SINGER W1563 User Manual

How To Use and Care For Your

Zigzag Sewing Machine

MODEL 1563

LET’S SEW Perforating Plain Paper

Ycxir new vvonderfull machine was delivered ready for ZIGZAG siiiching. Certain, kinds

of STRAIGHT stitching can also be done with the same NEEDLE PLATE and PRESSER

FOOT which were on the machine when you received it. A NEEDLE was also properly

installed, along with a partially filled BOBBIN underneath.

Without threading needle "sew" on a piece of PLAIN PAPER for a few minutes while you

become well acquainted with the few easy-to-use CONTROLS pictured and briefly ex

plained on pages 2 and 3; also 4 and 5. Later on you are urged to study all the operat

ing details indexed on page 1 which you should skip for the time being.

Time saving wonder working sewing aids such as rufflers, binders, zipper sewing foot and

many other are available at modest prices and sold by the dealer from whom you purchased

your new machine.

e

c

&

it

is

is

e

e

e

c

c

c

Contens of This Book Indexed

As you have time, study all these instructions carefully to obtcdn the -wanderful

performance your machine -was designed and built to give. Constant reference

to these instructions will reward you with troublefree sowing satisfaction.

Subject Page

Attachments - - sewing aids

Automatic (with cams) fancy stitches

Bobbin--removal, threading, replace

Button--sewing on with machine

..................

.........................

..............................

14,15,16,17

........................

12

Buttonhole making by machine ................................ 11

Darning on machine

............................................

4, 12

Embroidery - - stock designs and creative ■ • • 2,5

Guarantee--parts warranty--service

........................

24

Light Bulb replacement ............................................. 18

hionogramming on machine ............................... 4, lid

Needle--proper one for the job

•••installing in machine

■ *■ tlxTwSciincf . .

...................................

............................................

...

..............................................

Needle Plates --proper for job; changing ••• 3,15

Subject Page

Oiling Machine--important

2

9

Other care and maintenance................................. 19

Good sewing habits ............................................ 4, 9

......................................

18

Parts cmd functions controls..........................3, 4, 15

Pressure-bar and Feet ................................... 2, 4, IS

Reverse stitching--sewing backward

..........................

4

Stitch adjustments--Z2 and straight stitch - -

stitch length per inch-ZZ width

.............................

3

Take-up Lever .............................................................. 4

Tensions--upper and lower threads ......................... 10

6

7

7

Threading machine--needle--bobbin

case ....................................................................... 7, 9

Troubles and remedies

.......................

20, 21, 22, 23

Two simple precautions--start and finish

make these a habit

.............................................

4, 9

To Saw Fancy Stitch Pattarns AUTOMATICALLY Use the Cams

Look over your large assortment of molded plastic cams. Their color or

colors do not affect function. ■ A basic design sucb as diamond, half-moon,

triangle, (as examples), is embossed on top flat side of each. The cam used

automatically guides needle to repeatedly reproduce its jjattem.

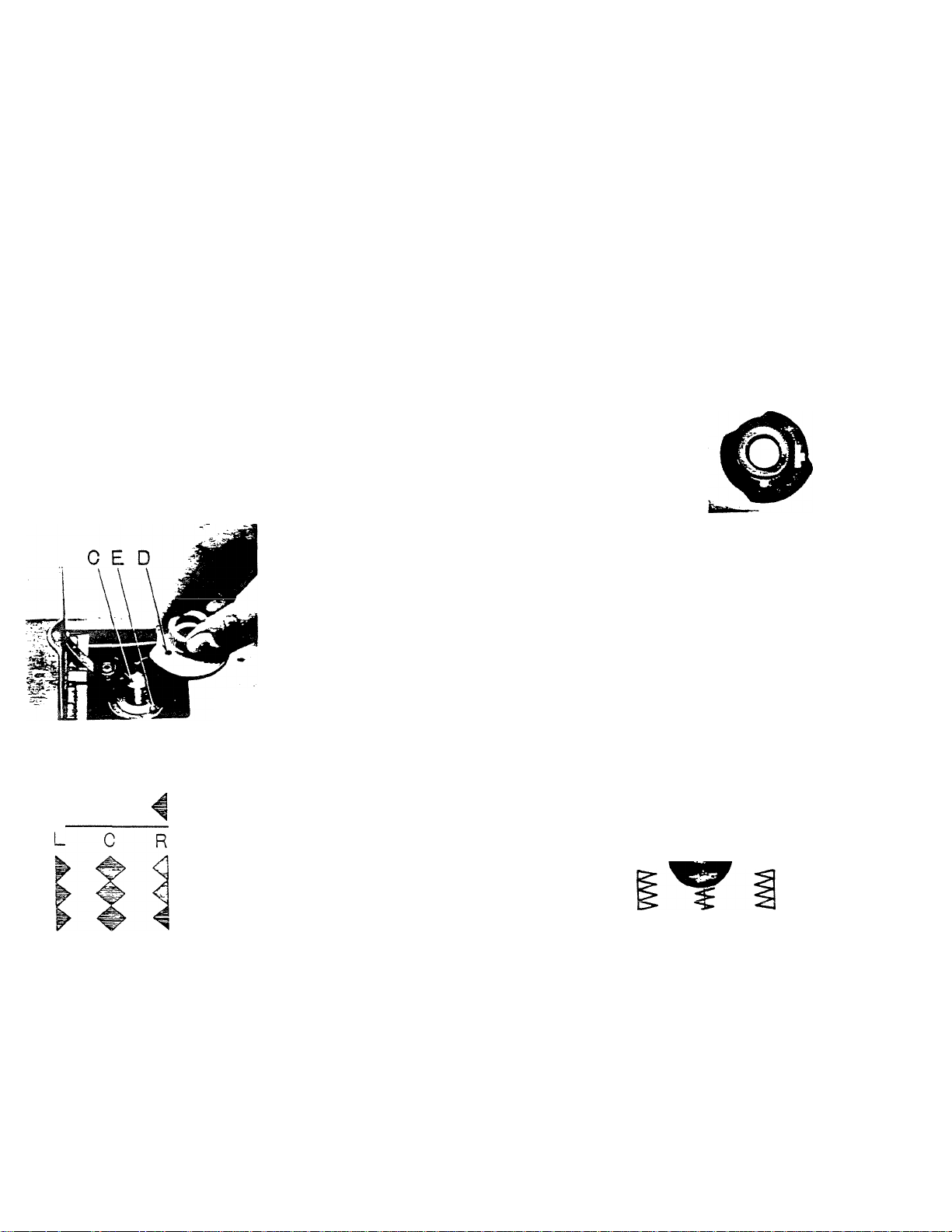

- To Place A Replaceable Cam In Machine

Do two things before selecting a cam. (1) Look directly below

needle. Be sure presser foot and needle plate are those pictured

at TOP LEFT next page. (2) turn controls BOTTOM RIGHT-next

page tintil hanging lever can be sewing from 0 to 5 on dial. Now

lift open small cam chamber cover on top of machine. While hold

ing ZZ Width Lever (next page) at extreme left (5), drop selected

cam on spindle C. While still holding 22 Width Lever, revolve

cam, pressing down lightly, until hole a its bottom surface slides

over pin E. Close cam chamber lid. Run machine slowly while

• you adjust Stitch Length Dial at MIDDLE LEFT next page. Most

cam patterns appear best on Stitch Length Dial setting between

and 1-V2-

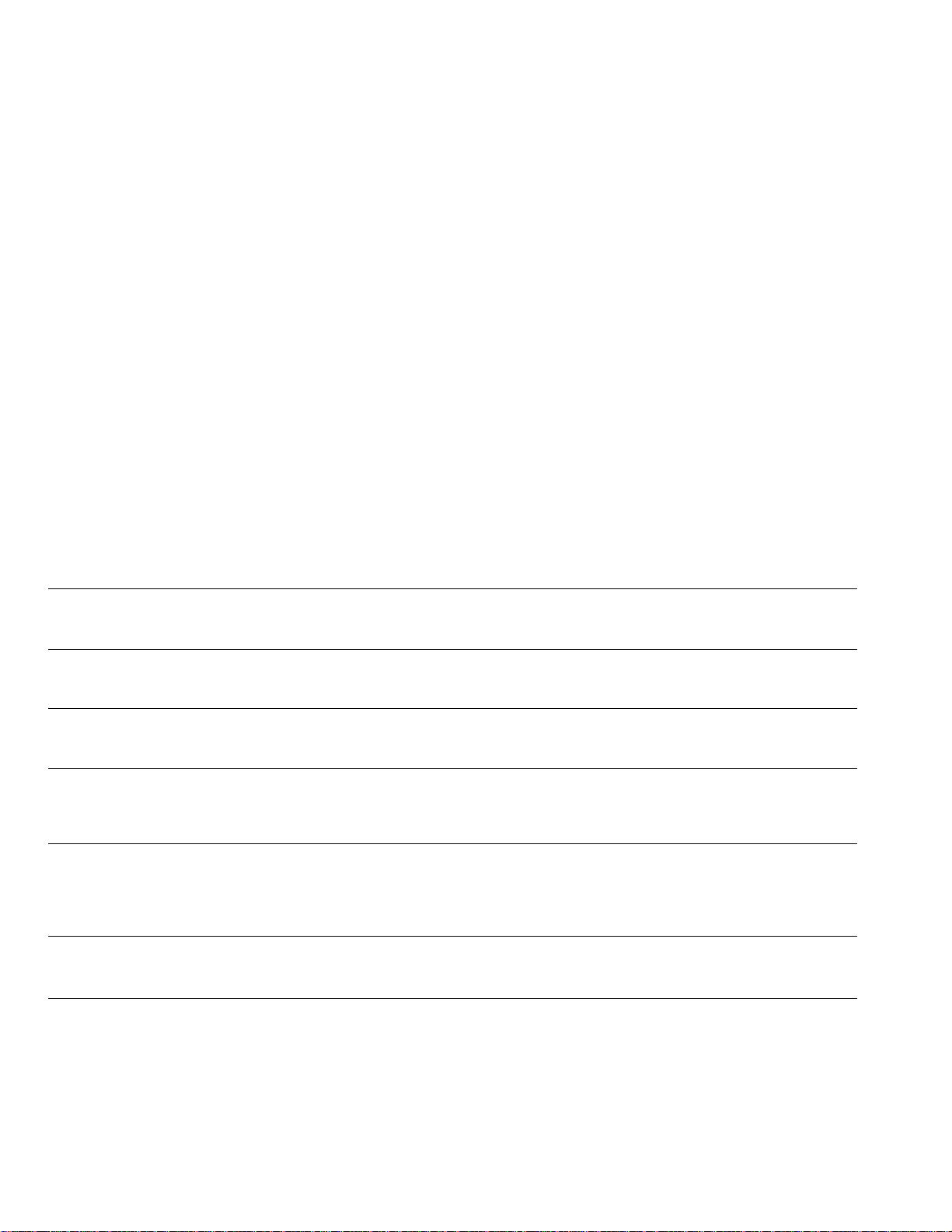

Changing Path of Needle Multiplies Variety of Designs —

Lever NP can be set at Left, Center or

IF CAM IS

DESIGNED

Right. Each different position alters basic

stitching line and therefore the appea

rance of most all zigzag stitch designs.

r NEEDLE_POSITION

Set lever NP at LEFT for straight stitch

ing. Pull lever NP toward you and it

clicks when sliding into the three posi

tion notches. Pushed in, lever NP avoids

the notches, moving freely for hand con

trolled creative embroidery explained

page 5; without a cam in machine.

e

im

t0

y

y

c

e

e

e

e

e

e

c

c

r

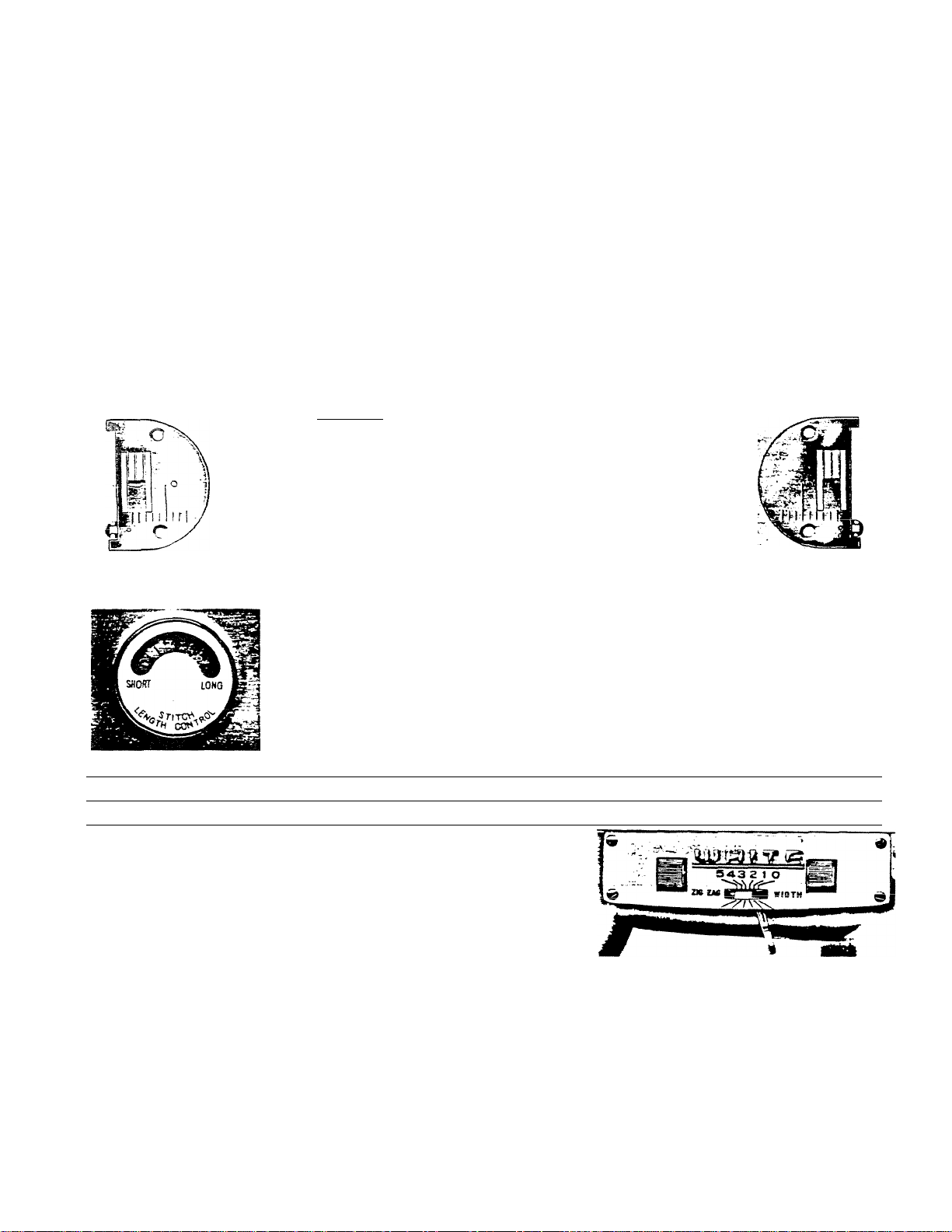

BE SURE - For Zigzag Stitching

- Use This Needle Plate and Presser Foot

These two parts are slotted crosswise to

allow for needle swinging sideways while

moving up and down. Slots are about %

inch wide.

Later On-For Straight Stitching Some Fabric—

Presser foot and needle plate with small -

round hole instead of wide slot-best for finest STRAIGHT stitching in sheer, fine or very soft

materials. For changing this standard equipment see page 15.

— Setting Stitch Length - For Zigzag or Straight Sewing

Turn this speedometer type died CLOCKWISE to lengthen stitch COU

NTER-CLOCK-WISE to shorten, for more stitches per inch. Refer to

chart just below and find your favorite settings. Note the numbers for

quick and easy duplication any time. Remember that material must

move along or "feed" under presser foot in down position. Whenever

it does not, stitch must be lengthened slightly.

Dial Settings For Approximate Number of Stitches Per Inch

Figures on

Number of

Setting Width of Hand Controlled Zigzog Stitching -

For Straight Stitching and Cam Controlled Zigzag Keep

Lever at O

indicator 0

stitches per inch

No Feeding 60

1 2

40

3 4

20

16

12

5

10

Adjust by turning horizontal finger rollers to number on

dial or in between. To make the sides of buttonholes for

example you may set left side number at 4; right side at 2.

6

8 9

7

7

8

6

To Sew Backward - - Zigzag or Straight Stitching —>

Reverse siitcii push bution marked. R is in base of maciiine

directly below Stitch Length Dial. To sew backward, push

button down and feeding teeth will move material in reverse to

normal sewing direction as long as push button is held down.

It's foolproof. When comfortably placed R button is released

material sews forward again.

To Drop Feeding Teeth for Darning or Mo nog ramming

Control knob is just to left of Reverse feed button. To drop

feed teeth entirely below needle plate surface, turn knob clock

wise to extreme left position marked DN. For most normal

sewing jobs knob will be in extreme right position marked HI.

Occasionally the middle position (LO) will be ideal for very

delicate filmy fabric - providing enough grip to feed material

without tearing or scraping.

— Adjusting Pressure on Feed Teeth

For normal sewing. Bar (B) should be pushed down-its top

about even with automatic locking ring (A). Single finger

pressure on edge of ring will release bar causing it to pop

all the way up. That is position for most darning and

monogrcim work with Feed Teeth in DN position. When

sewing on delicate materials with Feed Teeth in LO posi

tion, the presser bar should be pressed down about half way.

A Good Sowing Habit - - The Take-Up Lover -

As each sewing operation is finished - - before starting machine - - while

threading it--ALWAYS when machine is not running be sure Take-Up

lever is at top end of slot. Every time you stop machine turn the wheel

by hand to position lever at highest point. The only exception is to oil.

Never Run Threaded Machine Without Sewing In Fabric - - Be Kind - - Use Oil

■

c

c

€0

'

e

e

e

e

c

e

e

e

c

c

c

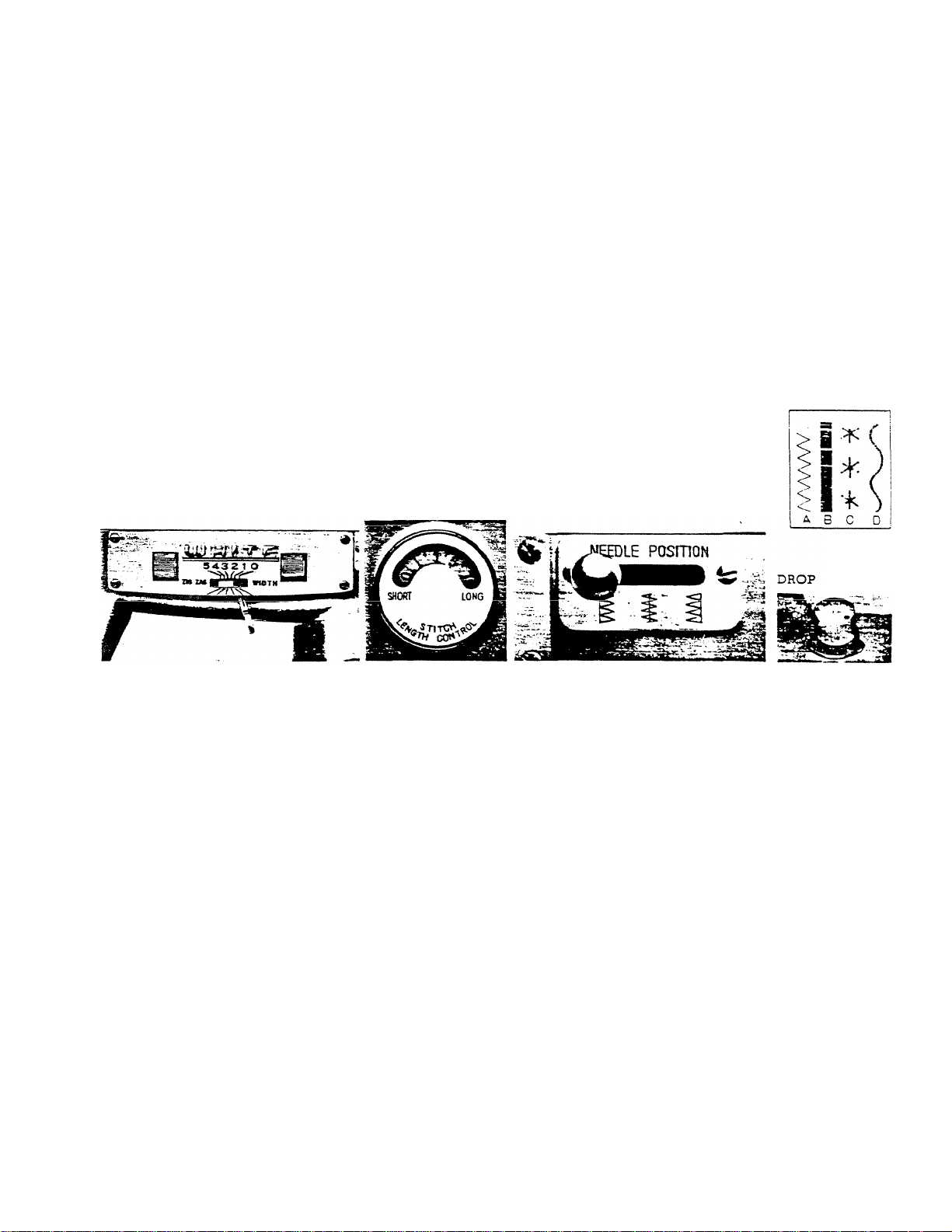

You Move Some Levers For Plain Zigzag—Satin Stitch--Creative Embroidery

There is no limit to the variety of stitch patterns you can sew WITHOUT ANY

CAM in machine. Get well acquainted with the use and effect of the four

controls pictured below. Practice moving zigzag Width Lever from side to side

while running machine. Do likewise with Needle Path Selector after pushing it

in toward machine.

ZIGZAG STITCH WIDTH LENGTH OF STITCH NEEDLE PATH SELECTOR

FEED DIAL

Plain Zigzaging (A'l Set Stitch LENGTH Dial at 4--after a few stitches very length as desired.

Set Zigzag WIDTH so dial white area extends from 1 to 5. Now sew, holding Zigzag

Width lever the LEFT side.

For Satin Stitching ( B) Set Stitch LENGTH Dial at marked MP. (about halfway between 0 and 1:.

Set Zigzag. Dial white area for width of stitch desired. Now sew, holding zigzag lever to

LEFT. For variations move Lever right, left, right while sewing.

Make Flower Petals (C) Turn drop feed knob to DN. Set ZZ Width Dial white area to extend

from 1 to 4. Sew three or four stitches holding Zigzag lever to LEFT. Stop machine with

needle down in cloth at center of petal design. Pivoting on needle, turn fabric to next

petal and repeat steps to complete. Turn right side roller on ZZ Width Dial so Lever

goes right to 0. Put three or four stitches in center of design to lock threads.

Serpentine Stitching (D) Set ZZ Width Dial white area to extend from 2 to 5. Press Needle

Path Selector Lever in toward machine - - then as you run machine move that lever alternately

from left to right continuing the motion back and forth in rhythm.

Match Needle

! Size dnd

Thread To Your

Fabric - - Sew Like "A

Pro”

Approximate Stitches Per Inch

Also important

Machine

Stitches Cotton

Per Inch

Thread Thread

6 iU

8 30

8 30

to to Heavy Duty

Fabric

Extremely heavy

tarpaulin, sacking,

canvas, duck, etc

Heavy upholstery

ladric, ticking.

Needle

No.

4 to to

3

denim, leatcherette 10 40

Medium heavy drapery

fabric, velveteen.

suiting, felt, terry, etc.

Medium broadcloth.

percale, gingham, linen,

chintz, taffeta, sheer

wool, snantung, etc.

Sheer voile, lavm.

dimity, crepe.

handkerchief linen.

plastic film, etc.

2 to to

1

n

u

10 40

12 60

12 “

to

14

14

to

16

(Plastic iiim)

60

80

100

8 to 10

Very sheer chiffon.

batiste, lace, organdy.

ninon, net, marqtiisette,

00. - to to

etc. 20 150

16 100

to

80

to

Mercerized

Heavy Duty

Heavy Duty

50

50

50

Silk

or

Nylon

A

A

A

Loading...

Loading...