Page 1

INSTRUCTION MANUAL

FOR

SEWING MACHINE

FREE-ARM MODEL 1640

Page 2

Section 1. FEATURES AND PARTS

Front View .......................................................................................................2

Rear View ....................................................................................................... 3

Convertible Extension Plate.............................................................................4

Attaching Extension Plate ...............................................................................4

Electrical Equipment....................................................................................... 5

Sewing Light ................................................................................................... 5

Accessories.........................................................................................................6

Section 2. BASIC INFORMATION

Needle. Thread and Fabric Chart.....................................................................7

Changing Presser Foot .....................................................................................8

Changing Needle............................................................................................ 8

Removing Needle Plate....................................................................................9

Removing Bobbin Case.....................................................................................9

Section 3. THREADING MACHINE

Winding Bobbin............................................................................................. 10

Threading Bobbin Case

Inserting Bobbin Case................................................................................... 11

Threading Upper Thread .............................................................................. 12

Bringing Up Lower Thread

Twin Needle Upper Threading and Sewing................................................. 13

Rewinding Bobbin When Machine Is Threaded

INDEX

.................................................................................

..........................................................................

.........................................

11

13

14

Section 4. CONTROLS

Checking Tension of Upper Thread

Checking Tension of Lower Thread............................................................. 16

Feed Cover..................................................................................................... 17

Adjusting Pressure For Regular Sewing

Adjusting Pressure For Embroidery, Darning and Sewing on Buttons . 17

Stitch Length.................................................................................................. 18

Reverse Stitching........................................................................................... 18

■ ■ ■ ■ :

............................................................

......................................................

15

17

Page 3

Section 5. SEWING

Preparing To Sew.......................................................................................... 19

Stitching Tips...............................................................................................19A

Keeping Stitching Straight.............................................................................20

Pin Basting......................................................................................................20

Straight and Zigzag Sewing

Stretch and Decorative Stitches

Section 6. FINISHES

Buttonholes .................................................................................................. 23

Blindstitching (Hems)....................................................................................24

Sewing on Buttons..........................................................................................25

Adjustable Cording and Zipper Foot

Cloth Guide.....................................................................................................26

QuOting Guide............................................................................................... 26

...........................................................................

Instructions For Sewing On Stretch Materials

.....................................

20

21

Multiple Zigzag Stitch.............................................................................21

Scallop Stitch Double Overlock Stitch...................................................21

Satin Stitch............................................................................................. 22

Triple Seam Stitch and Rickrack Stitch Stretchable Blindstitch ... 22

Smocking Stitch, Overcast Stitch Box Stitch.......................................22A

Super Stitches (Swan, Tlip, Dog)

.........................................................

............................................................

22A

26

Section 7. CARE AND MAINTENANCE

Cleaning Shuttle Hook and Race ..................................................................27

Oiling....................................................................................................... 27, 28

Section 8. PROBLEMS AND PROBABLE CAUSES................................................................29

-lA-

Page 4

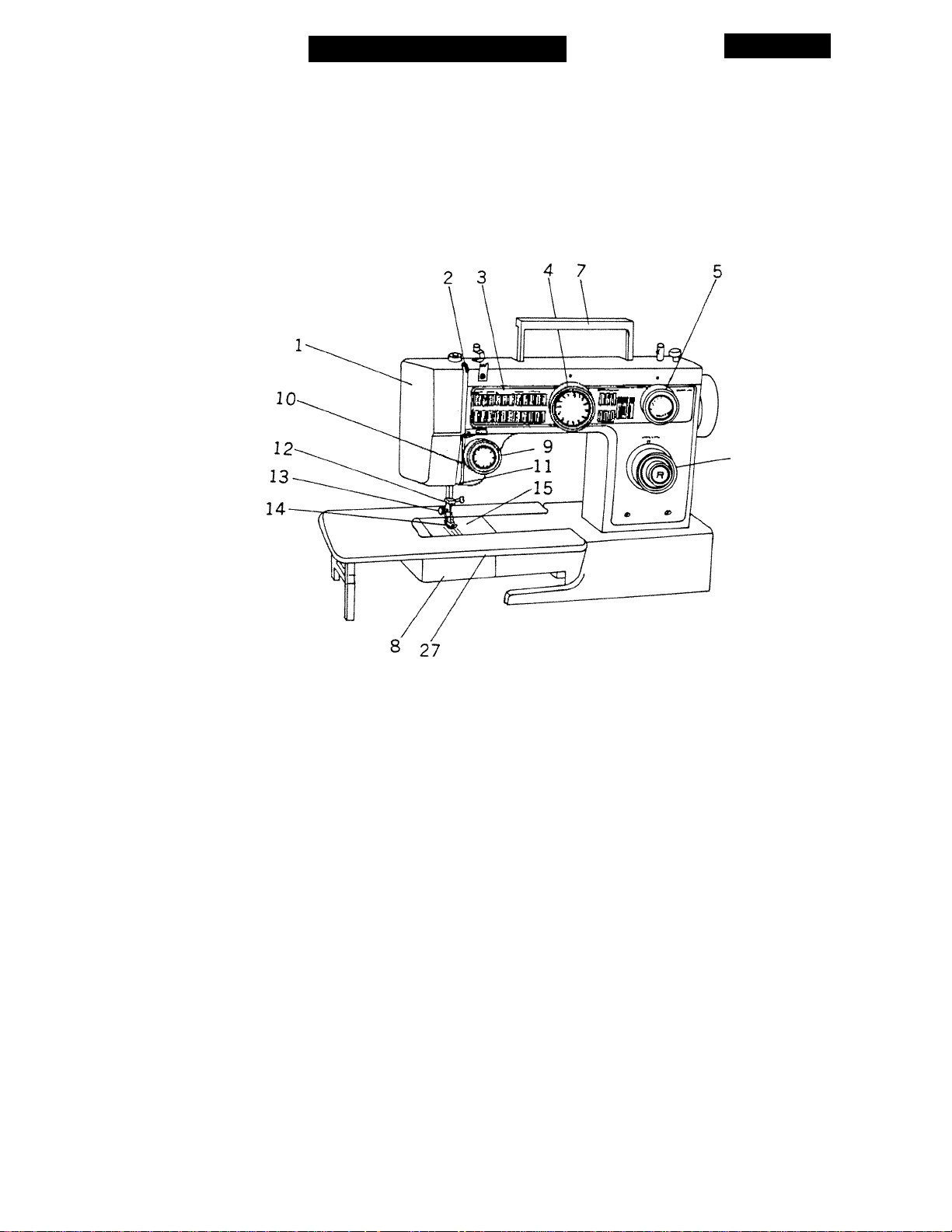

FRONT VIEW

features and parts

Section 1

1. Face Plate

Thread Take-Up Lever

2.

Pattern Panel

3.

Stitch Selector Dial

4.

Stitch Width Dial

5.

Stitch Length Dial & Reverse

6

Push Button 14.

Handle On Top Cover

7.

8. Hook Cover

Thread Tension Dial

9.

Tension Check Spring

10.

Thread Guide (G)

11.

Needle Bar Thread Guide

12.

Presser Foot Thumb Screw

13.

Presser Foot

Needle Plate

15.

Page 5

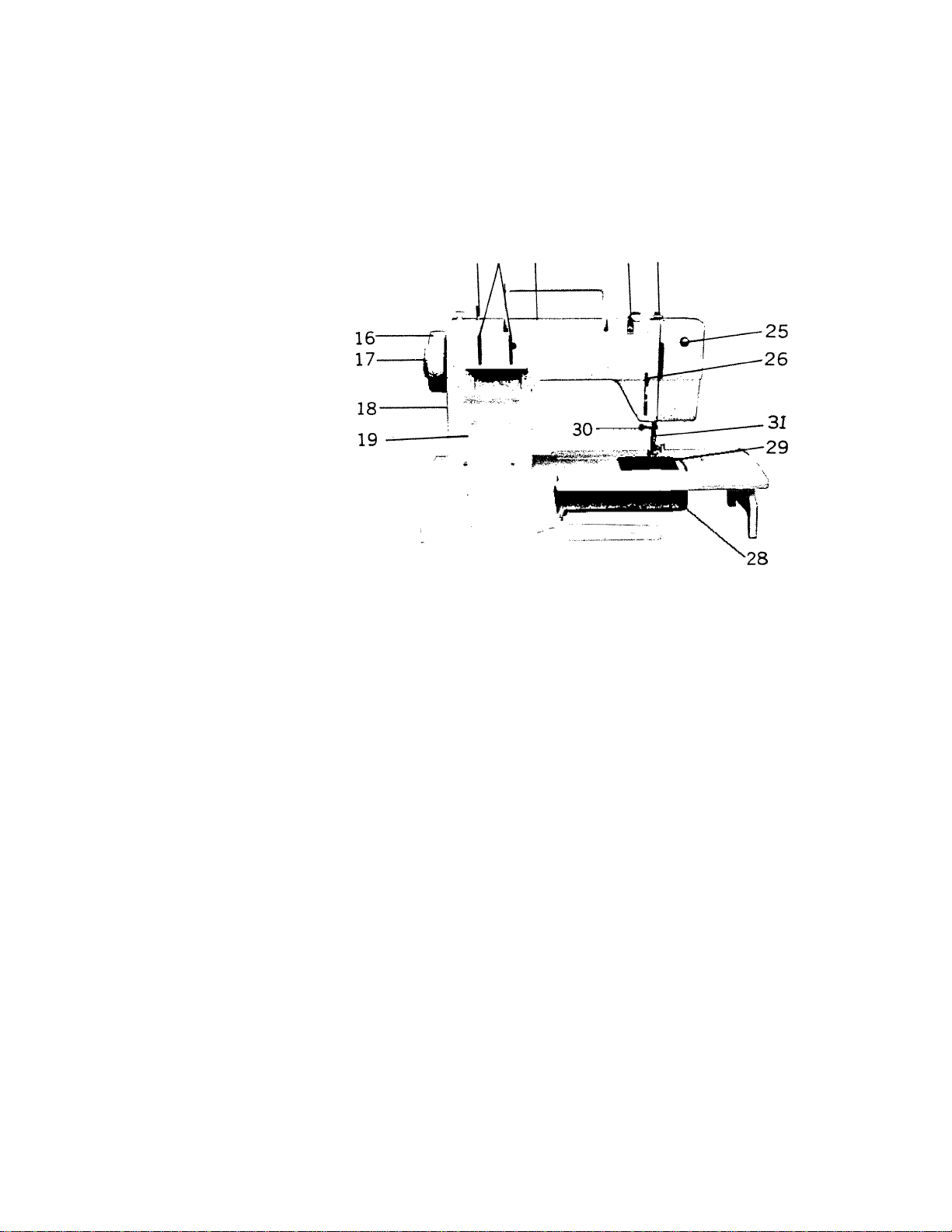

REAR VIEW

20 21 22

23 24

16.

17.

18.

19.

20.

21.

22.

23.

24.

Hand Wheel

Stop Motion Knob

Cover Plate

Bobbin Holders

Bobbin Winder

Spool Pin

Top Plate

Thread Guide and Bobbin

Winder Thread Tension

Patch-O-Matic Darner

25.

Sew Light Switch

26.

Presser Foot Lifter

27.

Extension Plate

28.

Free Arm

29.

Steel Plate

30.

Needle Clamp Screw

31. Thread Cutter

Page 6

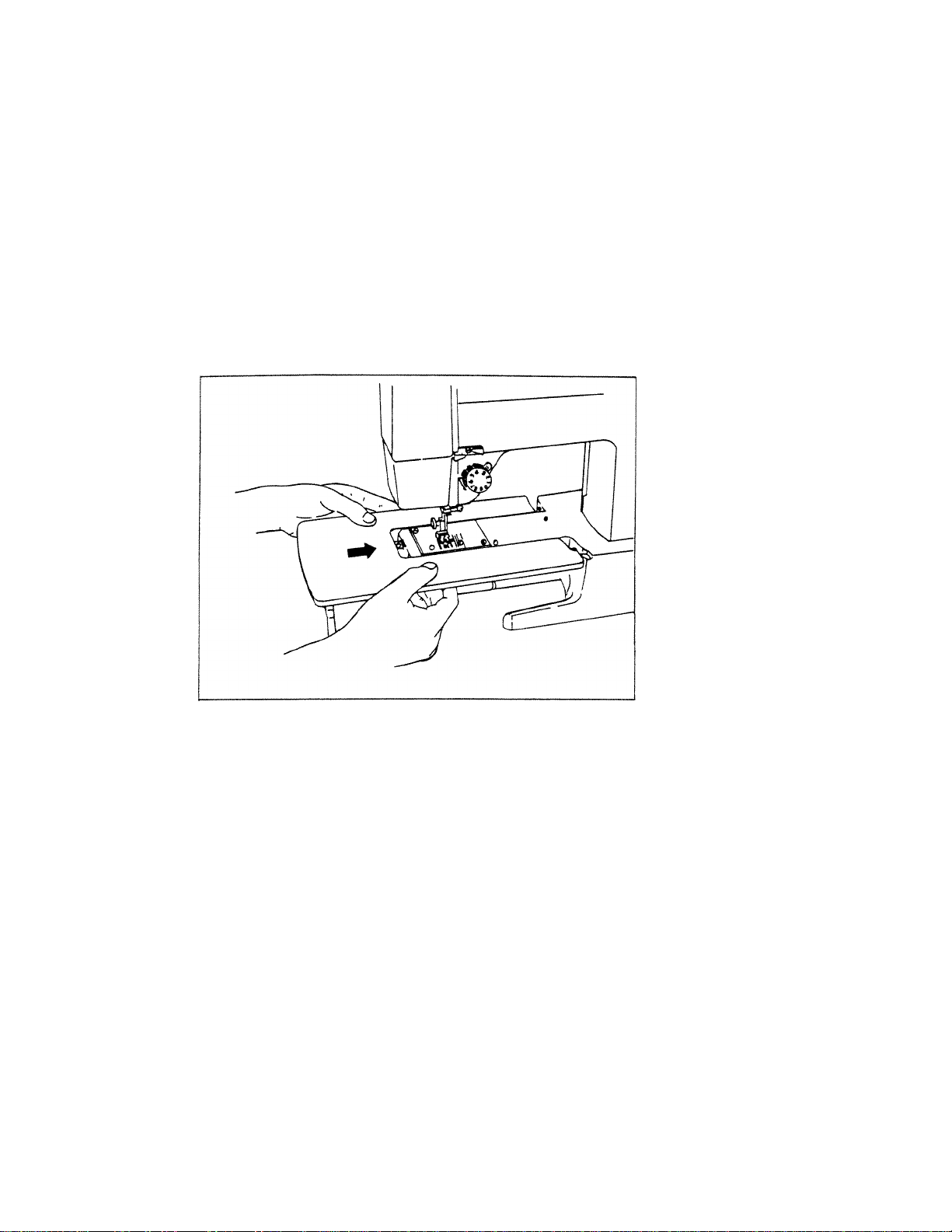

CONVERTIBLE EXTENSION PLATE

The built-in, snap-up extension plate quickly converts the sewing platform from

free arm to flatbed.

Attaching the Extension Plate

For ordinary sewing, the extension plate will make your work easier.

Carefully place the extension plate on the free arm, levelling the plate with the

free arm, inserting pins on plate into corresponding holes on base of arm.

Fig 1 A

Page 7

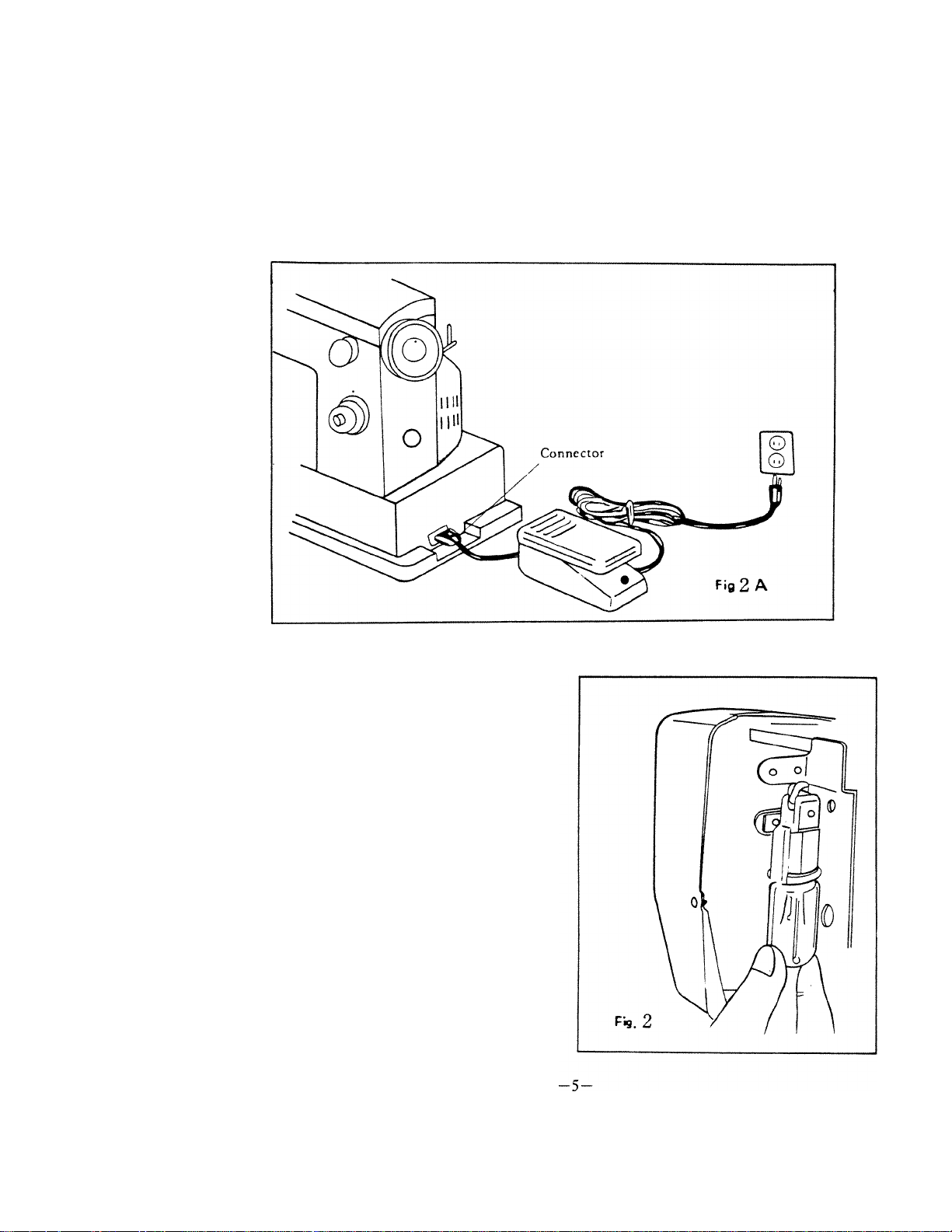

ELECTRICAL EQUIPMENT

3m

he

Plug foot pedal cord into your wall outlet, and connector to terminal box

on machine as shown in Fig. 2A

CAUTION: When not in use, please be sure to disconnect the cord plug

from electrical outlet.

SEWING LIGHT

Sewing light is located directly over the

needle so as to better illuminate stitching

area. Turn sew light switch on and off

behind face plate.

To replace bulb, turn light off, and open

face plate. Unscrew bulb as you do a

conventional light bulb. Place new bulb

in socket and screw in place. (Fig. 2)

CAUTION: Please be sure to disconnect

the cord plug from electrical outlet before

replacing bulb.

Page 8

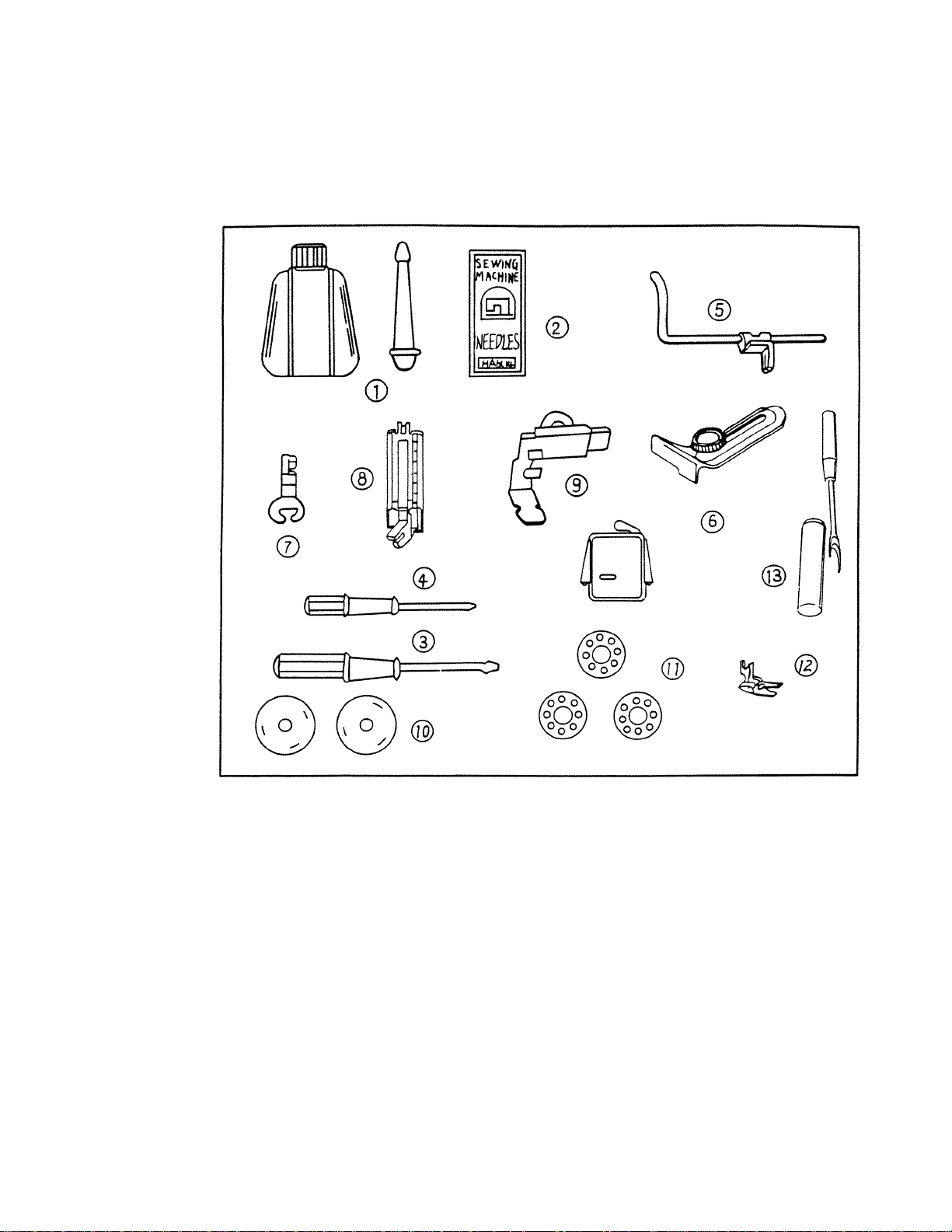

ACCESSORIES

Plastic Oiler (sealed and fillecf)

1.

Package of Needles (5 straight

2.

needles and 1 twin needle)

Large Screw Driver

3.

Small Screw Driver

4.

Quilting Guide

5.

Cloth Guide with Thumb Screw

6.

Button Sewing Foot

7.

Buttonhole Foot (on machine)

8.

Zipper Foot

9.

Felt Washers (2) for spool pins

10.

Bobbins (3)

11.

12. Zigzag Foot (on machine)

Seam Ripper

13.

Feed Cover

14.

Page 9

BASIC INFORMATION

Section 2

needle, thread and fabric chart

fhe needle and thread you choose depends upon the fabric you are stitching.

The correct needle size is important to avoid damaging the fibers of lightweight

or tightly woven fabrics and to prevent needle breakage when stitching heavy or

stiff fabrics.

Needle

size

9

fine

Thread

• polyester

• cotton covered polyester

• fine mercerized cotton (70-100)

chiffon, fine silk, tricot, lingerie

fabrics, sheer lace, net, voile,

organdy

Fabric

• silk A

light weight knits and jersey, silk,

batiste, taffeta, satin, lace, crepe

11

light

• polyester

• cotton covered polyester

• mercerized cotton (50-60)

• silk A

double knits, linen, poplin, gingham,

pique, seersucker, velveteen, light

weight wools, fine corduroy

14

medium

• polyester

• cotton covered polyester

• mercerized cotton (50)

• silk A

heavy wools, corduroy, felt,

terrycloth, canvas, upholstery,

and drapery fabrics

16

heavy

• polyester

• cotton covered polyester

• heavy duty mercerized (40)

• silk D (buttonhold twist for

topstitching)

Use only style 15x1 (European equivalent 705) on this machine. This style or

system is the most commonly used on household sewing machines.

• Always use same type and size of thread in both needle and bobbin.

• Always use a sharp needle. A blunt point can cause skipped stitches or snag

the fabric. Chemical finishes and man-made fibers blunt the needle faster.

• Never use a bent needle.

• If your machine is skipping stitches, replace the needle before looking for

trouble elsewhere.

Special Needles with blue shaft or ballpoint are particularly designed to sew knits

and stretch fabrics. Such special needles can prevent sewing from skipping stitches

and damaging stretch fabrics. Available in size 9, 11, 14 and 16.

Page 10

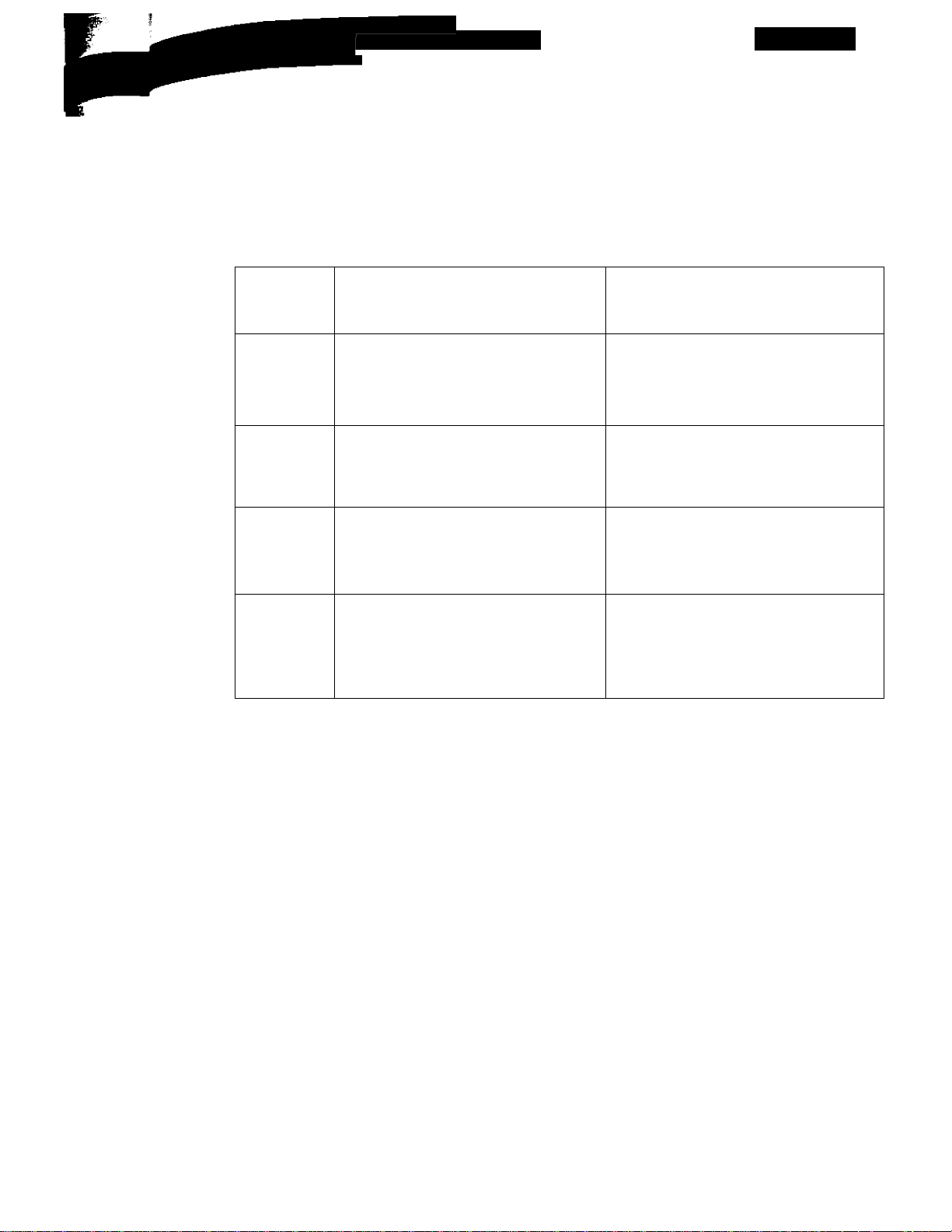

CHANGING PRESSER FOOT

Raise needle to its highest position by

turning hand wheel toward you. Raise

presser foot by lifting Presser Foot

Lifter located on back of machine.

Loosen thumb screw and remove

foot.

Place grooved side of selected presser

foot against presser bar. Tighten

screw securely with screwdriver.

Do not operate machine with presser

foot lowered unless fabric is between

presser foot and fabric feed.

Fig 3 B

CHANGING NEEDLE

Raise needle to its highest position by

turning hand wheel toward you.

Loosen Needle Clamp Screw and

remove needle.

Place new needle so its flat side faces

back. Push up into needle clamp as

far as possible. Tighten screw with a

screwdriver.

Turn hand wheel toward you one. com

plete rotation to be sure needle is

correctly positioned.

Page 11

REMOVING NEEDLE PLATE

(T

by

Raise

IjU-

Foot

S8t

ffiacbine.

remove

(j presser

Tighten

if.

, presser

fjetween

(NOTE: If extension plate is on machine, remove it.)

a) Raise Needle to its highest position by turning hand wheel toward you.

b) Op .1 the hook cover towards you

c) Remove the screws from needle plate. Then remove needle plate.

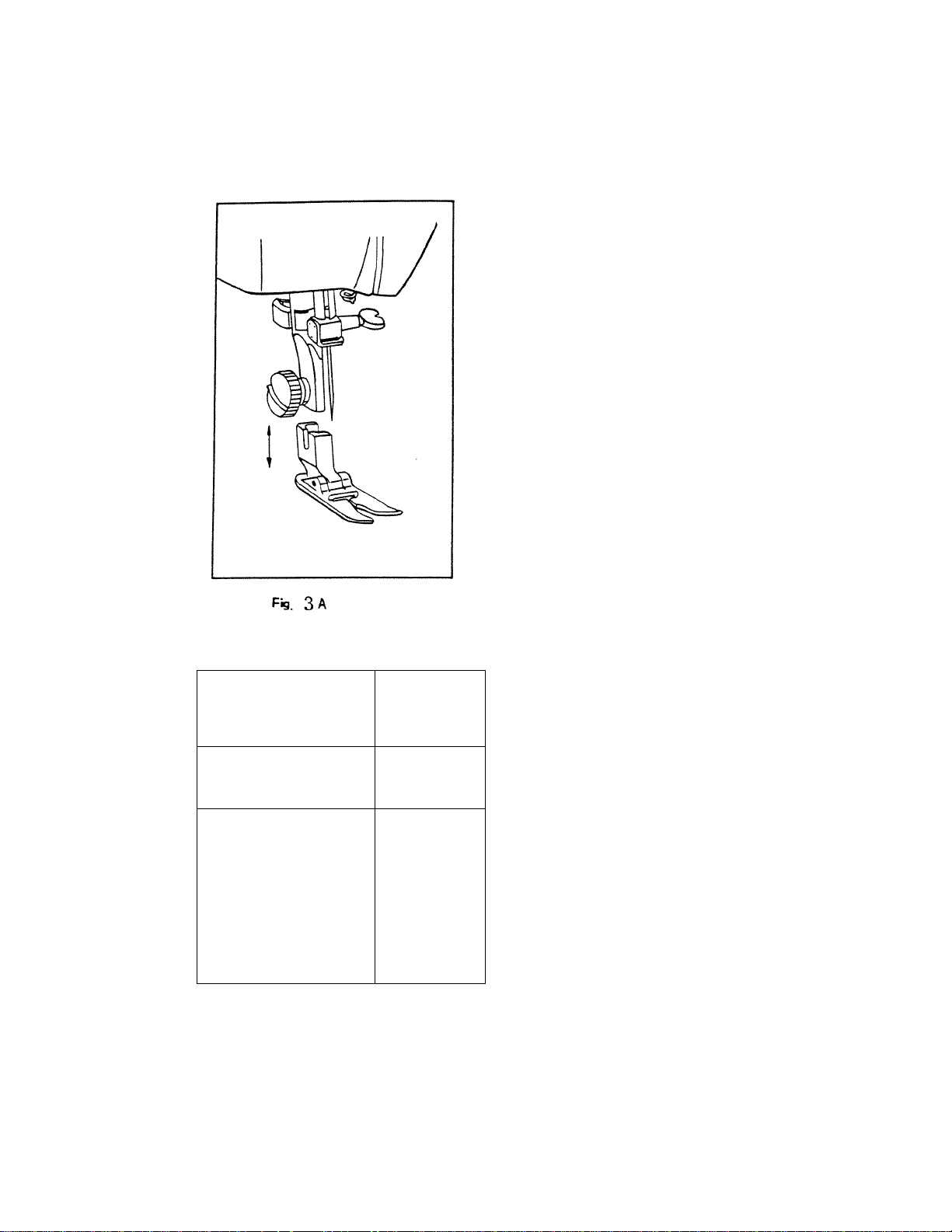

REMOVING BOBBIN CASE

Raise needle to its highest position by turning hand wheel toward

you. Open Hook Cover.

ition by

I you.

w and

le faces

amp as

with a

e cornidle is

Lift open hinged latch of bobbin case (Fig. 10) and pull case straight

out of machine (Fig. 11).

Bobbin will remain in case as long as latch is open. To remove

bobbin, hold bobbin case down, close latch, and bobbin will fall out

(Fig. 12) ■

Page 12

THREADING MACHINE

Section 3

Rear View of Machine

WINDING BOBBIN

Place spool of thread on spool pin and

thread as shown in illustration. Be

sure thread goes under tension disc on

Bobbin Winder Thread Tension. (Fig. 1)

Put thread through one of the holes in

empty bobbin from inside to outside.

Push bobbin down firmly on bobbin

spindle at top of machine with slot in

bobbin fitting into spring on bobbin

spindle. Push bobbin and spindle to

the right. (Fig. 2)

Release sewing mechanism by holding

Hand Wheel and turning Stop Motion

Knob toward you (Fig. 3). Hold end

of thread and press down on foot

pedal as when sewing. Release end

of thread as soon as winding starts.

Run machine slowly to wind bobbin

evenly.

Bobbin winder will stop itself when

bobbin is full. Pull bobbin and spindle

back to the left until a click is heard.

(Fig. 4) Break off thread and remove

bobbin. Tighten Stop Motion Knob.

Winding Bobbin Evenly

If bobbin winds unevenly, adjust

thread guide by loosening screw at

base of guide:

• if more thread winds at top of

bobbin, shift thread guide slightly

downward.

• if more thread winds at bottom of

bobbin, shift thread guide slightly

upward. (Fig. 5)

• after adjustment tighten screw.

Bobbin Winder Stop

For a fully wound bobbin, the

knob should just slightly overlap

edge of bobbin.

If too far out, thread will extend

beyond bobbin. Loosen screw at

top of knob and turn plastic

knob to adjust; tighten screw.

Knob can also be adjusted to ex

tend farther into bobbin for less

amount of thread. (Fig. 6)

Page 13

threading bobbin case

Hold bobbin as shown in Fig. ,3 so that thread goes over top of bob

bin and away from you.

Place bobbin in case without turning it around.

uT «"-on

Puli out thread ,0 check that bobbin turns clockwise. (Fig. 15)

INSERTING BOBBIN CASE

Be sure that 6 inches of thread extends out

of bobbin.

Hold bobbin case so long finger on case

points up. Open latch. (Fig. 16)

Slip case over center pin in shuttle and

press in place until long finger enters

notch. Release latch, and press down

(Fig. 17) ■

Close Hook Cover.

-11-

Page 14

THREADING UPPER THREAD

Raise presser foot and needle to their

highest position by turning hand wheel

toward you.

Place thread on spool pin at back of

machine. Pass thread through slots of

two top thread guides (A), then down

behind arm thread guide (B) (Fig. 7)

Place thread around bottom of Thread

Tension Dial (C) and slide it up between

tension discs (Fig. 8).

Hold thread stationary with right hand

and pull thread with left hand until check

spring wire loop (D) goes up above top

hook (E).

Release thread so wire loop will spring

back into place and thread will slip into

hook.

Lower presser foot.

Place thread behind arm thread guide (B),

up through hole in take-up lever (F)

theading from right to left, and back down

behind arm thread guide (B) again.

Draw thread down through thread guide

(G) and needle bar thread guide (H). Thread

needle from front to back. Pull thread

towards rear about 6 inches.

Side view of thread passing through tension discs for single (or normal) needle.

INCORRECT

CORRECT

i|

I'-— Threads

Fig 8

-12-

Page 15

HhI

|ir

BRINGING UP LOWER THREAD

of

7)

ck

Itop

)l,

IF)

foi

Raise presses foot. Hold needle thread

loosely with your left hand. Turn hand

^eel toward you until needle moves

down and then up again to its highest

position, catching bobbin thread and

(Fibril "

To prevent thread from slipping out of

needle when you begin sewing, pull both

reads out about 6 inches and place under

(FigTg)^““' machine.

TWIN NEEDLE-UPPER THREADING AND SEWING

2 Follow '' "'ready on machine.

. Follow threading instructions for single needle with

these exceptions;

A - Place thread, matching or contrasting in color

on both spool pins. '

B

C

D

Pass threads through arm thread guide

Down around tension discs with one thread

passing between the back discs and the other

between the front discs.

Treat both threads as one, until you reach the

needle.

E - Pass one thread through each needle eye. (Fig.

^ indication

marks (Fig. 21) otherwise needle will break Turn

hand wheel slowly toward you to make certain twin

needle dows not hit needle plate

4. All normai stitches and ail st'retch stitches can be

made with the Twin Needle.

T3-

Page 16

RE-WINDING BOBBIN WHEN MACHINE IS THREADED

If bobbin runs out of thread while sewing, it is not necessary to completely unthread

machine to re-wind bobbin.

Simply bring thread from needle up through top thread guide in front of machine (Fig.

9). Insert end of thread from inside to outside in one of the holes of empty boddin.

Proceed according to instructions starting in paragraph 2, page 10 section 3 (Winding

Bobbin).

If you wish to wind a bobbin while sewing, here is another method:

Place spool of thread on second spool pin and proceed as shown in illustration on page

10 Section 3 (Winding Bobbin). DO NOT RELEASE SEWING MECHANISM by turning

stop motion knob toward you. In this way, while you continue to sew, bobbin will be

filled.

-14-

Page 17

CONTROLS

upper Thread Tension too strong

Upper Thread Tension too weak

Pig. 22

Section 4

TENSION OF UPPER THREAD

An important point when sewing is

to make sure that the thread tension

is correct. The Thread Tension Dial

is marked with 0 to 9. Normal thread

tension is obtained by setting the Dial

at 5 against the top hook. Your

machine has been tested using the

thread supplied, and with the Dial

set at 5. It might prove necessary to

adjust the tension slightly when using

threads or fabrics of different thick

ness.

By Turning Thread Tension Dial

counterclockwise close to 0, upper

thread will be pulled down below and

lower thread lies straight. By turning

dial clockwise close to 9, upper

thread will be straight and lower

thread forms loops on the top side.

(Fig. 22)

Thread tension is correct when stitch

knots occur in the mid-layer of ma

terial. Before sewing garment, try to

make a sample on a double folded

scrap of material with which to test

various tensions by sewing to make

certain tension is correct.

-15-

Page 18

CHECKING TENSION OF LOWER THREAD

If you are unable to balance the stitch by adjusting tension on the

upper thread, you may have to make a slight adjustment in the

bobbin tension.

Take out bobbin case, remove bobbin and clean out any dust or lint

which has collected around the case.

Turn screw on bobbin case slightly in either direction using the small

screw-driver (Fig. 24):

To increase tension - turn screw slightly to the right (clockwise).

To decrease tension - turn screw slightly to the left (counter

clockwise)

If stitch is satisfactory but the seam is puckered, it may be necessary

to loosen tension on both top and bottom threads.

CHECKING TENSIONS

An easy test for checking tension balance:

Fold fabric on the bias and stitch (12 stitches/inch) ’/2” in from

fold.

Grasp stitching and pull with a snap to make threads break

(Fig. 25)

• if both threads break (even though not at the same place) —

tensions are balanced.

• if upper thread breaks — loosen top tension.

• if lower thread breaks — tighten top tension.

-16-

Page 19

Section 4

essories, there is a feed cover, to sew mebroidery, darning, mond-

on buttons which need no feeding to fabrics, use this 'TEED

iiiig O'"

tfl"

f.ed cover on needle plate

. edie to its highest position.

j|fise oe studs and one back stud into holes on needle plate, as shown in

¡¡Ijck two

fig. 26.

sure normal sewings, should always take this feed cover, that is, without

i

i

'il O n

Uu

JO D U

JSTING PRESSURE FOR REGULAR SEWING

)ressure of the presser foot must be regulated for different types of fabric to

1 proper feeding. To adjust pressure push down outer ring (A; Fig. 27)

itch-O-Matic Darner with thumb and forefinger. The center button (B,

27) will spring up and then the pressure can be easily adjusted by being

d down partially for light fabrics (Fig. 28), or all the way down for medium

ivy fabrics (Fig. 29).

STING PRESSURE FOR EMBROIDERY, DARNING AND SEWING ON BUTTONS

button (B, Fig. 27) will pop up. The pressure will be completely released.

j.

il

the outer ring (A, Fig. 27) down with thumb and index finger and the

-17-

Page 20

STITCH LENGTH

Length of the stitch is regulated by Stitch Length Dial (Fig.30)

Turn the dial to right to lengthen and to left to shorten the stitch. Near point A

Fig. 30 is the shortest stitch and near point B Fig. 30 is the longest.

In general, short stitches are best for light weight fabrics; longer ones for heavy

fabrics. Most normal sewing is done with stitch length set about 12 stitches per

inch.

Stitch Length (Approximate)

Marks on dial

Number of stitches per inch

( point A )

No Feeding

REVERSE STITCHING

Press in center button of Stitch Length

Dial (Fig. 30) and hold for reverse

stitching. Fabric will immediately start

feeding backwards. Release button and

machine will resume normal forward

stitching.

A few reverse stitches are very useful

for fastening beginning or end of seams

and darts without having to tie threads.

-

36

—

20

12

9

7

-18-

Page 21

SEWING

Section 5

¿firing

^^J^ggest that you practice all of the various instructions given in this Section before

ictually Lise your sewing machihe to make a garment.

^ with straight stitch, zigzag stitch and then try all of the decorative and stretch

' ches, afLl finally a buttonhole.

Thread machi..e.

, Wind bobbin and place it in bobbin case. Insert into shuttle. Bring up lower thread

pull both threads out about six inches and place under presser foot to rear of '

machine.

Set machine for stitch length, stitch width, desired stitch and tension

Place fabric under presser foot. ’

5.

Lower presser foot by releasing presser foot lifter.

6.

TO SEW

7.

dlTonfooTpldL'”''' pressing

3.

Run machine at slow even speed, until you get the "feel" nf it

3.

AHow fabric to feed Ward with .o.^en. of frie“;::,. ,,,

fabric back as needle may bend or break Inctoari n 'a t u ■

hand in front of presser foot. ' V“-

toward you. L,ft presser foot lifter, gently pull fabric and threads backward

Pull threads over thread cutter and press down to cut. ’

-19-

Page 22

STITCHING TIPS

Check that dials are set correctly for the stitch you want — stitch pattern,

stitch length, and stitch width.

Use proper needle and thread for your fabric. Needle should be straight,

sharp and inserted properly. Change your needle frequently.

Test machine stitch on double thickness of a scrap of the fabric you plan to

use. Adjust machine for length of stitch, tension and pressure, if necessary.

Place fabric under presser foot with bulk of material to the left of needle.

For most seams, place right edge of fabric on the 5/8" seam marking on

needle plate. Pull thread ends behind presser foot. (Fig. 31) Lower presser foot.

To prevent fabric from being drawn into needle hole when you begin

stitching, start about %" from edge of fabric.

To reinforce beginning and end of seams, backstitch about Vi" from edge of

fabric.

Regulate speed of machine by increasing or decreasing pressure on foot

pedal. Run machine at a slow even speed. I.

Allow fabric to feed forward with the movement of the fabric feed. Don't

pull or hold fabric back as needle may bend or break. Instead, guide fabric

gently with your hand in front of presser foot.

When finished stitching, turn hand wheel toward you to raise needle to its

highest position before removing fabric from under presser foot. Raise presser

foot. Pull threads over thread cutter located at back of presser bar, and press

threads down to cut. (Fig. 32)

-19A-

Page 23

Keeping Stitching Straight

Your machine has three aids to help keep

your stitching straight, whether stitching

seams or doing decorative stitching.

1) Numbered guidelines on the right

side of needle plate. (Fig. 33)

Numbers indicate distance, in eighths

of an inch, from the needle. For

5/8" seam, line up your fabric with

the numbered 5/8 guideline.

2) Quilting attachment (Page 26)

3) Cloth guide attachment (Page 26)

Pin Basting

Place pins at right angles to pressar foot

with pins just nipping into fabric at

stitching line. Never place pins on

underside of fabric in contact with fabric

feed or so presser foot rides over head

of pin. (Fig. 34)

STRAIGHT AND ZIGZAG SEWING

For sewing straight stitch and zigzag.

Turn Stitch Selector (C Fig. 35) at

By turning Stitch Width Dial (B Fig. 35)

clockwise, the stitch width will be in

creased; and counter-clockwise will be

decreased. Set Stitch Width Dial at bottom

indication mark for straight stitching.

-20-

Page 24

STRETCH AND DECORATIVE STITCHES

iNSTRUCTIONS FOR SEWiNG ON STRETCH MATERIALS

Attach zigzag presser foot.

1.

2.

Thread machine with same weight and type of thread on top and in bobbin,

(preferably polyester thread)

3.

Set Thread Tension Dial at 5. If tension is too tight it will draw the material.

4.

On exceptionally heavy material, release the pressure on the presser foot to

allow machine to feed evenly.

5.

If stitches skip, refer to NEEDLE-THREAD-FABRIC chart on page 7 to select

correct size needle and suitable thread. Use special needle with blude shaft or

ballpoint needle.

MULTIPLE ZIGZAG STITCH

1. Turn Stitch Selector (C Fig. 35) at ;> .

2. Turn Stitch Length Dial (A Fig. 35) to shorter stitch length.

3. Turn Stitch Width Dial (B Fig. 35) to desired width.

Use to overcast edges of seams, facings and hems to prevent raveling and to keep

lightweight knits from rolling. Besides knits, use for edges of thin, easily frayed

fabrics which have a tendency to pucker when overcast with ordinary zig-zag.

Also suitable for overcasting heavy fabrics such as woolens and terrycloth.

Use for attaching elastic. Mark elastic and garment waistline in fourths. Place

elastic over fabric and pin together at the markings. Take a few stitches to anchor

elastic to fabric, then stretch elastic between pins as you sew.

Mend tears and patches on knits and lightweight fabrics with stretch zig-zag rather

than regular zig-zag.

SCALLOP STITCH

1. Turn Stitch Selector (C Fig. 35) at ]

2. Turn Stitch Length Dial (A Fig. 35) to fine stitch (sating stitch)

3. Turn Stitch Width Dial (B Fig. 35) to desired width

tin stitches. Use for monograms, appliques and embroidery.

DOUBLE OVERLOOK STITCH

1. Turn Stitch Selector (C Fig. 35) to |

2. Turn Stitch Length Dial (A Fig. 35) to lengest stitch.

3. Turn Stitch Width Dial (C Fig. 35) to 3-5.

This stitch is used to avoid fraying the edge of material. Sew near the edge of the

-natenal and trim the excess portion as close as possible to the edge of the stitch

after sewing up the seam. > u.e Miicn

-21-

Page 25

SAtiN STITCH (See Fig. 35) i

Turn Stitch Selector (C Fig. 35) at

Stitch Length Dial (A) to shortest indication mark.

3’ Turn Stitch Width Dial (B Fig. 35) to desired width.

Closely spaced zigzag stitches which form a smooth, satin-like surface are

called satin stitches. May be used for monograms, appliques and embroidery.

triple seam stitch and rickrack stitch

»f ^

1. Turn Stitch Selector (C Fig. 35) at , .

2 Turn Stitch Length Dial (A Fig. 35) to longest stitch.

3. Turn Stitch Width Dial (B Fig. 35) to "0” position for triple seam stitch, to

wider zigzag width for rickrack stitch.

Stretch straight stitch is a triple lock stitch, combining stretchability and strength.

Use for stitching regular seams in knits and stretch fabrics.

Use for stitching seams in woven fabrics that receive a lot of strain when worn,

such as side seams, crotch seams, and armholes in sportswear and children's

clothes.

Also use for topstitching when you want a heavier row of stitching without using

buttonhole twist.

Guide fabric gently allowing machine to make the back-and-forth stitches that

give stretch to the seam.

STRETCHABLE BLINDSTITCH

1. Turn Stitch Selector (C Fig. 35) to ^

2. Turn Stitch Length Dial (A Fig. 35) to desired length.

3. Turn Stitch Width Dial (B Fig. 35) to desired width.

This stitch is specially designed for sewing and invisible hem on stretch fabric.

1. Fold material into size of hem desired and fold back as shown below with 1/5

inch (5 mm) overlapping on bottom fold of edge.

2. Start to sew on the fold, having narrower zigzag stitches sewn on hem edge and

wider zigzag stitches slightly touching folded top.

3. Unfold the fabric, and you will have an invisible hem.

-22-

Page 26

SMOCKING STITCH

1. Turn Stitch Selector (C Fig. 35) to |

2. Turn Stitch Length Dial (A Fig. 35) to longest length.

3. Turn Stitch Width Dial (B Fig. 35) to wider zigzag width.

Smocking can be a very time consuming process when done by hand. However,

you can obtain the same heavy stitched look with your machine, using stitches

with either a single or double needle.

Use for a yoke, insert, or band on baby clothes, little girls' dresses, smocks and

lingerie.

Space rows of stitches on crosswise fabric grain.

OVERCAST STITCH

1. Turn Stitch Selector (C Fig. 35) to |

2. Turn Stitch Length Dial (A Fig. 35) to longest length.

3. Turn Stitch Width Dial (B Fig. 35) to No. 3-5.

Useful for overcasting rough edges of stretch fabric, or sewing narrow seams in

garments. The seam is formed and finished in one operation. Use for sportswear,

bathing suits and hand-knitted garments.

BOX STITCH OR ELASTIC STITCH

1. Turn Stitch Selector (C Fig. 35) to |

2. Turn Stitch Length Dial (A Fig. 35) to 1-3.

3. Turn Stitch Width Dial (B Fig. 35) to No. 3-5.

The box stitch is used for special edge finishing and special stretch stitch for sewing

elastic such as sportswear, girdles and other garments that require stretch.

SUPER STITCHS-SWAN, TULIP, DOG STITCH

1. Turn Stitch Selector (C Fig. 35) to or or

2. Turn Stitch Length Dial (A Fig. 35) to longest length.

3. Turn Stitch Width Dial (B Fig. 35) to widest width.

-22A-

Page 27

BUTTONHOLES

jurn Hand Wheel toward you and raise needle to its highest position.

1.

Attach buttonhole foot shown in Fig. 36.

Turn Thread Tension Dial clockwise between 5 and 4 to slightly tighten thread

2.

tension.

Set Stitch Length Dial (A Fig. 35) to buttonhole symbol, and Stitch Width

Dial (B Fig. 35) to Button Hole Symbol..

4.

Mark fabric, with pencil or tailor's chalk, center line of buttonhole and

length of the buttonhole desired. 3/8"-1/4" lonaer than outside diameter of

the button.

Place fabric under buttonhole foot with center line marked on fabric in

5.

center of buttonhole foot.

Turn Stitch Selector (C) to marking No. A position, and start to sew

6.

left side along line.

7.

Stop with needle on left side of stitch (Step 1, Fig. 37)

8.

Raise needle, and turn Stitch Selector (C) to marking No. B " U". Sew a

few stitches to make bar tack. (Step 2).

9.

Turn the Stitch Selector (C) to marking No. C " □ " Sew the right side.

of the buttonhole guiding fabric so machine sews parallel to the left side

(Step 3).

10.

Turn Stitch Selector (C) to marking No. B"Q'.' Take a few stitches making

the bar tack to close other end of buttonhole. (Step 4).

11.

Cut slot in center of buttonhole with seam ripper.

NOTE. Make sure Stitch Selector (C) is firmly positioned in either marking

C " iGl ", B " n " or A ' ' c ", and always make a practice button

hole on a scrap of the same fabric you are sewing.

-23-

Page 28

BLINDSTITCHING (HEMS)

1. Turn Stitch Selector (C Fig. 35) at ^

2. Turn Stitch Length Dial (A Fig. 35) to

desired length.

3. Turn Stitch Width Dial (B Fig. 35) to

desired width.

Blind stitch consists of six straight stitches

and one zig-zag or blind stitch. It provides

a durable hem that is almost invisible when

using thread the same color as the fabric.

Only the blind stitches will show on right

side of garment. Best suited for straight or

slightly curved hems.

Turn up hem the desired width and press.

Turn raw edge in Va" and press or baste

in place. Fold hem back against right side

of garment with top edge of hem extending

about to right of garment fold.

(Fig. 38)

Fig 38

Place garment under presser foot so that

straight stitches will fall on hem edge and

zig-zag stitch just catches one thread of

the folded edge. Guide fabric evenly while

stitching or use cloth guide as an aid. For

better control, use low speed setting.

Press hem.

For a less bulky hem in heavy fabrics

finish raw edge of hem with tape or lace

to eliminate turning in raw edge. Fold

fabric so straight stitches will fall on tape

or lace.

-24-

Page 29

SEWING ON BUTTONS

You can sew both two and four holes of

buttons with your machine.

Change presser foot to the button sewing

foot (Fig. 39) and lower drop feed by

placing feed cover on needle plate (See

Page 17). Set Patch-O-Matic Darner so

pressure is completely released. (See Page

17, A. Fig. 27.) Set Stitch Selector (C Fig.

35) at l| Place button under button sew

ing foot so that needle enters left hole

freely. Set Stitch Width Dial the same width

as the hole in the button. Turn Hand Wheel

toward you and test carefully that the

needle goes through the center of first one

hole and then the other. If necessary, adjust

zigzag width. Then sew 5 to 6 stitches.

Turn Stitch Width Dial (B Fig. 35) for

straight stitching and take about 3 stitches

to lock the thread.

Thread Shank

Sew-through buttons on coats and jackets

should have a thread shank to make them

stand away from the fabric.

Place a straight pin or sewing machine

needle on top of button between the

holes, and sew over the pin or needle.

(Fig. 40)

Pull thread to back of button and wind

around stitches to form a firm shank.

Tie thread ends securely.

-25-

Page 30

ADJUSTABLE CORDING AND

ZIPPER FOOT

The zipper foot allows you to stitch

right next to a raised area such as a

zipper or cording. (Fig. 41)

Attach zipper foot and set dials for

straight stitching. To adjust zipper

foot for side of needle: loosen screw

at back of foot and slide foot to the

side so that needle passes through

notched side of foot. Lower needle

slowly to be sure it will not hit zipper

foot, and tighten thumb screw. Zipper

package will contain easy to follow

instructions for stitching.

CLOTH GUIDE

This attachment is most convenient

for guiding the fabric to keep the

stitching parallel to edge of the fabric.

(Fig. 42).

Use for stitching seam widths that

are wider than markings on needle

plate, and for making wide hems.

Also use as a guide for blindstitching.

Fasten cloth guide to machine by

inserting thumb screw into hole in

bed of machine. Adjust cloth guide

to desired distance from needle and

tighten screw.

Fig 43

sii'

QUILTING GUIDE (Fig. 43)

Use for stitching parallel lines without

marking fabric when quilting, shirring,

smocking, or making rows of decorative

stitches.

Loosen presser foot thumb screw and

insert prongs of guide between screw

and presser foot. Slide end of guide

to the distance you wish to space the

rows of stitching. Lower presser foot

and stitch first row.

Move fabric over until guide rests on

first row of stitching and stitch second

row. Continue stitching rows in same

manner. (Fig. 44)

-26-

Page 31

CARE AND MAINTENANCE

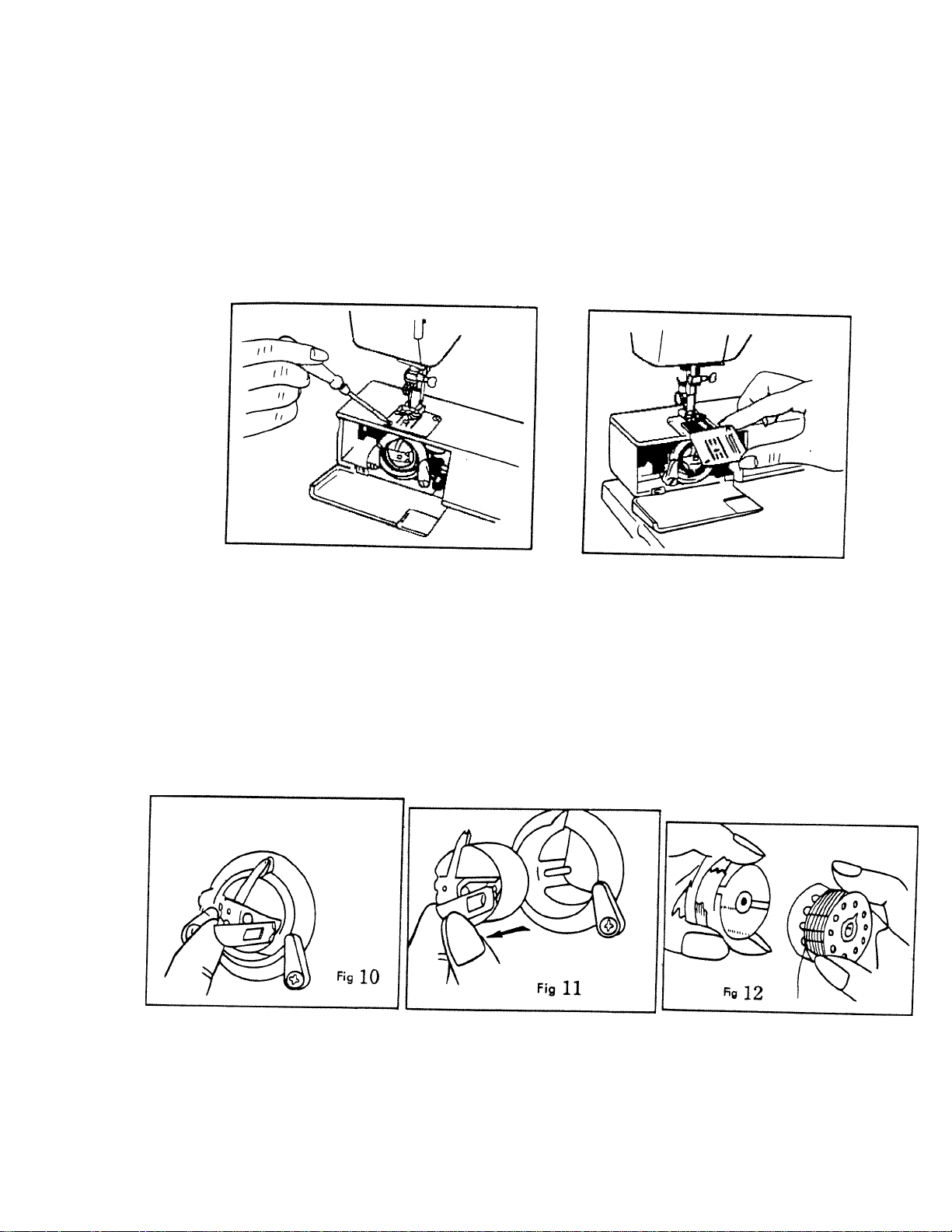

CLEARING SHUTTLE HOOK AND

VA/hen thread is tangled in the rarp h

^ook and shuttle race, follow this procedure"^- between shuttle

RACE

I, Raise needle to its highest position, open hook cover anw

Tilt head back on its hinges. remove bobbin case.

2.

Release the levers (A) at both sides of shuttle race (Fia 4fiS h. h- u

outward, then remove the front rinn ir\ ^ Pushing them

fingers (Fig. 47). ^ ^ook (D) with your

3.

With small brush thoroughly dean nnHpr ^ r,

from all parts of shuttle and Wipe with lightly oiledlth

4.

A.er ,Hu„le race and ahu.„e hook have been cleaned, p„, ,he. hack In reverse

5.

Snap levers (A) into place as seen in Fig. 46.

6.

Put bobbin into case and place case into shuttle.

OILING

e^e" week™ "S'

every day if frequently and

use If m in continual

a period S'"r '

staSSng vou

machlnl "o7af e"“h

shown In the Pictures:

“n'aS'oS’:,rr"^

friction points. (Fig. 48)'"'^^

Page 32

Under Top Plate - Remove Top Plate by unscrewing two screws and oil points on

top of machine head. (Fig. 49)

Fig 49

It is important that you do not give the machine too much oil which will only

run out and spot your fabric. After oiling machine, sew a few rows of stitches on

a scrap of material to be sure that machine sews cleanly. Also wipe off any excess

oil from top of machine.

Do not oil the motor. Lubrication is not required as motor has been permanently

oiled.

Underside - A. Raise needle to its highest position and remove rear plate by

unscrewing two set screws on it. Oil the points as indicated.

(Fig. 50)

B. Open Hook Cover and press it down to get a better view to oil

the points as indicated. (Fig. 51)

28 -

Page 33

PROBLEMS - and PROBABLE CAUSES

Section 9

Problem

If Machine

Binds

Skipping

Stitches

Irregular

Stitches

Uneven Stitches

Probable Cause

Thread or lint in

raceway

Bent needle

Needle placed in

correctly in clamp

Too fine a needle

for thread being used

Upper thread tension

too loose

Improper threading

Bobbin not wound

evenly

Pulling or holding

material

Not enough tension

on upper thread

Poor quality thread

Needle too fine for

thread being used

Correction

See instruction, page 28.

Discard and replace.

See instruction page 8.

See needle and thread chart,

page 7

Tighten upper tension.

See threading instruction,

page 12.

Rewind bobbin, page 10

Avoid pulling or holding

material, just guide it.

Increase tension.

Try different thread.

See needle and thread chart,

page 7.

Upper Thread

Breaking

Material

Puckering

Improperly threaded

Too much tension

Starting with take-up

in incorrect position

Improper setting of

needle

Bent needle or eye of

needle too sharp

Bent or blunt needle

Tensions too tight

Dull needle

Stitch length too long

Refer to threading instructions.

See page 12.

Loosen tension on upper thread

by turning thread tension dial

to lower number.

Always start sewing with take-

up lever in highest position.

Refer to needle setting in

struction. See page 8.

Insert new needle.

Insert new needle.

See tension adjustment

page 15 and 16.

Insert new needle.

Reduce stitch length.

29

Page 34

Loading...

Loading...