Page 1

How to use and care for your

SUPER ZIGZAG SEWING MACHINE

MODEL 150

Page 2

INDEX

Page

Features and Parts

To Replace the Needle..........................................................5

Needle and Thread................................................................5

Needle and Thread Size

Winding the Bobbin..............................................................7

Threading the Bobbin Case

Placing Bobbin Case in Shuttle

Threading the Machine

Straight Stitching................................................................11

Setting the Stitch Length

Sewing in Reverse...............................................................12

Adjusting the Tensions..................................................12-13

Adjusting Pressure and Feeding of Fabric

Sewing Thin or Light Weight Fabric

Creative Embroidery

..........................................................

........................................................

..................................................

............................................

.......................................................

.....................................................

.........................

............................

.....................................................

2-3-4

iQ

13

14-15

15-16

Page

Embroidering with a Hoop..................................................17

Darning................................................................................17

Making Buttonholes.......................................................18-19

6

8

9

H

Sewing on Buttons...............................................................19

Seam Gauge or Cloth Guide................................................20

Quilting................................................................................20

The Adjustable Cording and Zipper Foot...........................21

Sewing in a Zipper..............................................................21

Care and Maintenance of Your Machine

Cleaning and Oiling the Shuttle.....................................23-24

How to Change the Motor Belt......................................24-25

The Built-in Light

Unsatisfactorg Conditions-Cause and Remedies......................

......................................................................................26-27

Three Needle Position.........................................................28

...............................................................

............................

22

25

Page 3

-á

Cvî

Page 4

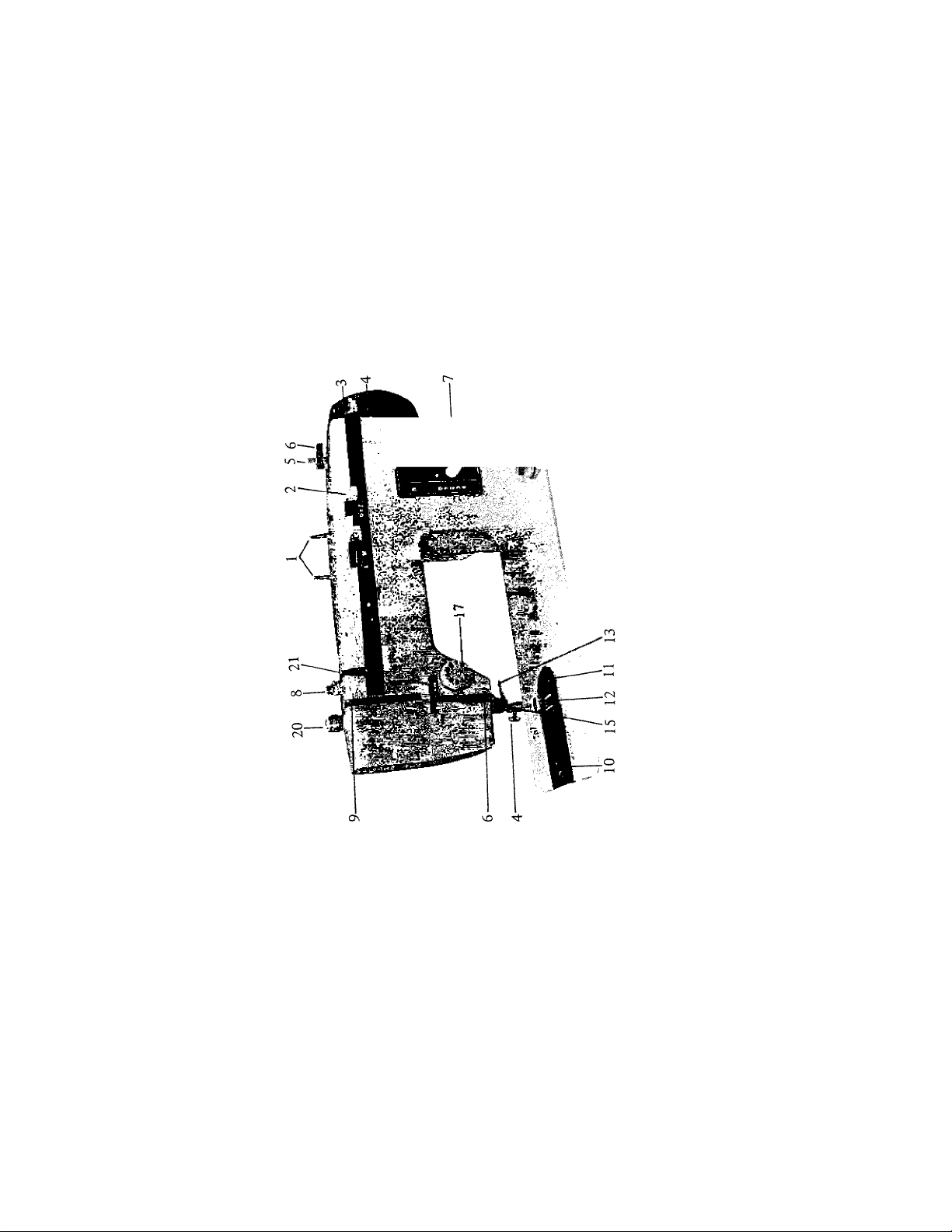

FEATURES AND PARTS

Front View

1. Spool pins

2. Zigzag width control lever

3. Balance wheel

4. Stop motion knob

5. Bobbin winder spindle

6. Bobbin winder lever

7. Stitch length lever

8. Bobbin winder thread guide

9. Drop feed knob

10. Slide plate

11. Needle plate

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

Page 5

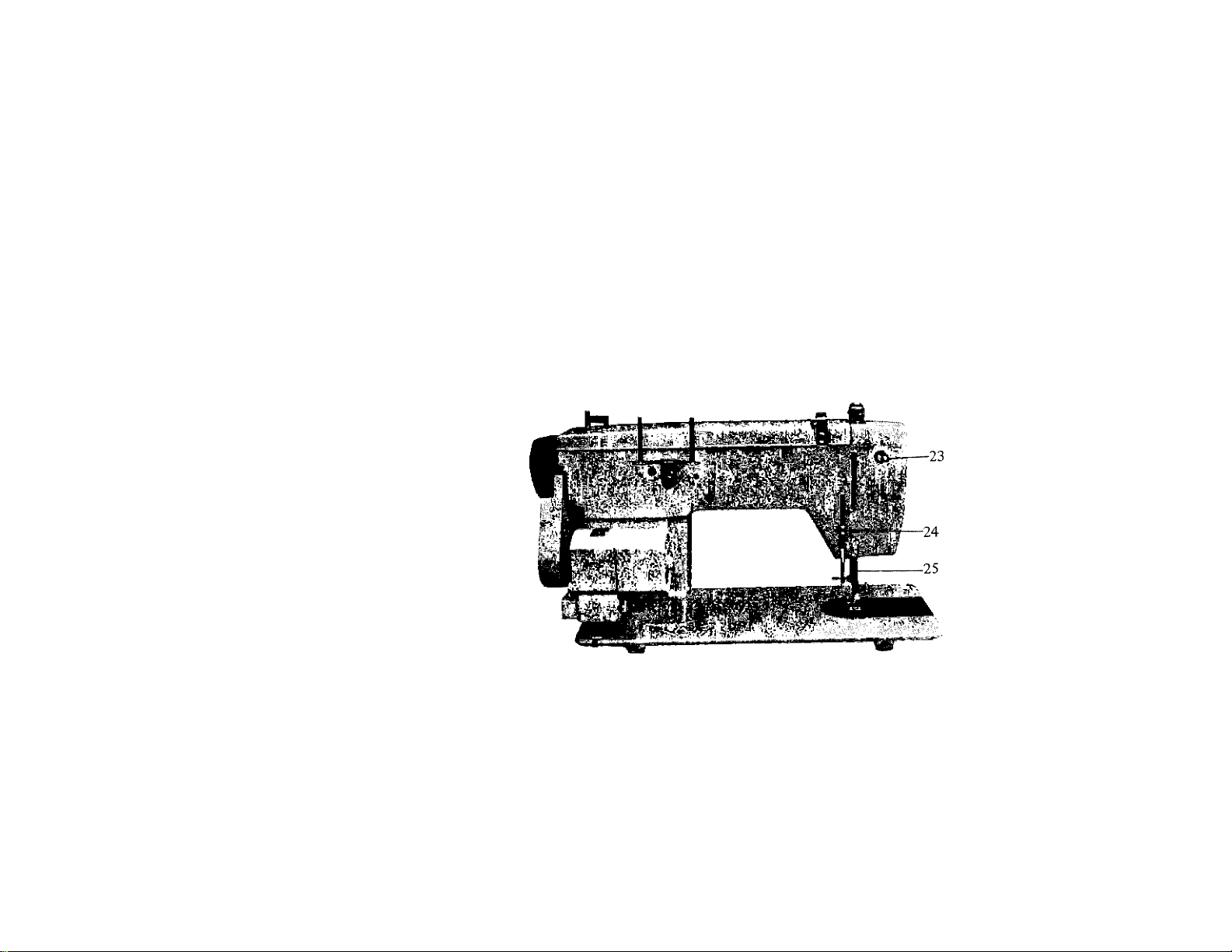

23. Light switch

24. Presser bar lifter

25. Thread cutter

FEATURES AND PARTS

(Rear View)

Page 6

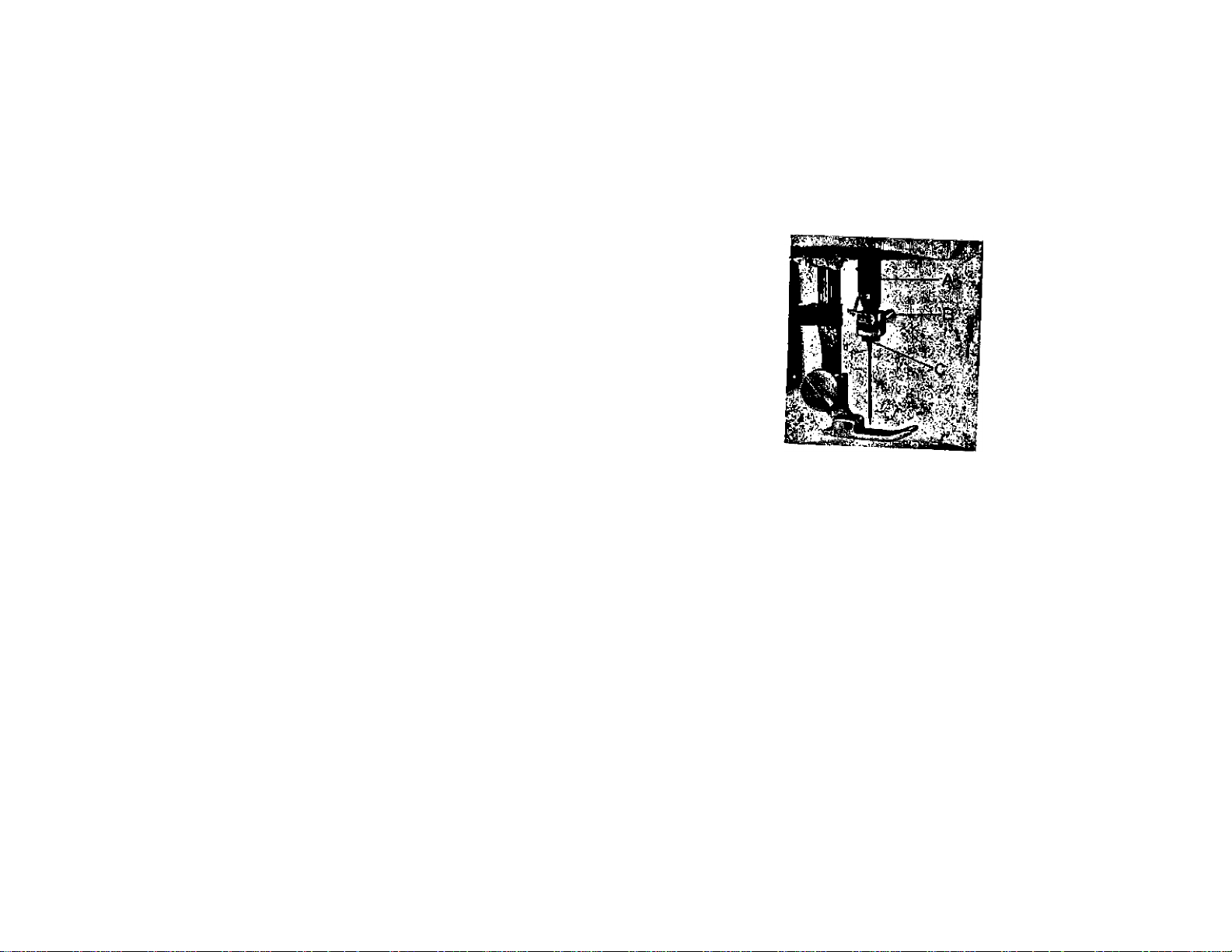

TO REPLACE THE NEEDLE

aise the needle bar A to its highest point turning the balance wheel Fig. 1, toward

you y and. Loosen the needle clamp screw B. Remove the old needle and sUde

new one up, FLAT SIDE FACING TO RIGHT. ,s fa, as I, will go. Fasten

needle clamp securely with a screw driver.

bv^hTnd needle make one complete revolution of balance wheel

y and to be sure the needle is in the correct position.

NEEDLE AND THREAD

N™, use a bent needle, no, one wiU, a bltm, point, since this catses hnperf.ct

Fig. 3

J.TZZ,7 T ? T"“' “ •“

thtead in le 00^ n

mreau m the bobbm as is used on top.

FLAT

'SURFACED

SIDE

GROOVED SIDE

Page 7

NEEDLE AND THREAD SIZE

The following table will show you the size of needles generally used with various sizes of thread. The size or grade refers

to the “eye” of the needle.

Needle Cotton Mercerized or |

Fabric No. Thread Thread Nylon

Extremely heavy

tarpaulin, sacking,

canvas, duck etc.

Heavy upholstery

fabric, thicking.

denim, leatherette

Medium heavy drapery

fabric, velveteen.

suiting, felt, terry, etc.

Medium broadcloth.

percale, gingham, linen.

chintz, taffeta, sheer

wool, shantung, etc.

Sheer voile, lawn.

dimity, crepe.

handkercliief linen.

plastic film, etc.

4

3

2 to

1

0

10 |.

to

30

30

to

40

40

60

60

to

80

80

to

100

Heavy Duty

Heavy Duty

Heavy Duty

50

50

SUk

A

i

! |,

j

!

l-'l

A > 1

II'

t

f-

1

t

1

1'

t

If

i

t

1'

1

r

Very sheer chiffon.

batiste, lace, orgady.

ninon, net, marquisette, etc.

100

0

-6-

to

150

50

A

i 1

I

Page 8

WINDING THE BOBBIN

t»d ro^dript‘fbb“® ’"'“V'” '^‘ '^»‘i“'toX»T(°Bl wms:

Fig. 4

7 -

Page 9

threading THE BOBBIN CASE

Step 1 (illustrated in Fig. g)

iioW bobbin case between th„ k

--- o";::::, T” “-

Step. 2.

insert bobbin into bobbin c

” T«-7. and d,a„i,

aod into the fort ,h '‘’™®

as shown in Pig. 8

Oie fork.eh.ped openipg of a..

Fig. 6

Fig. 7

Fig. 8

Page 10

PLACING BOBBIN CASE IN SHUTTLE

IMPORTANT; In the foUowing operations the needle must always

be above the surface of the machine. Raise tlie needle by turning

balance wheel TOWARD YOU by hand

REMOVING THE BOBBIN CASE (See Fig. 9)

Open the slide plate (10, Fig. 1) by sliding it out. With left thumb

and forefinger, open the

hinged latch (D) at the

front of the bobbin case

and hold securely as you

with-draw bobbin case

from the stud of the

shuttle body (C).

When held in the above

manner the bobbin wOl

not fall out of the

Fig. 9

bobbin case.

INSERTING THE BOBBIN CASE

After wmdmg a fresh bobbin and threading the bobbin case (See Fie 6 7 * S'» UoW i, uu-

thumb and forefinger. Keeping the protruding finger IF'» tn -n f ‘ ^

case around the stud of the shuttle body (Cl until th r ^ bobbin

never FORCE IT. Thr“ o7four inle/S r u operation is easy-

needle plate hole as shown in Fig. 11. brought up through the

-9-

Page 11

THREADING THE MACHINE (See Fig. 10 & 11)

]) Turn balance wheel toward you to raise take-up lever (F, Fig. 10)

to its highest point.

2) Place spool of thread on upper spool pin

3) Lead thread through arm thread guide B1 to B2, Fig. 10.

4) Down and around thread tension dial C from right to left.

5) Into the check spring D over thread tension dial.

6) Then down under thread bar E.

7) Up into take-up lever F from right to left.

8) Down into lower face plate thread guide G on face plate.

9) Through the needle bar thread guide H.

10) And into needle from left to right. Pull three or four inches of

thread through needle.

Hold the end of upper thread loosely and turn balance wheel toward you untO the needle goes all the way down and

comes back up. A loop (Fig. 11) will be formed over the lower thread which then can be pulled out straight. Place both

thread ends under the slot of the presser foot and draw toward the back of the machine, leaving both threads three or four

inches long.

Fig. 13

10

Page 12

STRAIGHT STITCHING

Be sure to set the stitch width at “0” position. Adjust lever (2) to

left side 0 position.

(Fig. 12)

SETTING THE STITCH LENGTH

The length of the stitch is regulated by lever 6 shown m Fig. 12.

Near 0 is the shortest and 4 is the longest. Set the lever to the down

to lengthen and to the up (near 0) to shorten the stitch.

STITCH LENGTH CHART Approximate

11

Fig. 12

Page 13

SEWING IN REVERSE

When you wish to sew in reverse to tie the thread at the beginning or the end of a seam, set the stitch length lever to “R”

position. The machine will sew backward. Only 4 or 5 stitches are needed to tie a seam securely.

ADJUSTING THE TENSIONS

Always adjust the upper tension with the presser foot down, as the

tension is mechanically released when it is raised. To increase the tension on

the upper thread, turn dial (Fig. 13) to the left or clockwise. To decrease,

turn to the left. The higher the number on the dial the tighter the tension.

Before adjusting lower tension be sure that the machine is threaded properly.

When it is necessary to change the bobbin tension, turn small screw (Fig.

14) on side of the bobbin case clockwise to tighten, counter-clockwise to

loosen.

12 -

Page 14

When the upper and under tentions are properly balanced, a perfect

stitch will be formed with both threads interlocking in fabric. (Fig. I's)’

ALWAYS BE SURE THAT YOUR STITCHES LOOK LIKE FIG. 15.

When the upper tension is too tight, the lower thread is pulled up

over the upper thread which is lying flat on the fabric. (Fig. 16)

When the upper tension is too loose the upper thread forms loops

over the lower thread lying flat on the fabric. (Fig. 17)

ADJUSTING PRESSURE AND FEEDING OF FABRIC

GENERAL SEWING

Usually for straight sewing and zigzag stitching, the pressure bar cap or darner release. Fig. 18, is at its lowest

position and the drop feed knob. Fig. 19. is turned to “2” position.

Fig. 16

Fig. 17

Fig. 19

Page 15

SEWING THIN OR LIGHT WEIGHT FABRIC

When lighter pressure is required to sew satisfactorily on thin silk or fflmy

material, the pr assure cap should be about half-way down. Release all the way by

pressing the snap lock, A. Fig. 20, and then press cap B down again to half-way

spot. Lower the feed slightly by turning the drop feed knob Fig. 19. to “1” posi

tion.

DARNING AND MONOGRAMMING.

In order to move the fabric freely in any direction for darning, mending and

certain kinds of free-hand embroidery, release the pressure cap B completely by

pressing down on the snap lock. A, Fig. 20. Turn the drop feed knob Fig. 19, the

feed well below the needle plate. To “0” position.

Fig. 20

PREPARING TO SEW

Have take-up lever at its highest point before starting to sew. Do not try to help the feeding by pulling the material as

this may deflect the needle and cause it to break.

NEVER RUN MACHINE WITHOUT MATERIAL UNDER PRESSER FOOT.

Place material and threads in position under the presser foot and lower the presser foot. You are now ready to begin sew

ing. By having the needle at its highest point, it is not necessary to touch the balance wheel to start the machine. You merely

press the control. The speed of the machine is regulated by increasing or decreasing the amount of pressure exerted on the

control.

14

Page 16

REMOVING THE WORK

Be sure to stop the machine when the thread take-up lever and needle bar

are located at the highest position. Now raise the presser foot and draw the

fabric back and to the left, Fig. 21-A and B. and pass the thread over the thread

cutter*

Pull down slightly, holding thread in both hands, so as not to bend the

needle.

Leve the ends of thread under the presser foot.

CREATIVE EMBROIDERY

BE SURE ZIGZAG PRESSER FOOT AND ZIGZAG NEEDLE PLATE

ARE IN PLACE.

v"‘ wmMmmmmm

...H tlip lin,is for most embroidery, is

by settioB dre sdteh le.gd. .s ne. 0 as possible without stoppmg the

^“T^th may be set auywhere from l»s. past to 0 the widest (»r

Fig. 21-A

position).

Fig. 21-B

15

Page 17

ADJUSTING THE STITCH WIDTH

move between any two wW&, ("n Jotat free^S e^mbroTd ^ y°>^ ^

desired width. ^ ® embroidery), move zigzag width control lever to the right and left hand at

EMBROIDERY PATTERNS

conttol k,er bTcW Si*» STi iSvSTcl'SarofSl'’’' *' “ “«“8 width

control. length and width end the manipulation of the zigzag width

:: iscr Sd^ia:“ rrs a? rd r *

16

Page 18

EMBROIDERING WITH A HOOP

It is easy to follow a sketched design or to work free hand

when embroidering or monogramming. (See Fig. 24)

Release the pressure from the foot by pressing down the snap

lock on the pressure release darner. Turn the drop feed knob Fig.

19 to “0” position.

Stretch the fabric in an embroidery hoop, and place under the

needle after removing the presser foot. Set the stitch width at the

size you prefer and lower the presser bar lifter. Then operate the Fig- 24

machine at a rather high speed while moving the hoop slowly with both hands. Work carefully and be sure to keep fingers out

of the path of the needle.

DARNING

Release the pressure from the foot and drop feed as directed above.

Place fabric to be mended under foot, and stitch around hole, moving the fabric firmly and slowly in any direction. Be

sure to hold the fabric taut or skipped stitches will be encountered.

TI7-

Page 19

MAKING BUTTONHOLES

Mark the beginning and end of the buttonltole on fabric with a basting line or

tailor’s chalk. Make one on scrap fabric to be sure machine adjustments are correct.

PREPARATION:

(1) Replace presser foot with buttonhole foot, Fig. 25, which provides maximum

visibility and allows closely spaced stitches to feed evenly.

(2) Set the stitch length lever 6, Fig. 1, as near to 0 as possible witliout stopping

feeding action.

(3) Set the zigzag width control lever by the size of buttonhole.

OPERATION

After finishing above preparation, set the machine as follows.

(1) Turn the drop feed knob Fig. 19. to “0” position

(2) Turn the zigzag width control lever completely to right

side, to make the upper bar tack of buttonhole. Now

sew 5 or 6 stitches.

(3) Release the zigzag width control lever to the home posi

tion.

(4) Turn the drop feed knob Fig. 19, to “2” position. And

sew the left hand side of buttonhole desired length.

(5) Keeping the needle in fabric (needle stays in the middle width position of part A Fig. 26), lift up the presser foot

and turn the fabric centering needle.

Set the presser foot down and remove the needle to the left end of buttonhole turning the balance wheel by hand.

(6) Now repeat the same way from (1) to (5) process.

(7) After finished buttonhole making, sew two or three stitches to fasten bar tack threads and prevent ravelling, by set

ting stitch length lever to 0.

(8) Cut the buttonhole opening with seam ripper, being careful not to cut the stitching.

Fig. 26

Fig. 27

M

__________

_ 18 _

Page 20

If you plan to make buttonholes on sheer or soft material, place paper under fabric

which can be torn away after stitching, it is always wise to make several buttonholes on

scraps of fabric before working on the garment.

SEWING ON BUTTONS

Remove hinged presser foot and attach button sewing foot. (See Fig. 28, 29 & 30)

Turn the drop feed knob Fig. 19. to “0” position.

Move zigzag width control lever to “ ,0 ” position to the extreme left. Place the

button so that its left hole comes directly under the needle, then gently lower the

presser foot. Move the zigzag width control lever to the right until the needle comes

exactly over the right hole of the button and set left stop. Turn the balance wheel

slowly by hand to be sure the needle clears both holes of the button. Correct width if

necessary.

When needle goes into the center of each hole, run the machine at medium speed,

4.

making five or six stitches, stopping with the needle in the left hole.

To lock the zigzag stitch and prevent ravelling, set the stitch

5.

width at 0, and take a few stitches in the same hole. If you wish

to place a rounded toothpick over the button, between the two

holes, and sew button to fabric in regular way. Remove the

toothpick and wind thread under button, forming a shank.

Fasten it. Apply the above method to sew on buttons with four

holes, hooks and snaps, etc.

Fig. 30

Fig. 29

19

Page 21

SEAM GAUGE OR CLOTH GUIDE

Use a seam gauge as guide for straight seams and even rows of

top stitching along edges of fabric. Fasten gauge with accompany

ing screw in threaded hole in bed of machine (Fig. 30). Adjust to

seam width desired.

QUILTING

The quilter (Fig. 31) will enable you to sew equidistant lines

on padded fabrics without the necessity of marking them in

advance.

1. To attach the quilter to the presser bar of the machine,

loosen the presser foot thumb screw and place the quilter

astride the presser foot. The quilter must be on top of the

presser foot when secured on the presser bar.

2. Adjust the width guide of the quilter to the desired width

and drop guide on material.

3. Sew with the quilter width guide following the previous

stitches as in Fig. 31.

Fig. 30

20-

Page 22

THE ADJUSTABLE CORDING AND

ZIPPER FOOT

This attachment is used to make and insert

covered cording, and to sew in zippers. Loosen

thumb screw to slide foot to either right or left of

needle.

CORDING. Fold bias strip of fabric over cord.

Loosen thumb screw and set foot so needle is

centered in needle hole. Machine baste cord in place

(Fig. 49).

To sew covered cord to material, reset adjust

able foot so needle stitches closer to cord, and on

edge of base fabric.

Fig. 32 -B

Fig. 32-A

SEWING IN A ZIPPER

Loosen thumb screw and slide foot so needle enters center of

needle hole. Guide metal of zipper along edge of foot (Fig. 33).

Stitching should be close to z,ipper to allow easy opening and

closing. Adjust to sew from either right or left side, whichever is

more convenient.

Fig. 33

21

Page 23

care and maintenance of your machine

OILING YOUR MACHINE

«ke.up leve, i, ™ ,1,“

two screws on cover. ^ loosening

a- app, a P„p „p„p .. p,„;,:i!:;r

Co oil moving parts inside the face nlate wh.vn i

require oiling, open plate. Oil at spots indicated i^ Fig. 36^^

Fig. 34

Fig- 35

Fig. 36

22

Page 24

CLEANING AND OILING THE SHUTTLE

The stitch forming mechanism occasionally becomes clogged with loose threads and lint. This will interfere with the

efficient operation of the machine. To remove the shuttle assembly, proceed as follows.

1, Turn the balance wheel until the needle reaches its highest position. Tilt head back on its hinges.

2. Remove bobbin case A, Fig. 38.

8. Turn the two shuttle race cover clamps B outward and remove the shuttle race cover C and shuttle body D.

4. Clean the shuttle race, the shuttle and shuttle race cover by removing all threads, lint, etc.

5. Apply a drop of oil with finger tip to outer edge of shuttle. When the cleaning has been completed, proceed as follows

to replace the shuttle assembly;

1) Turn the balance wheel until the needle reaches its highest position.

2) Place shuttle body, D against shuttle driver and adjust into position.

D

Fig. 37

Fig. 38

23

Page 25

3)

Replace shuttle race cover, C, fitting pin at lower edge into notch, and lock into

position with shuttle race cover clamps, B, making certain the clamps have been

snapped securely into position.

4)

Place bobbin into the bobbin case.

5)

Set the bobbin case into the shuttle race, fitting tongue into notch E of race

cover.

HOW TO CHANGE THE MOTOR BELT

If it should become necessary to replace the

as follows.

Fig. 39

motor belt on your machine, proceed

Remove clutch nut B in center of balance

wheel Fig. 39 by taking out small screw C.

Turn nut counter-clockwise by holding the

(take-up lever) until it can be lifted off.

2.

Before moving hand wheel, note position of

lips on washer D Fig.40Aas it will fall off

when changing the belt.

3.

Turn the screw on motor bracket (E Fig.40B)

counter-clockwise to let old belt can be

removed-from motor.

4.

Slide old belt over motor pulley Fig. 40.

5.

Pull balance wheel away from machine just

far enough to allow the belt to slip over

wheel.

6.

Put new belt in grooved section of balance

wheel and then over motor pulley.

7.

Replace washer D in original posilion.

-24-

Fig. 40-B

Page 26

8 Replace clutch nut and screw C. After doing this, turn clutch toward you to disengage sewing mechanism. If the needle

still moves up and down as you turn the balance wheel, again remove the clutch nut, give washer D a half turn and

replace the unit.

THE BUILT-IN LIGHT

FRONT SEW LIGHT

1. The lamp housing is enclosed in the hinged face place. Screw out bulb as shown in Fig.

42, and then insert the new bulb.

2. For replacement, use lO-C-7 or 7-C 7. or “night light” bulb available everywhere. Use

switch on face plate to turn this light on and off.

Fig. 42

25

Page 27

UNSATISFACTORY CONDITIONS: CAUSES AND REMEDIES

THE UPPER THREAD BREAKS

CAUSE

1. The needle is not threaded correctly.

2. The tension is too tigh t.

3. Something is wrong with the needle.

4. The thread used is too heavy for the needle.

5. Thread take-up spring is broken.

6. The needle is not set correctly.

7. The needle plate, the hook, or tlie presser foot is damaged.

THE LOWER THREAD BREAKS

1. When the lower thread is not wound correctly, it gets entangled

2. Ihe lower thread is off the tension spring of the bobbin case.

SKIPPED STITCHES

1. ' needle is not attached to the needle bar correctly

2. The needle is either bent or blunt.

3. A worn needle is used.

THE NEEDLE BREAKS

1. The needle is bent.

2. The needle is not attached properly.

3. The material is too thick or heavy.

4. The material is being pulled by the operator.

5. The needle is of inferior quality.

REMEDY

Thread the needle correctly.

Loosen it.

Replace it.

Replace it.

Replace it.

Set it correctly.

Replace it.

Wind it properly.

Put it in its proper position.

Attach it properly.

Replace it.

Replace it.

Replace it.

Attach it correctly.

Use a needle of the correct size.

Do not pull on the cloth.

Replace it with better needle.

26

Page 28

STITCHING FORMS LOOPS

CAUSE

1. The thread tension is not properly adjusted.

2. The needle is not threaded correctly and/or the bobbin is

not wound properly.

3. The weight of the material and the size of the thread are

not appropriate.

4. Thread take-up spring does not work well.

See instructions for adjustment of upper and lower iliread

tensions.

Thread the needle and/or rewind the bobbin properly.

See instructions covering the use of proper needle and

threads with varying materials.

Replace it.

REMEDY

SEAMS SHRINK OR PUCKER

1. The thread tension is too tight.

2. The pressure of the presser foot is too strong.

3. Stitches are too small for the weight of the material.

See instructions for adjustment of upper and lower thread

tensions.

See instructions for adjustment of the pressure of the

presser foot.

Adjust the stitch length.

IRREGULAR STITCHING

1. The upper and lower threads are of inferior quality. Use thread of best quality.

2. The thread is wound around the bobbin unevenly.

Rewind it.

THE MACHINE DOES NOT WORK SMOOTHLY AND IS NOISY

1. The machine is in need of oil

2. Dust and waste thread have collected in the shuttle mechanism.

3. Oil of inferior quality is used and has coagulated.

4. The tension on the belt is too tight.

Apply oil as per instructions.

See instructions pertaining to cleaning the race and shuttle.

Clean thoroughly and oil again with proper sewing machine oil

of the best quality.

Loosen the belt tension.

27

Page 29

NEEDLE POSITION SELECTOR

With the zigzag width regulator set at “0” and the needle posi

tion selector at “L”, the machine sews a straight line at the left

position.

With the needle position selector at “M” and “R” the machine

sews at the center position and the right respectively.

As the zigzag width increases, the machine sews stitching

patterns as shown here at each needle position.

L M R

28

Loading...

Loading...