Page 1

DELUXE i/-7s:ftss

ZIC ZAC SEWING MACHINE

Page 2

CONTENTS

Welcome

Description of machine-Model , . ' ^ . 3

Replacing the Needle

Needle arid Thread ...........................................................................,' ' '

Winding the Bobbin, How to wind the Bobbin evenly

Threading the Bobbin cast'................................................................................

Ad|ustinq the Bobbin tension...........................................................................

Removing the Bobbin case................................................................................

Inserting the Bobbin case...................................................................................

Threading the machine

Straight stitching

To Remove the work.........................................................................

To Regulate the length of stitch

Reverse sewing

To Regulate the stitch foimation

To Regulate the needle tension...................................„ a

TO Remove accumulated lint or clean Hook & Race ■

................................................................

......................................................

.....

......................................................................

.....................................................

......................................................................

....................................................

9

9

10

10

n

11

12

To make zigzag stitch

To make satin stitch.................................................................................

To make zigzag stitch ............................................................................

To sew vanous pattenis ■ • •

Needle position lever ....................................................................................

To sew various patt6irns....................

To change the presser foot

To make Buttonholes

To make over lock stitch

To turn a corner...............................................................................

To blind stitch

To hem (Hemrner foot)..............................................................................

To make a felled seam

To use cloth guide and thumb screw

Zippers ............................................................................ ■

Three positions of feed dog, Adiusting the pressure. To do

embroidery, darning and for sewing on buttons

Embroidery ........................................................................................................

Darning ....................................................................................

Buttons sewing ..........................................................................

Stretch stitching

Sewing light. To replace the bulb

To oil the machine...........................................................................................

Do not oil the motor......................................................................................

Operating hints...................................................................................

................................................................

...

■

............................................................................

............................................................

.................................................................

...........................................

..................................................................................

...

' '

...................................................................

..............................................

....................

...............

'

13

14

14

14

15

15

16

17

18

18

18

19

20

20

■ 21

22

■ 23

24

25

■ 26

28

28

29

Page 3

WiLCOMi

W»lcc»Tit to the growing family of h<^y ov¥n«rs of this new model zigzog

mochine.

You now hove one of the finest modern fcncy zigzog mochines mode, wirti oil

these wonderful features.

★ Tension Dial-allows the tension of the upper

thread to be easily and accurately adjusted to

suit the material.

★ Instant Reverse Sewing-by pushing the reverse

button in,

★ Zig-Zag Pattern-can be easily changed while

sewing by moving the zigzag lever.

ir Modern disc Balance Wheel.

★ Snap out Race-for convenient cleaning of race

and hook.

★ Automatic Zig-Zag Petterns-can by easily

replaced.

•k Stretch Stitching-by selecting lever.

MODEL

217EDSS

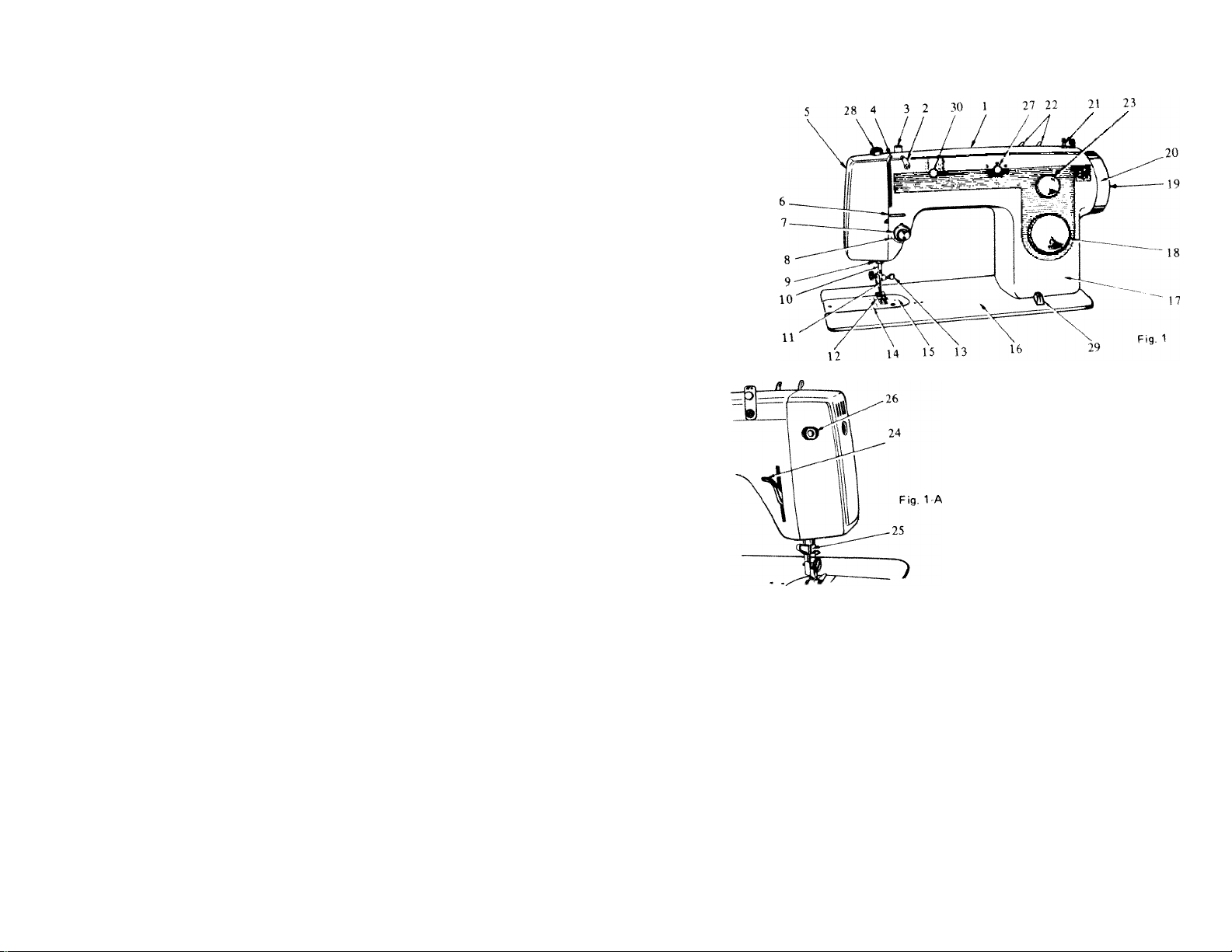

DiSCRIPTION OF MACHIN!

1. Arm cover

2. Arm cover thread guide

Bobbin winder thread

3.

guide

Thread take up lever

4.

Face plate

5.

Armthread guide A

6.

Tension dial

7.

Check spring

8.

Arm thread guide B

9.

Needle bar

10.

Needle

11.

This mochin« is precision built for o lifetime of sewing pleosure It will reqtrire

o mlnimimt omount of molnlenonce and will give the moxitnum in first clots

service.

This mortual provides oil the informotion necessory to operate the mochine ond

we suggest you reod the following instructions very carefully in order to get

the most from your mochine.

Page 4

REPLACING THE NEEDLE

MODEL

207EDSS

1 2. Presser foot

13. Needle damp

14. Slide plate

15. Needle plate

16. Bed plate

17. Arm of machine

18. Stitch Regulator dial

(Reverse button)

19. Stop motion knob

20. Balance wheel

21. Bobbin winder

22. Spool pins

23. Zigzag dial (lever)

24. Presser bar lifter

25. Thread cutter

26. Sewing light switcli

27. Needle position lever

(Reset lever)

28. Pressure regulator

29. Drop feed

30. Stretch stitch selector lever

NEEDLE

CLAMP

Note; Use standard 15 X 1 needles,

ovoiloble at all sewing mochine stores. (For

correct size consult chort on page 4).

-FLAT

SIDE

To replace the needle, raise the needle (11)

to its highest point by turning the balance

wheel (20) TOWARD YOU by hand.

Loosen the needle clamp screw (A)

F,9. 3

Remove the present needle ond slide the new needle up into the needle clomp

(13) I flat side toward the balance WHEEL 'i as for as it will go.

When the needle hits the top it is m correct position, then fasten the needle

clomp securely. For best sewing results chonge needles frequently.

Page 5

NEiDLI AND THREAD

Never use a benf needle, nor cxie with o blunt point, since this couses imper

fect stiJehes ond moy couse the needle to breok. Unless the needle is in

CLEAR TO THE TOP, FLAT SIDE TOWARD THE BALANCE WHEEL, the

machine will be out of "time", ond skipped or imperfect stitches will result

end needles moy break.

The size of the needle should conform- to the size of the thread ond both should

be suiloble to the material. Use a needle sufficiently lorge to permit the

threod to poss freely through the eye. In general sewing, use the some size

threod in the bobbin as used on top. For detoiled informotion consult follow

ing chort,

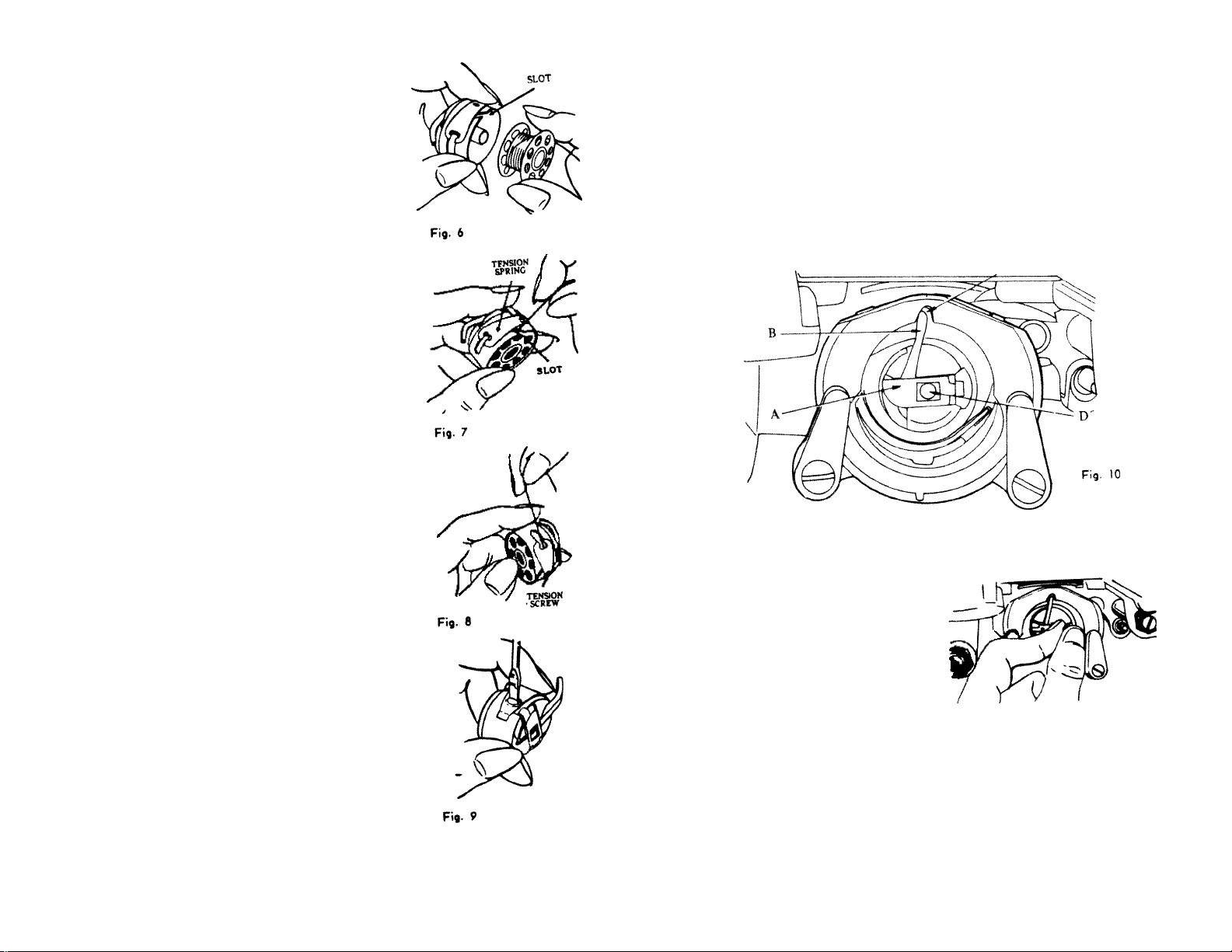

NEEDLE AND THREAD SIZES (USE 15x1 NEEDLE ONLY) CHART

Sizes & Grades

of Needles

( Medium-Fine)

Type of Fobric

ond

Work to be Done

Medium light.weight & summertime fobnes.

For house dresses. children 's dresses

woshoble cotton dress, oprons, light-weight

cur toms.

SIZE OF THREAD

“

Cotton Silk

80

to

Twist

100

..........

Linen

0

WINDING THE iOBBIN

Fig. 5-A

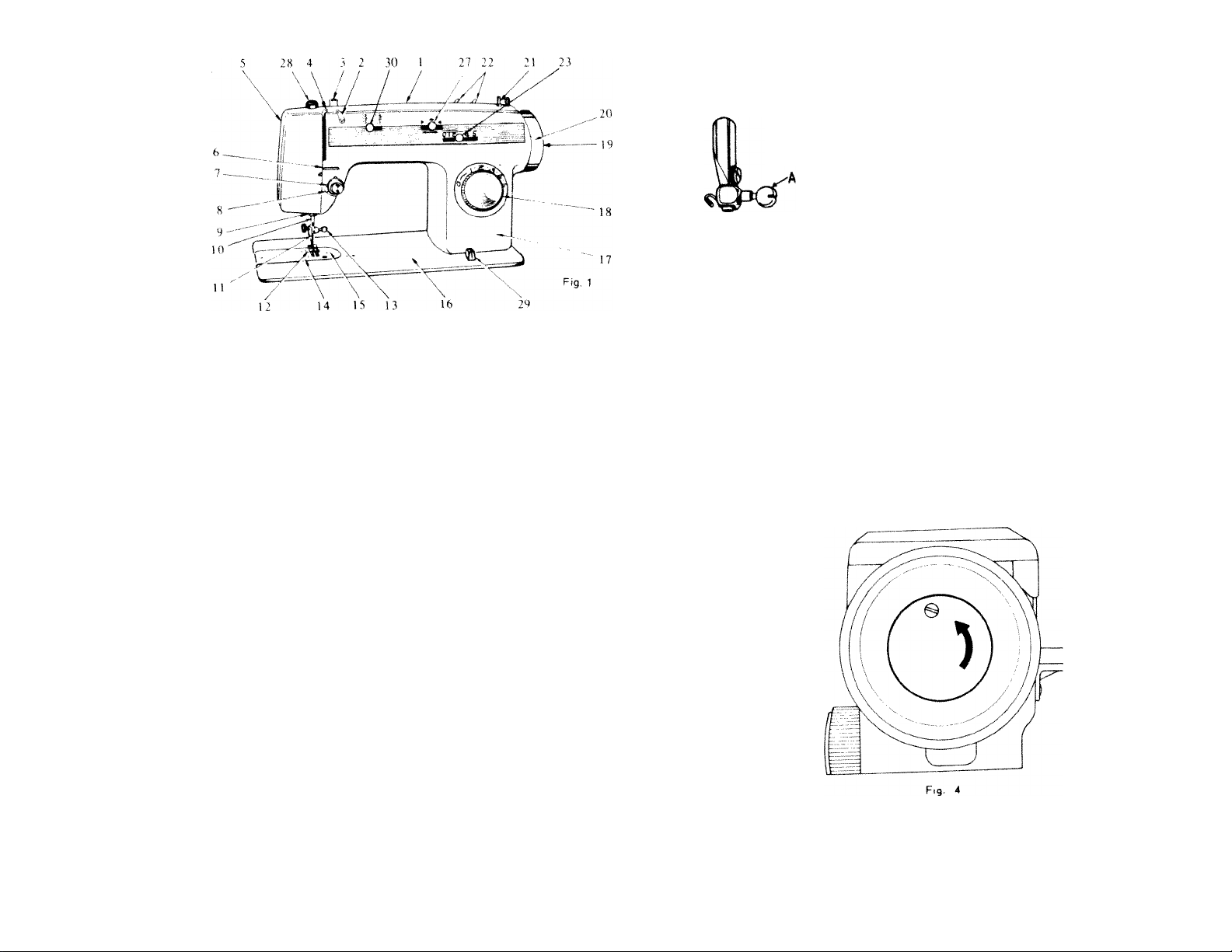

1, Hold the balance wheel (20) with your left hand, and with your right hand loosen

the stop motion knob (19) by turning it toward you. You can now turn the

balance wheel without the needle bar and other sewing mechanism moving.

2 Place the bobbin on the bobbin winder spindle (C) and push it down firmly. Press

the bobbin winder spindle (C) to right until a "Click" is heard. This engages the

bobbin winder with the balance wheel.

3, Place a spool of therad on the spool pin (A), run the thread under the tension disc

(E) and then through the left slot of thread guide (B) and back to the bobbin on the

spindle.

4 Bun the end of the thread through any hole in the top side of the bobbin from the

inside out, leaving 3 to 4 inches of thread projecting from the bobbin. Thread

should not be allowed to catch over the edge of the bobbin.

5. Now, you can operate the machine as in ordinary sewing and the thread will be

wound. Operate the machine slowly to wind the bobbin evenly.

6. The loose end of the thread which is threaded through the hole in the bobbin should

be held by hand until a few coils are wound. Then break off the loose end.

7. When the bobbin is completely wound, stop the machine and press the bobbin

winder spindle (C) to left so that the bobbin winder disengages the balance wheel.

Do not wind the bobbin so full that the thread extends beyond the sides of the

bobbin.

8. Break off the thread, and remove the bobbin.

9. Hold the balance wheel with your left hand and with your right hand tighten the

stop motion knob by turning it away from you. (See Figs. 5-A, 5-B & 5-C)

14

(Medium )

16

( Light. Heovy)

18

(Medium-

Heavy)

19

(Heovy)

Dress silks ond coMon. iighl-weight woolens,

draperies, fobric furnishings. For genero!

household sewing, fine men’s shuts, smocks,

window droperies and fobric decorations.

Heavy cretonne, modros, m usfm, brocodes

and, qu’lts.

For men’s wo rk shirts, smocks ond oprons.

heovy quilling ond fobne furnishings.

Heavy woven cooling, light-weight convos.

bed ticking, upholstery ond owning moterials, slipcover fob rics.

For work or sports uniforms, suits mode

of strong linen or cotton fo brics. ownmg

slip covers ond mottre sses.

Heavy woven suiting, coating duck, tick,

ing. drilling, convos and socking, for heovy

wash uniform s, bedding supplies for hospilois ond comps.

60

to

80

40

60

30

40

______

10

to

30

A & B

Twist

C

Twist

D

Twist

E

Twist

HOW TO WIND THE BOBBIN EVENLY

Rear view

of machine

Fig. 5-B

To correct uneven winding of the bobbin, proceed as follows.

1. If more thread winds at the top of the bobbin, loosen screw (D) and shift thread

guide (£) siightiy downward.

Repeat as necessary until bobbin winds evenly. (Fig. 5-B).

2. If more thread winds at the bottom of the bobbin, loosen screw (D) and shift

thread guide (E) slightly upward.

Repeat as necessary until bobbin winds evenly. (Fig. 5-B).

3. When winding the bobbin, be sure that the thread goes under the tension disc and

through right slot (F), and then to the bobbin winder. (Fig. 5-C).

Not* : This machine uses standard 15 class bobbin.

5 -

i'

Fig. 5-C

Page 6

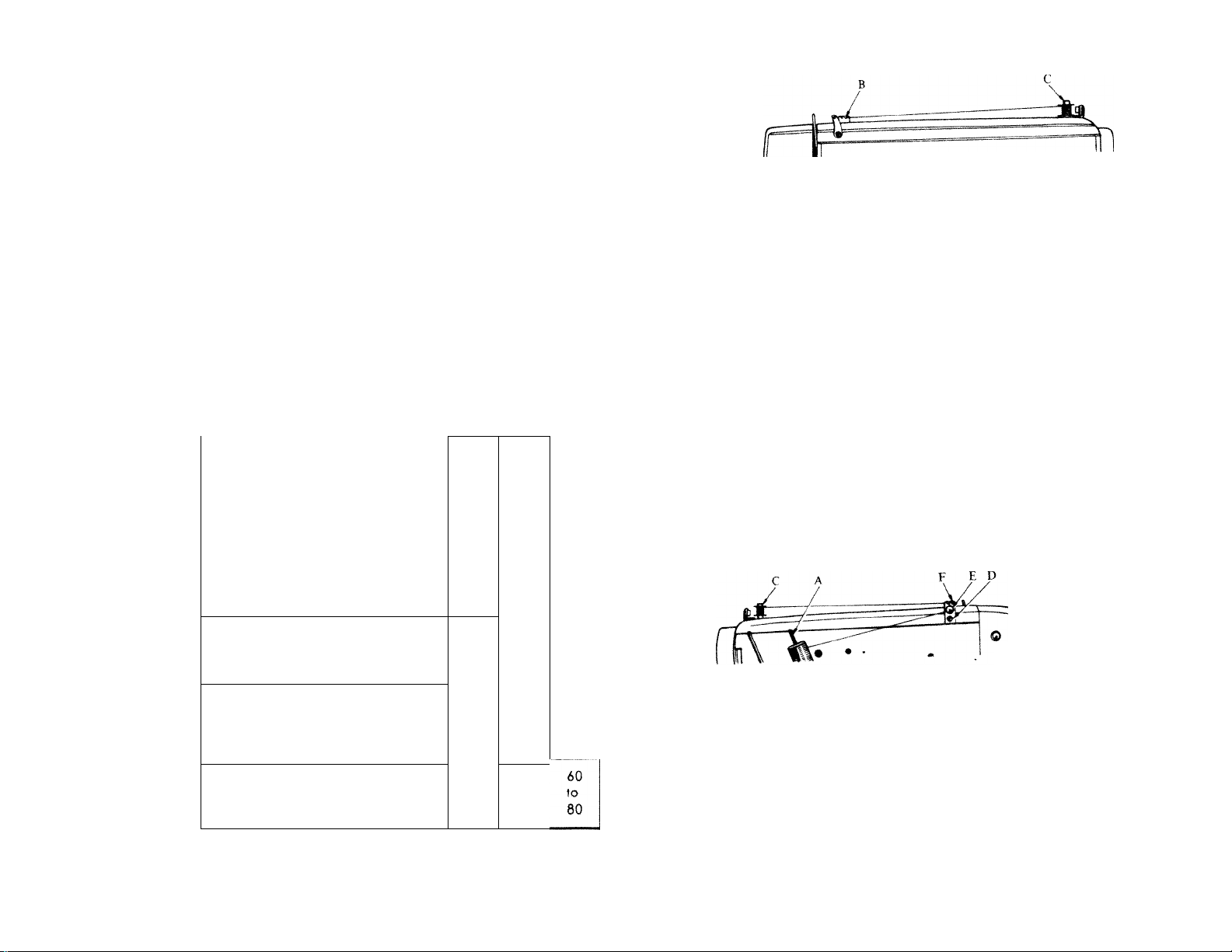

THREADING THE BOBBIN

CASE

Hold the bobbin cose between the thumb

Old forefinger of the left hcnd with the

slot focing upword. With 3 or 4 inches

of thread trolling in the pdm, hold the

bobbin between the thumb end first two

fingers of the right hend. (Fig. 6)

Insert the bobbin into the bobbin cose ond

pull the (roiling threod into the slot,

down ond to the left until it enters the

long opening under the tension spring.

(Fig. 7)

There should be a slight tension on the

threod -s It IS pulled through the spring

ond the bobbin should unwind freely,

(Fig, 8) Bobbin rotates counter-clock

wise if, inserted correctly,

ADJUSTING THE BOBBIN

TENSION

All mochines ore correctly odjusted before

leaving the factory, therefore it is seldom

necessory to alter the BOBBIN tension.

Should it become necessary, however,

to do so. tighten the tension spring screw

slightly to increose the tension ond

loosen the screw slightly to lessjn the

tension, using the smoll screw driver

provided for the purpose. (See Fig. 9)

Make sure to turn the screw o quarter

turn or less in one adjustment ond test

•he tension.

- 6 -

INSERTING THE BOBBIN CASE

After winding о bobbin ond plocing it in the bobbin case (see родеs 5 ond

6) hold %e bobbin cose lotch with left thumb and forefinger (os expióme

bove) to prevent the bobbtn from falltng out. Keeping the protruding

finoer (ВТ stroight up toword the notch (C) of the roce ring, press the

ьГып cose into the holder post (D) until the protruding finger enters he

notch When in correct position, the mechonism of bobbin cose

the holder post of shuttle hook holding the bobbin cose firmly m ploce^

This operotion is eosy-.. NEVER FORCE IT. Leove three

thread hanging free. This will be brought up through the needle plote hole

os shown on роде 8.

REMOVING THE BOBBIN CASE

Turn the bolonce wheel (20) toword

you until the needle is at its high

est position.

Slide the Slide Plate (14) to the left.

With left thumb ond forefinger, grasp

the hinged latch (Fig. 10-A) at

the front of the bobbin case, hold

ing it securely as you withdrew

the bobbin cose from the holder

post (D) toward you and out of

the machine, (As long os you hold

the hinged lotch (A) as exploined

above, -the bobbin will no. foil out of the bobbin cose.) To

bobbin from the bobbin cose, hold the bobbin cose downword ond permit

the lotch to snap bock .into ploce.

Fig. 11

7

Page 7

THREADING THE MACHINE

STRAIGHT STITCHING

Turn the balance wheel

is at its highest point

Place a spool of thread on the spool pm

through the upper thread guides (A) and (

disc (C') from the Right to Left.

Now bring the threod up, pulling up the check spring

threod guide (D'l and in the thread guide (F'),

4.

and f J'). , I j

Now'thread the needle (Ki from the LEFT to RIGHT ond drew the threod

out about six inches.

Holding end of the thread, turn the bolonce wheel toward you until the

6.

needle moves down ond up again, thus catching the under thread.

When the take-up lever (4) is ot its highest point, puli the end of the

Carry the thread up to and into the eye of the threod take-up lever

(20) by bond toword you until the needle (K)

(22) and pass the thread

S'), down between the tension

possing over

RIGHT to LEFT and down through the threod guides fH"), (I)

needle threod you are hold

ing and the under thread

will be brought up with it

through the needle hole in

■the needle plate (15), os

shown (Fig. 12)

8. Lay both ends of threod

under ond to the bock of

the presser foot (12), os

shown in Fig. 13.

till

) f '

/

23

Fig. 14

Thread the machine. The machine wiU

ft, ,.gz,9 d,., 123) a, I 1 > as show" F,,. 14 The

™,hes„ai9h,s,,.ch.

T„,„ *= hdlonc. wh. 20

t

„ „ ed-habl. .0 1.0 ih. ..™od on -he 0 I. 9

breok. The machine feeds without ossisionce.

Never operate .he moc „„rhine will lock ond connot

,S His IS no. strictly odhered to, your moch.ne will o

be operoted until the thread is cleoned out o*

.............................

he ,d,e,a, ,F. holddc. .heel .0^4,20.

,h h.h.h „0,»

....

::eG:.:rrr:rd:.i.. .h.n..di.ond 00™ „ .o

NOTE f

. ,1,» mnrhine without motenoi under the presser foot.

_______________

..

Fig. 12

TO REMOVE THE WORK

Stop stitching. Turn the bolonce wheel whh He nght ^

you .0 roise the threod toke up lever (4 o s ^ e P

threods.

Fig. 13

8 -

Page 8

TO REGULATE THE LENGTH OF STITCH

The "STITCH REGULATOR DIAL" (18) mokes it possible to obtain different

stitch lengths by a simple turn. Numbers (Bi around the dial lAI and the

Indicotor vC) ore your stitch length guides. The higher the number the

longer the stitch. For heovier materials, use the high numbers. For silks,

nylons and thin moteriols, use the low numbers.

To regulate the stitch, turn the Dial (A) until the Indicator ¡C

stitch length you wont.

if too close to 0, the machine will not feed ot o

in one spot.

NEVER SEW OR USE THE MACHINE

IN ZERO POSITION

and wilt continue sewing

points to the

REVERSE SEWING

The stitch regulator dial (A) is also used to stitch in reverse.

When reverse stitching is wanted for tacking seams, push the Reverse button

(A) in until it stops. The stitch length will remain ttie same because this is

controlled by ttre mechanism.

TO REGULATE THE STITCH FORMATION

(A)

( B)

(C)

Flfl. 16

For perfect stitching, the tension on the upper ond under threads should be

equal and just sufficiently strong to lock both threads in the centre of the

moteriols os shown above (A).

If the tension of the needle threod is too tight, or if that of the bobbin thread

too loose, the needle threod will lie straight along the upper surfoce of the

moterial, thus moking on imperfect stitch, os shown in (B).

if the tension of the bobbin threod is too tight, or if that of the needle is too

loose, the bobbin threod will be stroight olong the under side of the materiol,

thus making on imperfect stitch, os shown above (C).

Note: Be sure to uso the threod suitable to the material. (See page 4)

TO REGULATE THE NEEDLE TENSION

A correct stitch ccn usually be obtained by varying the tension on the needle

threod.

sion of thread. Hence, it is necessary for the user to become fully fomiliar

with the correct tensions through proctice.

All adjustments should be made while

the presser foot is down since an

releose does not permit odjustments

to be made while the presser foot

is up.

To increose the tension, turn the thumb nut

on the tension dial (7) clockwise. To

decrease the tension, turn the nut in the

opposite direction. The thumb nut should

not be turned abruptly but regulated little

by little until the desired tension is ob-

toined.

The quality of sewing depends on the ten

10

^ 11

Page 9

TO REMOVE ACCUMULATED LINT OR

CLEAN HOOK AND RACE

K Turn the bolonce. wheel (20! by hand loword you untM needle ¡s ot us

highest point,

2. Remove bobbin cose,

3, Turn levers (A) & (B) one half turn sideward owoy from pm

4, Remove rjloming ring (O, and hook (D). by grasping stud of hook 'Do

5, Remove accumulated Imt and thread from race ring, hook and race body.

6, Replace hook (D> m race body, with stud focmg ouiword forming perfect

circle with driver i E ),

7. Reploce retoinmg ring (C), polished side out, with pm ot bottom ploced

TO MAKE ZIGZAG STITCH

I

i I I I t I

O D Y Y r' C

Fig. 19

in notch of the roce body,

8. Lock retaining ring with levers (A) ond (Bf.

9. Reploce bobbin and bobbin cose, and commence sewing,

DO NOT ATTEMPT TO FORCE ANY OF THE ABOVE OPERATIONS,

itili

■Y Y h r r"

Fig. 20

1! The Zigzag dial (23) controls the width of the stitch. By moving the

dial from right to left you can widen the stitch from STRAIGHT to

MAXIMUM ZIGZAG WIDTH.

2) When the dial is set at the extreme right position, the machine will make

straight stitch, {See Fig. 19)

3! The further you move the dial to left, the wider zigzag stitch will be.

The widest zigzag stitch is obtained when the lever is set to the extreme

left. (See Fig. 20)

4) By moving the dial, you can select the zigzag width you desire and sew

the various zigzag stitches.

12

13

Page 10

To make the "Satin" stitch (See 3-page 14

NEEDLE POSITION LEVER

1 Set zigzag dial (23) at the widest position.

2. Bring the stitch regulator dial (18) gradually to closest stitc ,

No?e;^Adjust thread tension so that lower thread stould not appear on

surface of material, and you can get a perfect satin stitch.

To make zigzag stitch V\AA/W

1. Set zigzag dial (23) at the widest position.

2. Set the stitch length at 2 to 4.

3. Commence to sew.

To sew various patterns

By moving zigzag dial (23) as follows, you can sew the various patterns as

shown or by use of zigzag

Pattern to be sewn

1

---------------------------------

3

‘ jiÊÊèK^ JÊ.

7 ttWWL JiWL-

cams

Move zigzag dial (23)

Set lever (23) at the extreme

right position.

Set lever (23) at the widest

zigzag stitch length at 4.

Set the stitch length at Fine,

At slow, even, speed from the

extreme right to left and from

the extreme left to right.

Repeat from the extreme right

to left and from the extreme left

to right at fast speed. To get

uniform curve, the moving speed

must be controlled.

Repeat from the extreme right

to left and from the extreme left

to right at fast speed and rest.

~'Riit~¥t~tHe^l!x and

change to the extreme right

quickly and rest. Repeat this

_stee,

____

_______________________________

Rest at the extreme left and

change to the narrowest zigzag

quickly, and rest. Then change

to the extreme left quickly and

rest.

Slow, even speed from the ex

treme right to left then quickly

back to the extreme right,

_______

Illustration ,

Fig, 19 1

Fig, 20 i

Fig, 20

When selecting needle position, tte needle Set nLdl

position in order not to tear t - respective needle position

position lever (27) to left, center or right for respective

Noi 'ooTorchange needle position while sewing. Otherwise it w.l, caus

the needle breaking.

dZZ)

CH3

dZË)

TO SEW VARIOUS PATTERNS (OR USE OF ZIGZAG CAMS)

Needle position

lever (27)

◄

♦

►

fi

11

i i

1

1 f

"slow, even speed from the extreme right to left, then

i

Position of Zigzag Dial (23)

Best at zigzag and change to the widest

zigzag quickly, and rest.

Then change to the narrowest zigzag quickly, and

to left and from the

“Cl ,o ..0> .. »»7

curve, the moving speed must be controlled,________________

quickly back to the extreme right.

At slow, even speed from the extreme right to left

and from the extreme left to right.

15

_________

- 14 -

Page 11

TO CHANGE THE PRESSER FOOT

1, Roise the needle to ds highest point by turning the bolonce-wheel (20)

toward you,

2, Roise the presser foot (12) by lifting the presser bor lifter (24)

3, loosen me presser foot thumb screw ond remove the foot,

4, Place the grooved side of the selected presser foot ogoinst the Pot of

the presser bar,

TO MAKE BUTTONHOLES

u

1. Set Zigzag dial (23) to the narrow zigzag and Stitch regulator dial (18) to

fine stitch between 0 and 1. (Fine)

2. Sew to desired length (K to L) and stop the machine with Needle in the

material and at left position as shown in Fig. Q.

3. Then, set Zigzag dial to the medium zigzag and turn balance wheel one

rotation so that needle is at right position M (Fig. R) and needle bar at

lowest position, and turn the material 180 degree as shown in Fig. S.

4. Sew a tew stitches (M to N) with the Zigzag dial to the widest zigzag

as shown in Fig. T.

5. Re-set Zigzag dial to the narrow zigzag and sew other-side (N to 0) of

button hole as shown in Fig. U,

6. Sew a few stitches (0 to P) with Zigzag dial to the widest zigzag as shown

in Fig. V.

7. Cut buttonhole using seam ripper, being careful not to cut

stitching on either side. (Fig. 27)

Note ; We suggest you moke lest somples on a piece of the some garment

moteriol, before you sew the -buttonhole on the work you are doing.

Troce length of buttonhole with cholk on the moteriol ond sew slowly

following the markings so that you con perform the buttonhole exoctly

os you desire.

When turning the moteriol 180 degrees, if you pull the moteriol by

force, needle will bertd or breok. Turn it slowly with care.

Needle thread should be slightly tighter than thot of regular sewing

so that you con get belter work.

,5, fosten the thumb screw.

17

Page 12

то MAKE OVER LOCK STITCH

TO HEM (HEMMER FOOT)

r Set stitch regulotor dia! (18) ot 2 or

longer os desired.

2, Set zig/ag dial (23) at desired zigzag

width.

3. Ploce the moterial under the presses foot

and lower the presser bar lifter (24) so

thol zigzag stitching locks over outer edge

of the moterlol. (Fig, 28;i

TO TURN A CORNER

The mochme should be stopped with the needle m the moterial. Roise the presses

bor 'lifter (24) and turn the material m the direction you wish. lower

the presser bar I Tier and start to sew.

TO BLINDSTITCH

Fold the rnateriol to the size of

the bottom fold os shown in A,

Set stitch regulator dial (18) a! 2 or longer os desired.

Set zigzag dial (23) ot desired zigzog width.

Ploce fabric under the presser foot ond lower presser bar lifter (2 i

so that when the machine zigzogs, the stitch will catch mostly on the

hem and will just borely bite into the fold. (B)

After stitching is completed, unfold the moterial os shown in C,

5.

hem desired, with

1/16" overlap on

The spiral formed tongue or scroll of the hemmer foot turns in the edge of

the fobric and forms the hem.

1. Attach hemmer foot.

2. Fold the edge of the fobric over approximately }4 of an inch, then fold

it over again in the some way for a length of about 2 inches.

3. Place the needle ond bobbin threods under the hemmer foot,

4 Insert the fold into the spirol formed opening of the hemmer fool. Move

' the fabric slightly bock and forth until the fold forms scrolled shape.

(Fig, 30-A)

5, Draw the fabric loword you until the start of the hem edge is lUst below

the needle.

6. Lower the hemmer foot ond begin to sew. Guide the fobric into the

hemmer foot while sewing. (Fig. 30-B)

Not* ! Don't push or pull the fabric. Even feeding ts essentiol for good

hemming. The fabric must be kept at the some width in the scroll

of the hemmer foot ot all limes. Prior to 'olding the edge of the

fobric, cut a corner off the edge of the fobric and you can eosily

insert the fabric into the scroll of the hammer foot.

18

19 ■

Page 13

TO MAKE A FILLED SEAM

ZIPPERS

The hemrrmr foot con olso be used for felling. Proceed in the following m^er =

, LOY two pieces of cloth one on top of the other with the.r RGHT

■ sides facing eoch other. The right edge of the tottom p^e must ex-

lend c±>out Vs inch beyond the right edge of the top piece.

2. Sew both pieces of cloth together,

using the hemmer foot like a regulor

presser foot. Use the right edge

of long toe of hemmer fool to

guide the bottom piece of material,

while the left edge of the some toe

serves os a guide for the top piece

of moterial.

3. Open ond spread out motenal ond

place right sides down. Moke sewn

edges of material stand up.

4. Fold the sewn edges over to the

left ond insert them into the scroll of

the hemmer foot. Sew os you would for ordmory hemming.

Use left edge of long toe of hemmer foot os guide, nov.ng ongmol

seom alongside of it, (fig. 3i i

TO USE CLOTH GUIDE & THUMB SCREW

This is on attachment designed os a guide for straight stitching when makmg

wide .hems, pm tucks or when seom widths are wider thon presser foot

ollows.

Fasten the cloth guide to the bed of the mochine (as Hlustroted m

1,

fig. 32) by meons of the thumb screw, inserting the thumb screw into

either one of the two holes in the bed of the machine,

Adiust the cloth guide to the required distonce from the needle and

2.

tighten thumb screw.

Right side of needle

Fig, 34

Machine Setting - |

Zipper foot allows you to stitch right

next to a raised area such as a zipper

or cording. The foot is adjustable so

it can be moved to the left or right side

of the needle without having to turn

the fabric.

Raise needle to its highest position,

attach zipper foot, and set dials for

straight stitching.

To adjust foot for left side of needle;

loosen screw at back of foot and slide

foot to the left so that needle passes

through notch on ri^t side of foot.

Lower needle slowly to be sure it will

not hit zipper foot, and tighten thumb

screw.

For right side of needle, slide foot to

the riglit.

Zipper package will contain easy to

follow instructions for stitching.

Corded tom

Cording gives a professional finish to

slipcovers, pillows, children s clothes

and lingerie.

First, make welting by covering cord

ing with bias fabric and stitching close

to the cord with zipper foot.

Tlien stitch welting into seam using

zipper foot.

20

-- 21 -

Page 14

THREE POSITIONS OF FEED DOG

The drop feed or feed dog moves

fabric forward or backward under the

preser foot. It can be .raised or

lowered by turning(iww ^ icic| )knob

located on the machine base plate.

For ordinary straight or zigzag stitch

ing, turn knob to(-;vvw)' This raises

drop feed to its highest position.

For light weight fabrics, knob can be

moved slightly to the left of^AAAZA )to

prevent feed from marking fabric.

For darning, embroidering and sewnig

Fig 36

on buttons, turn knob to(^ ) to

lower the feed so fabric can be moved

freely by hand

ADJUSTING THE PRESSURE

The pressure of the presser foot (11)

must be regulated for different types

of fabric to obtain proper feeding.

To adjust pressure push down outer

ring (A) Fig. 37-A with thumb and

forefinger. The center button (B)

Fig. 37-A will spring up and then the

pressure can be easily adjusted by

teing pushed down partially for light

fabrics (Fig. 37-B , or all the way

down for medium to heavy fabrics

(Fig, 37-C

EMBROIDERY

Machine Setting-

or

Free-motion embroidery allows you to

move the fabric in any direction under

the needle in order to create your de

sign. Use either a straight stitch or a

plain zig-zag stitch.

Trace design on right side of fabric.

For best results, place fabric in an

embroidery hoop.

Remove all pressure from fabric -

• turn fabric feed to DARN

• press down on outer ring of pressure

regulator to release pressure com

pletely

Place hoop under needle. Run machine

at medium speed, guiding hoop care

fully so needle moves along pattern

lines.

Use straight stitch for outlining and

zig-zag stitch for filling in design. Vary

length of stitch simply by moving hoop

faster or slower under needle. Place

stitches close together for a smooth,

satiny surface. Overlap stitches for an

irregular surface.

TO DO EMBROIDERY, DARNING AND

FOR SEWING ON BUTTONS

Press the fringe (A) of the darner down with thumb and index finger and the

presser knob (B) will pop up. (Fig. 37-A) The pressure will be completely

released. As well, press the "darn” button on the Drop Feed (29)

completely down,

22 --

- 23-

Page 15

darning

BUTTON SEWING

Turn bolonce wheel towards you to get needle to its highest position.

Machine Setting - 1

I

Worn spots on clothing and household

linens can be darned easily with your

machine.

Completely release pressure on fabric

by turning fabric feed knob to DARN

and by pressing down on outer ring o

pressure regulator until center button

pops up.

For greater control, especially when

darning larger areas, place fabric m

embroidery hoop. For large holes

baste a piece of mending material

underneath hole to use as a base for

stitching.

Place fabric under needle. Move fabric

back and forth with an even motion to

cover darning area with closely spaced

rows of stitching. Then turn fabric

and sew another layer of stitching

across first layer of stitching.

Raise presser bar and replace regular presser foot, with button

sewing foot, as shown in Fig. 40. Drop the feed dog os required

for darning and embroidering. Upper and lower threod tensions

remain the same os for ordinory sewing.

Place moteriol or garment together with button under the presser

foot, so that holes in button line up with oWong hole in presser foot.

Adjust width of zigzag stitch to permit needle to pass through

centre of holes in button.

Before sewing with power, turn the balance

wheel by hand towards you to make sure

thot needle will stitch in the centre of the

holes in button. If the needle hits the button

it will break.

Then sew five to six stitches to ottoch button.

When attoching four-hole buttons, first sew one

set of two holes, then stitch into second set of

two holes and lock thread with two or three

plain stitches in lost hole.

24

25

Page 16

STRETCH STITCHING

SEWING LIGHT

When sewing knitted or stretch fabrics, choose one of the stretch stitches which

allows the seam to stretch with the fabric without breaking the thread. Select

polyester or cotton covered polyester thread which has an extra amount of give

and is designed for knits and stretch fabrics. Use a ball point needle, especially

on lightweight knits.

Machine Setting — ¡¡j

il -2

Stitch

pattern

Presser

foot

Zig-zag

STRETCH STRAIGHT STITCH

III

Needle

position

Zig-zag

width

Stitch

length

•

Fabric

feed

Ô

Stretch straight stitch is a triple lock

stitch, combining stretchability and

strength. Use for stitching regular

seams in knits and stretch fabrics.

Use for stitching seams in woven

fabrics that receive a lot of strain when

worn, such as side seams, crotch seams,

and armholes in sportswear and child

ren’s clothes.

Machine Setting - | RICKRACK STITCH

Stitch

length

@

Fabric

feed

Dam Sew

Fig, 42

Needle

position

Zig-zag

width

^3

Rickrack stitch can be used as a heavyduty all-purpose stretch stitch. Each

zig-zag stitch consists of three threads

or stitches, giving strength and perma

nence

II -2

1 f¥

Stitch

pattern

Presser

foot

Zig-zag foot

Rickrack stitch is a triple stitched zig-zag that resembles rickrack trim,

reversible, looking the same on both the right and wrong sides.

It is

If your machine has the sewing light inside the -face plate (A), by turning

pushing in the light switch (C) on the back of the machine the light can '

turned on and off as you wish. Fig. 44-A

To operate the machine, the switch must be turned on.

Î.-

Fig. 44-A

TO REPLACE THE BULB

Turn the light switch (C) off.

2.

Loosen the Screw (B) with a screwdriver or a coin as shown in Fig. 44 1:

3.

Move the face plate away from you (switch (C) passes through the hole which is at the back of the face plat<

and then lift up ( f ) the face plate so that you can remove it from th

machine.

4.

When bulb has the “screw in socket” type base, remove the bulb as you di

a conventional light bulb. Fig. 44-C.

When bulb has the “bayonet socket” type base, push in the bulb and 1/4

turn to the left and the bulb will drop out. Fig, 44-C.

5.

Replace the bulb, and place the face plate in the correct positon b

securing the Screw (B).

...............

) as shown in Fig. 44 A until th

-26-

-27-

Page 17

TO OIL THE MACHINE

Fig. 45

Fig. 46

The mochine will olways work best if properly oiled ond cleoned ot regulor

intervals

Ploce o drop of good grode sewing mochine oil into eoch of the oiling points

on the machine os shown by orrows in Figs. 45 ond 46 once every work

ing doy or after obout 8 hours of use. Should machine stand idle for a

prolonged period, oii it before you start sewing.

Oiling mochine excessively will couse soiling of the moleriol to be sewn.

After oiling mochine. sew a few rows of stitches on o scrop of motenol

be sure thot the mochine sews cleanly. Also wipe off ony excess oil

10

from the top of the mochine.

To Oil needle bor, presser bar ond other ports inside the foce plote. swing

foce plote (5) to the left so moving ports ore accessible. Oil oH moving

ports at friction points, ^

NOTE

Use Sewing Machine Oil

DO NOT OIL THE MOTOR

OPERATING HINTS

SEi THAT THE PRESSER FOOT (12) is securely in ploce ond fits snug

ogoinst the presser bar so thof the needle moy poss through the opening in

the foot without any interference.

SKIPPED STITCHES. May be coused by o bent or blunt needle : by incorrect

setting of the needle ; the wrong size needle ; by threod too thick for the

size of the needle

BREAKING NEEDLES ore usuolly due to pulling on the work, cousing the

needle to get out of line ond 'o strike the needle plote (15), thus breoking or

bending the needle. It moy also be due to presser foot or oltochments riot

being securely fosiened to presser bor. Be sure to use correct size needle

and threod for moteriol. See needle chart.

THE UPPER THREAD BREAKING. Moy be coused by i

( 1 ) Incorrect threoding.

(2) Not bringing up under threod correctly,

(3) Upper tension too tight.

( 4 ) Needle incorrectly set.

(5i Needle rubbing ogoinst ottochmenfs or presser foot,

I 6 1 Needle eye loo smoll for threod,

(7) Storting the machine at full speed.

(8) Storting without take-up 'ever (4) at highest point.

THE LOWER THREAD BREAKING. Moy be coused by :

( ! ) Incorrect threoding of bobbin cose.

( 2 ) Too tight Q tension,

( 3 ) Bobbin wound too full to revolve freely.

(4) Not bringing up under-thread correctly,

(5) Hole in the needle plote being rough, due to needle sinking the plate.

UNEVEN STITCHES. May be coused by,

(1) Presser foot not resting evenly on moteriol.

(2) Feed not high enough. (3) Too short a stitch.

(4) Pulling the cloth.

(5) Too fins a nsedle used with loo coarse or poor threod.

If your machine is equipped with a motor, do not oil the motor because the

motor shaft revolves in permanently oiled impregnated cast bronze

bearings.

No Lubrication is Required.

-28^

BASTING

(1) Reduce the tension of upper threod.

I 2) The stitches may then be easily removed by pulling the lower thread.

-29-

Loading...

Loading...