Page 1

',4j;,r'SÍ- ■-■ ■■ . -.. ' -

?■ ' ; ■ ;^ V:-.' ■■ " ' ■■ ■ L - ■

'ШШШЧ' ^ 'л; ^

■ ■ l

-. ■■ ■^,;..■ ,1- ;. .I- ■

■ - I

< : - '

s.ii --V"

<

INSTRUCTIGN

i -^Ììf'; 'Г-- .¡г^ --.--^ . -

'Áí -■- - i.«'.- 'j.bfi-'P , ■ :. .,

ílfllÉÉiHMSlHÉHHlíBtí^awiraSsfiRú^fSJi^^^Bttib—^V *

. .-^tri,’#;

î;ïMî‘*^^ jiÿ - -Г'

>y^v- /V,

Page 2

“IMPORTANT SAFETY INSTRUCTIONS” '

‘When using an electrical sewing machine, basic safety precautions should always be followed,

including the following.”

“Read all instructions before using this sewing machine.”

“This sewing machine is designed for household use.”

“DANGER- TO REDUCE RISK OF ELECTRIC SHOCK:”

“A sewing machine should ne¥er be left unattended when plugged in. Always unplug this

sewing machine from the electrical outlet immediately after using and before cleaning.”

“Warning- To reduce the risk of burns, fire, electric shock or injury to persons...”

1. “Do not allow to be used as a toy. Close attention is necessary when this sewing machine is

used by or near children.”

2. “Use this sewing machine only for its intended use as described in this manual. Use only

attachments recommanded by the manufacturer as contained in this manual.

3. “Never operate this sewing machine if it has a damaged cord or plug, if it is not working

properly, if it has been dropped or damaged, or dropped into water. Return the sewing

machine to the nearest authorized dealer or service center for examination, repair,

electrical or mechanical adjustment.”

4. “Never operate the sewing machine with any air openings blocked. Keep ventilation

openings from the sewing machine and foot control free from the accumulation of lint,

dust, and loose cloth.”

5. “Never drop or insert any object into any opening.”

6. “Do not use outdoors.”

7. Do not operate where aerosol [spray] products are being used or where oxygen is being

administered.”

8. To disconnect, turn all controls to the off [“0”] position, then remove plug from outlet.”

9. “Do not unplug by pulling on cord, To unplug, grasp the plug, not the cord.”

Page 3

i;»

A.

A. Sewing Machines

10.

‘Keep fingers awav

machine needle."

f

-.i- ■

:t - .

j.

j#-:.

:P

11.

12.

1.^

14.

15.

16.

■ fiwtf ©f

-s,

------ w.. L ^ j »»noil iiiafMiiy any ctujusimenis m ine needle

area, such as threading needle, changing needle, threading bobbin, or changii

presser foot and the like.”

“Always unplug sewing machine from the electrical outlet when removing covers,

lubricating, or when making any other user servicing adjustments mentioned in

the instruction manual.”

-

‘SAVE THESE INSTRUCTIONS’

I

Page 4

CONGRATULATIONS!

As the new owner of a Stretch Stitch Sewing Machine, we hope you will take a

few minutes to read through this booklet before using your machine for the first

time.

Experiment with the many stitches. See how easy it is to dial the stitch patterns,

stitch width, and stitch length. '

Become aquainted with all the special features such as built-in button-holer,

automatic bobbin winder, and twin needle sewing.

As you go through this booklet, you will discover how these and many other

features will simplify your sewing. Additional advice on the operation and care

of your machine is always available through the Toil Free number.

We believe our machine is simple and fun to use. We hope you will have many

years of successful sewing.

-i ' ■ •

Page 5

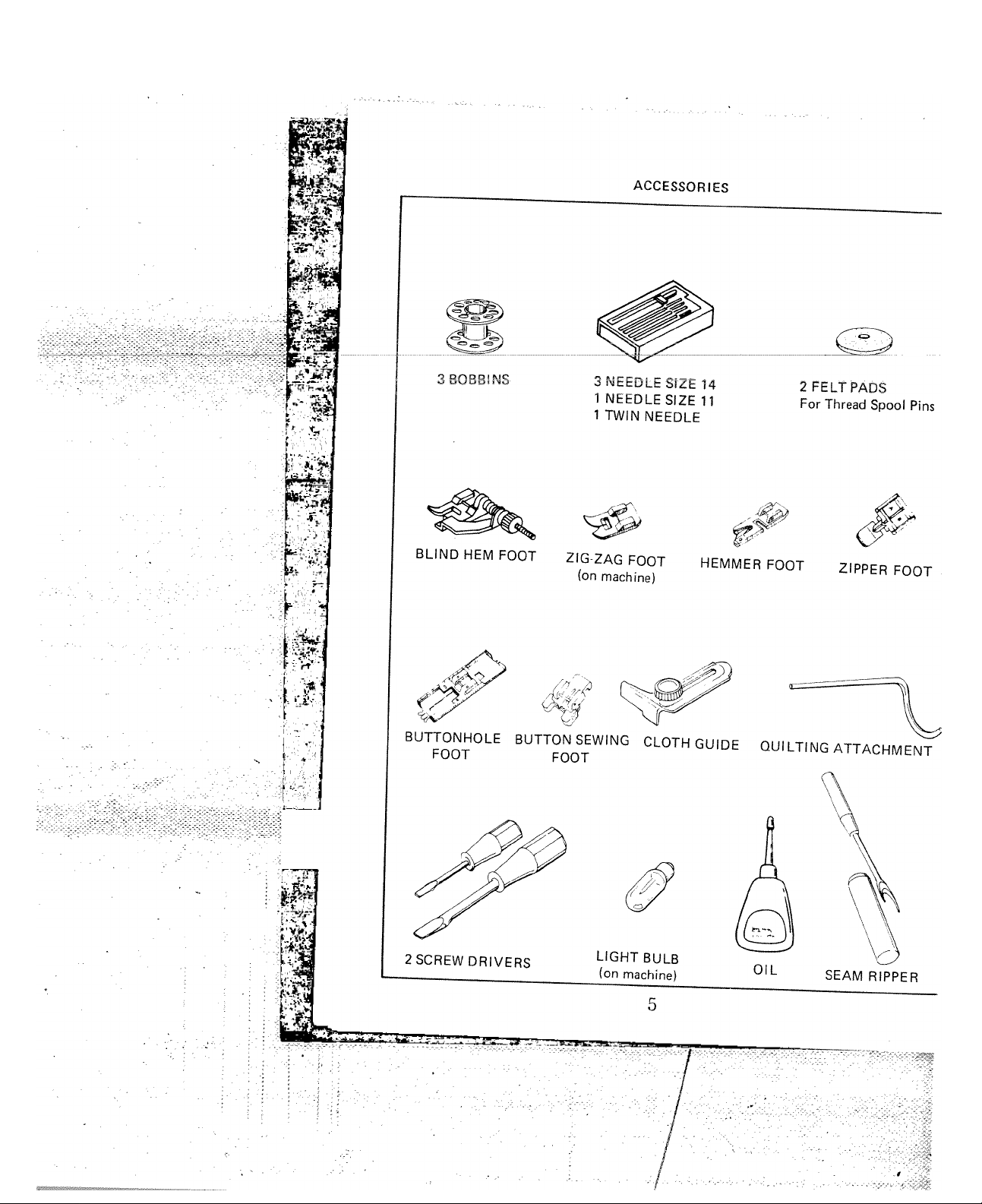

TABLE OF CONTENTS

part I

KNOWING YOUR SEWING MACHINE

Know the parts.

Front View .... o

Back View

Accessories. . ir

Speed control dIuq. .

Light switch....

Sewing light. ' g

Foot control. ... G

Installing extension table

Needle, thread and fabric chart

Changing the needle. . . ,

To select a suitable needle.

Removing and attaching the oresser font

Winding the bobbin .

Adjusting bobbin winder.

Threading top thread . n

Threading the bobbin case. .

Picking up bobbin thread

Pattern selector

* Selecting stretch stitch.

Stitch length dial, reversing button

and dropping the feed dog

Adjusting top thread tensions

Adjusting bobbin tensions

Regulating the presser foot pressure

(Patch-O-Maticj ....

Presser foot lever. ... in

.................

........................

/t

ir

..........................D

tjiS

^ ’

1

i V

m

1

&

VW '« Him

PART II

START SEWING

Keeping stitching straight..........................................

Straight stitch. . . .

Basting

..........................................

Staystitching ....

Changing sewing directions . . .

Fastening seams ....

............

on

..........21

...................

23

Page 6

Zigzag stitching.................................................................................. 24

Overcasting

Interfacing darts

Checking tensions........................................................................ 25

.

.................

Shell stitching..................................................................................... 25

........................-.^.-.^...-............-............-............-............

..................................................................................

...........................................................................

......................................................................................................................................................................................

24

24

g:>><:;g:g$4

:■!

Appliqueing,....,.

Bar tacking..................................................................................... js

STRETCH AND UTILITY STITCH SEWING

Stretch stitching................................................................................. 27

Triple straight stretch stitch

Rickrack Stitch.................................................................................. 27

3-Step stretch zig-zag stitch.............................................................. 28

Smocking stitch................................................................................ 23

Overlook stitch................................................................................... 29

Sewing with a twin needle

Sewing buttonholes

Buttons.............................................................................................. 22

Sewing blind hems............................................................................ 33

Double action stitch.......................................................................... 3^

Double overlock stitch....................................................................... 3^

Sewing zippers . .............................

Hemming. .

Mending and Darning ■ • • •

Embroidery

PART III CARING FOR YOUR MACHINE

Cleaning feed dog and shuttle

Oiling............................

Problems — and Probable causes

Shuttle cleaner. ... ^1.42

^ Og

Mending

Darning . ,

............................

^ ............................................................................

.....................................................................................

............................................

...............................................................

.................................................................

...................................................

.....................................................................

.....................................................................43

.....................................

.............................

............

^ 25

27

29

30 31

.........................

...............

...............

38

Page 7

PARTI KNOWING YOUR SEWING MACHINE

KNOW THE PARTS

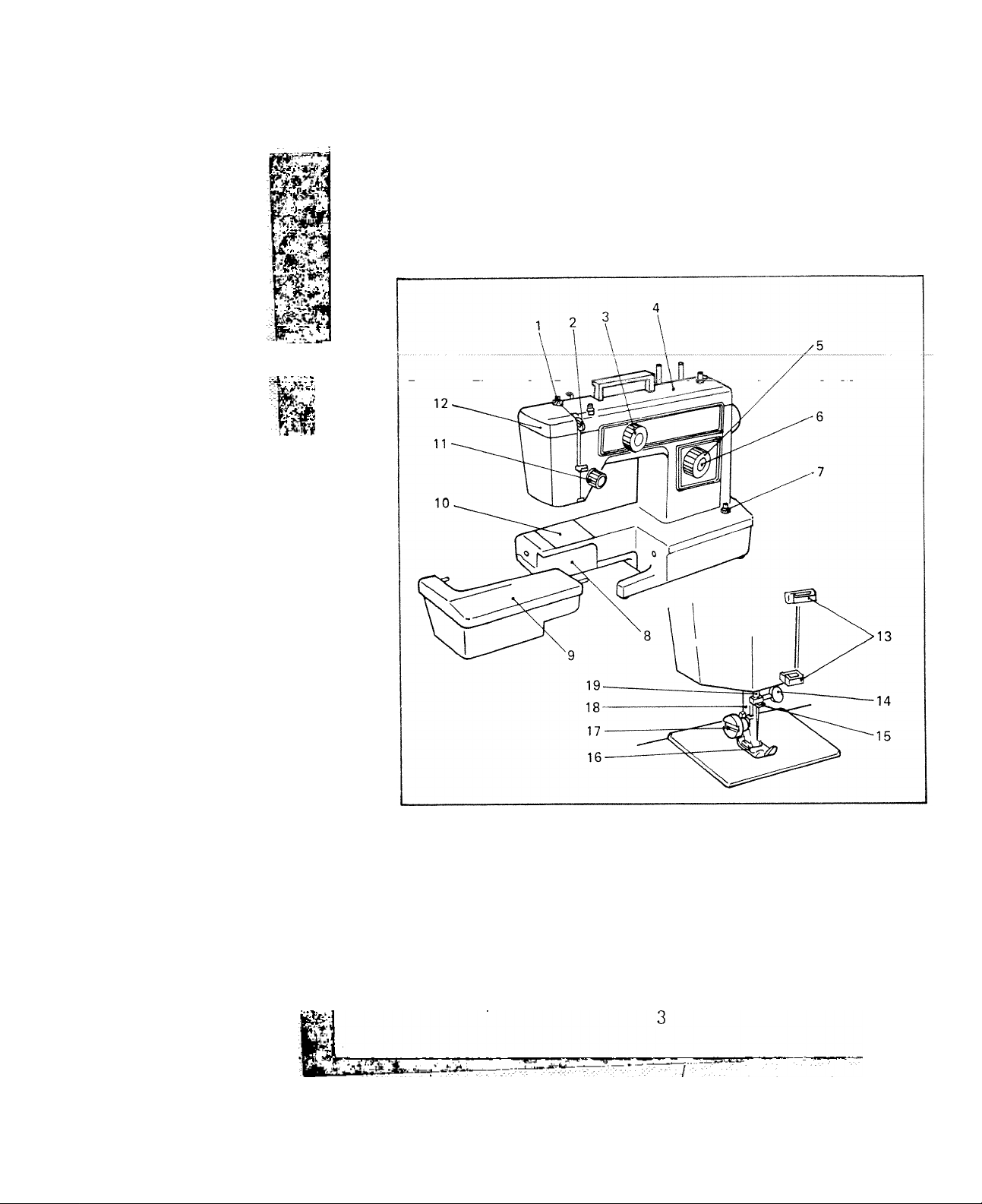

FRONT VIEW

i

1. Pressure regulator (Patch-GMatic)

2. Thread take-up lever

3. Pattern selector dial

4. Top cover

5. Stitch length dial

6. Reversing button

7. Switch

8. Shuttle cover

9. Extension table

10. Needle plate

11. Thread tension dial

12. Faceplate

13. Face piate thread guides

14. Needle damp and screw

15. Needle bar thread guide

16. Presser foot

17. Presser foot bracket thumb screw

18. Presser bar

19. Needle bar

Page 8

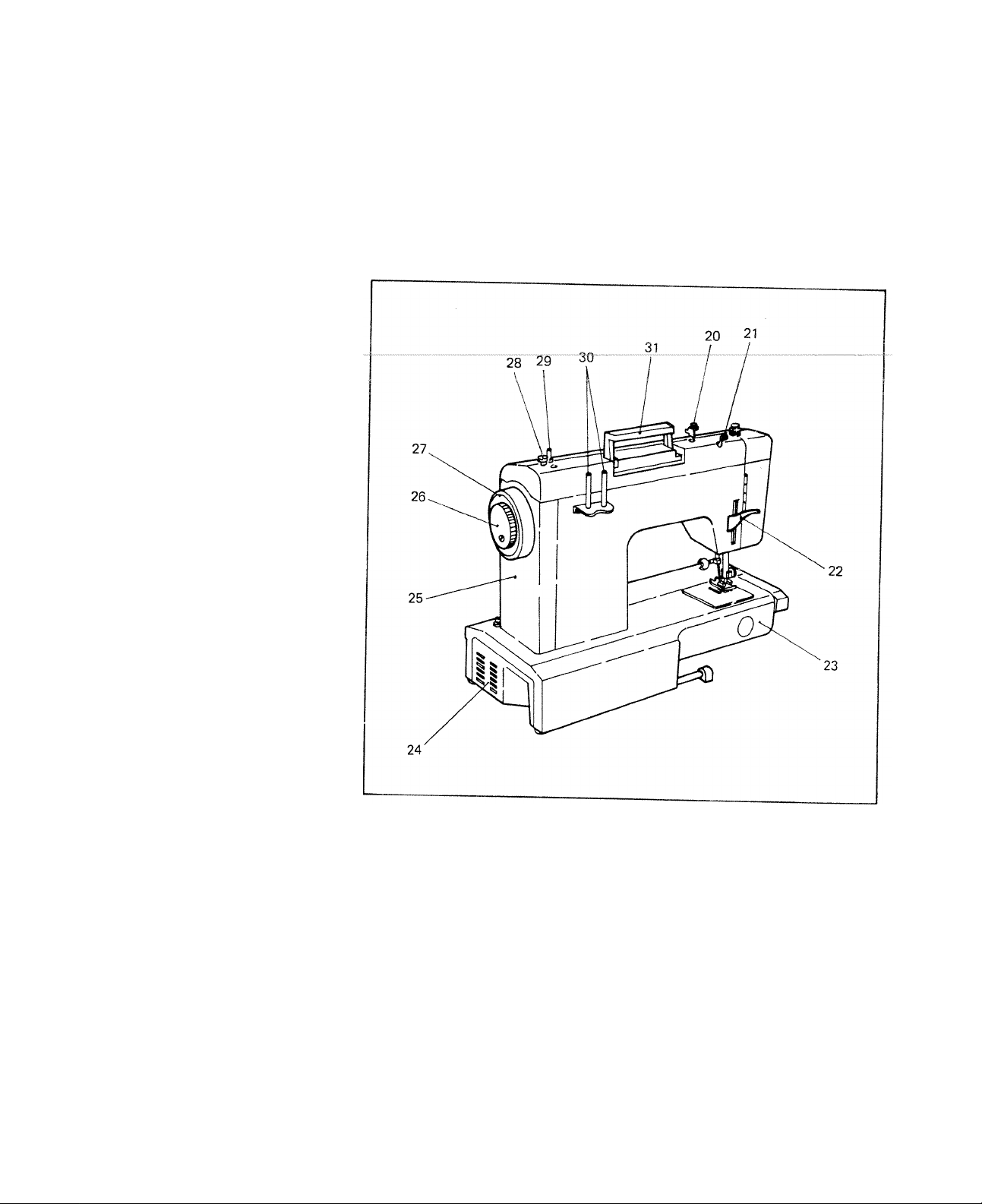

BACK VIEW

i;:-"ii.

-i i-.

20. Bobbin winder thread guide

21. Upper thread guide

22. Presser bar lifter

23. Free arm

24. Terminal cover

25. Belt cover

26. Clutch knob

27. Hand wheel

28. Bobbin winder stopper

29. Bobbin winder spindle

30. Spool pins

31. Carrying handle

a

Page 9

Page 10

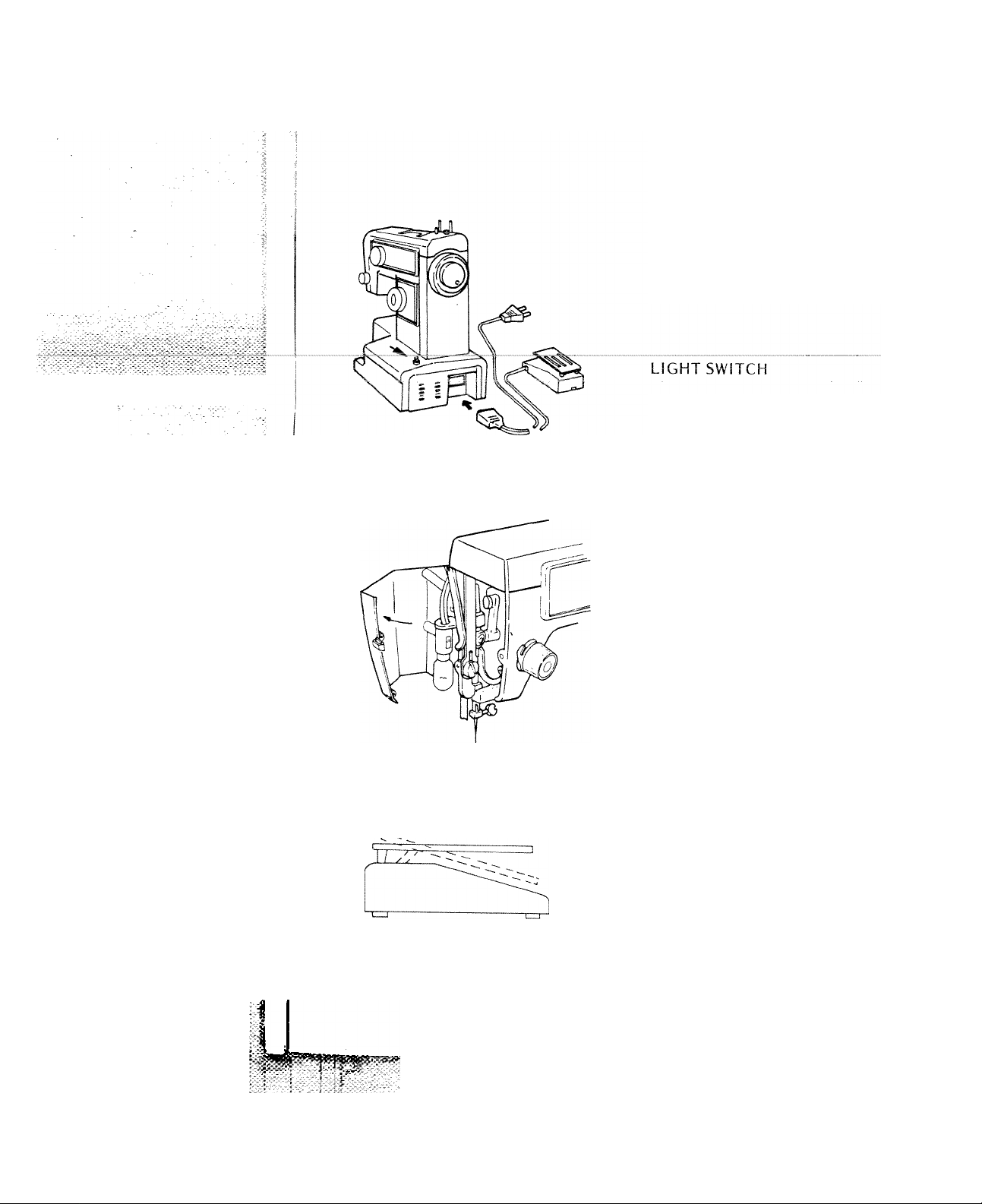

ELECTRONIC SPEED CONTROLLER

Push the speed control plug onto three

prong connector.

Plug machine cord into any 110 ~ 120

volt wall outlet.

Turn light on and off by pushing light

switch.

SEWING LIGHT

The sewing light is located in the face

cover as shown. To replace the bulb,

turn the light off and open the face

cover. Push the bulb up and turn the

bulb counter-clockwise and remove d

from the socket.

Push a new bulb m and turn it clockwise.

NOTE:

First, unplug the machine prior to re

moving and replacing the bulb. Be

aware that the light bulb may be warm.

FOOT CONTROL

Step on this control to start tosew. The

harder you press on the control, the

faster the machine will sew. Slow down

by reducing foot pressure on the control.

You may want to practice your speed at

different levels when you first use the

machine.

Page 11

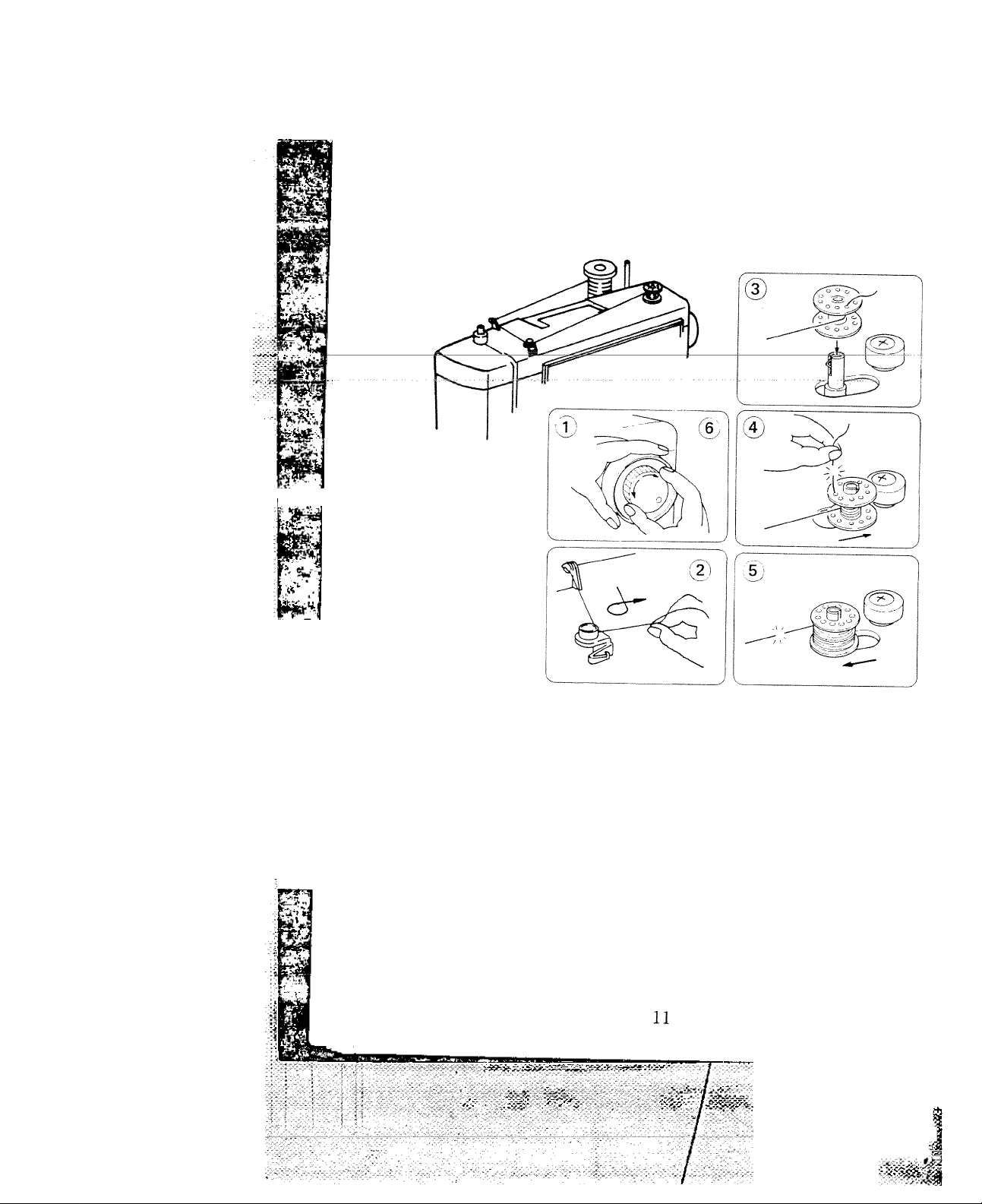

INSTALLING EXTENSION TABLE

For all flat-bed sewing use the extension table provided with the machine. To

install the extension table, simply slide the table along the free arm until the two

Pins (A) and (B) enter fitting holes in the machine.

Lower the support leg.

^To ^tension

.table .from the machine .by puIJing-itTo-thefeft.

.................................................

Page 12

NEEDLE, THREAD AND FABRIC CHART

The needle and thread you choose depends upon the fabric you are stitching.

The correct needle size is important to avoid damaging the fibers of light weight

or tightly woven fabrics, and to prevent needle breakage when stitching heavy

or stiff fabrics.

Needle

size

9 * cotton covered polyester

fine "fine mercerized cotton |70-100| organdy

11

light "mercerized cotton (50-60)

■ ■ ■ - 'i 14

medium

■ ;■ .--i

■ ■■ ^ ^

- ■■■■—■; ->■ ■

' -T

■ • ' . ' ■' • ,

.............

16

heavy

Thread

potyeifer

"silk A

"polyester

"cotton covered polyester

"silk A

"polyester

"cotton covered polyester

"mercerized cotton (50)

"silk A

"polyester heavy wools, corduroy, felt.

"cotton covered polyester

"mercerized cotton (40-50) and drapery fabrics

"heavy duty mercerized (40)

"silk D (buttonhole twist for top-

stitching)

trrcot, lingeriefatincs, chtffoTi,

net, voile, sheer lace, fine silk.

light weight knits, jerseys, silk.

batiste, taffeta, satin, lace, crepe

double knits, linen, poplin.

gingham, pique, seersucker, fine

corduroy, velveteen, light weight

wools

terrycloth, canvas, upholstery

Fabric

1 * Always use same type and size of thread in both needle and bobbin.

* Always

the fabric. Chemical finishes and man-made fibers blunt the needle faster.

Never use a bent needle.

If your machine is skipping stitches, replace the needle before looking for

trouble elsewhere.

When sewing very fine fabrics, use tissue paper underlay to prevent yarn distor

tion.

When sewing stretch, very fine fabrics and synthetics, use a BLUE TIPPED

needle. The blue tipped needle effectively prevents skipped stitches.

use a sharp needle. A blunt point

can cause skipped stitches or snag

8

Page 13

(3)

{___

i

CHANGING THE NEEDLE

1. Turn the hand wheel towards you

until the needle is at is highest posi

tion.

2. Loosen the needle clamp screw by

turning its top edge towards you.

Remove the needle from the damn

I

(4)

.......

3. Place the new needle into the needle

clamp with its flat side facing away

from you. Push the needle up into

needle clamp as far as possible.

4. Tighten the needle clamp screw

firmly.

V

.............

I -^1

TO SELECT A SUITABLE NEEDLE

Stem

T—)

a'l-lt I —f: ■ ri^V 'iL.lL--

A number indicating the size of

needle is marked on the stem. The

higher the number, the thicker the

needle.

Do not use any needle which is bent

or blunted.

Page 14

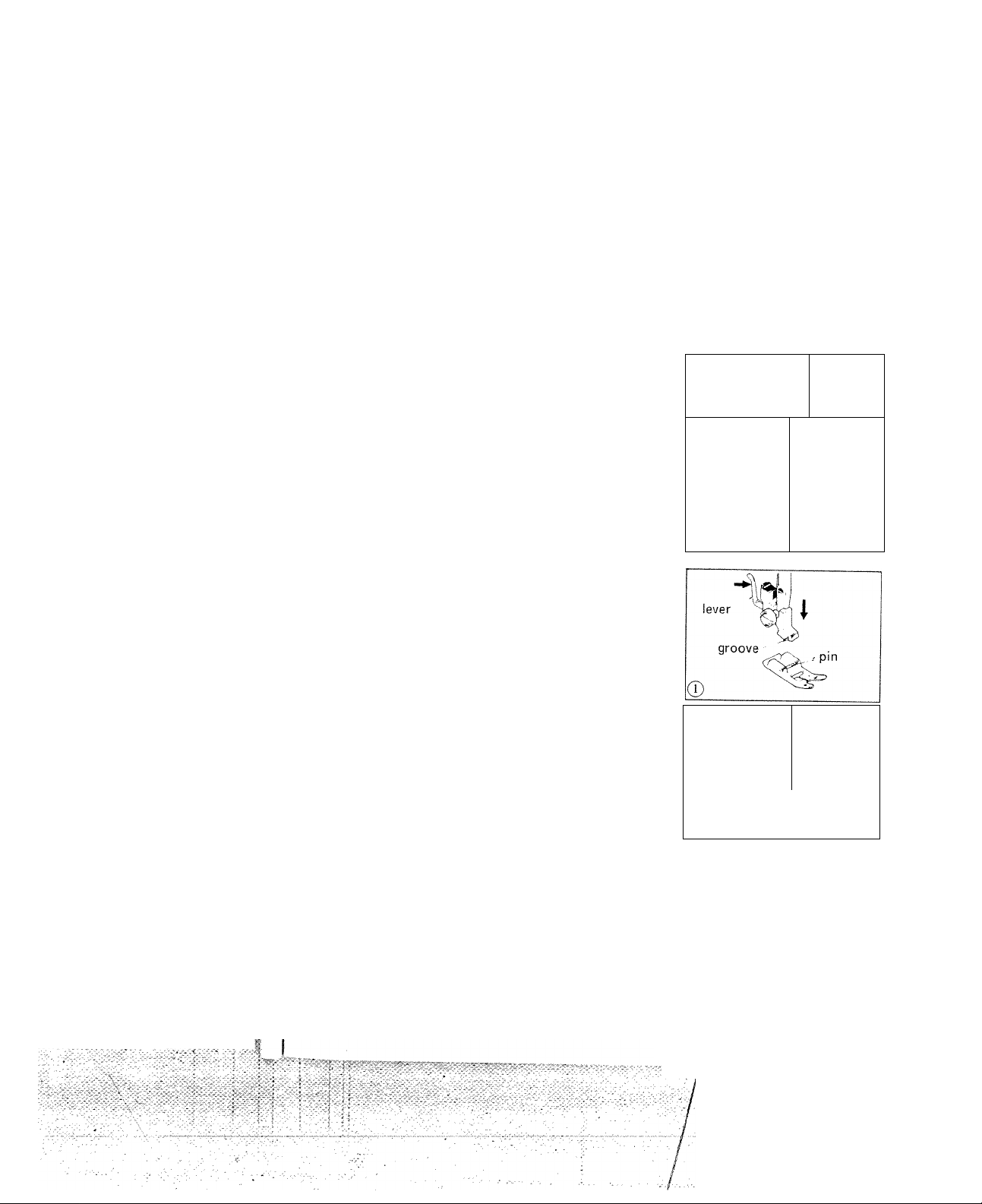

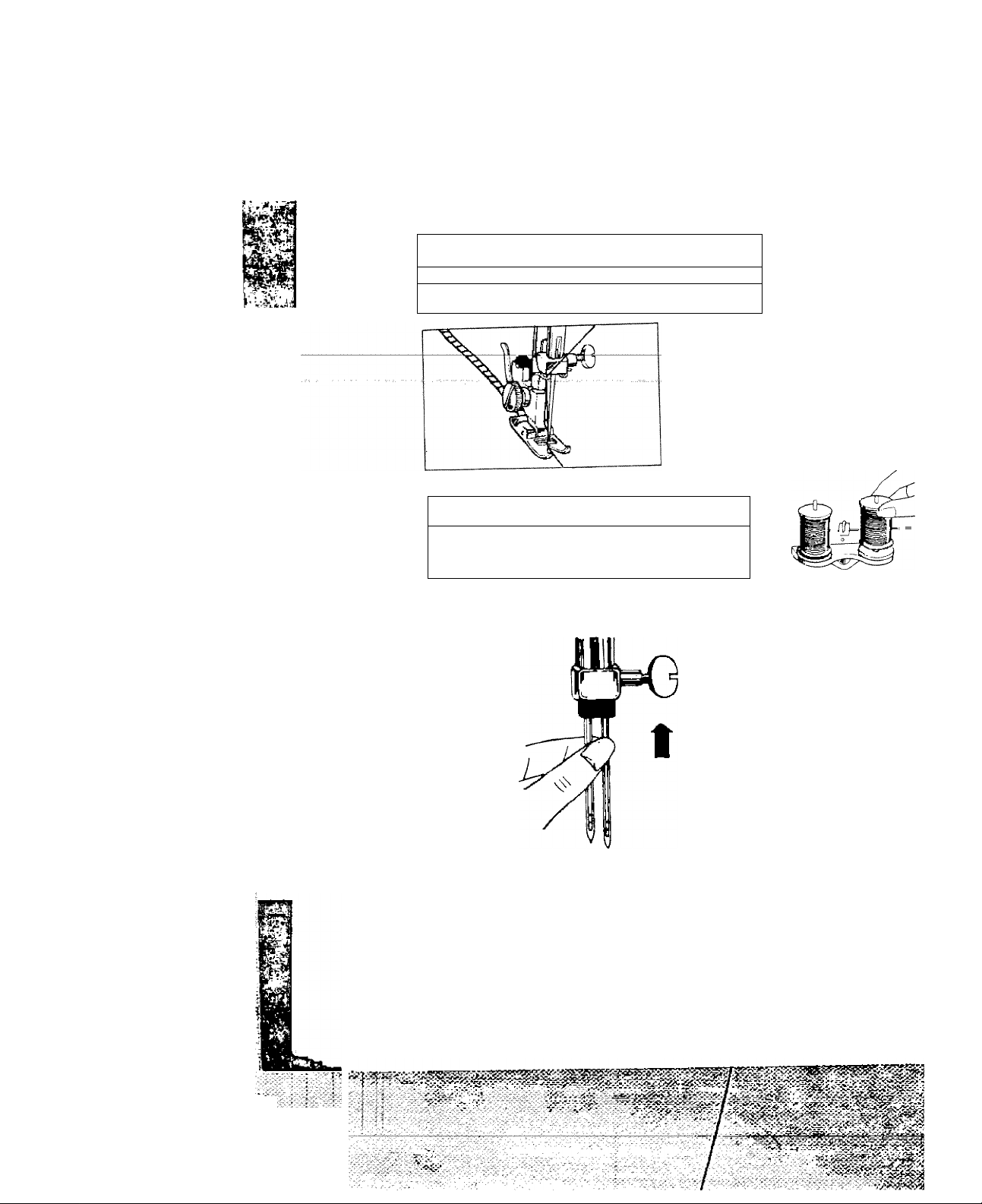

REMOVING AND ATTACHING THE PRESSER FOOT

To Remove;

1. Turn the hand : wheel towards you until

the needle is at its highest position. Raise

the presser foot by lifting the presser foot

lifter.

^ 2. By lifting the^Jeveron^he back of the foot

holder, the presser foot will drop off.

Note: *Do not force the presser foot to

remove it.

To Attach:

1. Place the presser foot so that the pin on

the foot lies just under the groove of the

foot holder. Lower the foot holder.

2. When the presser foot lifter is raised

you'll find the presser foot is locked in

place.

1 ^ ' foot

(D '

Presser -^ / |

1

1

....

10

(D ^

Page 15

WINDING THE BOBBIN

1. Release clutch by turning clutch

knob toward you.

2. Draw thread from spool through

bobbin winder tension disc as shown.

3. Pull end of thread through hole in

bobbin as shown.

4. Place bobbin onto bobbin winder

shaft with end of thread coming

from the top of the bobbin. Push

bobbin winder shaft to the right

until it clicks. Holding onto end

of thread, start machine. When

bobbin is slightly filled, snip off

end of thread.

5. Wind thread until winder stops.

Remove bobbin. Clip thread.

6. Tighten clutch knob.

■ -A

'

Page 16

1

ADJUSTING BOBBIN WINDER

Correct

The thread must be wound onto the bobbin

evenly.

- - - - - ■ . - ■ , ■ -

':y

■ I

I

1

Incorrect

Incorrect

Bobbin winder thread guide

Fixing screw

Set the winder stop so that the bobbin is

filled to about % with thread. The bobbin

must stop turning when the required amount

of thread is wound. If the amount of

thread is not correct, loosen the screw and

move the winder stop as shown in the

illustration at the right.

If the thread piles up at the bottom, loosen

the fixing screw of the winder tpruipn and

set the tension a little higher.

If more thread is wound on at the top of the

bobbin, push the winder tension down a

little.

After adjustment, do not forget to tighten

the fixing screw!

To locate fixing screw, open face plate. This

screw is directly under bobbin winder thread

guide inside the top cover.

bobbin

winder

stopper

LESS MORE

12

/

Page 17

i®

(DM

------------------

1

N

Place spool on spool pin as shown, with

thread coming from the back of the

spool.

Draw thread through top thread guides.

Holding spool stationary with right

hand, pull the end of the thread between

the tension discs as shown above (3).

Pull the end of the thread taut with left

hand. This will pull the spring wire up

and past the end of the hook. The

thread will then slip into the hook when

the spring is released as in (4i.

V

Release spool of thread and thread

machine through take-up lever (5) and

thread guide (6i as shown above. Thread

then passes through guides (7) and (8).

Thread needle (9) from front to rear.

13

J

Page 18

THREADING THE BOBBIN CASE

. ' - V I.

■> v:-:'5

- ‘ :

; ■

‘ 7 :

: =

-4- -4

■ -

"r'-TC-

..

1. Remove the extension table from the

machine by pulling it to the left

Open the shuttle cover by pulling

down the embossed part on the left

side of the cover.

2. Raise needle to its highest position

by rotating hand wheel toward you.

3. To remove bobbin case from shuttle,

pull open latch of bobbin case.

4. Pull bobbin case straight out

shuttle.

-i

.VC7

5. Insert bobbin into bobbin case

making sure thread is coming from

bobbin as shown.

6. Pull thread through slot of case as

shown.

7. Pull thread under tension spring.

8. Holding latch open, position case

into shuttle, and release latch. Case

of

should lock into place when latch

is released.

14

Page 19

PICKING UP BOBBIN THREAD

1. Raise presser foot iever. Hold needle

thread loosely in left hand and rotate

hand wheel toward you one complete

turn.

2. Bring bobbin thread up by pulling

upper thread.

3. Pull both threads under and to the

back of the presser foot, leaving 3

to 4 inches of thread clear.

If you cannot pick up bottom thread

by following steps given above, then

check:

1. Is needle threaded from front to

back?

2. Is thread tangled around needle?

3. is there 3 to 4 inches of thread com

ing from the bobbin case?

4 Is thread from bobbin case tangled?

Page 20

THE PATTERN SELECTOR

The desired pattern can be selected by turning

the pattern selector dial. The marks on the dial

correspond to the patterns shown on the panel

respectively, as follows:

A( cJD ) straight stitch, middle needle posi

tion

Bi ) straight stitch, left needle position

ilgzagTIitch with variable width

) 3-step-stretch-zigiaf-stitch - - -

E(

^ ) stretch blindstitch

F(

^ ) double action stitch

G(

^ ) reverse blindstitch

m ^ m automatic buttonhole sewing

Selecting Stretch Stitch:

When sewing stretch stitch, set the stitch length

dial at "S.S."

When you release the "S.S.” engagement on the

dial, the stretch stitch mechanism will be off

automatically.

A( cSd ) triple straight stretch stitch, middle

needle position.

B( ) triple straight stretch stitch, left

needle position.

C( Avwv ) triple zigzag stretch stitch or rick-

^ rack stitch

D( ^ ) smocking stitch

E( ^ ) fancy stretch stitch or blanket

stitch

F( 0 ) double overlock stitch

G( ^ ) overlock stitch

If you use a twin needle,

zigzag stitch width should

be in the range " ”

(zigzag width less than

" ff " mark).

Note:* Raise the needle to its highest position

before turning the pattern selector.

16

Page 21

STITCH LENGTH L„AL, .EVERS,NG BUTTON AND DROPPING T,

lO r'hanno +u« i_ .1 _

Jo change the length of the stitches

proceed as follows:

Turn the dial so that the number for the

required stitch length is at setting mark.

sl tr-hT T approximate

stitch lengths in mm. The lower the

reverse STITCH;

Press center of the stitch length dial

reversing button) and hold for reverse

feldi ™"^®diately start

feeding backwards. Release button and

machine will resume normal forward

sewing.

.'!,ddrf“"r

andd„Bw„h„d,ha.in8,„,ie,h,„ds

and for strengthening seams. '

dropping the feed DOG:

Embroidering and darning are best

carried out with the feed mechanism

disengaged. This is done by setting the

tie f drops

he feed and allows the material to be

moved freely under the needle

The feed starts its normal function again

as soon as you turn the stitch length

dial to 0" or beyond it.

stitch leng

.■w/-- * •

Page 22

ADJUSTING TOP THREAD TENSIONS

Probably the most important control on

your machine is this one that regulates

your top thread tension.

There are many reasons for having to

reset your tension. The best tension for

one fabric may not be correct for

another. The recjulred tension depènds

upon the stiffness of the fabric, thickness

of the fabric, numbers of layers of fabric

being sewn, as well as the type of stitch

you are making.

It is best to test the stitching on a scrap

of the fabric you are using before starting

to make a garment. Use the straight

stitch function as shown at the right.

ADJUSTING BOBBIN TENSIONS

An ideal straight stitch will have

threads locked between the two

layers of fabric.

TJppenttreaaTooTfgfrr

Decrease Tension ( o

Upper thread too loose

Increase Tension

Bobbin tension requires adjusting less

frequently than the upper thread ten^

sion.

If the stitch is satisfactory but the seam

is puckered, it may be necessary to

loosen the tension on both the top and

bottom threads. Be sure to balance

them.

When adjusting the tension on the bobbin

case, make slight adjustments with a

screw driver.

DECREASE TENSION

18

Page 23

REGULATING THE PRESSER

FOOT PRESSURE (Patch-O-Matic)

To release the pressure, push ring (A)

downwards. The machine is now free

from any pressure of the presser foot.

For sewing medium or light materials, push

regulator (B) down just a little to provide

"^freffglrt^esstife-reqtttfed:

If you are sevvirig ,thick or heavy materials,

push the regulator (B) farther down to

increase the pressure on the material.

---------------------------

ring (A)

-top®f

regulator

PRESSER FOOT LEVER

To aid you in the placement of heavy

fabrics under the presser foot, the lever

can raise foot beyond the normal "up"

position. This is also an aid in changing

your presser feet.

19

Page 24

PART II START SEWING

Now that you are familiar with the controls on your machine and with the acces

sories provided for the machine, you are ready to start to sew with your new

sewing machine. Below are some good habits to follow each time you sit

down to sew:

..

...........

-tlr#.n66(jl6

the correct size for the fabric and thread being used. Do not be afraid to change

your needle frequently. Many of the new fabrics made of synthetic blends tend

to dull the needles more easily than fabrics made of natural fibers.

2. Before placing the material on the machine, see that the ends of the threads have

been drawn about 4 inches to the rear of the machine. Hold on to threads

during the sewing of the first 3 or 4 stitches of the seam.

3. Test the machine stitch on a scrap of fabric you plan to use. The fabric should

be double thickness. Adjust the machine for the length of stitch and tension

suitable to your fabric.

4. Fabric should be placed under the presser foot with the bulk of the material to

the left of the needle and the right edge of the material placed on the 5/8” seam

marking on the needle plate when making a simple seam.

5. Run the machine at a slow even speed. The more pressure you put on the foot

control, the faster the machine will sew.

....

it gh0y|r|

.....

1^9 Strsight, prOpSfly SSt SHCJ $fl3fp Qfl

.......................

poiflt. SofSCt

.........

6. Fasten each seam by back tacking at the beginning and end of the seam.

7. Always finish sewing each seam with the needle at its highest point.

8. Guide the fabric gently with your hand in front of the needle. Never pull or

hold the fabric in such a way that the normal feeding is altered.

9. When turning the hand wheel manually, always turn it toward you.

20

Page 25

-nm

Keeping Stitching Straight

Your machine has three aids to help

keep your stitching straight, whether

stitching seams or doing decorative

stitching.

* Numbered guidelines on the right

side on needle plate.

Numbers indicate distance, in eights

L

of an inch, form the needle. For 5/8"

seam, line up your fabric with the

' numbered 5/8" ^guideline.

Cloth guide attachment

Use for stitching seam widths that

are wider than markings on needle

plate, and for making wide hems.

Also use as a guide for blindstitching.

Fasten cloth guide to machine by

inserting thumb screw into hole in

bed of machine. Adjust cloth guide

to desired distance from needle and

tighten screw.

Quilting attachment

Use for stitching parallel lines with

out marking fabric when quilting

shirring, smocking, or making rows

of decorative stitches.

Insert bar (A) into hole in the Foot

Bracket (B). It is movable from side

to side to set it at the desired position.

Pin Basting

Place pins at right angles to presser foot

with pins just nipping into fabric at

stitching line. Never place pins on

underside of fabric in contact with

fabric feed or so presser foot ride;

over head of pin.

21

.....

.

Page 26

STRAIGHT STITCH

Presser foot

Pattern selector

Stitch length dial.......................0.3 ^'4 '

Ypu..will

temporary and parmanent ‘ “

'■ .mg:rray„TSpTo°’Thf' »"»' «»"= “ =

M^Tof ti'h®' '^'^'=hing that holds the garment together

iipt“Sdr.r:^t's«re:;,fj^

.a“m™;-rSam'° S“ rriaalTra^“”'" '-ra o,

.............................

.......................

...

find

...in..

gaimfini

Sng ° temporary stitching are:

Stay stitching

Guide line marking

Common two layer seams

Curved two layer seams

Top stitched three layer seams

Top stitched four layer seams

zigzag foot

A{ C±D ) or B( dZ3 )

..

----------

---------

'»'P“ »»<"9-

zigzag foot

rx X nXioraorLxxxxCarsir

Starting Sewing

1. Be sure both the threads are drawn

back under the presser foot.

2. While holding the threads with your

left hand, turn the hand wheel

toward you to bring the needle into

the fabric where you wish to start

sewing.

3. Lower the presser foot, and press the

speed controller gently, then start

Page 27

fWM

Basting

Machine basting is very useful for join

ing seams for trial fittings, marking

construction guidelines, and basting

pleats and hems.

Use longest stitch possible, setting

stitch length at 4. Loosen tension on

upper thread. Choose thread color to

.

conttast.with.y our. fabric.so.it.can.he

easily seen.

Basting ^ stitches can be'removed ^easily

by clipping upper thread, then pulling

out lower thread.

Staystitching

Staystitching prevents stretching and

acts as a guideline for clipping and

joining curved edges. Staystitch any

edge that might stretch during handl

ing before the final stitching.

Staystitch on a single layer of fabric;

always stitching in the direction of the

grain. Place stitching 1/8" away from

seamline in the seam allowance. Use

12 stitches per inch for most fabrics.

Changing Sewing Directions

1. Stop the machine, and turn the

hand wheel toward you to bring

the needle down into the fabric.

Raise the presser foot.

2. Pivot the fabric around the needle to

change direction as desired.

3. Lower the presser foot and continue

the sewing.

Fastening Seams

1. For fastening the ends of seams,

press down the reversing button and

sew several reverse stitches.

2. To remove the fabric, raise the presser

foot and draw the fabric away from

you.

3. Sever threads on thread cutter at the

rear of presser bar or with a pair of

scissors.

Leave about 15 cm (6 inches) of

thread hanging from the needle eye.

23

Page 28

ZIG-ZAG STITCHING

Presser foot

Pattern selector ....

Stitch length dial. .. .

This type of stitching greatly expands the use of your machine. This is the feature

.

tOBl 6D.3.Dl.fiS- y-.Qii- .i.Q_Qy.firjC3$t $63015, 3ppIi QU6 3D.Q-Oil Dii-t.t.OQS,-—Us ftn.& T3ITQ6

of widths as indicated on the pattern selector, you can sew any width you desire.

Since this is a range, you may set the dial between the illustrated widths.

................

.........

zigzag foot

. . . . . C( Ì

.........

0.3 - 4

OVERCASTING

This is one of the more frequently used

zigzag stitches in garment construction.

You may want to overcast along the raw

edge of each seam allowance or fold the

raw edge toward the garment and stitch.

Fig. 1 shows the raw edge finished.

Fig. 2 illustrates the folded edge stitched.

Stitch so the needle pierces the fabric

just short of the outside edge. Raw or

worn edges of older garments can be

overcast to prevent further raveling.

INTERFACING DARTS

To reduce bulk of interfacing darts, cut

interfacing down center between dart

lines. Overlap cut edges, matching dart

lines. Zigzag stitch along marking line

from point to wide end of dart. Trim

both raw edges close to stitching.

24

Page 29

CHECKING TENSIONS

The easiest way to check tensions is to

sew a medium zigzag stitch on the fabric

you will be using.

Use the appropriate type of thread and

needle. Use different colors of thread

ohtfieDdiDDirram^

Sew a line of medium zig-zag stitches.

The bobbin thread should not show on

the top of the fabric.

Adjust the top tension if necessary to

achieve the stitch formation mentioned

above.

SHELL STITCHING

Presser foot

Pattern selector. . . .

Stitch length dial. . .

...............

. . . zigzag foot

■ ■■ -G(

.................

1.5

UNDESIRABLE

TOP SIDE OF FABRIC

DESIRABLE

..M

When sewing this stitch, allow needle to

just clear the right edge of the fabric

when it zigzags.

NOTE:

You may need to increase your tension

slightly to achieve the shell affect.

Page 30

SATIN STITCHING

Presser foot

Pattern selector.. . .

Stitch length dial. . .

Closely spaced zigzag stitches are called satin stitches. This is an attractivfi stitrh

used for appliqueing, bar tacking or sewing on buttons.

Whenever you^ are ustnf this stitch/ft is weff-to' remember to loosen^WeheHsioft of ^

the top thread slightly. The wider the stitch sewn the looser the tension.

If you are stitching on a very soft fabric, it is well to use a backing of tissue paper

or interfacing for a well formed stitch. Puckering of the material will be eliminated

and the bobbin thread will not be visible on the top side of the fabric.

It is best to practice a sample design on a fabric scrap before sewing design on

garment.

..............

.. .zigzag foot

. . .C( M/Vw )

.. .0.3 to 1

APPLIQUEING

SETTINGS

Same as with Satin Stitching

Select an applique design to be applied

to your garment and baste it in place.

Satin stitch around the raw edge of the

applique completely covering the edge.

You may want to do this with a con

trasting color of thread or self color.

BAR TACKING

This stitch is similar to a very short satin

stitch and is used to reinforce points of

strain such as corners of pockets and

straps on lingerie.

Sew 4 to 6 zigzag stitches.

Page 31

STRETCH AND UTILITY STITCH SEWING STRETCH STITCHING

When sewing knitted or stretch fabrics, choose one of the stretch stitches which

allows the seam to stretch with the fabric without breaking the thread. Select

polyester or cotton covered polyester thread which has an extra amount or give

and is designed for knits and stretch fabrics.

“IrisT'ecorrffTOTTdedTT/yherr^sewlTTg^^stretch^TatencsTTIiM^T^speciailTTeedle^wTth

.shaft,is,,used.„..This..will.preMent.skipping,stitches..,.Also,.refer.,ta.Meedl.e, Thread

and Fabric Chart on page 8 to be sure that you use correct size needle and thread.

TRIPLE STRAIGHT STRETCH STITCH

Presser foot................................................zigzag foot

Pattern selector...........................................A( rtth)) or B ( dt!~) 1

Stitch length dial.........................................S.S.

Stretch straight stitch is a triple lock

stitch, combining stretchability and

strength. Use for stitching regular

seams in knits and stretch fabrics.

Use for stitching seams in woven fabrics

that receive a lot of strain when worn,

such as side seams, crotch seams, and

armholes in sportswear and children's

clothes.

Also use for topstitching when you

want a heavier row of stitching with

out using buttonhole twist.

Guide fabric gently allowing machine

to make the back-and-forth stitches

that gives stretch to the seam.

..........

blue

RICKRACK STITCH

Presser foot................................................zigzag foot

Pattern selector

Stitch length dial..........................................S.S.

Rickrack stitch can be used as a heavyduty all-purpose stretch stitch. Each

zig-zag stitch consists of three threads

or stitches, giving strength and perma

nence.

..........................................

C( AVvw )

27

Page 32

3-STEP STRETCH ZIG-ZAG STITCH

Presser foot

Pattern selector

Stitch length dial

SMOCKING STITCH

....................

...................

....................

3-Step stretch zig-zag stitch gives added

.

.......... ..

Use to overcast edges of seams, facings

and hems to prevent raveling and to

keep lightweight knits from rolling.

Besides knits, use for edges of thin,

easily frayed fabrics which have a

tendency to pucker when overcast

with ordinary zig-zag. Also suitable for

overcasting heavy fabrics such as wool

ens and terrycloth.

Use for attaching elastic. Mark elastic

and garment waistline in fourths. Place

elastic over fabric and pin together at

the markings. Take a few stitches to

anchor elastic to fabric, then stretch

elastic between pins as you sew.

Mend tears and patches on knits and

light weight fabrics with stretch zig

zag rather than regular zig-zag.

Presser foot................................................zigzag foot

Pattern selector

Stitch length dial

.........................................

.........................................

pj ^ j

5,3. -

With a narrow strip of fabric directly

under the line of gathering, stitch

over the gathers. The design will be a

series of small diamonds.

When smocking a garment, the stitching

should be done before the piece is sewn

into the garment.

Page 33

( Л — -tf I

OVERLOOK STITCH

Presser remove foot

Pattern selector

Stitch length dial

SEWING WITH A TWIN NEEDLE

Presser foot

Pattern selector

Stitch length dial

................

.......................

......................

..................

............

............

.........

...........

.............

..............

...............

zigzag foot

^ lAVVW'

0.5 to 1

zigzag foot

G( к )

S.S.

Overlook stitch is used for finishing

~seam “gdgesTrr’fetfrrcs^itralrstretott...-Ais-o ■■■

can be used to replace both straight

stitching and zig-zag overcasting in

knitted sports wear, lingerie, and handknitted garments. Makes a thin, flexible

seam that stretches.

Set the pattern selector in the range

1.

of "0-3", otherwise needle may hit

the needle plate and break.

Insert the twin needle in the same

way as a single one (flat side away

from you).

Place two spools of threads on the

spool pins.

Thread machine, taking care that the

3.

two strands of thread are separatee

as much as possible when placini

them in the holes of the threae

guides and the tension discs.

Be sure to place the two round felt

provided in the accessories over th

spool pins.

To turn a corner with a twin needle

stop stitching when right hand needl

just pierces fabric. Raise presse

foot, turn fabric half a turn pivotin

fabric on tip of needle. Lowe

presser foot and take one stitci

Raise presser foot again, complei

turn, and begin stitching in ne’

direction.

29

Page 34

SEW I NG BU T TO N HO L ES

Ths buttonhoie mschanism buiit'in this machine makes it possibie to sev\/ button

holes in a short time without turning the material.

N311 A

Presser foot

Pattern selector

Stitch length dial

...................................

..............................

.............................

buttonhole foot

0.3 to 1

PREPARATION

1. Change the presser foot with buttonhoie foot.

2. Push the sleigh to the bottom end, than put

button between nail A & nail B, fix the button

by the fixing screw (Drawing B)

3. Take away the button from buttonhold foot,

you than get the identical buttonhole size, start

to sew and pull the sleigh all the way forward

to the fixing screw.

*The yellow mark on the stitch length

dial shows range of buttonhole sewing.

An adjustment can be made by setting

the mark, as shown.

coarse

stitches

for heavy

fabrics

n

< <>

> <•

p

iJ

Fixing scrc>N

iOir.wng AS

(Draiving ¡3)

dense

stitches

for light

fabrics

(CONTINUED)

Page 35

f

SEW I NG BU T TO N HO L ES ( co n tin ue d )

1. Set the pattern selector at " C - Then

pass the needle thread through the

opening in the buttonhole foot and draw

both needle and bobbin threads to the

left side. Turn the hand wheel towards

you until the needle comes to the point

TIT ^

Lower the foot and srv'/ slowly until a

desired length is sewn, then stop the

machine at (2).

Raise the needle and set the pattern

selector at " Ш ". Then sew several

stitches of bar tack until the needle

is at point (3).

4. Raise the needle and set the pattern

selector at " H ", then sew the right

side of buttonhole just as the same length

as the left side of buttonhole. Stop the

machine at (4).

5. Raise needle and set the pattern selector

at " Q] ", then sew several stitches of

final bar tack. Stop the machine with the

needle at point (5). To lock threads, set

the pattern selector at "B Izero point of

zigzag width)” and sew a few stitches.

6. Cut the buttonhole open carefully using

a seam ripper, taking care not to damage

the bar tacks.

Place a pin across each end of buttonhole

to protest end stitching.

Page 36

1

BUTTONS

::

0

1

Presser foot.........................

Pattern selector

Stitch length dial

...................

..................

...............

#

1. Align two holes of button with slot

of presser foot and lower foot to

Button foot

hold the button securely.

27Turri hind wheel riTariuaiiy untlT

....

needle-'PoInt' butiofiv

3. Adjust stitch selector so needle enters

right hole of button.

4. Turn hand wheel by hand so needle

enters second hole. The stitch selector

may need to be adjusted again. Stitch

a number of times.

NOTE:

You may find it helpful to use trans

parent tape to position your button

and to keep it in place during sewing.

Tear away after stitching.

5. Finish sewing with an extra two

inches of thread remaining. Draw

these threads to reverse side of gar

ment and tie.

Holes of button

Thread Shank

Sew-through buttons on coats and

jackets should have a thread shank to

make them stand away from the fabric.

Place a straight pin or sewing machine

needle on top of button between the

holes, and sew over the pin or needle.

Pull thread to back of button and wind

around stitches to form a firm shank.

Tie thread ends securely.

Page 37

SEW I NG BL IN D H EM S

Presser foot

Pattern selector.'‘

Stitch length dial

- .............

... .................................................. to 3

........................................

anrpfei^TfFi^TJj

2. Fold hem back against the right side of

the garment with top edge of hem extend

ing about 4 mm (1/6 inches) to right

side of garment fold. (Fig. 2)

3. Place the garment under the foot so that

Z ='»"=

guide and lower the foot

Sew for better control, making

I stitches will fall

on the hem edge and wide zigzag stitches

w II just catch one thread of folded edge.

.........

, ^

il'h" have a

blindstitch hem (Fig. 4)

33

(Fi

Page 38

DOUBLE ACTION STITCH

Presser foot

Pattern selector

Stitch length dial

m

DOUBLE OVERLOCK STITCH

.......................................

.................................

................................

zigzag foot

F ( ^ )

1 to 2 5

This is a good, stitch

or binding elastic fabrics and stretch

lace, lingerie stretch knit. The stitch is

decorative as well as useful.

DECORATIVE EDGING

Turn the raw edge under 2" and press.

Place the fabric right side up with the

middle of the turnover under the center

of the presser foot, so that the stitch

sews on to the fold and just over the

raw edge underneath.

...to..

u,se-^4^n-att3chio^^

i

Presser foot.......................................zigzag foot

Pattern selector

Stitch length dial

.................................

................................

F ^ ^ I

S. S.

Use this versatile stitch to insert elastic

in garments. Simply stitch elastic into

place, making sure it is evenly spaced.

To do this, mark the correct length

piece into quarters, then match these

markings with center front and isde

seams.

Page 39

V. •

t:r 1.

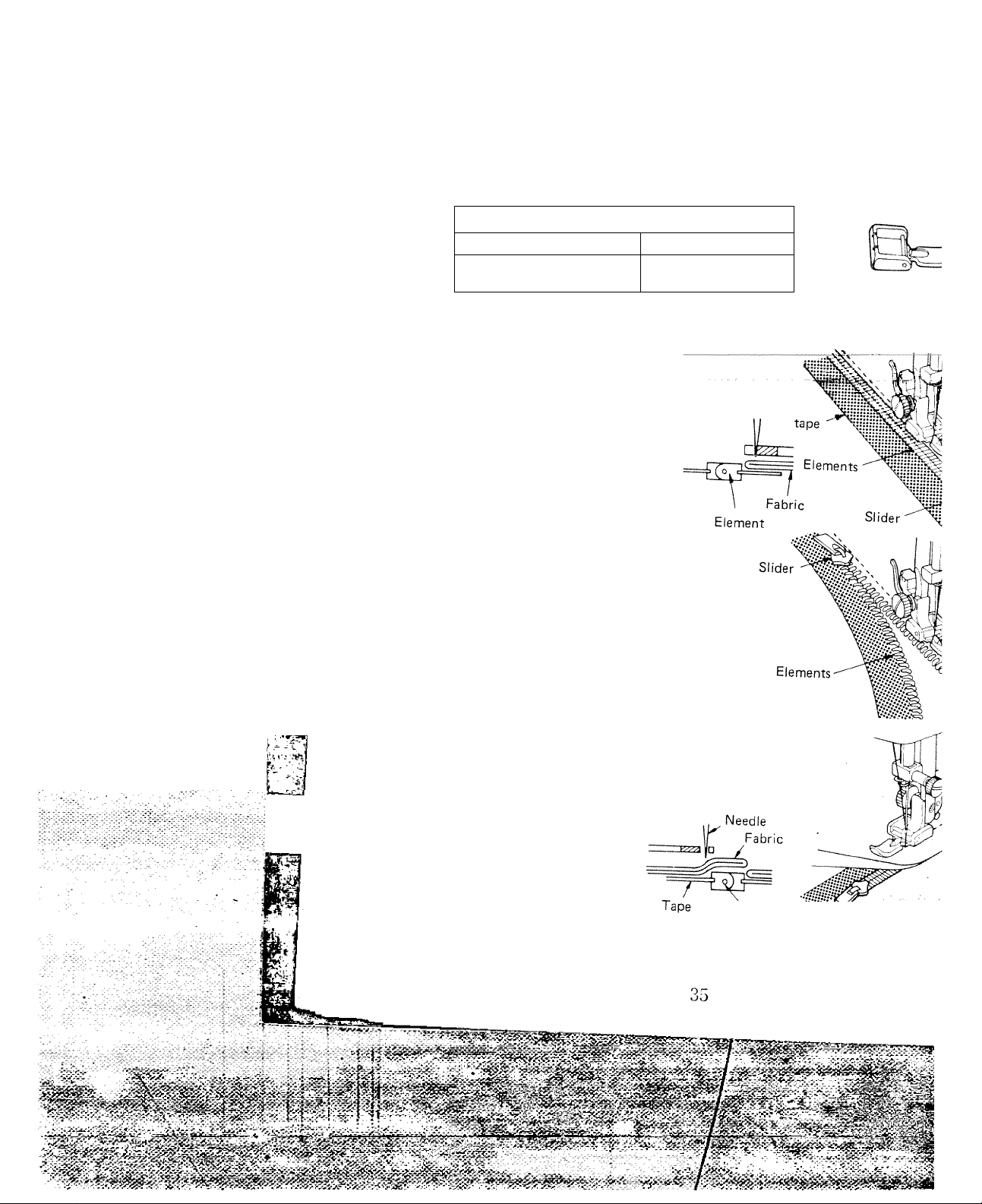

SEW I NG ZIP P ER S

Presser foot. . . ■ ,

Pattern selector..

Stitch length dial.

Zipper foo

Raise the foot. Raise needle to its

highest position by turning the hand

jAfieL^owards^you^^Repface-tfre-f00T

with the zipper foot.

T. Pin or baste the zipper tape to the

fabric and place the work-piece in

position under the foot.

Attach snap on zipper foot so that

the needle passes on its left hand

side.

When starting to sew, both needle

and bobbin threads ends should be

drawn under the foot.

2. Sew on the right side of the zipper

by guiding zipper teeth as close as

possible to the needle drop. Before

the foot reaches the slider on the

zipper tape, raise the foot and open

the zipper by keeping the needle in

the fabric.

Lower the foot and sew on the

remainder of the seam.

3. To sew the left side of zipper change

position of foot to bring the foot

to the left side of the needle. Sew

in the same way as on the right

side of zipper.

Zipper foot

\

Element

Page 40

HEMMING

- . . ; ... -. . .

Presser foot

Pattern selector

Stitch length dial

..................

............

............

.........

A{ C±D )

Raise the foot. Raise the needle to its

highest position. Replace the foot with

the hemmer foot.

Trim and straighten fabric edge. For

easy insertion of fabric in hemmer

foot, first cut off corner of fabric. Then

fold edge of fabric over about 1/8", then

fold it over again for a length of 2".

Insert fabric fold into spiral opening of

hemmer foot. Move fabric back and

forth until the fold forms a scrolled

shape. Draw fabric toward you until

beginning of hem is underneath needle.

Lower foot.

Stitch slowly as you guide fabric into

hemmer foot. Do not push or pull fabric.

If edge of material tends to slide out of

hemmer, guide it to the right. If too

much material enters hemmer, draw

fabric to the left.

hemmer foot

Page 41

MENDING

ME ND IN G A N D DA R N IN G

Presser foot

Pattern selector................................................D( )

Stitch length dial

.....................................................

............................................

zigzag foot

1 to 2

To repair a straight or three-cornere

tear, position the tear under the need

in such a way that the stitching catchi

both sides of the tear. When mending

three-cornered tear, stitch from eac

end to the center. It is well to use

piece of fabric under the tear fc

reinforcement.

t tl t V !

DARNING

Presser foot

Pattern selector. ,

Stitch length dial

.............

. .zigzag foot

■ A( cb

.2 to 3 '

Push down the outer ring of the pressur

regulator. This will release the pressur

on the presser foot.

Stretch fabric between embroider

hoops with hole centered. Lower presse

bar and sew at a slow speed movin

fabric back and forth with a stead

rhythm to cover darning area. When i

is covered, turn fabric 1/4 a turn an.

sew layer of stitching across first layer

If fabric is thin or badly damaged i

hole area, you may want to put a separat

piece under the hole for reinforcemeni

Be sure to return pressure on presse

foot to original adjustment after darr

ing.

Page 42

EMBROIDERY

Remove presser foot

Pattern selector

Stitch length dial........................................^

Place the fabric in an embroidery hoop.

........................................

^^SeTTPTFltrfchTengfR^lJiS^^a^

Lower the-presser foot lifter.'-' 'Held""the

embroidery hoop firmly with your hand.

While sewing the desired pattern, move

the embroidery hoop slowly and do not

allow your fingers to get near the needle.

*Set the needle thread tension a little

looser so that the bobbin thread is

not pulled through to the right side

of fabric.

*lt is recommended to mark the required

embroidery pattern on the right side of

the fabric with a pencil ortailor'schalk.

A( C{D

_ •■" •■• •, "1,5“' r */

.-' •

............

•■^:- • •;■ V.--< .. ■ ■. ■

■

38

Page 43

PA RT II I C A RI NG FO R Y OU R M A CH IN E

CLEANING FEED DOG AND SHUTTLE

Lever

Shuttle Assembly

Lever

Fig. 1 Cleaning the feed dog wi

brush.

To insure the best possible open

of your machine, it is necessary to

the essential parts etean ' at all ti

Using a small brush, remove the lint

accumulates in the shuttle area

around the feed dog.

Fig. 2 Parts of the Shuttle Assembly

To Clean the Shuttle Area:

1. This area must be kept free of i

lint and occasional tangled thi

Raise the needle to its highest

point and remove the bobbin i

2. Push levers of shuttle race aside

lift shuttle race cover and shuttle

3. Clean the shuttle race with s

brush.

4. Put a drop of oil on the center p

the shuttle and shuttle race,

arrows).

A-. --V-

l-.-i

Shuttle Race Cover

Pointed

hook

Shuttle

Shuttle driver

To Replace Shuttle Assembly;

1. Position shuttle race as illustrate

that race is forming halt moor

the left side of the machine.

2. Hold shuttle by center pin and :

tion shuttle so as to form a half r

on the right side. Pointed hook

be on the bottom.

3. Place shuttle race cover into t

over shuttle assembly.

4. Snap the levers into position.

* See additional shuttle cleaner infe

tion on page 43.

Page 44

OILING

As is the case with all precision machinery, it is necessary for maximum efficiency

to properly oil and clean at reasonable intervals. Even though the machine is not

in constant use, it is important to oil your machine since the oil will dry after

standing over a period of time. Use a good grade of sewing machine oil.

NOTE: Before oiling, clean away all lint or foreign matter. One or two drops of

oil are sufficient at each point.

The machine should be oiled at the arrow points shown. After you have

cleaned and oiled your machine, it is advisable to run the machine at high

speed so that the oil will penetrate all moving parts.

: After cleaning and oiling machine, wipe away all excess oil and sew on a

scrap of material to be sure machine sews cleanly.

Inside Face Plate

Sewing face plate open and

oil all moving parts at

friction points.

Page 45

PROBLEMS — and PROBABLE CAUSES

In most cases poor sewing results are due to a damaged needle. Always examir

needle first before checking other items.

1. SKIPPING STITCHES

* bent or blunt needle

* wrong size needle

* needle inserted incorrectly

* upper thread tension too tight

pressure on presser foot too light

2. UNEVEN STITCHES

* bent or blunt needle

* wrong size needle

* incorrect threading

pulling fabric while sewing

* upper thread tension too loose

* pressure on presser foot too light

* loose presser foot

* bobbin wound unevenly

bobbin inserted incorrectly in case

3. NEEDLE BREAKS

* bent needle touches needle plate or presser foot

* needle inserted incorrectly

pulling fabric while sewing

* loose presser foot touches needle

needle too fine for fabric

turning Pattern Selector dial with needle in fabric

* *

............................................................................

4. UPPER THREAD BREAKS

* bent or blunt needle

* incorrect threading

* upper tension too tight

needle inserted incorrectly

needle touches presser foot

* needle eye has sharp edges

* poor quality thread

* knots in thread

* starting to stitch too fast

...........

Page 46

Mi

5. lower thread breaks

* inh?" incorrectly

^ bobbin wound too fu ll

* bobbin tension too tight

* "®®dle plate hole has sharp edges

^ bent bobbin ^

* poor quality thread

^ bent or blunt needle

I upper thread tension too tight

. upper and lower tensions too tight

(use tissue paper underlay)

7. machine does not feed fabric

, stitch length dial set at 0

^ pattern selector on "

thread knotted under fabric

S^CHINGOF THREAD UNDER FABRIC

upper and lower thre^^dc n + ^

* pattern selector on '• i P^^^^er foot

■ '■ M

9. BOBBIN DOES NOT WIND PROPERLY

* r k! 3^'^" uot properly adjusted

* positioned correctly

bobbin winder stnn • correctly

top not positioned correctly

T‘r«'NE runs SLUGGISHLY

; dir!"!,™ '“■*

, machine needs oiling

stop motion knob not tightened

11- machine WILL NOT SEW

* oord not plugged into outlet

Totor belt too toot, ot b.oL.!

42

^ i-

v'>'i

l'Si

Page 47

CLEANING THE SHUTTLE

Note;

If the machine turns hard, has a bind, or

becomes noisy, these are all symptoms of

thread tangled in the shuttle mechanism

or an accumulation of dust and lint that

is interfering with the smooth action of

the shuttle, A thorough cleaning usually

corrects the problem.

SHUTTLE CLEANER

cleaner which removes accumulated lint

and thread from the shuttle race to help

keep it clean and prevent jamming.

If thread gets caught in shuttle by turning

hand wheel backwards or stitching without

fabric in the machine, the thread will break

and be swept out of the shuttle. The

machine will not jam. If machine becomes

stiff for a moment, turn hand wheel toward

you to free it.

Should the shuttle cleaner jump out from

the race, insert cleaner in space A, with

the protrusion B fitting in slot C, forming

a perfect half circle with the driver D.

TO REMOVE SHUTTLE:

Raise needle to its highest position anc

remove bobbin case. Turn levers awa^

from shuttle and lift our retaining ring anc

shuttle, by grasping center pin.

Clean the reverse side of feed dog with a

small brush. Remove line and thread from

all parts of shuttle and wipe with a lightly

oiled cloth.

TO REASSEMBLE:

Hold shuttle by center pin and fit careful

ly back into shuttle race, forming perfect

circle with shuttle driver.

Replace retaining ring polished side out,

making sure the bottom pin fits into notch.

Lock retaining ring by turning levers back

into position. Refit bobbin case with bobbin.

Loading...

Loading...