Page 1

Page 2

] K l SI le u C l lO Ai s f ot

w

13 ‘i

f

NEEDLE - THREAD - FABRIC - STITCHING GUIDE

Fabric No. Per Inch

Needle

Extremely heavy

tarpaulin, sacking. 4

canvas, duck, etc.

Heavy upholstery

fabric, ticking. 3

denim, leatherette

Medium heavy drapery

fabric, velveteen,

2

suiting, felt, terry, etc.

Medium broadcloth, percale.

gingham, linen, chintz, taffeta.

1 to

sheer wool, shantung, etc.

Sheer voile, lawn.

dimity, crepe.

0 to

handkerchief linen.

plastic film, etc.

Very sheer chiffon.

batiste, lace, organdy.

00

ninon, net, marquisette, etc.

When doing embroidery work, finer

embroidery thread regardless of the

Machine

Stitches Cotton

6 10

to

8

8

to

10

10

to to

12

12

14

14

16 100

(Plastic film)

16 100

to

20

results will be obtained with machine

weight of fabric.

8 to 10

Thread

Mercerized

Thread

to Heavy Duty

30

30

to Heavy Duty

40

40

Heavy Duty

60

60

to

50

80

80

to

to

50

50

150

Silk

or

Nylon

A

A

A

‘"1

O’ 'F

C .

6»’ f

C- f

1

i,, 1

C' (

<*' i

c. ?

W,'

W'

C !

ft.

c ,

C-

1

.........

1

r

Page 3

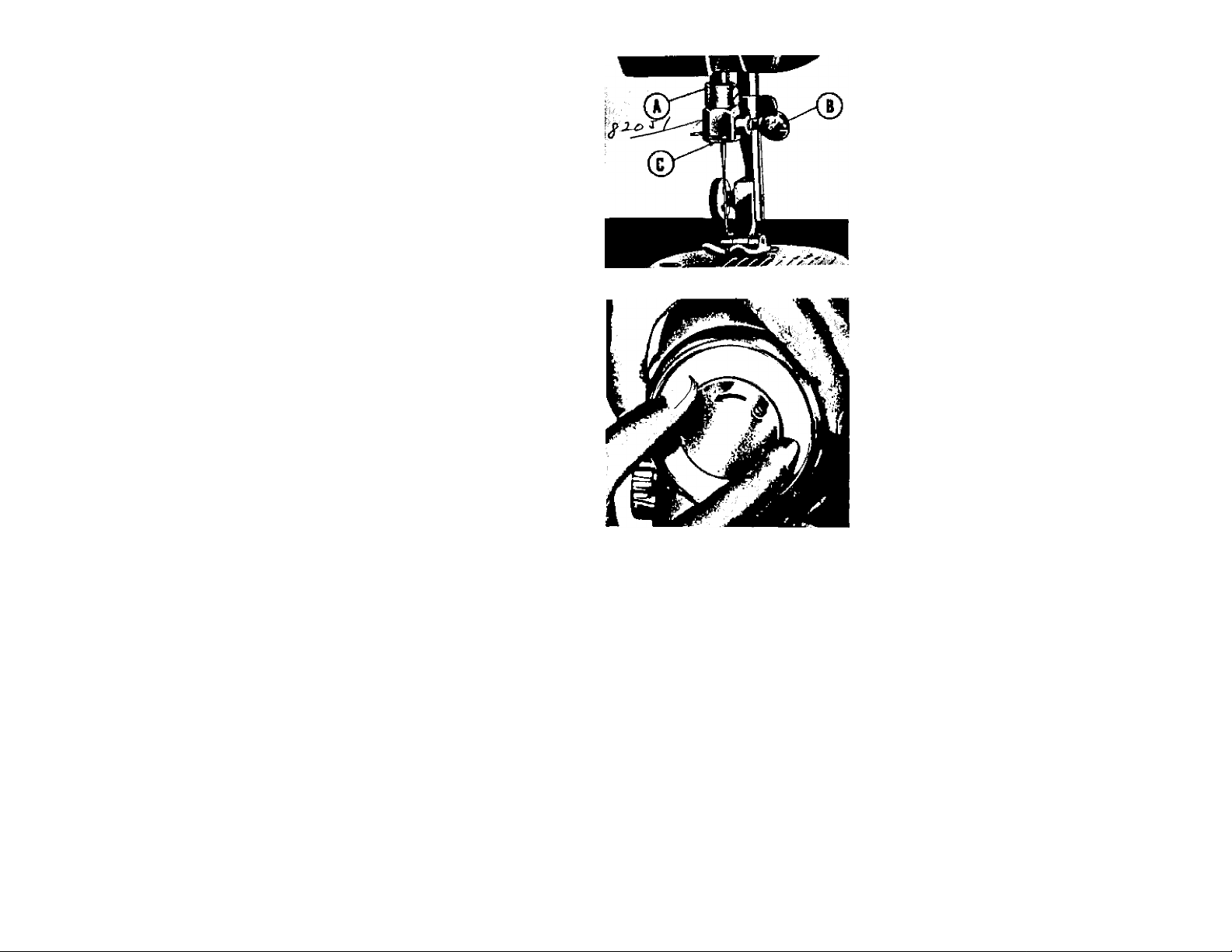

SETTING THE NEEDLE

See Fig. 3. Raise the needle bar A to its highest point, turn

ing wheel toward you by hand. Then loosen the needle clamp

screw B and the needle clamp C will open. Place needle (flat

side to back; in the needle clamp and push it upward as far

as it will go into the needle clamp hole, fastening the needle

clamp securely with a screw driver.

WINDING THE BOBBIN

Disengage the hand wheel (Fig. 4) from the stitching

mechanism by turning the clutch toward you or counterclock

wise. Place a spool of thread on one of the spool pins, lead

thread under the handle and through the upper thread guide

on the arm, and down through the tension disc (11, Fig. 5) at

the base of the machine. Run end of thread through a hole in

the bobbin edge and place bobbin on spindle B of winder

4, fitting the notch on bobbin over small pin on spindle. Push

_ 7 _

Fig. 3

Fig. 4

Page 4

C- E

71

тШШШЖ

bobbin windeT pulley against hand wheel. Hold

thread end loosely and start machine slowly. Bob

bin will be released automatically when it is filled.

Break oH loose thread end used to start the winding.

Turn clutch away from you until sewing mech

anism is again engaged so that needle moves when

you turn the hand wheel.

If the bobbin winds unevenly, adjust bobbin

winding tension disc to the right or left by loosen

ing the screw. When disc is in proper position,

tighten screw.

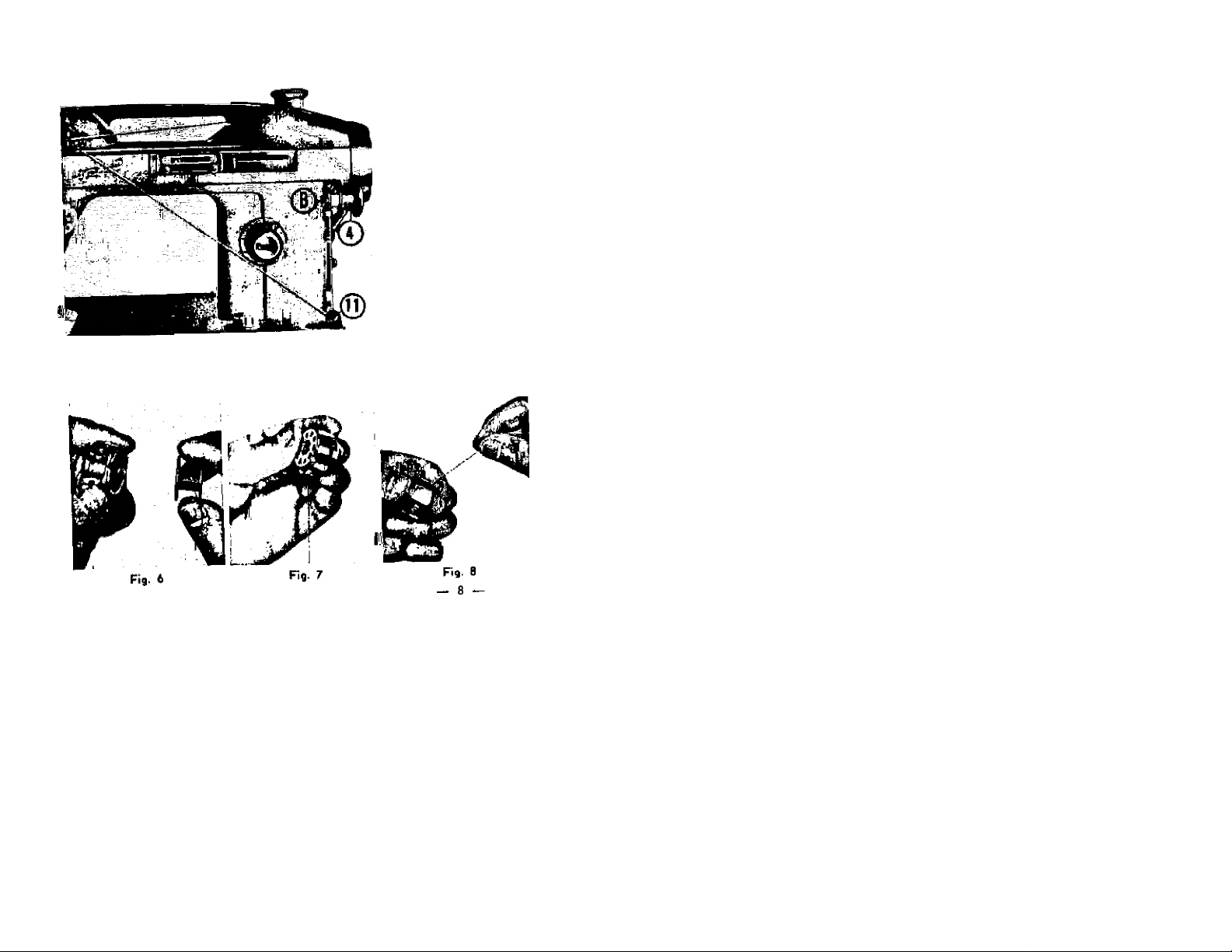

THREADING THE BOBBIN CASE

Reier to Fi,B. 6, 7 «id 8 to youreelf »1th the ptooedute_ Hold the bobbta

— case in your left hand. Let about

two inches of thread hang free from

the bobbin, and insert bobbin into

case so that thread will be rotating

counterclockwise. Guide the thread

end through the slot on the side

of the case and under the tension

spring until it enters the small notch

on the edge of the spring.

'€> Г

G ^

c

f

f"'

1^

irf»- *

« *

■.>

Page 5

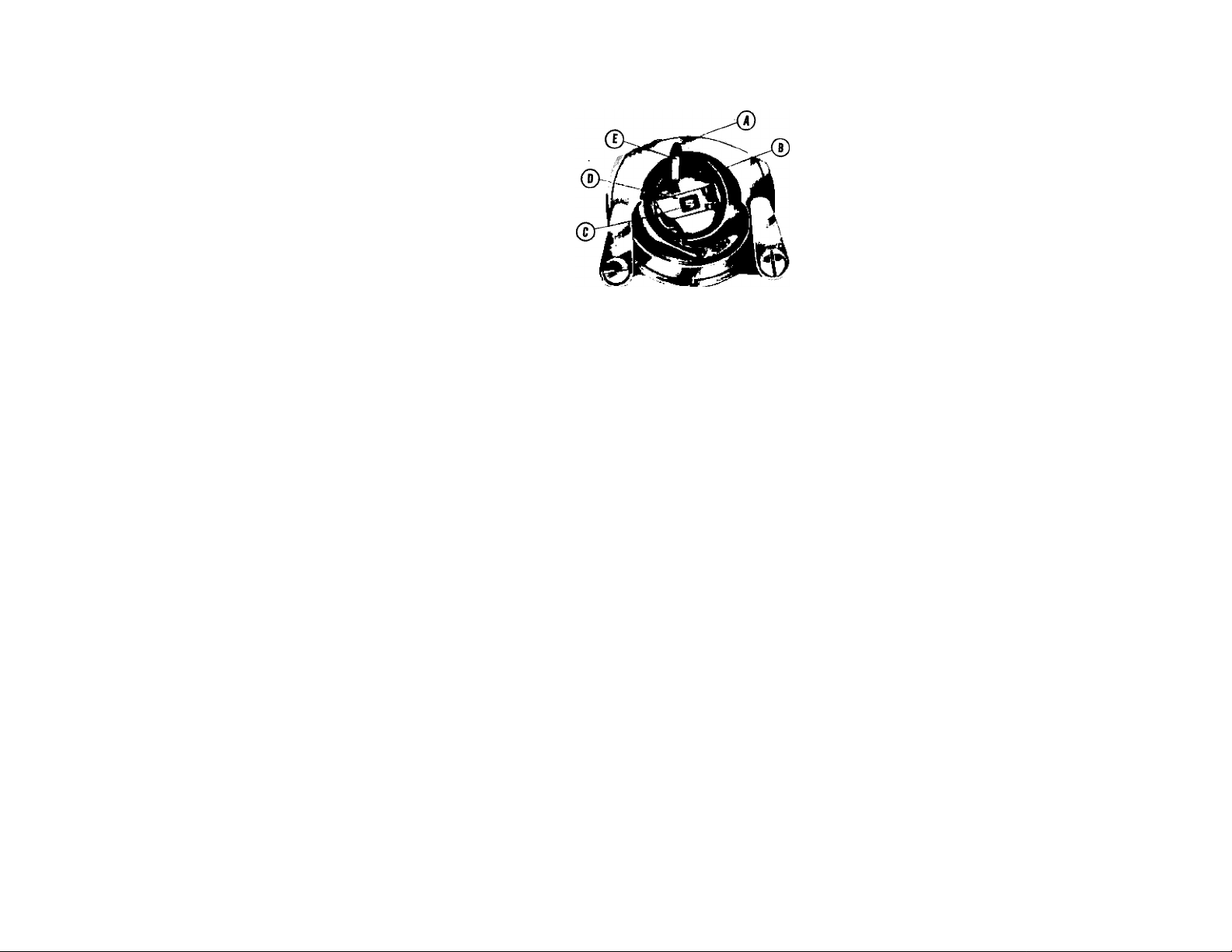

PLACING BOBBIN CASE IN SHUTTLE

Open hinged cover plate in front of the needle. (See

15, Fig. 1). Hold the bobbin case latch, (D), Fig. 9,

between the thumb and forefinger of the left hand, with

at least three inches of thread running from the top of

the bobbin case to the right. Insert and center the

bobbin case on the stud of the shuttle body, (C . Be

sure the bobbin case finger, (E), is opposite shuttle

race notch, (A). Press the bobbin case into the shuttle as far as possible until latch

catches on the center post of shuttle. THEN release the bobbin case latch, (D). Press

bobbin case again after latch has been released to make sure the bobbin case is locked

securely in place. Close the cover plate.

Fig. 9

Page 6

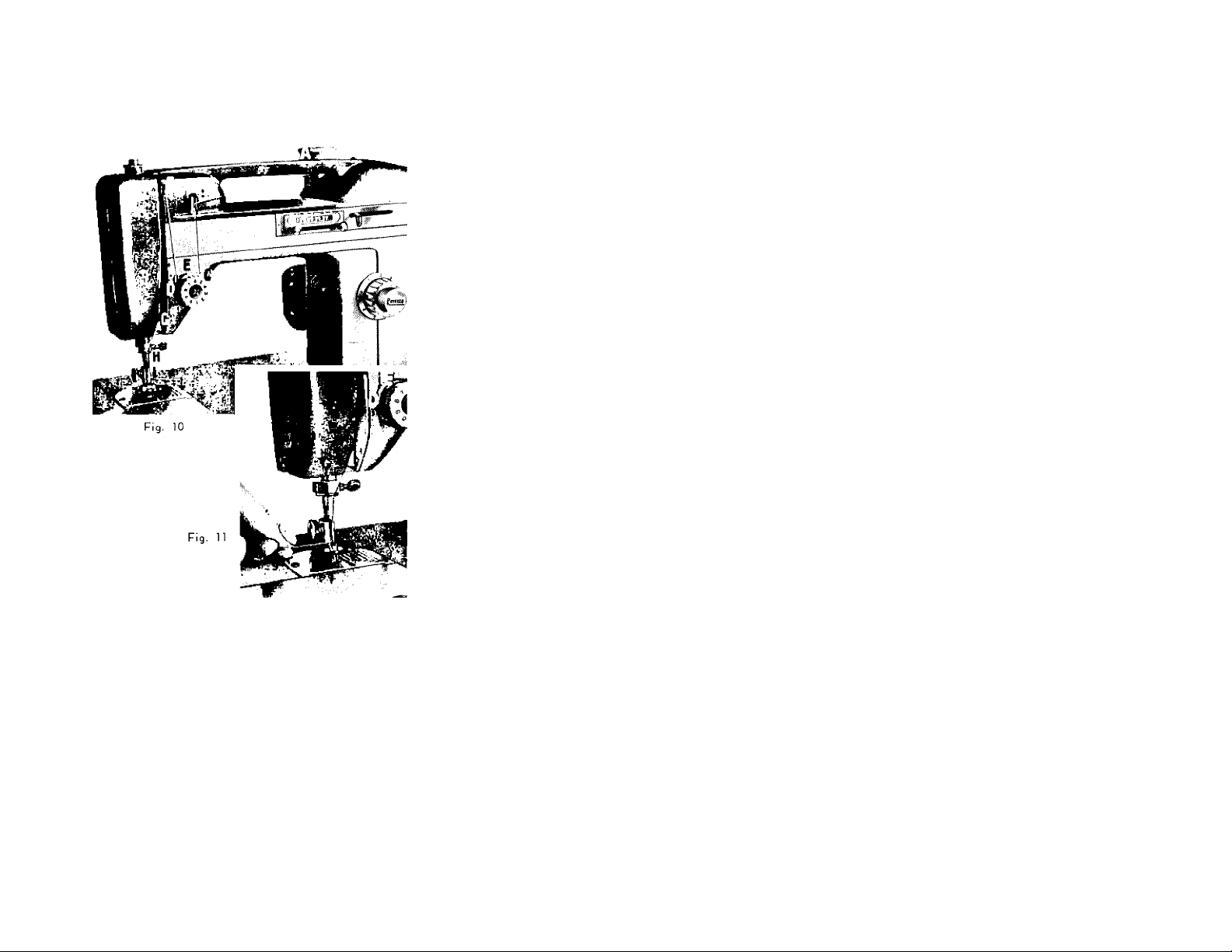

HOW TO THREAD THE MACHINE

(Single Needle, Fig. 10)

r ^

■

Q' -

O' ^

c,. ■

Turn hand wheel toward you to raise take-up lever

to highest position.

1. Place a spool oi thread on spool pin A,

2. lead thread through eyelet in arm thread

guide B,

3. pass the thread down and around tension discs

C from right to left

4. into check spring D

5. then tug on thread to pull it around and into

hook E Fig. 11 j

lead up to take-up lever F, threading from right

6.

to left,

down into thread guide G

7.

into needle bar guide H

8.

and through needle I from front to back.

9.

c

C,'

Page 7

Pull about lour inches of thread through needle. Hold thread end and

wheel toward you. As the needle goes down and comes up again, the bobbin thread

will be drawn up m a loop see tig. ii;. y^rasp oorn

1 '11 i firaso both threads and pass under presser

foot toward back of machine.

THREADING TWIN NEEDLES

(See Fig. 3 for inserting needles)

J

'3

3

‘3

3

3

3

3

3

'J

3

3

Follow above procedure with these exceptions:

Place thread, matching or contrasting in color, on both spool

pins. Draw threads through separate eyelets in upper arm thread

guide (B). Pass threads from right to left through front and

back tension discs and into check spring (D , then into hook

(Ej. Now treat both threads as one until you reach the needle

eyes. Pass thread from the spool on the left through left needle

and the thread from the right spool through the right needle.

Extra twin needles may be purchased from your sewing machine

.^11

the shanl'

dealer.

Flat side

of

■ tj

Page 8

'3 /]i^^

j-\ f

STRAIGHT STITCHING

ii»n~ Ilf m\ iiiri ■iiiMi-M

For straight sewing on fine fabric or very soft material,

it is advisable to use the straight stitch presser foot and

the straight stitch needle plate which are included in

your accesory box. Both have narrow needle slots.

Changing the Foot and Plate.

To change presser

foot (16, Fig. 1) loosen thumb screw 17 and remove

zigzag foot. Replace with hinged straight foot and

Fig. 12 tighten screw securely.

To change needle plate (14, Fig. 1) remove screw and lift off with cover plate 15

attached. Hold needle plate with left hand and cover plate with the right. (Fig. 12)

Press upper corner of cover plate (right side up) down slightly and slip pin from

groove in needle plate. Avoid using too much pressure. When the pin is released the

two plates will separate.

Attach cover plate to straight stitch plate by reversing the above procedure.

Slip pin on lower side of cover plate into groove on needle plate. Insert tongue

into square opening and slide upper pin into position. Put plates on machine and

fasten securely with needle plate screw.

.

...

12 ^

o

G? ;

G ""

G "

G

Q “

Q "

G

G

C'

%

c

C '

%

p.

►

k

I

\

Page 9

Be sure to set the stitch width at O,

needle will break in striking the foot or plate.

Push the zigzag lever 17, Fig. 13) all the way to the

left so that pointer is over 0 in stitch width window.

Set both locks, 6, as far to the left as possible.

To move locks, pull knobs slightly and slide, then

release.

or the

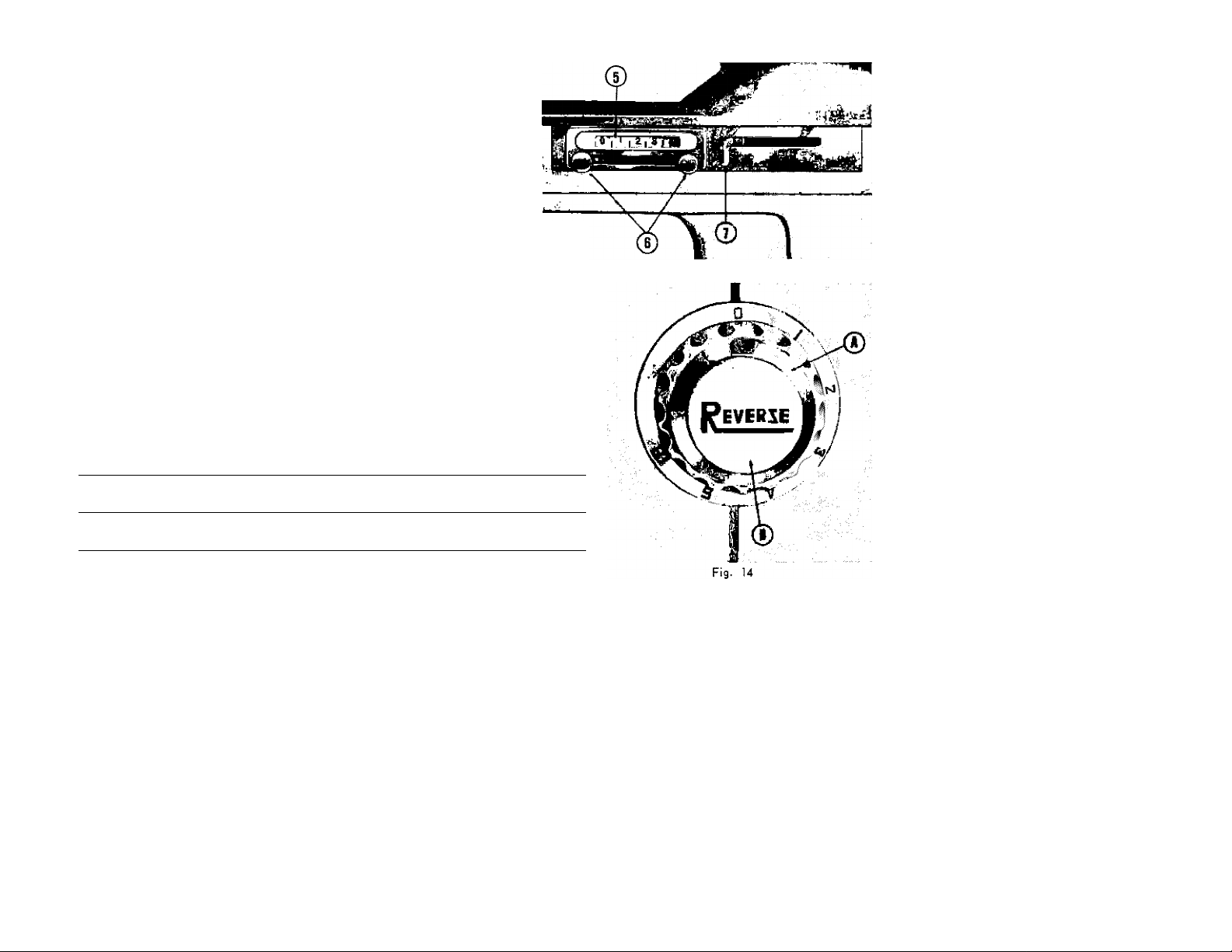

SETTING THE STITCH LENGTH

The length of the stitch is regulated by the dial A shown

in Fig. 14. Near 0 is the shortest stitch and 6 is the longest.

Turn the dial to the left to lengthen and to the right to shorten

the stitch.

STITCH LENGTH CHART (Approximate)

Fig. 13

Figures on dial

Number of

stitches per inch

2 3

0

No feeding 36 20

1

12 9

13

4 5

6

7 5

Page 10

SEWING IN REVERSE

When you wish to sew backward to tie the threads at the begin

ning or end of a seam, press in the reverse button B, Fig. 14, as far

as it will go. The machine will sew backward as long as the

button is held in.

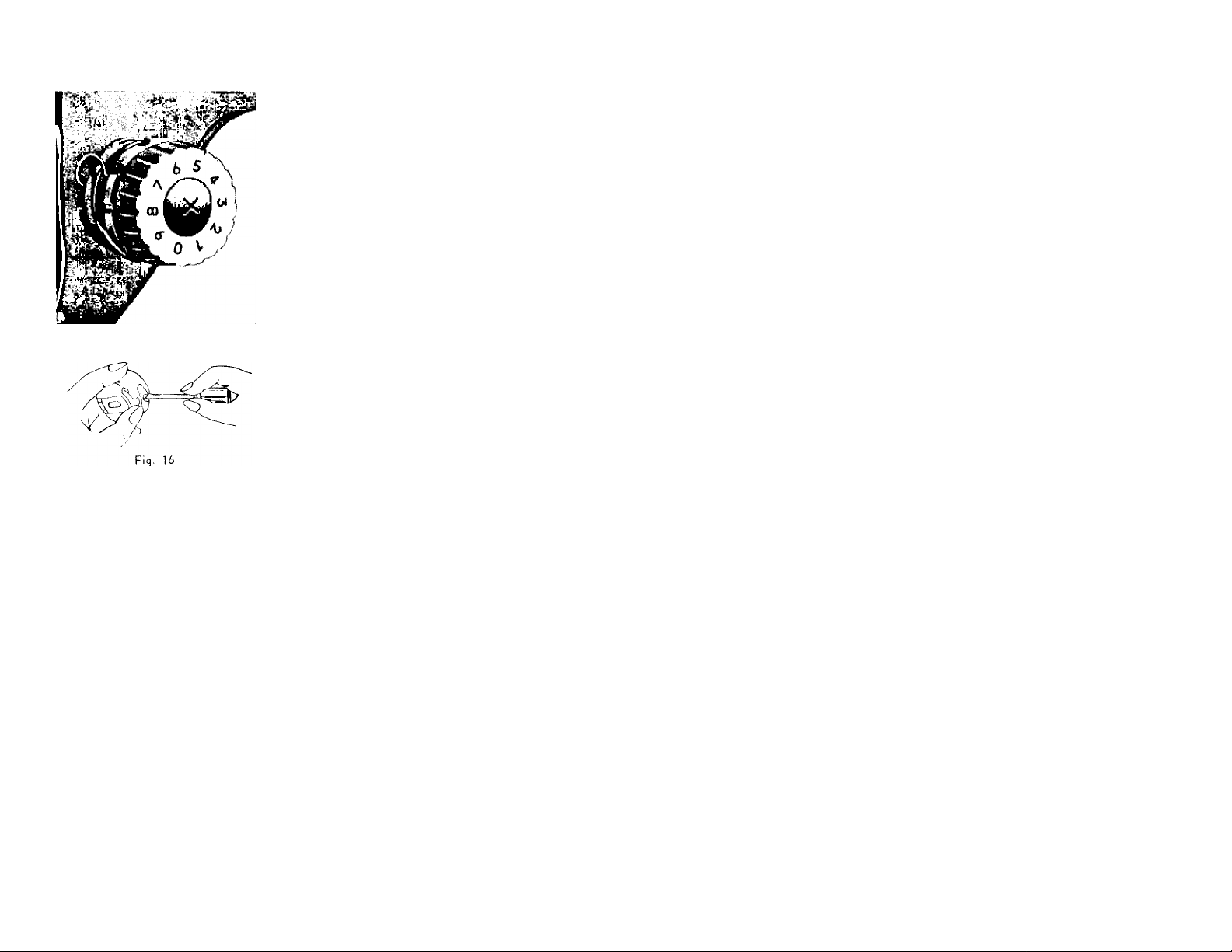

Fig. 15

Always adjust the upper tension with the presser foot down, as

the tension is automatically released when it is raised. To increase

the tension on the upper thread, turn dial Fig. 15 to the right,

or clockwise. To decrease, turn to the left. The higher the number

on the dial the tighter the tension.

Before adjusting lower tension be sure that the machine is threaded properly. When

necessary to change the bobbin tension, turn small screw ¡'Fig. 16 on side of the

bobbin case clockwise to tighten, counterclockwise to loosen.

ADJUSTING THE TENSIONS

c

C,'

c

C'

(.

c

c

c.

c

c,

c.

C.'

c

c.

c

c

.... 14 -

Page 11

When the upper and under tensions are properly

balanced, a perfect stitch will be formed with both

threads interlocking in fabric. (Fig. 17)

When the upper tension is too tight, the lower thread

is pulled up over the upper thread which is lying flat

on the fabric. When the under tension is too tight, the

upper thread forms loops over the lower thread lying

flat on the fabric.

ADJUSTING PRESSURE AND FEEDING OF FABRIC

Perfect Stitch

— —-K.

i

Upper thread tension too tight

Under thread tension too tight

Fig. 17

_____ __ __ __

A_

General Sewing.

Usually for straight sewing and manual embroidery, the pressure

bar cap or darner release, B, Fig. 18, is at its lowest position and the feed is at its

highest level, with the red triangle on the drop feed knob A, Fig. 19, turned to REG.

Sewing Thin or Light Weight Fabrics.

When lighter pressure is required to

sew satisfactorily on thin silk or filmy material, the pressure cap should be about halfway

down. Release all the way by pressing the snap lock. A, Fig. 18, and then press cap

15

Page 12

Fiq. 18

Fiq. 19

B down again to halfway spot. Lower the feed slightly by turn

ing the drop feed knob to SILK.

Darning and Monogramming.

In order to move the fabric

freely in any direction for darning, mending and certain kinds of

free-hand embroidery, release the pressure cap B completely

by pressing down on the snap lock. A, Fig. 18. Turn the drop

feed knob to DARN position, which drops the feed well below

the needle plate. To return feed to normal, turn knob to REG.

PREPARING TO SEW

Have take-up lever at highest point before starting to sew. Do

not try to help the feeding by pulling the material as this may

deflect the needle and cause it to break.

NEVER run machine without material between presser foot and

and feed. Place material and threads in position under the pres

ser foot and lower the presser foot. Turn the hand wheel toward

you until the needle is at its highest point. You are now ready

16

h

c

4

C:

u

u

c.

c.

u

c.

p

c

Page 13

to begin sewing. By having the needle at its highest

point it is not necessary to touch the hand wheel to start

the machine. You merely press the control. The speed of

the machine is regulated by increasing or decreasing the

amount of pressure exerted on the control.

REMOVING THE WORK

Be sure to stop the machine when the thread take-up

lever and needle bar are located at the highest position.

Now raise the presser foot and draw the fabric back and

to the left, Figs. 20 and 21, and pass the threads over

the thread cutter. Pull down slightly, holding thread in

both hands, so as not to bend the needle. Leave the ends

of thread under the presser foot.

17

Fig. 20

Fig. 21

Page 14

__

_____

=* -I- -r-

ZIGZAG STITCHING

Setting the Stitch Width and Locks. Move

Hit

» ^

(. '

4' '

"

^ '

r

Ctfs* r

G i

zigzag lever 7, Fig. 22, clear over to right

edge oi its channel. Pull left stop, 6, out

slightly and slide it to the right until the

black pointer on the lower part of indicator,

5, is under the width required. Then move

Pig. 22 lever, 7, back to the left until it forces left

lock to snap into its groove. The red pointer on the upper part of the indicator is

then above the number stitch width required.

To set the right stitch width lock, move lever to the left and slide the lock toward

the right to the width required. Move lever back to snap lock into its groove.

When the left and right locks are set at two different widths the zigzag lever can

be moved freely between the two settings.

18

C- I

i|:

C«'

t,'

C.' .

■

^ :

^ I

№■

c- .

r

I

:

k

Page 15

CREATIVE EMBROIDERY

Be sure zigzag presser foot and zigzag needle plate are in place.

The satin stitch, Fig. 23, which is really just a very

short zigzag stitch, and the basis for most embroidery,

is obtained by setting the stitch length as near 0 as

possible without stopping the feeding action. The width

may be set anywhere from just past 0 to the widest, 4, for single needle work. For

twin needles

twin needles, always turn hand wheel manually until you are sure needles clear the

needle hole.

Embroidery Patterns.

With the machine set for a short stitch length, different designs can be made by

swinging the stitch width or zigzag lever back and forth between 0 and 4 or any other

combination of widths. Try setting the locks at 1 and 4, 2 and 4, etc. Set a rhythm

for yourself and then proceed. After a while you will become quite skillful, varying

your designs by the speed of the machine, stitch length and width, and the manipula

tion of the lever. Always run the machine at a uniform speed, whether fast or slow.

the stitch width must be

no wider than No.

19

1V2

setting.

When using

Page 16

SAMPLE EMBROIDERY PATTERNS (Fig. 24)

i;

4* -

C '

c. '

Q, r

The following patterns will be altered by the machine speed. At slow speed the

patterns will be shorter than at moderate or fast speed.

A. Sew a few stitches at #4 width, then quickly move lever back to 0 for a short

period. Count, if necessary, to establish

JiLiUiUiUiUmLM^

a rhythm.

B. Set width locks at II/2 and 4, then move

lever slowly between settings, operat

ing machine rather fast.

C. Set width locks at 1 and 4. Gradually

move lever from 1 to 4, then snap it

back quickly to 1.

D. Set locks at 1 and 4.

Fig- 24

at moderate speed,

you count "1, 2, 3."

and 4 for the same count. Return to 2.% and 1. Repeat.

20

Operate machine

Stitch at 1 while

Then stitch at 2/2

4' :

4 ;

4 ;

Si

4 r

4

4

4

4 :

4 :

4

C- .

4

C :

•»

I*.

%

4

Page 17

E. Drop feed, lock stitch width at 4, take 3 or 4 stitches, leave needle in fabric left

of stitches. Pivot fabric on needle to make next daisy petal. Continue until flower

design is complete. Lock threads by setting stitch width at 0 and taking 3 or 4

stitches in center of design.

Twin Needle Work (See Figs. 24 and 25)

Variations of the designs shown in Fig. 24 (with the exception of the daisy) may be

done with twin needles

Always turn the wheel by hand to be sure needles do not strike either side of the

needle plate hole.

A. Set locks at 0 and 1V2. Move lever at even pace from 0 to II/2, and back. Keep

repeating in rhythm.

B. Set stitch length at 2, the stitch width at 1. ,Do a few zigzag stitches, drop feed

for 3 or 4 stitches, then raise feed quickly. By operating the feed knob rh5dhmically, it is not necessary to count stitches to obtain uniformity of pattern.

C. Set width locks at ^ and 1%. Sew a few stitches at 1V2, then quickly move

lever to 1/2. Repeat the back and forth movement while running machine rather

slowly.

when the right stitch lock is set on No.

21

I1/2

width.

Page 18

■ si'Ss

Fig. 25

D. Set locks at 0 and IV2. Gradually move lever from 0 to IV2, then snap it back

quickly to 0. The speed of the machine will govern the length of the triangular

pattern.

E. Set the stitch length at 1, then follow directions for pattern A.

For double rows of straight stitching, lengthen the stitch and set the. stitch width

at 0, with lever as far to the left as it will go. Keep the zigzag foot on the machine.

dimMMBiisirM:

I:.

r-

■G G

f

. .. 22 —

Page 19

EMBROIDERING WITH A HOOP

It is easy to follow a stamped design or to work

free hand when embroidering or monogramming.

(See Fig. 26). Release the pressure from the foot

by pressing down the snap lock on the automatic

darner. Turn the drop feed knob to "DARN" posi

tion. Stretch the fabric in an embroidery hoop,

removing the presser foot

presser bar lifter,

hoop slowly with both hands

Set the stitch width at the size you prefer and lower the

Then operate machine at a rather high speed while moving the

Work carefully and be sure to keep lingers out of the

snd. plac© unci©r th.© ne©cil© aft©r

_

Fig. 26

_£

i

path of the needle.

MAKING BUTTONHOLES

First, mark the begimiing and end of the buttonhole on fabric with a basting line or

tarlors chalk. Make one on scrap fabric (following directions below) to be sure

machine adjustments are correct.

1. Replace presser foot with buttonhole foot which is grooved deeply underneath to

.....

23

Page 20

Fig. 28

riirm

prevent piling up of thread. (See Fig. 27.)

2

.

Lock the stitch width at 2 with the left stop, and at 4 with the

right stop. Set the stitch length near 0.

3.

Lower needle carefully into the mark on fabric indicating the

beginning of buttonhole. Stitch to the mark for the end of the

buttonhole, step 1, Fig. 28, stopping machine with needle in

fabric at right side of stitching.

Lift the presser foot and using the needle as a pivot, turn the

fabric end for end.

5. Lower presser foot and turn hand wheel

just enough to raise needle out of fabric.

6. Turn feed knob to DARN and move zig

zag lever to 4. Take five or six stitches to

form bar tack, step 2, Fig. 28.

7. Raise needle out of fabric and return feed

to REG. position. Return stitch width to

2.

8. Stitch second side of buttonhole, step 3.

- 24 —

|t

Cii f

& )

& r

c, -

C ;

i

4, i

C.

G

C..

*•'

e;

Page 21

9. Make bar tack by repeating 5 and 6 above (step 4).

10. Return stitch width to 0 and take two or three stitches to fasten bar threads and

prevent raveling. Cut the buttonhole opening with the seam ripper, being careful

not to cut the stitching.

If you plan to make buttonholes on sheer or soft material, place tarlatan or paper,

which can be torn away after stitching, under the fabric. Änd it is always wise to

make several buttonholes on scraps of fabric before working on the garment.

For narrower buttonholes, set the left stitch width lock at less than 2, the right lock

at the setting which will produce a bar tack twice as wide as one bank of buttonhole

stitching.

SEWING ON BUTTONS

1. Remove hinged presser foot and attach button sewing foot. (See Figs. 29A, B and C.)

2. Turn drop feed knob to DARN.

3. Move zigzag width lever to 0 position or to the extreme left. Place button so that

its left hole comes directly under the needle, then gently lower the presser foot.

25

Page 22

Fig. 29A

Fig. 293

Move the zigzag width lever to the right until needle comes

exactly over the right hole oi the button. Turn the balance

wheel slowly back and forth by hand to be sure needle drops

£j-00^y through both holes of the button. Lock stitch width,

either at right or left.

4. Run the machine at medium speed, making five or six stitches,

stopping with the needle in the left hole.

5. Move the lever to the left or to 0. Finish off with a few stitches.

you wish you may place a rounded toothpick over the button,

between the two holes, and sew button to fabric in regular way.

Remove toothpick and wind thread under button, forming a

shank. Fasten.

If a four hole button is to be sewn, follow the same procedure

above lor the two hole button. Now lilt

presser loot slightly and move fabric to

permit stitching the remaining two holes.

Hooks, snaps, etc., are sewn to the fabric

with the same procedure as for sewing

two hole buttons.

Fig. 29C

26

c.

c-

Page 23

HEMMING WITH THE ZIGZAG STITCH

Heavy or pile fabrics such as tweed, camel s hair,

5

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

felt and velveteen can be hemmed neatly and softly

with a zigzag stitch. Smooth, figured material may be

finished in the same way as the sidewise stitches

will be barely noticeable and the fabric will hang as

Fig. 30

¿eorre^fSlritTot hemming either by stitching seam tape to the right side, or by

folding the fabric under one half inch. Stitch one fourth inch from the edge wit a

fei SIS' Then fold the garment or large part of the fabric back on the

herllold. Let the edge of the hem extend beyond the folded fabric one-guarter inch.

Hold in place with pins set TeVon T'sclap of'the fabric to

will show less on the right side, but thicker fabrics require a ' ,

- — fr

Place material under zigzag presser foot with the quarter-inch extension to the right.

Guide told of tLVonly the left side of the

rohtlhs Ld. The" i*t side of the etitch should be only ou the

quarter-inch extension of the hem.

27

Page 24

Fig. 31

Fig. 32

HOW TO USE ACCESSORIES

NARROW HEMMER. With the needle at its highest

position, replace regular presser foot with narrow

hemmer (Fig. 31). For a plain narrow hem, make a

1/8-inch double fold for about two inches along edge

of fabric. Hold each end of the two inch fold, slip

underneath hemmer. Bring fold up into the scroll of

hemmer, draw forward to end and fasten with point

of needle. Lower presser bar lifter.

Gently pull ends of thread as you start stitching.

Guide material slightly to right, and it will automa

tically take a double turn through scroll.

LACE TRIMMED HEM. To sew a narrow hem and

attach lace in one stitching, insert lace in the slot

next to needle (Fig. 32). Sew hem as above, guiding

lace under needle and hem into scroll.

LACE EDGE WITH INVISIBLE STITCHING. Hold

C#'

<0"" I'

Q r

C г

C г

c i

b i

Ce !

О

i,.

O'

о

C.'

G

О

G

C«’

c

t

Q-

28 -

Page 25

lace 1 8-inch from raw edge on right side of fabric.

Insert both in scroll as for plain narrow hem 'Fig.

33;. Let hem roll over and sew in lace. Press lace

out flat along edge with hem turned up. ^

It is possible to have a little fullness in lace by

feeding it freely under scroll.

french seam. With right sides together, place

Fig. 33

top piece of material 1 H-inch inside edge of lower piece

F/:r::r

FIAT FELLED SEAM. Open out Erenoh seam and insert rolled edge in soroll oi

hemmer. Edgestitch to lay seam flat.

1 a .3 stitch

Q NG GUIDE. This guide for making parallel rows ol stitching is attached by

(Frg. 34,,. Adjust the curved bar to press lightly on the fabric. By letting the guide

- 29

Page 26

ride on the first stitching line, successive rows will

be an equal distance apart. When the bar is attached

so that the curved part is to the right of the needle,

it may also serve as a seam width guide.

SEAM GAUGE OR CLOTH GUIDE. Use the seam

gauge as a guide for straight seams and even rows of

top stitching along edges of fabric. Fasten gauge with

accompanying screw in threaded hole in needle plate

or in bed of machine (Fig. 35). Adjust to seam

width desired.

00'

c*

c

r.

Fig, 35

CARE AND MAINTENANCE OF

YOUR MACHINE

HOW TO OIL YOUR MACHINE

Your machine should be oiled occasionally to keep

it operating smoothly — how often depends on the

amount of sewing you do. Oil the upper part of the

sewing unit at points indicated by arrows in Fig. 36.

Avoid over-oiling — only a drop is needed at each

point.

30

o

G

G

G

G

Page 27

Fig. 39

Occasionally remove the

top cover by removing screws

and oil moving parts not ac

cessible through oil holes,

Fig. 37.

To oil parts under the bed

of the machine, tip the unit

back on its hinges and apply

a drop of oil at each point

indicated in Fig. 38.

Fig. 37

Fig. 38

To oil moving parts inside the face plate, which only

rarely require oiling, remove plate by taking out the

screws. Oil at spots indicated in Fig. 39.

Use gear lubricant on gears indicated by white arrows

in Figs. 37 and 38. Lubricate only when machine seems

to sew more slowly than usual.

31

Page 28

Fig. 42

HOW TO REPLACE LIGHT BULB

Grasp light bulb button (see 31, Fig. 2; and pull light bracket down

ward. Unscrew bulb and replace with bulb of same size, which is

available from your sewing machine dealer.

HOW TO CHANGE THE BELT

If it should ever become necessary to replace the belt on your ma

chine, the hand wheel must first be loosened and moved out.

To do this, follow these instructions :

1. Remove clutch nut A in center of wheel by taking out the small

screw B near the edge. Fig. 40. Turn nut counterclockwise until

it can be lifted off.

2. Before moving the hand wheel, note the position of the washer,

C, Fig. 41, which fits under the clutch nut. It may fall out when

you are changing the belt.

3. Pull hand wheel away from the machine carefully. Fig. 42. Pull

it just far enough to make the grooved section which holds the

belt accessible.

4. Slide old belt over hand wheel and over pulley on the end of

motor.

-- 32 ^

Page 29

5. Slide new belt into grooved section and over motor pulley.

6. Push hand wheel back against the machine.

7. If washer C has fallen off, replace so that the lips D, Fig. 41, are pointing toward

the clutch nut.

8. Replace nut and tighten screw securely.

After doing this, turn the clutch toward you to disengage the sewing mechanism. If

the needle still moves up and down as you turn the hand wheel, again remove the

clutch nut. Give the washer a half turn and replace the nut.

CLEANING AND OILING THE SHUTTLE

(See Figs. 43 and 44)

The stitch forming mechanism occasionally becomes

clogged with loose threads and lint. This will interfere

with the efficient operation of the machine. Cleaning

and removal of the lint will safeguard the performance.

To remove the shuttle assembly, proceed as follows ;

1. Turn the balance wheel until the needle reaches

its highest position. Tilt head back on its hinges.

2. Remove bobbin case (A), Fig. 43.

33

Fig- ^3

Page 30

CHECK UP FOR SMOOTH SEWING

Be sure needle is inserted properly.

Check on correct way to thread machine.

Use correct needle size for thread.

Do not have upper tension too tight.

Lower Thread Breaks

Check correct method of threading bobbin case.

Be sure lower tension is not too tight.

Needle Breaks

rroaT‘the“lodre“" “

Be sure presser foot is firmly attached to bar.

Although your sowing maohino is designed for maximum efficiency should any of

35 -

.»wi.

Page 31

Skipped Stitches

Do not use a blunt or bent needle.

Insert needle correctly.

Use correct needle size for thread.

Be sure pressure on foot is sufficient when sewing heavy fabrics.

Stitches Loop

Make sure tensions are properly balanced and that machine is threaded correctly.

Machine Binds

Clean thread, dust and lint from hook, shuttle and race.

If condition continues it may be that the machine is gummy with oil. Apply

kerosene to oil holes, run rapidly for a while, and wipe dry. Then lubricate again

with fine sewing machine oil.

(p

Cr f

C- r

C i

C j

c-;

Qi' f

W' '

c.

Wi'

(•

w

i«' :

I

t

f

le.

I»

36

c

C.'

Loading...

Loading...