Page 1

SINGER

145W103,W203,W303

Page 2

2848w

INSTRUCTIONS

FOR USING AND ADJUSTING

SINGER SEWING MACHINES

Machine 145w303

145wl03, 145w203

and 145w303

THE SINGER MANUFACTURING CO.

Page 3

To all whom it may cortcern:

The placing or renewal of the name “Singer” (Reg. U. S.

Pat. Off.) or any of the trade marks of The Singer Manu

facturing Company on any machine that has been repaired,

rebuilt, reconditioned, or altered in any way whatsoever

outside a Singer factory or an authorized Singer agency

is forbidden.

THE IMPORTANCE OF USING

GENUINE SINGER PARTS AND NEEDLES

IN SINGER MACHINES

The successful operation of Singer machines can only be

assured if genuine Singer parts and needles are used. Sup

plies are available at all Singer Shops for the Manufacturing

Trade and mail orders will receive prompt attention.

Genuine Singer Needles should be used

These Needles and their Containers

Company’s Trade Mark “SIMANCO.” 1

in Singer Machines.

are marked with the

Needles in Containers marked

“For Singer Machines”

are not Singer made needles.

DESCRIPTION

MACHINE 145W103 Is a two-needle lock stitch machine with compound

feed and hlgh-llft alternating pressers. It Is used for tents, awnings,

furniture upholstery, leather coats, automobile work, etc. It has a

high arm with a working space of 10 Inches at the right of the needle

bar. The machine Is furnished In gauges from 1/4 to 2-1/2 Inches.

MACHINE 145W203 Is a long-arm machine with working space of 20

Inches at the right of the needle bar and is used for stitching

tarpaulins, tents, automobile door panels and for similar large work.

Otherwise the machine Is the same as Machine 145W103.

MACHINE 145W303 Is the same as Machine 145W203 except that It has

an extra long arm with a working space of 30 Inches at the right of

the needle bar. Has hand wheel at front of machine for convenience

of operator.

Speed

The maximum speed recommended for these machines Is ISOO revolu

tions per minute, when permitted by the nature of the material being

sewn. The machines should be run slower than the maximum speed until

the parts which are In movable contact have become glazed by their

action on each other. When the machines are In operation, the balance

wheel should turn over toward the operator.

Need Ies

Needles for Machines of Class 145w are of Class and Variety 7x23

for cloth, and 7x21 for stitching cardboard and fibre door panels.

They are made In sizes 22, 23, 24, 25 and 27.

The size of the needle to be used should be determined by the

size of the thread which must pass freely through the eye of the needle.

If rough or uneven thread Is used, or If It passes with difficulty

through the eye of the needle, the successful use of the machine will

be Interfered with.

Orders for needles must specify the quantity required, the size

number, also the class and variety numbers separated by the letter x.

The following Is an example of an Intelligible order:

"100 No. 24, 7x23 Needles."

The best results will be obtained when using the needles furnished

by the Singer Sewing Machine Company.

Page 4

Oiling the Mach ine

When the machines are received from the factory, they should be

thoroughly cleaned and oiled,

be oiled at least twice a day.

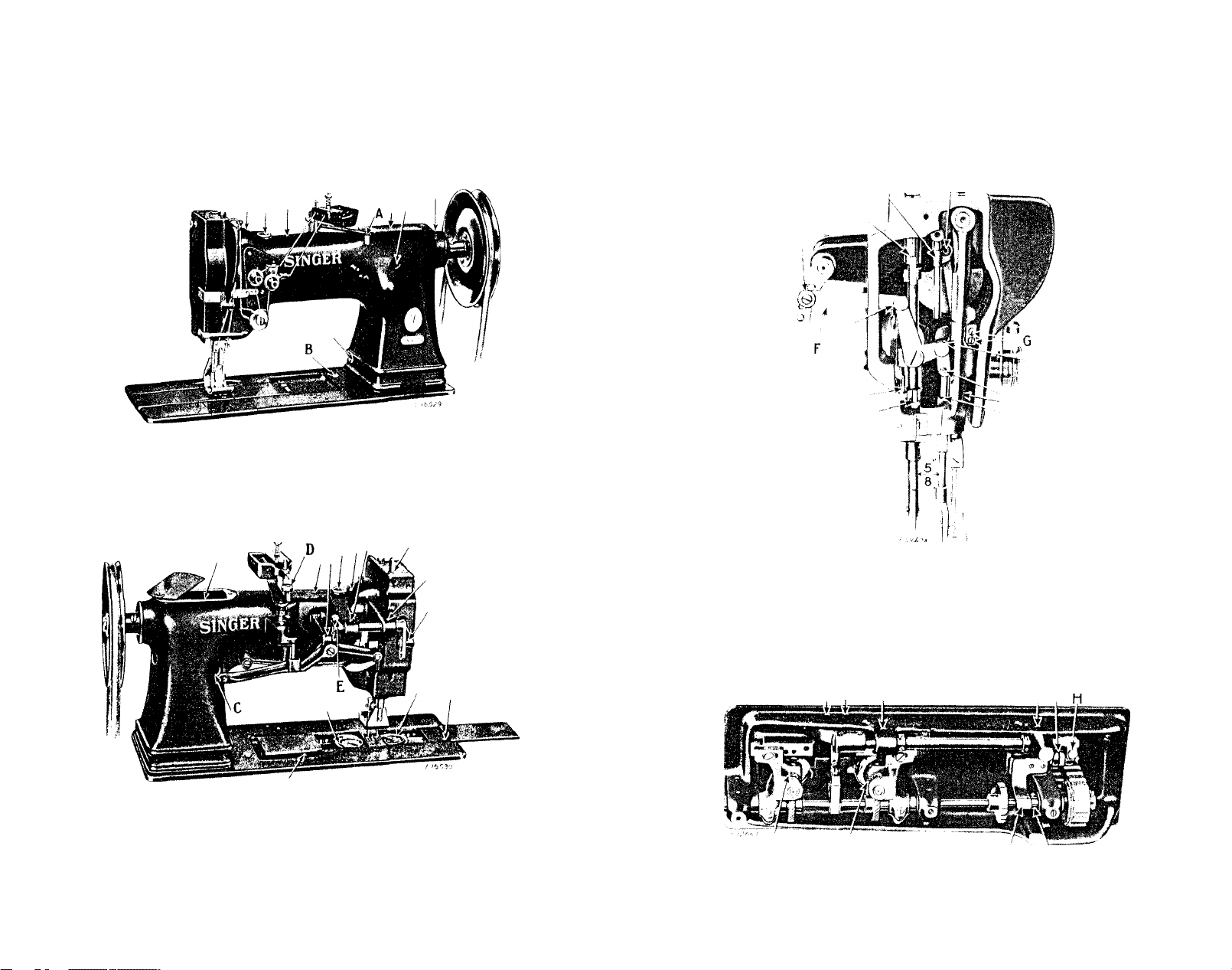

Fig. 2. Front View of Machine 145W103

Showing Oiling Points

Oil should be applied at each of the places designated by arrows

In Figs. 2, 3, 4, 5 and 25.

When In continuous use, they should

Loosen the thumb screw In the upper end of the face plate, turn

the face plate upward and oil the wick and bearings which are thus

uncovered, then turn dcwn the face plate and tighten the thumb screw.

Fig. 3. Rear View of Machine

Showing Oiling Points and Adjustments

Fig. 4. End View of Machine Showing Oiling Points

Also Adjustments on the Machine

Apply a few drops of oil four times dally to the felt pad In the

side wall of each bobbin case as Illustrated In Fig. 10.

J K

Fig. 5. Base of Machine Showing Oiling Points and Adjustments

Page 5

Th read

Use left twist thread for the needles,

twist thread may be used for the bobbins.

Fig. 6. How to Determine the Twist

Hold the thread as shown above. Turn the thread over tcward you

between the thumb and forefinger of the right hand; If left twist,

the strands will wind tighter; If right twist, the strands will unwind.

Either left or right

To Set the Need Ies

Turn the balance wheel over tcward you until the needle bar moves

up to Its highest position; loosen the set screws In the needle holder

and put the needles up Into the holder as far as they will go, with

their long grooves facing each other and their eyes In line, then

tighten the set screws.

To Remove the Bobbins

Draw back the slide plates In the bed of the machine and turn the

balance wheel until the bobbin case openers (M,Flg.7) move clear of

the bobbins. With the forefinger or a screwdriver, raise the latches

(L) to a vertical position and lift out the bobbins.

L M

To Wind the Bobbins on Machines IU5wl03 and IU5w203

(See Fig. 8)

Fasten the bobbin winder to the table with Its driving pulley In

front of the machine belt, so that the pulley will drop away from the

belt when sufficient thread has been wound upon the bobbin.

Fig. 8. Winding the Bobbin

Place the bobbin on the bobbin winder spindle and push It on as

far as It will go, being sure that stud (C) enters a hole In the bobbin.

Pass the thread dcwn through the thread guide (1) In the tension

bracket, around the back and between the tension discs (2). Then wind

the end of the thread around the bobbin a few times, push the bobbin

winder pulley over against the machine belt and start the machine.

When sufficient thread has been wound upon the bobbin, the bobbin

winder will stop automatically.

If the thread does not wind evenly on the bobbin, loosen the

screw (A) In the tension bracket and move the bracket to the right or

left as may be required, then tighten the screw.

The amount of thread wound on the bobbin Is regulated by the

screw (B). To wind more thread on the bobbin, turn the screw (B)

Inwardly. To wind less thread on the bobbin, turn the screw outwardly.

Bobbins can be wound while the machine Is stitching.

Fig. 7. Removing the Bobbin

Page 6

8

To Wind the Bobbins on Machine IU5w303

(See Fig. 9)

Place the bobbin on the bobbin winder spindle and push It up

against the shoulder until It Is In line with the bobbin winder latch.

To Replace the Bobbins and

Thread the Bobbin Cases

Hold each bobbin between the thumb and forefinger with the thread

drawing on the bottan frori left to right as shown In Fig. 10 and place

Is». to

Fig. 10. Direction of Thread on Bobbin

it on the center stud of the bobbin case, then push down the latch

(L,Fig.11). Draw the thread Into the slot (1,Fig. 10), under the

tension spring and Into slot (2) as shown In Figs. 10 and 11, leaving

a loose end of thread about two Inches long above the slide. When

closing the slide plates, leave Just enough space for the threads to

pass through.

Fig. 9. Winding the Bobbin

Pass the thread from the imwlnder, under and between the tension

discs (1), through the eyelet (2), and wind the end of the thread

around the bobbin (3) a few times. Push the bobbin winder pulley

against the balance wheel and press the latch against the bobbin. When

sufficient thread has been wound on the bobbin, the bobbin winder will

stop automatically. Bobbins can be wound while the machine Is

stitching.

Fig. 11. Bobbin Cases Threaded

Page 7

10

Threading the Needles

(See Fig. 12)

TO THREAD THE LEFT-HAND NEEDLE, pass the thread from the unwinder

through one of the holes (l) In the thread oiler, and under the wire

Z I

11

thread guide, over between the right tension discs (7R), down around

the front thread controller disc (8R) Into the thread guide (9) and

the take-up spring (10), up through guide (11), through the take-up

lever eyelet (12R), down through guide (13), Into the right thread

guide (MR) (used only for thread smaller than No. 12), back of lower

guide (15), Into right needle holder eyelet (16R), and from left to

right through the eye (17R) of the right needle.

To Raise or Lower the Presser Feet

The presser feet are raised by pressure on the foot treadle and

may be locked In the raised position by moving the lever (A,Fig.2)

all the way to the left. A slight pressure on the treadle will

autonatlcally release the locking device.

To Prepare for Sewing

with the left hand hold the ends of the needle threads, leaving

them slack from the hand to the needle. Turn the balance wheel over

I7L

17R

Fig. 12.

guide (2) (which may be raised by prying the end (x) out of Its posltlm

hole with a screwdriver and turning It to the right), then under the

oil pad (3) and out through one of the notches (4) In the thread oiler;

upward through eyelet (5L) and downward through eyelet (6L) In the

left thread guide, over between the left tension discs (7L), down

around the rear thread controller disc (8L) and Into the tlread con

troller thread guide (9), Into the tliread take-up spring (lo), up

through the guide (11), from right to left through the eye (12L) In the

take-up lever, down through the guide (13), Into the left thread guide

(14L) (used only for thread smaller than No. 12), back of the lower

guide (15), Into the left needle holder eyelet (16L) and from right to

left through the eye (17L) of the left needle.

TO THREAD THE RIGHT-HAND NEEDLE, pass the thread from the unwinder

through the thread oiler the same as for the left thread, then upward

through eyelet (5R) and downward through eyelet (6R) In the right

Fig. 13. Pulling Up the Bobbin Thread

tcward you until the needles move dcwn and up again to their highest

point, thus catching the bobbin threads; draw up the needle threads

and the bobbin threads will cone up with them through the holes In the

feed dog. Lay the threads back under the presser feet and close the

slides.

To Commence Sewing

Place the material beneath the presser feet, lower the presser

feet and commence to sew, turning the balance wheel over toward you.

Page 8

12

To Remove the Work

Have the thread take-up lever at the highest point, raise the

presser feet, draw the work back and cut the threads close to the

goods. Lay the ends of the threads back under the presser feet.

Tens i ons

The needle and bobbin threads should be locked In the center of

the thickness of the material, thus:

Fig. 14. Perfect Stitch

If the tension on the needle threads Is too tight, or If that on

the bobbin tlireads Is too loose, the needle threads will lie straight

along the upper surface of the material, thus;

Fig, 15. Tight Needle Thread Tension

13

To Regulate the Length of Stitch

The length of stitch Is regulated by the feed eccentric (B, Fig, 17)

located on the arm shaft.

If the tension on the bobbin threads Is too tight, or If that on

the needle threads Is too loose, the bobbin threads will lie straight

along the under side of the material, thus:

Fig. 16. Loose Needle Thread Tension

To Regulate the Tensions

The tension on the needle threads Is regulated by the two thumb

nuts (N, Fig. 18) at the front of the tension discs cn the front of the

machine. To Increase the tension, turn these thumb nuts over to the

right. To decrease the tenslai, turn the thumb nuts over to the left.

The tension on the bobbin threads Is regulated by means of the

screw nearest the center of the tension spring on the outside of each

bobbin case. To Increase the tension, turn this screw over to the

right. To decrease the tension, turn this screw over to the left.

Fig, 17. Feed Eccentric. Arm Cap Removed.

To lengthen the stitch, loosen screw (C,Fig.17) turn the feed

regulating screw (A,Fig.17) over toward the left. To shorten the

stitch, turn this screw (A,Fig. 17) toward the right. When the desired

length of stitch Is obtained, securely tighten screw (C).

To Regulate the Pressure on Material

To Increase the pressure of the presser feet on the material, turn

the thumb screw (D, Flg.3), at the back of the machine, downward. To

decrease the pressure, turn this thumb screw upward.

The pressure on the material should only be sufficient to enable

the feed to move the work along evenly.

Page 9

15

INSTRUCTIONS

FOR

ADJUSTERS AND MACHINISTS

Thread Controller

The thread controller spring should be set so that It reaches Its

lowest point as the eyes of the needles nearly reach the goods In

their descent.

Fig. 18. Aljustment of Thread Controller

For more controller action on the thread, loosen the stop screw

(P, Fig. 18) at the right of the controller and set the stop Icwer, and

for less action set the stop higher.

To strengthen the action of the controller spring on the thread,

loosen the spring stud screw (Q, Fig. 18) at the rear of the stop screw

and turn the spring stud (0, Fig. 18) slightly to the left with a screw

driver, or to lighten Its action turn to the right and retlghten the

spring stud screw.

Page 10

16

To Set the Needle Bar

See that the needles are up In the holder as far as they will go.

There are two lines across the needle bar about two inches above the

Icwer end. When the needle bar is at Its lowest position, the upper

mark should be Just visible at the end of the needle bar frame.

In case the needle bar Is not correctly set, loosen the needle bar

connecting stud pinch screws (G, Flg,4) and place the needle bar in

correct position as directed above, then retlghten the screws (G).

To Set a Needle Bar Which Has No Mark

Adjust the feed eccentric (B, Fig.17) so that there Is no feed

movement of the needle bar frame, then set the needle bar so that when

It rises 1/8 Inch from Its lowest position, the points of the sewing

hooks will be about l/ie Inch above the eyes of the needles.

17

To Change the Amount of Lift of

the Alternating Pressers

The height of lift of the pressers Is adjustable by moving the

link (F, Flg.4) to any of the four holes In the rock shaft crank. The

majclmum lift Is secured with the link In the bottom hole. The amount

of lift should be regulated according to the thickness of the material

being sewn. The feet should lift Just high enough to clear the

material.

To Adjust the Relative Height of Lift of the Vibrating and Lifting Pressers

As a rule, the vibrating and lifting pressers should lift an equal

height, but some grades of work may require that they lift an unequal

height. To change the relative lift of the presser feet, loosen the

screw (E,Flg.3) at the back of the machine and move the vibrating

presser bar upward or downward as required, then securely tighten

the screw (E).

Relative Positions of Vibrating Presser Bar

and Lifting Presser Bar

The distance between the vibrating presser bar and lifting presser

bar, after adjusting the feed eccentric (B, Fig. 17) so that there is no

feed movement of the needle bar, should be 5/8 Inch as shown In Fig. 4.

If the distance between the vibrating presser bar and the lifting

presser bar Is more or less, Insert a screwdriver In the hole at

(C,Flg.3) at the rear of the machine and loosen the clamp screw which

holds the needle bar rock frame rock shaft. While this screw Is loose,

the needle bar frame can be moved forward or backward to the required

distance. A piece of metal of the correct width may be used to deter

mine the correct distance. When making this adjustment be sure to see

that the feed eccentric (B,Fig. 17) Is set so that there Is no feeding

movement of the needle bar. When the adjustment has been made, securely

tighten the clamp screw at C.

,' i.'

To Time the Sewing Hook

Adjust the feed eccentric (B,Fig. 17) so that there Is no feeding

motion.

Remove the throat plate and turn the balance wheel over toward

you until the lower mark across the needle bar Is Just visible at the

end of the needle bar

If the needle bar and sewing hooks are correctly timed, the points of

the hooks will be at the centers of the needles and about 1/16 Inch

above the eyes.

In case the sewing hooks are not correctly timed, turn the balance

wheel over toward you until the needle bar has descended to Its lowest

point and has risen until the Icwer timing mark across the needle bar

Is Just visible at the end of the needle bar frame.

Loosen the two screws In the hub of each hook driving gear (T, Fig.

I

19) and tap this gear to the right or left on the hook driving shaft

until the point of the hook Is at the center of the needle. Tapping to

the right gives an earlier hook timing, and to the left a later hook

timing. Securely tighten the two set screws In each gear (T).

frame on the upward stroke of the needle bar.

Page 11

18

To Set the Sewing Hooks To or From the Needles

To prevent the points of the hooks from dividing the strands of

the thread, they should run as close to the needles (within the scarf)

as possible.

R S T U S T R >

Fig, 19. Adjustment of Hook Saddles

Turn the balance wheel over toward you until the points of the

sewing hooks are at the centers of the needles. Loosen the four screws

(R, Fig. 19) underneath the bed of the machine and move the hook saddles

to the right or left, as may be required, until the points of the hooks

are as close to the needles as possible without striking them, then

securely tighten the four screws (R).

The needle guard (Y,Fig.21), which Is attached to the side of each

sewing hook, should be sprung until It prevents the needle from striking

the hook In case the needle is deflected towards the hook.

Fig, 20. Removing Bobbin Cases

19

To Remove the Bobbin Cases from the Sewing Hooks

Remove the bobbin case openers (M, Fig. 20); remove the four hook

gib screws (W,Fig. 20) from each sewing hook, lift off the hook gibs

(Z, Fig. 21) and remove the bobbin cases (X, Fig. 20).

To Remove the Sewing Hooks from the Machine

Remove the throat plate, feed dog and the bobbin case openers.

Loosen the two screws In each hook shaft gear (S, Fig. 19) and lift out

the sewing hooks.

Fig. 21. Sewing Hook Removed from Machine

Shewing Hook Gib and Needle Guard

To Raise or Lower the Feed Dog

Usually when the feed dog Is at Its highest position. It should

show a full tooth above the throat plate.

Remove the throat plate; clean the lint and dust from between the

feed points and replace the throat plate; tip the machine back and

turn the balance wheel towards you until the feed dog Is at Its highest

position; loosen screw (U, Fig. 19) In the feed lifting cam fork on the

feed bar and raise or lower the feed dog, as may be required, and

re tighten the screw (U).

Vihen raising or lowering the feed dog, be careful that Its under

side does not drop low enough to strike the sewing hooks.

The feed dog should be set so that the needles are centered In

the needle holes. In case the needles do not enter the holes In the

feed dog correctly, loosen the pinch screw (H, Flg.5) and adjust the

feed dog as required, then securely tighten the pinch screw (H).

Page 12

20

To Remove the Needle Bar Rock Frame Rock Shaft

Remove the face plate and needle bar rock frame, then loosen the

clamp screw at (C,Fig.?) and draw out the rock shaft.

To Remove the Arm Shaft Connection Belt

from within the Arm

Slide the connection belt off the lower belt pulley; remove the

balance wheel; loosen the three screws In the arm shaft bushing near

the balance wheel and remove the bushing; lift the belt up through the

arm cap hole as far as possible and draw It out through the space

normally occupied by the bushing.

Owing to the fact that the sewing hooks make two revolutions to

one revolution of the hook driving shaft, and that the feed lifting

eccentric Is on the hook driving shaft. It Is possible to have the

sewing hooks correctly timed without having the feed correctly timed.

To overcane this, the plate (J,Flg.5) Is attached to the underside of

the bed of the machine. This plate Is marked with an arrow at Its

lower end and directly aloTigslde of the plate Is the collar (K, Flg.5)

mounted on the hook shaft, which Is also marked with an arrow. After

replacing the belt over the upper pulley, replace the arm shaft bushing

and securely fasten It In position by Its three screws; replace the

balance wheel. With the belt on the upper pulley, turn the balance

wheel fron you until the thread take-up lever Is at Its highest point.

Then turn the hook shaft with the fingers until the two arrows, one on

the plate (J) and the other on the collar (K), are directly In line.

New, without disturbing either the arm shaft or the hook shaft, slip

the belt over the lower pulley. The feed will then be correctly timed

with the needle bar.

21

To facilitate the replacing of the belt on the lower pulley, use

belt replacer 265068 (A, Fig. 22). Rest the replacer In the loop of the

the belt and slide It ov'er the hub of the pulley, as shewn In Fig. 22,

having the notches In the replacer engage the two set screws In the

hub of the pulley. Catch the belt clips In the groove at the lower

part of the pulley and turn the balance wheel toward you until the

belt Is fully over the pulley, assisting the belt clips from under the

pulley rhn with a screwdriver when necessary. Then remove the replacer.

NOTE: As belt replacer 265058 will serve for several machines

It Is not regularly furnished with the machine, and must be ordered

separately.

To Re-engage the Safety Clutch

The hook driving shaft and the shafts of the sewing hooks are

spllned to prevent the hooks from getting out of time. The safety

clutch located In the lower belt pulley prevents damage In the event

of any unusual strain on the sewing hooks by releasing the locking

lever In the pulley from the notch

hook driving shaft.

(Dl,Flg. 24) In the collar of the

Fig. 22. Putting Belt on Lewer Pulley with

Belt Replacer 265058

Fig. 23. Safety Clutch Disengaged Fig. 24. Operating Position

Draw back the bed slides, turn the balance wheel back and forth

slightly, and remove the material that may be Jamming the hooks. If

necessary to re-engage the clutch, press down the lock stud (B, Fig, 2)

^near the base of the arm to engage the hook driving shaft lock ratchet

(Al,Flg. 23) which will prevent the hook driving shaft from turning

backward. Turn the balance wheel away fron you until the locking lever

(Bl) snaps Into the notch (Dl) In the shaft collar as shewn In Fig. 24.

Release the lock stud and resume sewing.

Page 13

22

To Adjust the Hand-Wheel Shaft

on Machine IU&W303

The hand-wheel shaft bushing (FI,Fig.25) Is eccentric and may be

rotated to bring the hand-wheel gear (Gl,Flg.25) Into proper engagement

Fig. 25. Rear View, Showing Adjustments and Oiling Points

at Top of Lcng-Arm Machines

with the gear on the arm shaft. Loosen the bushing set screw (El, Fig.

25) and the bushing (Fl) may then be tapped around by means of a screw

driver In holes In Inner end of bushing until there Is only a trace of

bac)tlash between the gears. Then tighten the set screw (El).

Parts Required for Changing the Gauge of a Machine

The following Hook Saddle Bearings are used for different gauges:

Gauge

1/4 to 1-1/8

1-5/32 to 2-1/16

2-1/8 to 2-1/2

Hook Saddle Bearings

(Left)

265272

265274

223680

(Right)

265273

265275

223681

When changing the gauge frcm one of these ranges to another, a new

pair of hook saddle bearings must be ordered. In addition to these,

a new feed dog, throat plate, presser foot and needle holder will be

required for each gauge.

Loading...

Loading...