Page 1

Page 2

CONTENTS

Description of Machine...........................................................................

1

. To Wind the Bobbin.......................................................................... ^

2. Inserting new Needle.............................................................................

3

. To Thread the Bobbin Case....................................................................

4

. To Insert and Remove the Bobbin Case..................................................0

5

. To Clean the Snap-Out Race..................................................................

6. To Thread the Machine & Needle...........................................................

7

. To Prepare for Sewing

8. To Commence Sewing................................................................... 0

9

. To Remove the Work

10

. To Regulate the Thread Tension............................................................^

11

. To Regulate the Stitch Length...............................................................

12

. To Regulate the Pressure of the Presser Foot

13

. To Use the Drop Feed Dial.....................................................................

14

. To Oil Sewing Machine................................................................................

15

. Some Useful Sewing Hints...........................................................................

16

. Correction for minor Difficulties.............................................................

17

. How to Use the Zigzag Regulators.........................................................q

18

. How to Change the Presser Foot............................................................

19

. To Make Buttonhole............................................................................... ^

20

. To Sew Buttons...................................................................................... ^

21

. To Make Hem......................................................................................... ^

22

. How to do Felling............................................................... ^

23

. To Sew Braid and Raised Applique Stitches

24

. To do Quilting........................................................................................ ^

25

. Cloth Guide & Thumb Screw..................................................................

26

. Hemming with the Zigzag Stitch

Needle and Thread S ize

.................................................................................

.......................

..............................................

........................................

...........................................

...........................................................

0

......

(§)

......

......

......

......

......

......

......

......

......

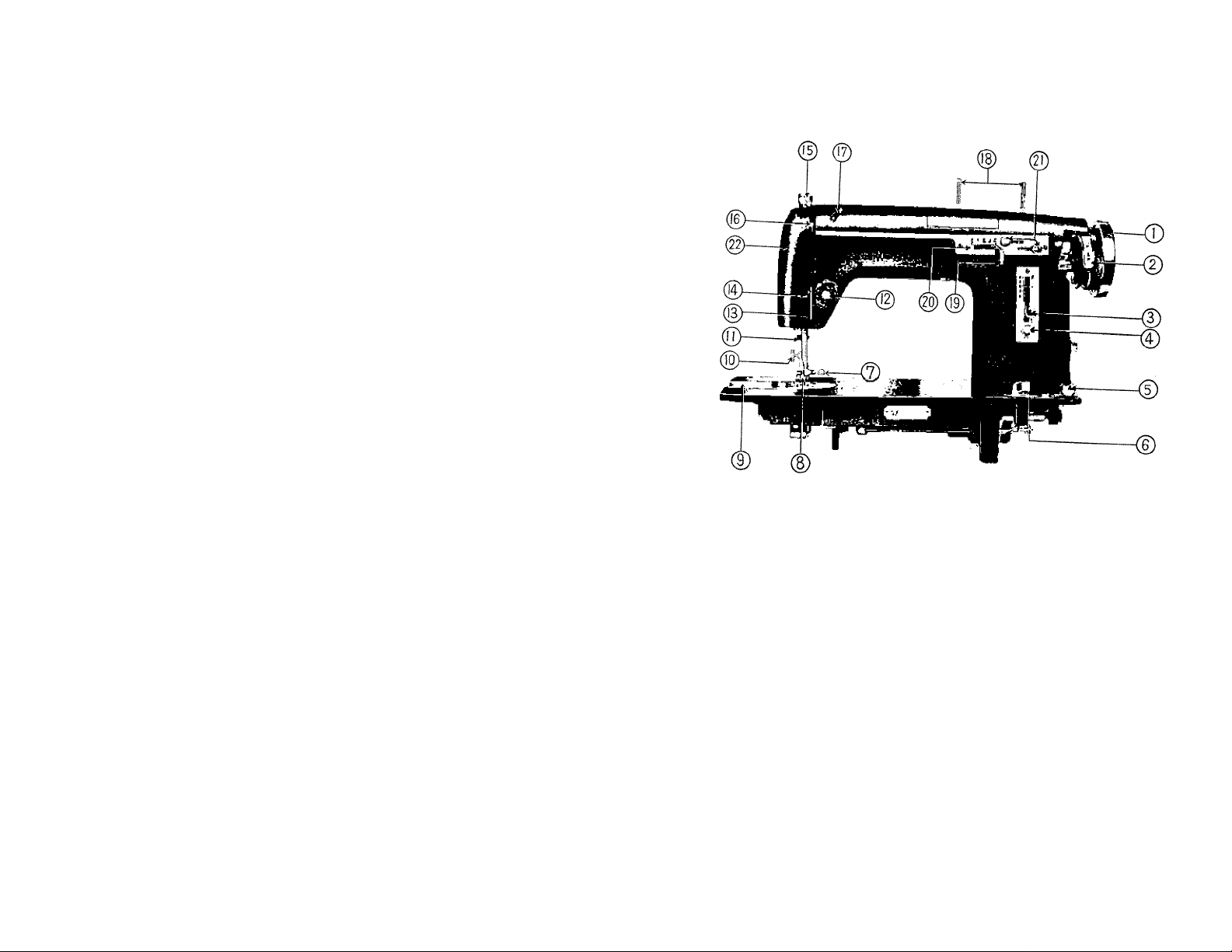

1.

Balance wheel

2.

Bobbin winder

3.

Stitch regulating lever

4.

Stitch length look

5.

Bobbin winder thread

tension bracket

6.

Drop feed dial

7

Needle clamp

8.

Presser foot

9.

Hinged plate

10.

Presser foot thumb .screw

II.

Thread cutter

Thread tension regulator

DESCRIPTION OF MACHINE

13. Slack thread regulator

14. Face plate thread guide

15. Patch-o-matic darner

(Pressure regulator)

16. Thread take-up lever

17. Arm thread guide

18. Spool Pins

19. Zigzag regulating lever

20. Indicator for stopping

lever No. 19

21. Lock screw for indicator No.20

22. Face plate

(Dial tension)

C 1 )

Page 3

1 To Wind the Bobbin

1. To wind the bobbin the balance wheel must te disconnected from the stitching

mechanism. Hold the balance wheel with your left hand and turn the stop

motion knob (Fig. II toward you with your right hand. This will permit the

balance wheel to turn treely while the needle bttr remains motionless.

The balance wheel is now disconnected for the bobbin winding operation.

2. Place a spool of thread on the spool pin (Fig. 2), Draw thread from the spool

over guide then down-ward across machine from left to right.

3. Pass the thread through the tension device at the right corner of the base of

the machine.

4. Now wind the end of the thread around an empty bobbin seven or eight times

and place the threaded bobbin on the spindle of the bobbin winder.

5. By pressing on bobbin winder lever, the small rubber wheel is brought in con

tact with the balance wheel. To lock into position, press bobbin winder lever

until a click is heard.

Now .set the machin in motion, and when the bobbin is completely full it will

stop turning automatically. Slip tobbin from spindle. Hold balance wheel

irmly with your left hand and with the rigth hand turn stop motion knot

away from you until it can not be moved any further and the needle bar

moves with the turning of the balance wheel.

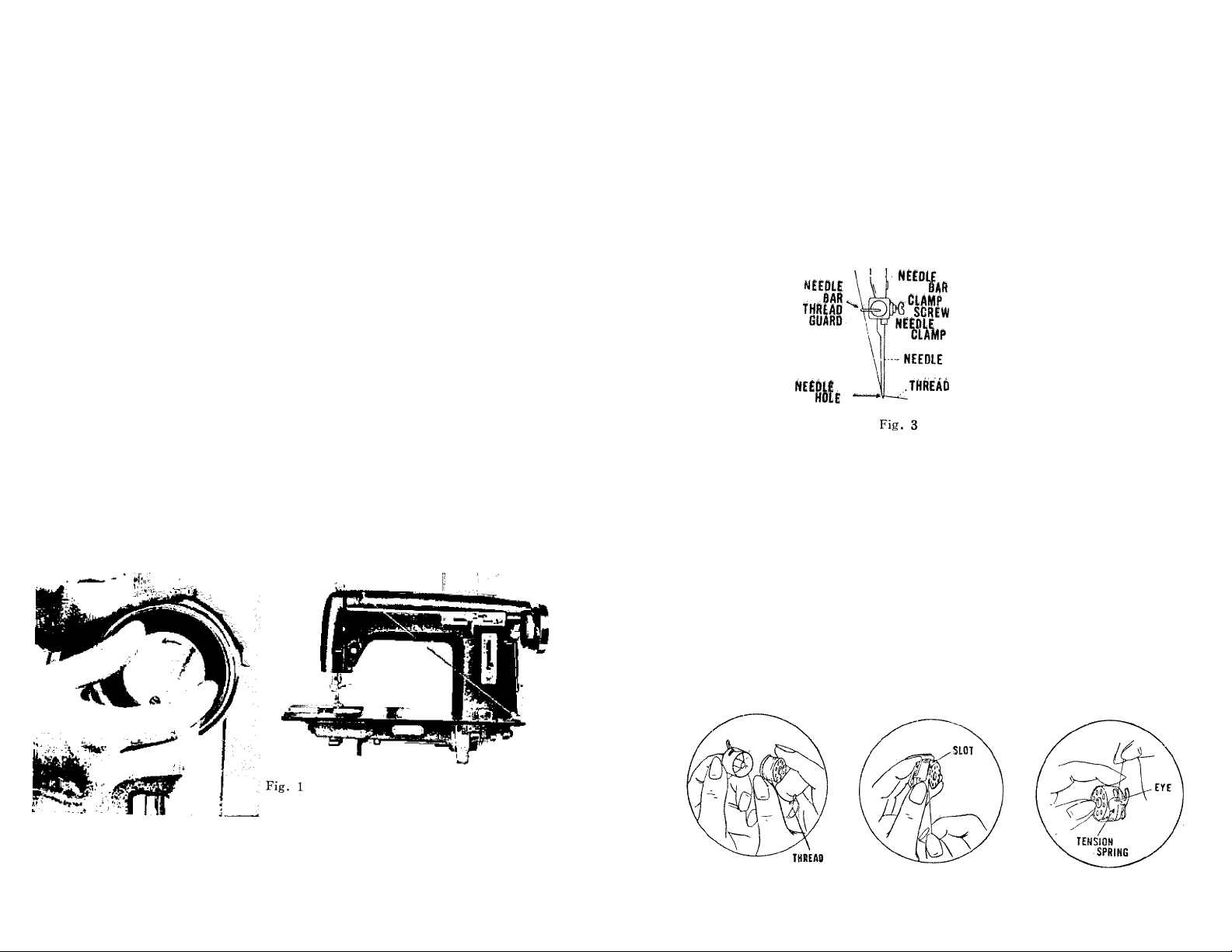

2. Inserting New Needle

1. Turn the balance wheel toward you, raising needle bar to its highest position,

and loosen the needle clamp screw. .

2. Hold the needle in the left hand with the point down, and insert the needle

up into the needle clamp as far as it will go, with its flat surface to the right,

then retighten the clamp screw (Fig. 3).,

fliEOLf

FLAT

SURFACE

3. To Thread the Bobbin Case

1. Hold the bobbin case with your left hand and put the bobbin into the bobbin

case with your right, leaving about two inches of the thread end unwound (Fig.

4). As the bobbin is being inserted in the bobbin case, thread flow is clockwise.

2. While holding the bobbin case as before, grasp the thread end with your right

hand, and guide it into the cross slot (Fig. 5).

3. Then pull it through under the tension spring of the bobbin case (Fig. 5) until

it enters the delivery eye (Fig. 6).

( 2 )

Fig. 2

Fig. 4

Fig. 5

( 3 )

Fig. 6

Page 4

4. To Insert and Remove the Bobbin Case

1. Raise the presser bar

by lifting the presser

bar lifter,

2. Raise the needle bar

to its highest position

by turning the balance

wheel toward you.

3. Spring up hingal plate

CFig- 2),^

4. After threading the

bobbin case, hold its

latch between the thumb and forefinger

of left hand, with its position finger

opposite the notch at the top of the

shuttle race, replace it on the center

stud of the shuttle ( Fig. 8).

5. Then release the hitch and press the

bobbin case in until the latch catches

the groove ncttr the end of the stud

waih a click that can be heard.

6. Allow the end of the thread to hang free about 2 to 3 inches.

7. Snap back hinged plate. To remove the bobbin case do ailahe above in revers.

order.

Fig. 8

3. After shuttle-race and shuttle have been cleaned, put all of them back in

reverse order.

4. Snap lever into place as seen in Fig. 9.

Fig, 9

5. To Clean the Snap-Out Race

When the thread is tangled in the race or dust gets into the space between the

shuttle-race, follow this procedure.

1. Raise the needle bar to its highest position and take bobbin ctise cut.

2. Release the l.EVER (A) on both sides of shuttle race by turning them down

ward. Then take .out the front ring and the shuttle body wuh your fmgers

(Fig. 9. 10). ^

f 4 )

Fig. 30

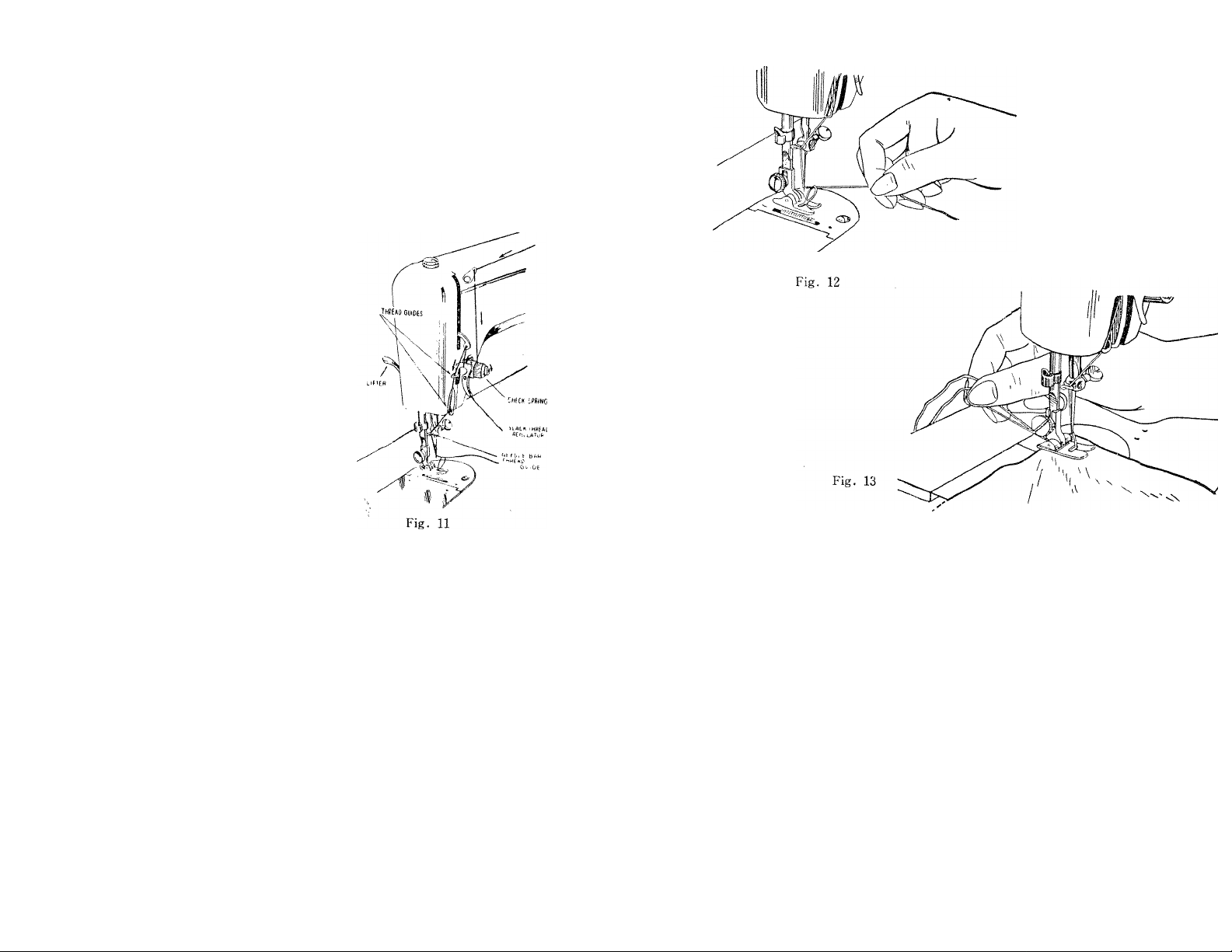

6. To Thread the Machine & Needle

1. Turn the balance wheel toward you to raise the needle bar to its highest

position.

2. Place a spool of thread on the spool pin.

( 5 )

Page 5

Lead the thread through the arm thread guide (Fig. 11).

Run the thread down from the ihrettd guide to the tension discs and around

them from right to left and up. Draw the thread up through the check

spring.

5.

Then downward again around the underside of the slack thread regulator and

up through the eye of the thread take up lever from right to left.

Now run the thread down through the

face plate guides and then through the

loop of the needle bar thread guide

from the back.

7.

Finally, run the end of the thread thr

ough the eye of the needle from LEFT

to RIGHT, drawing it through about

3 or 4 inches.

You are now ready to sew.

8. To Commence Sewing

7. To Prepare for Sewing

1.

Hold the end of upper thread loosely, leaving it slack from the needle.

Turn the balance wheel toward you until the needle goes down and rises to its

2.

highest position.

Pull the thread you are holding, and lower thread will be brought up with it

through the hole in the needle plate, as shown in Fig. 12.

Place both ends of the upper and lower thread behind the presser foot (Fig. 13)

4.

( 6 )

1. Place the fabric to be sewn beneatth the presser foot.

2. Lower the prestser foot by lov/ering the presser bar lifter.

3. Commence sewing by slowly turning the balance wheel in direction toward you

while gradually pressing the lever of the foot or knee control. Always turn

balance wheel toward you and not away from you.

9. To Remove the Work

1. Raise the needle bar to its highest position, by turning the balance wheel toward

you.

2. Lift the presser foot by lifting the presser bar lifter.

3. Move the fabric back to the left and cut off the thread by passing it over the

thread-cutter above the presser foot,

4. Leave both ends of the thread a few inches long, under and to the back of

the presser foot

( 7 )

Page 6

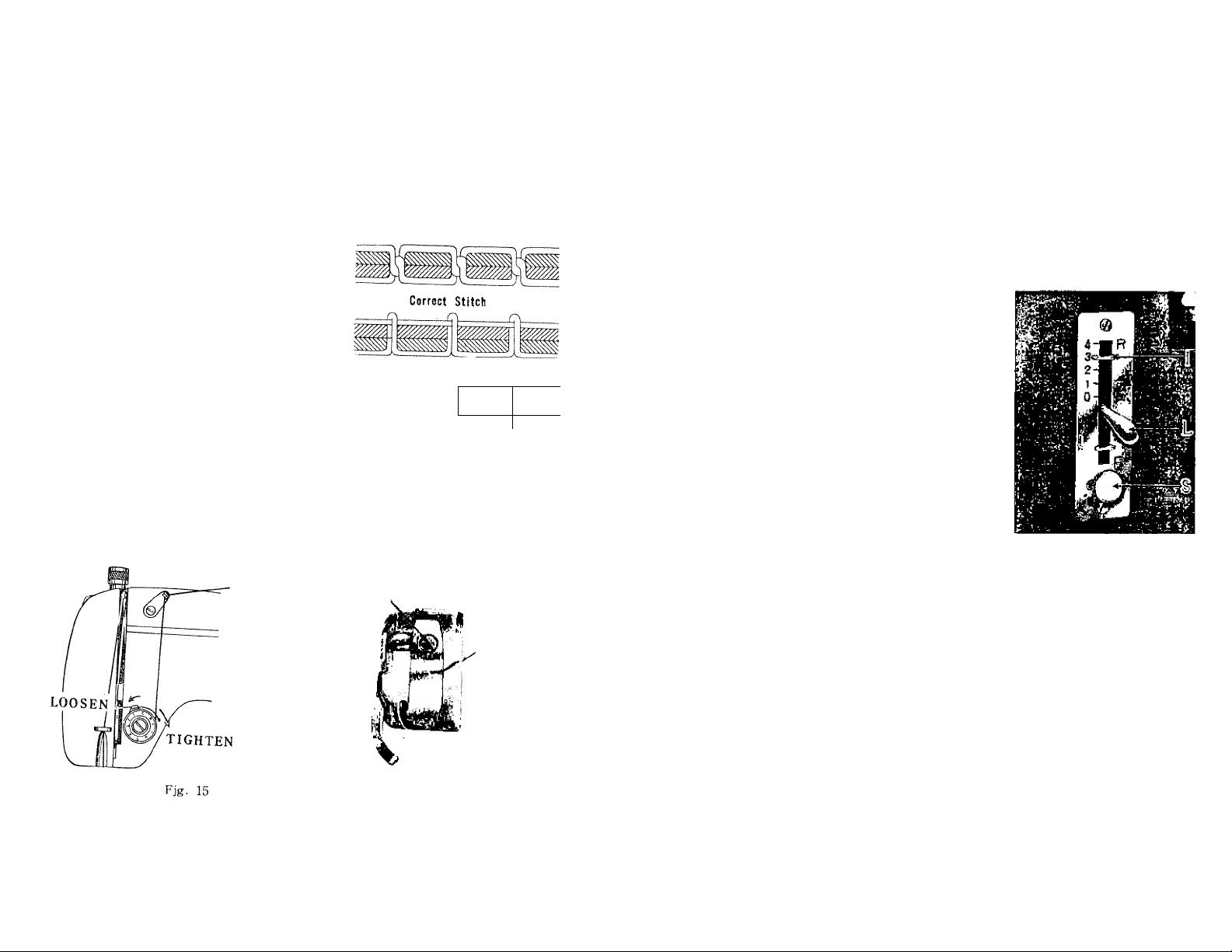

10. To Regulate the Thread Tension

11. To Regulate the Stitch Length

For ordinary stitching the tension of the upper and lower threads should be

equal so as to lock both threads in the center of the material (Fig. 14.). If one tension

IS stronger than the other, imperfect stitching will result. Fine materials require

a light tension, while heavy materials require more tension to obtain a perfect stitch.

TO INCREASE the tension, turn the thread tension dial (Fig. 15) clockwise.

TO LESSEN the tesion, turn the thread

tension dial in the opposite direction. (When

regulating always have the presser foot down.)

As all machines are correctly adjusted before

leaving the factory and readjusted before the

dealer delivers them to yo, the lower tension

seldom needs to be altered, but, if this be

Needle Thread Tension too strong

comes necessary, tighten the screw in the

tension spring on the outside of the bobbin

case for more tension, or loosen the screw

■slightly for lesser tension (Fig. 16).

Needle Thread Tension too weak

Rg,14

'У/^

Ь' - ■

NOTE; Do not turn screw in either direction more than about one-quarter turn at

a time. Then check for results.

The length of stitch can be changed by adjusting the stitch length regulating lever

“L” (Fig. 17).

When the lever is at O, the niiUcriai is not being fed througli the machine.

To change stitch length, loosen lock .screw “S” by turning n to the left.

Now move the lever gradually downward lo feed material forward and to lengthen

stitch.

The indicator “I" indicates the length of stitch. Set lever to desired length of stitch

and lock the screw by turning to the right.

To sew backward move stitch regulating

lever upw'ard past O until it stops.

Machine automatically maintain same length

of stitch forward and backwttrd.

Fig 1 /

( 8 )

TENSION REGULATING

SCREW^

Fig. 16

SLOT

12. To Regulate the pressure of the presser Foot

You can regulate the pressure of the presser foot by using the automatic darner.

To loosen the pressure for darning and embroidering, press release latch down as

shown in Fig. 18.

To increase the pressure push the cap down (Fig. 19).

While you are pushing the cap it can be set at whatever position required. For

sewing very light fabric light pressure is needed. For heavier material you must

have greater pressure on the fabric.

Make sure the prc.sscr foot is down when regulating pressure.

( 9 )

Page 7

t4. To Oil Sewing Machine

Fig. la

Fig. 19

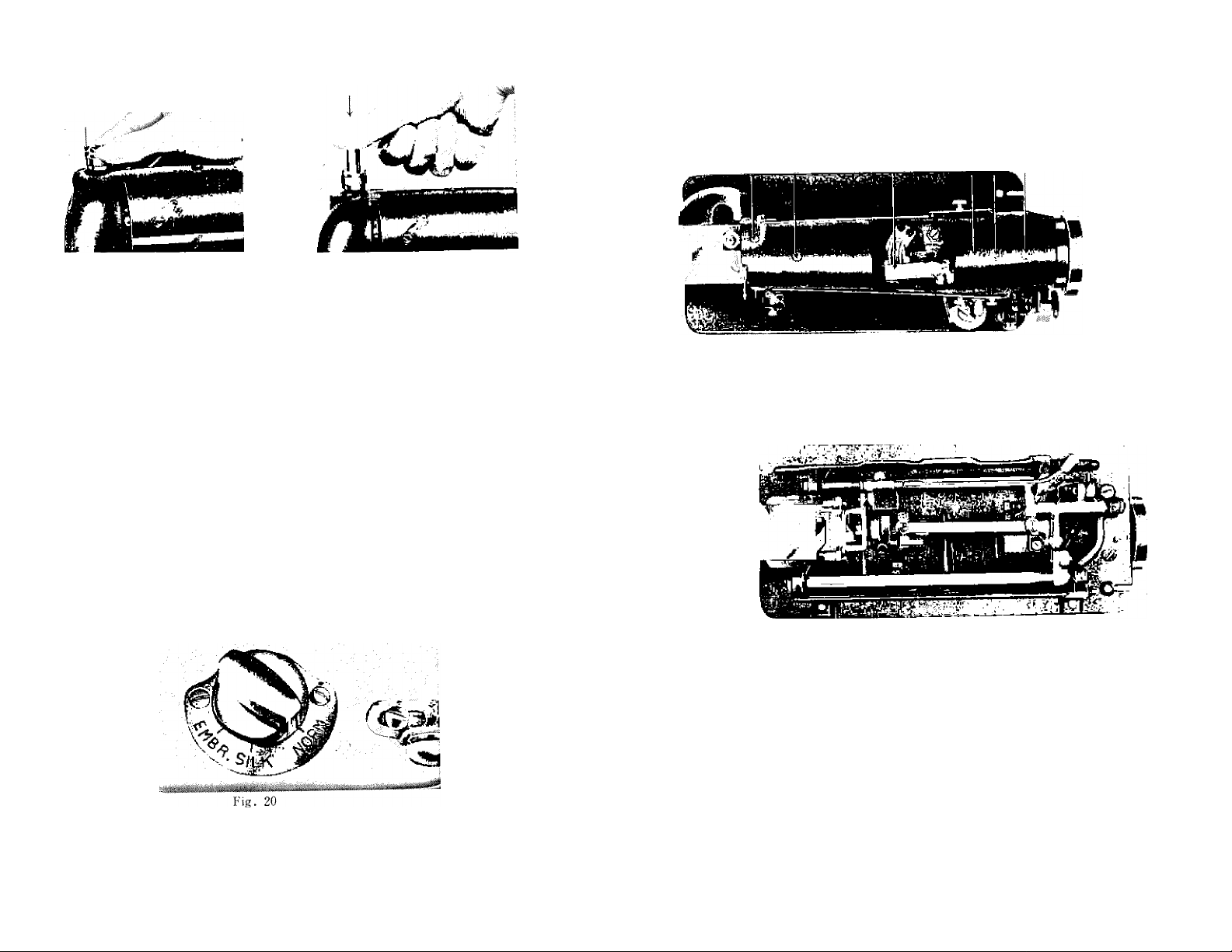

is. IJrtfp* Fefetf'Dial

By using the drop feed dial you may adjust the feed dog for sewing different

tyix of material and for embroidering or darning (Fig. 20).

1. For sewing very light fabric, move indicator to “SILK” for heavier favric to

“NORM”.-

2. When the indicator is at the “EMBR” position, the feed dog will be lowered

below the surface of the needle plate.

This is embroidering and darning, and you will be able to move your work

freely about in any direction you choose.

3. For embroidering and darning, first reduce pressure of presser foot (Fig. 18).

Fig. 21

To see that your machine is always in smooth running condition you must keep

it oiled at ail times. No greas is required. Just a drop of oil is sufficient at each

time of oiling. Points to be oiled are illustrated in Fig. 21. To oil your machine

thoroughly, it will be necessary for you to remove the small cover plate on top of

the arm. Turn the machine over to get to parts underneath the bed.

After-oiling, run the machine at high speed for a few minutes to get oil to penetrate

( 10 )

to air’parts.

( 11 )

Page 8

I 5. Some Useful Sewing Hints

16. Corrections for minor Difficulties

TO TURN CORNERS;

I, Stop the machine while needles still in the material,

U Raise the presser foot and turn the fabtic using the needle as a pivot.

Lower the presser foot and resume sewing.

TO SEW ELASTIC FABRICS :

in sewing such elastic materials as jeiseys, bias cut cloths, etc., it is advisable

to sew them with reduced upper thread tension, otherwise the thread will break

when the sewn materials arc stretched.

TO SEW VERY THIN CLOTH:

When sew'ing very thin cloth which tends to gather as you sew, place a sheet

of newspaper or any other thin paper underneath the mateial and sew with the

shortest stitch laossible. This will keep your work from gathering.

BASTING:

Reduce the tension of the upjxi thread and employ the longest stitch possible.

The stitches may then be easily removed by pulling the lower thread.

TO KEEP YOUR MACHINE IN PERFECT CONDITION:

Keep all moving parts of the machine constantly oiled and clean.

Always turn balance wheel toward you.

3.

Do not run machine without fabric under the needle.

4, When sew'ing, do not pull the material otherwise you will bend the needle.

The machine is designed to feed the material automatically.

5.

Do not operate machine when the presser bar lifter is raised.

BREAKING OF THE UPPER THREAD:

Incorrect threading.

2.

Upper thread tension too tight.

3.

Defective needle, or needle inserted incorrectly.

4.

Needle rubbing against pre.s.ser foot or other attachments.

5.

Needle eye too small for thread used.

6.

Knots in .sewing thread.

7.

Stitch hole in needle plate damaged and rough.

BREAKING OF THE LOWER THREAD:

1. Incorrect threading of the bobbin case.

2. Lower thread tension too tight.

3. Bobbin being wound too full.

BREAKING OF THE NEEDLE:

1. Pulling the fabric while machine is sewing thus causing the needle to strike

the needle plate.

2. Using bent needle.

SKIPPING STITCHES;

Using bent or blunt needle.

Needle inserted incorrectly.

Needle threaded improperly.

Using wrong size needle.

Pressure of presser foot insufficient, especially when sewing heavy material.

UNEVEN STITCHES;

1. Pre.sser foot not resting evenly on material.

2. Feed dog not adjusted high enough.

3. Too short stitches used.

4. Pulling the cloth while the machine is sewing.

5. Needle too fine for material or thread too coarse.

( 12 )

( 13 )

Page 9

17. How to use the Zigtag Regulators

18. How to chancre the Presser Foot

1. Rai.se the needle to its highest position by turning the balance wheel toward you

2. Raise the pres.ser foot by lifting the presser bar iilter.

3. Loosen the presser foot thumb screw and remove the fool (Fig. 23),

4. Place the groved side of the desired foot against the flat of the presser bar

5. Tighten the thumb screw.

mm

Fig. 22

Fig. 23

Your zigzag sewing machine, by virtue of its design, permits you to do zigzag

sewing and numerous other kinds of work requiring a similar stitch. The controllers

for the zigzag stitch are located on the arm of the machine, as may be.seen on

Fig. 22. Notice lever “A” which adjusts the width of the zigzag seam. For

ordinary straight sewing this lever must be set to the left of O on the dial plate.

By moving this lever gradually to the right toward 4 the machine will sew a zig

zag seam of increasing width, depending on the posi ion of the lever. For the

purpose of reverting to a previously used width of zigzag stitch after having done

some straight sewing, or for special types of work such as sewing buttons or mak

ing tacks, indicators “B” and “C” will be found useful. These indicators serve

as the STOPPERS for lever “A”. To sef “B” ("C”), loosen lock screw “D”

(“E”). hiring it to the left. You then will be able to slide same sideways which,

at the .same time, moves indicator “B” (“C”) to the desired marking. Tighten

lock screw “D" (“E”) by turning it to the right. Thus, when you want to

alternate between narrow and wide zigzag stitch, you use both indicators “B” and

“C”. For example, set indicator “B” at 1 and indicator “C” at 3, tightening

the lock screws. This will assure you of being able to always revert to the same

narrow and wide zigzag seams. You will find this feature especially convenient

when making buttonholes.

( 14 )

19. To make Buttonholes

Attach the Buttonhole Fixit.

Set the Zigzag Lever at marking 2 and tighten lock "B .

2.

Set the Stitch at 1 (Page. 9), or near O,

3.

Insert “Gimp" if desired through hole under the foot (Fig. 24).

'4,

Sew to desired length and turn the material diametrically as shown in Fig, <

5.

Set the Zigzag Lever at 4, sew several stitches, then reset the^ Zigzag L

6.

at 2 and sew the other side of buttonhole as shown in Fig. 25-C & D.

Set the Zigzag Lever at 4, sew several stitches.

7.

Now you must cut the material between both sides of the seam of the bu

8.

hole with the buttonhole cutter (Fig. 25-F).

A B c D E F

Fig. 25

( 15 )

Page 10

Notice: You can make the buttonhole without braid or gimp in the same way as

front page.

4. At first, it might be necessary for

you to lead the material until

beginning of the hem is just be

20. To sew Buttons

1. Change the presser foot to the Button Foot.

2. Turn the Drop Feed Knob to “EMBR".

3. Place material or garment with button under the foot, so that holes in button

line up with oblong hole in the foot (Fig. 26)_.

4. Adjust the Zigzag Lever so that width

of zigzag stitch permits needle to pass

through center of holes in button.

5. Sew several stitches and remove mate

rial from machine and snip thread.

Fig. 26

Notice: When attaching four-holes button, first sew one set of two holes, then

stitch into second set of two holes and lock thread with two or three

plain stitches in last hole as described above.

low the needle.

5. Fewer presser foot and begin to

sew.

6. Keep guiding the material, so

that the scroll is filled all the time (Fig. 27).

Notice: Do not crowd the material into scroll and do not leave scroll only partly

filled by the material. Feed just enough material into the hemmer foot

to fill out the scroll. Instead of a straight stitch, you can also use a

zigzag stitch, width of the zigzag stitch-to be as wide as the hem

itself. Using a long stitch and tight tensions will produce a shell stitch.

Fig. 27

22. How to do Felling

The hemmer foot can also be used for felling. Proceed in the lollowing manner:

I. Lay two piece.s of doth one top of the other with their RIGHT sides facing

each oihc. The right edge of the bottom piece must extend about 18" beyond

the right edge of the top piece. See Fig. 28,

21. To make Hem

1. Use the Hemmer Foot.,

2. Clip the corner of the material td be hemmed, so that it will be easier for

you to insert the material in the hemmer foot.

3. Feed the clipped edge of the material by curling it into the spiral tongue or

thè- scroll of the foot. '

( 16 )

( 17 )

Page 11

2. Sew both both pieces of closh together, using thè hemmer foot like a regular

presser foot. Use the right edge of long toe of hemmer to guide the bottom

piece of material, while the left edge of the toe serves as a guide for the top

piece of material. Fig. 28 shows this detail.

3. Open and spread out material and put back on machine right sides down

ward. Make sewn edges of material stand up.

4. Fold over the edges to the left and insert them into the scroll ol the hemmer

foot. Sew as you would do ordinary hemming. Use left edge o( long toe of

the hemmer foot as guide, having original seam run alongside of it (Fig. 29).

23. To Sew Braid and Raised Applique stitches

25. Cloth Guide & Thumb Screw

Fig. 32

This is an attachment designed as a guide for straight stitching when making

wide hems, deep tucks or seam widths which are greater than the presser foot

1. Attach the Cording Foot.

2. Set the Zigzag Lever at lor 2 according

to width of cord or gimp you are using.

3. Insert the cord or gimp through the

hole of under foot.

4. Sew slowly and follow the design care

fully (Fig. 30).

24. To do Quilting

The Quilter helps you to sew equidistant

lines on padded fabrics without any marking

them in advance.

1. Attach the Quilter.

j 2. Adjust the quilter to spacing desired and

1

let it touch the material.

3. Sew the material so that quilter follows

the previous stitching (Fig. 31).

( 18 )

Fig. 30

Fig. 31

allows (Fig. 32).

It is attached to machine as illustrated

..............

a very simple operation.

26. Hemming with the Zigzag Stitch

1. Fold the material to the size of hem desired, with 1 16 operlap on tl >

bottom fold as shown in Fig. 33-A.

2. Make the stitch as shown in Fig. 33-B.

3. After stitch is finished, unfold the material as shown in Fig. 33-C. You will

have practically invisible stitching.

Fig. .33

B

( 19 )

Page 12

MEMO

NEEDLE-THREAD-FABRIC-STITCHIN6 GUIDE

Fabric

Extremely heavy

tarpaulin, sacking,

canvas, duck, etc.

Heavy upholstery

fabric, ticking.

denim, leatherette

Medium heavy

drapery

fabric, velveteen.

suiting, felt, terry.

etc.

Medium broadcloth,

percale, gingham.

linen, chintz.

taffeta, sheer

wool, shantung, etc

Needle

No.

4

3

2

1

Machine

Stitches

Per Inch

6

to

8

8

to

10

10

to

12

12

to to

14

Cotton

Thread

10

to

30

30

to

40

40

to

60

60

80

Mercerized

Thread

Heavy Duty

Heavy Duty

Heavy Duty

50

Silk

or

Nylon

A

Sheer voile, lawn.

dimity, crepe,

handkerchief linen,

plastic film, etc

Very sheer chiffon,

batiste, lace.

organdy

ninon, net, marqu

isette, etc

00

0

1 4

to

16

(Plastic film)

8 to 10

16

to

20

oU

to

100

100

to

150

50

50

...

A

A

Loading...

Loading...