SINGER W164 User Manual

¥

SEWING MACHINES

SINCE 1868

You are now the owner of a new Domestic straight stitch machine, the most

versatile machine of this type you can possess.

To aid you in obtaining the greatest performance from your machine this book

on its care and uses has been written for you. Read the instructions carefully as a

thorough understanding of your machine will reward you with many hours of troublefree sewing.

Time-saving attachments, such as ruff lets, binders, buttonholers, edgestitchers,

cording feet, automatic decorators, and soforth to complement the accessories furnished

with your machine, are available from your dealer.

DOMESTIC SEWING MACHINE CO., INC.

Cleveland, Ohio 44111

DOMESnC SEWING MACHINES

1470 Birchmount Road

Scarborough, Ontario, Canada

-.i

m

INDEX

Pages

Accessories.............................................................. 13

Attachments............................................................ 20

Adjustable Cord & Zipper Foot........................26

Decorator

Attachment Foot

Binder................................................................23

Blind Stitch Hemmer .......................................31

Buttonholer

Button Sew-On..................................................30

Edgestitcher

Hemmers.......................................................... 24

RuHler...............................................................28

Bobbin

Placing In Shuttle .............................................. 7

Threading Case

Winding..............................................................5

Needle.................................................................4

..........................................................

..............................................

.......................................................

.....................................................

..............................................

31

21

21

6-7

30

Pages

Stitch Length

Thread

Trouble.................................................. 16-17-18

Darning and Mending................................................ n

Features and Parts

Maintenance and Care.........................................14-15

Needle Setting............................................................5

Reverse Sewing...........................................................g

Sewing

Light and Thin Weight Fabrics

Preparation.......................................................12

Tips

..................................................

Tension Adjustment

Threading ................................................................. jq

Bobbin.............................................................. 6

Upper..................................................................0

.....................................................9

............................................................

..................................................2-3

.......................

32-33-34-35

...4

11

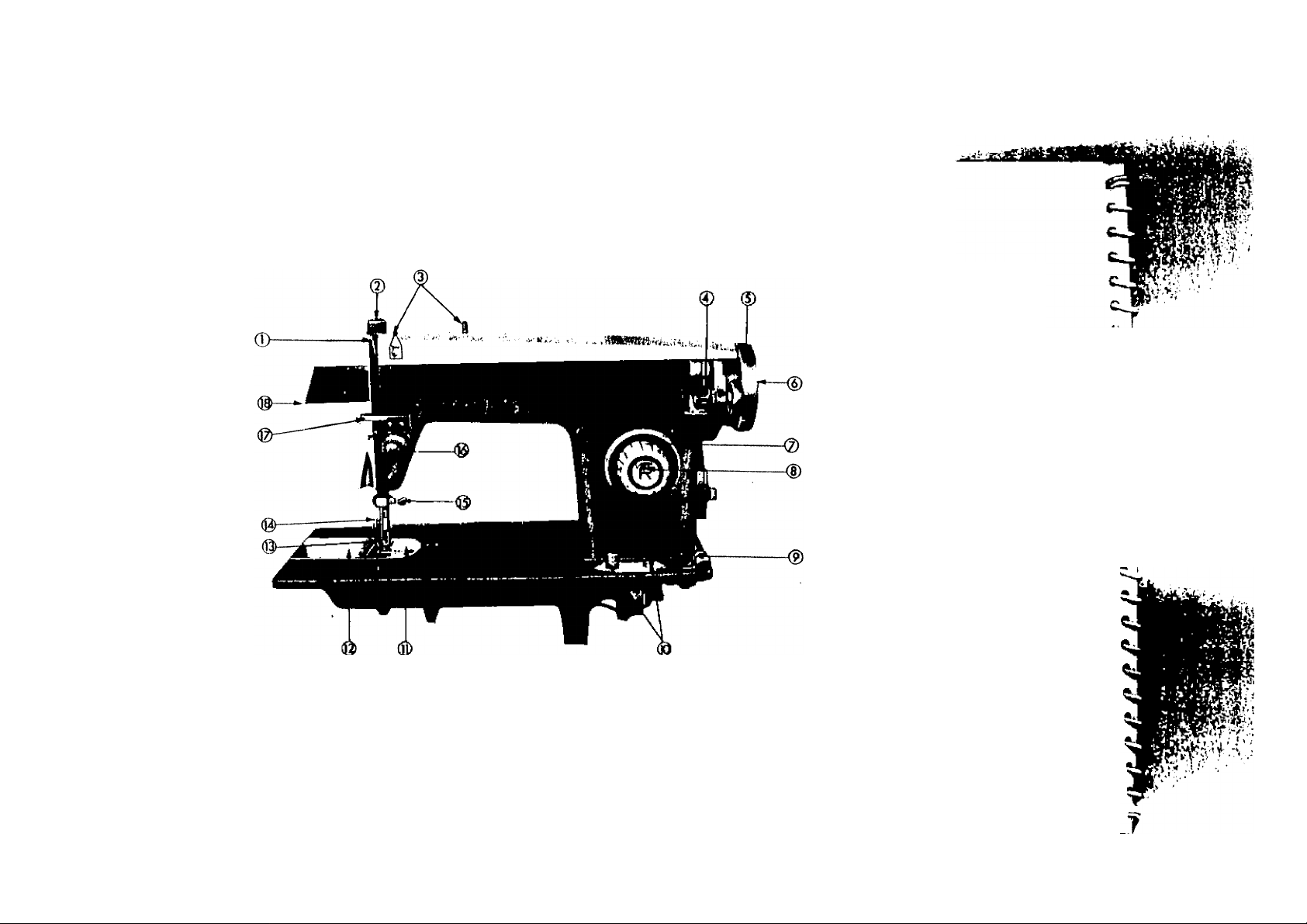

FEATURES AND PARTS

(Front View)

Fig. 1

1. Thread Take-up Lever

2. Pressure Release

(Darning)

3. Arm Thread Guides

4. Bobbin Winder

5. Hand Wheel

6. Clutch

7. Stitch Length Control

8. Push Button Reverse

9. Bobbin Winding

Tension

10. Drop Feed Buttons

11. Heedle Plate

12. Cover Plate

13. Presser Foot

14. Presser Foot Thumb

Screw

15. Needle Clamp

16. Tension Regulator

17. Thread Bar and Guide

18. Sew Light Switch

'T

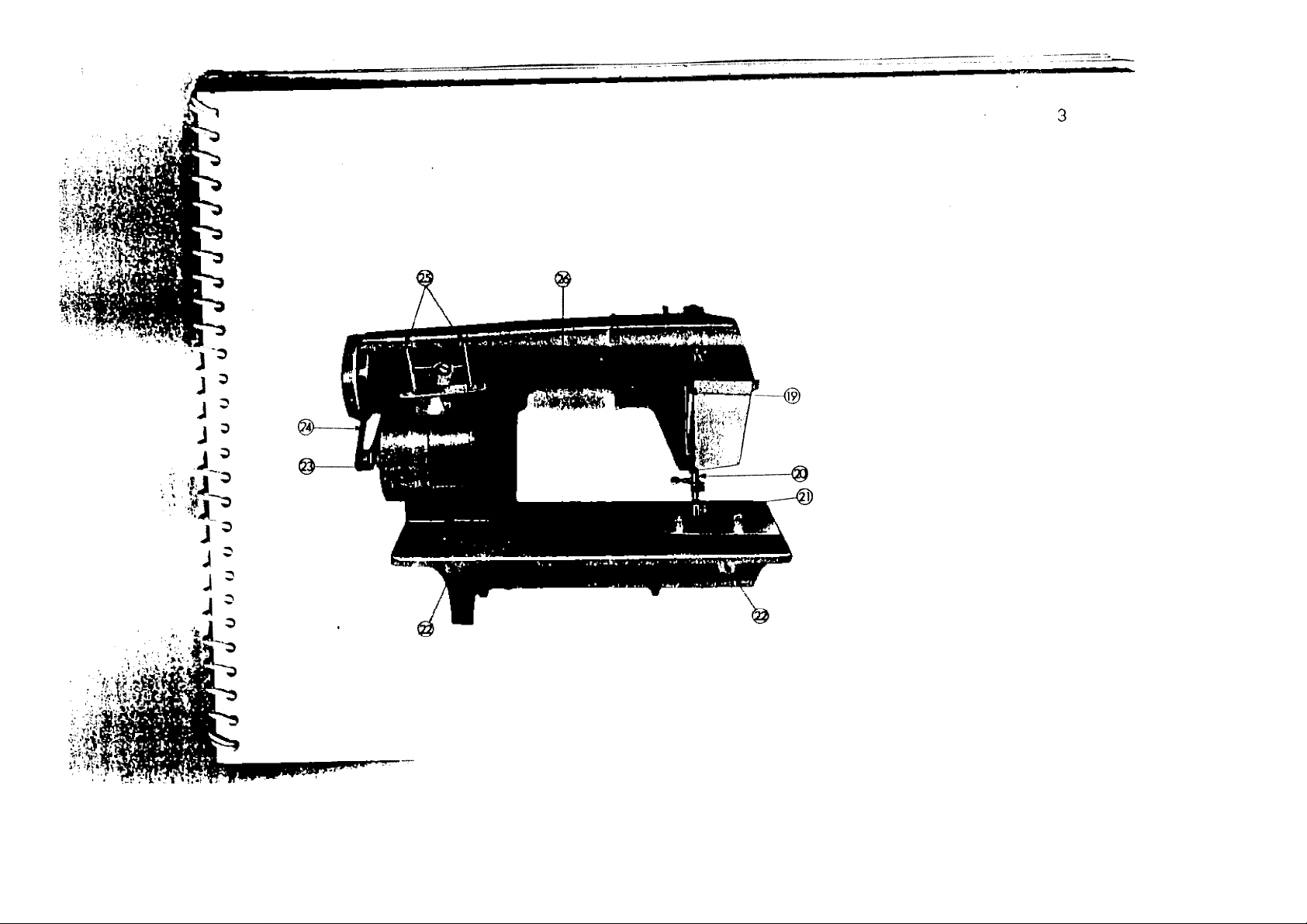

FEATURES AND PARTS

(Back View)

Fig. 2

19. Presser Bar Lifter

20. Thread Cutter

21. Feed

22. Head Hinge Mounting

Holes

23. Motor

24. "N" Bell

25. Spool Pins

26. Handle

NEEDLE - THREAD - FABRIC - STITCHING GUIDE

Fabric

Extremely heavy

tarpaulin, sacking,

canvas, duck, etc.

Heavy upholstery

fabric, ticking.

denim, leatherette

Medium heavy drapery

fabrc, velveteen.

suiting, felt, terry, etc.

Medium broadcloth,

percale, gingham, linen.

chintz, taffeta, sheer

wool, shantuna, etc.

Sheer voile, lawn,

dimity, crepe.

handkerchief linen,

plastic film, etc.

Very sheer chiffon.

batiste, lace, organdy.

ninon, net, marquisett, etc.

Machine

Needle

No. Per Inch

4 to

3 to

2 to

1

0

00

Stitches

(Plastic tilm)

Cotton

Thread Thread

6

8 30

8

10

10

12

12

14

14

to

16

8 to 10

16

to

20

Silk

Mercerized or

Nylon

10

to

30

to

40

40

to

60

60

to

80

80

to

100

100

to 50 A

150

Heavy Duty

Heavy Duty

Heavy Duty

50 A

50 A

Fig. 3

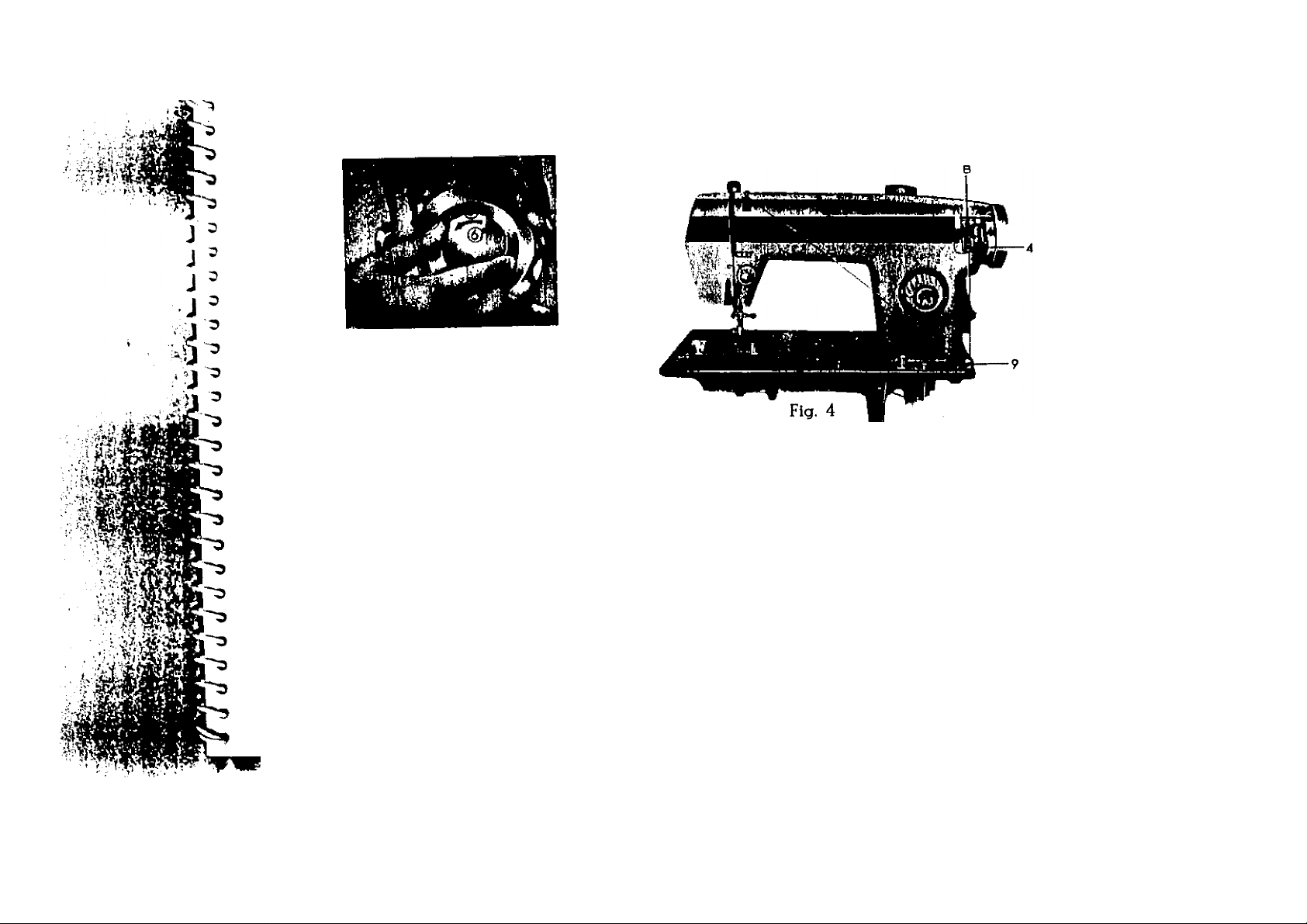

WINDING THE BOBBIN

Disengage the hand wheel (5, Fig. 3;) from the stitching mechanism by turning the clutch (6,

Fig. 3) toward you or counterclockwise.

Place a spool of thread on one of the spoof pins. Lead thread through the upper thread guide

on the arm and down through the tension disc (9, Fig. 4) at the base of the machine. Run end of

thread through a hole in the bobbin edge and place bobbin B on spindle of. bobtm winder (4,

Fig. 4) fitting the notch on bobbin over small pin on spindle. Push bobin winder pulley against

hand -wheel. Hold thread end loosely and start machine slowly.

Bobbin will stop v/inding when it is filled. Turn clutch away from yd until sewing mecha

nism is again engaged so that needle moves when you turn the hand wheel.

Break off loose thread end used to start the winding and thread bobbin as stated on page 6.

»

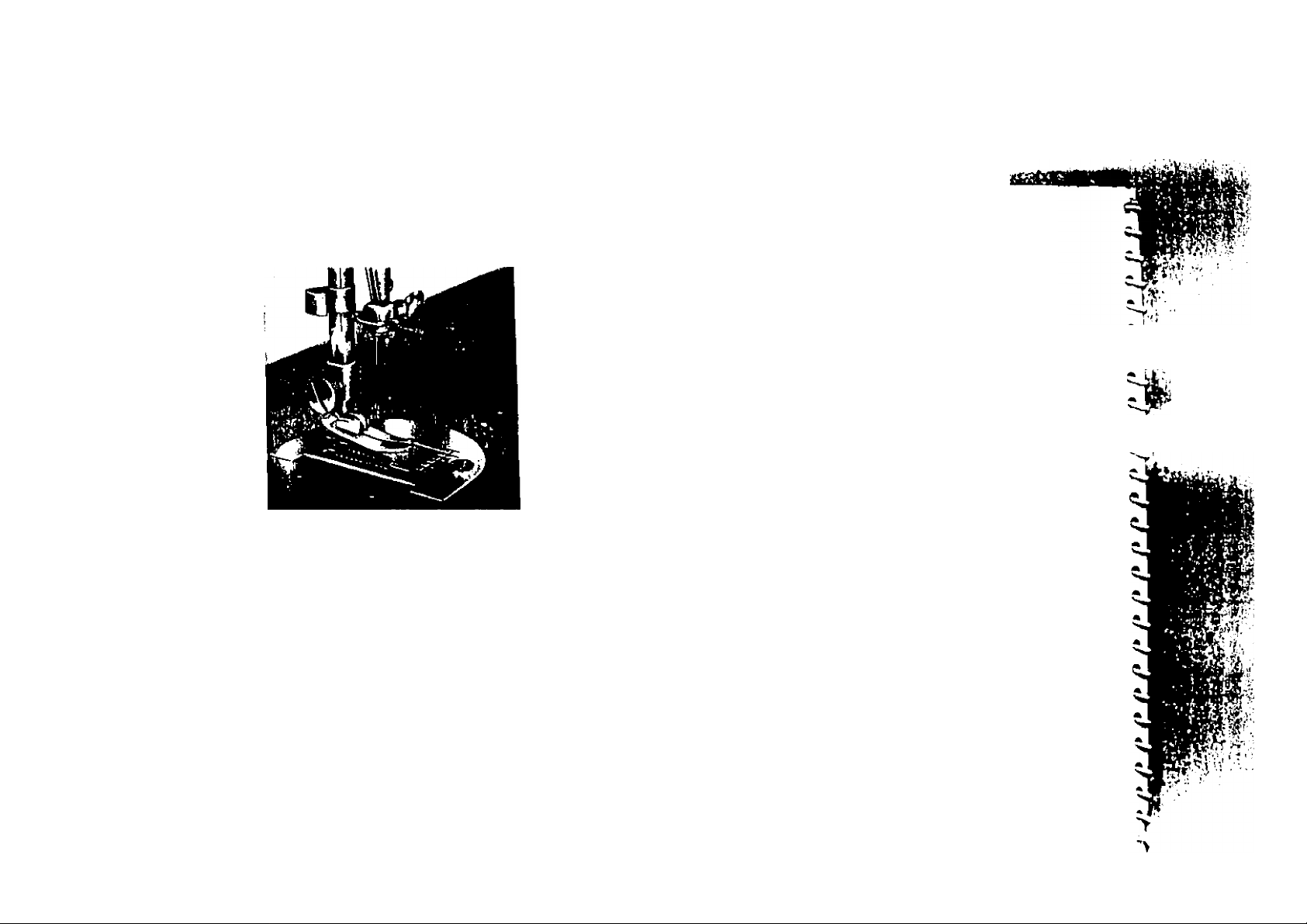

SETTING THE NEEDLE

See Fig. 5. Raise the needle bar A to its highest

point, turning wheel toward you by hand.

Then loosen the needle clamp screw B and the

needle can be inserted into clamp C. Place needle

(flat side to right) in the needle clamp and push it

upward as iar as it will go into the needle clarnp

hole, tightening the needle clamp screw securely

with a screw driver.

Alter changing the needle make one compíete revolution ol the balance wheel by

hand to be sure the needle is in the correct

position.

Flat BUtlace

oi needle

shank

Fig. 6

k;

fc. .

Fig. 5

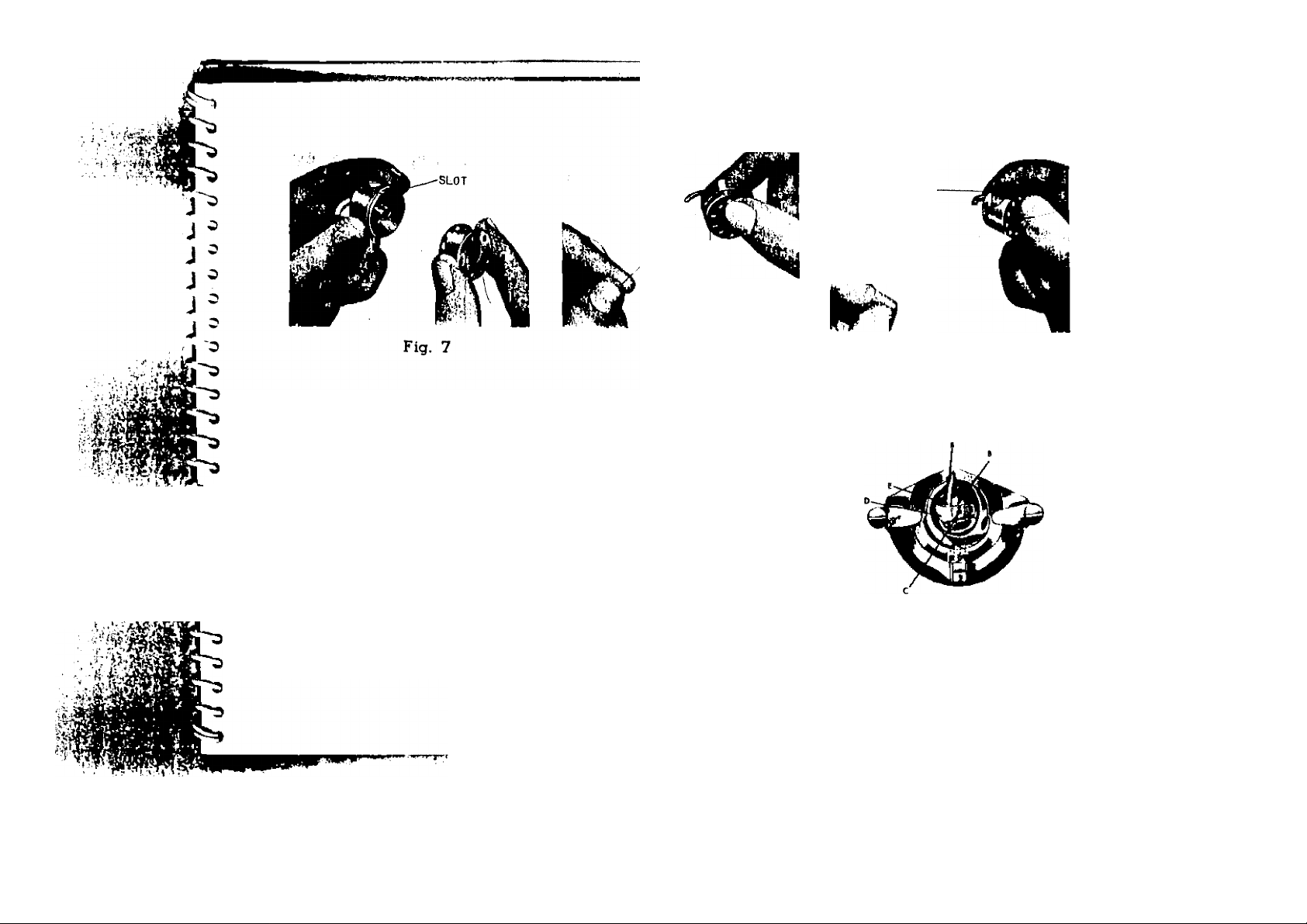

THREADING THE BOBBIN CASE

Step 1 (.llustr.led in Fig, 7). Hold bobbio case between thumb and lo.ellnger ot lelt hand,

eo that the slot in the edge ol the bobbin case ia on lop. Take the bobbin between thumb and

forefinger of right hand so that the thread on lop leads from loft to tighf.

Step 2 Insert bobbin into bobbin case, pull the thread into the slot ol the bobbin case as

shown in Fig, 8 and draw it under tension spring and into the fork-shaped opening ol the spring

as shown in Fig. 9.

’i^

SLOT

Fig. 8

PLACING BOBBIN CASE IN SHUTTLE

Raise needle bar to highest position, and slide cover plate

to the left. (See 12, Fig. 1) Hold the bobbin case latch, (D,

Fig. 10) between the thumb and forefinger of the left hand,

with at least three inches of thread running from the top of

the bobbin case to the right. Insert and center the bobbin

case on the stud of the shuttle body, (C). Be sure the

bobbin case finger, (E), is opposite the shuttle race notch (A).

Press the bobbin case (B) into the shuttle as far as possible

until latch catches on the center post of the shuttle. THEN

release the bobbip case latch, (D). Press bobbin case again

after latch has been released to make sure the bobbin case

is locked securely in place. Close the cover plate.

TENSION SPRING

'0- i

Fig. 9

Fig. 10

8

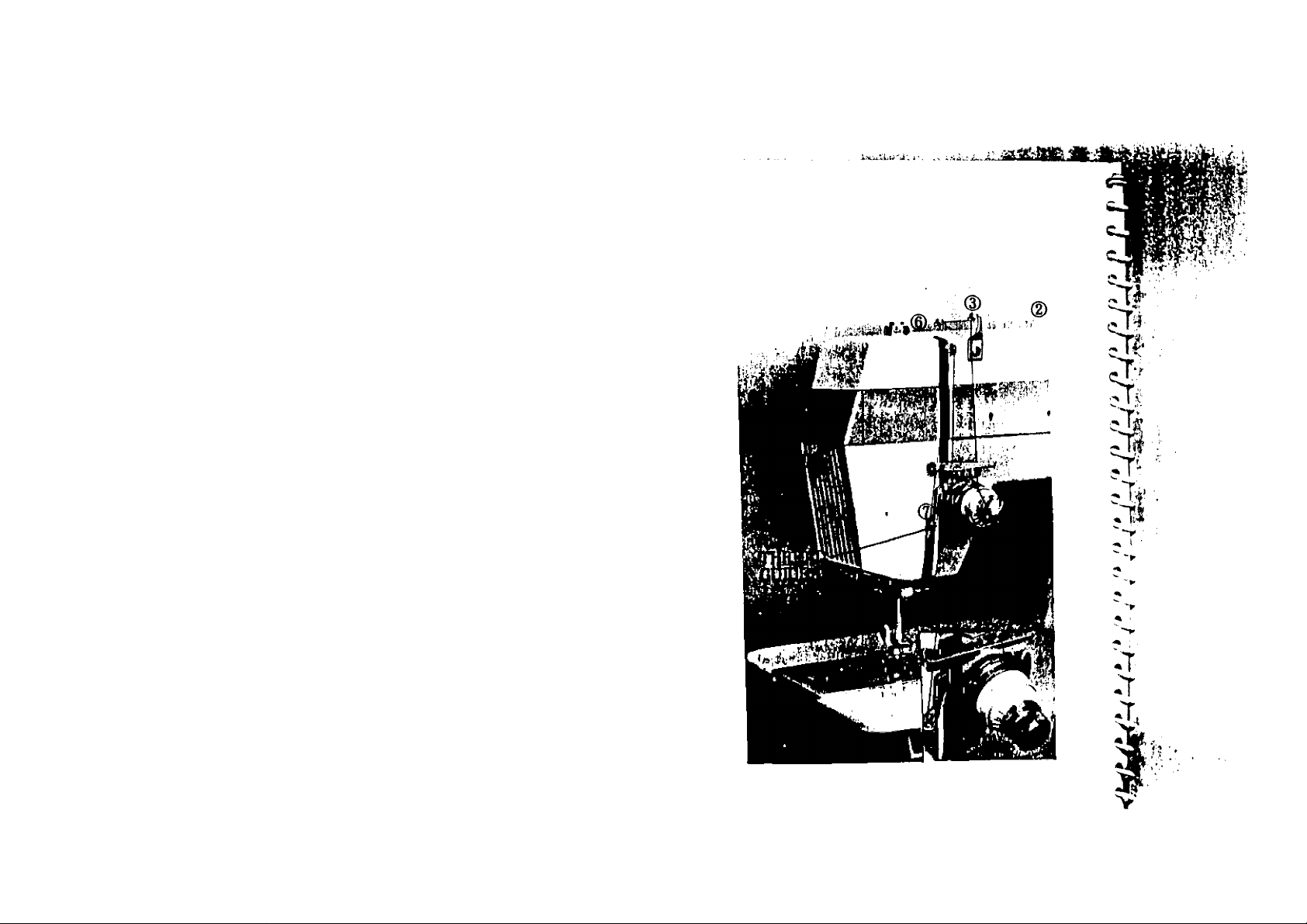

UPPER THREADING

Turn the balance wheel toward you to raise

the take-up lever to its highest position.

Place a spool of thread on the spool pin.

2.

Lead the thread through the upper arm thread

3.

guides.

Run the thread through the thread guide bar

4.

to the tension discs, then around and be

tween them from right to left.

Draw the thread up through the check spring

5.

and with a slight tug into the hook. (See

insert, Fig. H) , u

Pass the thread under the bar and up through

the eye of the take-up lever from right to

Lead thread down under bar, through the

7.

face plate guides and then through the needle

bar guide from the back. mnUT

Thread needle FROM LEFT TO RlGHl,

8.

drawing it through about 3 or 4 inches.

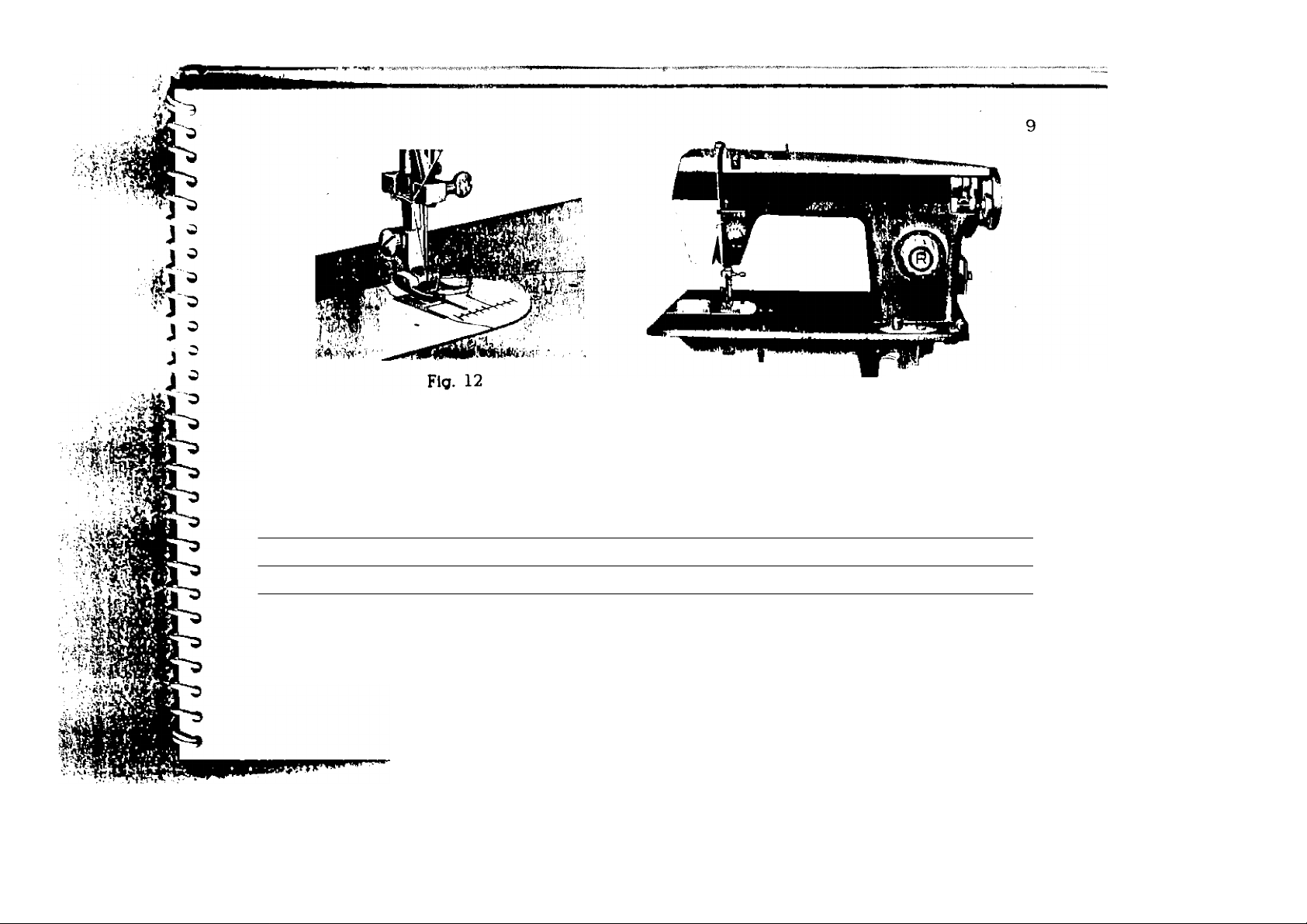

Hold the end of the upper thread loosely and

turn the hand wheel toward you until the needle

goes all the way down and comes back up.

A loop (Fig. 12) will be formed over

upper thread which then can be pulled

straight. Place both thread ends under

slot of the presser foot and draw toward

back of the machine, leaving both threads

three or four inches long.

the

out

the

the

Fig. 11

Fig. 13

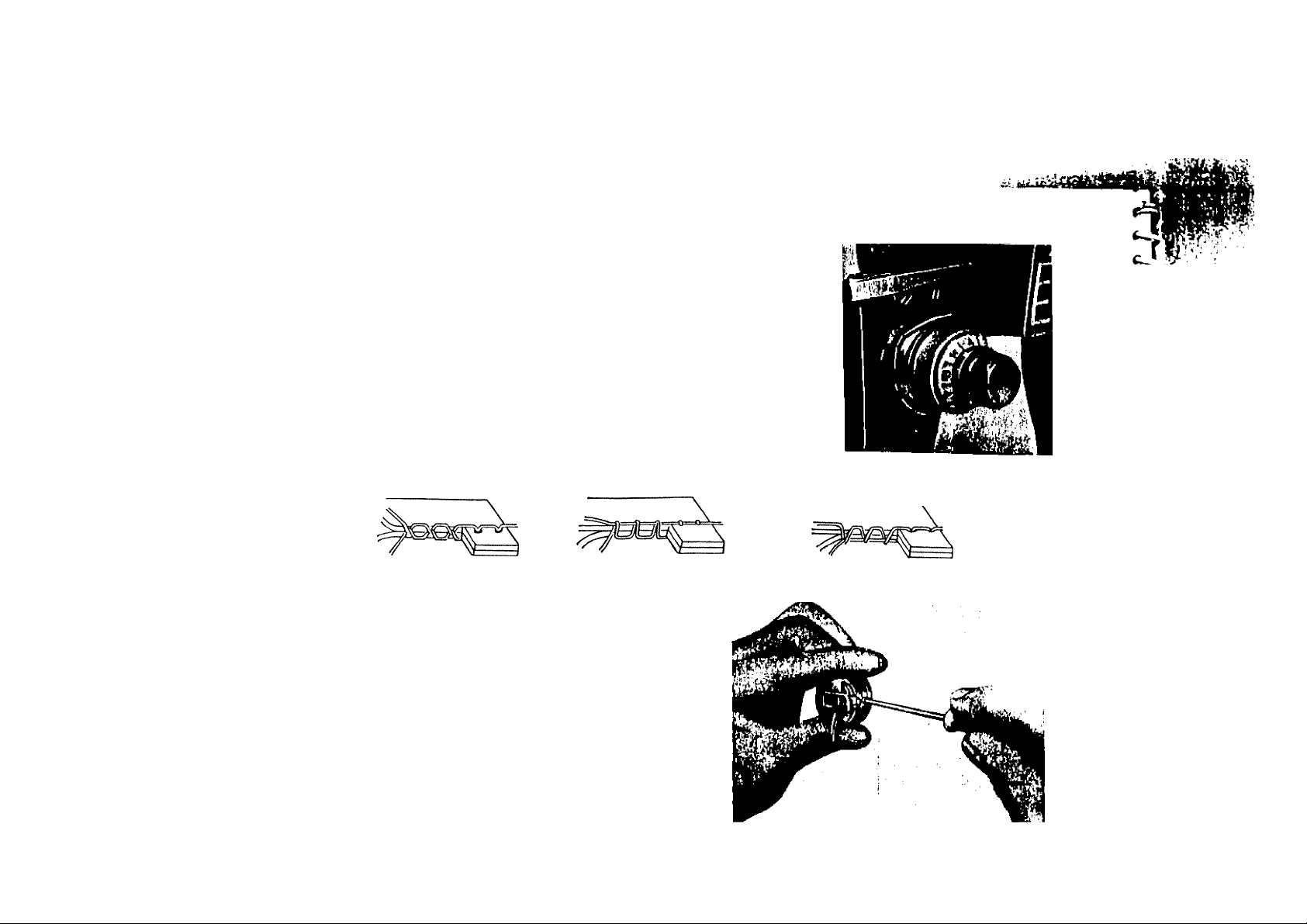

SETTING THE STITCH LENGTH

The length of the stitch is regulated by the dial, shown in Fig. 13. Near 0 is the shortest

stitch and 5 is the longest, but the dial may be set at any spot between the markings for a

variety of lengths. Turn the dial to the right to lengthen and to the left to shorten the stitch.

The number stitch length you choose is indicated by the pointer.

STITCH LENGTH CHART (APPROXIMATE)

Figures on indicator

Number of stitches per inch

SEWING IN REVERSE

When you wish to sew backward to tie the threads at the beginning or end of a seam, press

in the button R, Fig.-, 13^ as far as it will go. The machine will sew backward as long as the

button is held in.

0

No Feeding

30

1

25

2

15

3

4

8

5

6

10

ADJUSTING THE TENSIONS

Always adjust the upper tension with the presser foot down,

as the tension is released when it is raised. To increase the

tension on the upper thread, turn dial (Fig. 14) to the right, or

clockwise; to decrease, turn to the left. The higher the number

on the dial the tighter the tension. Before adjusting lower tension

be sure that the machine is threaded properly.

When it is necessary to change the bobbin tension, turn

the small screw (Fig. 16) on side of the bobbin case clockwise to

tighten, counterclockwise to loosen.

•K 1

*‘V'M

ill. ' Lii 1

Fig. 14

Fig. 15 A Fig. 15B

Wheri the upper and under tensions are properly

balanced, a perfect stitch will be formed with both

threads interlocking in fabric (Fig. 15-A).

When the upper tension is too tight, the lower

thread is pulled up over the upper thread which is

lying flat on the fabric (Fig. 15-B).

When the upper tension is too loose, the upper

thread forms loops over the lower thread lying flat

on the fabric (Fig. 15-C).

Fig. ISC

Fig. 16

ADJUSTING PRESSURE AND FEEDING OF FABRIC

GENERAL SEWING. Usually for straight sewing and various embroidery work, the pressure

bar cap or darning release, Fig. 18, is at its lowest position and the feed at its highest level-with

the drop feed button marked UP pressed all the way down. Fig. 17.

SEWING THIN OR LIGHT WEIGHT FABRICS

When lighter pressure is required to sew satisfactorily on thin

silk or flimsy material, the pressure cap should be about halfway

down. Release all the way by pressing the snap lock. A, Fig.

19, and then press cap B down again to half-way spot. Lower

the feed slightly by pressing the DOWN button (Fig. 17) to the

red line.

Fla. 18

DARNING AND MENDING

In order to move the fabric freely in any

direction for darning and mending, release

the pressure cap B completely pressing

down on the snap lock. A, Fig. 19. Press

DOWN button (Fig. 17.) all the way down,

which drops the feed well below the needle

plate. To return feed to normal, press the

UP button all the way down.

Fig. 17

Fig. 19

11

Loading...

Loading...