Page 1

Instruction Book

MODEL 1717

Page 2

IMPORTANT SAFETY INSTRUCTIONS

POLARIZED PLUG CAUTION

To reduce the risk of electric shock, this appliance

has a polarized plug (one blade is wider than the

other). This plug will fit in a polarized outlet only

one way. If the plug does not fit fully in the outlet,

reverse the plug. If it still does not fit, contact a

qualified electrician to install the proper outlet. Do

not change the plug in any way.

SEWING MACHINE

Record in space provided below the Serial No.

and Model No. of this appliance.

The Serial No. is located Rear of arm.

The Model No, is located Rear of arm.

Serial No.___

Model No. 1 71 7

Retain these numbers for future reference.

________________

Read all instructions before using (this

appliance).

DANGER - -To reduce the risk of electric shock:

An appliance should never be left unattended when plugged in. Always unolua this

appliance from the electric outlet immediately after using and before cleaning^

WARNING—To reduce the risk of burns, fire,

electric shock, or injury to persons:

1.

Is'^se^bfo^Lr“ ^ """"" " ^PP'-nce

2.

attachments recommended by the manufacturer as contained in this manual.

3.

properly, If It has been dropped or damaged, or dropped into water Return the

appliance to the nearest authorized dealer or service center for examination repair

electrical or mechanical adjustment. '"Mauon, repair,

4.

innrnf tT« appliance with any air openings blocked. Keep ventilation open-

S, and ircloth"" accumulation of lint,

Never drop or insert any object into any opening.

Do not use outdoors.

appliance only for its intended use as described in this manual. Use only

has a damaged cord or plug, if it is not working

be,ng"adZ'str”d''°''’

duSef P'"9

Do not unplug by pulling on cord. To unplug, grasp the plug, not the cord.

DANGER

1. Always unplug before relamping. Replace bulb with same type rated 15 watts

3 ni 'r " ? immedia””,

« i“! '9" Pdlled into a tub or sink.

Do not place in or drop into water or other liquid.

Page 3

WARNING

CONTENTS

1. Keep fingers away from all moving parts. Special care is required around the sewinn

machine needle. “

2. Always use the proper needle plate. The wrong plate can cause the needle to break

3. Do not use bent needles.

4. Do not pull or push fabric while stitching. It may deflect the needle causing it to

break.

5. Switch the sewing machine off (“0”) when making any adjustments in the needle

area, such as threading needle, changing needle, threading bobbin, or changing

pressar foot, etc.

6. Always unplug sewing machine from the electrical outlet when removing covers

lubricating, or when making any other user servicing adjustments mentioned in thè

instruction manual.

7. Never operate on a soft surface such as a bed or couch where the air openings

may be blocked.

SAVE THESE INSTRUCTIONS

10.

11.

12

1 3.

14.

1 5.

16.

1 7.

1 8

1 9.

20

21

names of parts 2

accessories................................................................................................................................................3

BEFORE SEWING a

Detaching Extension Table........................................................................................ 4.

Connecting Foot Controller and Power Cord 5

Changing Needle................................................................................................................................6

Changing Foot.......................................................................................................................................7

Bobbin Winding...................................................................................................................................g

Inserting Bobbin..............................................................................................................................-| i

Adjusting Lower Tension............................................................................................................12

Drop Feed Lever............................................................................................................................... -] 2

Threading Upper Thread............................................................................................................13

Twin Needle Threading................................................................................................................14

Decorative Tucks or Designs...................................................................................................14

Drawing Up Lower Thread.......................................................................................................15

Foot Pressure.......................................................................................................................................-] g

Fabric, Thread and Needle Table....................................................................................... 16

Pattern Setting.................................................................................................................................. 17

STRAIGHT SEWING ig

Pattern Selection Dial....................................................................................................................ig

Stitch Length Dial............................................................................................................................i g

Starting to Sew..................................................................................................................................i g

Double Presser Foot Lifter..................................................................................................... i 9

Cloth Guide.................................................................................................................................20

Adjusting Thread Tension.........................................................................................................20

Applications of Straight Stitch.............................................................................................21

ZIGZAG SEWING 22

Zigzag Width Control....................................................................................................................22

Needle Position Control.............................................................................................................22

Thread Tension for Zigzag Stitch

MAKING BUTTONHOLES 23

Determine Length...........................................................................................................................23

Determine Width.............................................................................................................................23

Left and Right Side Balance of Buttonhole 25

Cutting Buttonhoies......................................................................................................................26

Corded Buttonholes......................................................................................................................26

SEWING ON BUTTONS 27

OVERCASTING 28

OVERLOCKING 29

Applications of the Elastic Overlockstitch 30

Application of Ultra Stretch.................................................................................................. 31

Application of Rick-Rack........................................................................................................... 32

Application of Decorative Fun Patterns

BLIND HEM STITCH 34

Elastic Blind Hem Stitch.........................................................................................................35

STRETCH SEAM35

.

ZIPPER SEWING

SHELL STITCHING 33

PIN TUCKING

QUILTING

SCALLOPING.....................................................................................................................................................

MENDING 42

Patching....................................................................................................................................................

Mending a Rip....................................................................................................................................42

.

APPLIQUE WORK 43

EMBROIDERY 44

.

MAINTENANCE 45

Cleaning.....................................................................................................................................................

Oiling............................................................................................................................................................

TROUBLE CHART 47

Changing Light Bulb......................................................................................................................43

......................................................................................

.......................................................................

22

33

37

39

40

....

....

...

....

Page 4

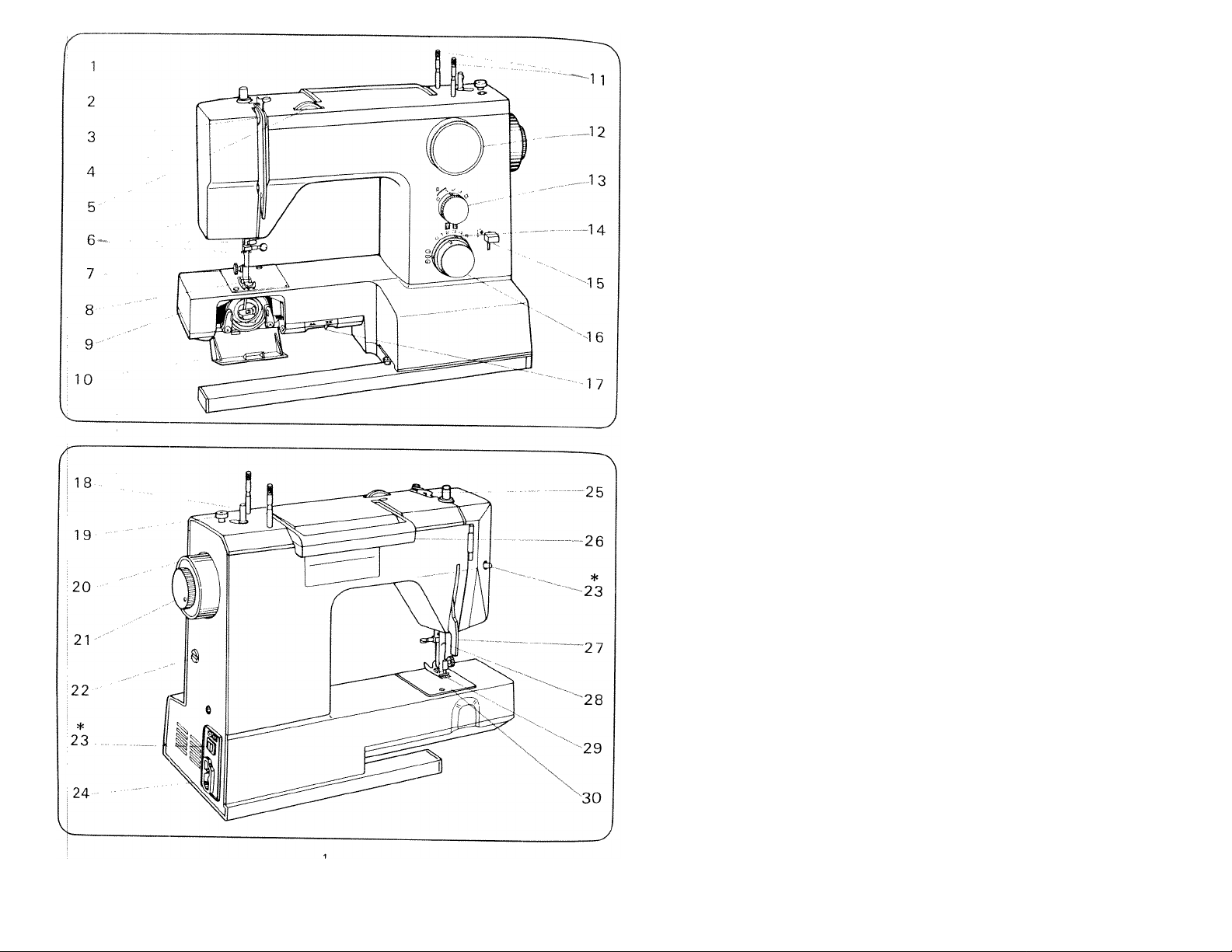

I. NAMES OF PARTS

1, Thread guide for bobbin winding

2, Pressure regulator

3, Take-up lever

4, Face cover

5, Upper thread tension dial

6, Thread guide for upper threading

7, Presser foot thumb screw

8, Presser foot

9, Free arm

10. Shuttle cover

II, Spool pins

12. Pattern selection dial

13. Stitch length dial

14. Needle position control

15. Reverse sewing lever

16. Zigzag width control

1 7. Drop feed lever

18. Bobbin winding spindle

19. Bobbin winding stopper

20. Handwheel

21. Stop motion knob

22. Special buttonhole adjustment

23. switch *

24. Socket

25. Thread guide for upper threading

26. Handle

27. Presser foot lifter

28. Thread cutter

29. Feed dog

30. Needle plate

* Specifications vary from country to country.

Page 5

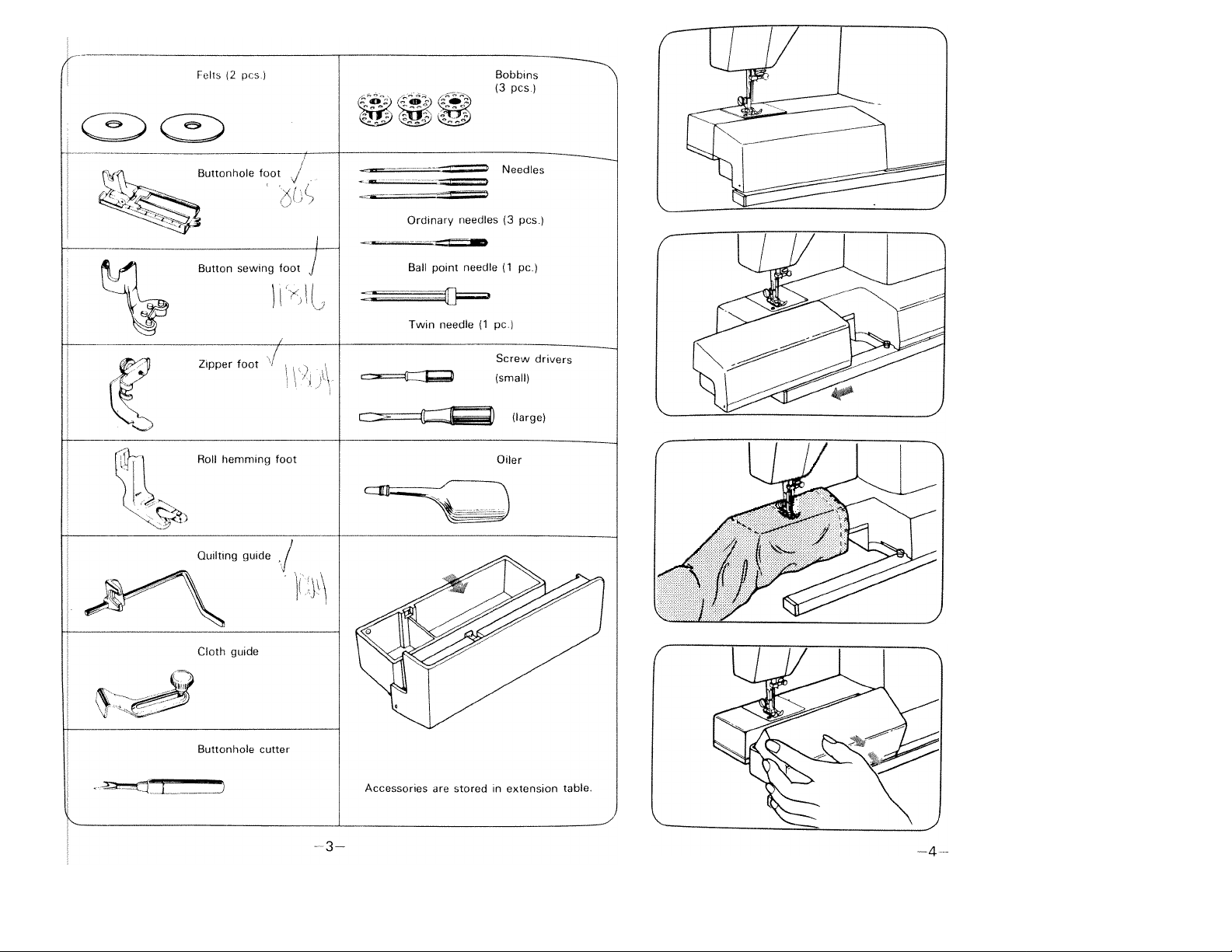

2. A C CE S SO R IE S

3. BEFORE SEWING

Machine is stored in flat-bed style

which makes your work easier in

ordinary sewing.

Detachable Extension Table

Slide table off and the machine

is used as a free-arm model.

Free-arm is convenient to sew or

embroider; trousers, sleeves, cuffs

of T-shirts, blouses, etc.

Do vice-versa of above steps to

attach extension table.

To open lid of accessory box, push

it open, as illustrated.

Page 6

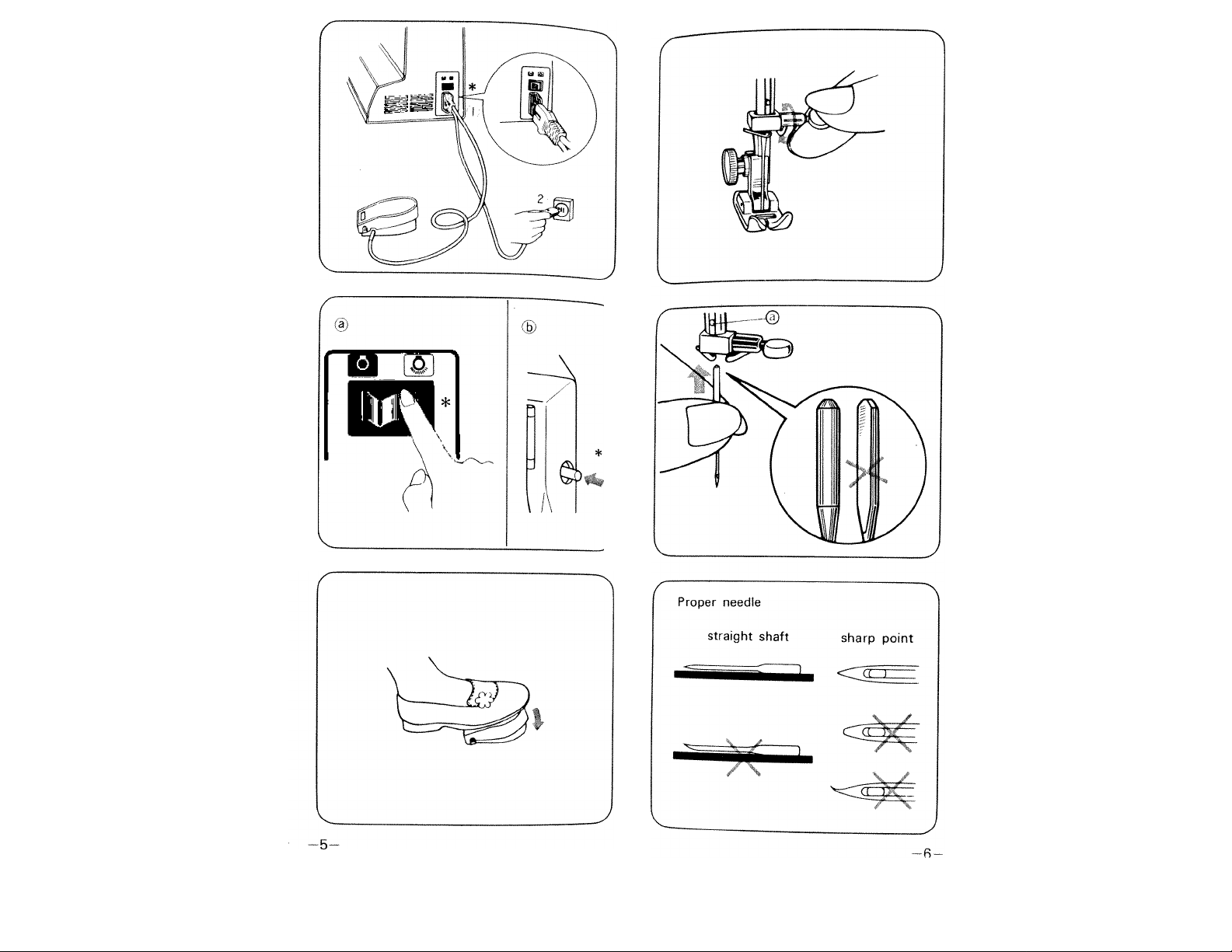

Connecting foot controller

and power cord

Oonnect foot controller and

power cord '1,1 2a

Changing Needle

Set needle in the highest

position by turning handwheel

towards you.

Before plugging in your machine,

sure that voltage is same as

that of your machine, (written on

a:plate at back of machine)

a Switch on put power on the

machine and turn on the sewing

lifht.

bj Push button to turn sewing

li|ht on and off.

Always switch off or unplug

machine when not in use.

* Specifications vary from country

tp country.

The more you press foot controller,

the faster the machine runs.

Loosen needle clamp screw and

remove needle.

With flat face away from you,

insert a new needle into groove

of needle bar.

Push needle until it reaches

stopper (a) and tighten needle

clamp screw firmly.

Always use a straight needle with

a sharp point.

Using defective or worn needles

not only causes stitch skipping,

breakage of needles or snapping

of thread: it also can damage

hook and needle plate.

Page 7

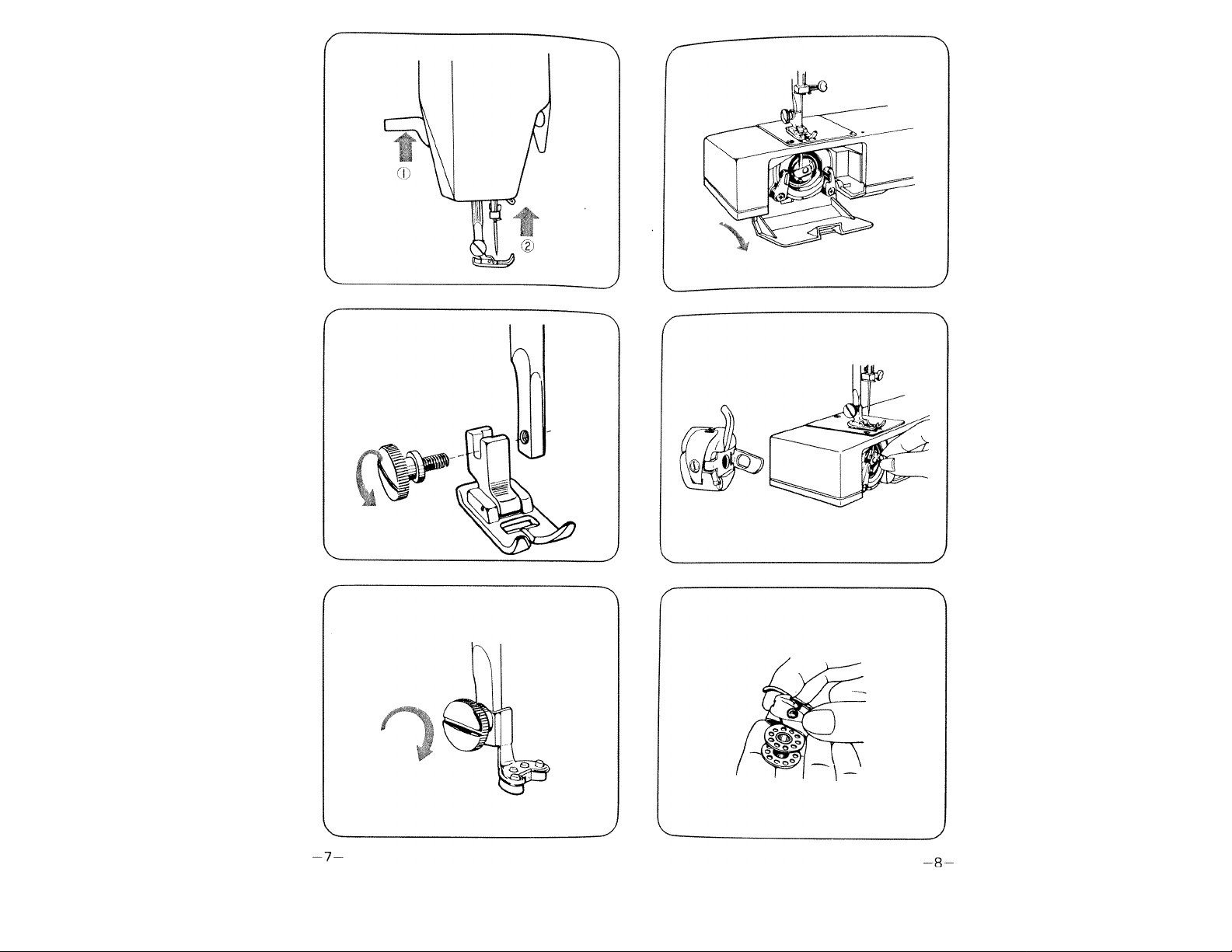

Changing Foot

Bobbin Winding

Raise presser foot lifter (\).

Set needle in the highest

position by turning handwheel

towards you (ZJ-

Remove foot holder by loosening

screw with screwdriver.

Set needle in the highest position

by turning handwheel towards

you.

Open shuttle cover.

Open latch of bobbin case and

take it out.

Replace screw-snap type presser

fbot and tighten screw.

Close latch of bobbin case and

bobbin comes out easily.

Page 8

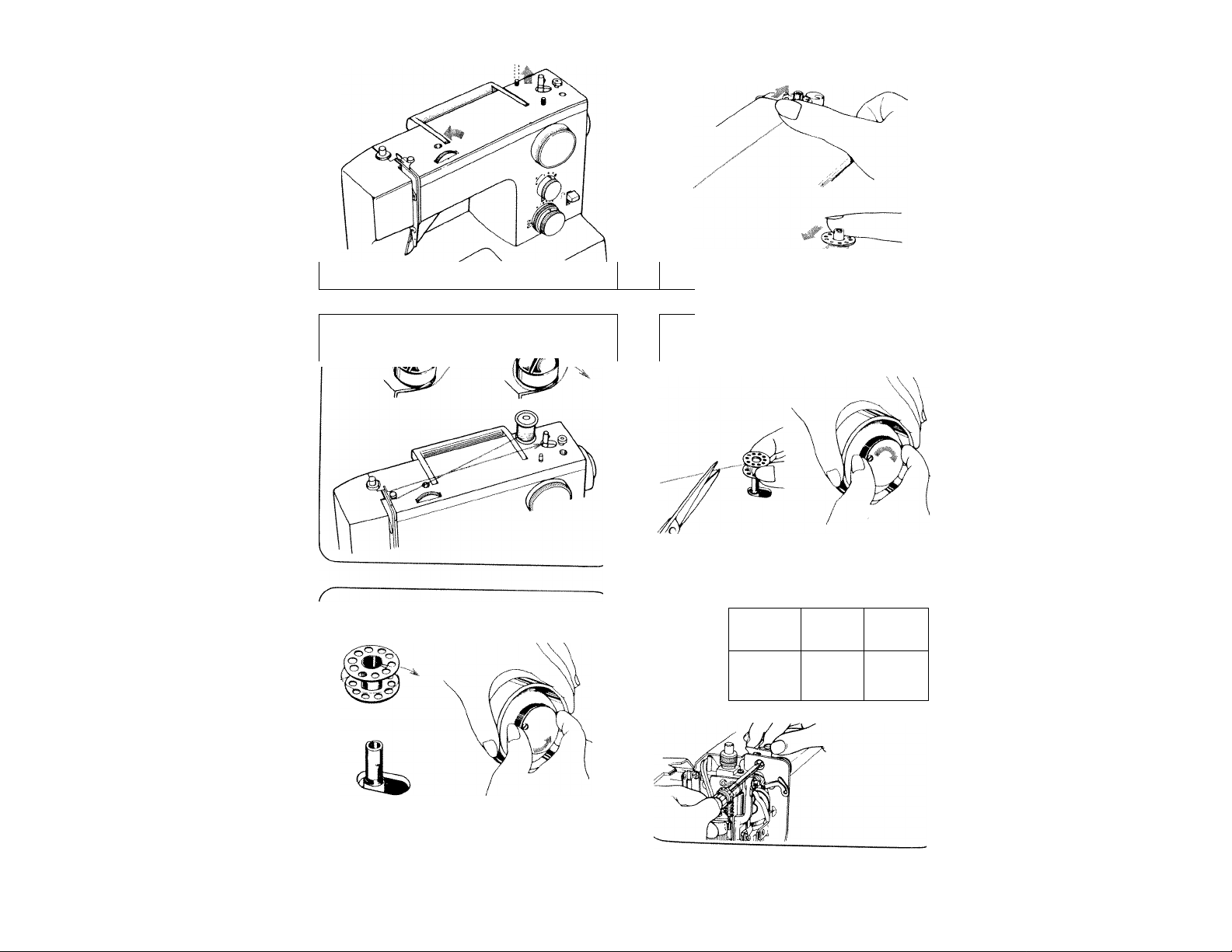

push back to fold handle,

full out spool pin and put a felt

iin spool pin.

Push bobbin to right and press

down foot controller.

Machine stops automatically

when bobbin is full.

Push bobbin to left, to disengage

from wheel.

Rut a spool on spool pin.

Draw thread from spool pin

through thread guide and pre

tension device, following numb-

rs (I; and (Z).

W

'ind thread clockwise around

bo

ibbin several times.

Pu

ish bobbin on to spindle.

Holding handwheel with your left

hand disengage handwheel by

unscrewing stop motion knob.

V

V

Take off bobbin from spindle

and cut thread.

Retighten stop motion knob.

If bobbin is wound unevenly

trouble

correction

; '6

y 1

as shown, open face cover and

loosen set-screw of the guide for

bobbin winding: Use screw driver

to adjust height.

9-

1 n -

Page 9

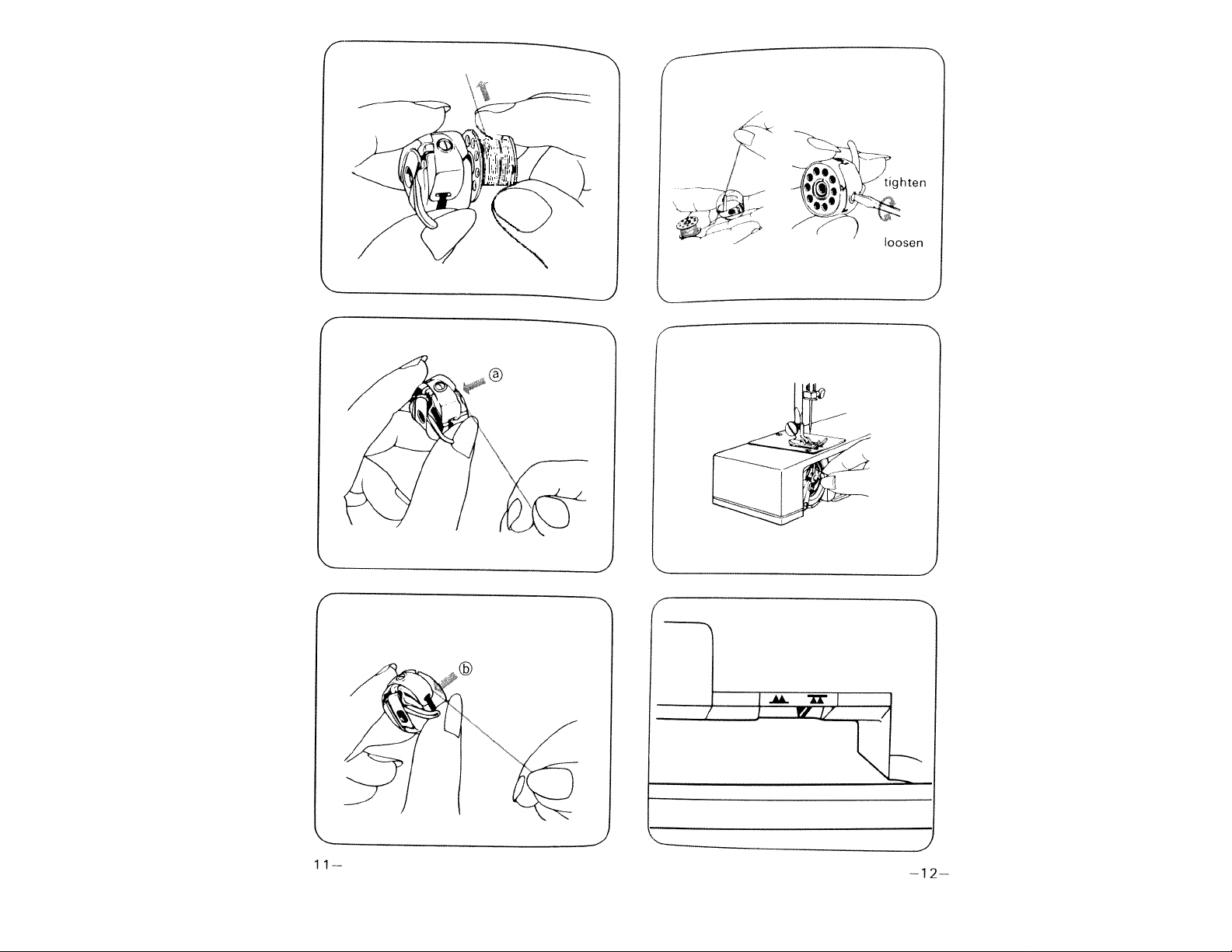

Inserting Bobbin

Place bobbin in its case with

thread running in direction of

arrow.

Adjusting Lower Tension

To test bobbin tension, hang and

shake bobbin case as shown.

At proper tension bobbin case

will gradually drop a small

amount.

To adjust tension, turn adjusting

screw with small screwdriver.

Guide thread into slot

bpbbin case.

Pulling thread to left, bring it

under tension spring then to

delivery eye (b).

(a) of

Raise needle in the highest

position.

Leave end of thread of about 10

cm (4") from bobbin case.

Take hold of latch and push

bobbin case into shuttle

Release latch when bobbin case

is fully inserted.

DROP FEED LEVER

The lever is in the right side of

shuttle cover. For normal sewing,

move the lever to ^ position.

To lower feed dog, move the

lever to 22 position.

This position is used for button

sewing, darning and embroidery.

Page 10

I

Threading Upper Thread

Raise presser foot lifter.

Raise take-up lever to the highest

position by turning handwheel

towards you.

Thread following numbers "l>T).

Pass thread through guide (T).

Twin Needle Threading

Thread in the same way as

normal threading, except at

points (2;, ® and

At point (|), pass threads separatly to right and left of tension

disc.

Lead thread either side of tension

disc (2).

Hook it to guide (3,; from down

to upwards.

¡Thread take up lever

Pass thread to guide CD from right

to left, and guide (|) (left one)

then needle eye (7).

Leave end of thread of about 15

cm (6").

At guide (6), pass one of threads

to right guide anc^ the other at

left guide.

At point (7), thread from right

guide should be lead to right

needle eye, and from left guide

to left needle eye.

Leave ends of threads of about

15 cm (6").

Decorative Tucks or

Designs

Any stitch can be used with the

twin needle for decorative effects.

Most attractive are the multiple

stitch zigzag and blind hem stitch

for fancy tucks. The satin stitch

or tapered zigzag designs in two

colors are effective for creative

trims.

Caution: Remember to use no more

than 2.5 zigzag width and needle

position control at CED- for twin

needle sewing.

Page 11

Dfawing Up Lower Thread

Fabric, thread and needle table

H(|ld end of upper thread with

left hand.

Turn handwheel slowly towards

you until needle moves down and

up; again.

Pull upper thread slowly and

lo\|/er thread will be brought up

in a loop.

Pu I out both threads to about 1 5

cm (6") and place them together

under presser foot on left.

Foot Pressure

Pugh down the outer ring of the

pressure regulator. This will re

lease the pressure on the presser

foct. To increase the pressure,

push down inner pin until suitable

pressure is obtained.

Inslufficient pressure may cause

poor feeding of the fabric, skipped

stitiches, or difficulty in guiding

the fabric. If feed dogs or presser

foct marks appear on the fabric,

reduce the pressure.

Wfien sewing multiple thickness

or heavy fabric, reduce the

pr^sure. Increase pressure when

sevying lighter weight fabrics.

THREAD

FABRIC

European

Cotton

very sheer. Lace,

Voile, Chiffon, Net

SHEER: Blouse Crepe,

Law n, Organdy, Taffeta

50-70

LIGHT-WEIGHT; Crepe,

Wool, Brocade, Velvet

MEDIUM: Wool, Silk,

Linen, Velvetten, Cotton

Mercerized

Cotton

70

30

30

Faille, Terrycloth

HEAVY: Denim, Duck,

Sailcloth

extra HEAVY:

Upholstery, Canvas,

30

30

Heavy

Heavy

Awning

IKNITSI

LIGHT-WEIGHT: Tricot

Power net

50-70

MEDIUM-WEIGHT:

Jersey, Double Knit,30

Power Net

HEAVY-WEIGHT: Double

knit, Power Net

FAKE-FURS, VELOURS

30

30

Heavy

ILEATHERI

VINYLS FILMS

LIGHT-TO-MEDIUM-

WEIGHT

HEAVY LEATHER

30

30

30

Heavy

[DECORATIVE TOUCHES]

TOP STITCHING

MACHINE EMBROIDERY

Silk twist

Size 50-70

Cotton

Covered

Polyester,

Silk, Nylon

60

60

Silk

Nylon

Silk

Nylon

50 Silk

50 Silk

Duty

Duty

60

C.CPoly,

C.CPoly.

Silk

Nylon

Silk

50 Nylon

C C Poly,

Silk

50

Nylon

C.CPoly.

Duty

50

50

Duty

C.CPoly.

C.CPoly. 90

C.CPoly,

C.CPoly,

NEEDLE

European

U S SizePoint

705 15x1

65-70 9

65-70

75-80

80-90

1 1

11-14

100

120

70

70-80

80-90

90 -1 00

90-100

100-110

100-110

65-80

9-10

11-14

14-16

14-16

16-18 Wedge

16-18 Regular

9-11 Regular

9

16

19

9

14

REMARKS

Style

Regular

Loosen up^

per tension

one or two

points

"

"

"

"

Light

Ball

Light

to Medium

Ball

Medium

to Heavy

Ball

Ball or

Sharp

Wedge

Wedge

-16-

Page 12

Pattern Setting

ir A

la ^ Ц

PATTERN SELECTOR

1 4

5

mm

6

7

' Л A /

8

9

10

1 1

12

13

14

15

16

1 7

18

19

' / \ / \ ,

V V V

/

ФФ

\_\\

[1ЁИ

VTVT

YYT

МАЛЛ^

======

ш\л\\

wv

vuvu

w<

4. STRAIGHT SEWING

Set machine as shown.

PATTERN

NAME

TWIN

NEEDLE

BUTTONHOLE

— — —

----

—

л/wwvw

7WWWW

'■Vwywyi/

'ЛЛ'ЛЛ'^^'

/V''

■MWV»'«WWyv'

ziAW/AV/AW

ziAW/AW/AW

—

STRAIGHT

ZIGZAG

BLIND HEM

STRETCH

BLIND HEM

MULTIPLE

ZIG ZAG

SCALLOP

PEARL

DECORATIVE

CHECKER

STRAIGHT

STRETCH

RICK RACK

DECORATIVE

ULTRA

STRETCH

OVERLOCK

OVERLOCK

BRIAR

...

FISH

SWAN

COLOR

CODE

orange

yellow

YELLOW

YELLOW

YELLOW

YELLOW

YELLOW

YELLOW

YELLOW

PURPLE

PURPLE

PURPLE

PURPLE

PURPLE

PURPLE

PURPLE

PURPLE

PURPLE

Pattern Selection Dial

Turn dial to choose pattern.

Dial can be turned either to right

or to left.

* Always make sure needle is

in the highest position when

operating dial.

Stitch length dial

For a longer stitch, turn dial in

clockwise. For a shorter stitch,

turn it in counter clockwise.

For normal sewing it is set

between 2 and 3.

Page 13

starting to Sew

Pllace fabric under foot about 1

cm (0.4") inside the edge.

Lower presser foot lifter.

Inliportant:

Hold on both threads during the

siiwing of the first 3-4 stitches

of the seam.

Double Presser Foot Lifter

In order to obtain winder gap

when using very thick materials,

firmly push presser foot lifter up

as far as it will go.

Reverse Sewing

"to reinforce seam, sew backv|/ards to the edge of fabric by

flushing down reverse sewing

lOver.

Cloth Guide

Use cloth guide when sewing a

long seam of regular distance

from edge of material.

Set guide in hole on arm, at right

of needle plate, and adjust

distance.

Run machine with edge of fabric

touching guide.

Position cloth guide at an angle

to sew a curved seam.

Sew reverse stitches for rein

forcement at end of seam.

Draw fabric to left when sewing

is finished.

Cut threads with thread cuttei

behind presser bar.

Release lever and commence

forward sewing guiding fabric by

(land as it is fed.

Never pull material.

Adjusting Thread Tensior

Test stitch performance on

scrap of material you are goin

to use.

With correct tension ((a;), upp<

and lower threads tension

equal and strong enough to lo(

both threads in center.

If upper tension is too tig

(loose), upper (lower) thread li

straight along upper (low.

surface of fabric ({br.ic,). Corrt

by turning tension dial.

Page 14

Applications of Straight

Stitch

A Seams

The normal stitch length for most

fabrics is 3, but the length chosen

should depend on the fabric and

area of usage. Usually, heavier

faarics require longer stitches, and

lighter weight fabrics require

shorter stitches. For curved seams

and bias cut areas use a shorter

stitch length to add strength and

elasticity to the seam.

B.

Basting/T opstitching

Se

!|wing a seam with a longer

St

itch

se$

sti

ga

ca

thei

bo

sa

on

he^

twi

but

{sh:

in

is useful for temporary

ms prior to fitting. Basting

inches also may be used when

ithering in fullness. Topstitching

be done very effectively with

long straight stitch. For a

der stitch, two threads of the

irnetype can be threaded through

needle (size 14 or 16). A

ivier thread such as buttonhole

St may beusedfortopstitching,

be sure to use a larger needle

e 16 or 18). Basting instructions

glossary.

5. ZIGZAG SEWING

Set machine as shown.

To prevent seam ends unravelF

ing, set machine for straight

stitch and sew in reverse at

beginning and ending of seam.

Zigzag Width Control

Set control at required number.

Larger the number, wider the

stitch.

Set it at 0 for straight sewing.

Make sure needle is in upper

position when you set control.

Needle Position Control

Needle position can be changed

by turning needle position

control.

When selecting position, make

sure needle is in upper position

to avoid tearing material or

bending needle.

Thread Tension for Zigzag

Stitch

Better looking zigzag stitching

requires less upper tension than

straight stitching.

Loosen upper tension slightly.

Page 15

^.MAKING BUTTONHOLES

$et machine as shown.

Bar tacking: Set pattern selection

dial to 1 (,B^) and sew 5^6

stitches.

Left side: Change pattern to 2

(al]). Sew left side from front to

back until it reaches end line.

Determine Length

Nleasure diameter and thickness

of button and add 0.3cm (1/8'')

f(jir bar tacks.

Mark buttonhole size on material.

Determine Width

Dptermine width according to

diameter of button, its thickness,

arjid kind of material.

Attach buttonhole foot,

Co

mpletely push back sliding part

of buttonhole foot,

PIB

ice material under foot so that

m

arking of buttonhole passes

thr

ough center of foot and arrow

'.b.

of foot indicates beginning line

of

marking.

Remember the point where arrow

shows so that it is not necessary

to mark end lines for all

buttonholes.

Bar tacking: Change pattern to 3

( ) and sew 5-6 stitches.

Right side: Change pattern to 4

([(■*) and sew right side until it

catches first bar tack.

Quick finish; To prevent

unstitching, set zigzag width at

0 and proceed for a few stitches.

Page 16

Left and Right Side Bajlance of Buttonhole

Cutting Buttonholes

Stick a needle through bar tacks

to prevent over-cutting.

Stitch density on right and left

sides of buttonhole can be adjust

by buttonhole balance control

digl.

This dial should usually be in a

neutral position (between " +

and " —"j

If the stitches on the right side of

thf buttonhole are too close

together, turn the dial to the left

(+j)-

♦ turning dial to left opens right

side and closes left side.

Cut buttonhole along center with

buttonhole cutter.

Corded Buttonholes

For stretch fabrics such as knits,

a corded buttonhole is effective

to keep finished buttonhole

in shape.

Hook filler cord on top spur and

lead ends of cord under foot, pull

taut, and hook them to bottom

notches as shown.

Proceed with stitching as for

regular buttonholes.

the stitches on the right side of

If

le buttonhole are too open, turn

th

le dial to the right ( —).

th

Turning dial to right closes right

♦

side and opens left side.

When buttonhole is completed,

pull filler cord ends so that loop

on the other end disappears into

buttonhole stitching.

Thread ends of cord to reverse

side and tie, or cut both ends of

cord.

Page 17

7. SEWING ON BUTTONS

Set machine as shown.

8. OVERCASTING

For light weight material:

Set machine as shown.

Overcasting prevents edge of

fabric from fraying and produces

neat finish.

Position a button and material

under foot. When needle comes

to left side of stitch, lower foot.

Raise needle and adjust zigzag

width so that needle comes to

night hole of button.

Run machine at medium speed

and sew 5-6 zigzag stitches.

Stop machine when needle is in

upper position.

;a Set zigzag width control to 0

and sew 3-4 stitches to prevent

unstitching.

OR

ib: Draw out work and cut off

threads.

Draw thread ends through to

wrong side and tie a knot.

Sew carefully so that all stitches

on right side are flush with edge

of fabric.

For thick and elastic material;

Set machine as shown.

Sew in the same way above.

-27-

tv ly

-28-

Page 18

p. OVERLOCKING

bverlocking stitches make it

possible to sew and overcast

seams at the same time.

Set machine as shown,

a For medium, thin material

b For medium, thick material

Applications of the Elastic

Overlockstitch

This stitch is very effective for

overcasting, edgestitching, etc,

on knits and very stretchy fabrics,

also, for decoration.

Topstitching

A decorative topstitch can be

produced with the elastic edging

stitch. Stitch around the structural

lines of the garments for a dramat^

ic effect. Topstitch a braid or

decorative inset with the elastic

edging to add an additional

decorative flair.

Put two pieces of cloth together

with right sides facing and sew.

To prevent edges from fraying,

sew so that right side stitches

drop outside the edge of material.

In some cases overlooking

stitches can be used for

overcasting.

Pattern: AA

Length: 5

width: 5

Feed Dog: Up

Pressure: Normal

Foot: Embroidery

Needle Position: L or R

Edging

As with the stretch blind hem,

the elastic edging stitch can be

used for a decorative edge on

place mats, napkins and table

cloths. Proceed as you would

with the stretch blind hem stitch,

but use the elastic edging stitch

instead.

Pattern :AA

Length: 5

Width: 3-5

Feed Dog: Up

Pressure: Normal

Foot: Embroidery

Needle Position: M, L or R

-29

Page 19

Application of Ultra Stretch

Stitch

Vii

A. Seaming

On most knits, a 3/16 inch finished

seam, such as stitch and overcast

or the overlock stitch, is more

desirable than a 5/8 inch opened

seam allowance. These stitches

can create a neater, more profes

sional finish, eliminate bulky seams

prevent curling, permit the gar

ment to "give" under stress, and

at the same time they cut down

on the amount of work involved

in making a garment. If ever in

doubt as to which of the two

stitches to use, test both on the

particular fabric in question and

choose according to their perform

ance.

The stitch and overcast stitch

is excellent for stretch fabrics

such as sweater knits, bathing suit

knits, and cotton knits. It has

the greatest strength and elasticity

of all.

For patterns with 3/16 inch seam

allowances: Feed the fabric such

that the needle goes over the

raw edge of the fabric when it

swings to the right.

For patterns with 5/8 inch seam

allowances; Feed the raw edge of

the fabric along the etched guide

line "1/2", then trim away the

excess fabric close to the stitch

ing.

B. Procedure:

•Overlock stitching is used for

seaming and finishing the cut

edge of knit fabrics, all in one

operation.

•This overlook stitch is especially

good for stretch fabrics such

I as double knit and jersey and

; will give a firm, neat edge finish.

Application of Rick-Rack

\wmi\

A. Topstitching/Rick-Rack

A decorative topstitch can be

produced with the rick-rack

stitch. Stitch around the structural

lines of the garment for a special

effect. Topstitch braid or a deco

rative inset to add an additional

creative flair.

B. Tapering/Rick-Rack

The rick-rack stitch may be tape-

red to form creative stems and

petals of flowers, embroidered

pictures and wall hangings. As in

tapering the zigzag, slowly turn

the stitch width lever from 0 to 5

and back to 0. A group of these

tapered rick-rack stitch will form a

bouquet-like effect.

C. Procedure:

•The elastic rick-rack stitch is a

zigzag line of stitching that is

desired so that seams may be

pressed open.

•Apply this stitch to areas of stress

on both wovens and knits.

• Use narrow width of zigzag as a

heavy duty triple stitch for seams

• Use medium and wide widths of

zigzag for overcasting edges of

seams, facings and hems of

heavier weight fabrics such as

terrycloth, and for attaching ela

Stic. Use also for decorative

stitching.

• Guide your fabric from the front

Do not pull or push as it will

cause poor stitching.

Page 20

Application of Decorative

Fun Patterns

A. Fun stitches Swan-Fish-Briar

The reverse stitch patterns pro

duce swan, fish, briar designs for

use on household linens and

children clothes. These reverse

stitch pattern can be used to sew

in hems as the scallop stitch.

The reverse stitch patterns can

also be used for topstitching

bindings and ribbons for decorative

effect. This is done in the same

manner that lace is applied with

the zigzag stitch. The straight

stitched edge of the reverse stitch

patterns on the left should be

sewn on the left edge of the

binding or ribbon. This decorative

effect can be used on towels

and placemats for a pleasant

appearance. The reverse stitch

patterns can also be corded for

stronger decorative edges on placemats and tablecloths. Simply place

four strands of pearl cotton, em

broidery floss or yarn under the

presser foot. A transparent foot

will help guide the cord evenly

while sewing the reverse stitch

patterns. The reverse stitch pat

terns can be sewn with two threads

through one needle for a more

effective decorative stitch. Simply

thread two sewing threads through

the upper threading system. A

larger needle should be used to

accommodate the two threads.

Use this decorative technique for

enhancing tablecloths, placemats,

napkins, and curtains,

10. BLINU ncivi o III v^> ■

Set machine as shown.

Fold material as shown and place

it under foot.

For a neater finish, it is preferable

to baste or iron hem before hand

Sew carefully, so that straigh

/

c

stitches are made on hem edgi

and slanting stitches pierce onl

one or two threads of fold.

NOTE: Narrow patterns may be

made by setting zigzag width to

4 3-2.

-33-

/

L__—--—J

Page 21

a; Correct seam.

(b; Needle is catching edge of fold

too much.

(C; Needle is not catching edge of

fold at all.

Elastic Blind Hem Stitch

For elastic materials, set machine

as shown and sew in the same

way as for normal blind hem

stitch.

11. STRETCH SEAMS

A ball point needle is essential.

Paper may be laid under knits for

smoother feeding.

(a Medium-weight fabrics

double knit, jersey.

Apply elastic triple stitch.

b Light-weight fabrics

Apply small zigzag. Reduce upper

and lower thread tension.

-35-

(c) For Very elastic fabrics

spandex (power net)

Use lapped or abutted seam.

Apply multiple zigzag.

Page 22

12. ZIPPER SEWING

Set machine as shown.

By using special zipper foot with

sliding adjuster, zipper sewing

can be easily done without

turning fabric.

Loosen screw (aj and set foot so

that needle comes into position

(b). Tighten screw.

Sew right side of zipper guiding

fabric carefully so that right side

teeth of zipper are parallel with

left edge of foot.

13. SHELL STITCHING

Silk, nylon organdy or similar

sheer fabrics are suitable.

Set machine as shown.

Fold edge of material. With

folded edge to left, place it under

presser foot.

Pull thread ends towards back

when starting sewing.

Re set foot so that needle comes

into position (c).

Sew left side of zipper in the

same way.

Make sure needle misses raw

edge of fold when it moves side

ways.

Page 23

l4. PIN TUCKING

Set machine as shown.

Far better appearance, use sheer

material and tighten lower thread

a little.

For twin needle threading see

p. 14.

Loosen presser foot thumb screw

and insert square cut of quilting

guide holder between screw

and foot.

Tighten screw.

15. QUILTING

Set machine as shown.

Baste layers of material to

prevent them from slipping out

as you sew.

Attach quilting guide and sew in

the same way as pin tucking.

Mark first line with pencil or

tailor's chalk, and sew.

From second line, just sew,

following seam of first line using

guide.

Interval between seams can be

adjusted by moving guide in

direction of arrow.

-T9-

-40-

Page 24

1(6. SCALLOPING

Sfet machine as shown.

Rut two pieces of cloth together

vtith right sides facing, and sew.

’ rim edge 0.3 cm (1/8") away

from stitching.

Make notches on seam edge at

Evenly spaced intervals.

17. MENDING

Patching

Set machine as shown.

Place the patch over the worn

part.

Sew along the edge of the patch

on the right side. Trim away the

worn part close to the seam on

back side.

Turn two pieces to right sides

out. Bring stitching line to very

edge by pushing seam edge

gently with your fingers, and

Dress.

Mending a Rip

Set machine in the same way

as for patching.

Sew the edges of tear together

first.

Then sew two more seams on

either side.

A piece of gauze can be placed

underneath to reinforce the rip.

-42

Page 25

18. APPLIQUE WORK

Set machine as shown.

19. EMBROIDERY

Set machine as shown.

Remove foot, and holder screw.

To avoid lower thread being

pulled up, reduce upper thread

tension.

Draw design on material to be

used as an applique and cut it out.

Place cut out on base material

and baste it.

Sew around outline with zigzag

stitch adjusting stitch length and

width according to shape and

size of cut-out and type of base

material.

To change direction at corners,

or to sew very small circles, stop

machine, positioning needle just

away from edge of cut-out, lift

presser foot and turn material.

Lower presser foot and continue

sewing.

Sew a few stitches at end with

zigzag width at 0.

This is to prevent unstitching.

J

r

V

Nee dle

No. 9

No. 11

No. 14

Thr ead

120 -100

100 -80

60- 50

For good embroidery, it is

important to use correct needles

and thread.

Use thin embroidery silk for

upper thread and a thinner silk

of same kind and color for

lower thread.

Trace your design on material

and center it in embroidery hoop.

J

Make sure material is taut.

Pull out lower thread by turning

handwheel towards you while

holding upper thread lightly.

Lower presser foot lifter.

Hold both threads and start

sewing along outline of design

with satin stitch.

Continue sewing guiding hoop

by hand.

To finish filling, sew several

stitches with zigzag width at 0.

Lay typewriting paper underneath

when embroidering sheer fabric.

Page 26

20. MAINTENANCE

Your machine requires regular

cleaning and oiling for satis

factory sewing performance.

A machine which is used for a

few hours a day needs to be

cleaned and oiled once a month.

Cleaning

Remove foot and needle.

Remove needle plate.

Brush off all dust and lint on feed

dog with cleaning brush.

Turn latches outwards.

Oiling

Use oil manufactured specially

for sewing machine use. Other

oils will eventually cause

mechanism to jam.

Apply one drop of oil to part of

shuttle where friction occurs.

Open face cover and apply oil in

the same way.

Be careful not to apply too much

oil or it may stain your material

and cause some sewing difficulty.

After oiling, run machine for 1-2

minutes to allow oil to penetrate

to every part.

Remove Top Cover:

Pull out spool pins and push

bobbin winding spindle to right.

Loosening screws a and b with

large screwdriver, then take off

top cover.

Remove shuttle race cover.

Remove shuttle Clean shuttle race

with a cleaning brush and a soft

cloth.

-45-

ly one drop of oil to lubricating points indicated by arrows.

Apply

-46-

Page 27

21. TROUBLE CHART

PROBLEM

Breaking lower

thread

Skipping stitches

Irregular stitches

Thread not wound evenly on the bobbin

or not drawn up correctly

Lower thread tension too tight

Lint stuck in the bobbin case and inside

the tension spring

Needle not fully inserted

Needle bent

Size or type of needle and thread not

suitable for the material

Incorrect upper threading

Too much oil on the hook

Incorrect size of needle for the material

Upper thread tension too loose

Incorrect lower tension

PROBABLE CAUSE

‘^ORRECTioiTl

P. 10, P. 1 5

P.12

Remove lint

and fluff with a

cleaning brush

P. 6^^

....

P. 6

P.16

P.13

P.46

P.16

P.20

P.12

""Problem

material

puckers

Upper or lower thread tension too tight

Stitch too long for material

PROBABLE CAUSE

Thread too thick

Incorrect threading of upper or lower thread

Breaking needle

Needle not correctly inserted

Needle bent

Needle clamp screw too loose

Upper thread tension too tight

Needle too fine for the material

Dials have been changed while the needle

was down in the material

Zigzag width set more than 2.5 while twin

needle was attached

lî trOUUIC to ...............

...............................- ---------------

Do not try to correct fault by yourself.,

CORRECTION

P.12, P.20

P.18

P.16

P.13, P.11

P. 6

P, 6

P. 6

P.20

P.16

P.18, P.22

P.14

-

The material not

fed correctly

Pattern selection dial not set correctly

Incorrect feed dog height

Lint stuck on the feed dog

.47-

P.17

P.12

P.45

Changing Light Bulb

Unplug the machine.

Open face cover as shown.

Remove bulb by unscrewing it

in counterclockwise.

Install a new bulb by screwing it

in clockwise.

Loading...

Loading...