Page 1

Instruction Book

MODEL 17TO

Page 2

SEWING MACHINE

Record in space provided below the Serial No.

and Model No. of this appliance.

The Serial No. is located Rear of arm.

The Model No. is located Rear of arm.

Serial No________________________

Model No. 1710

Retain these numbers for future reference.

Page 3

CONTENTS

1. NAMES OF PARTS......................................................................................2

2. ACCESSORIES............................................................................................3

3. BEFORE SEWING........................................................................................4

(1) Detaching extension table

(2) Connecting foot controller and power cord,.1...................................5

(3) Threading upper thread...................................................................... 6

(4) Drawing up lower thread......................................................................8

(5) Fabric, thread and needle table...........................................................9

4. STRAIGHT SEWING..................................................................................10

(1) Pattern selection dial..........................................................................10

(2) Stitch length dial.................................................................................10

(3) Double presser foot lifter...................................................................11

(4) Cloth guide...................................................................................... 12

(5) Adjusting thread tension....................................................................12

5. ZIGZAG STITCH SEWING........................................................................ 13

(1) Zigzag width control...........................................................................13

(2) Needle position control......................................................................13

(3) Thread tension for zigzag stitch........................................................13

6. OVERCASTING........................................................................................ 14

7. BLIND HEM STITCH..................................................................................15

8. MENDING...................................................................................................17

9. MAKING BUTTONHOLES.........................................................................18

(1) Changing presser foot

(2) Determine length.................................................................................19

(3) Determine width..................................................................................19

(4) Buttonhole sewing..............................................................................19

(5) Cutting buttonholes...........................................................................21

(6) Corded buttonholes

(7) Adjusting both side balance of buttonhole......................................22

10. SEWING ON BUTTON...............................................................................23

11. DROP FEED LEVER..................................................................................24

12. FOOT PRESSURE.....................................................................................24

13. OVERLOCKING........................................................................................ 25

14. APPLICATIONS OF THE ELASTIC OVERLOCKSTITCH........................26

15. APPLICATION OF RICK-RACK................................................................27

16. STRETCH SEAMS.....................................................................................28

17. ZIPPER SEWING

18. ROLL HEMMING........................................................................................30

19. SHELL STITCHING...................................................................................31

20. PIN TUCKING............................................................................................ 32

21. QUILTING...................................................................................................33

22. LAPPED SEAM SEWING..........................................................................34

23. APPLIQUE WORK................................................................................... 35

24. EMBROIDERY........................................................................................... 36

25. THICK CLOTH SEWING............................................................................37

26. TWIN NEEDLE THRE.ADING....................................................................38

.....................................................................................

...................................................................

.......................................................................

...........................................................................

4

18

21

29

VERY IMPORTANT

27. NEEDLE CHANGING AND SETTING........................................................39

28. WINDING BOBBIN

29. INSERTING BOBBIN............................................................................... 43

30. LOWER TENSION ADJUSTMENT.

31. CLEANING SHUTTLE CASE....................................................................46

32. MAINTENANCE.........................................................................................47

(1) Cleaning............................................................................................ 47

(2) Oiling....................................................................................................48

33. TROUBLE CHART

34. CHANGING LIGHT BULB.........................................................................50

....................................................................................

........................................................

..................................................................................

40

44

49

Page 4

-1-

Page 5

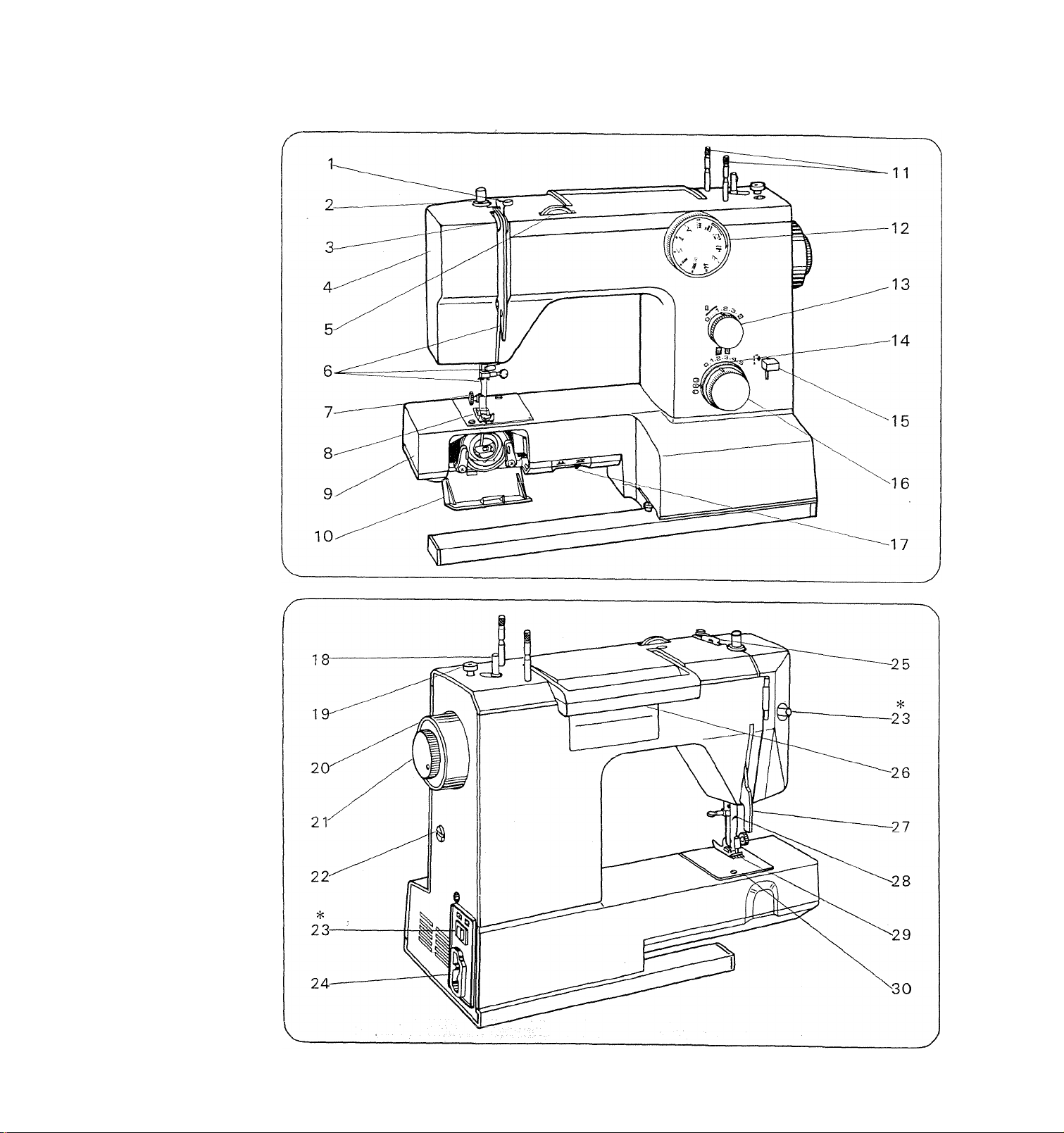

, NAMES OF PARTS

1. Thread guide for bobbin winding

2. Pressure regulator

3. Take-up lever

4. Face cover

5. Upper thread tension dial

6. Thread guide for upper threading

7. Presser foot thumb screw

8. Presser foot

9. Free arm

10. Shuttle cover

1 1. Spool pins (retractable)

1 2. Pattern selection dial

13. Stitch length dial

14. Needle position control

1 5. Reverse sewing lever

1 6. Zigzag width control

17. Drop feed lever

18. Bobbin winding spindle

19. Bobbin winding stopper

20. Handwheel

21. Stop motion knob

22. Special buttonhole adjustment

23. Switch *

24. Socket

25. Thread guide for upper threading

26. Handle

27. Presser foot lifter

28. Thread cutter

29. Feed dog

30. Needle plate

Specifications vary from country to country.

Page 6

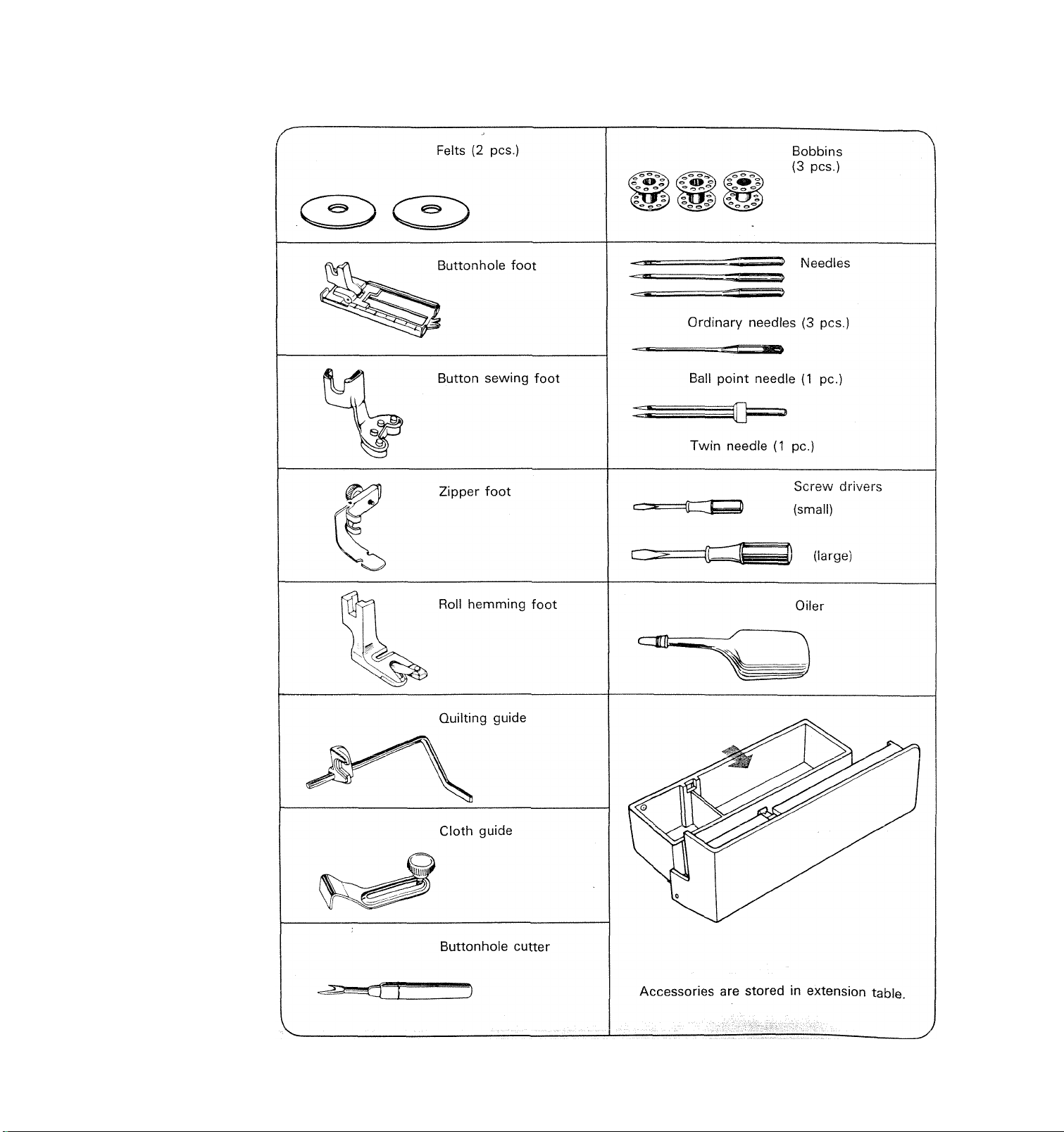

2. ACCESSORIES

-3-

Page 7

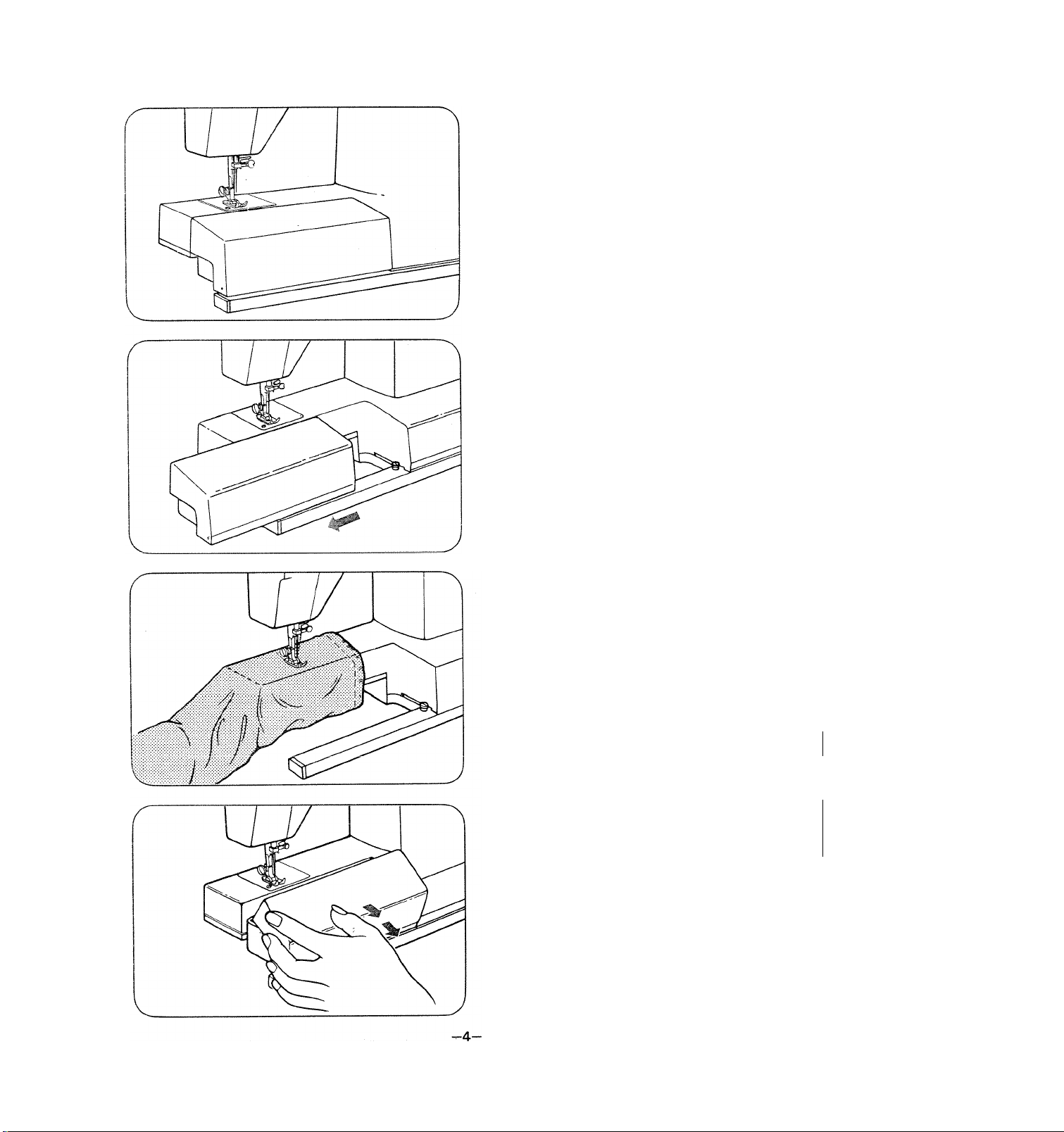

BEFORE SEWING

Machine is stored in flat-bed style which makes

„your work easier in ordinary sewing.

(1) Detaching extension table

Slide it off and the machine is used as a

free-arm model.

Free-arm is convenient to sew or embroider,

trousers, sleeves, cuffs of T-shirts, blouses,

etc.

Do vice-versa of above steps to attach

extension table.

To open lid of accessory box, push it open, as

illustrated.

...

<■

; ,

Page 8

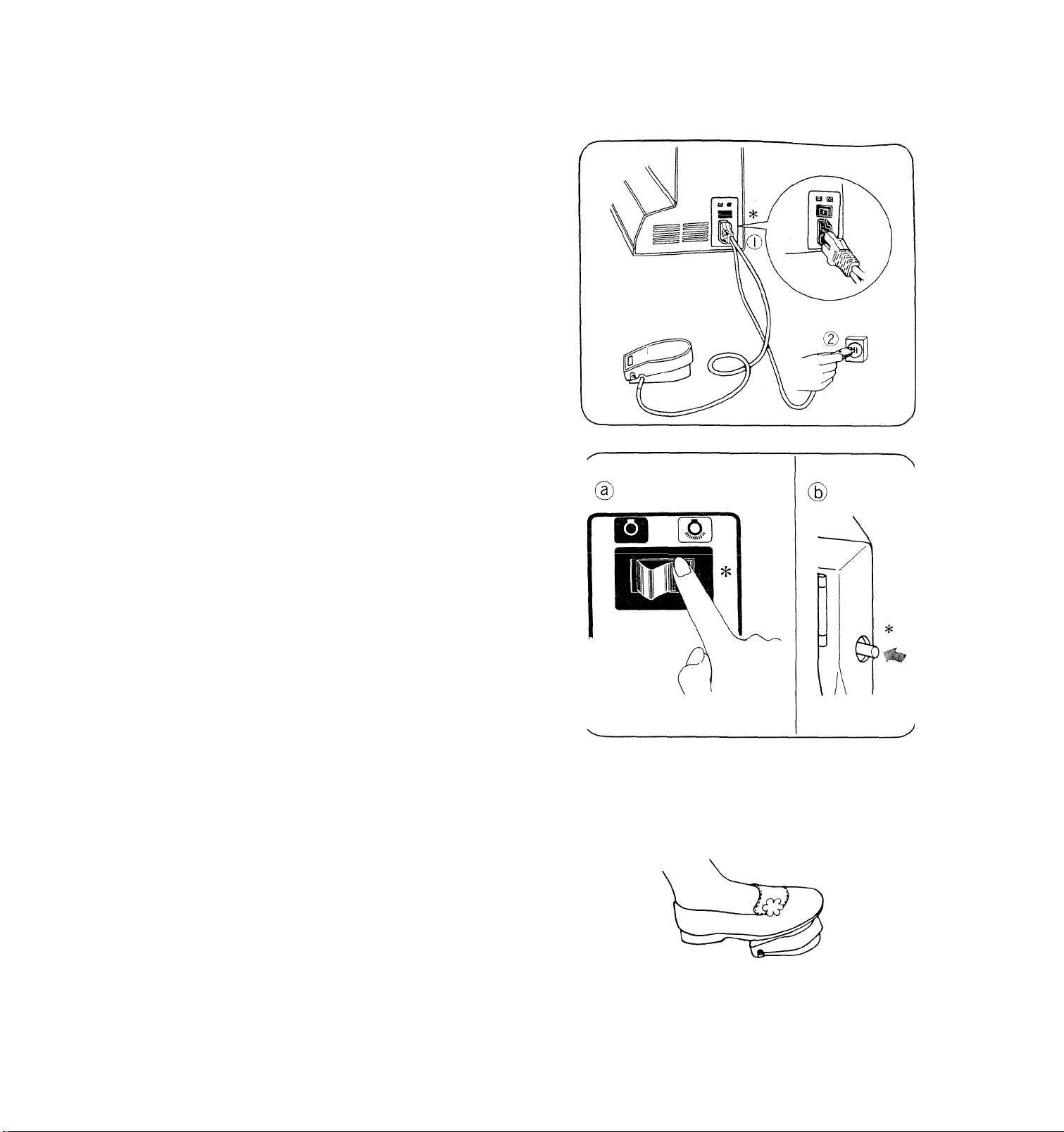

(2) Connecting foot controller and

power cord

Connect foot controller and power cord ©

Before plugging in your machine, be sure that

voltage is same as that of your machine,

(written on a plate at back of machine)

d) Switch on, put power on the machine and

turn on the sewing light.

(B) Push button to turn sewing light on and

off.

Always switch off or unplug machine when

not in use.

Specifications vary from country to country.

The more you press foot controller, the faster

the machine runs.

5-

Page 9

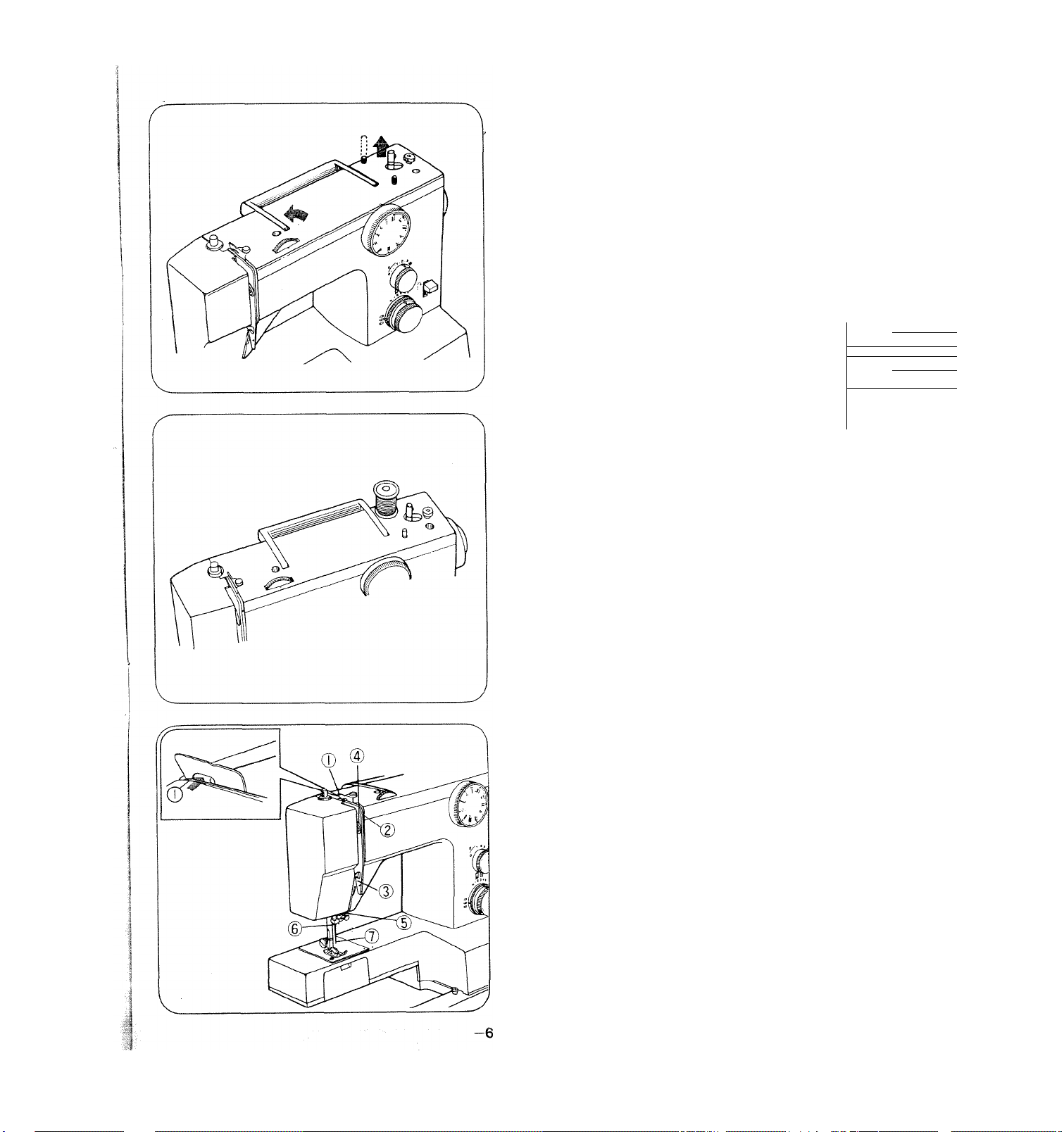

(3) Threading upper thread

Push back to fold handle.

Pull out spool pin and put a felt on spool pin.

Put a spool on spool pin.

TT-'T-'. TT-r-r-r-T-;

Raise presser foot lifter.

Raise take-up lever to the highest position by

turning handwheel towards you.

Thread following numbers ©-<7).

Pass thread through guide ®.

iii

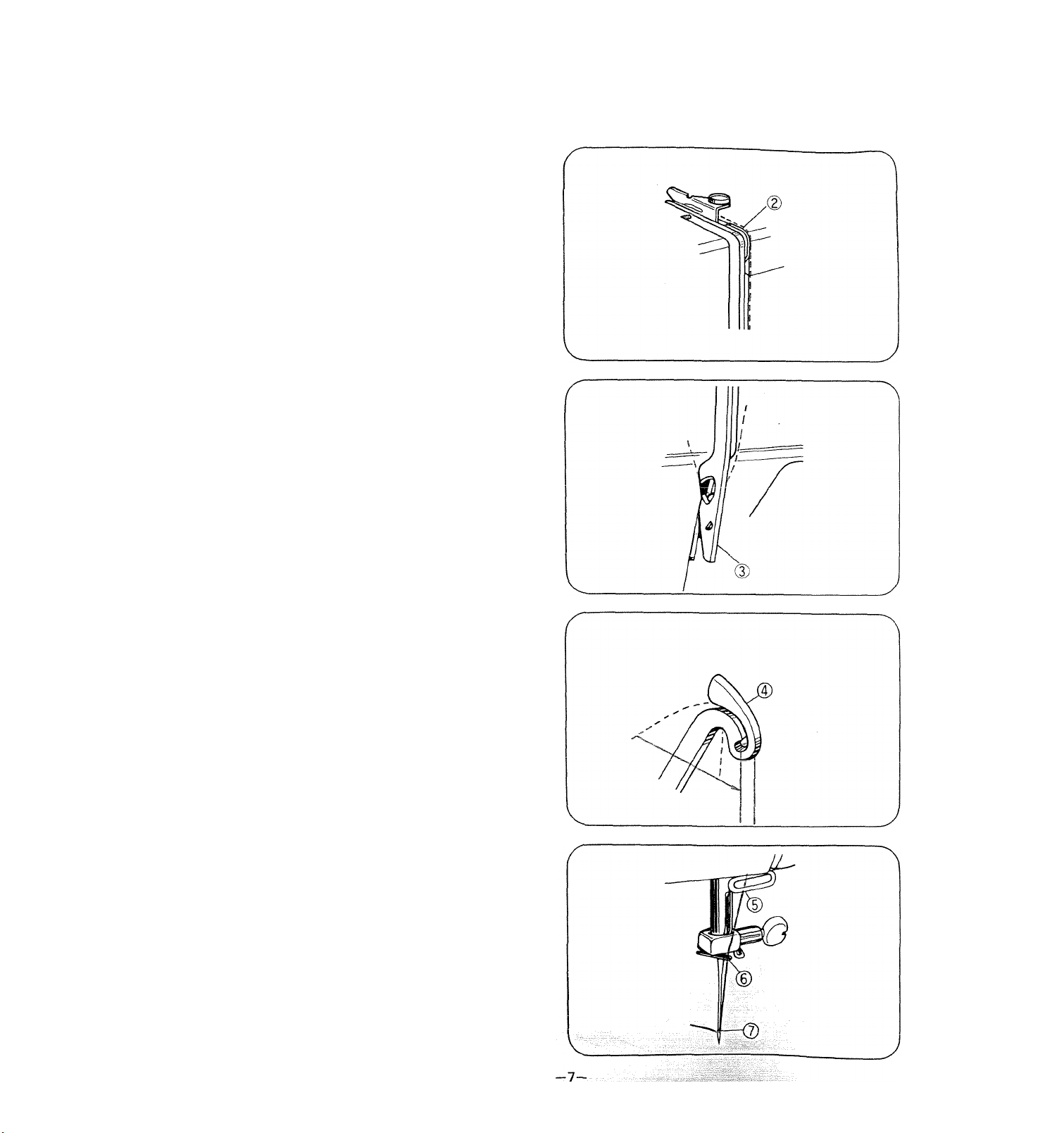

Page 10

Lead thread either side of tension disc

Hook it to guide (3) from down to upwards.

Thread take-up lever

Pass thread to guide © from right to left, and

guide ® (left one) then needle eye

Leave end of thread of about 15 cm (6").

Page 11

(4) Drawing up lower thread

Hold end of upper thread with left hand.

Turn handwheel slowly towards you until

needle moves down and up again.

Pull upper thread slowly and lower thread will

be brought up in a loop.

-----

------------------

------------------------------- ---------------------------

Ptil! r'ii !t hrvth tKrocaHc tr» taK/-\M+ 1 ^

1 VJH ' VJ I- k_/ 1. IW

place them together under presser foot on

left.

-.-Kv*-:-

/

-8

.

Page 12

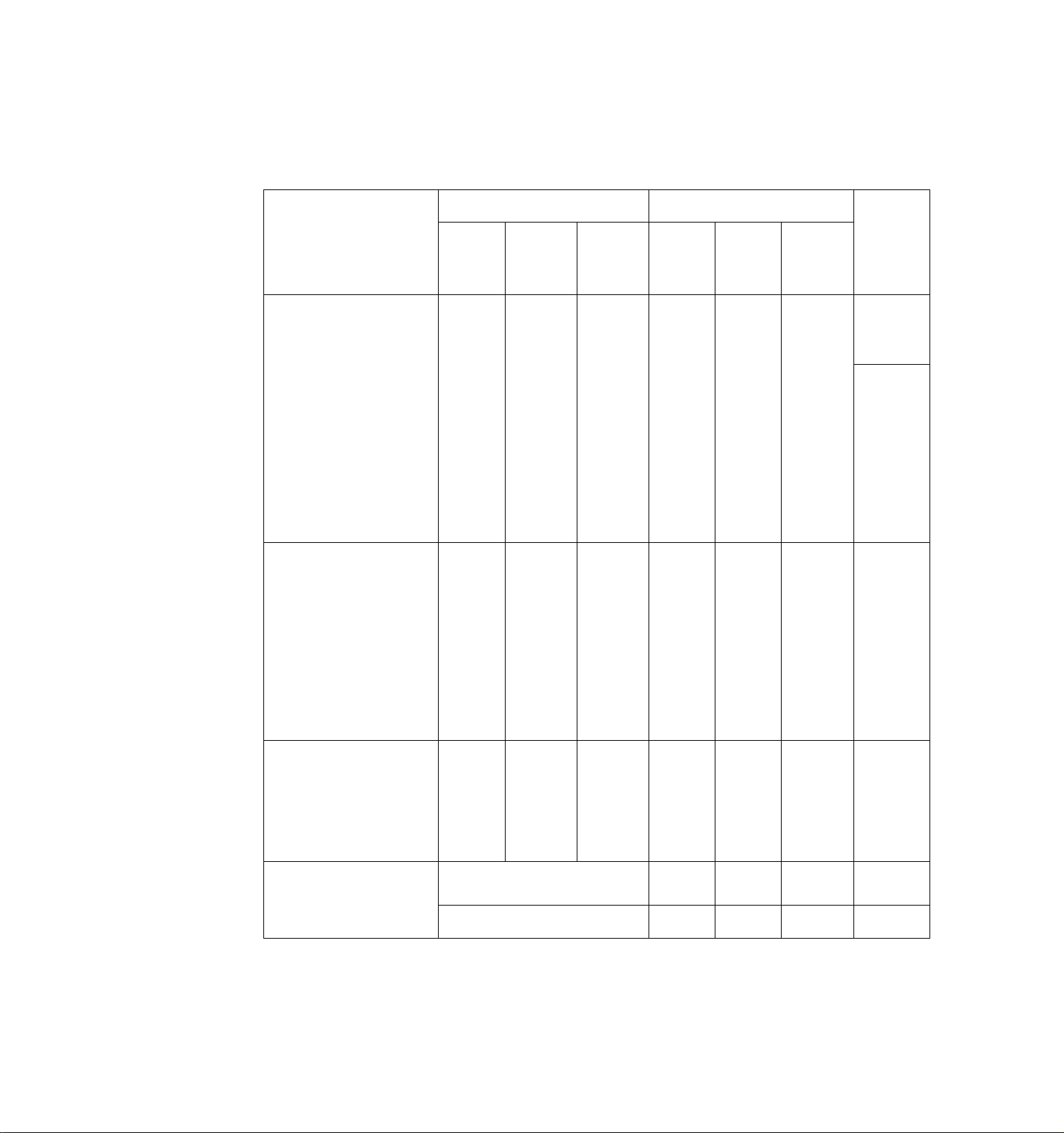

(5) Fabric, thread and needle table

FABRIC European Mercerized

VERY SHEER; Lace,

Voile, Chiffon, Net

SHEER; Blouse Crepe,

Lawn, Organdy, Taffeta

LIGHT-WEIGHT; Crepe,

wool, Brocade, Velvet

MEDIUM; Wool, Silk,

Linen, Velvetten, Cotton,

Faille, Terrycloth

HEAVY; Denim, Duck,

Sailcloth

EXTRA HEAVY;

Upholstery, Canvas,

Awning

[KNITS]

LIGHT-WEIGHT; Tricot

Power net

MEDIUM-WEIGHT;

Jersey, Double Knit,

Power Net

HEAVY-WEIGHT; Double

Knit, Power Net

FAKE-FURS, VELOURS

THREAD

Cotton

Cotton

70 60

50-70 60

30

50

30 50

30

30

50-70

Heavy

Duty

Heavy

Duty

60

30 50

30

50

Heavy

30

Duty

NEEDLE

Cotton

Covered

Polyester,

Silk, Nylon

Silk

Nylon

Silk

Nylon

Silk

Silk 80-90

C.C.Poly. 100

C.C.Poly.

Silk

Nylon

European

U.S. Size Point REMARKS

705 15x1 Style

65-70 9

65-70 9

75-80 11

11-14

16

120 19

70

9

Regular

Light

Ball

Silk Light

Nylon 70-80 9-10 to Medium

C.C.Poly. Ball

Silk

Nylon

80-90

11-14

C.C.Poly.

C.C.Poly. 90-100 14-16

Mfidii im

to Heavy

Ball

Ball or

Sharp

Loosen up

per tension

one or two

"

points

»

II

II

"

[LEATHER]

VINYLS FILMS

LIGHT-TO-MEDIUM-

WEIGHT

HEAVY LEATHER

[DECORATIVE TOUCHES]

TOP STITCHING

MACHINE EMBROIDERY

30

30

30

Silk twist

Size 50-

70

50

50

Heavy

Duty

C.C.Poly. 90

C.C.Poly.

90-100 14-16

C.C.Poly. 100-110 16-18

100-110 16-18 Regular

65-80

-9-

9-11 Regular

14

Wedge

Wedge

Wedge

■

Page 13

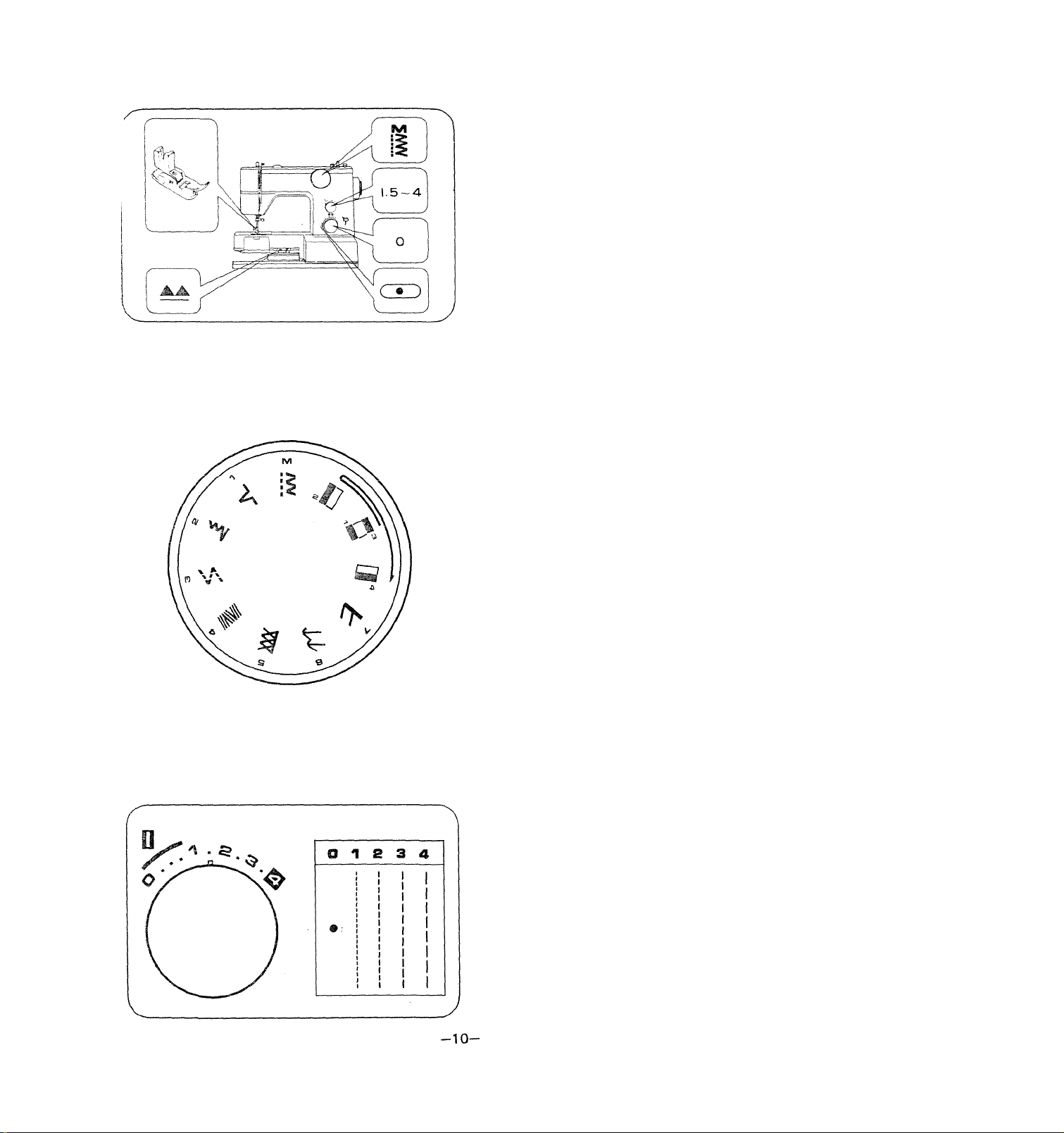

k STRAIGHT SEmUG

Set machine as shown.

(1) Pattern selection dial

Turn dial to choose pattern.

Dial can be turned either to right or to left.

M Straight & Zigzag Stitch

1 Blind Hem Stitch

2 Elastic Blind Hem Stitch

3 Multiple Zigzag

4-7

Super Automatic Reverse Stitches

□ Buttonhole

* Always make Sure needle is in the highest

position when operating dial.

-1?;

-T'

(2) Stitch length dial

For a longer stitch, turn dial in clockwise. For

a shorter stitch, turn it in counter-clockwise.

For normal sewing it is set between 2 and 3.

■■

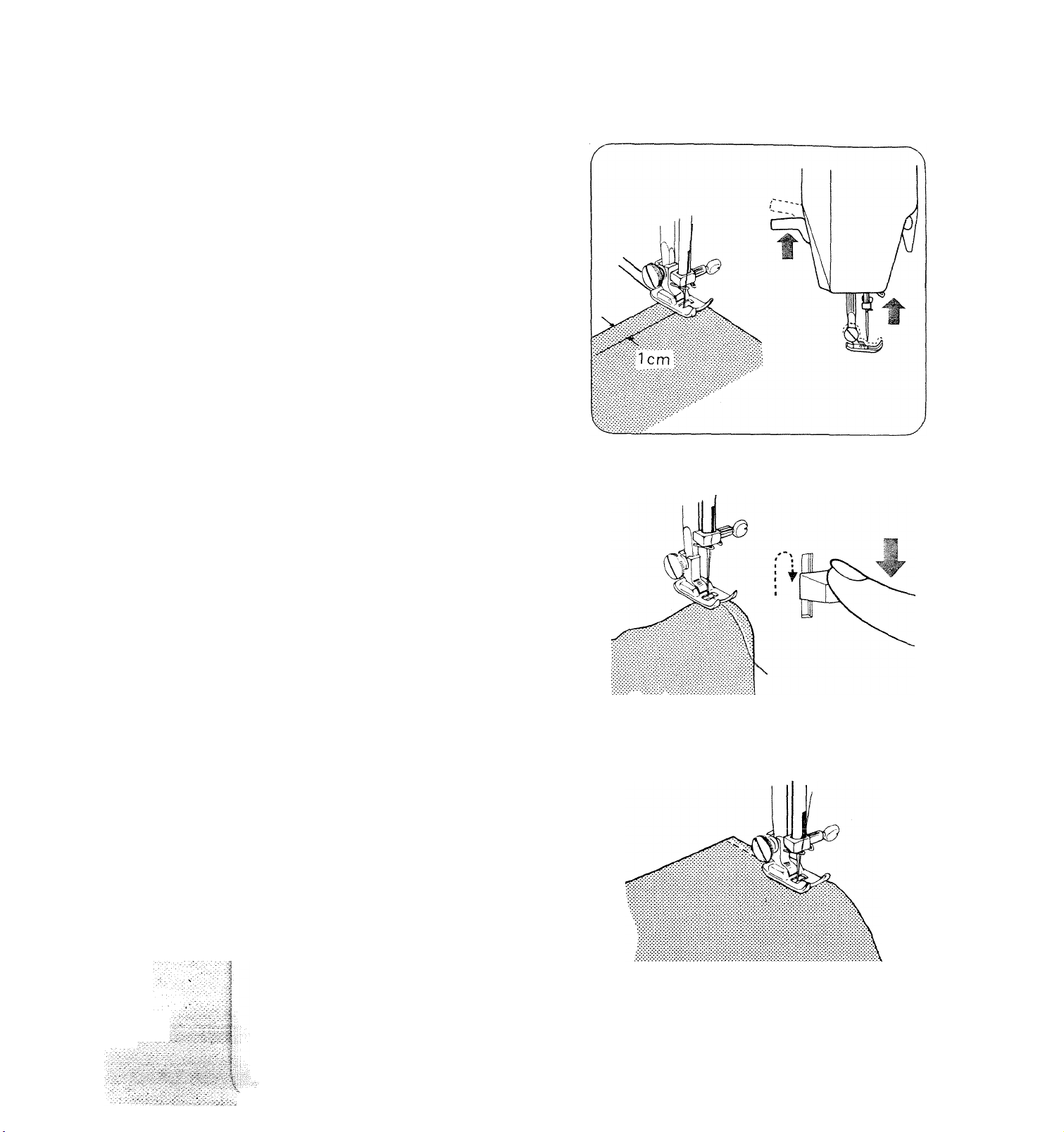

Page 14

Place fabric under foot about 1 cm (0.4")

inside the edge.

Lower presser foot lifter.

Important:

Hold on both threads during the sewing of

the first 3—4 stitches of the seam.

(2) Double presser foot lifter

In order to obtain wider gap when using very

thick materials, firmly push presser foot lifter

up as far as it will go.

To reinforce seam, sew backwards to the edge

of fabric by pushing down reverse sewing

lever.

Release lever and commence forward sewing

guiding fabric by hand as it is fed.

Never pull material.

-11-

..

J

Page 15

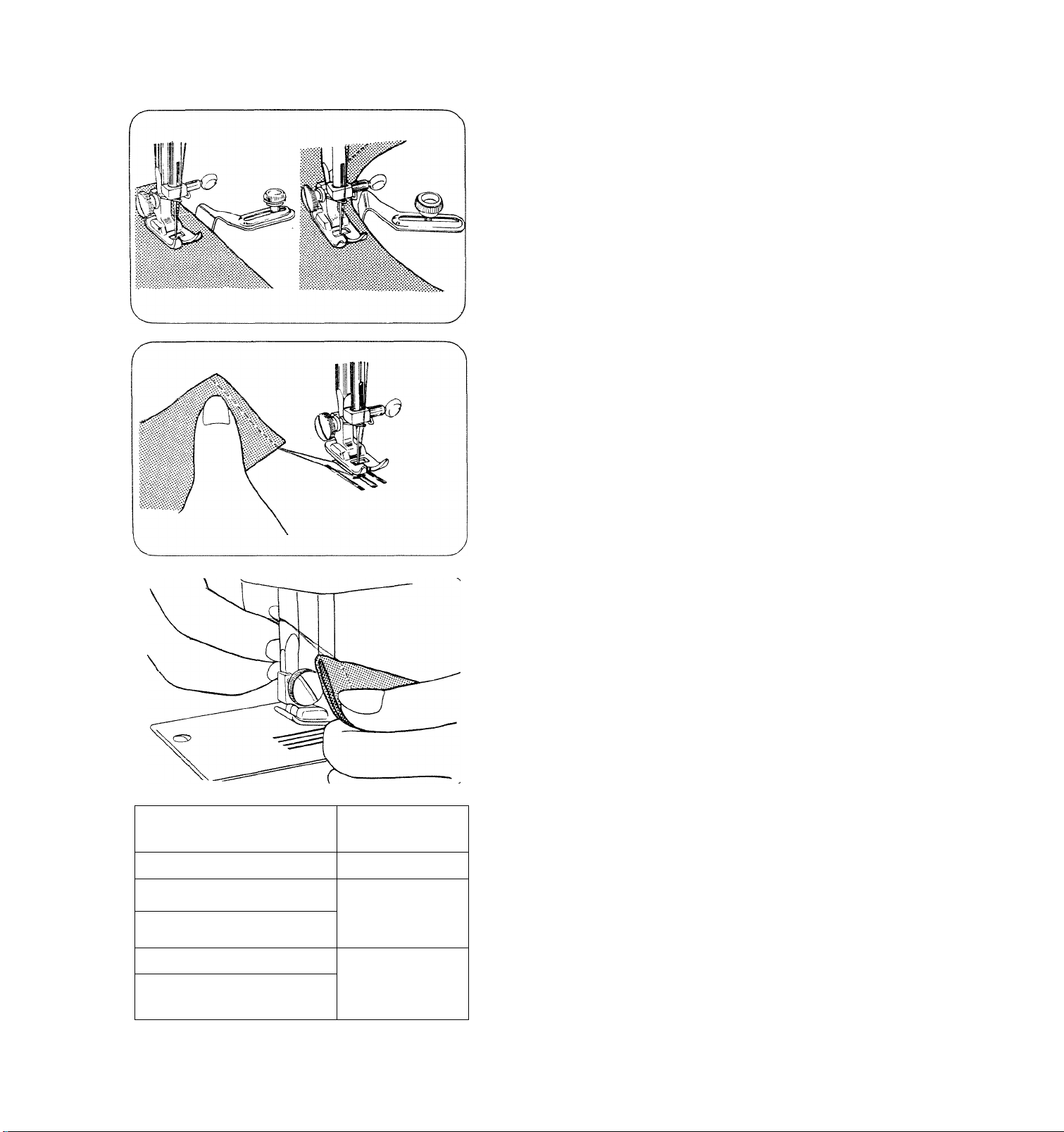

(4) Cloth guide

Use doth guide when sewing a long seam of

regular distance from edge of material.

Set guide in hole on arm, at right of needle

plate, and adjust distance.

Run machine with edge of fabric touching

guide.

Position cloth guide at an angle to sew a curved

seam.

Sew reverse stitches for reinforcement at end

of seam.

Draw fabric to left when sewing is finished.

(

................................

---------

(P---------(p

-------

............

Cut threads with thread cutter behind presser

bar.

(5) Adjusting thread tension

5

^

Test stitch performance on a scrap of material

you are going to use.

With correct tension ((a)), upper and lower

threads tension is equal and strong enough

to lock both threads in center.

If upper tension is too tight (loose), upper

(lower) thread lies straight along upper (lower)

surface of fabric ((B).(c)). Correct by turning

tension dial.

-12-

Page 16

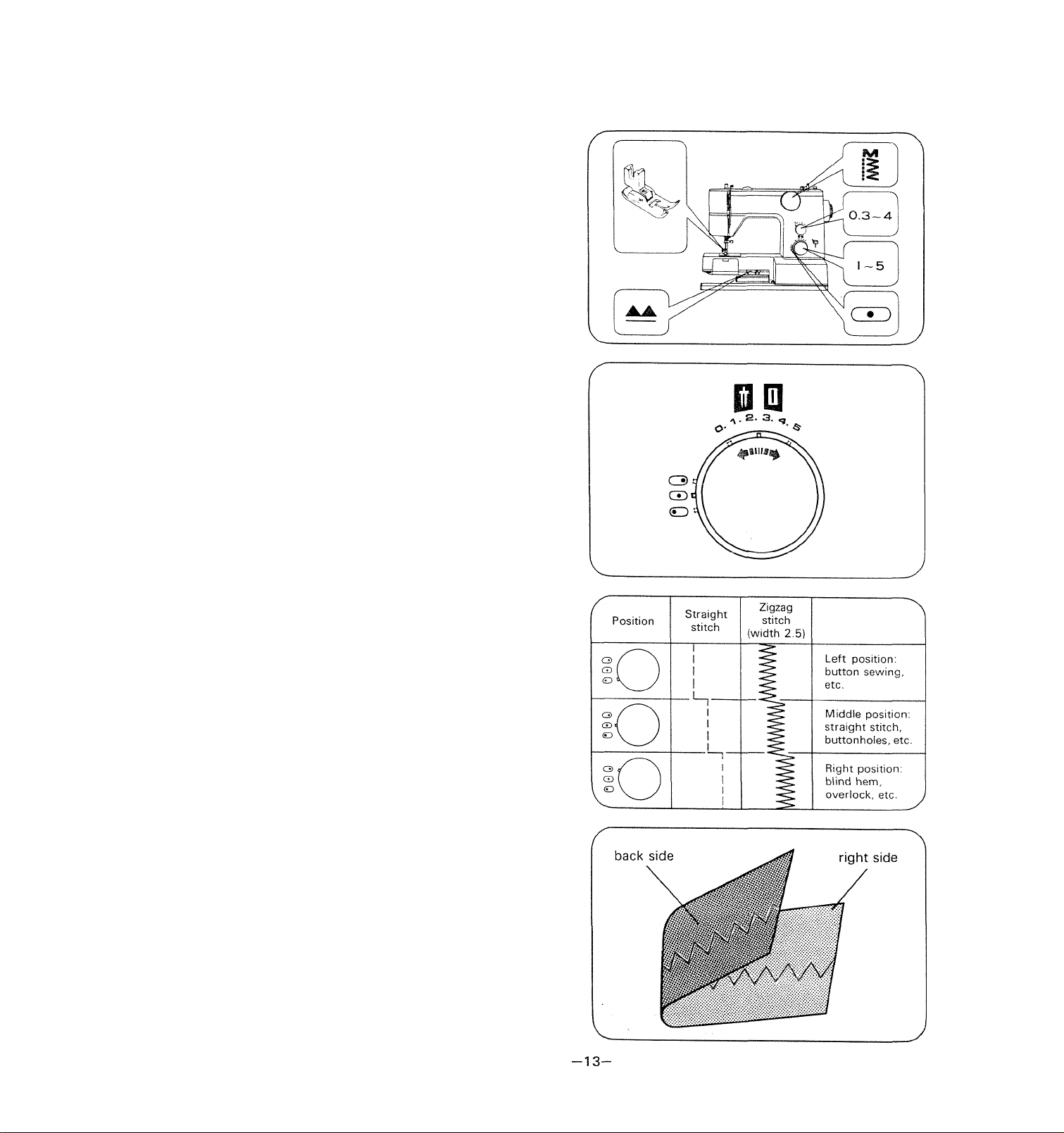

5. ZIGZAG STITCH SEWING

Set machine as shown.

To prevent seam ends unravelling, set machine

for straight stitch and sew in reverse at

beginning and ending of seam.

(1) Zigzag width control

Set control at required number.

Larger the number, wider the stitch.

Set it at 0 for straight sewing.

Make sure needle is in upper position when you

set control.

(2) Needle position control

Needle position can be changed by turning

needle position control.

When selecting position, make sure needle is

in upper position to avoid tearing material or

bending needle.

(3) Thread tension for zigzag stitch

Better-looking zigzag stitching requires less

upper tension than straight stitching.

Loosen upper tension slightly.

Page 17

5. OVERCASTING

For light weight material:

Set machine as shown.

'•r-r-r-

w-

Sew carefully so that all stitches on right side

are flush with edge of fabric.

For thick and elastic material:

Set machine as shown.

Sew in the same way as above.

-m-.

■A®-

Page 18

7. BLIND HEM STITCH

Set machine as shown.

Fold material as shown and place it under

foot.

For a neater finish, it is preferable to baste or

iron hem before hand.

Sew carefully so that straight stitches are made

on hem edge, and slanting stitches pierce only

one or two threads of fold.

-15-

mwim

Page 19

right side

rntm

wrong side

I<* ^

• 1

t '<

(a) Correct seam.

(g) Needle is catching edge of fold too much.

IMppHIa i<i nnt patr.hinn pHnp nf fnid pt p!1

. ~3

---

CJ -

Elastic blind hem stitch

For elastic materials, set machine as shown

and sew in the same way as for normal blind

hem stitch.

ii:

Page 20

8. MENDING

{1) Patching

Set machine as shown.

Place the patch over the worn part.

Sew along the edge of the patch on the right

side. Trim away the worn part close to the

seam on back side.

(2) Mending a rip

Set machine in the same way as for patching.

Sew the edges of tear together first.

Then sew two more seams on either side.

A piece of gauze can be placed underneath to

reinforce the rip.

-17-

*.*

.........................

.................................................................................................................................................................................... • .jfc►

S

. Vji 1 jM j, TJ 9 Ji yji ^4 4a -Mu

............

.'i if 4 J i ^ I i ^ i 4

Page 21

MAKING BUTTONHOLES

Set machine as shown.

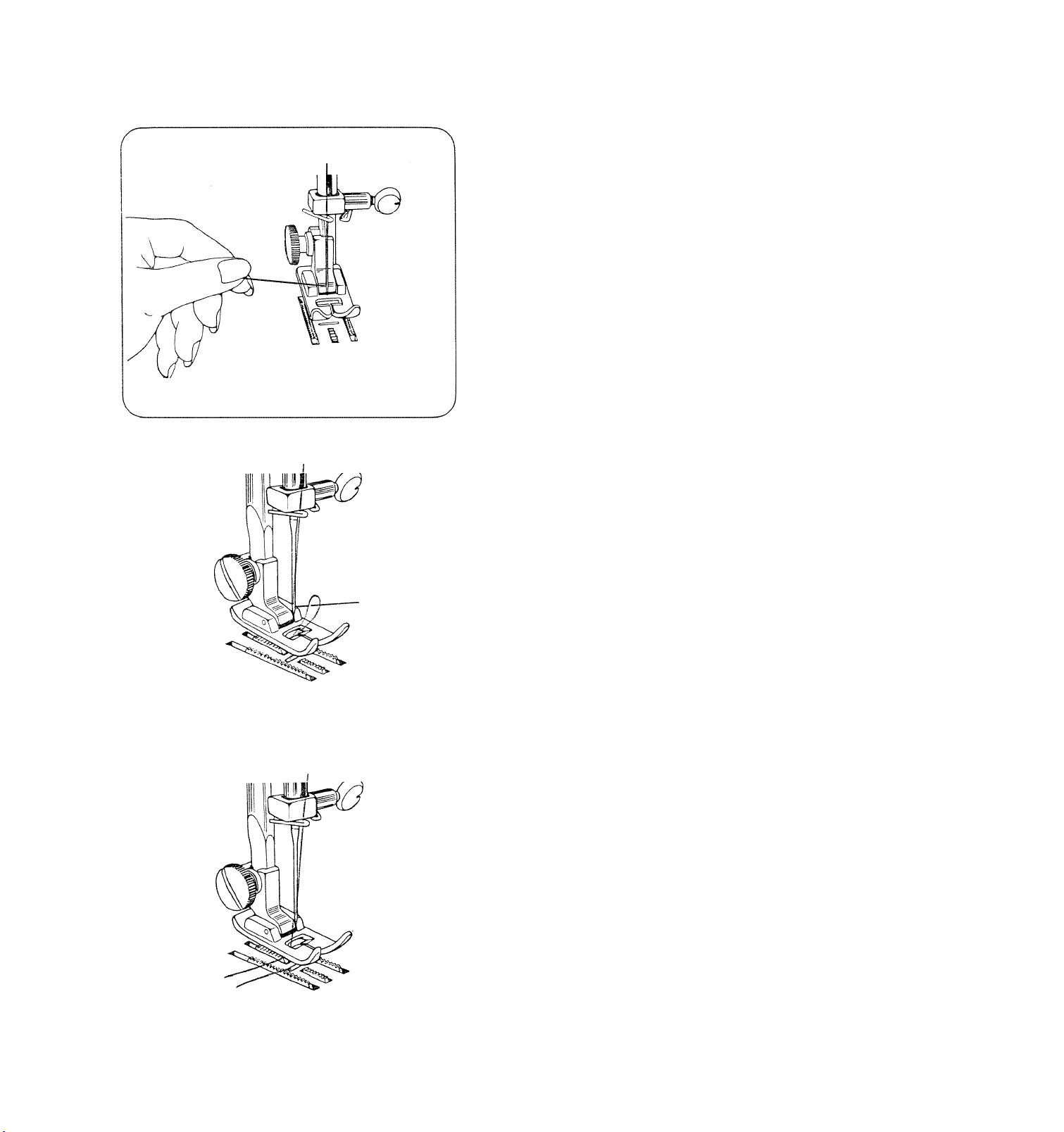

(1) Changing presser foot

Raise presser foot lifter ®.

Set needle in the highest position by turning

handwheel towards you

Remove foot by loosening screw with

screwdriver.

Replace new foot and tighten screw.

-18-

Page 22

(2) Determine length

Measure diameter and thickness of

button

and add 0.3cm (1/8") for bar tacks.

Mark buttonhole size on material.

(3) Determine width

Determine width according to diameter of

button, its thickness, and kind of material.

Completely push back sliding part @ of

buttonhole foot.

Place .materia! under foot so that marking of

buttonhole passes through center of foot and

arrow ® of foot indicates beginning line of

marking.

marking

a:

(4) Buttonhole sewing

Bar tacking: Set pattern selection dial to 1 (CTi

and sew 5-6 stitches.

■ -- -■ :

r

-19-

Page 23

Left side: Change pattern to 2(2!]). Sew left

, side from front to back until it reaches end line.

Remember the point where arrow shows so

that it is not necessary to mark end lines for

all buttonholes.

Bar tacking: Change pattern to 3

and

sew 5-6 stitches.

Right side: Change pattern to 4 ([(“) and sew

right side until it catches first bar tack.

Quick finish: To prevent unstitching, set zigzag

width at 0 and proceed for a few stitches.

-20-

Page 24

(5) Cutting buttonholes

Stick a needle through bar tacks to prevent

over-cutting.

Cut buttonhole along center with buttonhole

cutter.

(6) Corded buttonholes

For stretch fabrics such as knits, a corded

buttonhole is effective to keep finished

buttonhole in shape.

Hook filler cord on top spur and lead ends of

cord under foot, pull taut, and hook them to

bottom notches as shown.

Proceed with stitching as for regular

buttonholes.

When buttonhole is completed, pull filler cord

ends so that loop on the other end disappears

into buttonhole stitching.

Thread ends of cord to reverse side and tie, or

cut both ends of cord.

Page 25

(7) Left and right side balance of

, buttonhole

Stitch density on right and left sides of

buttonhole can be adjust by buttonhole balance

control dial.

If the stitches on the right side of the buttonhole

are too close together, turn the dial to the left

( + )■

A

y

* Turning dial to left opens right side and

closes left side.

If the stitches on the right side of the buttonhole

are too open, turn the dial to the right { —).

^Turning dial to right closes right side and

opens left side.

II

-22-

Page 26

10. SEWING ON BUTTON

Set machine as shown.

Position a button and material under foot. When

needle comes to left side of stitch, lower foot.

Raise needle and adjust zigzag width so that

needle comes to right hole of button.

Run machine at medium speed and sew 5-6

zigzag stitches.

Stop machine when needle is in upper position.

(a) Set zigzag width control to 0 and sew 3-4

stitches to prevent unstitching.

(b) Draw out work and cut off threads.

Draw thread ends through to wrong side and

tie a knot.

Page 27

DROP FEED LEVER

V

12. FOOT PRESSURE

The lever is in the right side of shuttle cover.

For normal sewing, move the lever to .AA

position.

To lower feed dog, move the lever to aa

position.

This position is used for button sewing, darning

and embroidery.

Normal sewing: Usually for straight sewing

;.iy£.uy ocjvviliy, picooujc piii oi iwuiu uc

r~\ I T~l . f' l-l » 1 ! «-1 t-\

maintained in the lower position. While the

advancement is normal, drop feed lever is on

position.

Thin or delicated fabric sewing: Because lighter

pressure is desirable for perfect sewing of fine

silk or weak fabric, pressure button should be

adjusted in the middle.

Loosen pressure with outer ring J and then

push pressure pin (a half way towards the

bottom.

Oversewing and embroidering: To be able to

move fabric freely in case of darning,

mending and embroidering, loosen pressure

pin @ by pushing outer ring (B,., move drop

m--

Page 28

13. OVERLOOKING

Overlooking stitches make it possible to sew

and overcast seams at the same time.

Set machine as shown.

(a) For medium, thin material

(b) For medium, thick material

Put two pieces of cloth together with right

sides facing and sew.

To prevent edges from fraying, sew so that

right side stitches drop outside the edge of

material.

In some cases overlooking stitches can be used

for overcasting.

-25-

Page 29

^4. APPLICATIONS OF THE ELAS

TIC OVERLOCKSTITCH

This stitch is very effective for overcasting,

édgestitching, etc, on knits and very stretchy

fabrics, also, for decoration.

TOPSTITCHING

A decorative topstitch can be produced with

the elastic edging stitch. Stitch around the

structural lines of the garments for a dramatic

effect. Topstitch a braid or decorative inset

with the elastic edging to add an additional

decorative flair.

Pattern: AA

Length: 5

Width: 5

Feed Dog: Up

Pressure: Normal

Foot: Embroidery

Needle Position: L or R

EDGING

As with the stretch blind hem, the elastic

edging stitch can be used for a decorative

edge on place mats, napkins and tablecloths.

Proceed as you would with the stretch blind

hem stitch, but use the elastic

edging stitch instead.

Pattern: AA

Length: 5

Width: 3-5

Feed Dog: Up

Pressure: Normal

Foot: Embroidery

Needle Position: M, L or R

-26-

Page 30

15. APPLICATION OF RICK-RACK

A. Topstitching/Rick-Rack

A decorative topstitch can be produced with

the rick-rack stitch. Stitch around the struct

ural lines of the garment tor a special effect.

Topstitch braid or a decorative inset to add

an additional creative flair.

B. Tapering/Rick-Rack

The rick-rack stitch may be tapered to form

creative stems and petals of flowers, embro

idered pictures and wall hangings. As in

tapering the zigzag, slowly turn the stitch

width lever from 0 to 5 and back to 0. A

group of these tapered rick-rack stitch will

form bouquet-like effect.

C. Procedure:

• The elastic rick-rack stitch is a zigzag

line of stitching that is desired so that seams

may be pressed open.

■ Apply this stitch to areas of stress on both

wovens and knits.

• Use narrow width of zigzag as a heavy duty

triple stitch for seams.

• Use medium and wide widths of zigzag for

overcasting edges of seams, facings and

hems of heavier weight fabrics such as

terrycloth, and for attaching elastic. Use

also for decorative stitching.

• Guide your fabric from the front. Do not

pull or push as it will cause poor stitching.

Page 31

STHETCH SEAMS

A ball-point needle is essential.

Paper may be laid under knits for smoother

feeding.

(a) Medium-weight fabrics-

double knit jersey.

Apply elastic triple stitch.

(g) Light-weight fabrics

Apply small zigzag. Reduce upper and lower

thread tension.

© For Very elastic fabrics-

spandex (power net)

Use lapped or abutted seam.

Apply multiple zigzag.

Page 32

17. ZIPPER SEWING

Set machine as shown. '

By using special zipper foot with sliding adjuster,

zipper sewing can be easily done without

t! irninn faKrin

• *" 'V/.

Loosen screw @ and set foot so that needle

comes into position Tighten screw.

Sew right Side of zipper guiding fabric carefully

so that right side teeth of zipper are parallel

with left edge of foot.

Re-set foot so that needle comes into position

fC,i,

Sew left side of zipper in the same way.

Page 33

ROLL HEMMING

Set machine as shown.

@ With straight stitch

With zigzag stitch

.....

mm

■mmmmmmmmmmssi

Make 0.3cm(1/8") double fold for about 5cm

(2") at very edge of material, and crease it.

Sew twice at 0.6cm(1/4") from edge.

Draw out work and leave about 15cm(6") of

thread.

Place material under presser foot and guide

edge into scroll, pulling six thread ends towards

back.

Sew a few stitches as shown.

Keep guiding material holding raw edge adout

0.6cm{1/4") in front of foot.

-m

Page 34

19. SHELL STITCHING

Silk, nylon organdy or similar sheer fabrics are

suitable.

Set machine as shown.

\

V

Fold edge of material. With folded edge to

left, place it under presser foot.

Pull thread ends towards back when starting

sewing.

Make sure needle misses raw edge of fold

when it moves side ways.

r

Page 35

20. PIN TUCKING

Set machine as shown.

For better appearance, use sheer material and

-tighten lower thread a little.

For twin needle threading, see p. 36.

Loosen presser foot thumb screw and insert

square cut of quilting guide holder between

screw and foot.

Tighten screw.

Mark first line with pencil or tailor’s chalk, and

sew.

From second line, just sew, following seam

of first line using guide.

Interval between seams can be adjusted by

moving guide - in direction of arrow.

Page 36

21. Q UI LT IN G

Set machine as shown.

Baste layers of material to prevent them from

slipping out as you sew.

Attach quilting guide and sew in he same way

as pin tucking.

22

-33-

Page 37

22. LAPPED SEAM SEWING

Set machine as shown.

Place one piece of fabric over another

according to the width of stitch size.

@ For non-fray fabrics.

(g) For easy to fray fabrics.

Page 38

23. APPLIQUE WORK

Set machine as shown.

Draw design on material to be used as an

applique and cut it out.

Place cut-out on base material and baste it.

Sew around outline with zigzag stitch adjusting

stitch length and width according to shape

and size of cut-out and type of base material.

To change direction at corners, or to sew very

small circles, stop machine, positioning needle

just away from edge of cut-out, lift presser foot

and turn material.

Lower presser foot and continue sewing.

Sew a few stitches at end with zigzag width

at 0.

This is to prevent unstitching.

Page 39

.yiBHOiDERY

Needle

No. 9

No. 11

Thread

120-100

100-80

Set machine as shown.

Remove foot, and holder screw.

To avoid lower thread being pulled up, reduce

upper thread tension.

For good embroidery, it is important to use

A

correct needles and thread.

Use thin embroidery silk for upper thread and

a thinner silk of same kind and color for lower

thread.

Trace your design on material and center it in

embroidery hoop.

Make sure material is taut.

Wi-

No. 14

60—50

J

Pull out lower thread by turning hand wheel

towards you while holding upper thread

lightly.

Lower presser foot lifter.

Hold both threads and start sewing along

outline of design with satin stitch.

Continue sewing guiding hoop by hand.

To finish filling, sew several stitches with zigzag

width at 0.

Lay typewriting paper underneath when

embroidering sheer fabric.

-36-

Page 40

25. THICK CLOTH SEWING

(particularly denim)

For thick fabric sevv'ing, it is' important to

respect scheme.

You remark that the sewing is set flat. Needle

is perpendicular on the seam and penetrates

cloth properly.

Improper setting causes slips and break of

needle. For sewing of importât thick cloth,

sew gently maintaining the cloth perfectly.

Breaking needle is not mechanical problem

but simply misuse.

it ;

Page 41

i6. TWIN NEEDLE THREADING

Thread in the same way as normal threading,

except at points (D, (|) and ©.

At point®, pass threads separatly to right and

left of tension disc.

At guide®, pass one of threads to right guide

and the other at left guide.

At point®, thread from right guide should be

lead to right needle eye, and from left guide to

left needle eye.

IR"\

Leave ends of threads of about 1 5

oi I I \\j } .

When using twin needle sewing be sure zigzag

width control setting between 0 and 2.5, and

needle position control at r~Tl . If zigzag width

control above 2.5 or needle position control

at (« ) , ( 5) this will cause needle break.

Page 42

27. NEEDLE CHANGING-AND SETTING

Set needle in the highest position by turning

handwheel towards you.

Loosen needle clamp screw and remove

needle.

With flat face away from you, insert a new

needle into groove of needle bar.

Push needle until it reaches stopper @ and

tighten needle clamp screw firmly.

Always use a straight needle with a sharp point.

Using defective or worn needles not only

causes stitch skipping, breakage of needles or

snapping of thread; it also can damage hook

and needle plate.

Proper needle

-5Q-

straight shaft

sharp point

cm

/ X

Page 43

28. V¥lNDiNG BOBBIN

Set needle in the highest position by turning

handwheel towards you.

Open shuttle cover.

V.

Open latch of bobbin case and take it out.

Close latch of bobbin case and bobbin comes

out easily.

y-;

iW

...'V

Page 44

Push back to fold handle.

Pull out spool pin.

Put a spool on spool pin.

Draw thread from spool pin through thread

guide and pretension device, following numb

ers © and (D.

Wind thread clockwise around bobbin several

times.

Push bobbin on to spindle.

Holding handwheel with your left hand

disengage handwheel by unscrewing stop

motion knob.

-41-

Page 45

Pnch HnHHln tn rinht anH r»roco rir\\A/ri

^ »-fvwMiii fcw It^iik V4ll\-4 \_4V^VVII

controller.

Machine stops automatically when winding

is full.

Push bobbin to left.

Take off bobbin from spindle and cut thread.

Retighten stop motion knob.

If bobbin is wound unevenly as shown, open

face cover and loosen set-screw of the guide

for bobbin winding, by using screw driver and

adjust height.

Page 46

29. IMSERTilMG BOBBIN

e„- *i

Place bobbin in its case with thread

in direction of arrow.

Guide thread into slot (a) of bobbin case.

running

Pulling thread to left, bring it under tension

spring then to delivery eye (g).

Raise needle in the highest position.

Leave end of thread of about 10 cm (4") from

bobbin case.

Take hold of latch and push bobbin case into

hook.

Release latch when bobbin case is fully inserted.

•fri, '«. -i

Page 47

30. LOWER TEIMSION ADJUSTMENT

Push latches towards outside.

In case of skipping stitch or loop stitch, your

machine is not out of order.

To check bobbin thread tension, suspend

bobbin, bobbin case and shuttle all together

by thread as illustrated.

Move back and forth vertically (like yo yo).

always use original bobbin.

Then it is easy to adjust upper tension on the

numbers 4, 5, 6.

Remove shuttle cover

Remove shuttle

Sfe-:

bobbin and

bobbin case

shuttle

all of them descend with light resistance

-44-

Page 48

For tension adjustment, turn screw using small

screwdriver.

attach shuttle

attach shuttle cover

push latches towards inside

-45-

Page 49

31. CLEANING SHUTTLE CASE

Thread stuck between shuttle and shuttle case

causes sudden rapid running or sudden stop

machine.

In this case you should proceed as follows:

© Lift presser foot and remove bobbin case.

© Push latches® towards outside and remove

shuttle cover and shuttle with finger.

(3) Clean shuttle and shuttle case and assemble

them in its place.

iiil'l

■ ■ ■ ■ ■ ............ ■ ; ■ ■ ■ ■ ■ ■ ■ ■ ■ ■

-46-

Page 50

32. MAINTENANCE

Your machine requires regular cleaning and

oiling for satisfactory sewing performance.

A machine which is used for a few hours a day

needs to be cleaned and oiled once a month.

(1) Cleaning

Remove foot and needle.

Remove needle plate.

Brush off all dust and lint on feed dog with

cleaning brush.

Turn latches outwards.

Remove shuttle cover.

Remove shuttle. Clean shuttle race with a

cleaning brush and a soft cloth.

_y

-47..

Page 51

(2) Oiling

Use oil manufactured specially for sewing

machine use. Other oils will eventually cause

mechanism to jam.

Apply one drop of oil to part of hook where

friction occurs.

v_

Open face cover and apply oil in the same

way.

Be careful not to apply too much oil or it may

stain your material and cause some sewing

difficulty.

After oiling, run machine for 1-2 minutes to

allow oil to penetrate to everv oart.

Remove top cover by loosening screws @

(b) with large screwdriver.

and

■Si:'.

Apply one drop of oil to lubricating points indicated by arrows.

a;/-;..

"V

Page 52

33. TROUBLE CHART

\ . :í-

PROBLEM

Breaking lower

thread

Skipping stitches

Irregular stitches

The material not

fed correctly

PROBABLE CAUSE CORRECION

Thread not wound evenly on the bobbin or not drawn

up correctly

Lower thread tension too tight

Lint stuck in the bobbin case and inside the tension

spring

Needle not fully inserted P. 39

Needle bent

Size or type of needle and thread not suitable for the

material

Incorrect upper threading P. 6

Too much oil on the shuttle

Incorrect size of needle for the material P. 9

Upper thread tension too loose P.12

Incorrect lower tension P. 44

Pattern selection dial not set correctly

Incorrect feed dog height

P. 8, P.40

P. 44

Remove lint

and fluff with a

cleaning brush

P. 39

P. 9

P. 48

P. 10

P. 24

Lint stuck on the feed dog P. 47

The material

puckers

Breaking needle

*lf trouble is still apparent in the machine, please consult your nearest dealer.

Do not try to correct fault by yourself.

For adjusting the tension of any belts, please do not try to adjust it by yourself but contact

your nearest dealer.

Upper or lower thread thread tension too tight P. .44, P. 12

Stitch too long for material P. 10

Thread too thick P, 9

Incorrect threading of upper or lower thread

Needle not correctly inserted

[SJooHjp h©nt

Needle clamp screw too loose

Upper thread tension too tight

N66UI6 too fin© for the mStSnai P. 9

Dials and levers have been changed while the needle

was down in the material

Zigzag width set more than 2.5 while twin needle was

attached

P. 6, P. 43

P. 39

P. 39

P. 39

P. 12

P. 10, P. 13

P. 38

-49-

Page 53

4. CHANGING LIGHT BULB

Unplug the machine.

Open face cover as shown.

Remove bulb by unscrewing it in counter

clockwise.

Install a new bulb by screwing it in clockwise.

iS::'.

-

-50-

«--A

Loading...

Loading...