

Presser Foot Lever

controls the raising and lowering of the presser foot.

With the lever down, the presser foot holds fabric for ^wing.

With the lever up to its first position, the fabric can be turned

freely without release of upper thread tension or slack of

upper thread, for changing sewing direction or turning the

corner.

With the lever up to the second position, the upper thread

tension is completely released to remove fabric after sewing.

An extra lift is also available for placement of heavy, bulky

fabrics under the presser foot by holding the lever up to its

extreme top position.

Thread Cutter

is located on the back of the presser bar for convenience.

Spool Pins

hold all types of spools effectively.

Power Switch

turns on both motor and light simultaneously. Allows

selection of high and low speed.

Coupling Wheel

releases the movement of the needle bar in order to wind a

bobbin.

Page 7

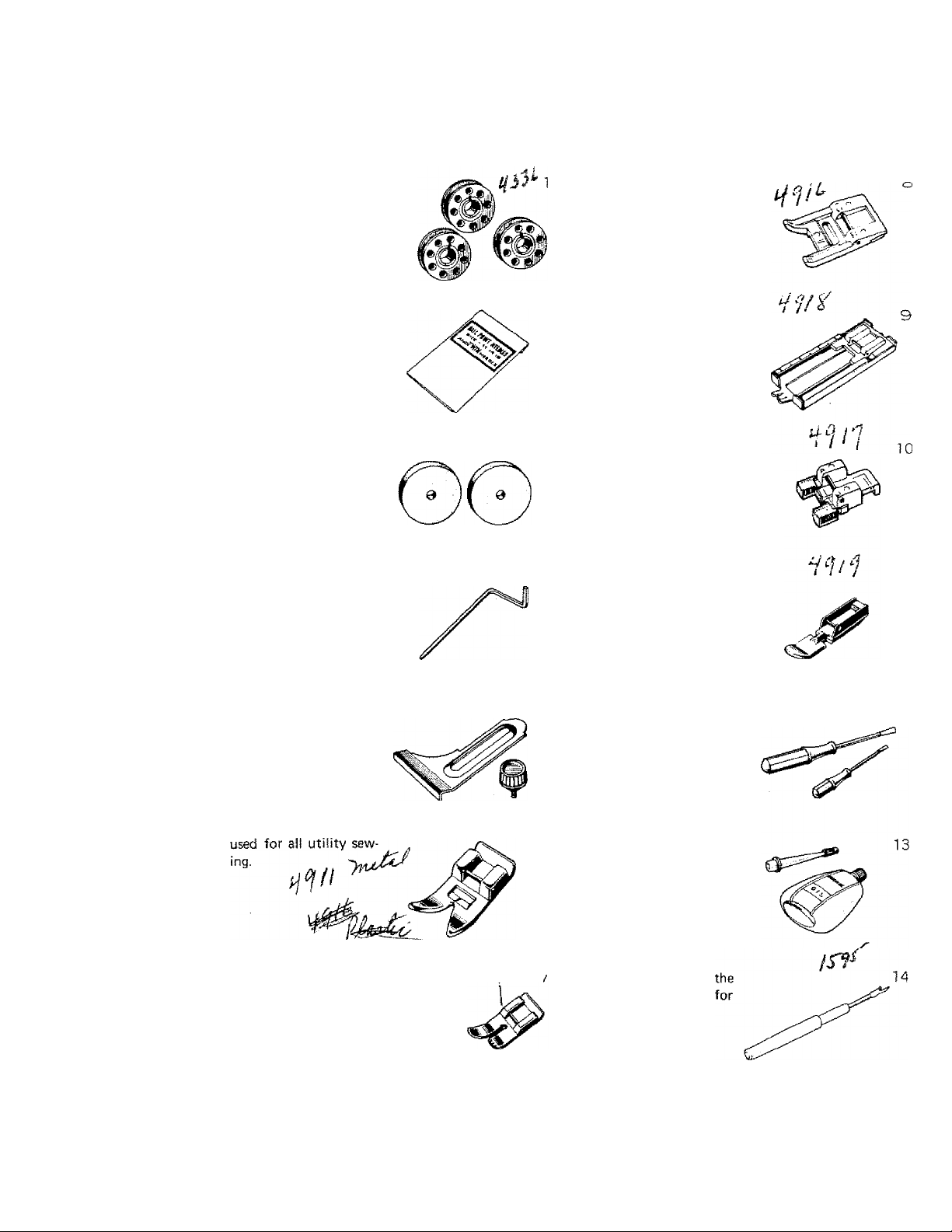

Your new White Rotary sewing nnachine comes equipped with the following set of acces

sories to make your sewing easier.

Three Metal Bobbins

The bobbins are made

of metal and hold

about 80 yards of

thread.

Needles / J 5^' '5

All-purpose needles sizes

11, 14 and 16 are

included. Twin needle

is also provided.

Two Felt Washers

Place the felt washers

under the spools for

best stitching results.

Quilting Guide

helps . make parallel

rows of stitching.

7^73 /

Embroidery Foot

has a wide groove on

the bottom which

allows the foot to pass

over dense stitches.

Also has two small tun

nels in front to accom

modate cord.

Buttonhole Foot

2

4-

has measuring lines to

insure exact buttonhole

length needed.

Button Sewing Foot

to hold button in place

for stitching.

Cording and Zipper Foot

for stitching very dose

to the edge of a cord or

zipper.

n

Cloth Guide and Screw

aids in sewing straight

seams.

All Purpose Foot

Straight Stitch Foot and

for straight sewing on

sheer and very light

weight materials where

extra support is needed.

7

Plate

Screw Drivers

Small one for use on

bobbin tension. Large

one for use on thumb

screw, needle clamp

screw, etc.

Tubed Oiler

for use in oiling the

machine. See page 59.

Seam Ripper

for cutting open

buttonholes and

removing stitches.

12

Page 8

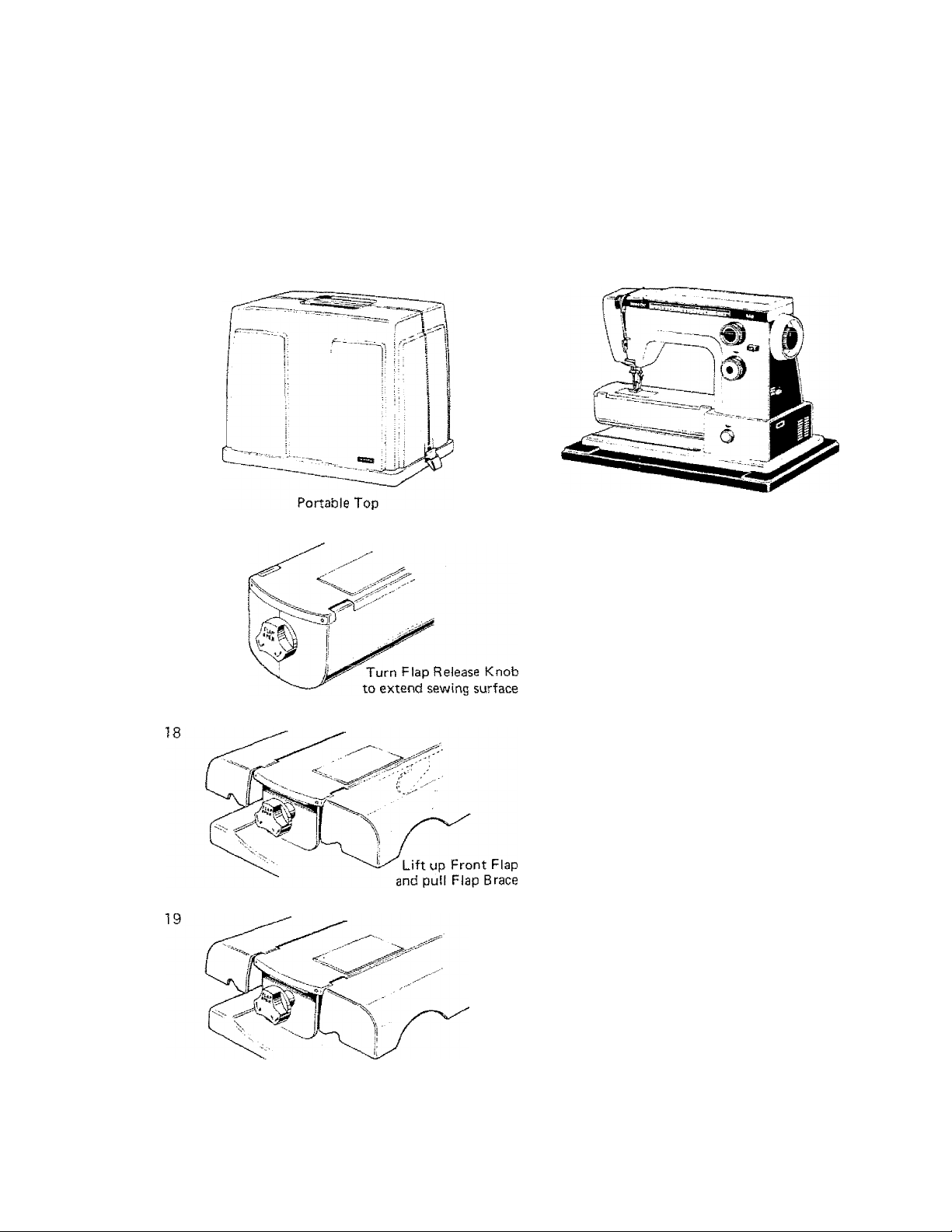

Portable case cover is fixed to the base with two latches at each narrow side of the cover, For

opening the case, press the latches out and down to release them from the hooks on the

bottom base of the case.

For closing, hang the latches to the hooks on the bottom base and press them up.

Unless installing machine into cabinet, it is not necessary to remove the bottom base of the

case from machine.

15

17

16

Sewing Machine and Base

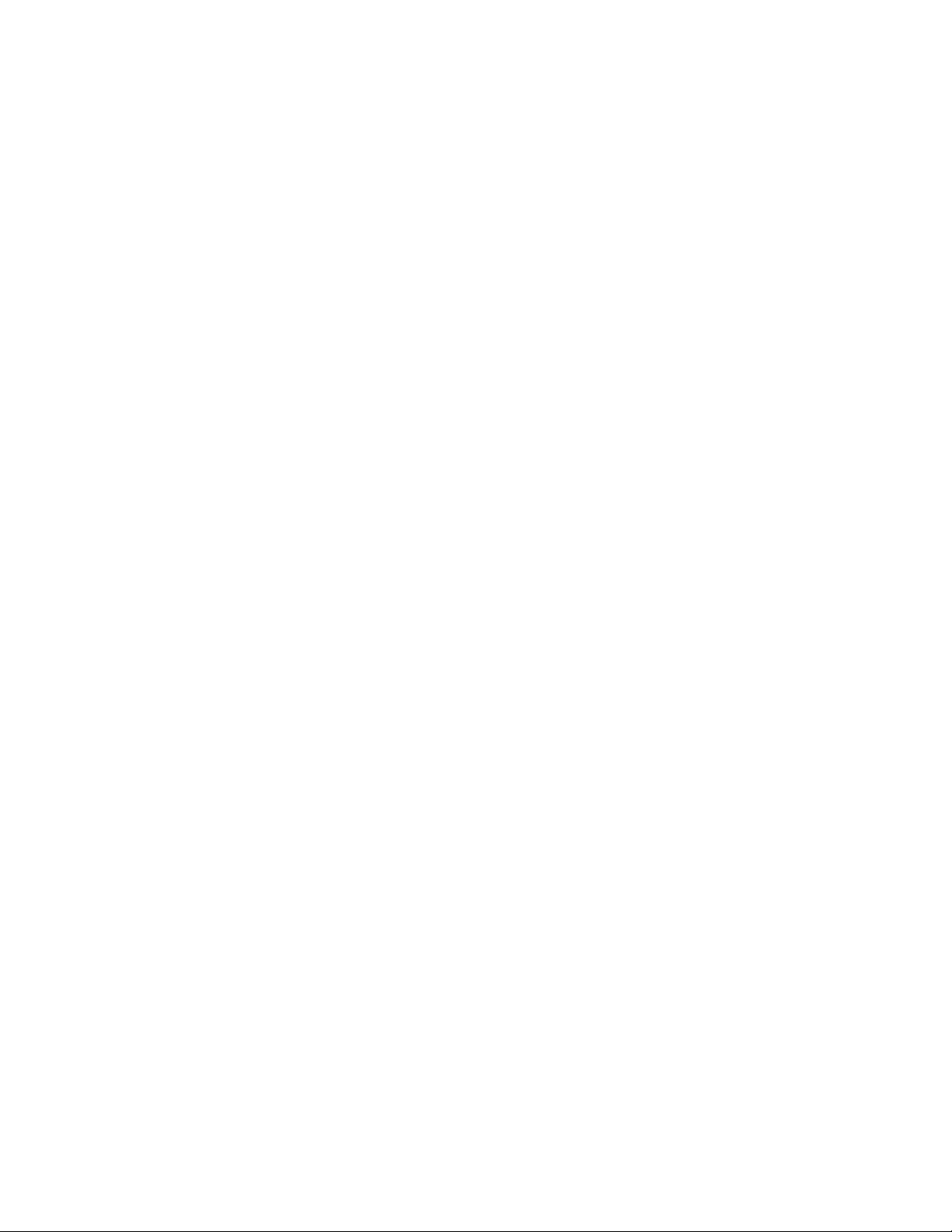

SETTING THE EXTENSION FLAPS

FOR SEWING ON FLAT SEWING

SURFACE

Turn flap release knob counter-clockwise

to release the front flap and clockwise for

the back flap. Pul! the flap brace to out

nnsitinn

SETTING FLAPS FOR FREE-ARM SEWING

Press the flap brace into the lower arm,

then, press both flaps down until they

click on the stopper latches of flap release

tM tuu*

Note: Free-arm setting of machine is for

simple handling of tubular and

hard-to-reach garment areas. (See

Page 55,1

Page 9

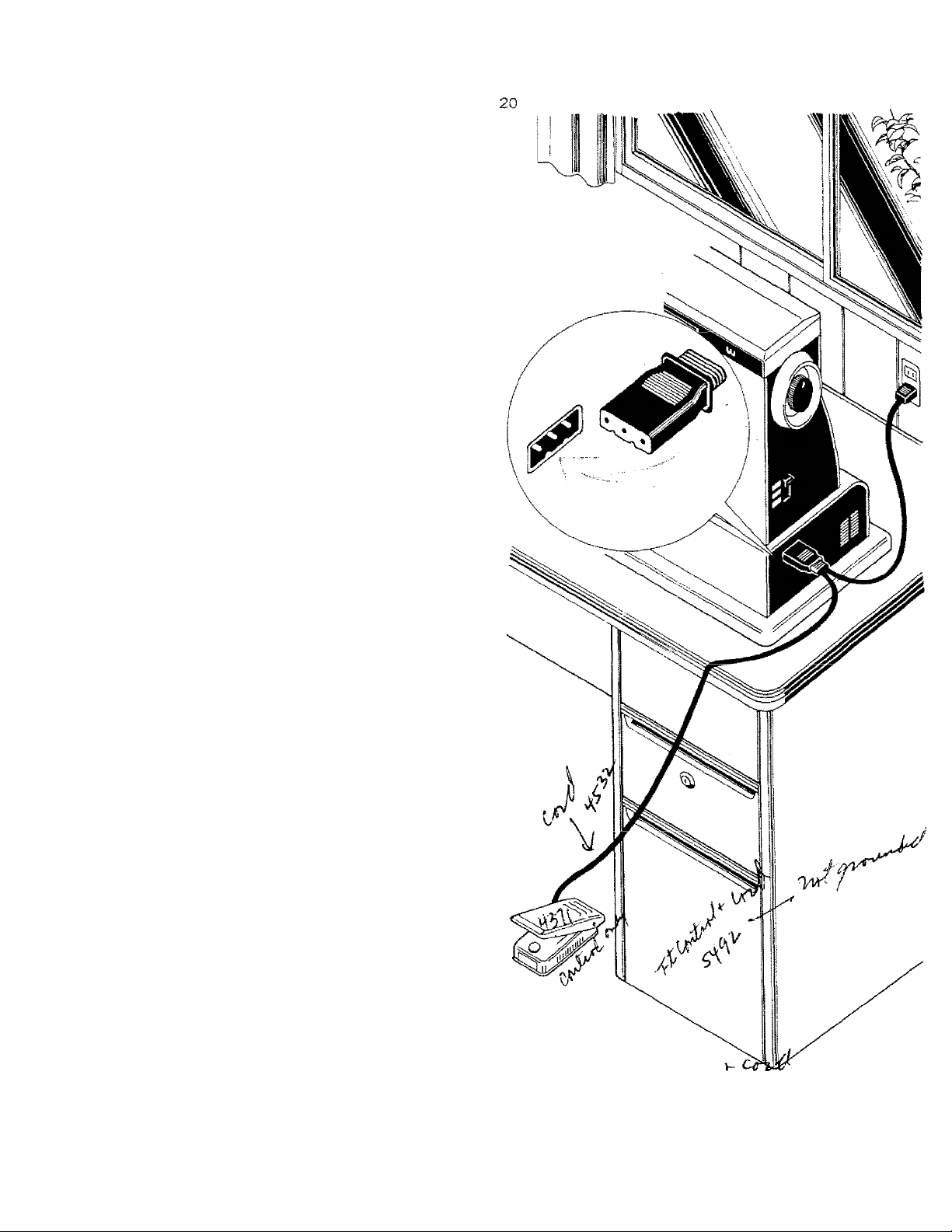

ELECTRICAL CONNECTIONS

Insert the plug with the indenta

tions on the underside into the

socket on the right side of the

machine. The plug will only go

in one way. Place the foot con

trol in such a position that your

foot rests comfortably on it.

insert the plug into a wall outlet,

110-120V.

SEWING LIGHT

The switch at the right side of

machine is the master switch for

on-off of both the light and the

motor. It is also for selection of

speed between fast and slow

sewing.

With the switch at "LOW" posi

tion, powerful slow speed sew

ing, less than 650 rpm is possible.

At "HIGH", sewing speed

reaches upto 950 rpm maximum.

The tight is turned on when the

switch is set at these positions.

At the lower range you may en

counter a noticable hum or in

crease in motor noise. This is

common due to the increased

power or torque needed to

operate your machine.

With the switch at "OFF" posi

tion, the electric circuits for both

light and motor are completely

shut off. When machine is not

in use, always turn the switch off

for safety.

Ths S6wiri3 iigHt is !oc3t6d in

face cover directly over the

needle to better illuminate the

stitching area.

With the power switch at the

right side of machine on "HIGH”

or "LOW” speed position, The

light simultaneously turns on,

and with the switch on "OFF"

the light also turns off.

TTC;.

Tt-

Page 10

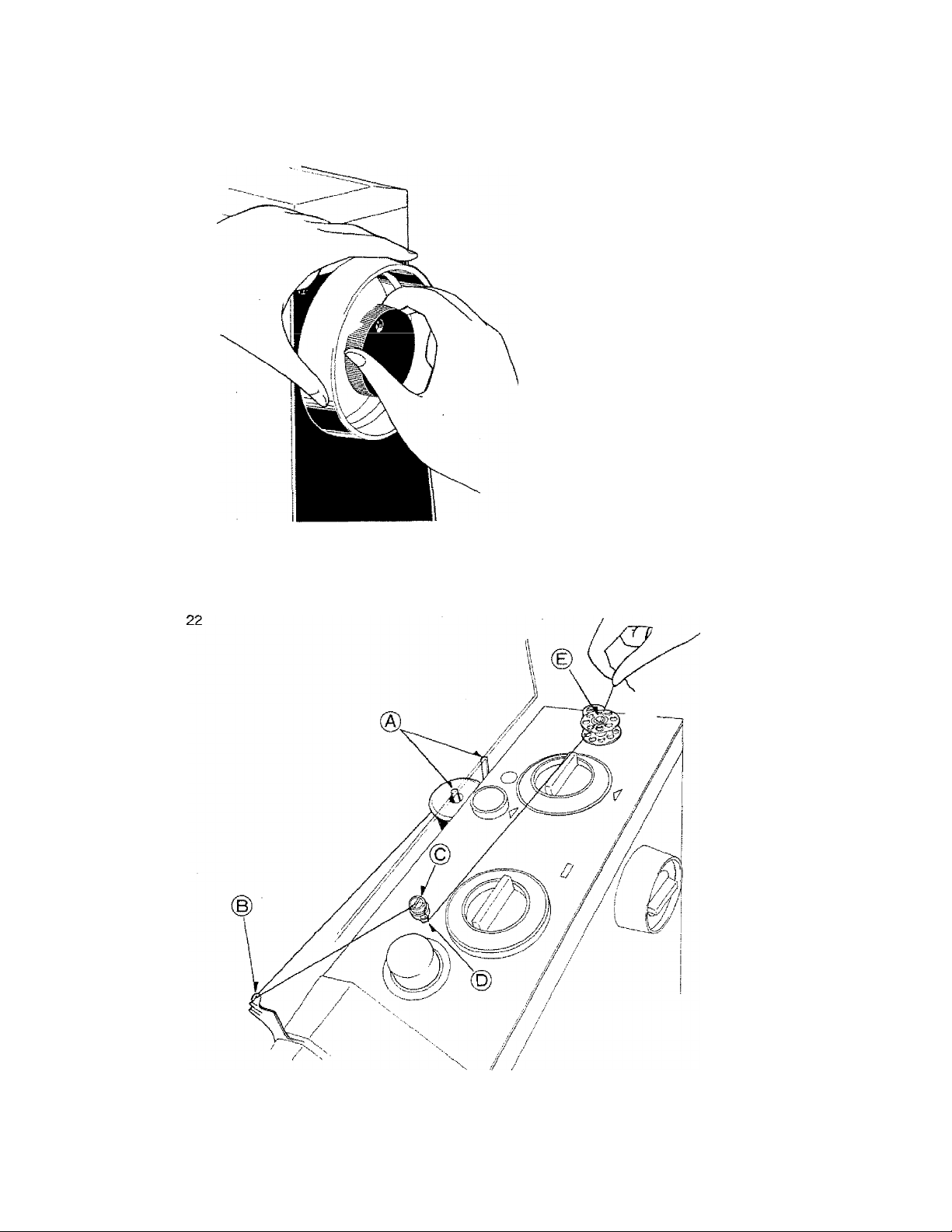

21

WINDING THE BOBBIN

Disengage the hand wheel by holding it

tightly with your ¡eft hand and turning

the coupling wheel toward you with your

right hand (Fig, 21), Place the spool

on spool pin (A), leaving about one foot

of thread free. Lead the thread around

the top thread hook of the guide (B) on

the left back of the machine and around

the bobbin winder tension disc (C). Then

thread guide (D) as illustrated (Fig, 22).

Run the end of the thread through a hole

on the riiTi of the bobbin on the spindle,

(E) and push the bobbin winder to the

right. Hold the thread end securely and

run the machine slowly. Bobbin will stop

\

turning when filled. Cut thread and push

bobbin winder to the left. Remove

\

bobbin from spindle. Tighten the coupl

ing wheel by turning it away from you as

you hold the hand wheel in place. The

needle should now move when you turn

the hand wheel.

Note: If the bobbin is winding unevenly,

adjust bobbin winder thread guide

(D) up or down as needed.

9

Page 11

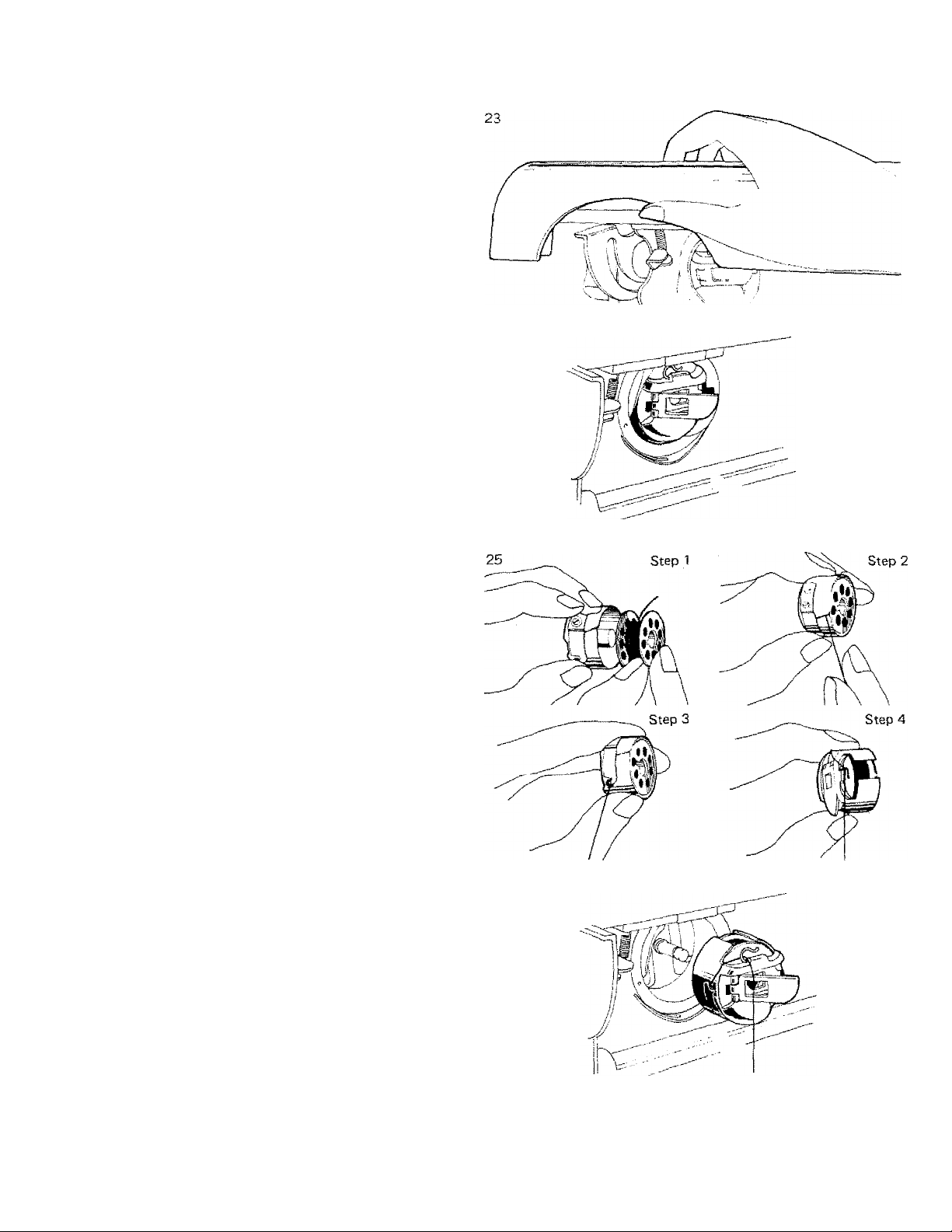

LOWER THREADING

• Threading Bobbin Case

Turn flap release knob back to

release the front flat sewing

surface flap. {Fig. 23) Raise the

front flap upward fully. Make

sure that the take-up lever is in

its highest position. Remove the

bobbin case, by opening the

bobbin case latch and pulling the

bobbin case out. (Fig. 24) Hold

the bobbin case between the

thumb and forefinger of the left

hand, so that the slot in the edge

of the bobbin case is on top.

Take the bobbin between the

thumb and forefinger of the right

hand so that the thread on top

leads from left to right. Insert

the bobbin into the bobbin case.

Draw the thread into the slot of

the bobbin case and then under

the tension spring into the fork

shaped opening of the spring.

(Fig. 25) Then lead the thread

through the thread guide on top

of bobbin case.

• Placing Bobbin Case in Shuttle

Hold the threaded bobbin case

in your left hand. Raise the

bobbin case latch with your

finger and hold open. Insert and

center the bobbin case on the

stud of the rotary hook. Be sure

the square opening of the bobbin

case is on top. Press the bobbin

case into the rotary hook as far

as possible until the latch catches

on the center post of the rotary

hook. Then release the bobbin

case latch. Press the bobbin case

to be sure the bobbin case is

locked securely, in place. (Fig.

26)

10

26

Page 12

27

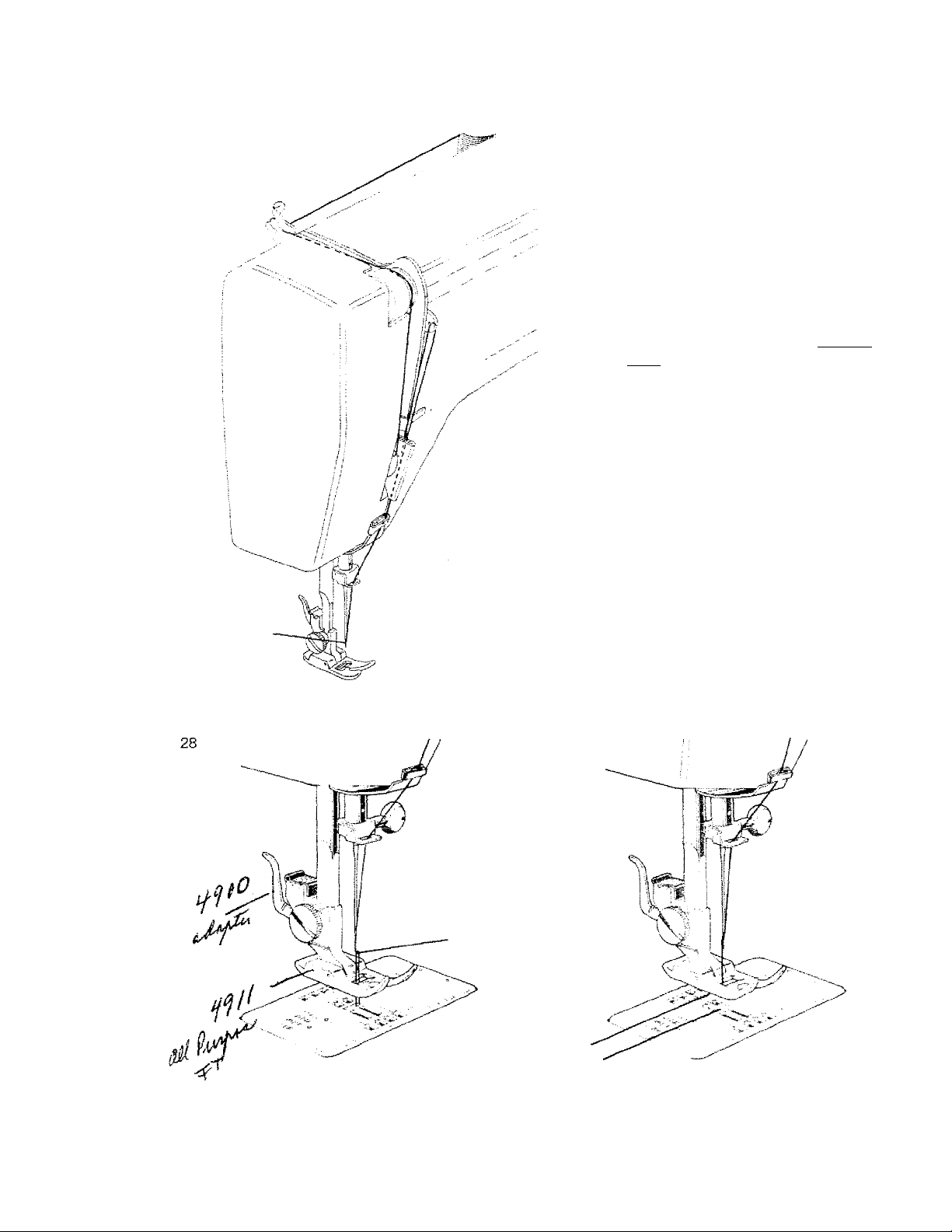

UPPER THREADING

Turn the hand wheel toward you

to raise the take-up lever up just

above red mark. The presser

foot should be in a raised posi

tion. Lead the thread from the

spool as illustrated. Draw the

thread through the rear thread

guide, then forward between the

tension discs, down and around

the check spring, up and around

the take-up lever, down through

thread guide on needle clamp.

Thread the needle from front to

back and leave the thread about

three to four inches long. (Fig.

27) Hold end of upper thread

N

\v.-

\

N

to the left of needle plate and

turn the hand wheel toward you

one complete revolution. Pull

the loop which has been formed

with lower thread through to the

upper surface. (Fig. 28) Place

both thread ends under the

presser foot and draw them to

the side leaving both threads

about four inches long. (Fig. 29)

29

11

Page 13

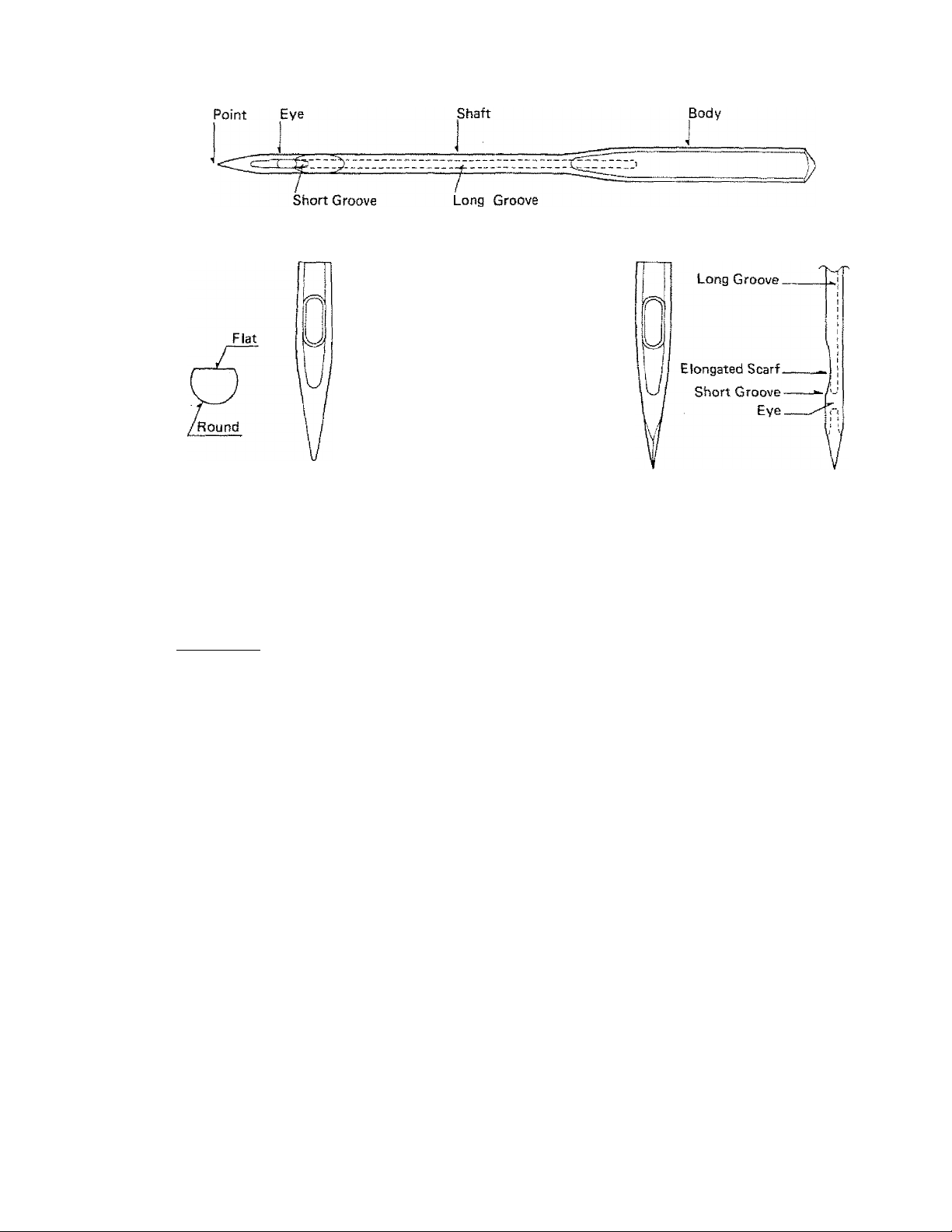

TYPES OF NEEDLES

The correct selection of needle to suit the thread and fabric being sewn gives the best stitching

results. Fine fabrics should be sewn with fine needles, heavier fabrics with heavier needles.

For best results, sewing machine needles should be replaced when they become even slightly

dull or bent or at the completion of every other garment.

______

_______ is suggested for use with woven fabrics. Needles, style 15 x 1, (European

equivalent System 705) are used on the majority of household sewing machines. They range

in sizes from 8 to 20 with the lower number indicating the finer needle. The most commonly

used sizes are 11 and 14.

________________

• is designed to handle knits as well as woven fabrics. It eliminates

skipped stitches and the slight ball will not damage delicate fabrics. This is the needle provided"

with your sewing machine and will be used for most of your sewing. A larger ball point may

still be necessary for certain knits, such as bathing suit fabric or power net.

_

____________

- is recommended for use with tricots, jerseys, lingerie and power nets.

Unlike sharp, pointed needles, which pierce fibers of knit fabrics, destroying elasticity, the

ball point slips between fibers, preventing damage to fabric and skipped stitches. These are

available in fine, medium, and heavy ball points,

__________________

is recommended for use with leather and leather-look vinyls. A wedge

cutting point pierces leather more easily than ordinary sewing machine needles, resulting in

more satisfactory stitching.

NEEDLE, THREAD, FABRIC & STITCHING GUIDE

The correct selection of needle and thread to suit the fabric will result in more satisfactory

stitching. Fine fabrics should be stitched with fine needles, fine thread and short stitches.

For best results on heavier fabrics, use coarser needles, heavier threads and longer stitches.

Replace the machine needle when it becomes even slightly dull or bent.

KNITS

WOVEN

LEATHER

DECORATIVE

STITCHING

12

LIGHT WEiGHT:Tricot, Power Net g

MEDIUM WEIGHT; Jersey, Double Knit, Power Net

HEAVY WEIGHT: Double Knit, Power Net 11-14

FAKE FURS-VELOURS

VERY SHEER;'Lace, Net, Chiffon, Voile

SHEER: Lawn, Taffeta, Blouse Crepe, Organdy

DRESS WEIGHT:Crepe, Woot, Brocade, Velvet

MEDIUM: Woo!, Silk, Linen, Pique, Faille,

Velveteen, Terrycioth

HEAVY: Denim, Duck, Sailcloth

EXTRA HEAVY: Canvas, Upholstery, Awning

VINYLS-FILMS

LIGHT TO MEDIUM WEIGHT: Leathers & Suedes

HEAVY LEATHER

MACHINE EMBROIDERY

TOPSTiTCHING

METALLIC EMBROIDERY

9-10

14-16

9-11

11 80 Sharp

16 100 Sharp

19 120 Sharp

14 90

14-16

16-18

9-11

16-18

11 80

70 Light Ball

70-80

80-90

90-100

9 70 Sharp

9 70

70-80 Sharp

90-100 Leather (Wedg

100-110

60-80

Light Ball to

Medium Ball

Medium Ball t

Heavy Bail

Ball or Shaft

Sharp

Leather {Wedo

Leather (Wedg

100-110

Page 14

30

(Fiai Side of Needle} (Round Side of Needle)

Regular Sharp All-purpose Medium Ball Wedge Point

Needle Needle Point Needle Needle

20

12

10-14

10

9

4-5 50

60

50

10 4-5 Heavy Duty

16-18

14-16 10

t 4.

12

10

8 3-4

10

8

6-8

10 60 70

60

9 50

7-8

6-7 Heavy Duty

7-8

3-4

3

50

Heavy Duty

50 30

50 30

Heavy Duty

Cotton Embroidery Thread Size 50—70

Silk Buttonhole Twist Size D

Metallic Thread

50-70 NO

30 YES

30 YES

30

50-70 NO A-Silk/Nyton

30

30 NO A-Silk

30 YES

30 YES

30

YES NO

NO A-Silk/Nylon

NO

YES

YES NO

YES NO

A-Si!k/Nylon

A-Silk/Nylon Roller Foot

A-Silk/Nyton

A-Si!k

NO

NO

NO

Roller Foot

Roller Foot

Roller Foot

Roller Foot

Roller Foot

Roller Foot

13

Page 15

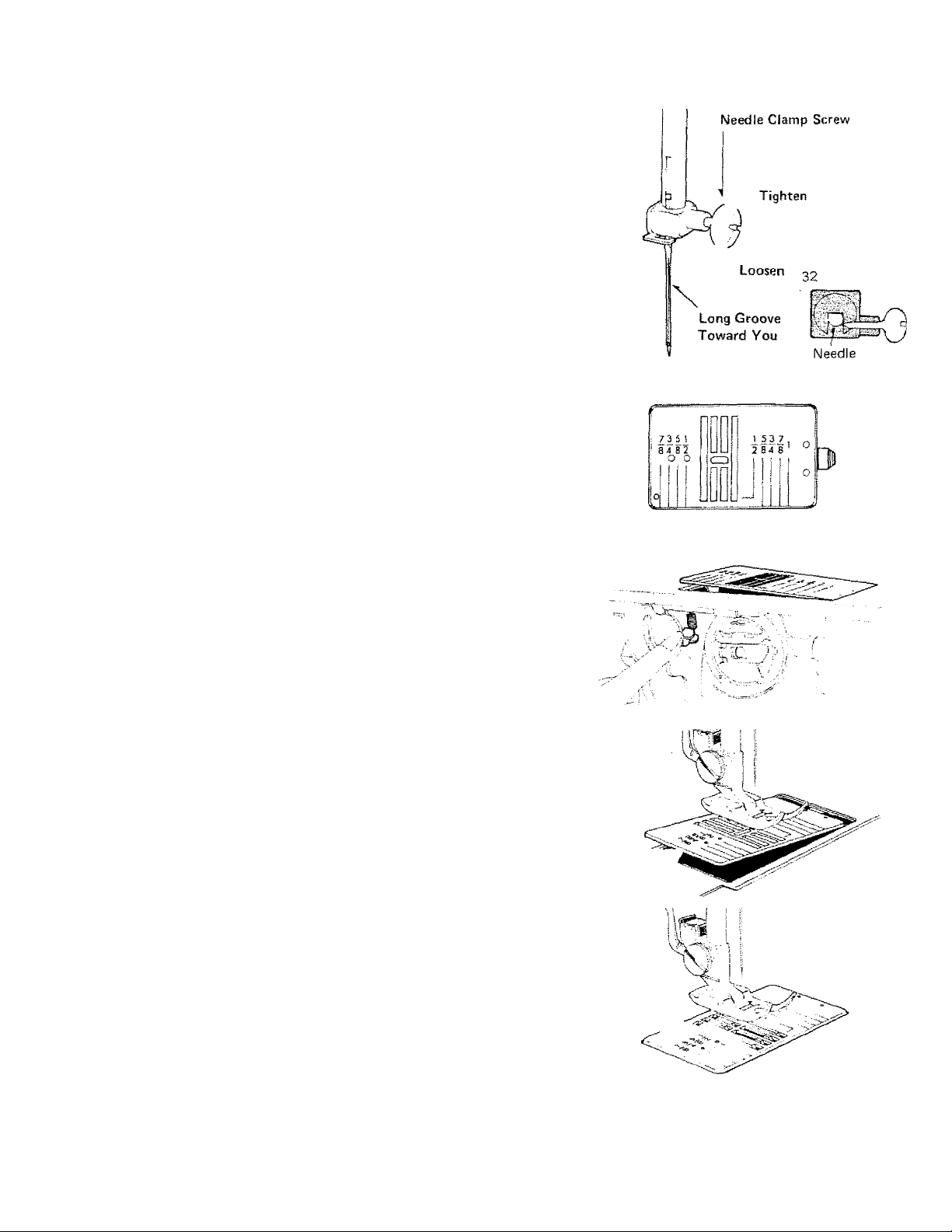

CHANGING THE NEEDLE

• To Change the Needle

1. Raise the needle bar to its highest position

by turning the hand wheel toward you.

2. LooSen needle clamp screw to remove the

needle. {Fig. 31)

3, Place needle (flat side to the back and

long groove toward you) (Fig. 32) in the

needle clamp and push it upward as far as

it will go, tighten clamp screw.

4, After changing the needle, make one

complete revolution of the hand wheel by

hand to be sure the needle is clearing the

needle plate.

31

33

34

CHANGING THE NEEDLE PLATE

To change the needle plate, release front flap

sewing surface and turn flap up. Push the

button on the left side of the bobbin case

and the needle plate will automatically raise.

(Fig. 34) Lift the needle plate. Replace the

needle plate by sliding the clip on the right

of the needle plate under the opening and

pressing the left side of the needle plate

down into place. (Fig. 35, 36)

The needle plate is removed for cleaning the

lint which may pile up between the needle

plate and the feed dogs. The straight stitch

needle plate is used for sewing very fíne or

soft materials. The zigzag needle plate can

be used for all of the norma! sewing. Care

should be taken to clean lint from the feed

dogs to insure smooth operation of the feed

mechanism.

35

36

14

Page 16

37

39

|U

Lr~

1

Li

1

1 U

o I

0 :

O

0

ADJUSTING THE STITCH

• Stitch Length Dial

This dial {Fig. 37) controls the forward

feeding of the fabric. At 0, the fabric does

not feed at all. As the numbers increase so

does the length of the stitch. Turn the blue

dial so that the desired number is below the

blue indicator.

• Reverse Lever

The "R" marked blue lever (Fig. 38} above

and to the right of the stitch length dial will

cause the machine to sew in reverse when

depressed. This lever may be used at the

beginning and end of sewing to lock the

threads.

To backstitch, simply push the lever down

and hold for the desired number of stitches.

It is advisable to tie the thread ends instead

of backstitching on soft sheer fabrics to

avoid puckering.

1 o

o

=J L_

Pattern;

Length: 2%

Width: 0-5

Feed Dog; Up

Pressure: Normal

Foot: AM Purpose

Needle Position: IV!

Pattern:

Length: 0—5

Width: 5

Feed Dog: Up

Pressure: Normal

Foot; Allpurpose

Needle Position; M

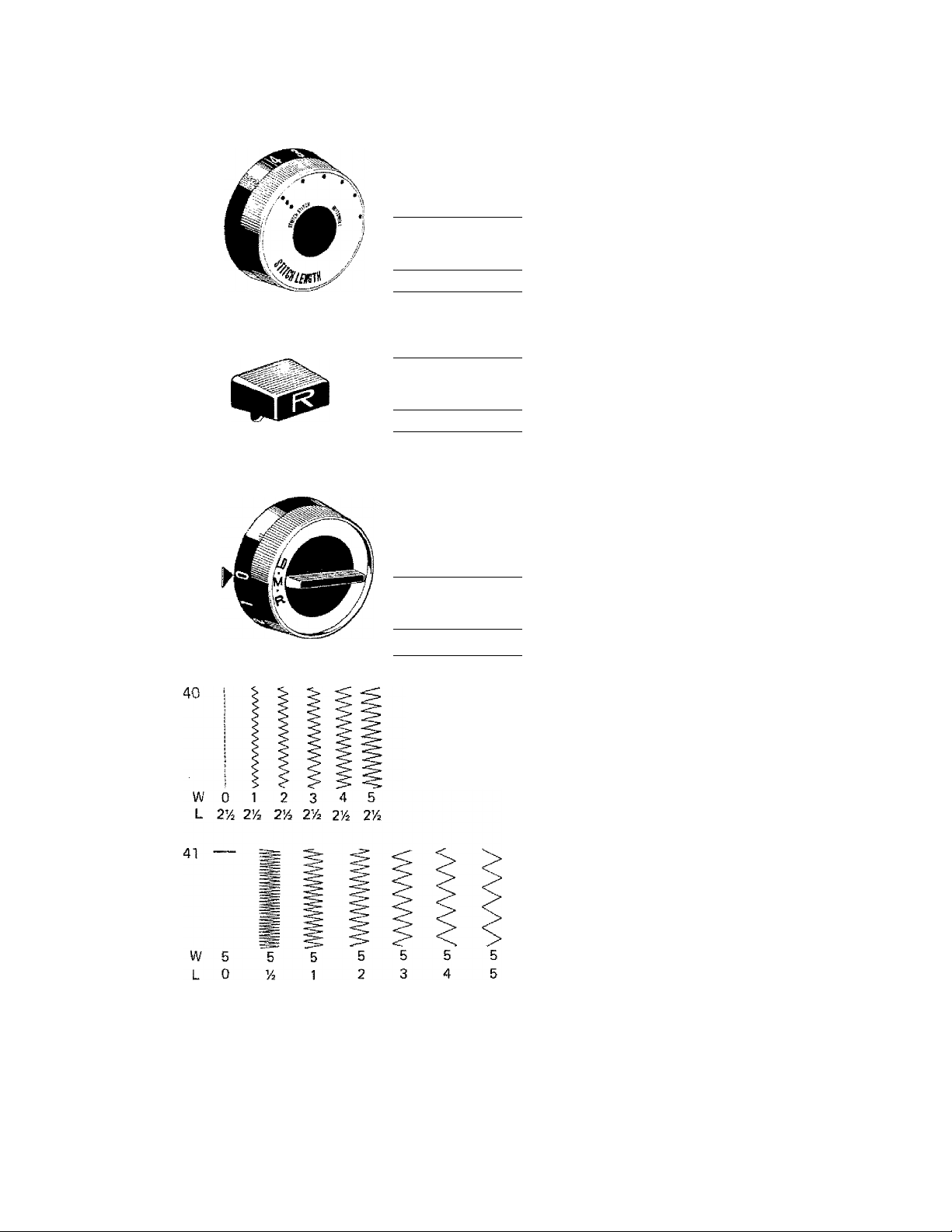

• Stitch Width Dial

This dial (Fig. 39) controls the swing of the

needle right and left for various widths of

stitches. At 0, the needle does not swing,

therefore, a straight line of sewing results no

matter which stitch is selected.

At 1, the needle takes a narrow swing result

ing in a narrow column of stitching. At 5,

the needle takes a large swing resulting in a

wide column of stitches. (Fig. 40)

• Relating Stitch Length to Stitch Width

When the width dial is engaged at one par

ticular width (such as 5), the stitch length

dial will now control how close those

stitches come together. At length 0, the

fabric does not move, resulting in a ball of

stitches formed one on top of the other, as

is used in button sewing. At about 1/4, the

feed pulls the fabric through slowly, result

ing in a dense column of stitches called a

satin stitch. At length 5, a very long open

zigzag results. (Fig. 41)

15

Page 17

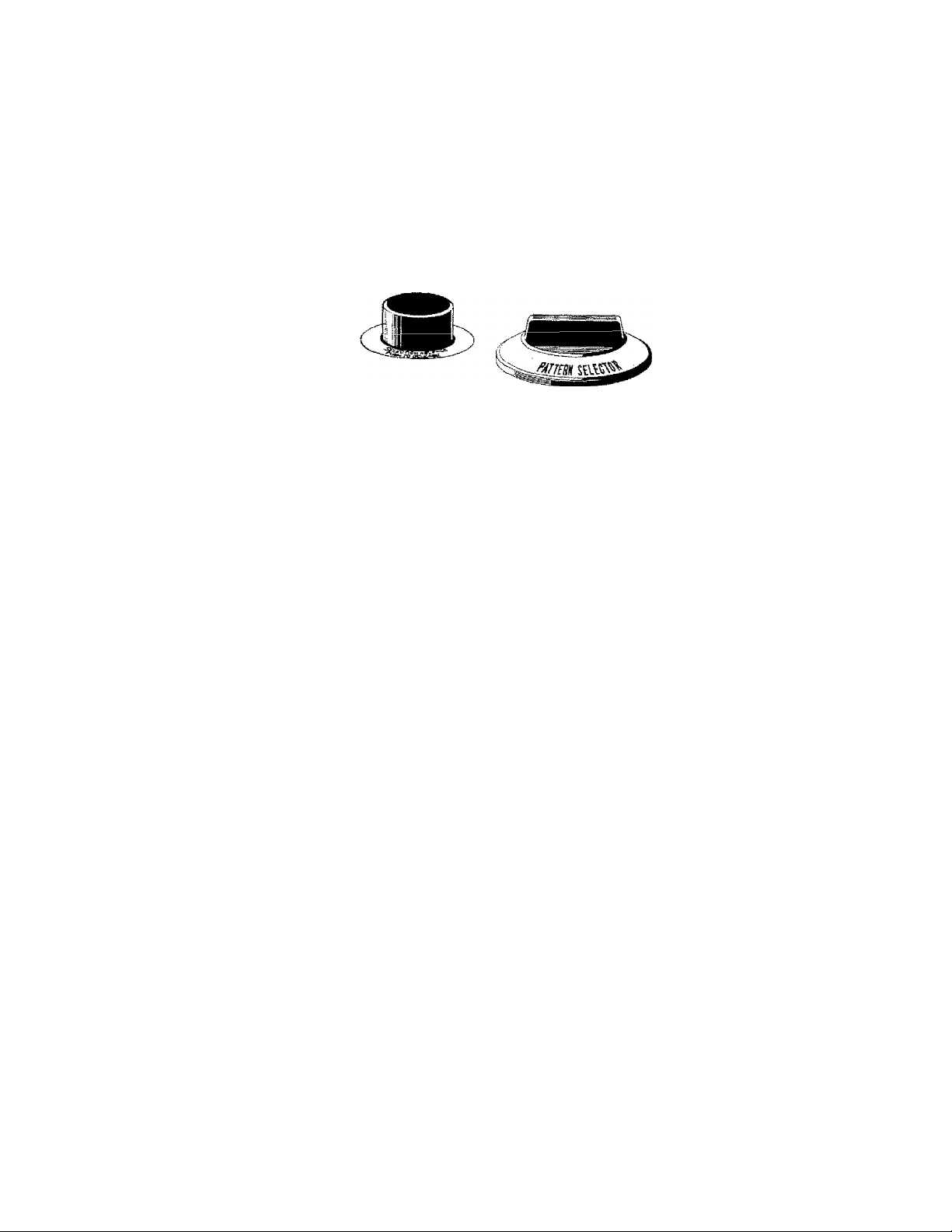

• Pattern Selector Dial, Pattern Selector Release Button and Pattern Indicator Window

Pattern Selector Dial selects the stitch pattern to be made according to the picture shown at

the yellow indicator in the pattern selector window. With the pattern selector release button

pushed down, the dial can be turned in any direction to the desired stitch. Release the button,

and the selected stitch is locked in place.

42

I ■

The stitches shown are as follows:

Forward Stitch Patterns {shown in blue)

1.

AAjVvV Results in a straight stitch when the width is at zero and a zigzag when the

width is engaged. Set the dial at this position for buttonholes.

2.

3.

4.

5.

6.

7.

8.

9.

A A Blind Hem, stitches forward then a zigzag bite to the left for use in

hemming, topstitching, and other applications. See Pages 35—36. Width 0 will give a

straight stitch, ail other widths will produce the blind hem stitch.

Stretch Blind Hem, takes two small zigzag stitches then a larger zigzag to

the left for blind hemming soft, stretchable knits. When used on a very short length,

an excellent edging stitch is produced. See Page 37, A straight stitch is obtained at width

0, All other widths produce the stretch blind hem stitch.

/\/\ Multiple Stitch Zigzag, takes three stitches from side to side for use in

overcasting, applying elastics, and mending as shown on Pages 38—39, Width 0, results

in a straight stitch, width 5 is the best choice for use of the multiple stitch zigzag.

/' Scallops, perfectly shaped half circles, are formed to the left for decorative

pin tucks and edging. Width 0 results in a straight stitch. Width 5 produces the widest

scallop. See Page 40,

~\f^f Reverse Blind Hem is similar to the regular blind hem (2) except that the

zigzag bite is toward the right and the straight stitch is to the left, for easier shell tucking.

Straight stitch is produced at 0 width, the reverse blind hem at all other widths. See

Page 40.

_AlAA. Interlock, one straight stitch is formed then a zigzag bite to the right for

seaming lightweight jersey and tricot as on Page 41. Width 0 results in a straight stitch,

ail other widths produce an interlock.

Checker Stitch takes small zigzag stitches in left, middle and right positions

for decorative effects as on Page 42. Width 0 will give a straight stitch alt other widths

produce the checker stitch.

Domino Stitch takes zigzag stitch in the left and right positions for

decorative effects as on Page 42. Straight stitches are produced at 0 width, while width 5

results in a domino stitch.

16

Page 18

4^'

V,.

V >

Decorative Reverse Stitch Patterns {shown in brown)

10.

11.

12.

13.

14.

15.

Reverse Action Stretch Stitches (shown in green)

16. ' The Crown Stitch forms a crown shaped pattern for decorative effects on

17. The Cross Stitch produces a hand embroidered replica of the cross stitch for

18. Overlock, takes a stitch to the left, then backwards, and then one stitch right

19.

20. ' This Decorative Stitch can be used for fagotting and borders on household

21. 3 ; ' Smocking Stitch is a honeycomb type pattern useful in seaming gauze and

22. Elastic Edging Stitch takes one stitch to left then forward, then a rick-rack

23. _ _ ' _ Stretch Overlock takes a stitch to the left and right then two straight stretch

24. l! e"":\ Rick-rack takes stitches forward and backward to form a triple reinforced

Note: For Decorative Reverse Stitch Patterns shown in brown and Reverse Action Stretch

__.__

Heart Stitch produces even shaped heart designs with the straight edge to the

left for trimming collars and cuffs of little girls dresses as shown on Page 43. Width 3

produces a small heart design with the widest heart shape at width 5.

Tuiip Stitch produces a straight stitch at left and a tuiip design toward the

right for border designs on guest towels and children wear. The widest tulip design is

produced at width 5,

1..,.. Swan Stitch results in swan shaped patterns to the right with a straight stitch

to the ieft for decorative effects on towels and children clothes. Width 5 produces the

largest swan design.

^ 21 Fish Stitch forms a fish pattern at the right with the straight edge to the

left for decorative effects on towels and children wear at a width more than-3. The

widest fish pattern is formed at width 5. See Page 43;

Leaf Stitch forms alternating leaf designs for decorating household linens

and garments. The largest leaf design is produced at width 5.

”^2. Greek Key Design is a traditional fashion pattern for decorative borders and

hems of household linens and garments. Width 5 produces the widest pattern. See Page

43.

table-clothes and napkins. See Page 44, Width 5 produces the widest pattern and width 0

produces the straight stretch stitch.

highlighting drapes and household linens. See Page 44. The straight stretch stitch is

formed at width 0. AM other widths produce the cross stitch.

to iform a straight seam and overcast all in one operation. This is excellent on both knits

and wovens for finished % inch seams on width 5, and for the straight stretch stitch at

width 0. See Pages 45—47,

____

The Stitch and Overcast for a straight stitch on the left and a stitch

diagonally to the right for stitching and overcasting Va inch seams on woven and knit

fabrics. See Page 48. Width 5 is best for seaming and overcasting in one step while

width 0 is used for straight stretch stitching.

linens at width 5. Width 0 produces the straight stretch stitch. See Page48.

sweater type fabrics as well as decorative effects. See Page 49. Width 0 results in a

straight stretch stitch while other widths produce the smocking stitch.

stitch, tor decorative uses. At width 0 the straight stretch stitch is produced and all

other widths results in the elastic edging stitch. See Page 50.

stitches for seaming softer, bulkier stretchy knits. Use at width 5 for completed 14 inch

seams and width 0 for the straight stretch stitch. See Page 51.

zigzag for decorative uses. Width 0 produces the straight stretch stitch, all other widths

result in the rick-rack stitch. See page 52.

Stitches shown in green, always set the stitch length dial at 5 at the brown and green

dots.

17

Page 19

• One-Step Buttonhole Control Dial

This dial (Fig. 43j is used for automatic,

one step buttonholes. The length may be

automatically set by selecting a number

or point on the dial between 1 and 5.

Normally, Number 1 produces a button

hole of about Vi inch in length on stiff

cotton, while Number 5 results in a V/i

inch buttonhole. Size will vary on

different types of material due to

stretching of the fabric. Once the number

or position has been selected, the button

hole size is produced automatically.

Each buttonhole can be made the same

size without any measurement on the

fabric. For normal sewing this dial ts set

at OFF, Further details are explained on

Page 31.

43

— SIZE —

• Stitch Density Control

This control is mainly used for fine tuning

the stitch density of the right side of the

buttonhole and the shape of decorative

reverse stitch patterns. A clockwise turn

of the knob increases the openness of the

right side of the buttonhole.

Conversely, a counter clockwise turn

makes the right side of the buttonhole

closer together and makes the reverse

stitch portions of decorative reverse stitch

patterns longer. Reverse stretch stitch

patterns may be a altered as to closeness

or openness of the stitch by turning the

dial counter clockwise for a more open

pattern and clockwise for a closer stitch

pattern. However, most sewing will be

done in the neutral position of the stitch

density control. (Fig, 44)

44

18

Page 20

45

46

o

V

Pattern:

Length: 2-5

1

Width: 0-5

Feed Dog: Up

Pressure: Normal

Foot: All Purpose

Needle Position:

u

1

Pattern

Length: 2—5

Width; 0—5

Feed Dog:

Pressure; Normal

Foot; All Purpose

Needle Position: M

0

• Needle Position Dial

This dial (Fig. 45) is used for changing needle posi

tion.

Three different needle positions, L-left, M-middle

and R-right can be selected. Also, those intermediate positions between left and middle and

between middle and right can be selected with the

dial at the middle between L — M, and IVl — R,

With the dial at L, M and R, the straight stitch line

is formed at left, middle and right respectively.

The etched guide lines on the needle plate are

measured from the needle in the middle position.

Never change the needle position while the needle

is in the fabric because it will bend or break the

needle.

Set the needle position at the left (Li when using

the one-step buttonhole.

ADJUSTING FOR THE FABRIC

• Feed Dog Control

This dial (Fig. 46) will raise and lower the feed

dog as indicated. Since the feed dog moves the

fabric through the machine, this dial allows the

]

feed to be regulated for various types of sewing,

UP -- for the greatest height of the feed dog

0

and the best grip on the fabric. This is

the position used for most sewing,

DOWN — in this position, the feed dog is com

pletely below the needle plate surface

and therefore does not move the fabric

3t 3!!.

Down position is used for sewing on but

tons, darning, and free hand embroidery.

♦ Pressure Control

This control (Fig. 47) regulates how heavily the

presser foot rests upon the fabric. To completely

release the pressure for freehand work, push the

pr6ssur8 r0!s3S6 button backwsrd until ths upp6r

plate pops up. To set half pressure for heavy bulky

fabrics, push the upper plate halfway down as

indicated on the picture panel inside the face

cover. Push the upper plate all the way down for

regular sewing. Light weight fabrics need more

pressure for better hold against the feed, whereas

heavier, bulkier fabrics require less pressure to

eliminate pushing of the top’layer of the fabric.

Pattern:

Length; 2—5

Width: 0-5

Feed Dog: Up

Pressure:

Foot; Allpurpose

Needle Position: M

19

Page 21

TENSION 48

The top tension (Fig. 48) consists of discs

between which the upper thread passes.

The numbered tension dial regulates how

tightly the thread is being held. When

necessary, adjust the top tension dial in

relation to the red line, turning to a lower

number to loosen and to a higher number

r

Iji

ii.

1.h

___

..........

1

.

^ @

i ■

. 'w'

to tighten the upper thread tension. The

top tension is engaged only when the

presser foot is down for sewing. Normal

top tension is usually about 5.

49

The bobbin thread tension is controlled

by a small screw on the side of the bobbin

case. (Fig. 49) This screw may be turned

with the small screw driver to the right

\

to tighten and to the left to loosen the

bobbin tension.

• Adjusting the Thread Tensions

The tensions may have to be adjusted for

Balanced tension

certain fabrics. . u;.

■ :c: :i Use a new

needle the correct size for the thread and

fabric being sewn. (See chart page 12)

It is best to test the tension on a scrap of

the fabric you are using for construction.

Always use a double thickness and always

sew on the bias when testing tensions.

The tensions are correct when the upper

thread and lower thread interlock be

tween the two layers of fabric with the

loops not showing on top or bottom.

(Fig. 50—A)

Adjust as follows:

1. If the seam is puckered both top and

bobbin tensions are too tight. Loosen

both tensions slightly.

2. If top thread lays on the fabric with

bottom thread looping over it, the top

tension is too tight,(Fig, 50—B)Loosen

the top tension slightly.

3. If the bottom thread lays on the fabric

with the upper thread looping over it,

top tension is too loose.(Fig. 50—C)

Tighten top tension slightly.

(B)

(C)

Top tension too tight

Top tension too loose

20

Page 22

51

55

56

THE PROPER PRESSER FOOT

• Changing the Foot

Pui! the presser foot shank iever

toward you to remove the foot.

(Fig. 51 — Step 1) To attach

place the desired foot under the

shank and lower the presser bar.

(Step 2) Foot will be locked

automatically. (Step 3)

• The All Purpose Foot •F‘77'/

This foot (Fig. 52} is flat on the

bottom and has a wide hole to

accommodate wide stitches. This

foot should be used for all

normal sewing.

• The Straight Stitch Foot

This foot (Fig. 53) is fiat on'the

bottom and has only a small hole

to accommodate only straight

stitching. It may be used on

sheer or soft fabrics for more

control when the all purpose

foot allows the fabric to be

pulled with the needle.

• The Buttonhole Foot ifR/ S

This foot (Fig. 54) has a frame

which holds the fabric taut

enough to produce a good

buttonhole. The markings on

the side allow exact buttonhole

length to be made.

• The Embroidery Foot

This foot (Fig, 55) has a wide

groove carved out on the bot

tom, This groove allows the foot

to pass over dense stitches such

as the satin stitch without

catching on the stitch. It is

transparent to make the stitch

more visible. It has two small

grooves in the front to make

cording easier. Do not use this

foot for normal sewing of light

weight fabrics. Since it is groov

ed it will not hold the fabric taut

enough to produce a good

straight stitch.

• Cording and Zipper Foot

This foot (Fig. 56) is very narrow,

with needle opening cuts at its

right and left sides to sew in

zippers and insert cording.

21

Page 23

Pinning may be used as a time saver instead of

hand basting. Place your pins at right angles

to the edge of the fabric with the pin head at

the raw edge. It is possible to sew over pins,

but for best results it is recommended that the

pins be removed as you approach the presser

foot. Sewing over pins can result in damaged

needles.

PLACEMENT OF FABRIC/STARTING A SEAM

Before placing fabric under the presser foot,

make sure that the take-up lever is at its

highest position. Place your fabric so that its

raw edge is even with the back edge of the

presser foot.

When "placing a heavy, bulky fabric under the

foot push up on the presser foot lever for extra

lift while you are positioning the fabric. Place

the thread ends, which are 3—4 inches long,

under the presser foot and either to the left or

to the right. Be sure that both thread ends are

under the presser foot. Always lower presser

foot before sewing. {Fig, 57)

Push the reverse lever down so that the machine

sews a few stitches backwards to the edge of

the fabric to backtack, then release the lever

allowing the machine to continue forward.

58

57

59

GUIDING THE FABRIC

• Etched Seam Guide

The etched seam guides on the needle plate are

graduated in 1/8 inch divisions measured from

the middle needle position, (Fig. 58) In order

to use the etched guides effectively, let the

edge of the fabric follow the line selected for

the seam. Therefore, for a 5/8 inch seam, place

the raw edge of the fabric on the line marked

"5/8". In order to sew a straight line, let your

eye follow the etched lines, not the needle.

• Cloth Guide

This guide may be placed on the machine for

extra help in keeping seams straight. It will

allow you to guide seams from 1/4 inch to

1-1/2 inch in width, so that it is useful for

seams of unusual widths. (Fig. 59)

• Presser Foot as a Guide

Straight Stitch Foot — for a 1/4 inch seam,

guide the fabric along the right side of the

foot. (Fig. 60)

All Purpose Foot — for a 1/8 inch seam,

guide the fabric along the right side of the

needle hole. (Fig. 61)

60

Jill

il,

silg'

61

J

ix

1

J II °

22

Page 24

63

• Holding the Fabric

For most fabrics, it is not necessary to hold the

fabric in both front and back. Merely guide the

fabric with one hand from the front.

For the fine delicate fabrics, such as chiffon,

georgette, and tricot, the best results will be

attained by holding the fabric in front and back

of the needle without pulling on it.

• Turning Corners

To pivot at a corner, (Fig, 62) leave the needle

in the fabric while on the upswing so that the

stitch is almost completed, thus preventing the

possibility of skipped stitches in the corner.

Lift the presser foot and pivot the fabric. Then,

lower the presser foot and continue sewing.

• Curved Seams

On a curved seam (Fig. 63} use a slightly shorter

stitch length than you are using for the rest of

the seams. For example, if length 2 is being

used for the seams, a 1-1/2 stitch length would

be preferred for curves. A smaller stitch length

will add strength and elasticity to the seam.

When guiding the fabric, keep your fabric edge

on the etched seam guide line directly across

from the needle rather than on the forward part

of the line. The seam guide may be used on an

angle as shown.

64

• Sewing Across Heavy Seams

When approaching a heavy seam, (Fig. 64) hold

the fabric upwards on an angle so that the heavy

seam falls under the upward curve of the foot.

This will help feed the heavy seam through the

machine.

• Ending Seam/Removal of Fabric

Stitch to the edge of the fabric, then press down

the reverse lever and backstitch for a few

stitches to reinforce the end of the seam.

Turn the hand wheel until the take-up lever is in

its highest position so that the stitch is complet

ed and the threads will pull freely. Lift the

presser foot and remove the fabric by drawing

the threads to the left and back,keeping them

under the foot so as not to bend the needle. Cut

the threads with the thread cutter on the back

of the presser bar. Leave the thread ends three

to four inches long.

23

Page 25

SEAMS

The normal stitch length for most fabrics is

3, but the length chosen should depend on

the fabric and area of usage. Usually, heav

ier fabrics require longer stitches, and lighter

weight fabrics require shorter stitches. For

curved seams and bias cut areas use a shorter

stitch length to add strength and elasticity to

the seam.

65

Pattern

Length: 2-4

Width: 0

Feed Dog: Up

Pressure: Normal

Foot: All Purpose

Needle Position: M

BASTING/TOPSTITCHING

Sewing a seam with a longer stitch is useful

for temporary seams prior to fitting. Basting

stitches also may be used when gat.hering in

fullness.

Topstitching can be done very effectively

with the long straight stitch. For a bolder

stitch, two threads of the same type can be

threaded through one needle (size 14 or 16).

A heavier thread such as buttonhole twist

may be used for topstitching, but be sure to

use a larger needle (size 16 or 18). (Fig, 65)

Left needle position may be used for more

support of fabric.

DARNING

Worn spots or small holes can be darned very

easily. Use of an embroidery hoop is option

al depending on the fabric. (Fig. 66) A fine

thread is recommended so that the fabric

and thread will blend together invisibly.

Trim the ragged edges from the area to be

darned. Hold the threads to start, then

move the fabric slowly back and forth while

running the machine very fast to fill the

area. More professional results will be

attained by moving the fabric in a figure

eight pattern while sewing. After filling in

the area lengthwise, reweave with crosswise

stitches in the same manner.

Pattern

Length: 5

Width: 0

Feed Dog: Up

Pressure: Normal

Foot: Straight Stitch

or All Purpose

Needle PositionrM or L

Pattern

Length: 0

Width: 0

Feed Dog: Down

Pressure: Darn

Foot: Norse or All

Purpose

Needle Position: IVl

66

67

ELASTIC THREAD SHIRRING

Wind elastic thread onto bobbin, (Fig. 67) as

shown, letting the thread pass through your

fingers. The thread should be wound

smoothly without stretching. Place bobbin

in case as usual, being sure that the elastic is

drawn through the tension. Use regular

thread on the top of the machine. Do a trial

run on the chosen fabric to test length of

stitch. Lay a piece of paper under the fabric

to keep it from gathering up as you sew.

This will enable you to sew many parallel

rows of stitching without difficulty. After

wards tear out the paper and the fabric will

be gathered. (Fig. 68)

24

Pattern

Length: 3—5

Width: 0

Feed Dog: Up

Pressure: Normal

Foot: All Purpose

Needle Position; M

Page 26

OVERCASTIWG

Pattern:

Length: 2—4

Width: 5

Feed Dog: Up

Pressure: Normal

Foot; Embroidery the fabric. (Fig, 69)

Needle Position: M

Place the edge of the material underneath

the opening of the sewing foot and guide

raw edge along the center groove of the foot,

allowing stitch to form half on and half off

The multiple stitch zigzag is a wiser choice

for most fabrics. See page 38.

71

Pattern:

Length: 2

Width: 1

Feed Dog: Up

Pressure: Normal

Foot: All Purpose

Needle Position: M

Pattern:

Length; 0

Width; 2-5

Feed Dog; Down

Pressure: Normal

Foot: Button Foot

Needle Position: L

SEAMING KNITS

The narrow zigzag can be used in seams of

firm knits for added strength. After sewing,

open seam and press fiat. Tiny zigzag

stitches can hardly be seen and the seam will

give when stretched. (Fig. 70)

SEWING ON BUTTONS ^f/7

Zigzag stitching is a very easy and conve^

nient method of sewing on buttons without

a shank. (Fig. 71)

Place the button so its left hole comes

directly under the needle, then gently lower

the button sewing foot. Take a stitch in

the hole.

Haise tne neeaie ana move zigzag wiotn aiai

to the right until the needle comes down

exactly over the right hole in the button.

Usually 6 to 8 stitches are adequate for

securing a button in place. Stop with the

needle in the left hole. To lock the threads,

set the stitch width at 0, and take a few

stitches in the left hand hole.

25

Page 27

• Forming a Thread Shank

Buttons sewn on coats or jackets should

have a thread shank to make them stand

away from the fabric. (Fig, 72) To form a

thread shank, sew over a pin or rounded

toothpick which can be inserted directly

into the button sewing foot.

After stitching the button to the fabric,

remove work from under the presser foot

leaving threads about six inches from fabric.

Remove pin or toothpick. Puli the threads

to back of button and form a shank between

button and fabric by winding threads tightly

around the attaching stitches. Pull threads

to back of the fabric and then tie thread

ends seburely. (Fig. 72)

73

SATIN STITCHING

This is useful for decoration such as taper

ing, manual designed embroidery, mono-

gramming, and applique. (Fig. 73)

The satin stitch, which is a very close zigzag

stitch, is obtained by setting the stitch

length as near to "0" as possible with

out stopping the feeding action. The setting

will vary for different fabrics. It may be

desirable to loosen the upper tension slightly

to cause the threads to lock underneath, in

order to make the top surface look especial

ly smooth. For lightweight fabrics, place

paper underneath the fabric while sewing for

best results.

TAPERING/CREATIVE EIVlBROtDERY

Tapering is done by gradually increasing and

decreasing the stitch width while sewing.

(Fig. 74) By this method, tapered mono

grams and other interesting designs can be

created. (Fig. 75) For tapered monograms

run the machine fast while turning the width

dial slowly from narrow to wide and back.

Pattern;

Length: Vi—14

Width; I—5

Feed Dog: Up

Pressure: Normal

Foot: Embroidery

Needle Position; M

Pattern: (VA

Length: Vi—14

Width: 0-5

Feed Dog: Up

Pressure; Normal

Foot: Embroidery

Needle Position; M, 75

Lor R

First, learn this stroke by letting the fabric

guide straight. Then, learn to pivot the

fabric as you are tapering by holding the

fabric at one point. Various strokes can be

combined to form letters and designs. Varie

gated thread can give attractive results.

26

Page 28

76

Pattern:

Length: 'A—A

Width: 0-5

Feed Dog: Up

Pressure: Normal

Foot: Embroidery

Needle Position: M, LorR

• Manual Embroidery Designs

Different designs can be made by turning the

stitch width dial between 0 and 5. By run

ning the machine at a constant speed and

turning the diai in a definite rhythm, various

designs can be created. (Fig. 76)

Pattern:

Length: 0

Width: 1—5

Feed Dog: Down

Pressure: Darn

Foot: Embroidery or None

Needle Position: M, L or R

FREEHAND MONOGRAMMING

For giving garments and linens a personaliz

ed touch, first transfer the design to the

right side of the fabric. An embroidery

hoop is recommended especially for soft

fabrics and toweling. {Fig. 77)

In order to monogram, you must move the

fabric slowly and run the machine rapidly.

Monogramming is like writing by moving the

paper under a stationary pen. Guide the

fabric slowly so that the zigzag falls close

together like a satin stitch, but be careful

that the stitches do not pile up. When guid

ing from side to side, move fabric slightly

faster to avoid a heavy area.

Practice by forming loops. Once this is

accomplished any letter is easy.

Sometimes the use of paper or non-woven

interfacing under the fabric may make

guiding the fabric easier. The paper or

interfacing may be torn or cut away at the

completion of the monogram. When mono

gramming towels, cellophane placed on the

top will help cover loops and make the

monogram smooth. Pull or cut away

remaining cellophane when finished.

27

Page 29

applique

Applying decorative shapes of

fabric scraps to household articles

and clothing is a very interesting

way of trimming an otherwise plain

article. First, trace the design on

fabric to be appliqued, then pin or

baste it securely in place on gar

ment, With a small straight stitch

or narrow zigzag, sew around the

transferred design, (Fig. 78)

Aftar

■f aKr

away, sew around the applique with

a satin stitch. For a smooth curve,

stop frequently at the inside edge

of the curve to pivot the fabric

slightly. Corners look much better

when the point is stitched by pivot

ing rather than just turned.

As with all decorative stitches,

paper may be used to give more

body to the fabric when stitching

and can be torn away when the

applique is completed. (Fig. 79)

GATHERING OVER A CORD

Ordinary gathering with a basting

stitch often breaks while pulling

in fullness. A small zigzag across a

cord such as crochet thread or

carpet thread, gives a much stronger

cord for gathering fullness Into

fabrics. (Fig. 80) Once the gathers

have been stitched in place, the

cord can be pulled out in order to

eliminate bulk. (Fig. 81)

79

Step 1

Pattern;

Length: 1

Width: 0-1

Feed Dog; Up

Pressure: Normal

Foot; All Purpose

Needle Position; M

80 81

Step 2

Pattern:

Length; %—’/3

Width; 2-4

Feed Dog; Up

Pressure: Normal

Foot: Ail Purpose

NIoorMa Pricl+ir^n* IV/l

or Embroidery

28

Pattern;

Length: 2

Width: 3

Feed Dog; Up

Pressure: Normal

Foot: Embroidery

Needle Position; L

Page 30

83

Pattern:

Length: 1

Width: 1-2

Feed Dog: Up

Pressure: Normal

Foot: All Purpose

Needle Position; M

LACE APPLICATIONS

Attaching laces or trims adds a

special touch to lingerie, dresses, or

linens. Pin or baste laces in place

easing or mitering corners where

necessary,

A straight edged lace or braid has a

convenient line to follow when sew

ing. (Fig. 82) When using a scallop

ed edged lace follow the design of

the lace for an almost invisible

application. {Fig. 83)

Note: Try Multiple Stitch Zigzag,

Overlook, Elastic Edge

Stitch, Smocking stitch.

Stretch Overlock or Rick-

Rack for different effects.

84

Pattern: fZZi:

Length: %

Width: 5

Feed Dog: Up

Pressure: Normal

Foot; Embroidery

Needle Position; M

FLUTTER HEM

An unusual way of hemming or

finishing edges of tricot or soft

knits is by a flutter edge. Hemming

in this manner is just like over

casting an edge, but the fabric is

stretched in back and in front of

the needle as you sew. For best

results, pull the fabric equally,

making sure the needle goes over

the edge. (Fig. 84) When you stop

to reposition your hands, keep the

needle in the fabric. (Fig. 85)

29

Page 31

Various fabrics require various methods of sewing 86

buttonholes. Four different methods are given

below, with suggested uses. If you are in doubt as

to which method is best for your fabric, test the

methods in question and choose the best according

to the finished appearance.

PREPARATION

For the best results, a good quality mercerized

cotton thread should be used. Polyester threads

often result in puckered or heavy unattractive

buttonholes. The finer your fabric is, the finer

your cotton thread should be. An interfacing

should be used under the buttonholes to give body, 87

to strengthen,and to help them withstand wear.

To establish the correct length of the buttonhole,

add the diameter of the button (A), plus the

thickness of the button (B), plus 1/8 inch for the

bartacks. {Fig. 86) The length may be marked on

the garment with a basting stitch, tailors chalk, or

transparent tape, as shown. (Fig. 87) Another way

to make sure that ail buttonholes will be the same

size is to cut a piece of cardboard as wide as the

buttonhole foot and long enough to make the

distance between the toe of the white slide and the

cardboard the size buttonhole needed. This

method works for buttonholes up to 1-1/8 inches

long. Horizontal buttonholes should extend 1/8

88

inch beyond the center line of the garment. (Fig.

88) Vertical buttonholes are placed so that the

cutting space of the buttonhole is directly on the

center line. (Fig. 89) Always make a practice

buttonhole on a scrap of the garment fabric before

making any buttonholes on your garment. On

your test sample, duplicate the thickness found in

the garment and be sure to include the interfacing.

The test sample should help determine the length

needed for the button to pass through easily, and

the stitch length for the particular fabric. As with

the satin stitch, the stitches should be close

together, but not so close that they pile up. Be 89

sure to use the buttonhole foot.

A+B+1/8 inch

1/8 inch

Center line of Garment

Center line of

Garment

Page 32

X

v>

BUILT IN ONE STEP BUTTONHOLES

With this buttonholer, you can produce as many buttonholes as desired which will be exactly

the same size simply by selecting the proper number or position. Automatically the button

hole will be produced. This buttonholer is used most often on light and medium weight

fabrics. The buttonhole lengths are relative to the numbers on the buttonhole control dial.

The lengths of the buttonholes are as follows;

NUMBER; 12345

LENGTH; 1" VA"

Most medium weight, stable fabrics will produce buttonholes of this length when the cor

responding number is chosen. In the case of slippery or sheer materials a smaller buttonhole

may result, which will require a slightly bigger number. It is best to test the buttonhole on a

scrap of fabric before making buttonholes on the garment. At this time you can also balance

the buttonhole density and adjust as necessary with the Stitch Density Control Dial for the

right side, and stitch length dial for left side.

90

1. Turn the Buttonhole Control Dial clockwise

from the OFF position to the ON position.

At the ON position press the dial down and

turn through the DOWN position. Release the

dial and turn to the desired buttonhole length

position. If the dial is turned past the desired

buttonhole length number, turn to the OFF

position and then turn the dial one more

complete turn to dear the mechanism and

repeat as above for buttonhole.

2. Lower the needle into the fabric at the

bartack marking line. Lower the presser foot

and start to sew. First, the bartack will be

made, then the right side of the buttonhole

91

will be sewn in reverse. The second bartack

will be made automatically when the desired

length is completed. Finally the left side of

the buttonhole will be made. Stop the

machine when the left side of the buttonhole

reaches the first bartack,

3. To lock the stitch, make sure the needle is out

of the fabric. Turn the dial to the OFF posi

tion and take a few stitches.

4. To make succeeding buttonholes, proceed as

above for an many buttonholes as necessary,

always turning to OFF and repeating steps 1

thru 3.

5. Score the buttonhole with the back edge of

the seam ripper several times. To prevent

cutting through the bartack, insert a straight

pin through the bartack. Cut the buttonhole

open with the seam ripper,

Length: Buttonhole

Width: 1

Feed Dog: Up

Pressure; Normal

Foot: Buttonhole or

Embroidery

Needle Position: L

NOTE: Stitch Width Control should always be

set at "V' while making buttonholes. For a

narrower cutting space, you may turn your

zigzag control knob close to 2’A for desired