Page 1

Page 2

You are now the owner of a new zigzag sewing machine, the most versatile type of its kind

you can possess.

thU i“*' by "*¡”6 design discs provided will.

Buttonholes, monogramming, overcasting and creative embroidery are done with ease and speed

and pobtemmg the greatest performance from your new machine this book on its care

and use has been written for you.

with many hours of trouble-free, creative sewing.

comrinrt'T "'“bments such as ruftlers, binders, edges,itchers, cording feet and soforth to

complement the accessories furnished w.th your machine .are available from the store where you

purchased your machine.

^ thorough understanding of your machine will reward you

WHITE CONSOLIDATED INDUSTRIES, INC.

CLEVELAND 11, OHIO

WHITE CONSOLIDATED INDUSTRIES, LTD.

Toronto 16, Ontario, Canada

Page 3

1 N D

Features and Parts

Needle and Thread Chart

Setting the Needle

Winding the Bobbin

Threading Bobbin Case

Plocing Bobbin Case in Shuttle

Upper Threadina

Stroight Stitching ..........................

Changing Foot and Plate ...................

Setting the Stitch Length ..................

Stitch Length Chart

Sewing in Reverse

Adjusting the Tensions

Adjusting Pressure and Fee,4

General Sewina ...................

Light Weight Fabrics

Doming and Monogramming

Weparing to Sew

Removing the Work

k-reafive Embroidery ..................

Satin Stitch

¿igzog Sewing

Automatic Zigzag Sewing

Automatic zigzag Patterns

Blind Hems

Embroidery With a Hood

...................

................

....................

..................

...................

...................

....................

.................

.......................

...................

.............

......................

.......................

...................

.............

................

..................

..............

..........................

...............................

.................

.................

................ 19

......

...........

........

........

........

.......

14 !

15 ;

17

18

Page

® i

10 1

Darning

............................

Making Bufionholes

Sewing on Buftons

How fo Use Accessories

Narrow Hemmer .......................................... ^2-23-24

Lace Trimmed Hem ............................................ ^2

Lace Edge .............................

French Seam

Flaf Felled Seam ............................................... 2^

Hand Rolled Effect

Quilting Guide .................................................. 23

Seam Gauge ............................... ...................... 23

Care and Maintenance

Oiling ............................................................. 24

Cleaning and Oiling Shuttle

Accessories

Trouble Charts

Attachments ................................................ 28-29-30

Attachment Foot

Edgestitcher

Binder ............................................................ 33

Hemmers ........................................................ 34

Darning Spring .................................................. 35

Ruffler

Cording & Zipper Foot

Sewing on Zipper

..................... ...................................

.........................................................

.......................

........................

....................... .............................

............................................

.............................................

..................... ..............................

.............................

............................. .......................

................................................

Роде

.........................

.Г.!!!!.!

...............

..................................

..........................

^2-33-34-35-36-37

...........................

22 o]

.......

26

33

35

........

27

37

^9

22

23

Page 4

CM

Page 5

/ 73 o 3

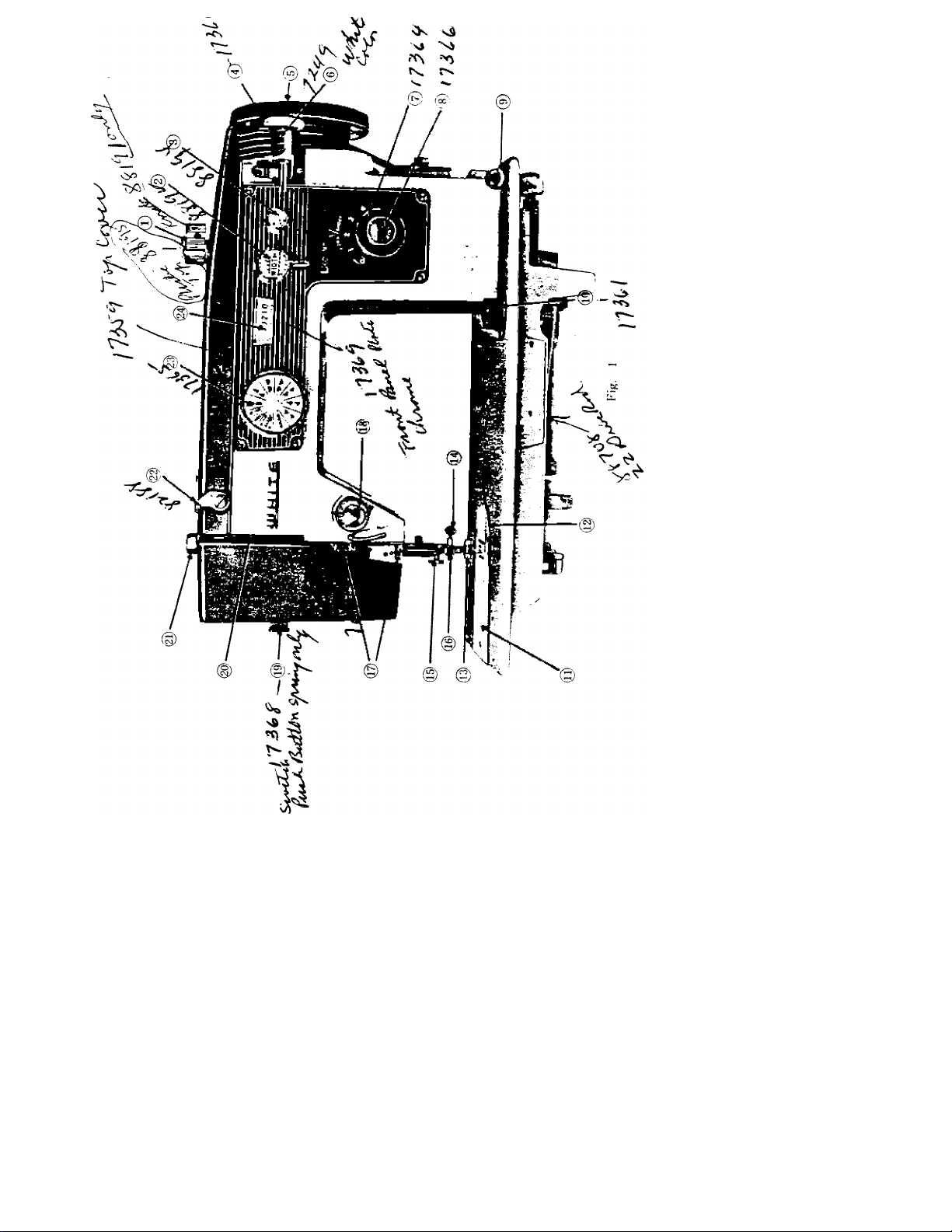

FEATURES AND PARTS

(Front View)

1 Button hole rantrol knob.tTn/^ #<>yf /

- Zig-zag width control knob.

3 Lock knob for Zig-zag width. y'

I

I f

4 Hand wheel. nd&o

5 Wheel clutch.

6 Bobbin winder. 7

7 Stitch length dial. j *y^ ^ ^

^ push button. / “J^

9 Bobbin winding tension.

19 Drop feed knob /73C, /

11 Cover plate.

1-i Needle plate-Seam guide.

'T-t-

13 Presser foot.

14 Needle clamp and screw.

15 Attachment and foot thumb screw.

Ifi Needle thread guide.

17 Thread guide. TJl'JS'

18 Tension regulator.

19 Light switch.

20 Thread take up lever.

21 Pressure release darner.

22 Arm thread guide.

“9 Pattern selecting dial. ^

24 Zigzag-width window.

Page 6

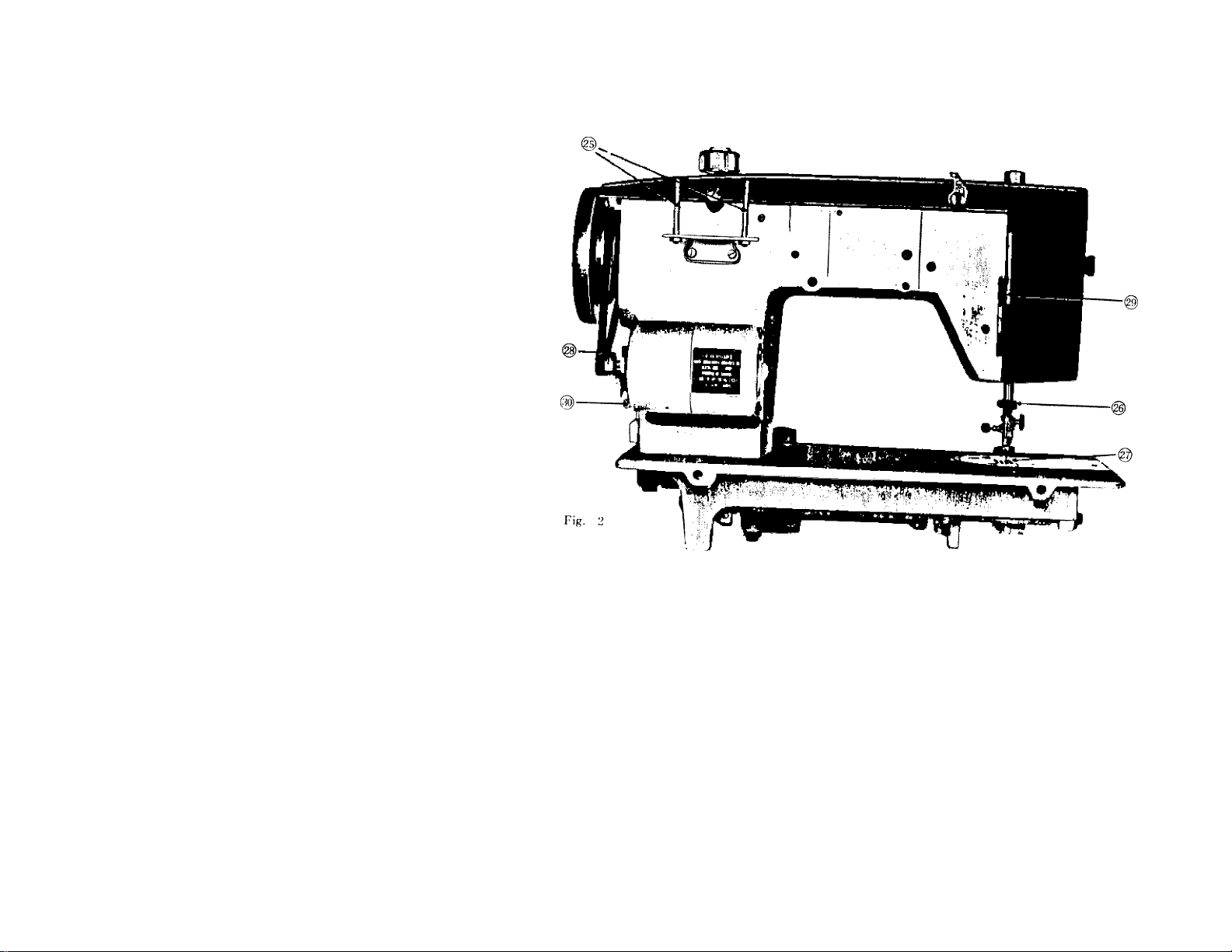

FEATURES AND PARTS

(Back View)

25 Spool pins.-7^(1^

26 Thread cutter.

27 Feed

28 Belt

29 Presser l)ar lifter.

30 Motor.

Page 7

NEEDLE - THREAD - FABRIC - STITCHING GUIDE

FabricExtremely heavy

tari)aulin, sacking,

canvas, duck, etc.

Heavy uiiliolstery

fabric, ticking,

denim, leatherette

Medium heavy drapery

labric, velveteen,

suiting, felt, terry, etc.

Medium broadcloth.

percale, gingham, linen,

chintz, taffeta, sheer

wool, shantung, etc.

Sheer voile, lawn,

dimity, crepe,

liandkerchief linen,

plastic film, etc.

Very sheer chiffon,

batiste, lace, organdy,

ninon, net, marquisette, etc.

Needle

No.

4

3

2

1

0

00

Machine

Stitches

Per Inch

fi

to

8

8

to to

10

10

to

12

12

to

14

14

to

16

(Plastic film)

8 to 10

16

to

20

Cotton

Thread

10

to

30

30

40

40

to

60

60

to

80

80

to

100

100

to

150

Mercerized

Thread

Heavy Duty

Heavy Duty

Heavy Duty

50

50

50

Silk

or

Nylon

A

A

A

Page 8

SETTING THE NEEDLE

See Pig. Raise tfie needle bar A tn n i - i

point, turning wheel toward you by ha„d

i len loosen the needle clamp screw' B and thp

№ Lr", rli',‘il“""; I'l“» «iic

" In "r*.,'

Afl.r than,r„g „„dl, „„I,, „„pie,,

HOW TO WIND THE BOBBIN

Disengage the hand wheel 4 (Fin 4^ from ,■ i •

l>y turning the clutch 5 toward you'or coumeridcwlse.'"^ tnechanism

pins, lead thread through the upper thread

lensS, Z "T,,“ r •

machine^ Run end of thread through a hole

sniniie C on

on bobbin over small pin on spindle Push

fll

FLA'

-SURI

SIDE

Turi'clm when it is filled

Break off loose thread end used to strriTlie winding.

yortur^thrilrTlTeel“'’"'"^

I'i«.

Page 9

fi.at

'SIIRFA(

;L‘d so that

S|

THREADING THE

BOBBIN CASE

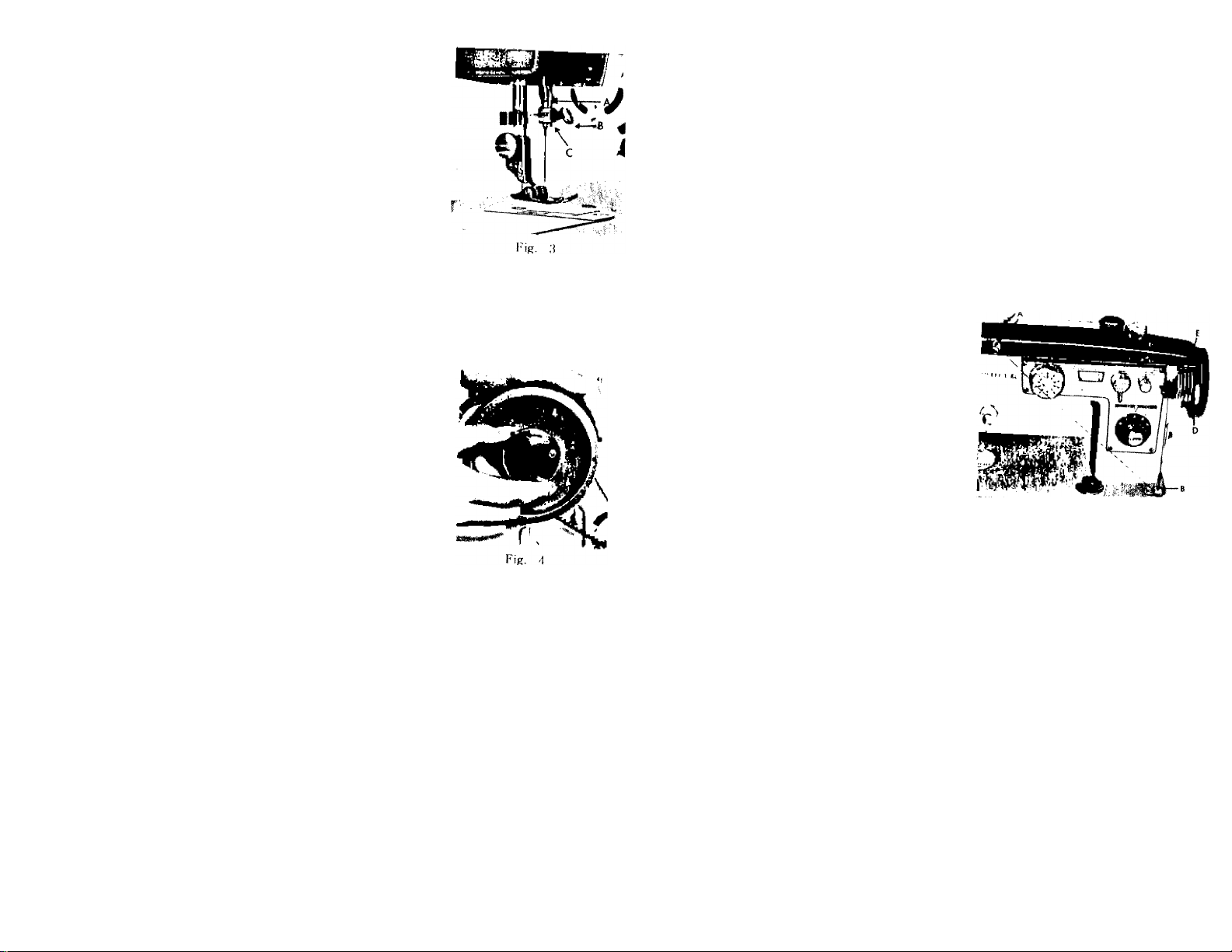

Step 1 (illustrated in Fig. 6).

Hold bobbin case between thumb and

forefinger of left hand, so that the slot

ill the edge of the bobbin case is on top.

Гаке the bobbin between tliumb

and forefinger of right hand so that the

thread on top leads from left to right.

Step 2. In.sert bobbin into bobbin

case, pull the thread into the slot of the

bobbin case as shown in Fig. 7, and draw

It under tlie tension spring and into the

fork-shaped opening of the spring as

shown in Fig. 8.

SLOT

Fig. 6 (

Fig. 7

Page 10

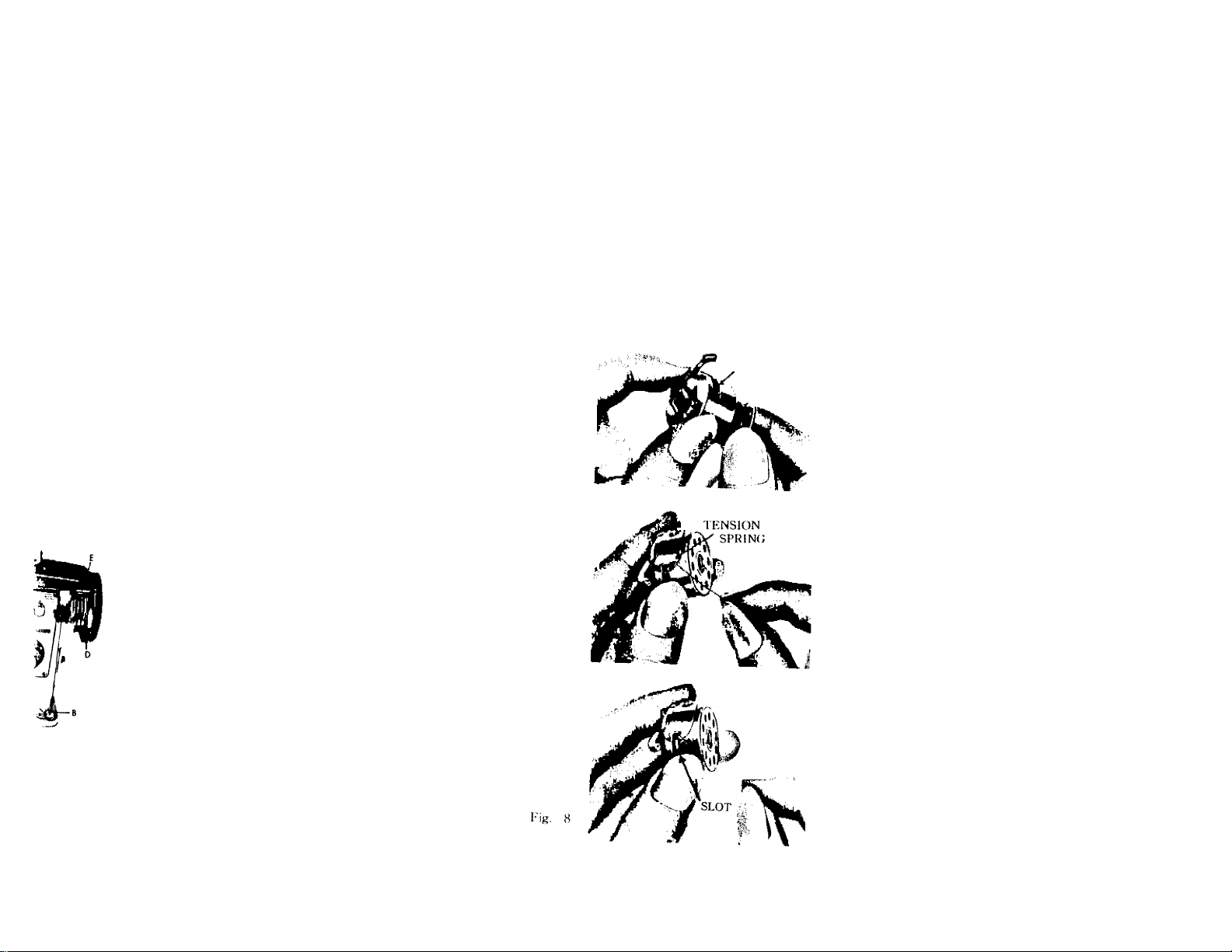

PLACING BOBBIN CASE IN SHUTTLE

Open hinged cover ¡jlate left of the needle

(See 11, Fig. 1) Flold the bobbin case latch, (D)

F.g. between the thumb and forefinger of thi left

and, with at least three inches of thread running from

le op of the bobbin case to the right. Insert and center

he bobbin case on the stud of the shuttle body, (C).

Be sure the bobbin

case finger, (E),

enters the shuttle

race notch, (A).

Press the bobbin case

(B) into the shuttle

as far as possible until

latch catclies on the

center post of the

9 shuttle.

THEN release the bobbin case latch, (D)

Press bofibin case again after latch has b^en released to

make sure the bobbin case is locked securely i„ place,

Close the cover plate.

Fig. 10

Page 11

UPPER THREADING

(Fig. 10)

1) Place spool of thread on upper spool pin,

2) lead thread through arm thread guide A

3) down and around tension discs B from right to left

4) into the check spring C over threaded discs.

5) then pull thread under bar D (See insert, P'ig. 10)

6) up into take-up lever E from right to left

7) down into thread guide P' on face plate

8) tlirough the needle bar thread guide G

9) and into needle from left to right. Pull three or four inches of thread through needle

Mold the end of upper thread loosely and turn hand wheel toward you until the needle goes all the

way down and comes back up. A loop (Fig. 11) will he formed over the lower thread whicli then can be

pulled out straight. Place both thread ends under the slot of the presser foot and draw toward the back

of the machine, leaving both threads three or four inches long.

Fig. 11

Page 12

10

STRAIGHT STITCHING

For straight sewing on fine fabric or very soft material,

you may want to use the straight stitch presser foot and the

straight stitch needle plate which are included in your accessory

box. Botli have narrow needle slots.

■gffANGlNG THE FOOT AND PLATE. To change

presser foot (13, Fig. 1) loosen thumbscrew (15, Fig. 1) and

remove zigzag foot.

Replace with hinged narrow foot and tighten screw securely.

To change Neelde plate (12, Fig. 1) remove it after you

pull out slide plate to the left (Fig. 12 A) and then you can

change needle plate to straight stitch plate.

—^ stitch width at 0 or the needle will

break in striking the foot or plate.

Fig. 11’A

I'ig. 11 H

Page 13

£tJLy

7 '7^> tf-

SETTING THE STITCH LENGTH

Tlie lengh of the stitch is regulated by knob 7 shown in h'ig. 12-B. Near 0 is the shortest length and

4 is the longest. Turn the knob to the left to lengthen and to the right to shorten the stitch.

STITCH LENGTH CHART (Approximate)

11

Figures on indicator ' ()

Number of stitcbes per inch No Feeding

24

1

12

2

3

8

4

6

SEWING IN REVERSE

When you wish to sew in reverse to tie the thread at the beginning or the end of a seam, press in

the reverse button 8 Fig. 12-B as far as it will go. Tbe machine will sew backward as long as the button

is held in. Only 3 or 4 stitches are needed to tie a seam securely.

ADJUSTING THE TENSIONS

Always adjust the upper tension with the presser foot down, as the

tension is automatically released when it is raised. To increase the

tension on the upper thread, turn dial (Fig. 13) to the right, or

clockwise. To decrease, turn to the left. The higher the number on the

dial the tighter the tension. Before adjusting lower tension be sure that

the machine is threaded properly.

\\ hen necessary' to chatige the bobbin tension, turn small screw

(Fig. 11) on side of the Itobbin case clockwise to tighten, counterclock

wise to looseti. Fig. i:t

Page 14

12

When the upper and under tensions are properly balanced,

a perfect stitch will be formed with both threads interlocking

in fabric (Fig. 15). ^

When the upper tension is too tight, the lower thread is

pulled up over the upper thread which is lying flat on the

fabric (Fig. 16)

When the upper tension is too loose the up,,er thread

forms loops over the lower thread lying flat on the fabric

(hig. 17).

ADJUSTING PRESSURE

AND FEEDING OF FABRIC

“tt «"fTís Í7

.

..........

..

Fig. la. ■ ‘'"'I' i» ......................

Fig- 15

Fig. 16

Fig. 17

ig. IH

■'ig. H

oil.

Page 15

;»p or

sition.

SEWING THIN OR LIGHT WEIGHT FABRICS

When lighter pressure is required to sew satisfactorily on thin silk

or filmy material, the pressure cap should be about halfway down.

Release all the way by pressing the snap lock, A. Fig. 20, and

then press cap B down again to halfway spot. Lower the feed slightly

by turning the red arrow on the knob to "LOW” Position.

DARNING AND MONOGRAMMING. In order to move the

fabric freely in any direction for darning, mending and certain kinds of

free-hand embroidery, release the pressure cap B completely by pressing

down on the snap lock. A, Fig. 20. Turn the knob to "DOWN” position,

which drops the feed well below the needle plate. To return feed to

normal, return knob to "HIGH”.

Fig. 20

PREPARING TO SEW

Have take-up lever at highest point before starting to sew. Do not try to help the feeding by pulling

the material as this may deflect the needle and cause it to break.

NEVER run machine without material under presser foot.

Place material and threads in position under the presser foot and lower the presser foot.

lurn tlie hand wheel toward you until the needle is at its highest point. You are now ready to

begin sewing. By having the needle at its highest point, it is not necessary to touch the hand wheel to

start the machine. You merely press the control. The speed of the machine is regulated by increasing or

decreasing the amount of pressure exerted on the control.

15

Page 16

14

REMOVING THE WORK

Be sure to stop the machine when the thread take-up lever

and needle bar are located at the highest position.

Now raise the presser foot and draw the fabric l,ack and to

the left, Fig. 21-A and B, and pass the threads over the thread

cutter.

Pull down slightly, holding thread in both hands, so as not to

bend the needle.

Leave the ends of thread under the presser foot.

CREATIVE EMBROIDERY

jg ^Цгe zigzag presser foot and zigzag needle plate are in place

The SATIN STITCH, Fig. 22,

which is really just a very short

zigzag stitch, and the basis for most pj 2‘>

embroidery, is obtained by setting the stitch lengUi as near 0 as

po-ssible without stopping the feeding action.

1 he width may he set anywhere from just ¡)ast 0 to the

widest, 4.

-

-----------------------------

f-i«. -I H

Page 17

'ìr^"

ZIGZAG SEWING

Your zigzag sewing machine, hy virtue of its

design, permits you to do zigzag sewing and

other kinds of work requiring a similar stitch.

The zigzag width control knob (A) is located

on right side of zigzag panel adjusts the width

of zigzag seam. For ordinary straight sewing,

zigzag width indicator (C) must he set at "0”

position on the window.

By moving this control knob (A) gradually

toward ”4” (as direction of arrow) the machine

will sew a zigzag stitch increasingly. (Fig. 22).

p'or special type of work such as sewing button

making tacks etc, zigzag width restricting knob (B)

will be useful.

To restrict the minimum width, turn restricting

knob (B) clockwise to tighten.

To release the locking of zigzag width, release

this knob then control knob (A) returns to "0”

position automatically.

15

Fig. 22

Page 18

16

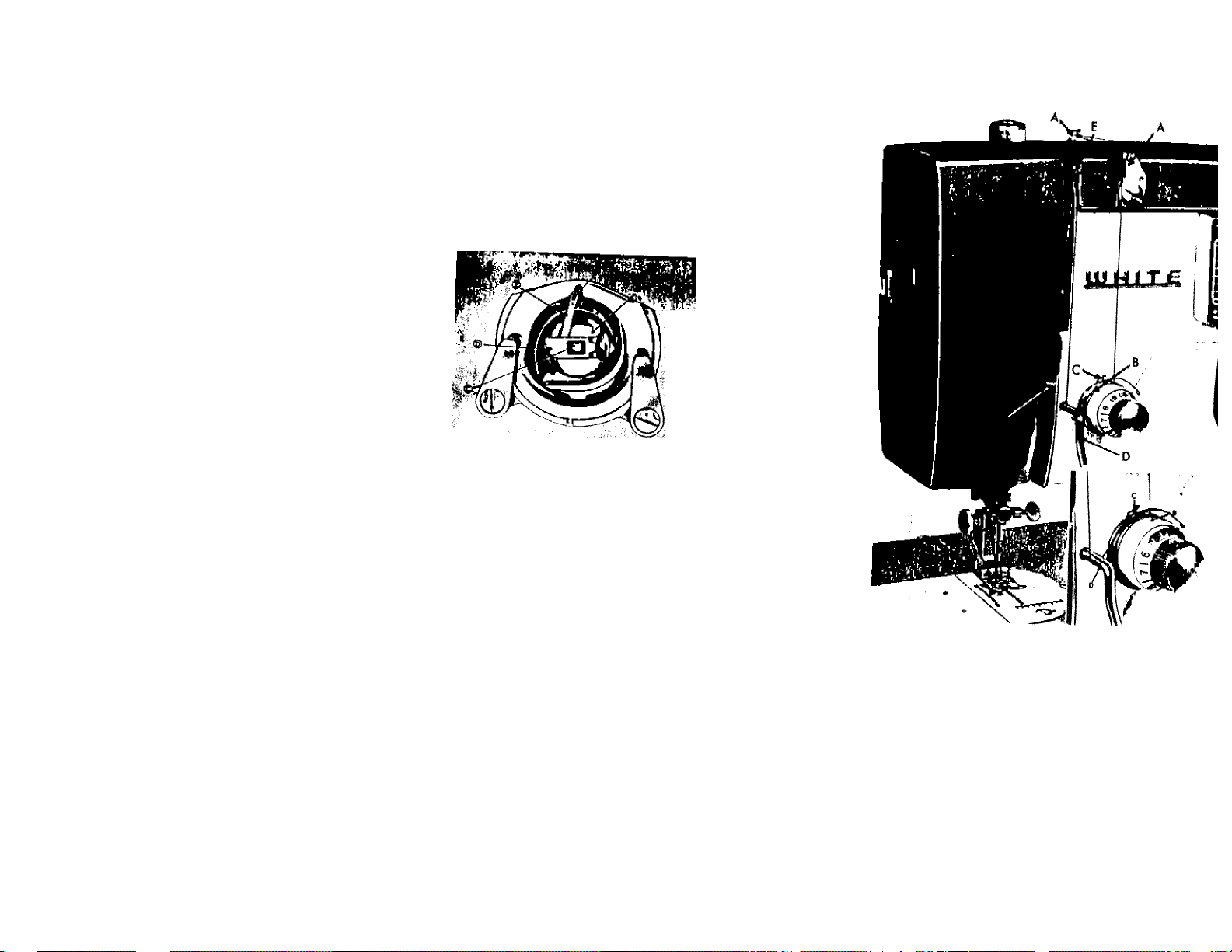

AUTOMATIC ZIGZAG SEWING

Also this machine can sew the most beautiful decorative

and embroidery stitches AUTOMATICALLY by means

of various cams built-in-machine, and obtained 9 l,asic

patterns by turning the pattern selecting dial (A)

1) Turn tlie zigzag width control knob (C) clockwise

until indicator shows "AUTO” in the window (13),

and hold the zigzag control knob (C) in the position.

(Fig, 2d).

2) Then turn the pattern selecting dial (A) counter

clockwise to the point of pattern you want.

NOTE If the dial (A) is turned to the right as far as

possible, then turn it counter-clockwise.

I'or ordinary straight and manual zigzag sewing, pattern

selecting dial should be indicating "NORMAL STITCII”

I'ìr. L’,!

Page 19

1) AUTOMATIC ZIG ZAG PATTERNS

17

Page 20

18

BUND HEMS

Prepare the garment in the same manner as for hand hemming.

Step 1. (Fig. 24) If hem with folded edge is used make first fold 3/8" deep.

Step 2. Turn hem the depth desired and baste 1/4" from upper edge. Press into place.

Step 3. Fold hern back toward right side of garment leaving 1/4" extended.

Step 4. Place material under presser foot and sew blind hem automatically.

Blind hem completed.

Turn automatic pattern selecting dial counterclockwise so that Blind Stitch | section of the

dial comes to the red triangle mark on the zigzag plate.

Set needle position to LEFT and stitch length regulator to M.5.

COM I> LET Er

The blind „¡ich .1 CENTER ,,r RIGHT needle pnsilinn |, reenm„,e,„l„l bee,,,,,,, n,,,

often tends to break the needle.

Page 21

embroidering with a hoop

19

OM I’LETED

m of the

tuse this

It is easy to follow a stamped design or to work free

hand when embroidering or monogramniing.

(See Fig. 25). Release the pressure from the foot by

pressing down the snap look on the automatic darner.

Turn drop feed knob to DOWN position (see Fig. 19).

Stretch the fabric in an embroidery hoop, and place

under the needle after removing the presser foot.

Set the stitch width at the size you prefer and lower

the presser bar lifter. Then operate the machine at a rather high speed while moving the

with both hands. Work carefully and be sure to keep fingers out of the path of the needle.

Fig. 25

hoop slowly

DARNING

Release pressure from foot and drop feed as directed above.

Place fabric to be mended under foot, and stitch around hole, moving the fabric firmly and

slowly in any direction. To fill in the hole, stitch from center outward, completing and stitching

in fabric.

Page 22

20

MAKING BUTTON HOLE

No.l

Right side

row

(reverse)

No.2

tacking

No.3

Left side

row

(forward)

No.4

tacking

^ Your zigzag sewing machine stitches button lióles automatically by

' mBfiSw means of buttonhole knob, without turning the fabric.

1st step: Set the needle position lever to LEFT.

2nd step: Turn the regulating knob (A) clockwise until mark 1 (over the

knob) comes to the arrow-mark printed on face plate.

Sew with desired length, (a little longer than button size) as Fig.No.l.

3rd step: Turn the knob (A) to mark 2. Sew 4 or 6 stitches as Fig. No. 2.

Fig. 26

4th step: Turn the knob (A) until mark 3. Sew with power same length

(tacking).

as 1st reverse sewing, as Fig. No. 3.

5th step: Turn the knob (A) to mark 4. Sew 4 or 6 stitches as F'ig. No. 4.

(tacking). Before starting to sew button holes on cloth, try one or two times on a separate piece of material.

After finishing button-holes, lift the presser foot, take out the fabric, then cut off inside of the button

hole pattern with seam ripper in the accessories box.

NOTE (1) Do not set stitch length control knob to “0” position, where machine does not feed material,

must be at “1” or longer position.

(2) In sewing second row of stitches, (3rd step), Fig. No. 3, be sure to guide first row of

stitches in groove provided for it one bottom face of button hole foot, then both row of

pearl stitches will be spaced apart properly. This also prevents row edge after the space

between these rows of stitches have been cut open.

tari

hefi

wid

Page 23

lacking

iioinatically by

Ik 1 (over the

ate.

e) as Fig.No.l.

as Fig. No. 2.

r same length

as Fig. No. 4.

ce of material,

of the button-

feed material,

ie first row of

I both row of

liter the space

If you plan to make Iruttonholes on sheer or soft material, place

tarlatan or paper, which can be torn away after stitching, under the fabric.

And it is always wise to make several buttonholes on scraps of fabric

before working on the garment.

For narrower buttonholes, set the stitch width at 1У2 and move stitch

width lever to 3 for bar tack.

SEWING ON BUTTONS

Remove hinged presser foot and attach button sewing foot. (See

Fig.27-A, B and C).

Turn drop feed knob to “DOWN”

Move zigzag width lever to “0” position or to the extreme left. Place

the button so that its left hole comes directly under the needle, then

gently lower the presser foot. Move the zigzag width lever to the right

until the needle comes exactly over the right hole of the button. Turn

the balance wheel slowly by hand to be sure the needle clears both

holes of the button. Correct width if necessary.

When needle goes into the center of each hole, run the machine at

medium speed, making five or six stitches, stopping with the needle in

the left hole.

To lock the zigzag stitch and prevent ravelling, set the

stitch width at 0, and take a few stitches in the same

hole. If you wish you may place a rounded toothpick

over the button, between the two holes, and sew

button to fabric in regular way.

log. 27-C

21

Page 24

22

Remove the toothpick and wind thread under button,

forming a shank. Fasten.

Apply the above method to sew on buttons with four

holes, hooks, and snaps, etc.

If a four hole button is to be sewn, follow the same

procedure above for the two hole button.

Now lift presser foot slightly and move fabric to permit

stitching the remaining two holes.

Hooks, snaps, etc., are sewn to the fabric with the

same procedure as for sewing two hole buttons.

HOW TO USi ACCESSORIES

NARROW IIEMMER. With the needle at its highest

postiton, replace regular presser foot with narrow hemmer

(Fig. 28). For a plain narrow hern, make a 1/8 inch double

fold for about two inches along edge of fabric. Hold each

end of the two inch fold, slip underneath hemmer. Bring

fold up into the scroll of hemmer, draw forward to end

and fasten with point of needle. Lower presser bar lifter.

Gently pull ends of thread as you start stitching.

Guide material slightly to right, and it will automatically

take a double turn through scroll.

LACE TRIMMED HEM. To sew a narrow hem

and attach lace in one stitching, insert lace in the slot next

to needle (Fig. 29). Sew hem as above, guiding lace

under needle and hem into scroll.

Fig. L'H

Fig. 21»

I.

of fahi

Fi

feedinj

F

lower

Fdgcsl

И

the na

Ql

pronge

Page 25

25

Fig. :i(i

Fig. ,il

LA(,E EDGE Will! INVISIBLE STITCHING. Hold lace 1/8 inch from raw edge on right side

ot labric. Insert both in scroll as for plain narrow hem (Fig. 30). Let hem roll over and sew in lace

Press lace out flat along edge with hem turned up. It is possible to have a little fullness in lace hy

leedmg it Ireely under scroll.

HiENCH SEAM. With right sides together, place top piece of material 1/8 inch inside edge of

scroll, allowing hem to roll over and sew in top fabric, making French seam.

l<L,Ai LELLEU SEAM. Open out hrench seam and insert rolled edge in scroll of hernmer

Edgestiich to lay seam flat.

HAND UOELED EFFECT. Use a narrow zigzag stitch, just wide enough to catch both edges of

the narrow, rolled hem.

QUHH’ING GUIDE. This guide for making parallel rows of stitching is attached by placing the

pronged holder between the presser foot and the pressar foot thumb screw (Fig. 31).

Page 26

24

Adjust the curved bar to press lightly on the fabric.

By letting the guide ride on the first stitching line,

successive rows will he an equal distance apart.

When the har is attached so that the curved part

is to the right of the needle, it may also serve as a

seam width guide.

SEAM GAUGE OR CLOTH GUIDE. Use the

seam gauge as a guide for straight seams and even

rows of top stitching along edges of fabric. Fasten

gauge with accompanying screw in threaded hole in bed

of machine (Fig.32). Adjust to seam width desired.

CARE AND MAINTENANCE OF

YOUR MACHINE

HOW TO OIL YOUR MACHINE

Your machine should he oiled occasionally to keep

it operating smootlily how often depends on the amount

of sewing you do.

Before oiling the upper part of the sewing unit at

points indicated by arrows in Fig. 36, turn hand wheel

toward you until the take-up lever is at its lowest point.

Remove top cover by loosening two screws on cover.

Fig. :?2

Fig. :!:i

Page 27

Fig. 34

Avoid over-oiling only a drop is needed at each point.

To oil p„„, onde, ,l,e bed of d,e .„.chine, ,ip .he n„i, Innck on i.s hinges and apply , drop of oil

at each point indicated in Fig. 34

25

Fig. 35.

To oil .„oving p,r.a inside the (ace pl.ne, „hid, only rarely re<,„ire oiling, open pla.e.

Oil at spots indicated in Fig. 35.

Page 28

26

CLEANING AND OILING THE SHUTTLE

(See Figs. 36 and 37)

The stitch forming mechanism occasionally becomes clogged with loose threads and lint. This will

interfere with the efficient operation of the machine. Cleaning and removal of the lint will safeguard the

performance. To remove the shuttle assembly, proceed as follows.

1. Turn the balance wheel until the needle reaches its highest position. Tilt head back on its hinges.

2. Remove bobbin case (A), Fig. 37.

3. Turn the two shuttle race cover clamps (B) outward and remove the shuttle race cover (C) and

shuttle body (D).

1/

Fig. .'!6

i

Fig. :n

Page 29

Clean the shuttle race, the shuttle, and shuttle race cover by removing all threads, lint, etc.

A|»ply a drop of oil with finger tip to outer edge of shuttle.

When the cleaning has been completed, proceed as follows to replace the shuttle assembly:

1.

I urn the balance wheel until the needle reaches its highest position.

2.

Place shuttle Itody, (D), against shuttle driver and adjust into position.

3.

Replace shuttle race cover, (C), fitting pin at lower edge into notch, and lock into position with

shuttle race cover clamps, (B), making certain the clamps have been snapped securely into position.

4.

Put bobbin into the bobbin case.

5.

Put the bobbin case into the shuttle race, fitting tongue into notch(E)of race cover.

ACCESSORIES

27

10 H

14

1 Large screw driver

2 Small screw driver

3 Ripper

4 Quilter guide

5 Presser foot for

straight sewing

6 Buttonhole Fooi^tV-f

7 Thumb screw

16

o„o

8 Cloth Guide

9 Small Heinmer Foot

10 Cording Foot

11 Button sewing Foot

12 Package of Needles

13 Needle plate for

straight sewing

14 Sew Light Bulb

15 Plastic Oiler

16 Bobbins (3)

17 Felt Washers

(for spool pins)

Page 30

28

TROUBLE CHARTS

Trouble

If machines

bind

Probable Cause

Thread or lint in race way

Correction

L- With take-up lever in highest position, tilt

head back on hinges and remove hohljin

case.

BOBBIN

CASE BOBBIN

NOTCH n*CE

RACE COVER CLAMPS

2. - Turn clamps downward and remove r:icc

cover.

3. - Remove hook.

4. Clean thread and lint from all parts, including

race.

5. - Run a drop of oil along rim of hook.

6. - Replace hook, then race cover. Snap clamps

into place.

7. Grasp threaded bobbin case by latch iuid

replace, fitting tongue into notch of race

cover.

Page 31

29

Trouble

Bent needle

Skipping

stitches

Irregular

stitches Improper threading

Uneven

stitches

Needle placed incorrectly in

clamp

Too fine a needle for thread

being used

Upper thread tension too

loose

Bobbin not wound even

Pulling or holding material

Not enough tension on

upper thread

Poor quality thread

Needle too fine for thread

being used

Probable Cause

Correction

Discard and replace.

See instruction page No. 6.

See needle and thread chart, page No. 5.

Tighten upper tension.

See threading instruction, page No. 9.

Rewind bobbin

Avoid pulling or holding material, just guide it.

Increase tension

Try different thread.

See needle and thread chart, page No. 5.

Page 32

50

Trouble

Upper thread

breaking

Material

puckering

Probable Cause

Improperly threaded

Too much tension

Starting with take up in

incorrect position

Improper setting of needle

Eye of needle to sharp

Bent or blunt needle

Tensions too tight

Dull needle

Stitch length too long

Correction

Refer to threading instructions see page

and rethread machine.

Loosen tension on u[)per thread by

thread tension knob to lower number.

Always start sewing with take up k

highest position.

Refer to needle setting instructions

page No. 6

Try a new needle.

Discard all blunt or bent needles and

with new.

See tensions adjustment page No. 11.

Change needle.

Reduce stitch length.

No. 9

turning

’ver in

see

replace

Page 33

Your sewing machine comes equipped witl, the basic set of accessories

described earlier in this book.

The following pages illustrate additional time saving attachments that have

)een designed specifically for your machine. They are available at modest

cost rom your dealer. If your dealer cannot supply you with these items

ask him to order them for you by part number. Then you will be’

assured of receiving tlie genuine part designed for best performance with

your machine.

51

If a sewing machine dealer is not available

directly to:

WHITE CONSOLIDATED INDUSTRIES, INC

CLEVELAND II, OHIO

In Canada:

WIIITH CONSOLIDATED INDUSTRIES, LTD.

111 BERMONDSEY ROAD

TORONTO 16, ONTARIO, CANADA

mail your inquiry

Page 34

52

SOME OF THE ATTACHMENTS AVAILABLE FOR YOUR MACHINE

PART #76553

PART ^

Attachment Foot

PART «4403

Ruffler

PART #76552

PART 11990

Darning Spring

PART #74159

Binder

Hem

mers

PART #76551

I’AKT #76551

Edgestitcher

PART «76550

1Î

Si

fa

Page 35

ATTACHMENT FOOT

In order to attach the binder, edgestitcher and the hemmers,

It IS necessary to remove the jjresser foot and replace it with

the attachment foot. Fig. 38.

Mount binder, edgestitcher or hemmers sliding the attach

ment to the left as far as possible and tighten screw.

I he mounting slot enables you to sew as close to or as far

away from the edge as desired, just move the attachment to

the correct position before tightening the mounting screw.

Fig. 38

THE EDGESTITCHER

The edgestitcher is used in making lace

insertions, edgings and pipings. The slots

serve as guides. To sew lace edging to

fabric, place the material you want on top

in slot. Fig. 39, and other piece in slot 4.

To irio, will, 0 wide pipiog, p|.,„ ¡„ slo, d

53

b (t o may he used as a guide m stitching a french seam.

Page 36

54

BINDER

This attachment folds bias binding, applies it to the edge of

material in one operation. Slots on scroll of the binder are for

corresponding widths of commercial folded bias binding.

The open mouth of binder scroll is used for unfolded bias

strips cut 15/16 inch wide.

FOLDED BINDING (Fig. 41)

Cut a point of folded binding, insert in appropriate slot. Draw

through slot and under binder with strong pin. Sliding binder

slot to right or left.

TWO-TONE BINDING (Fig. 41)

Two bindings can be sewn on fabric edge also in one operation.

When two are used, always skip one size between widths,

inserting each in correct size slot.

HAND-CUT BIAS BINDING (Fig. 42)

Cut 15/ 16 inch bias binding fold in half for a couple of

inches. Cut Binding diagonally toward end, almost to fold.

Slip fold into center of binder. Draw back until cut opens

and binding encircles open end of scroll. Test stitching to be

sure it is on the edge adjust if necessary.

:‘ig. 4 1

Fig. 4 2

IS

ill!

un

ho

Io(

e;u

of

yoi

HO

V/M

Page 37

THE SET OF HEMMERS

Before attacliiiig any of the hemmers, be sure bobbin thread

is pulled up. Then, with bemmer in place, bold top thread loosely

and turn handwheel one full turn toward you, making a loop

under bemmer. Cirasp bobbin thread with both hands and slip

horizontally under bemmer toward back. Bobbin thread will catch

loop and carry upper thread to back of bemmer.

bold material in 1/8 inch for two iticbes along edge, bold at

each end of fold. Slip fold into guide and up over spoon. (Fig. 43).

bold hem in material back of bemmer. Draw forward to end

of hem and fasten with point of needle. Pull on threads gently as

you start stitching.

DARNING SPRING

now TO ATl'ACn

Remove presser foot, unthread needle, place darner spring,

on needle and slip book up over bub on needle clamp.

35

Fig. 4.-i

PATCHING AND MONOGRAMMING

See page. No. 18 Fig. 44.

Page 38

56

R U F F L E R

' v::='

Fig. 45

Fig. 46

The ruffler will produce yards of delicate ruffling or precision pleating.

Ruffling can also be done and sewn to another piece of fabric at the same time.

This highly versatile attachment despite its wide range of use, is simple to use.

Use the ruffler for making aprons, curtains, pleating a skirt, adding fullness to the bodice of a dress and etc.

Fig. 47

ins(

eitl

ove

so

adji

con

Page 39

THE ADJUSTABLE CORDING

and ZII’PER FOOT

'riiis attachment is used to make and

insert covered cording, and to sew in zippers.

Loosen thumb screw to slide foot to

either right or left of needle.

CORDING. Fold bias strip of fabric

over cord. Loosen thumb screw and set foot

so needle is centered in needle hole.

Machine baste cord in place (Fig. 48).

lo sew covered cord to material, reset

adjustable foot so needle stitches closer to

cord, and on edge of base fabric.

57

3 i, J 7

Fig. 48

SEWING IN A ZIPPER

Loosen thumb screw and slide foot so needle enters

center of needle hole. Guide metal of zipper along edge

of foot (Fig. 49). Stitching should be close to zipper

to allow easy opening and dosing. Adjust to sew iron

either right or left side, whichever is more convenient.

Fig. .19

Page 40

Loading...

Loading...