SINGER W1600 User Manual

MSTRUCTION MANUAL

rpe^.

\\T%

MODEL 1600

INTRODUCTION

THANK YOU FOR CHOOSING OUR OVERLOOK MACHINE'

This overlock machine can stitch dependable seams on all kinds of fabric, both light and heavy,

including cotton, wool, rayon, tricot, jersey, and knits.

You do not need a special table for this portable machine.

We suggest that you read this instruction manual carefully before you start to operate the

machine.

;:S;:W;li

■■■

■ :-V-5

; ¿-::i

FOR YOUR SAFETY

1. Keep your eyes on the needles when operating the overlook machine. Do not touch the

handwheel, the cutter or the needles when the machine is running.

2. Turn off the power switch,and pull out the plug from electric socket in the following cases;

‘When you have finished your sewing.

‘When you leave the serger temporarily.

‘When replacing the parts.

‘When cleaning and adjusting the machine.

.................... .................

' '

.......

.

BEFORE YOU USE'

1. Wipe dust and oil off the machine to avoid any stains on the sewing materials.

2. Test sew by using the same sewing materials you intend to sew.

3. Read this instruction manual thoroughly before replacing the cutters and the needles. Follow the

instructions for correct replacements and adjustments.

_ 1 _

TABLE OF CONTENTS

NAME OF MAIN COMPONENTS........................................................................................3

SETTING UP YOUR MACHINE.......................................................................................4~8

The position of thread pole..............................................................................“4

Spool holders ....................................................................................................4

Spool caps ........................................................................................................ 4

Connecting the foot control

Controlling sewing speed..................................................................................5

Safety switch .................................................................................................... 5

Attaching the waste catcher............................................................................ 6

ACCESSORIES...................................................................................................................6

USING THE MACHINE ...................................................................................................... 7

Handwheel ........................................................................................................ 7

Front cover......................................................................................................... 7

Free arm

LOOPER THREADING.................................................................................................... 8

NEEDLE THREADING........................................................................................................9

TEST SEWING ................................................................................................................ 10

ADJUSTING THREAD TENSIONS ........................................................................... 11~12

Needle thread tensions

Looper thread tensions ................................................................................ 12

MACHINE ADJUSTMENT CHART.................................................................................. 13

CHANGING THE THREAD ............................................................................................ 14

BUILT-IN POCKET HANDLE...........................................................................................14

ADJUSTMENT OF STITCH LENGTH

CUTTING WIDTH ............................................................................................................ 18

CHANGING THE NEEDLE............................................................................................... 17

REPLACING THE BULB ................................................................................................ 17

REPLACING THE CUTTERS...........................................................................................18

THREE THREAD NARROW OR WIDE .......................................................................... 19

FREE ARM SEWING........................................................................................................20

CONVERTIBLE PRESSER FOOT--’-...............................................................................20

ROLLED AND NARROW EDGE.................................................................................21-22

DIFFERENTIAL FEED .............................................................................................. 23-24

Differential feed mechanism

Adjusting the differential feed........................................................................23

Gathering ....................................................................................................... 24

Stretching ....................................................................................................... 24

TROUBLE SHOOTING GUIDE........................................................................................25

CLEANING AND LUBRICATING.....................................................................................26

SPECIFICATION OF MACHINE .................................................................................... 26

...........................................................................................................

.............................................................................

...................................................................-.............

..............................................................................

..........................................................................

12

5

7

15

23

- 2 -

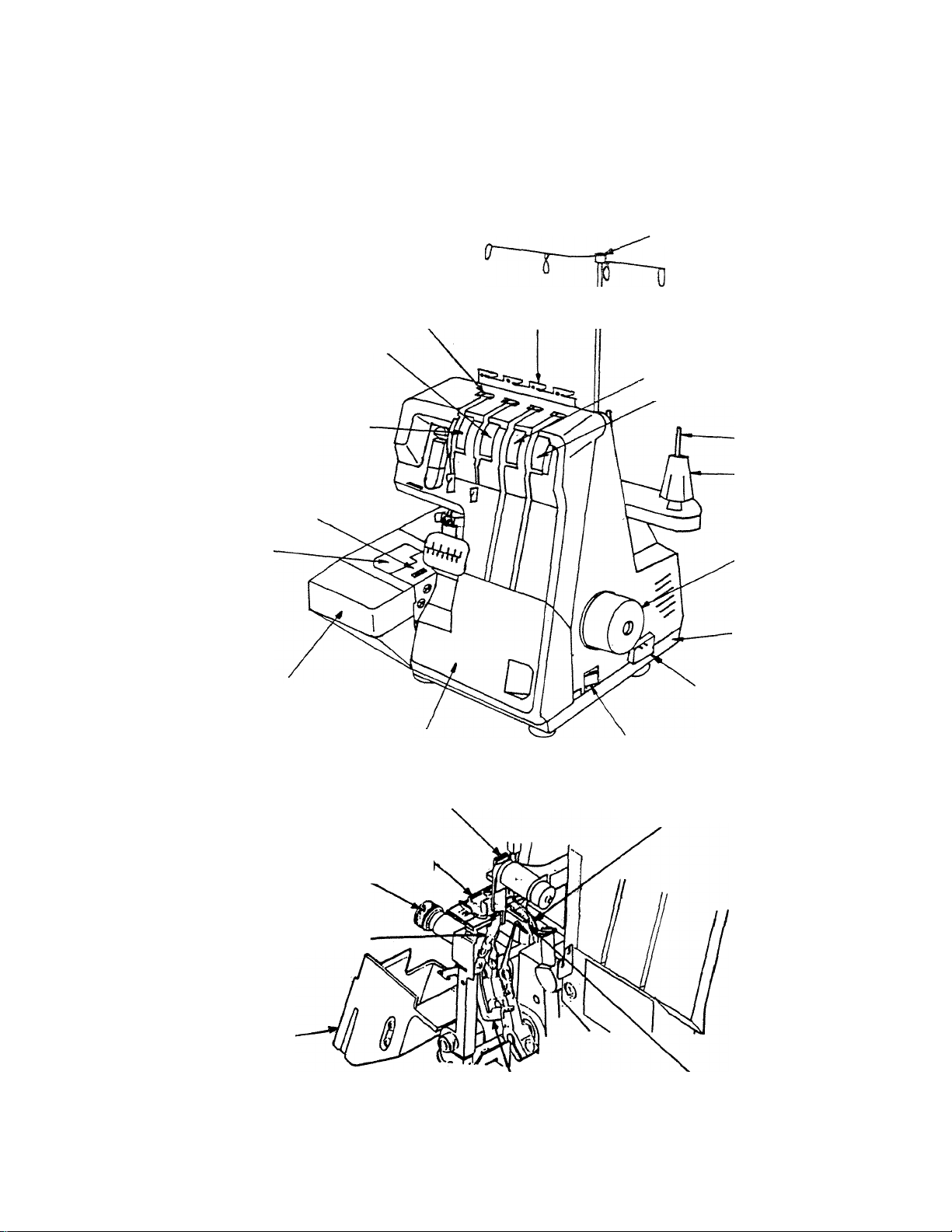

MAME OF MAIN COMPONENTS

Thread guide Thread guide plate

Right needle thread tension dial

Thread pole

Upper looper thread tension dial

Lower looper thread tension dial

Left needle thread tension dial

Needle plate

Free arm

Support bed

Cutting width adjustmentknot

Front cover

Upper knife

Presser foot

Spool pin

— Spool holder

Handwheel

Base

Machine socket

Power switch

Upperlooper

-•.-'-.-VX-.--

Lower knife

Free arm-

Free arm release lever Lower looper

- 3

SETTING UP YOUR

MACHINE

Set your Overlook machine on a sturdy flat

surface.

____________

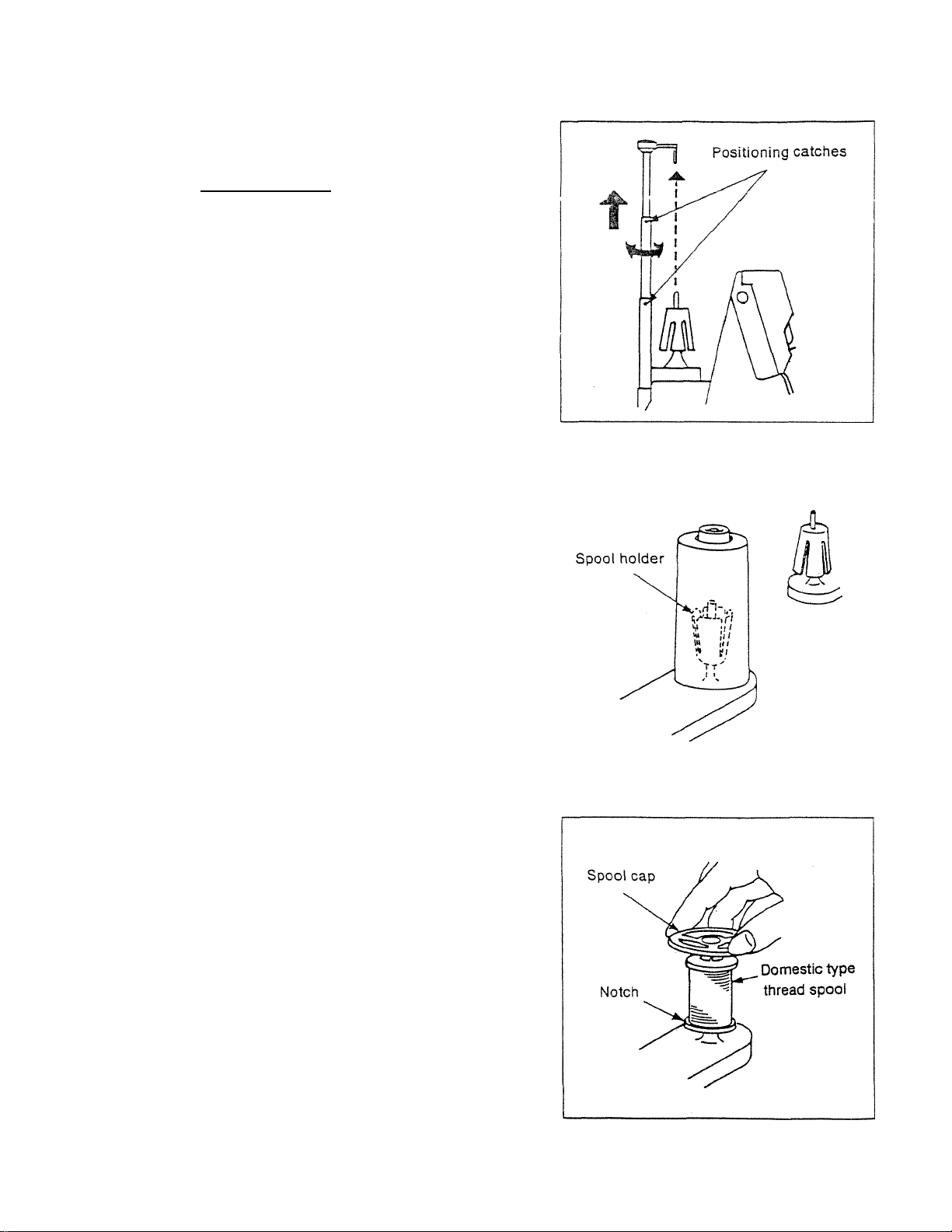

[THE POSITION OF THREAD POLE]

Pull up thread pole to its highest point before

threading.

Turn the thread pole so the thread guides come

right above the spool pins.

[CONE HOLDERS]

Both industrial cones and domestic type thread

spools can be used on this machine.

For large diameter industrial cones use the cone

holders with the large end at the top. For small

diameter cones, use the same cone holders with

the small end at the top.

Normal

[SPOOL CAPS]

When using domestic type thread spools, remove

the spool holders and place spool caps over,the

thread spools.

-a

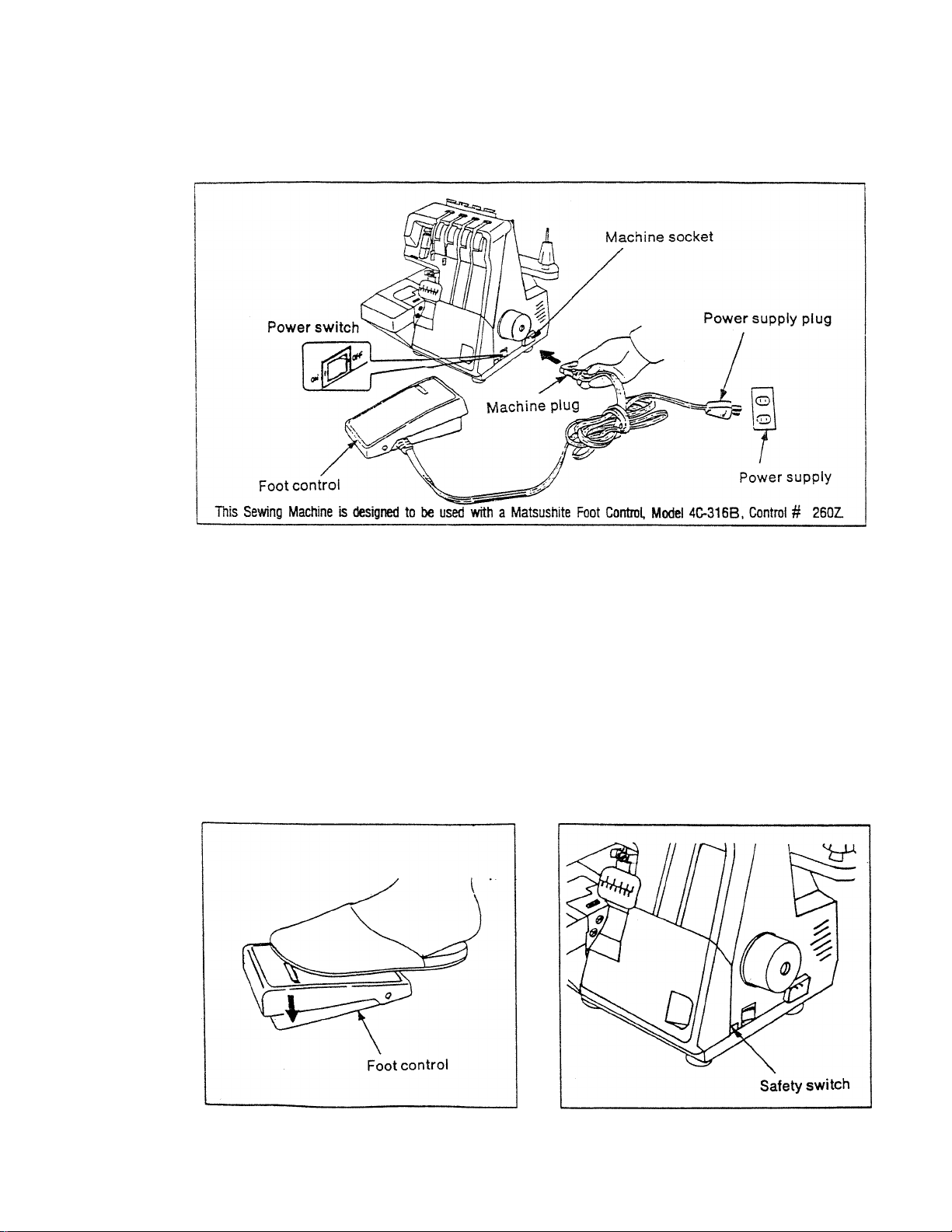

[CONNECTING THE FOOT CONTROL]

Push foot control plug into the machine socket and then into main socket.

Turn on the power switch. This power switch controls both the machine power and sewing light.

^ This appliance has a polarized plug (one blade widerthan the other). To reduce the risk of electric

shock, this plug is intended to fit in a polarized outlet only one way, if the plug does not fit fully in the

outlet, reverse the plug. If it still does not fit, contact a qualified electrician to install the proper outlet.

Do not modify the plug in any way.

[CONTROLLING SEWlNG SPEED]

The foot control regulates the sewing speed.

The sewing speed can be adjusted by

increasing or decreasing the pressure on

the foot control.

[SAFETY SWITCH]

This machine is equipped with a micro

safety switch.

The machine is automatically cut off from

the electricity supply if either the free arm

or front cover is open.

Close both free arm and front cover before

you start sewing.

- 5 -

•. ‘

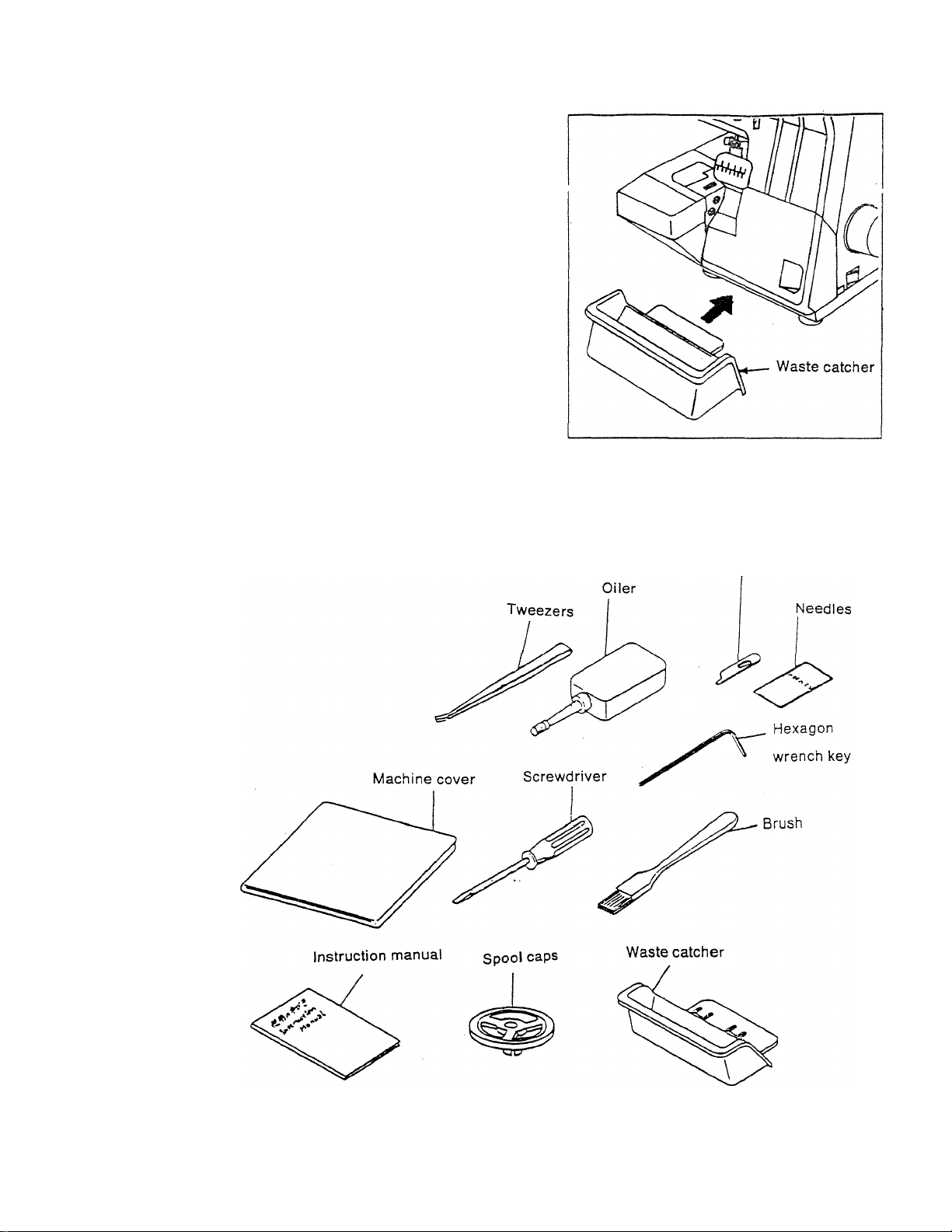

[ATTACHING THE WASTE CATCHER]

The waste catcher catches the cut-off fabric as

you sew, keeping your working area clean.

Place the waste catcher between the machine

and table.

ACCESSORIES

Spare upper cutter

wm, - -

- 6 -

USING THE MACHINE

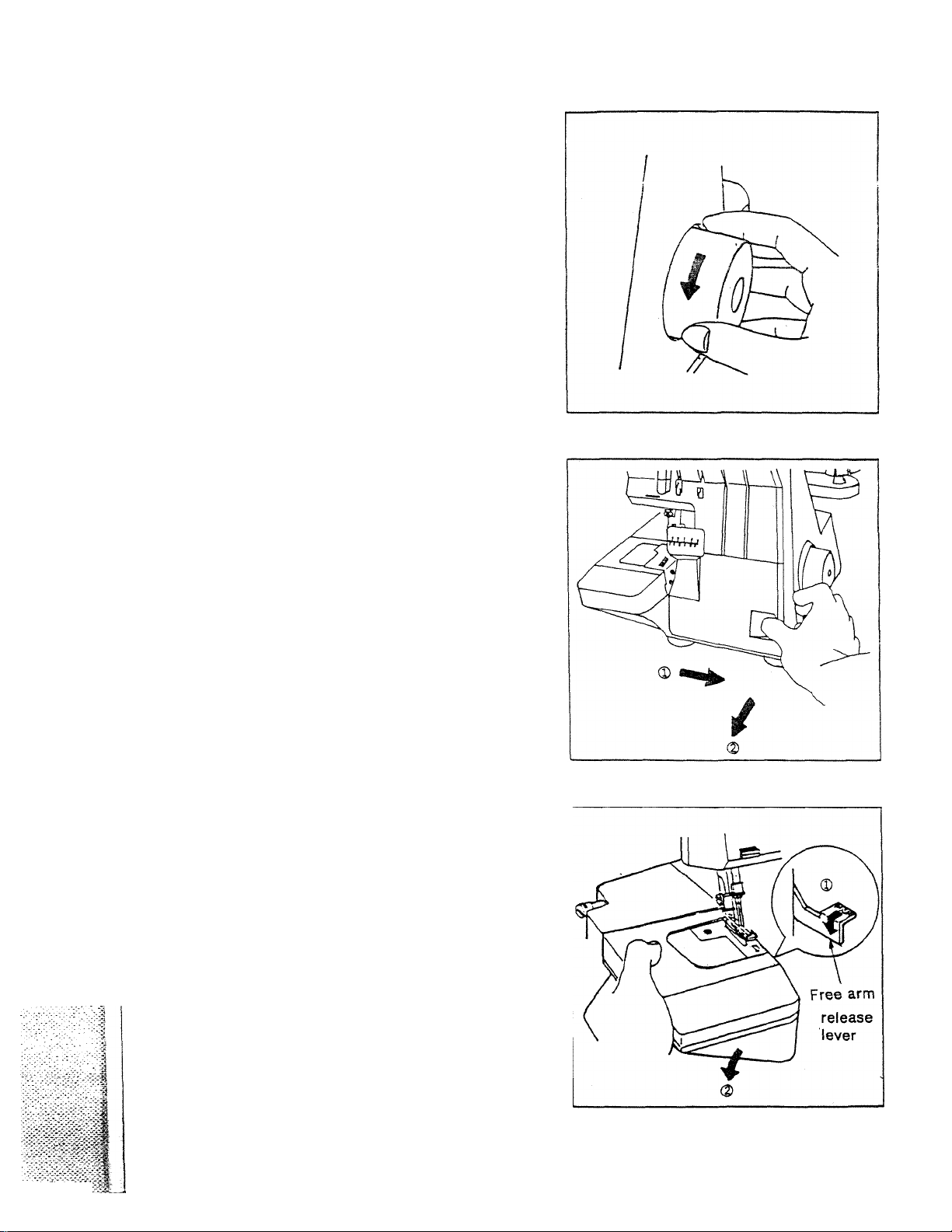

[HANDWHEEL]

Always turn handwheel toward youj.e. the same

direction as on a household sewing machine.

[FRONTCOVER]

To open front cover, slide the hollow to the right

as far as it will go then pull front cover toward

you.

The front cover won’t close while the free arm is

open.

[FREE ARM]

Open the free arm for threading.

Open the front cover first.

While pushing the release lever, push the free arm

down ward with your left hand.

- 7 -

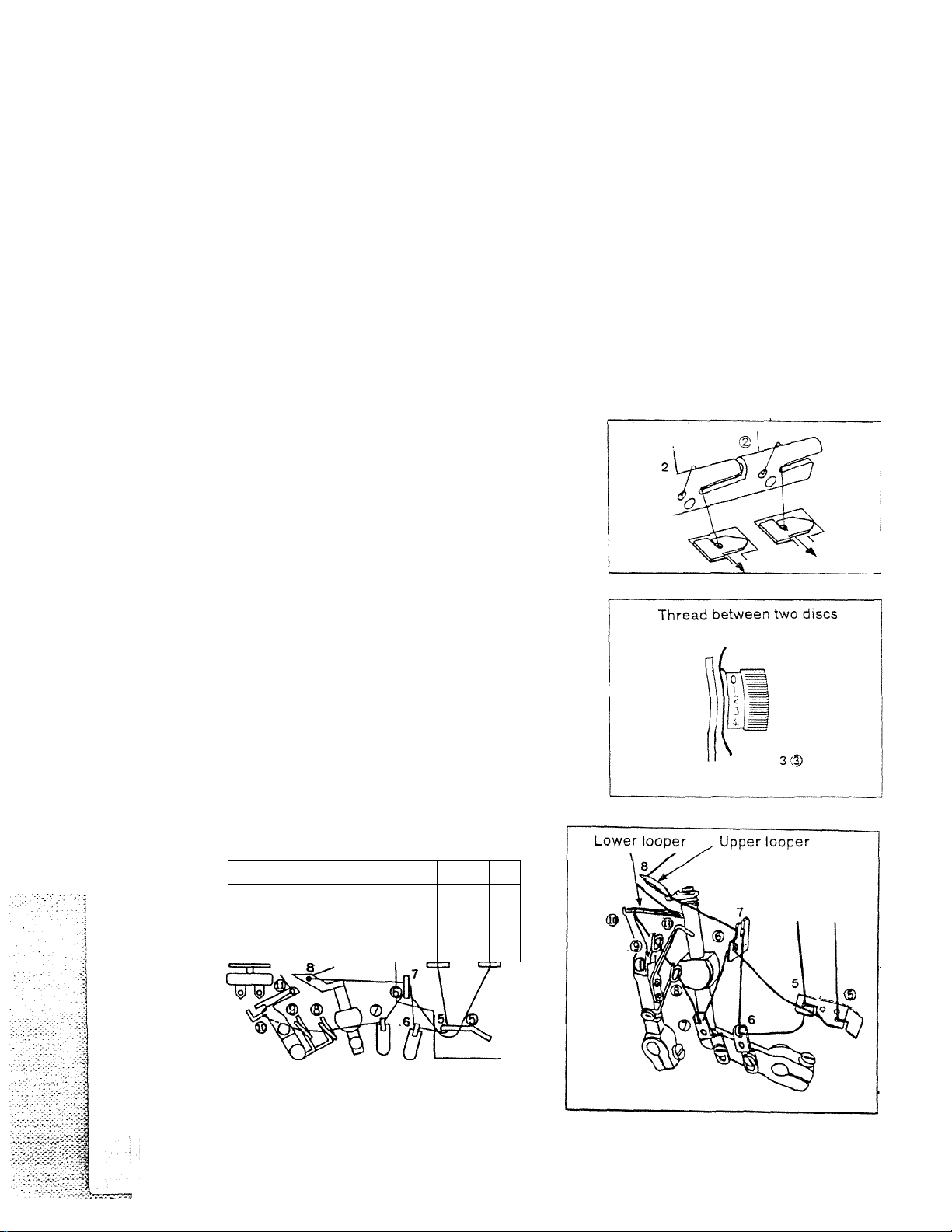

LOOPER THREADING

Correct threading is important otherwise uneven stitches or thread breakage may result

A convenient threading chart is placed on the front panel inside the front cover,

in addition, each thread guide is colored for threading

indication.

To help in threading, tweezers can be found in the

accessory box.

Threading must be carried out in the

following sequence.

I.FIRST................Upper looper

2.SECOND

3. THIRD

4. F1NALLY

l.Open the front cover and free arm.

2. Turn the handwheel toward you until, the

looper comes to best position for

threading.

3. Pass the upper looper thread and lower

looper thread as illustrated,

important; The thread must lie correctly

between the two discs inside the tension

dials.

4. Pull out the thread end about 10 cm

(4") long from the looper eyes. Raise the

presser foot and place threads under it,

then lower the presser foot.

...............

.............

.............

Lower looper

Right needle

Left needle

^ ^ V

7

V®

Upper looper thread Lower looper thread

,0

o a'0 grzdJ a

__Q

_____

O 0

n D D

J D 0

C2CiJ */<

3

4

i f

- 8 -

Loading...

Loading...