Page 1

INSTRUCTION MANUAL

MODEL 211 SEWING MACHINE

Page 2

for safer sewing ,

Please follow these instructions

carefully to avoid unexpected

3ccid6ots‘

1- Always disconnect the elec

trical plug from the outlet when

cleaning, oiling, changing

accessories and after sewing

2. Pay careful attention to your

hands and the movement of

the needle while sewing to

avoid injury to your fingers.

INDEX

Features and Parts

Accessories

Using the Foot Control

Using the Extension Plate ,

Free Arm Features

Changing the Needle

Changing the Presser Foot.

Winding the Bobbin

Changing Bobbins

Threading the Bobbin Case

Upper Threading

Adjusting Feed Dog Height

Picking-up

Adjusting Upper Tension

Fabric, Thread, Needle

and Stitch Length Guide

Preparing to Sew...............

Stitch Length Control Dial

Selecting Needle Position .

.................

................

................

...............

Straight Stitching

Changing Direction of Sewing

3

Removing the Material

Crossing Heavy Seams

Zigzag Stitching

Twin Needle Sewino

6

Buttonhole Preparation

7

Buttonholes on

Lightweight or Knit Fabrics

9

10/11

Sewing on Buttons

Embroidering

11

Darning . .

Monogramm ing

12

Sewing on Zippers

12

Quilting .

13

Care and Maintenance

Cleaning the Machine

14

Oiling. .

15

Trouble-Shooting gujjjg

15

16

. 17

. 18

10

19

20

21

¿1

90

23

25

26

28

Page 3

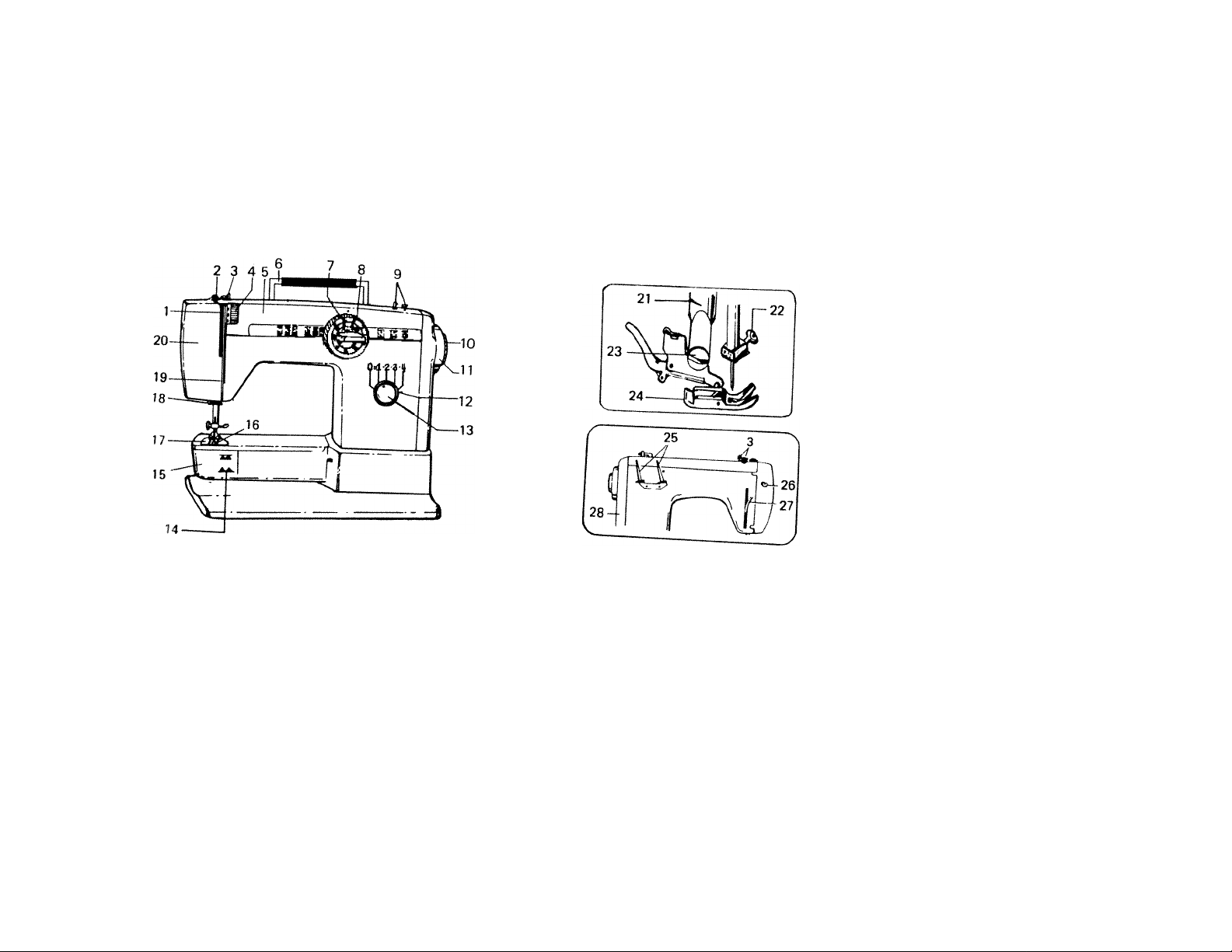

features and parts

1- Thread Take-up Lever

2. Pressure Release (Darning)

3- Top Plate Thread Guide

4. Tension Regulator

5. Top Plate

6- Handle

7. Needle Position Control Dial

8- Zigzag Width Control Dial

9- Bobbin Winder

10. Fly Wheel Clutch

11- Fly Wheel

12. Stitch Length Control Dial

13. Reverse Button

14. Drop Feed (under Shuttle Cover)

15. Shuttle Race Cover

16. Feed Dog

17. Needle Plate

18. Thread Guide

19. Thread Guide

20. Face Plate

21- Thread Cutter

22- Needle Clamp

23. Presser Foot Thumb Screw

Presser Foot

25. Spool Pins

26- Light Switch

27. Presser Bar Lifter

28. Motor and Belt Cover

Page 4

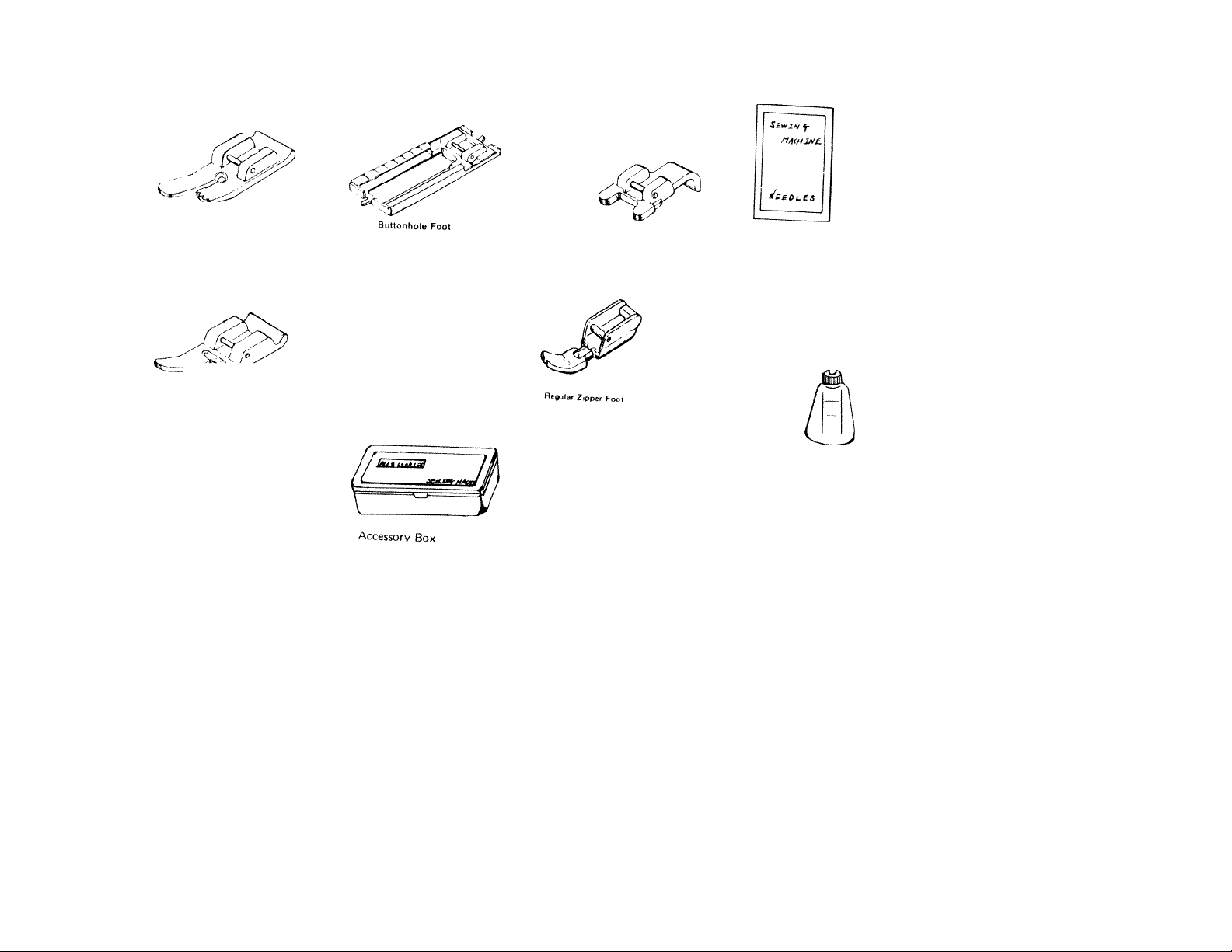

accessories

Straight Stitch Fool

Zigzag Foot {In Machine)

Ouiliiny Guide

Pells

Bobbins

Button Fool

Needles

Seam Ripper

Oiler

Screw Driver.

Page 5

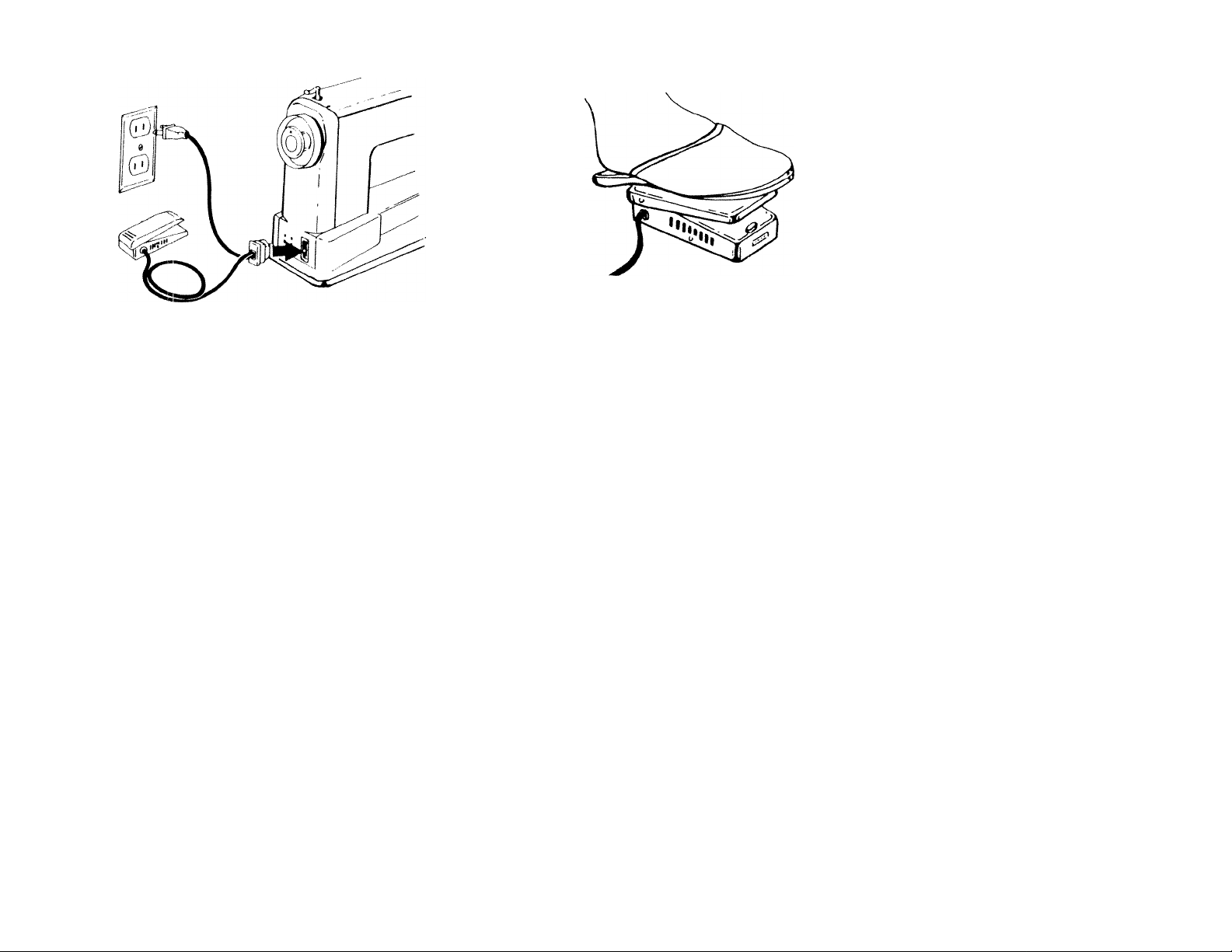

USING THE FOOT CONTROL

TO CONNECT THE FOOT CONTROL WIRES:

• Connect special plug to block on machine as

shown in diagram above.

• Connect outlet plug to electrical outlet.

• When sewing, keep children’s hands away from

foot control and wiring.

• After sewing, disconnect plug from electrical

outlet.

TO USE THE FOOT PEDAL:

• Begin sewing by turning the hand wheel toward

you and apply gradually increasing pressure to

foot pedal.

• Sewing at a constant speed will give best results.

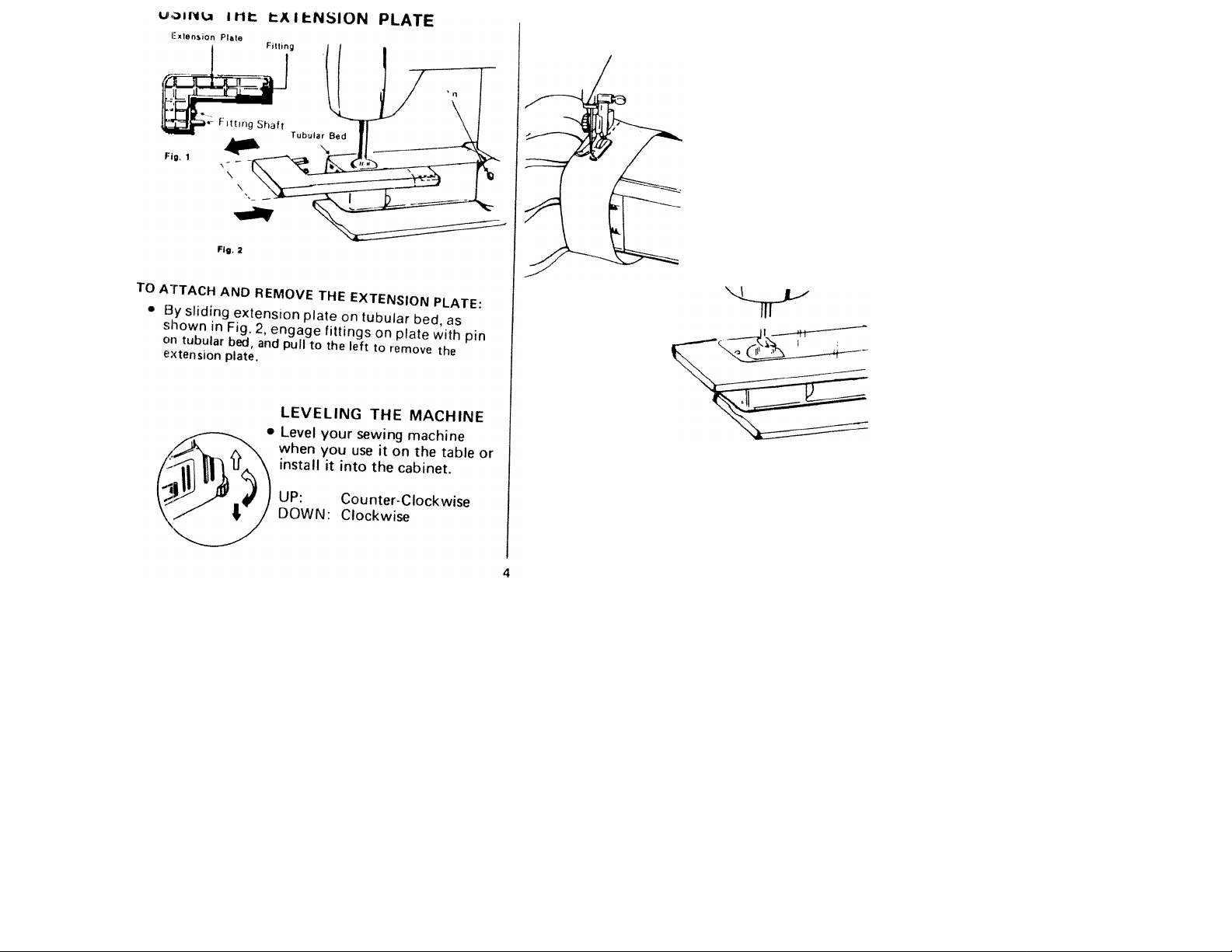

Page 6

FREE ARM FEATURES

TUBULAR SEWING

• The free arm design

simplifies the sewing of

tubular items such as

pant cuffs, shirt and

blouse cuffs and socks.

Simply position these items

over the tubular bed of

the machine and sew.

FLAT BED SEWING

" e><‘ension plate is attached, you have

all the advantages of a flat bed machine for

sewing flat items, and for sewing large tubular

Items such as flared pant legs.

Page 7

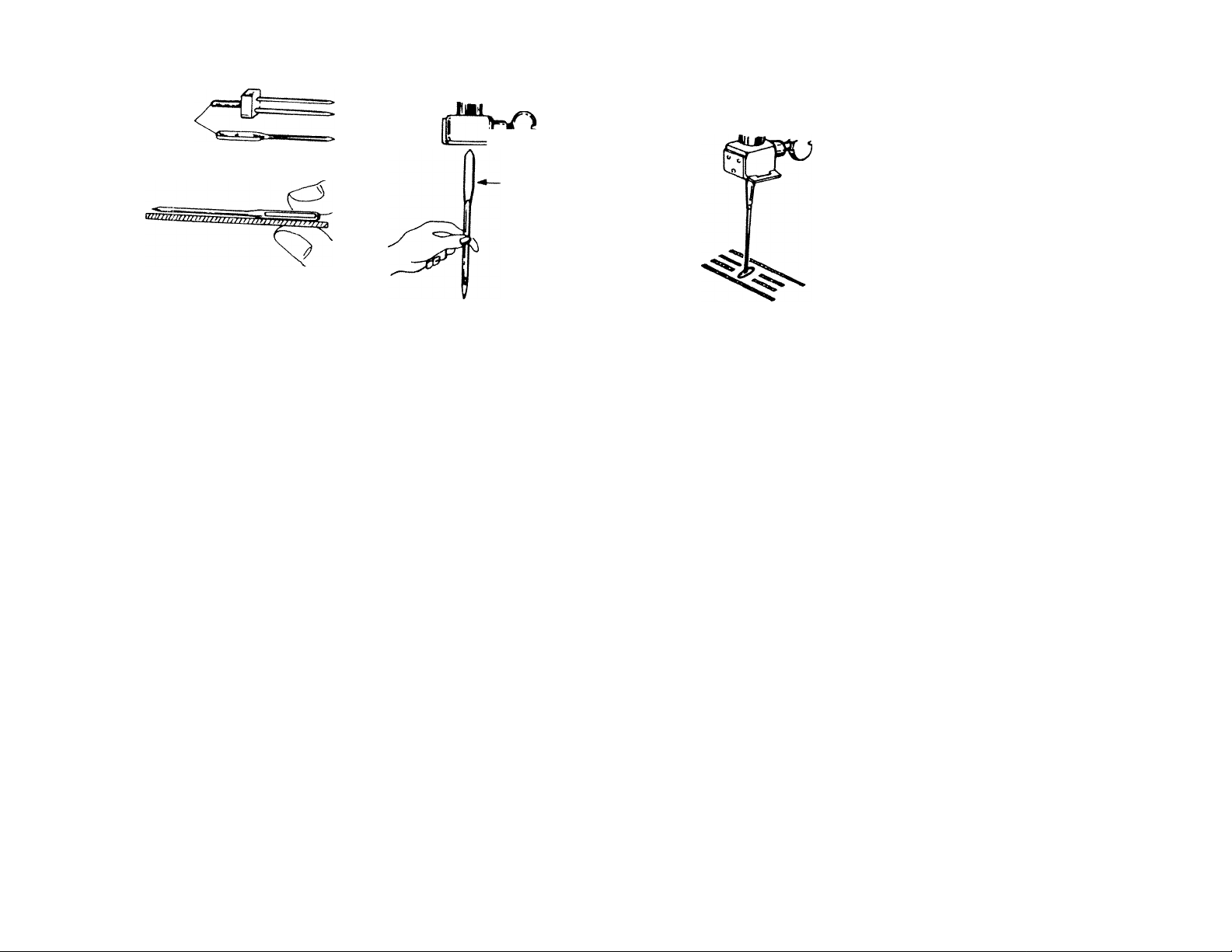

CHANGING THE NEEDLE

Flat Bide

• Afways make sure needle is

sfratghf.

If straightness of

needle, lay needle on a flat

SiM is

fn parallel as shown

in above diagram.

- Needle

Plat side towards

back of machifie

Clamp Screw I

• Turn hand wheel toward you to

posmCr'"‘’"^‘°‘‘^^‘9hest

• Loosen needle clamp screw

f''"«die as

back of ml '® 'awards

P„ .K °fj^3chine as shown

in the above diagram.

Tighten needle clamp screw

With screwdriver.

Follow the same procedure for

insertion of twin needle.

To make sure that needle has

h®®!] '^^^'■ted correctly turn

cfrth^P®®* •°'^ard you and

throlioh ,h®®^'®

nofw|9h the center of the

needle hole in the needle plate

Stitch selector dial must be set

®,f"'9ht stitch needle posi

Xnmem."'’""'^‘"^ ®®®‘^'®

^ skipped stitches occur, needle

may be incorrectly inserted.

Page 8

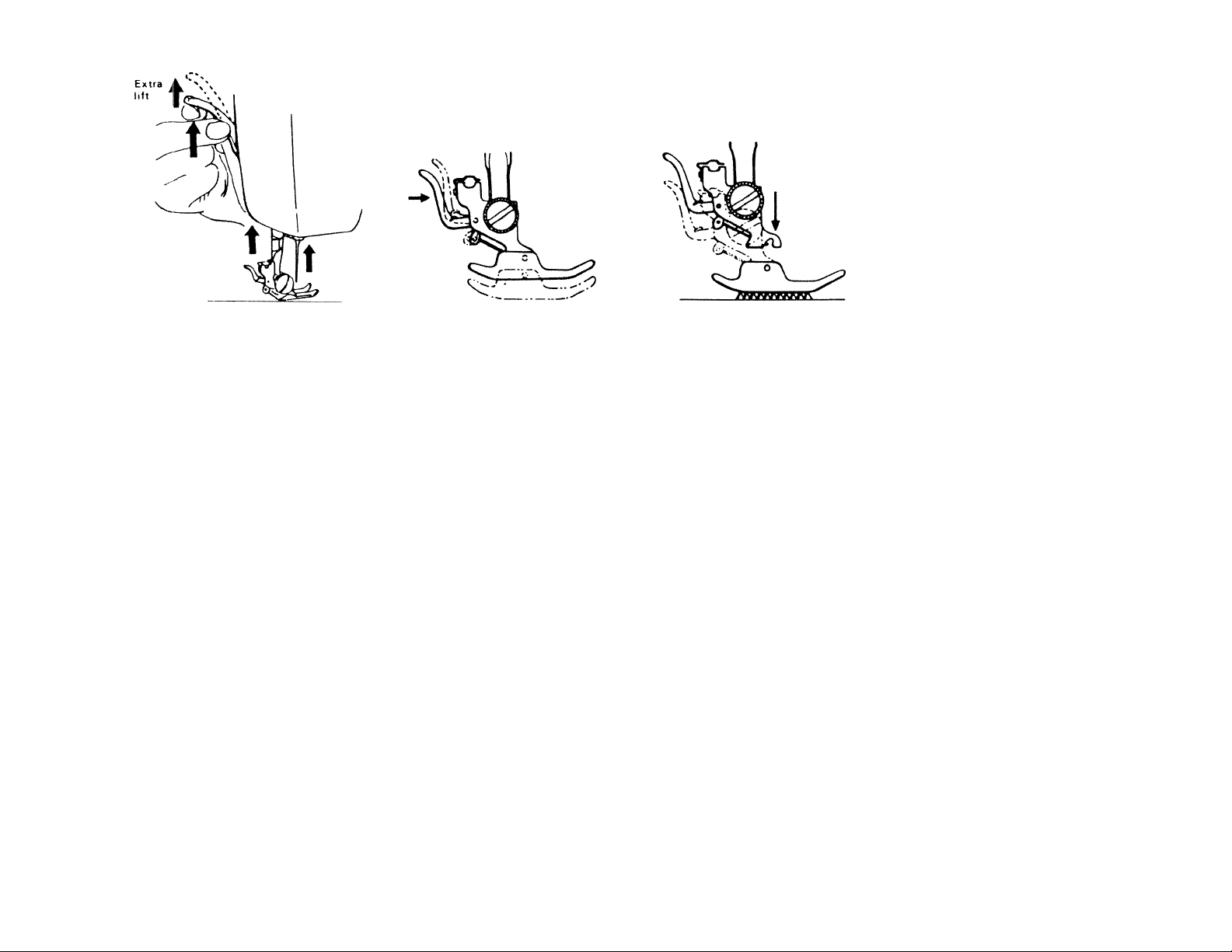

CHANGING THE PRESSER FOOT

Raise needle bar to highest

position and raise presser foot

as shown.

The extra lift for heavy fabric

rriakes it easier to place fabric

under the presser foot.

TO REMOVE

THE PRESSER FOOT:

• Press lever on back of presser

foot shank and foot will drop

from shank as shown above,

• It is not necessary to loosen

the thumb screw to change

presser foot.

TO ATTACH

THE PRESSER FOOT:

• Align desired presser foot to

shank as shown above.

• Lower presser foot lever and

shank will automatically attach

to foot as shown above.

Page 9

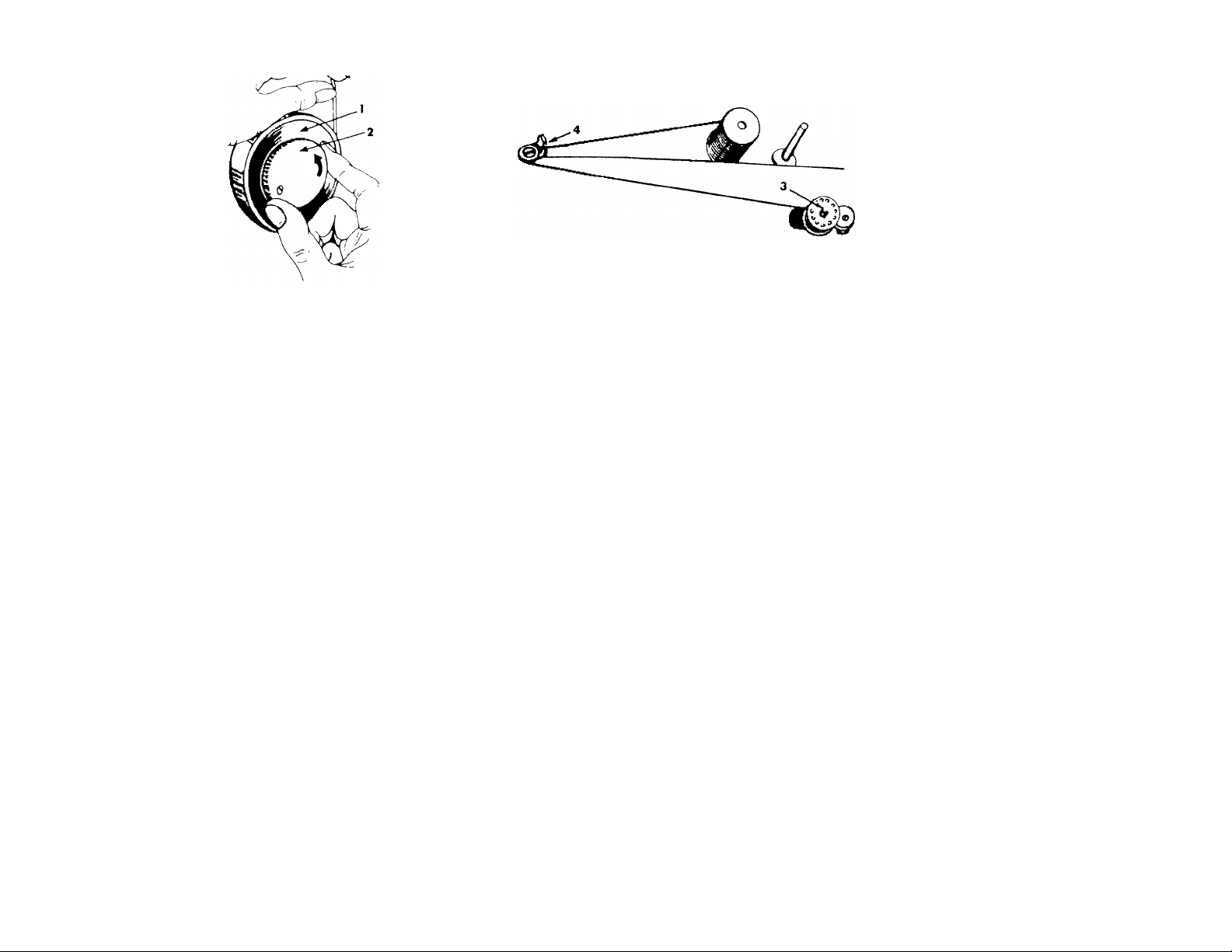

WINDING THE BOBBIN

TO DISENGAGE THE HAND WHEEL:

• Hold the hand wheel (1) with left hand, turn

clutch (2) counterclockwise with right’hand to

disengage as shown.

TO WIND THREAD ONTO BOBBIN:

• Lead thread through spring thread guide (4) and

through the hole in your bobbin from the inside

out.

• Place the bobbin onto the bobbin winder shaft

(3).

• Push the bobbin winder to the right.

• Hold loose end of thread firmly and turn hand

wheel to make thread tight. Apply gradual

pressure on foot pedal until automatic shut off

disengages bobbin winder.

• Cut off loose end of thread.

Page 10

CHANGING BOBBINS

TO REMOVE THE BOBBIN FROM BOBBIN CASE:

• Raise needle bar to its highest position. Bobbin

case cannot be removed when needle bar is

at low position.

• Open shuttle race cover, pull bobbin case latch

with two fingers and remove bobbin case as

shown above.

• Remove bobbin from bobbin case by releasing

latch.

TO ATTACH THE BOBBIN CASE:

• Pull thread at least 3 inches from bobbin.

• Thread bobbin as shown on page 9 .

• Making sure that needle bar is at its highest

position, insert bobbin case into shuttle race by

holding bobbin case latch. Make sure bobbin

case finger is inside shuttle notch. Press bobbin

case into shuttle as far as possible until latch

catches on center post of the shuttle.

Page 11

THREADING THE BOBBIN CASE

Tension Spring

Pull thread at least 3 inches from

bobbin. Insert bobbin in bobbin

case so that thread will unravel

clockwise.

Pull thread into slot of bobbin

case as shown in Fig. 2.

Draw thread under the tension

spring and into the fork-shaped

opening of the spring as shown

in Fig. 3.

TO ADJUST BOBBIN TENSION;

• Turn screw on side of bobbin

case clockwise to increase

tension.

• Turn screw on side of bobbin

case counterclockwise to

decrease tension.

Pull thread through hole in

bobbin case finger as shown in

Fig. 4. (Recommended for

zigzag sewing only)

Page 12

UPPER THREADING

Raise needle bar to its highest position.

Raise presserfoot.

Lead thread through top plate thread guide (1)

and between tension discs (2).

Pull thread down around arm thread guide (3)

and up to take-up lever (4).

Lead thread through eyelet on take-up lever

from right to left and down through face plate

guide (

5), hooking thread into guide.

Pull thread down through needle clamp guide (6)

and through needle hole from front to rear (7).

Always use the same type of thread on top and

bottom as different sizes or types of thread will

cause tension problems.

Example: Polyester thread on the bobbin and

cotton thread on top will result in poor tension

quality.

10

Page 13

(TWIN NEEDLE UPPER THREADING)

• Follow threading instruction for single needle with

these exceptions.

• Place thread, matching or contrasting in color, on

both spool pins.

• Draw threads through thread guides as normal, but

separate the threads at the tension.

• Pass thread through the left disc and one thread

through the right disc.

• Now treat both threads as one until you reach the

needle eyes.

ZIGZAG DIAL: Set at desired width between "O" and

"3", if you set dial hi^er than 3, the needle will hit the

needle plate and break.

STITCH LENGTH: Set at desired stitch length.

ADJUSTING FEED DOG HEIGHT

• Upper position of feed dog is used for normal sewing.

To raise feed dog.

• Press drop feed button ".^"located under shuttle cover, to

upper position.

• Lower position is used for Embroidering, Mending or

Sewing on Button. Press drop feed button “M" to

lower position.

11

Page 14

PICKING-UP LOWER BOBBIN THREAD REGULATING PRESSURE

Raise presser foot.

Holding upper thread, turn hand wheel toward

you one rotation. When take-up lever is at its

highest position, pull thread to pick up loop of

lower bobbin thread.

The amount of pressure that is applied to the

fabric by the presser foot is adjusted by the

pressure cap (1). The upper position gives the

least amount of pressure while the lowest position

gives maximum pressure.

To increase the pressure, push down on the

Pull both upper and lower

thread "to the left of"

presser foot approximately

6 inches.

This will prevent jamming.

pressure cap to obtain the desired setting. To

decrease the pressure, press down on the snap

lock ring (2) to allow the pressure cap to return

to its maximum height. Then reset to the proper

pressure.

Normally the pressure cap will be in the lowest

position. If the top layer of fabric tends to push

out further than the bottom layer of fabric,

Pressure should be decreased. This often happens

on bulky fabrics, such as wools, and on knits.

12

Page 15

ADJUSTING UPPER TENSION

Fig. 1

Fig. Z

Flg.3

'///A

k/zm

Upper Thread Tension Too Loose

Upper Thread Tension Too Tight

kirn

Proper Terulon

To increase upper tension, turn upper tension

regulator to higher number.

To decrease upper tension, turn upper tension

regulator to lower number.

Turning tension regulator from “0” to “9" will

increase tension. Normal sewing is performed

between ”4” and “5”.

Note: Normal stitches will be performed on the red

zone at 4, 5 and 6 for regular cotton threads.

A perfect straight stitch will be formed with both

threads interlocking in fabric as shown in Fig. 1.

When using the zig zag stitch for embroidery

(satin stitching), decrease upper tension so that

top surface will look smooth at the expense of the

bottom surface.

13

Page 16

FABRIC. THREAD. NEEDLE AND STITCH LENGTH GUIDE

NEEDLE (Lons Scarf)

FABRIC

, 130/705H

’ Europaar.

THREAD

STITCH LENGTH

DELICATE — tulle, chiffon, voile, fine lace, oraandv

lawn, crepe, taffeta

Knits - sheer tricot

LIGHTWEIGHT — batiste, orqandv. voile, taffeta,

silk, crepe, chiffon, velvet

KNITS — tricot, brushed tricot, iersevs. synthetic

leathers, p ower net

LEATHER S - plastic film, vinyls

MEDIUM WEIGHT - ainaham. oercale. linen chintz

(eille, satin, corduroy, velvet, suitings, wools, pique,

terry

KNITS — iersev. double knit oower net. barbina

suits

LEATHER S — vinyls, plastic film

MEDIUM HEAVY — gabardine, tweed sailcloth,

denim, duck, coatings, wools, drapery.

KNITS — double knit, power net

LEATHER — vinyl, rubber b acked drapery fabric

HEAVY ~ overcoatings, canvas, upholstery, awning

KNITS — fake furs, velours, sweater

LEATHER S - vinvis, plastics

65/9 70

light bail point

75/11 80

light ball point

Wed^ point

90/14

light or medium

ball point

Wedge point

100/16 100 Mercerized 50

heavy ball point

Wedge point

110/18 110

heavy ball point

Wedge point

Fine mercerized 60

European 50 — 70

•'A" Silk

Fine Synthetics

Fine mercerized 60

European 50 - 70

Fine Synthetics

"A" Silk

90 Mercerized 50

European 30

"A" Silk

Synthetic

Heavy Duty Mercerized

European 30

"A" Silk

Synthetic

Heavy Duty Mercerized

European 30

Synthetic

14

1-1/4 - 1-3/4

1-3/4 - 2

2-1/2 - 3

1-3/4 - 2

2-1/2 -3

2- 2-1/2

2-1/2 -3

2 1/2 - 4

Page 17

Before starting to sew, turn the hand

wheel toward you until the needle is

at its highest point. NEVER run ma

chine without material under presser

foot.

Place material and threads in position

under the presser foot and lower the

presser foot.

You are ready to begin sewing, by

having the needle at its hand wheel to

start the machine.

TO REMOVE MATERIAL, be sure to

stop the machine when the needle bar is

located at the highest point. Now raise

the presser foot with the presser bar lifter,

then draw the fabric back and to the left,

and cut the threads with the thread cutter.

0 a 1 • 2 ■ 3 ■ 4

STITCH LENGTH CONTROL DIAL

• Numbers on dial denote

length of stitches.

• To increase length of stitch,

turn dial to higher number.

STITCH LENGTH GUIDE

Numbers

on dial

Stitches

per inch

0 1 2 3 4

No

Feed

24

6 6

12

REVERSE STITCH BUTTON:

• Use for reverse stitching or

tacking.

• Keeping button pressed in will

allow you to sew reverse stitch

at same length as forward

stitch.

15

Page 18

SELECTING NEEDLE POSITION

Right Middle

• Three different needle positions, left, "4 " middle

and " ◄” right can be selected. Also, those intermediate

positions between left and middle and right can be

selected with the dial at the middle between -■ ►"-"f ",

and "^'"-"4" as shown

► - - • indicates the left hand needle position

A

____

indicates the m iddle needle position

^ - indicates the right hand needle position

>• 1

Page 19

CHANGING

DIRECTION OF SEWING:

REMOVING THE MATERIAL:

CROSSING

HEAVY SEAMS:

• Before changing direction,

stop the machine at the desired

point making sure that the

needle is down through the

fabric.

• Raise ttre presser foot, turn

the fabric to the desired posi

tion, lower the presser foot

and continue sewing.

Note: When sewing with a twin

needle, it is necessary to raise

the needles above the fabric

before turning. Be cautious to

realign the fabric to the position

where the last stitch ends.

After stopping the machine,

turn the hand wheel toward you

until the take up lever is at its

highest position.

Raise the presser foot, then

draw the fabric gently to the

left rear of the machine, making

sure that the threads are under

the foot. This avoids bending

the needle.

With two hands, lift the two

threads up and into the thread

cutter on the presser bar and

pull down firmly to cut the

threads.

17

When crossing heavy seams,

angle the fabric down into the

foot so that the foot can draw

the heavy area into the feeding

mechanism and pass over the

bulk easily.

Page 20

ZIGZAG STITCHING

Zigzag Foot

(single needle sewing)

• Set the needle position dial in the free position

• Set the zigzag width control knob from 1 to 5.

• Set the stitch length control dial from 1 to 4.

• Now you can start sewing as you wish.

SINGLE NEEDLE ZIGZAG STITCH PATI

Patterns

\A^AAVvV

mmwMiism

-----

imnrmn

JiivJiUJiU

Needle Position

Left. Middle

or right

Left, Middle

or right

Left, Middle

or right

Middle ♦

Right

Middle

Left ►

Left ►

Right ^

Stitch Length

Long

Short

Long and Short

{Repeat)

Long

Short

Page 21

BUTTONHOLE PREPARATION

0 ea 1 .

Step!. Step 2. Step 3. Step 4.

Step 5,

Seam Ripper

Needle PosIMon Selector ano

Zigzag Width Control Dial

Stitch Length

Control Dial

PROCEDURE:

• Attach buttonhole foot to machine.

• Before starting to sew, always pull the buttonhole box toward you

until it is fully extended.

• Mark position of buttonhole on fabric to assure proper alignment.

Step 1 ; Set ihe stitch length control dial between 0 and 1, and the

needle position dial at ” Press drop feed button,

take few stitches to bartack the end of marked buttonhole

with the zigzag width control dial "5".

Step 2; Press "MU drop feed button, set stitch width dial between

1 and 2, then sew down the left edge of marked buttonhole.

Step 3: With needle in the fabric on the left side, and repeat as in Step 1

at the left edge position of marked buttonhole.

Step 4: Press "MÈL drop feed button, and set the needle position dial at

"■4 " and between 1 and 2 of zigzag stitch width. Press reverse

button of stitch length for reverse stitching, then sew up the

right edge of marked buttonhole.

Step 5; With down position feed dog height, cut center open space with

seam ripper of buttonhole carefully not to cut into the stitches

19

Page 22

BUTTONHOLES ON LIGHTWEIGHT OR KNIT FABRICS

. • I

- •• •

I ‘

■ Cord String

Place cord string over tab on presser foot as shown.

After finishing the buttonhole, remove the foot from

the fabric, draw the loop of the cord string up to the

bar tack, tie the loose ends and trim the balance.

Position fabric in sewing area and attach button

hole foot to the machine. Sew the buttonhole so

that stitching covers cord string.

20

Page 23

SEWING ON BUTTONS

Button Foot

^ 0

Other Applications

0 a 1 •

SHlch Length

Control Dial

PROCEDURE:

Set drop feed button

" ►" position.

position with the needle position selector

Place button under button foot such that the needle is aligned

directly with the left hole in your button. Check alignment by

turning hand wheel and watching needle.

Bring the needle slightly above the button and turn stitch width

knob until needle aligns with the right hole in the button.

Run machine slowly and make 7—8 stitches.

With needle in left hole return zigzag width knob to the "0"

position and make 3-4 stitches to tie off your button.

Apply the above method to sewing on buttons with four holes, hooKs,

snaps, etc.

21

Page 24

EMBROIDERING

0 a 1

Needle Position Selector and

Zigzag Width Control Dial

Stitch Length

Control Dial

PROCEDURE:

• For free-motion sewing, press 'H" drop feed button,

and press down on outer ring of the pressure regulator

to release pressure completely.

• Place under needle of fabric into an embroidery, a

darning and a monogramming hoop.

• With the width at "O" make 5 or 6 stitches to

reinforce the starting point.

• At the desired zigzag width stitch to outline the

design by moving the fabric and hoop in a side

motion. To fill the design, move the fabric and

hoop from side to side in a rhythmic motion.

• To return feed to normal, press drop feed

button, and push down on the pressure cap to

obtain the desired setting.

22

MONOG RAMMING

Page 25

SEWING ON ZIPPERS

Reguler Zipper Fool

Oo 1 . 2• 3

Needle Position Selector and

Zigzag Width Control Dial

Stitch Length

Control Dial

PROCEDURE;

Set the needle position at " ►" or " as needed

to sew the right side or the left side of zipper

respectively, so that the foot sews very close to

the zipper teeth. (Fig. 1)

Set the needle position at and make the

welting by sandwiching the cord into a bias

strip of fabric. Stitch close to cord. (Fig. 2)

Set the needle position at Sandwich the

welting between two layers of fabric with right

sides together. Stitch a second time. The needle

stitches close to the cord through all thicknesses

(Fig. 3)

Attach zipper foot and adjust position depending on which side

of zipper foot you wish to use.

Open the zipper and place it face down on the back side of the

fabric with the zipper teeth along the fabric edge.

23

Page 26

QUILTING

. 4

Needle Position Selector and

Zigzag Width Control Dial

Stitch Length

Control Dial

PROCEDURE:

• Insert the quilter guide bar into the notch under the spring on the

shank and adjust the position according to the desired distance

between quilting seams,

• Stitches are easily aligned by guiding the quilter guide along the

previous seam line.

94

Page 27

CARE AND MAINTENANCE

A majority of service calls can be avoided by proper care of your machine. This involves three important

steps.

1 Cleaning Give your machine a light cleaning after each garment is completed. For light cleaning -

brush lint from feed dogs, needle bar and hook, and oil hook. A more extensive cleaning and oiling

can be done every two months.

2 Oiling - Use sewing machine oil only. Do not use any other household oils, as they will eventually

cause problems with the machine. Oil every two months, or more often if machine is in constant use.

3 Proper Use of Needles - Always use the proper needle for your fabric and thread.

Change needles often, as they dull quickly especially on synthetic fabrics.

If you are having a problem, before calling the service man;

1. Check to see that the machine is threaded properly.

2. Replace the needle and make sure it is attached correctly.

3. Be sure that the bobbin is wound evenly.

25

Page 28

CLEANING THE MACHINE

Caution; Eilelore cleaning Ihe machine, be sure to disconnect

the power cord trom Ihe wall outlet

CLEANING AND OILING THE HOOK ASSEMBLY

• Raise the needle bar to the highest position.

• Open the hinged shuttle cover and remove the

bobbin case with bobbin.

• Remove lint or dust with a soft cloth or lint brush

• Use only the oil in the accessory box.

• Replace bobbin case (See page 8 ‘or

instructions).

CLEANING FEED DOGS

• Lint or dust accumulated between the needle

plate and the feed dogs must be removed to

maintain good operation of the machine.

• Raise the needle barto the highest position and

remove the needle and presser foot.

• Loosen screw on the bed cover plate and remove

the plate.

• Clean lint and dust from the bottom of the needle

plate and the feed dogs with a lint brush.

• Turn the hand wheel slowly and be sure to clean

all areas.

• Replace the removed plate.

26

Page 29

OILING

-OIL

Swing open hinged face plate. Apply one drop of

oil at all points indicated by arrows.

OIL OIL

OIL OIL OIL

Using the large screw driver in the accessory box,

remove the two screws on the top plate and remove

plate.

Remove screw on the bed cover plate and apply

oil while turning the hand wheel.

27

Page 30

TROUBLE-SHOOTING GUIDE

MACHINE DOES NOT FEED

• Is drop feed up?

• Is needle plate correctly installed?

• Is presser bar pressure too light?

• Is the hand wheel clutch screw tight?

• Is the stitch length control dial set at “0" position?

NEEDLE BREAKS

• Is needle inserted and tightened correctly; is it

straight?

• Is the cloth being pulled excessively but

unknowingly?

• Are proper needle and thread being used for the

type of fabric being sewn?

UPPER THREAD BREAKS

• Is the machine properly threaded?

• Is the needle good?

• Is the thread too heavy for the needle hole?

• Is the upper tension set too tight?

• Is thread jammed somewhere between spool

and needle?

BOBBIN THREAD BREAKS

• Is the bobbin thread jammed in the hook or

bobbin case?

• Is the bobbin tension set too tight?

• Is the thread properly threaded in the

bobbin case?

STITCH SKIPPING OCCURS

• Is the needle inserted correctly and straight?

• Is the needle of poor quality or of the wrong size?

• Is the upper thread properly threaded?

• Is the thread used proper for the material

being sewn?

• Are the bobbin case and feed dogs free from lint?

THREAD LOOPS OCCUR

• Is the upper tension and bobbin tension properly

adjusted?

PUCKERING OCCURS

• Is the tension too tight?

• Is the needle threaded properly?

• Is bobbin thread wound evenly on the bobbin?

• Is the pressure of the presser bar too weak?

28

Loading...

Loading...