Page 1

WHITE

INSTRUCTION BOOK

FOR WHITE MODEL 671

ZIGZAG SEWING MACHINE

Page 2

!

CONTENTS

Name of Each Part

Accessories

Preparing to Sew

To Start Sewing

To remove the work.............................................................................................

Decorative Stitches

Zigzag sewing..................................................................................

Button sewing

Buttonhole sewing —

Braid sewing ..............................................................................

Darning and Embroidery.....................................................................................

Hemming .......................................................................................

Quilting...................................................................................................................

' Cloth (juide .................................................................................................

Maintenance

To open the Shuttle Race

To oil the machine................................................................................................

Check-up for smooth sewing ........................................................................................

NeedIc-thread-fahric-stItching guide

..................

Bobbin :

Needle ; To insert the needle ........................................................................................

Needle Plate : To change the Needle Plate ....................................................................

Presser Foot : To change the Presser Foot.....................................................................

Automatic Darner

Built-in Sewlight......................................................................................

To regulate the tensions ....................................................................................

To regulate the direction of feed and stitches .............................................................................

To remove the Bobbin Case .............................................................

To wind the Bobbin ..........................................................................

To thread the Bobbin Case ...............................................................

To insert the Bobbin Case ................................................................

To thread the needle

..........................................................................................

...................................................................................

...................................................................................

.................

...................................................................................................

...........................................................................

.

.......................................................

.........................................................

1

.

■13

•13

■1-1

■ir>

16

17

18

19

■19

■20

■21

■23

■ 8

8

9

9

10

11

If

Page 3

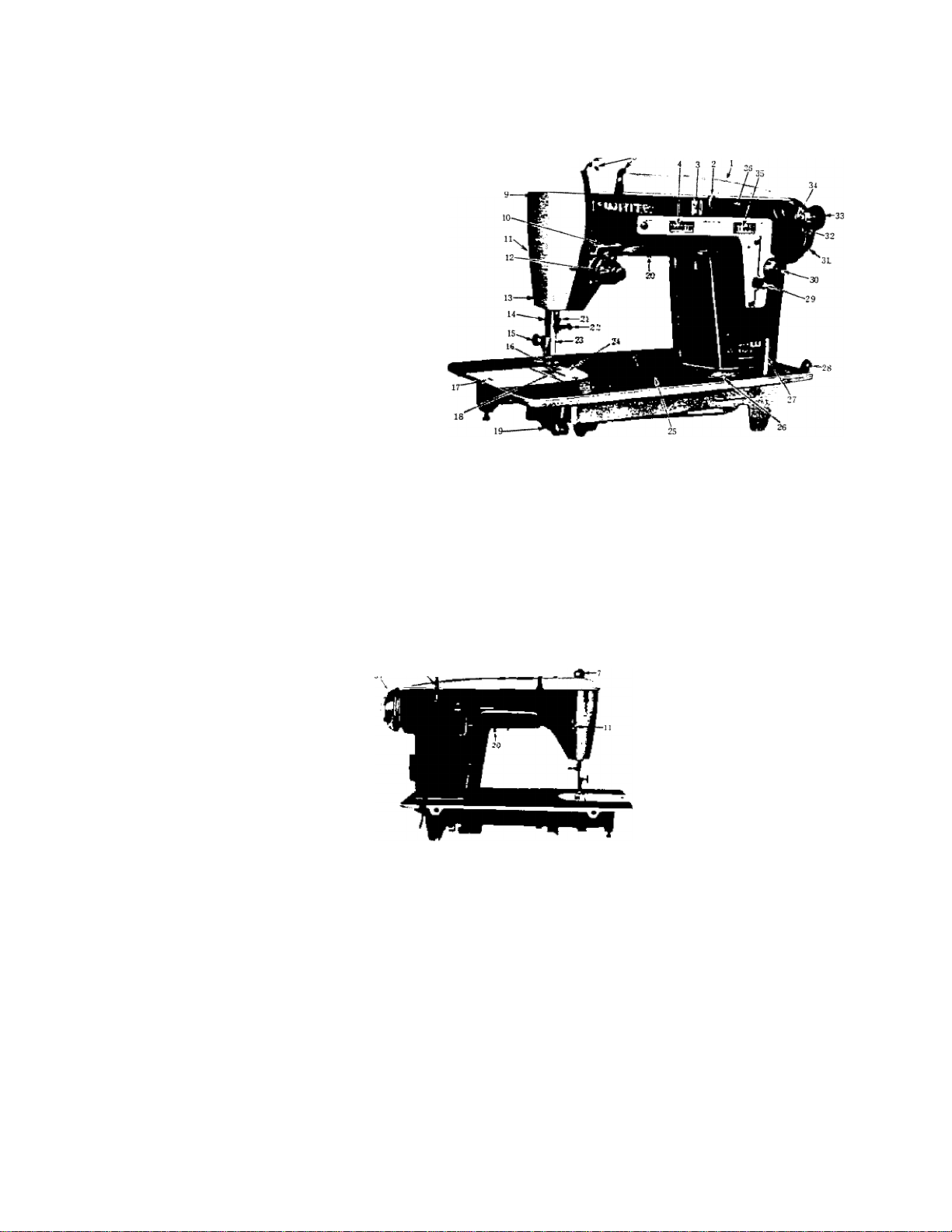

1. Arm spool pin

2. Zigzag width stop lock

3. Zigzag width regulating lever

4. Zigzag width indicator

5. Upper arm thread guide

6. Thread take-up lever

7. Automatic darner

8. Top cover

9. Face plate

10. Lower arm thread guide

11. Presser bar lifter

Name of Each Part

12. Thread tension regulator

13. Face plate set screw

14. Presser bar

15. Thumb screw

16. Presser foot

17. Slide plate

18. Feed dog

19. Shuttle race

20. Switch for light

21. Needle bar

22. Needle clamp

23. Needle

24. Needle plate

25. Bed

26. Drop feed buttons

27. Bed spool pin

28. Bobbin winder tension bracket

29. Reverse button

30. Stitch length regulating dial

31. Hand wheel

32. Bobbin winder push button

33. Bobbin winder wheel

34. Bobbin winder spindle

35. Stitch length indicator

(Pig. 1-B)

36. Arm

(Fig. "I—A)

Page 4

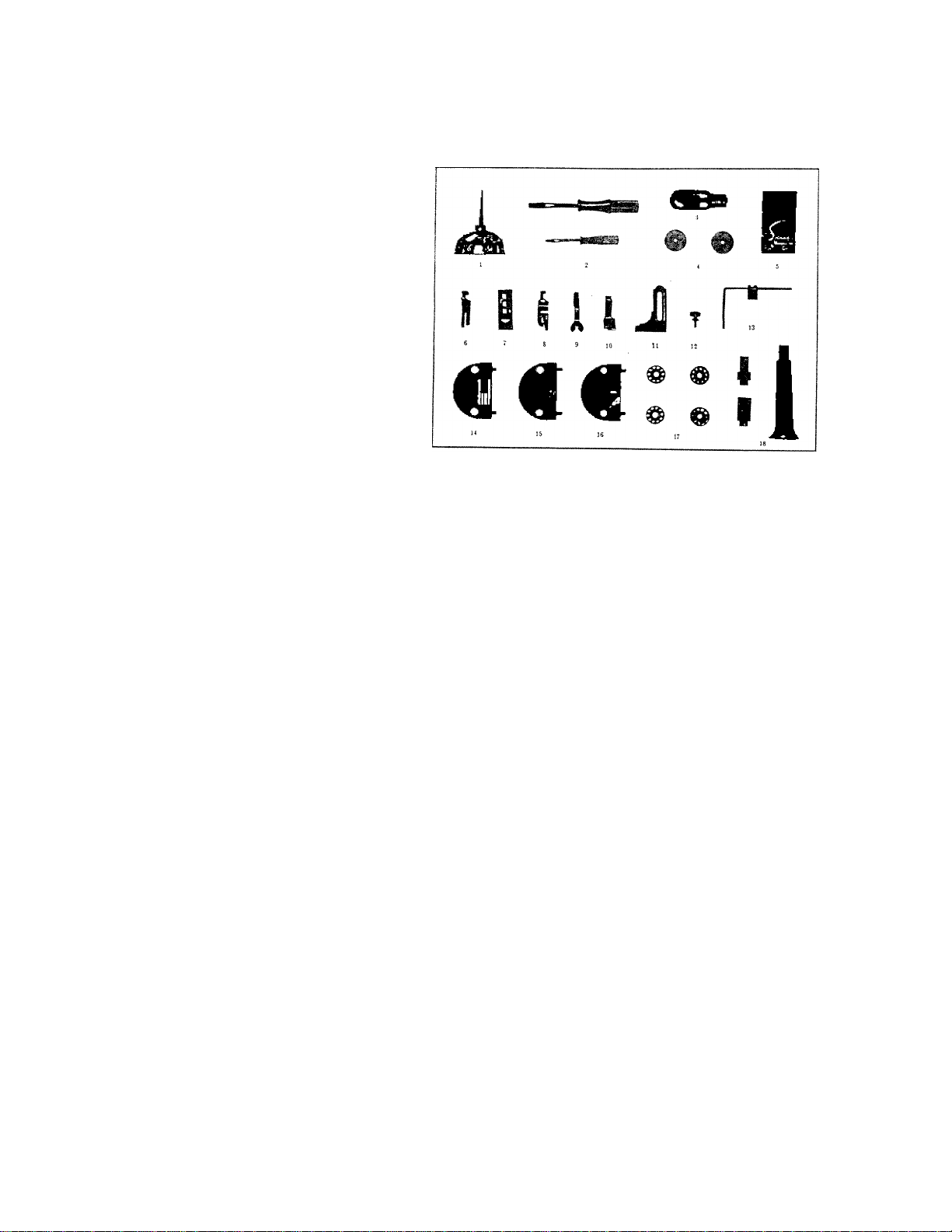

Accessories

(Fig. 2)

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15. 16.

17.

18.

Oil can

Screw drivers

Electric-bulb

Spool pin washers

Needles ■

Straight stitch foot

Buttonhole foot

Hemmer foot

Button foot

Braider foot

Cloth guide

Cloth guide set screw

Quilting attachment

Needle plate for straight stitch

Needle plates for embroidery

Bobbins

Buttonhole cutters

Page 5

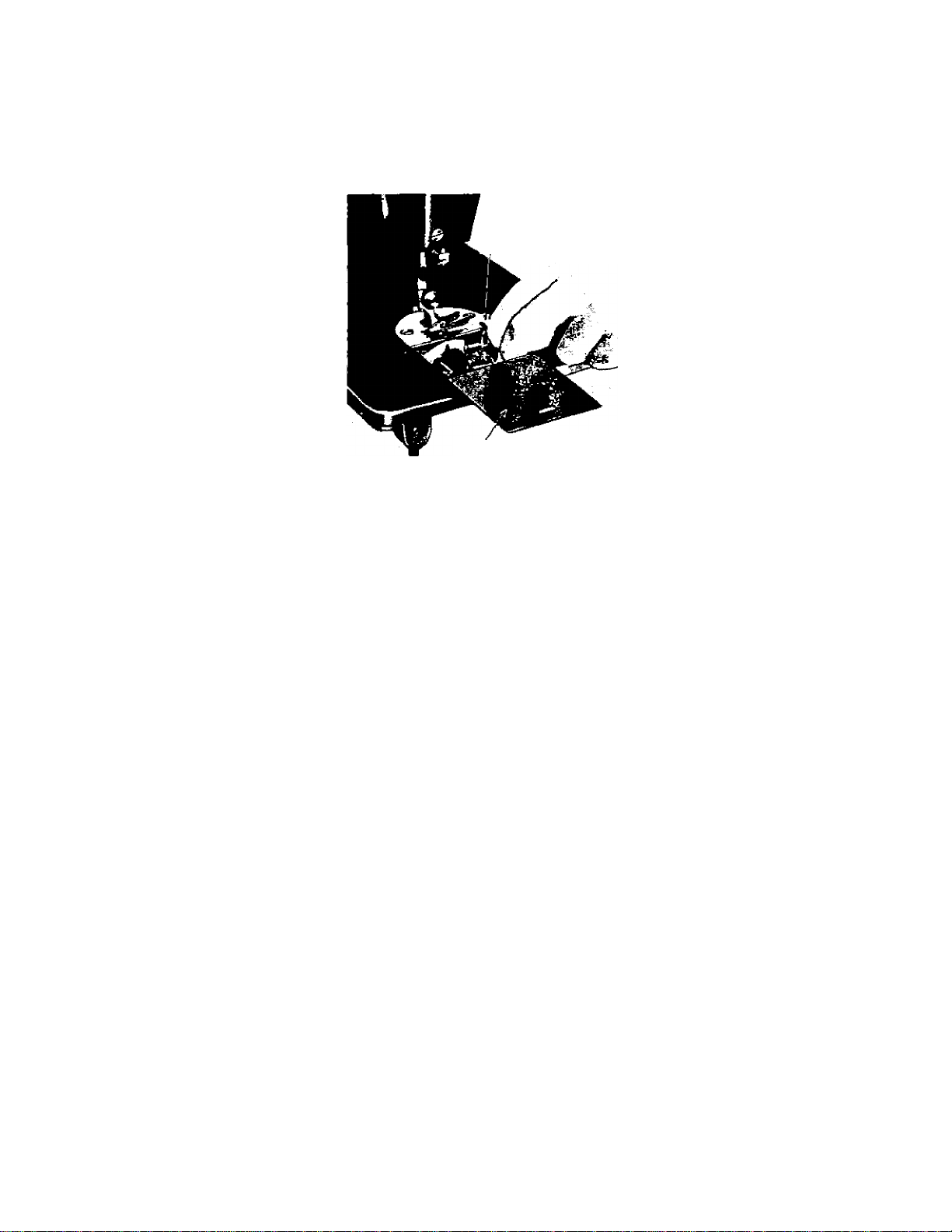

PREPARING TO SEW

To remove the Bobbin Case

Turn the hand wheel toward you until

BOBBIN CASE FrNGER

SUDE PLATE

(Fig. 3)

On releasing the latch and turning the bobbin case downward, the bobbin will

drop out.

The bobbin case must never be removed when the needle bar is in the lower

position. ■

the needle bar is at its highest point.

Open the slide plate in the bed of the

machine so that bobbin case can be

reached. (Fig. 3)

Insert the thumb and forefiinger to

open the latch and withdraw the bobbin

case.

While the latch is held open the bobbin

is retained in the bobbin case and will

not drop out.

Neither should a bent needle be used, as it is liable to damage the bobbin case

or the shuttle.

To wind the Bobbin

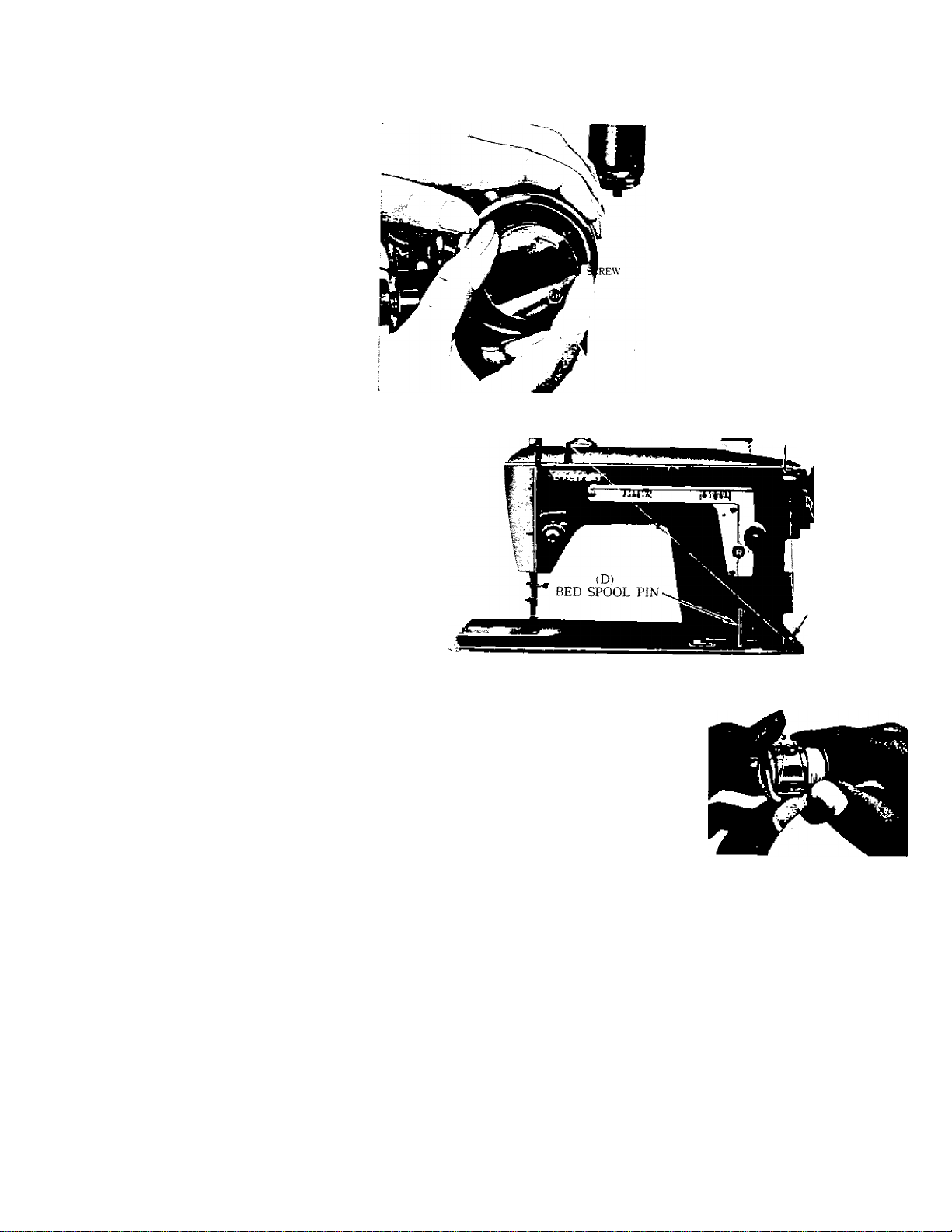

Disconnect the hand wneel by holding it in the left hand, while turning the stop

motion screw over toward you with the right hand, as shown in Fig. 4.

Wind the free end of the thread several times round the bobbin and press it oniu

the spindie (.4.), passing the thread through the tension bracket (B).

Press the push-button (C) until the latch fits securely into the bobbin. When the

Page 6

bobbin is filled, the latch automaticallr

disengages and stops the winding

operation. (Fig. 5)

By using the spool-pin on tlte machine

bed vD) spare bobbins can be wound

and prepared without interfering with

your sewing.

(Fig. 4'i

ARM SPOOL

P1N_,

(Fig. 5)

ARM THREAD

GUIDE

To thread the Bobbin Case

Hold the bobbin between the thumb and fore

finger of your right hand and pull out two or

three inches of thread.

Holding the bobbin case in your left hand, turn

the open side up and place the threaded bobbin

into it. (Fig. 6) g)

(A)

BOBBIN

WINDER

SPINDLE

(C)

PUSH

BUTTON

(B)

BOBBIN

WINDER

TENSION

BRACKET

Page 7

With the right hand guide the thread into the

slot in the edge of the bobbin case. tFig. 7)

Then pull the thread to the right, under the

tension spring and into the slot. (Fig 8)

In order to keep the bobbin from dropping out

(Fig. 7)

of the case when turned with the open side

down, always keep the hinged latch on the

SLOT

bobbin case open.

tFig- 8)

To insert the Bobbin Case

Hold the l)obbin case by the latch and place it on the center po.st ot me snuttle

with the finger of the bobbin case opposite the notch at the top of the shuttle.

Release the latch and press the bobbin case into the shuttle until the latch catches

on the canter post of the snuttle with a click. (Fig. 9)

FltvGhK .

LATCH ' ~

' Permit the bobbin thread to

CENTER POST

hang down freely a few

inches.

(Fig. 9)

Page 8

To insert the needle

Raise the needle bar (A) (Fig. 10) to

its highest point by turning the hand

wheel with your right hand.

Loosen the needle clamp screw (B) at

the end of the needle bar, and insert

the needle iC). with the flat side .

(Fig. 11 > to the right, into the slot of

the needle bar.

Insert the needle as far as it will go

until it touches the pin which is

visible in the slot above the needle

clamp and tighten the needle clamp

screw tirmlv.

(Fig. 10)

GROOVED SIDE

FLAT-SURFACED SIDE

(Fig. 11)

(Fig. 12)

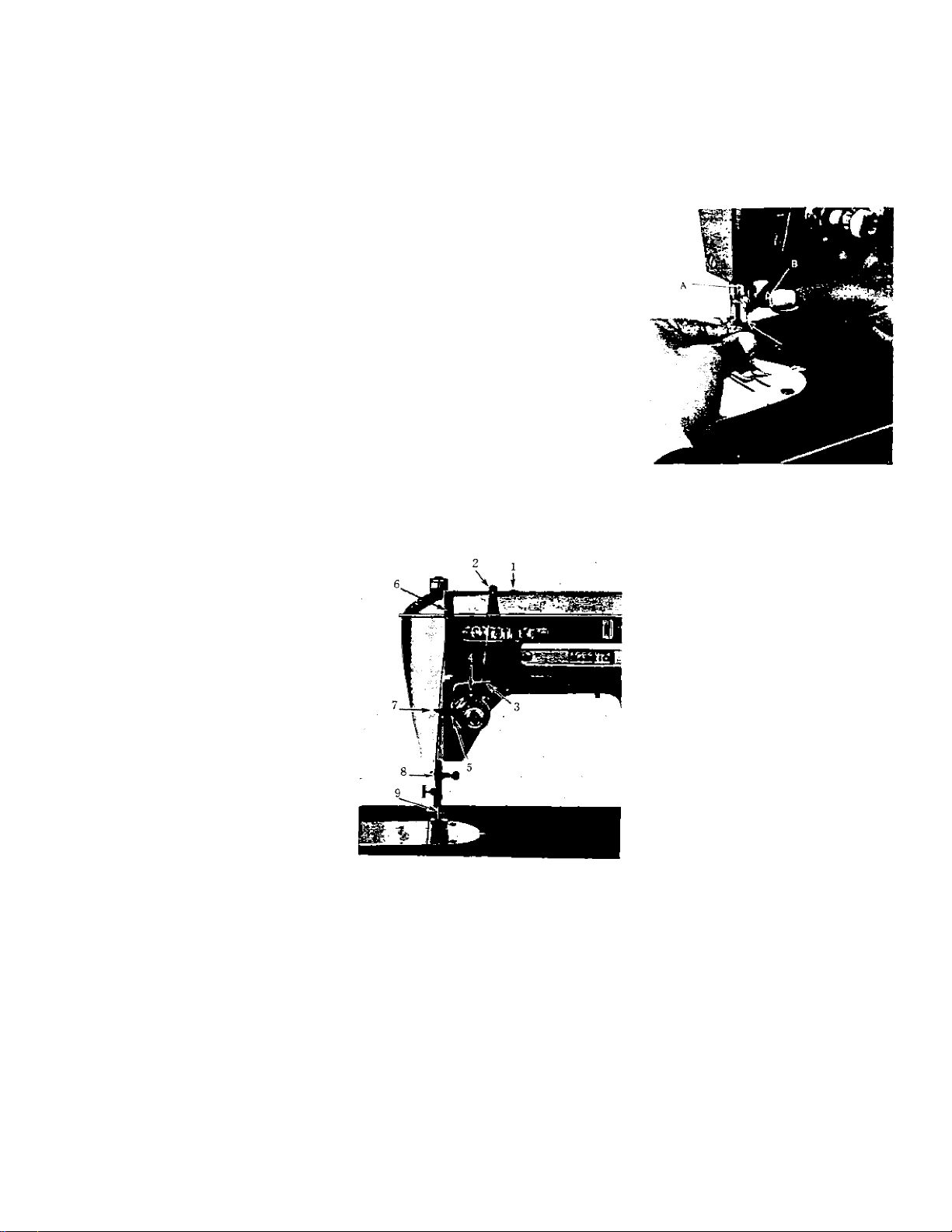

To thread the needle

Raise the take-up lever (6) to its

highest point.

Place a spool of the thread on the

spool pin on the back of the machine

arm.

Pass the thread through the upper

arm thread guides (1, 2). thrcugh the

lower arm thread guide (3i downward

Page 9

between the tension discs from the back, up over the tension thread guard (4)

from behind, down into the hook of the take-up spring. (t>t, up and through the

hole in the end of the take-up lever (6 .-. down through the face plate thread guide

(7 and into the wire thread guide (8), at the lower end of the needle bar; then

from left to right through the eye of the needle (9 .

Draw about four inches of thread through the eye of the needle with which to

commence sewing. (Fig. 12) .

To change the Needle Plate

Raise the needle to its highest point by turning the hand wheel, and raise the

presser foot by lifting the presser bar lifter.

Move the slide plate to the left and lift the needle plate out, as shown in Fig. 13.

Place another needle plate on the guide

screws and press it down.

Note : There are four different needle

plates for various purposes.

Needle plate for zigzag stitch,

i regular).

Needle plate for straight stitch.

Two needle plates for embroidery.

To change the Presser Foot

Raise the needle to its highest point, and raise the presser foot.

Loosen the thumb screw and remove the presser foot.

Attach another presser foot and tighten the thumb screw.

Note : There are six feet for different purposes.

8

(Fig. 13)

Page 10

Presser foot for zigzag stitch. (regulari>

Presser foot for straight stitch.

Presser foot for hemming.

Presser foot for button sewing.

Presser foot for buttonhole sewing.

Presser foot for braid sewing.

Automatic Darner

For releasing pressure on the foot, press

down the ring (A) (Fig. 14), which

will allow the darner to spring up to

its highest position and leave the

material free from any pressure from

the presser foot.

For sewing thin or light fabrics, press

the top of the darner (B) down lightly

to get the required slight pressure on

the fabric.

(Fig. 14)

For sewing thicker or heavier fabrics, push the top of the darner down further,

in order to get a stronger pressure on the presser foot.

Built-in Sewlight

To insert the electric-bulb, pull the

knob (A) (Fig. 15) until the socket is

tilted at an angle enabling you to

screw the bulb in.

(Fig. 15)

Page 11

Always push the socket back into position before sewing.

The light is turned on and off by means of the switch (B). (Fig. 15)

TO START SEWING

Pull the upper thread through the needle eye and hold it loosely with the left

hand. Turn the hand wheel toward you with the right hand until the needle

moves down and up again to its highest point, thus catching the lower (bobbin)

thread.

Now pull the end of the upper

thread you are holding and the

bobbin thread will be brought up

with it through the needle hole in

the needle plate, as shown in Fig. 16.

Place both ends of thread back under

the presser foot.

Place the fabric to be sewn beneath

(Fig. 16)

ing to the directions already given.

Note : For straight sewing, the zigzag width regulating lever (Fig. 1-3) must be

set to the right, so that the zigzag width indicator points to “ O ”. '

the presser foot, lower the foot upon

it and then start the machine accord-

10

Page 12

To regulate the tensions

For ordinary stitching, the tension on the upper and lower threads should be

equal so as to lock both threads in the center of the fabric.

thus :

If the tension on either thread is stronger than on the other, imperfect stitching

will be the result.

If the tension on the upper thread is greater than that on the lower thread,

it will lie straight along the upper surface of the fabric.

thus

If the tension on the lower thread is greater than that on the upper thread,

the lower thread will lie straight along the under-side of the fabric,

thus :

Tension i'n the upper thread

The sewing machine will give perfect per

formance when the upper thread tension

is correctly adjusted.

A) The tension on the upper thread be

comes stronger when the tension-dial

is turned in the direction marked

(+). (Fig. 17)

(Fig. 17}

11

Page 13

B) Contrariwise, the upper thread tension becomes weaker when the dial is

turned in the direction marked ( — ).

C) Once the tension has been adjusted satisfactorily, the dial can be returned to

the same dial-number to obtain the same results.

Tension on the lower thread

The tension on the lower thread is regulated

by the screw on the bobbin case tension

spring. (Fig. 18) Use the small driver and

tighten the screw slightly to increase the

tension, or loosen it to slacken the tension.

(Fig. 18)

To regulate the direction of feed and stitches

STTTCH LHNiiTH

rOiDiCATOit

Hirrrtw

For reverse stitching, keep pressing

reverse button "R" until the desired

length of stitches are sewn.

To regulate the length of stitch, turn

the stitch length regulating dial to the

required length, as shown in the stitch

length indicator window. (Fig. 19i

(Fig. 19)

12

Page 14

, To remove the work

Raise the needle bar to its highest point, lift the presser foot, draw the fabric

back and cut the ends of threads. Leave the machine threads about four inches

long for resuming sewing. -

DECORATIVE STITCHES

Zigzag sewing

ZIGZAt; WIDTH

REGUL.ATING LEVER

1 Ap .

s^apiol

(Fig. 21)

Make sure the needle plate and the presser foot

ZIGZAG FOOT & PLATE gj.g £pj. zigzag use. (Fig. 20)

(Fig. 20) ■

The controls for zigzag stitch are located on the arm of the machine, as shown

in Fig. 21.

Notice the lever A which adjusts width of the zigzag .seam. By moving this

13

Page 15

lever gradually to the left toward “5” the machine will sew a zigzag seam of

increasing width, depending on the position of the lever. (Fig. 21)

When sewing buttonholes, the stopper ‘"B" will be found useful. This stopper

serves as a stop for the lever “A”.

To set the stopper “ B ”, loosen the stop lock "C", move the stopper to the

desired position, tighten the stop lock “ C ”,

Button sewing

(1) Raise the needle bar to its highest point.

Raise the presser bar, remove the regular

presser foot, and attach the button sewing

presser foot. (Fig. 22)

(2) Drop the feed by pressing down the drop

feed button “DARN” on the right hand

corner of the bed. (Fig. 23)

(Pig. 22)

(3) Set the zigzag width lever

“ A” to 5 or less, according to

the distance between the holes

in the button.

(4) Place the fabric under . the

presser foot

(5) Place the button between the

presser foot and the fabric, (Fig- 23)

with the holes in a horizontal line and lower the presser foot.

14

Page 16

(6) Turn the hand wheel slowly toward you, making sure the needle enters the

holes in the button. Slowly start the machine, making about six or seven

stitches. To knot the thread, set the lever “A’' to “O" and make three

or four stitches.

When sewing four-hole buttons, first sew one set of two itoles, then stitch into

second set of two holes and lock thread with three or four plain stitches in last

hole in same way as described above.

Buttonhole sewing

(1) Remove the regular presser fcot

and attach the buttonhole presser

foot. (Fig. 24)

(2) Set the zigzag width lever “A" gauge

to a little less than 2.5. (Tig. 21)

(3) Set the stitch length, dial (Fig.

19) to obtain closely spaced

forward stitches. , BUTTON

(Fig. 24)

(4) Mark with pencil or chalk the position and e.xact length of the buttonhole

on the fabric.

(5) Place the buttonhole foot on one end of the marking, commence sewing the

left buttonhole seam until it reaches the end of the marking.

(6) To close the end, drop the feed by pressing down the drop feed button,

set the zigzag width lever “A” to “5” and sew three or four stitches.

(7) Now to sew the other side of the buttonhole, turn the fabric around 180

15

Page 17

degrees, and repeat the procedure as before.

(8) Remove the fabric from the machine and open the buttonhole with a button

hole cutter included in the accessories.

Note : It is sugguested that you make one or two sample buttonholes on a clipping

of fabric to test adjustments of the machine and to make corrections.

Braid sewing

Remove the regular presser foot from the machine

and attach the braider foot, as shown in Fig. 25.

Insert the braid through a small hole at the front of

the foot.

Adjust width of zigzag seam and length of stitch to

obtain a covering of the braid which appears the

(Fig. 25) most desirable for the material you are sewing.

Using a needle thread of a contrasting color will enhance the beauty of your

braiding.

Darning and Embroidery

Raise the foot lifting lever and remove the

presser foot.

Drop the feed by pressing down the drop feed

button, remove the regular needle plate and

attach the needle plate for darning and embroi

dery*. (see page 3)

Now* your machine is ready for embroidery and

darning.

Embroidery will be done most successfully when the fabric is stretched and fixed

16 "

(Fig. 26)

Page 18

in an embroidery hoop. (Fig. 26^

Hold the hoop closely on the machine bed with both hands, press the mtiterial

with your left forefinger in the vicinity of the needle. This will help in holding

down the material and will prevent the machine from making skipped stitches.

Manipulate work carefully and be sure to keep fingers out of the path of the

needles.

Adjust thread tensions for the best appearance of embroidery work and slightly

increase the bobbin thread tension to avoid the lower thread from being pulled up.

Hemming

Raise the needle to its highest point.

Raise the presser bar, remove the

regular presser foot, and attach hem

mer foot.

(1) Fold over the edge of the fabric

approximately 1 8 inch wide, then

fold it over again in the same

way for a length of about 2 inches.

Insert this folded end into the

spiral formed opening (scroll) of

the hemmer foot. fFig. 27)

Move the fabric back and forth until the hem forms itself in the scroll.

(2) Pull the fabric toward you until the beginning of the hem is just below the

needle.

(3) Guide the fabric into the hemmer foot while proceeding.

17

(Pig. 27)

Page 19

Note : Do not crowd fabric into the scroll, nor leave the scroll only partly filled

with fabric.

Instead of a straight stitch, you can also use a zigzag stitch for this hemming

operation. Be sure, however, to adjust the width of the zigzag stitch so that it is

as wide as the hem itself. '

Using a very long stitch and tight tensions will produce a SHELL STITCH.

Quilting

The quilting attachment

(Fig. 28') will enable you

to sew equi-distant lines

on padded fabrics without

the necessity of marking

them in advance.

To attach the quilter to the

presser bar of the machine,

raise the presser bar, loosen

(Pig. 28)

the quilter by the thumb screw'. (Fig. 28)

the thumb screw and clamp

Adjust the curved hook to the desired distance from the needle and adjust it to

press into the fabric.

When sewing, the hook should follow' the preceeding line f'f stitching.

Zigzag stitch quilting is done the same as straight stitch quilting except that the

zigzag width lever “A” (Fig. 21) should be set for the desired width of the

zigzag stitch.

18

Page 20

Cloth Guide

When you wish to sew close to the

edge of fabric or to make a wide hem

up to 1 h', inches in a straight (or

zigzag) and uniform line, the cloth

guide will be of help.

To attach the cloth guide, place it

over a hole to the right of the •

needle in the bed of the machine.

(Fig. 29) Attach with the thumb screw,

adjusting the guide to the desired dis

tance, then tighten firmly.

(Fig. 29)

MAINI'ENANCE

To open the Shuttle Race

To assure the best results with your sewing machine, it is necessary that the

shuttle race be cleaned out from time to time.

Moreover it will sometimes be necessary to open the shuttle race in order to

remove loose pieces of thread that have been

caught in the. hook.

The design of the shuttle race enables you

to do this most easily and efficiently, with

out sacrificing the precision which is so

essential to these parts.

SHUTTLE ^HU^RACF.

'■p'9- 30) needle bar to its highest point and remove

19

Page 21

the bolibin case. (Fig. 30)

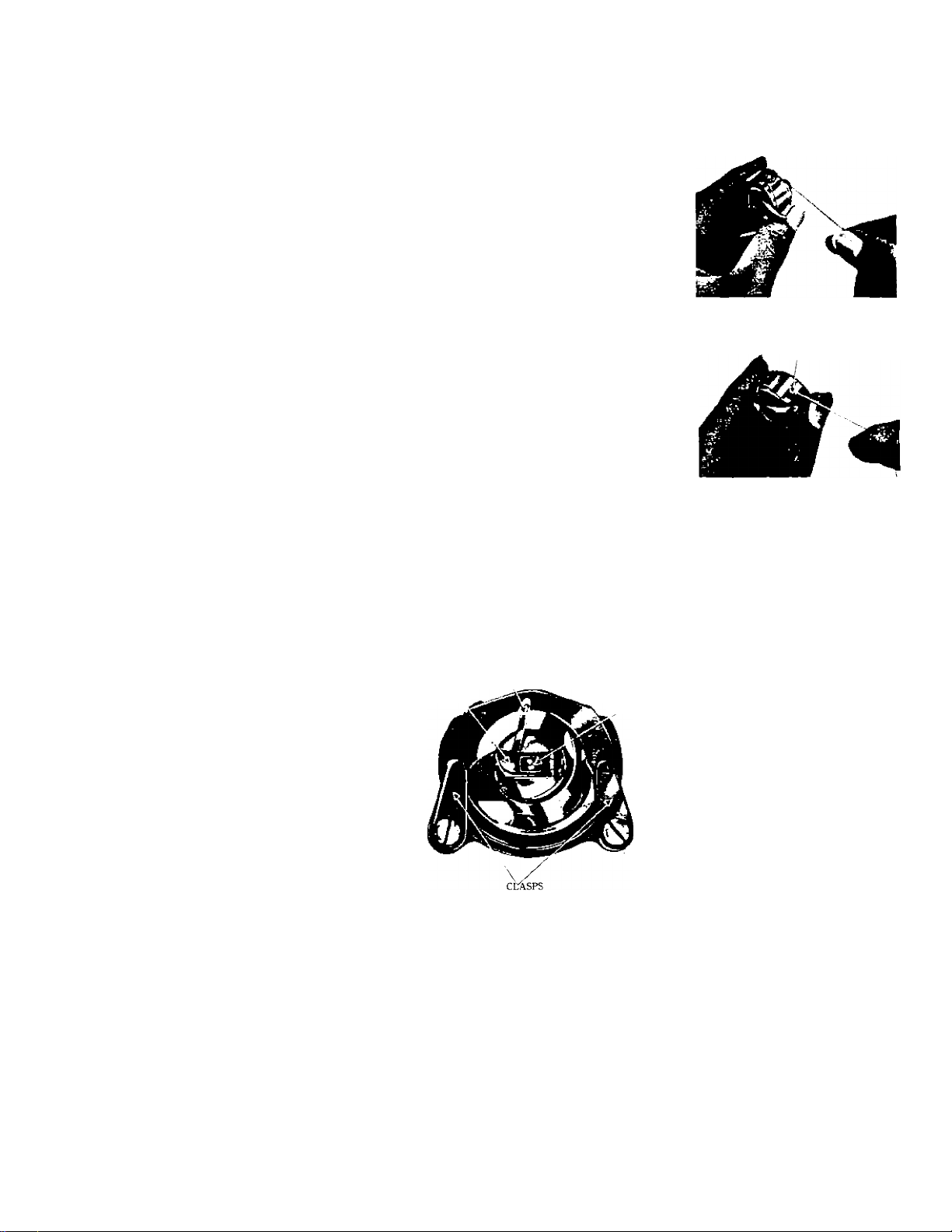

Next, twist the shuttle race ring clasps outward

(Fig. 31). then take out the shuttle race ring.

Carefully remove the shuttle and clean out

the shuttle race.

Replace the shuttle, the shuttle ring, and lock

with the clasps. Be careful not to drop or

(Pig. 31)

otherwise damage the shuttle. (Fig. 31)

To oil the machine

To ensure easy and free working of the

machine, it is necessary that all moving

parts be covered with a film of oil and

not be allowed to become dry.

The shuttle race should also be oiled

frequently.

The machine should be oiled at the

places indicated by arrows in Fig. 32 and

Fig. 33.

To remove the face plate, loosen the face

plate set screw. (Fig. 1—13)

After oiling, run the machine

rapidly for a few minutes to

■work the oil into the bearings.

When in constant use the machine

should be oiled two or three

times a week.

(Fig. 32)

(Fig. 33)

20

Page 22

CHECK-UP FOR SMOOTH SEWING

MACHINE WORKING HEAVILY

If the machine works hard after standing idle for some time, apply a little kero

sene in place of oil. Then run the machine rapidly to clean the bearings, and

oil with sewing machine oil.

The use of inferior oil is usually the cause of the machine working heavily.

THREAD BREAKS

If the needle thread breaks, it is probably due to one of the following causes:

The machine being improperly threaded.

The tensions being too tight.

The needle being bent or having a blunt point.

The thread being too coarse for the size of the needle, (.see page 23)

The thread take-up spring broken.

If the lower thread breaks, adjust the bobbin tension (Fig. 18) ; also see that the

inside of the bobbin case and the underneath part of the tension spring are free

from lint.

21

Page 23

SKIPPED STITCHES

A bent or blunt pointed needle is often the cause of this. See that the needle

plate is accurately inserted, (see page 8) Remove the needle plate and after

ascertaining that the feed is clean and working freely, replace the needle plate. ^

NEEDLE BREAKS

See that the needle is not bent and avoid pulling the material when stitching ;

either condition will cause the needle to strike on the needle plate and break.

MATERIAL PUCKERS

This is generally due to incorrect tension. See that both the bobbin case and

the needle are properly threaded : that the thread used is of good quality and the

correct size for the needle, (see page 23)

STITCHES LOOP

This is regulated by the tensions, (see page 11) See that both the bobbin case

and the needle are properly threaded ; that the thread used is of good quality

and the correct size for the needle, (see page 23)

22

Page 24

NEEDLE-THREAD-FABRIC-STITCHINQ GUIDE

Fabric

Ext rem el y he avy t arp au - 6

lin. sa cki ng . c an va s.

duc k, etc . 8

Hea vy up ho ls ter y f ab ric .

tick ing , d en im , l ea the re tte .

etc. 10

Me diu m -he av y dra pe ry

fabr ic , v elv ete en , s ui tin g.

felt , te rry , e tc . 12

Me diu m br oa d c lot h, pe r-

cale . g in gh am . l ine n,

chin tz . ta ff eta . s he er

woo l, sh ant un g, etc .

She er voi le, lawn, dimit y,

crep e, ha nd ke rch ie f li ne n,

plas tic hi m . et c.

Needle

No.

4

3

2

! 1

1 0

(Pla sti c F ilm

8 to 10 )

Machine

Stitches

Per Inch

i to

i

! 14

i

i 16

Cotton

Thread

to to

8

to , to

10

to

12

i to

1 ' 8 0

1

80

; to

to

10

30

30

40

40

to

60

60

100

Mercerized

Thread

Hea vy du ty

Hea vy du ty

Hea vy du ty

50

50

Sillc

or

Nylon

-

A

A

Ver y s he er ch iff on , b alisle . lac e. org an dy ,

nino n. ne t, ma rq uis et te,

I et c.

. to

1 15 0

100

50

A

= 1 6

00

i

; 20

1

to

23

Loading...

Loading...