Page 1

How to use and care for your

SUPER ZIGZAG SEWING MACHINE

MODEL 219R

Page 2

WHITE

SEWING MACHINE

Record in space provided below the Serial No. and

Model No. of diis appliance.

The Scerial No. is located on Bed Plate.

The Model No. Is located on Bed Plate.

Serial No. _____________________

Model No. 2 1 9

Retain these numbers for future reference.

.

..................

.....................

............

IPegel

...... 3

......

.... 7

.....

ig

Features and Parts ............................................

Winding the Bobbin...........................................

Upper Threading

Placing Bobbin Case..........................................

Adjusting the Tensions....................................................... g

Adjusting Pressure and Feeding of Fabric

Preparing to Sew ................................................................. j

Applications of the Smocking Stitch

Twin Needles Upper Threading and Stwing

Samples of Creative Embroidery

Creative Embroidery............................................................ jg

Embroidering With a Hoop..............................................

Making Buttonholes

To Regulate the Length of Stitch

Sewing in Reverse

..............................................

....................................

......................................................

.............................

...............................................................

INDEX

6

8

.10

12

13

..

g

{Item)

Straight and Zigrag Sewing

Sewing on Buttons

Straight Stretch Stitch........................................

Multiple Zigzag Stitch

Blind Stitch Hem...................................................

Manual Operation

The Adjustable Cording and Zipper Foot

Quilting Guide

Seam Gauge or Cloth Guide

Cleaning and Oiling the Shuttle..........-

Care and Maintenance of Your Machine....................28

Accessories

Trouble Chart

For Portabile......................................

Installing sewing Head.....................................................

................................................................. 20

...........................................................................

............................................................. '

............................

.............................................

........................................

...............................................

...................

............................................

.......................

{PageJ

■•■19

■ 20

■ -21

■■ 22

--23

••■24

25

26

27

..

Page 3

features AND PARTS ¡Front View)

Fig. 1

1. Take up Lever

2. Pressure Release (Darning)

3. Arm Thread Guides

4. Pattern Selector Dial

5. Zigzag Stitch Width Control

6. Bobbin Winder

7. Hand Wheel

8. Stitch Length Control

9. Reverse Stitch Button

10. Drop Feed Control

11. Model/Serial No. Plate

12. Needle Clamp Screw

13. Presses Foot

14. Needle Plate

15. Cover Plate

16. Attachment and Foot Thumb Screw

17. Tension Control

18. Thread Guide

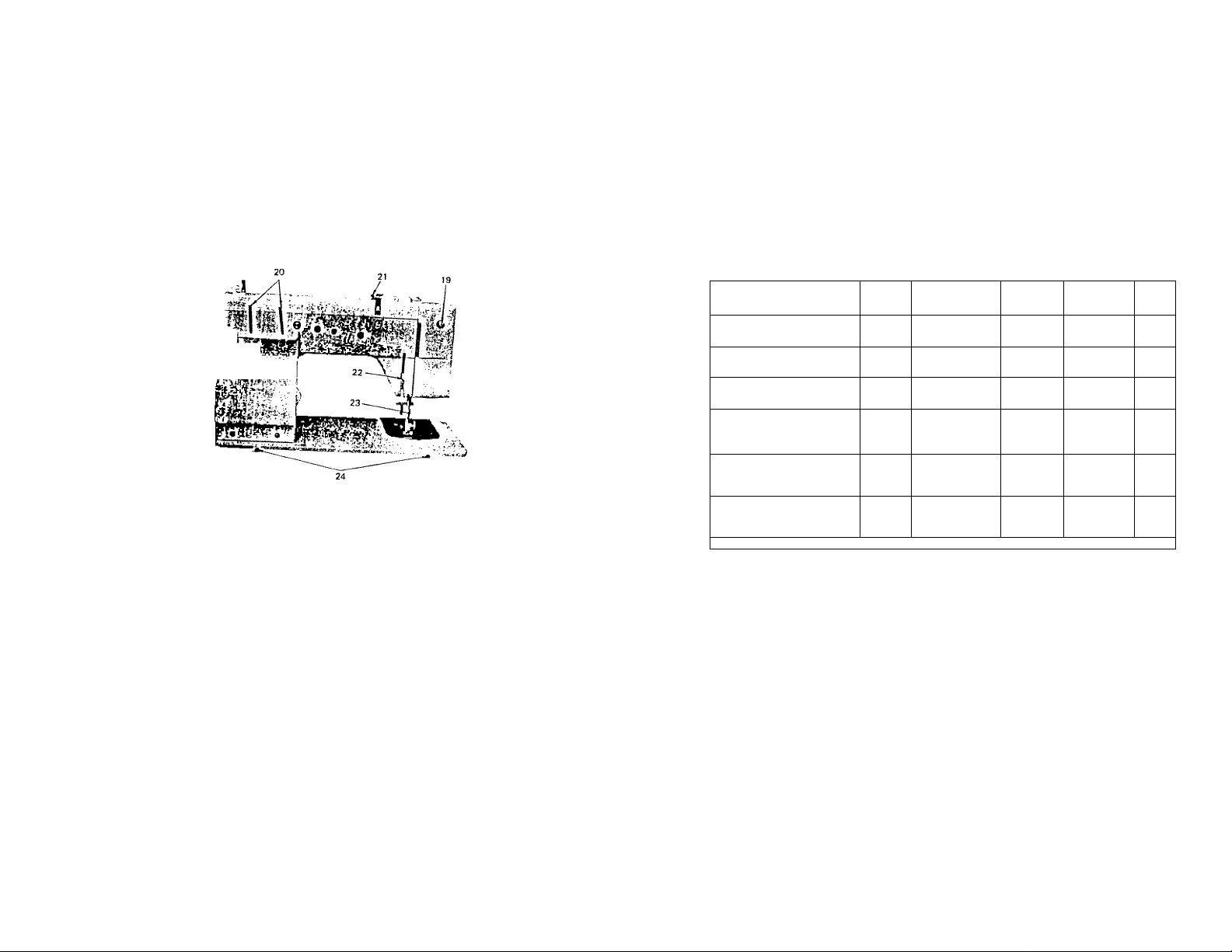

Page 4

I ,

Fig. 2

19. Sew Light Switch

20. Spool Pins Bar Lifter

21. Bohhin Wioder Tention .Thread Guide,

2a. Head Hinge Mounting Holes

NEEDLE-THnEAD-FABRIC-STITCHING GUIDE

Fabric

txtremely heavy tarpaulin,

sacking, canvas, duck, etc.

Heavy upholstery fabric,

ticking, denim, leatherette

Medium heavy drapery fabric,

velveteen, suiting, felt, terry, ¡tc.

Medium broadcloth, percale,

gingham, linen, chintz, taffeta,

sheer wool, shantung, etc.

Sheer voile, lawn, dimity, crepe,

handkerchief linen, plastic film,

etc.

Very sheer chiffon, batiste, lace,

organdy, ninon, net, marquisette

etc.

Needle

No

3 1181

2 116)

1 114)

0111)

00

4

Machine Stitches

Per Inch

8to8

8 to 10

10 to 12

[

---------

-----------

12 to 14

14 to 16

IPIsttic film)

8 to 10

16 to 20

..

~

Cotton

10 to 30

30 to 40

40 to 60

60 to 80

80 to too

100 to 150

----------

---

————- ‘

Mercerized

1>’read

Heavy Duty

Heavy Duty

Heavy Duty

50

50

50

Silk or

Nylon

A

A

A

Page 5

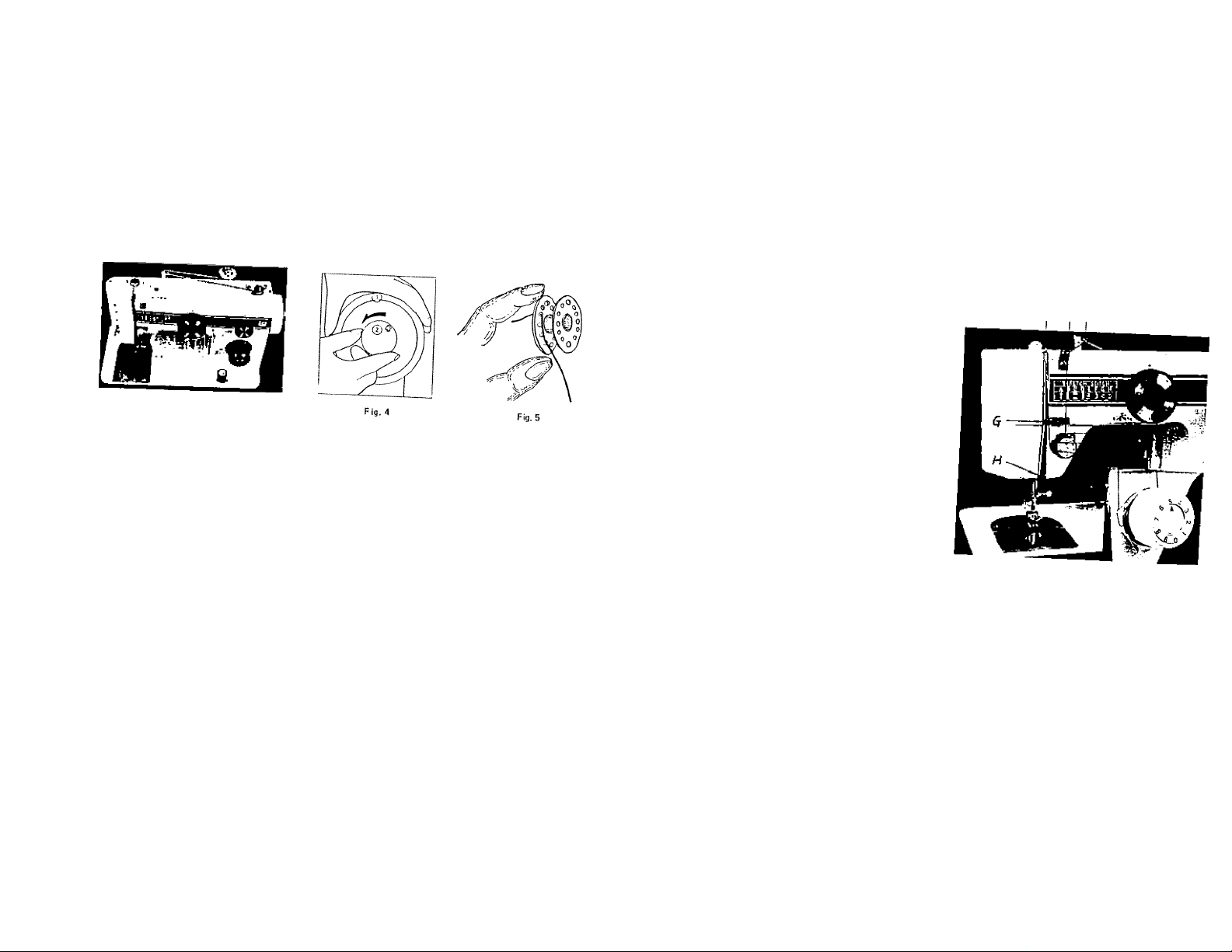

WINDING THE BOBBIN

Fig. 3

Disengage the hand wheel (I, Fig 4| from the cin^hi i. ■

Fig. 4) toward you or counter clockwise PlTc a It ^7

Icad thread through the arm thread guide (3 Fig Ttl 7 f T

bobbin edge and place bobbin on spindle of bobbin winder nuing‘'tr''t I

over small pin on spindle. Push bobbin (5 Flo ai i ,i u '“'"8‘^e notch on bobbin

!U„ ,l™„. ' ' -"I ll»“ «.'•« .»J looKi, ,h.n

UPPEFi THREADING

Turn the hand wheel toward you to raise the take,

up lever to its highest position.

Place a spool of thread on the spool pin

t.",

4.

S” “¿ft""" «'’™

Draw the thread up through the check spring (0

Fig 6^ ^ (E,’

Then up through the eye of the take-up lever (F

h»g-6) from right to left. ' '

Lead thread down, through the thread guide (G, F

ig. 6) then through the needle bar guide (I, Fig 6)’

Thread needle from front to back, drawing it

through about 3 or 4 inches. Hold the end of

he upper thread Ic-sely and turn the hand wheel

toward you until the needle goes all the way down

and comes back up. Aloop (Fig. 7) will be formed

over №e upper thread which then can be pulled out

traight. Place both thread ends under the pressed

foot and draw toward the back of the machine

leaving both threads three or four inches long.

Fig. 6

F B A

F«g. 7

Page 6

7A

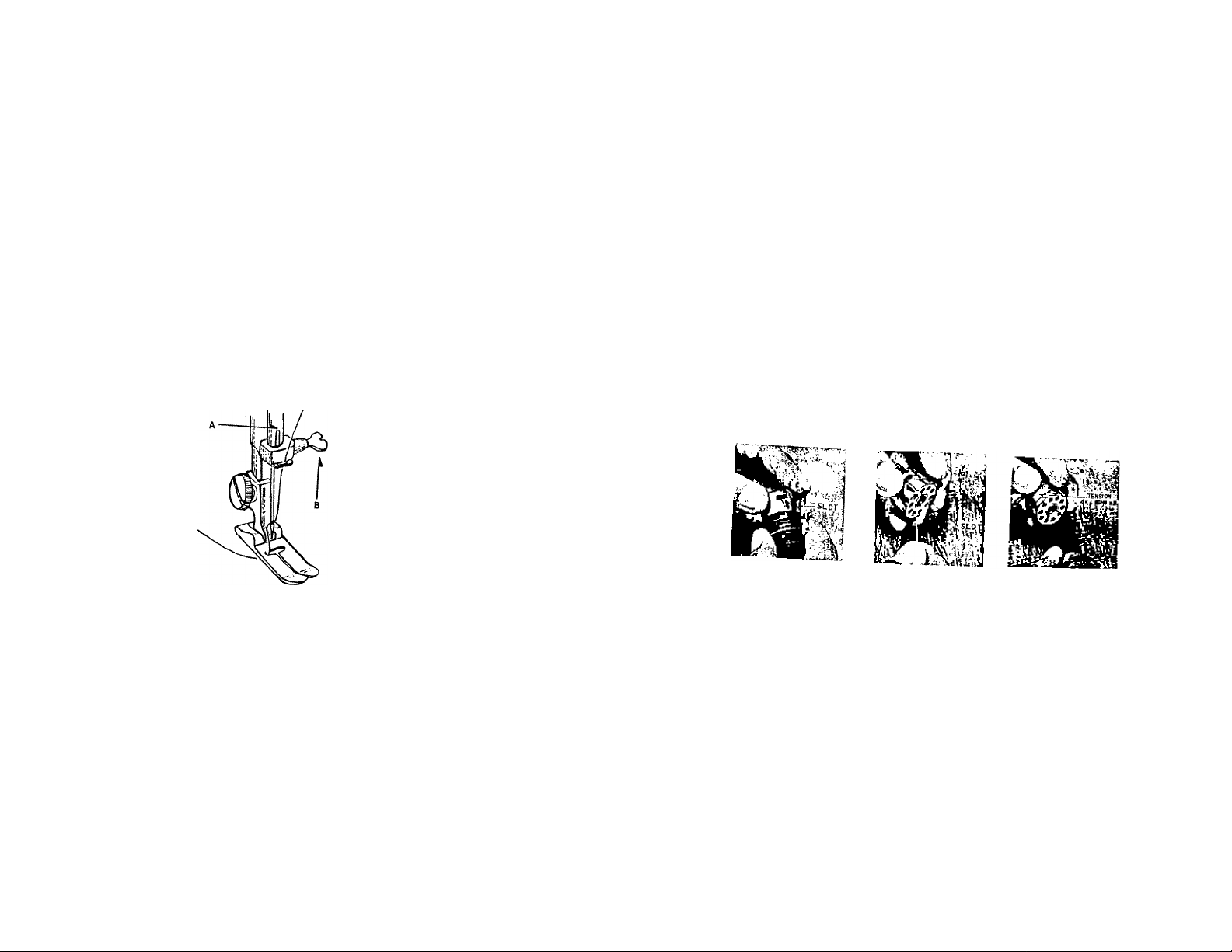

SETTING THE NEEDLE

TbI ‘aid ITneZle'c^n IT'

{Flat Side to BACKl in needle clamp push it uplTaTir « 7'^'

Tighten the Needle clamp sctew secutel, with a sctew Ihv“ *

THREADING THE BOBBIN CASE

.“:^L't”т;“ ;”.2 “• ‘."<'..0

forefinger of right hand so that the th '* bobbin between thumb and

1.» b..«„ ..i, r, ; r“iv:oi;;*r '•'■» t-

....

.......... ■“ - - »

78

Fig. A

Fig. B

Fig.C

Page 7

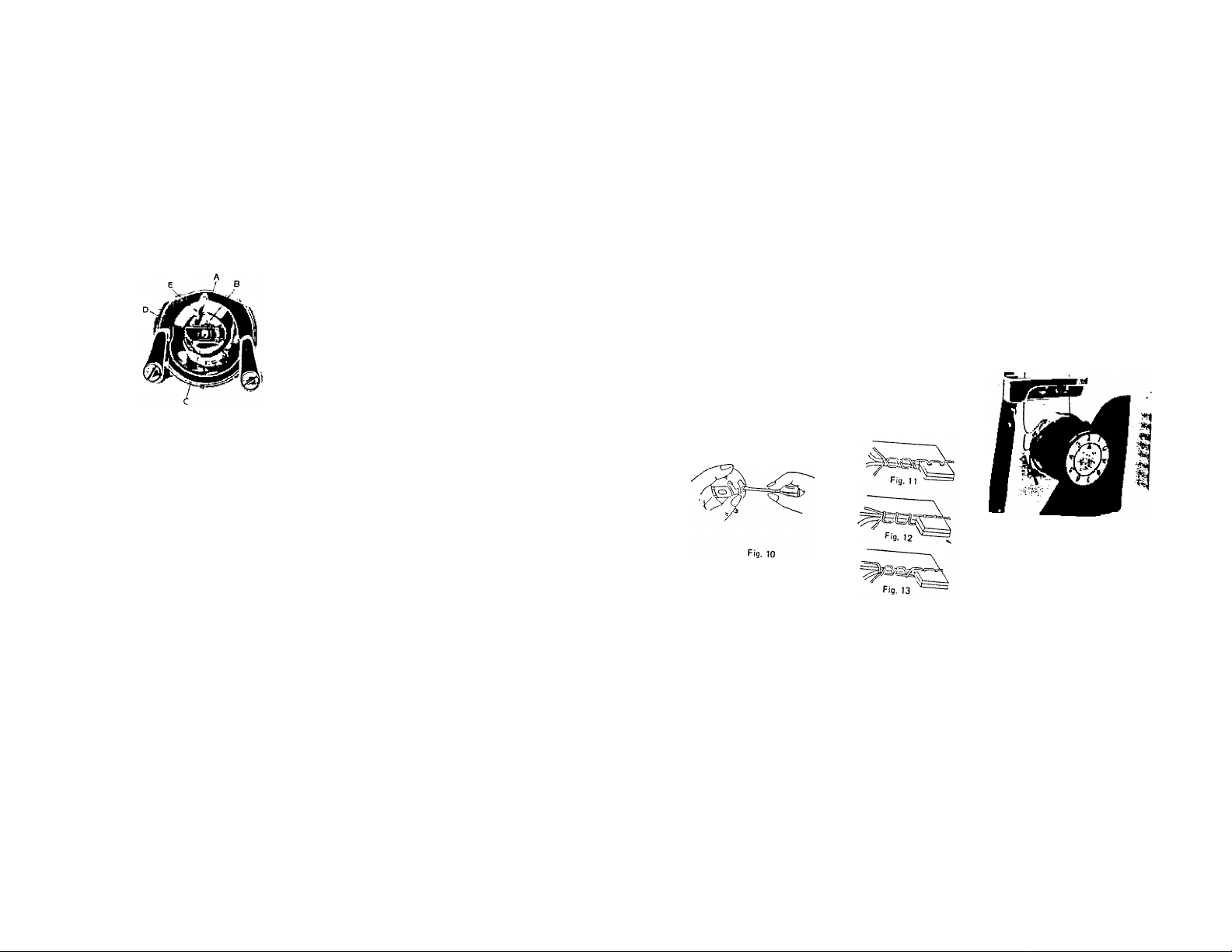

placing bobbin case

Fig. 8

Raise needle bar ,o highest position, and lif, hinged

atch p F,g. 8), between the thumb and forefinger of

‘he left hand, with at leas, three inches of .lead

running from the top of the bobbin case to the right

nser, and center the bobbin case on the stud of the

shuttle body, (C). Be sure the bobbin case finger (E)

.s opposite the Shuttle race notch, (A,. Press the Lbin

a e (B) into the shuttle as far as possible until latch

atches on the center post of the shuttle. Then release

the bobbin case latch, (D), Press bobbin case again

lie J I k T '"hhin

case IS locked securely.

Close the cover plate.

adjusting the tensions

«sSsHiSr=

perf«7s".i.fh win'be for"'n” balanced, a

ing in fabric (Fig. 11) threads interlock-

is plied ul oT thruo" " ‘r ‘bread

on the fabric (Fig. 2) V№en the

loose, the upper thread '’P" *s 'oo

lying flat on the fabric (Fig™3)°°^* ‘'’read

Fig. 9

Page 8

10

adjusting pressure and feeding of fabric

»»I...,1A

preparing to sew

n

Sewing Thin or Light Weight Fabrics. When lighter

requtred to sew satisfactorily on thin silk

pressure cap should be about halfway down L a'rairr""’

pressing the snap lock, (A, Fig. 141 and the '

to halfway spot. '' down again

Darning and Mending. In order to move the fabric r , ■

direction for darning and mending release the n ''

completely by pressing down on th; snap lock,

Turn drop feed control (Fig. 15) to •’ TTOT " •

Win drop the feed well below the needle pl^Tr

normal position, turn knob to ” ^ •• ">

Fig. 14

Fig. 15

Place materiarand thr;! inToshi

to “>ward you until the needle Tlut'h° h

to begin sewmg. By having the needle at its hiehes n • are now ready

wheel to start the machine. You merely press fte contrT Vh "°‘,'’"f’*^ry to touch the hand

by increasing or decreasing the amount 'of^ressure

removing THE WORK

Page 9

12

applications

Pattern :g

Length: 5

Width: 5

Feed Dog:

Pressure: Normal

Foot; Zigzag Foot

(51

OF THE SMOCKING STITCH

e -^rth '"^“’od is actually

easier than the overedge method for fabrics that curl

SEAMS

sre ^ inch seam in one

seams and I,"''’ " <he

seams and prevents the curling of the fabric that

often occurs with 5/8 Inch opened seams It is most

applicable to soft, thin knits such as nylon or acetate

kmts, but may be used on other fabrics arweil

Always make test seams with this stitch

strenaTh a*n7'" ^‘¡‘ch gives

Strength and prevents raveling. It can be used on

woven goods to replace flat felled or French seams.

rh P^llcrns with 'A inch seams: (Fig A ) Place

at the r!w i‘ comes down

allowan« ^cam

For patterns with 5/8 inch seams; (Fig 8 ) The

seam allowances may be trimmed to % inch either

prtred" T before sew ng

proceed as above. Otherwise, sew the seam with the’

raw edge of the fabric on the etched guide line ”¡5”

r1, I f"" '^Wih of a particuL;

VS inTt ,r'‘‘i 7'?’“"' '‘'S' fi>bHc

abri near°,h tcin’ the excess

TWIN NEEDLES UPPER THREADING AND SEWING

Be sure zigzag needle plate and presser foot are in place

Follow threading instructions for single needle with these exceptions-

b.

ead bl t?'

Lead both threads through arm thread guides.

Bring threads down and around tension discs with one thread

passing between the back discs and the other between the front

dtscs. "L/Mi

Now treat both threads as one until you reach the needle eye

d.

Pass one thread through each needle eye (Gid 18)

The maximum zigzag stitch width that can be sewn when using

A r . " 'I -n'™'

needle ^ ‘be twin

Straight stitching and decorative stitch designs can be produced

m the same manner as for single needle sewing except for the

maximum zigzag width.

13

spool pin.

Fig. 18

Page 10

14

SAMPLES OF CREATIVE EMBROIDERY

"A" Sew a few stitches at 5 width then turn knob back to O for a short period. Count if

necessary, to establish a rhythm. (A, Fig. 20) '

' '''' 2 and number 0

"C" Gradually move the zigzag width control from 0 to 5 and instantly return to O Then

repeat likewise. (C, Fig. 20). 'u lo u. men,

"D’

Set zigzag width at 5,^ch length at 2. Sew a few zigzag stitches. Turn the drop feed

no ( ig. 5)to " position for 3 or 4 stitches then normal position again By

ojraung the drop feed knob rhythmically it is not necessary to count stitches. (D

”E’

Set drop feed knob at " 222£ ..

width control at the number 5 position. Take 3 or 4

stitches, leave needle in fabric and pivot fabricon

needle to make next daisy petal. Continue until

flower design is completed. Lock threads by setting

stitch width at O and sewing 3 or 4 stitches in center

of design. (E, Fig. 20).

D WWWrtWA\VVWirW#AWWAWi'A1

Fig. 20

'"1'^

15

CREATIVE EMBROIDERY

Be sure zigzag presser foot and zigzag needle plate are in place.

1. Set pattern selector (C, Fig. 17) at "1 ” position.

2. With the zigzag width control {D, Fig. 17) set at the Number 5 and stitch length control

{A, Fig. 17) as near O as possible without stopping the feeding action, a sating stitch is

produced (Fig. 19).

4. With the machine set for a short stitch length, different designs can be made by turning the

zigzag width control back and forth between 0 and 5 or any other combinatio"s of widths.

Try setting the zigzag width control (D, Fig. 17) at the first line and the various other lines.

Set a rhythm for yourself and then proceed. After a while you will become quite skillful,

varying your designs by the speed of the machine, stitch length and manipulation of tiie

zigzag width control.

Fog. t9

Page 11

16

embroidering with a hoop

It is easy to follow a stamped design or to work free

hand when embroidering or monogramming. (Fig 21)

Release the pressure from the foot by pressing down the

«k on the darner. Turn the drop feed knob to

position (Fig. 15).

Stretch the fabric in an embroidery hoop, and place

under the needle after removing the presser foot. Set

t e stitch width at the size you prefer and lower the

presser bar lifter.

Then operate the machine at a rather high speed

while moving the hop slowly with both hands. Work

shi:::r:::::: t::" "r"" -u encounter skip

--bie from Tour dealer!,

MAKING BUTTONHOLES

3.' lerthfsmcMe^th 3'"°^ i:'?,o!i toT " T 'T

It is suggested that the stitch leng 1 d a be s^t Tn d" "

.. =r rirr"

the line the length of the buttoUoirdLh^eT's/V'-IM^ bottonhole and also mark on

the button. ' the outside diameter of

'■ blrontole "ol" cloth in the center of the

Fig. 23

17

Page 12

18

6- Turn the pattern selector (C, Fig 17) to marltin„ " t •>

along the line. 2 position, and start to sew left side

7. Stop with the needle on the left side of the stitch (Step 1 Fig

*'"""" S ■“ ■'».«..H. »

’■ .p ;:r -

NOTF L r u'"'" ‘’“»othole with the seam'ripper

■ e sure that the pattern selector is firmly positioned in every marking "2” -'S" or

stop here •

(STEP 1)

I Stop here

(STEP 2)

: Stop here

(STEP 3)

Fig. 23

finish here!

(STEP i ^

TO REGULATE THE LENGTH OF STITCH

longest. " "5" is the

Figures on dial g ^

Number of stitchs per inch No Feeding 36 20 12 9 7

SEWING IN REVERSE

^egInning“or'"tt end'of i'’se'am"pres°s tt*' ‘"''h*

Fis. 171 as far as if II t?' button (B,

aslongL^Ltuoi^ptfs^ed"'’'

STRAIGHT AND ZIGZAG SEWING

is set^at "straight & zigaag” shth^aNem P'“"" (C, Pig. 17|

increa^.^and by Tu^rlg'it runTel'<l«'f ° -HI be

machine .will sew^tra,"ghfs'titcher.‘"‘''“'‘"‘^'=’ and at "0 ’* position, the

Stitch Length Chart (Approximate!

Fig. 17

19

Page 13

20

SEWING ON BUTTONS

p«.» ,.p "■

and the needle enters the left hand hole of the button

’ ZdZ "r® T''“’ “"‘il ‘he

needle enters the „ght hand hole of the button. Turn the

bjance wheel slowly by hand to be sure the needle clears both

holes in the button. Correct width if necessary

5.

When needle goes into the center of each hole.'run the machine

at a medium speed, making five or six stitches, stopping with

the needle in the left hole. *

l^f you wish you may place a rounded toothpick over the

willTh M . ‘°°‘hPick and

wind thread under button forming a shank to fasten.

Fig. 24

to "1"

STRAIGHT STRETCH STITCH

Pattern: g ¡Sj

Length: 5

Width: 0

Feed Dog: ^

Pressure: Normaf

Foot: Zigzag foot

21

This stitch may be used on knits and wovens in areas of

tress as a reinforcement stitch. It is excellent for curved

seams such as armholes and crotch seams. For active wear

such as ski pants and girdle fabrics which endure a lot of

stress ,n bending and stretching, this stitch may be used

for seaming throughout the garment.

CAUTION - It IS difficult to remove this stitch from fabric

Pre-fit garment before using this stitch.

• TOPSTiTCHING

Because this stitch is heavier than an ordinary straight stitch.

Ideal for top-stitching, particularly on knits.

Page 14

22

MULTIPLE ZIGZAG STITCH

Pattern; ;i,' (7)

Length: 5

Width; 5

Feed Dog:

Pressure; Normal

Foot: Zigzag foot

aa>\

This stitch IS useful when replacing worn blanket bindings

or both a decorative and durable finish, and when

overcasting an edge to prevent fraying.

When applying elastic waist bands to skirts and dresses be

sure to stretch the elastic as it is applied to insure fullness

required in the garment. When sewing a zigzag stitch on soft

or sheer material it will prevent puckering.

There are hundreds of other uses which will become apparent

as you use the machine.

BLIND STITCH HEM

Pattern; ^ (sj

Length; 3-4

Width: 4-5

dog: ^

Pressure: Normal

Poot; Zigzag Foot

Step 2.' t1 Lm to teZl Sre/and basul/T.^

Prepare the garment in the same manner as for hand hemming.

st^i tt“ir

and make a side wise stitch about 'eve; oNn

23

COMPLETED

Fig. 27

Page 15

23A

SCALLOP STITCH

Pattern; ) |6i

Length: 0.5-1.5

Width: 5

Feed Dgo:

Pressure: Normal

Foot: Zigzag Foot

The scallop stitch particularly works out nice stitches to

decorate table cloth, sleeve fringe, stole and the like. And,

when sewing on the edge, it is easy to have a neat trimming

with removal of redundant material just close to those

Stitch«.

MANUAL OPERATION

in place and machine is set for manual operation. Use for:

Overcasting Worn Edges

Zigzag stitch along the worn edges, catching the fabric as

the needle swings to the left, and allowing the needle to just

pass over the edge of the fabric on the right (Fig. 29).

Patching

Machine bastes patch into place by placing fabric under hole

or worn area which has been cut away. Then zigzag stitch

the patch into place by overcasting around edge of hole

Applique

s'!!™ of ffollowing the

Ларе of the design outlining it entirely and remove excess

materia on the outer edge by trimming it away afterstitching.

around the design outlining it entirely

Hundred of other uses will become apparent as you continue

fpertifn:

operations. Also, for best result set speed control slower

when sewing around contours and faster for straight lines.

foot and zigzag needle plate are

to fabric and overcast a zigzag stitch

24

Page 16

25

THE ADJUSTABLE CORDING AND ZIPPER FOOT

This attachment is used to make and insert

covered cording and to sew in zippers. Loosen

thumb screw to slide foot to either right or left

of needle.

CORDING. Fold bias strip of fabric over cord.

Loosen thumb screw and set foot so needle is

centered in needle hole. Machine bastes cord in

place (Fig. 31).

To sew covered cord to material, reset adjus

table foot so needle stitches closer to cord, and

on edge of base fabric.

SEWING IN ZIPPER

Loosen thumb screw and slide foot so needle enters center of

needle hole. Guide metal of zipper along edge of foot

(Fig. 32). Stitching should be close to zipper to allow easy

opening and closing. Adjust to sew from either right or left

side, whichever is more convenient.

Fig. 31

quilting guide

Use this gtnde for making parallel rows of straight or decorative

stitching Attach standard presser foot. Slip U shaped holder on

screw (Fig. 34) Adjust the curved bar for the distance desired

Bv riRn'T ‘he fabric.

By letting the guide ride on the previous stitching line, successive

rows will be an equal distance apart (Fig. 34),

‘''9- Fig. 36

SEAM GAUGE OR CLOTH GUIDE

top stitching along edge of fabric (Fig. 33),

threaded hole in bed of machine. Adjust to desired width*

^ u'®’ 3'^eompanying screw (Fig. 36) in

'“=«ht seams and even rows of

Fig. 34

Page 17

27

CLEANING AND OILING THE SHUTTLE fSee Fig. 37 and 38|

^'°8ged with loose threads and Mnt, This

Mfeguard the performance. To remove the shuttle assembly, proceed as follows-

■ h7nges " Tilt head back on its

2. Remove bobbin case (A , Fig 37)

'■ JnTsh'u^le'rody Sr "" --- -e cover ,C,

A B

Fig. 37

; p:":rr ;:rr^—^

. lace shuttle body, (D), against shuttle driver and adjust into position

3.

'r* ri'*;r:,iS' !m7 ■'

into position. ^"^pped securely

4.

Put bobbin Into bobbin case.

CARE AND MAINTENANCE OF YOUR MACHINE

How to Oil Your Machine

your machine should be oiled occasionally to keep it

operating smoothly, how often depends on the amount

of sewing you do.

Before oiling the upper part of the sewing unit at points

indicated by arrows in Fig. 39 turn hand wheel

toward you until the take-up lever is at its lowest point

28

Page 18

23

Fin. 40

Fig. 41

HOW TO REPLACE THE LIGHT BULB

Open Face (Fig. 40). Unscrew bulb and insert new one.

ACCESSORIES

30

Page 19

31

TROUBLE CHART

Trouble

If Machine

Binds

Probable Cause

Thread or lint in

raceway

Correction

1~ With take-up lever in highest position, tilt head

back on hinges and rempve bobbin case.

LINT CLEANER

BOBBIN

race cover CLAMPS

Turn clamps outward and remove race cover.

3~ Remove hook.

4— Clean thread and lint from all parts, Including race.

5— Run a drop of oil along rim of hook.

6- Replace shuttle, then race cover.

Snap clamps into place.

7- Grasp threaded bobbin case by latch and replace,

!

fitting tongue into notch of race cover.

Trouble

Skipping

stitches

Irregular

stitches

Uneven

stitches

Probable Cause

Bent needle

Needle placed

incorrectly in clamp

Too fine a needle for

thread being used

Upper thread tension-

too loose

Improper threading

Bobbin not wound

evenly

Pulling or holdiftg

materia!

Not enough tension

on upper thread

Poor quality thread

Needle too fine for

thread being used j

Correction

Discard and replace.

See instruction, page 10.

See needle and thread chart, page 5.

Tighten upper tension.

See threading instruction, page 8 and 9.

Rewind bobbin.

Avoid pulling or holding material, just guide it.

Increase tension.

Try different thread.

See needle and thread chart, gage 5.

33

Page 20

33

34

Trouble

Upper

thread

breaking

Material

puckering

Probable Cause

Improperly threaded

Too much tension

Starting with take up

in incorrect position

Improper setting of

needle

Bent or eye of needle

to sharp

Bent or blunt needle

Tensions too tight

Dull needle

Stitch length too long

Correction

Refer to threading Instructions, see page 8 and

rethread machine.

Loosen tension on upper thread by turning

thread tension knob to lower number.

Always start sewmg with take up lever in highest

position.

Refer to needle setting instructions, see page 10.

Try a new needle.

Discard all blunt or bent needles and replace with

new.

See tensions adjustment, page 14.

Change needle.

Reduce stitch length.

FOR PORTABLE INSTALLATION

Please read these important instructions

which were written to aid you In placing your

new sewing machine on its portable base.

First, remove the nail which holds the foot

control inside the base to avoid damage in

shipping. If a small plastic clamp is fastened

to the back and not to the top of the partition

at one end of the base, remove it, too.

After unpacking the sewing machine unit,

being certain to take out the instruction book,

guarantee and accessory box, lay the unit face

down on a table. You will see two clamping

screws "A" entering head hinge holes "B" on

the underside of the back.

On the base you will find two head hinges

'C" which will fit into holes "B". Lower the

baw onto the sewing machine fitting hinges

C into holes B. Tighten screws "A" securely

with a screw driver.

Vyith machine In sewing position attach

plastic clamp "D" to top of partition with

screw provided so that it may be turned across

the bed of the machine, to hold it down.

(On some bases the clamp may be positioned

in the proper spotl.

To make the electrical connection draw

the two wires through the slot in the partition

of the base. Plug the cord labeled "Motor"

into the receptacle marked "Motor" on the

block attached to the outer section of the base

Then insert the other cord into the "Light"

receptacle.

Place the foot control on the floor, insert

plug into a wall outlet (110-115 voltsj and

you are ready to sew. But Brst read the

instruction book to become familiar with the

threading of the machine, tension adjustments

and all the other features designed to make

sewing a pleasure.

Page 21

35

36

INSTALLING SEWING HEAD IN CABINET

1. Loosen both head hinge set screws until

head hinge hole is clear.

2.

Tilt head hinge fingers up and back as far

as they will go.

3.

Carefully slip head onto head hingesmaking sure fingers are inserted as far as

they can go into head hinge holes.

4.

Allow the head to rest in its tiltedback

position.

5.

Tighten both set screws securely with screw

driver.

6. Plug electrical leads into sockets located

inside cabinet. Cord atUched ‘'motor"

tag must be plugged into socket marked

"motor”. Untagged cord goes to "light"

socket.

Page 22

MEMO

■ Head Measurement

56

Bust Measurement

Waist Measurement

Hip Measurement

Loading...

Loading...