Page 1

Page 2

INDEX

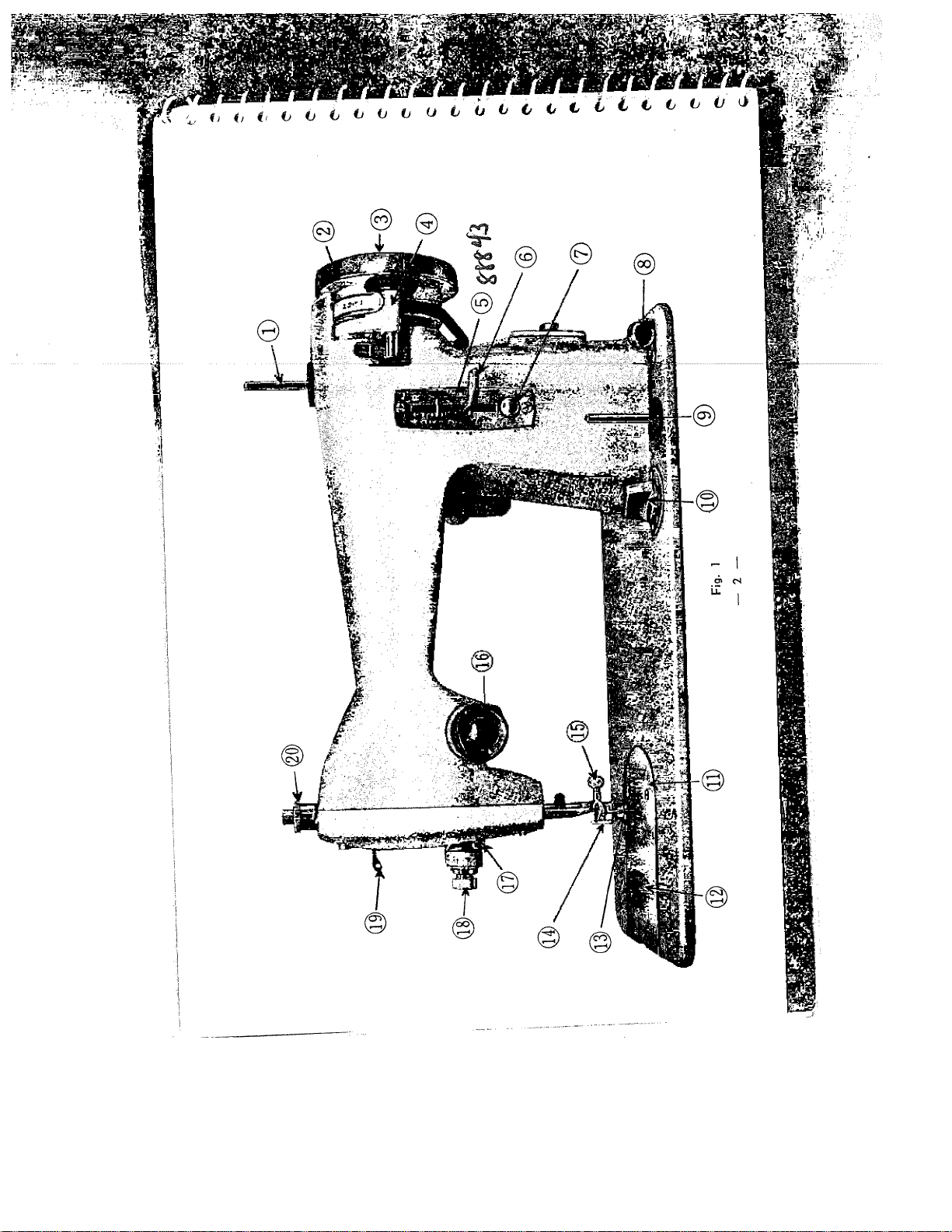

Features and Parts

Setting the Needle............................................................

Needle-Thread-Fabric-Stitching Guide

How to Wind the Bobbin

How to Thread the Bobbin Case

Placing Bobbin Case in Shuttle ..............................

Upper Threading

Setting the Stitch Length ................................................

Adjusting the Tensions....................................................

How to Use the Darner, Adjusting Pressure

Drop Feed Adjustment

Preparing to Sew

Removing the Work

Care and Maintenance of Your Machine

How to Oil your Machine

Cleaning and Oiling the Shuttle

How to Replace Light Bulb .............................................................i...........................

To Replace Belt

Check Up for Smooth Sewing

...........................................................

..........................

...............................................

.....................................

.............................................................

............................................

.............................................................

.......................................................

18

Page 3

Page 4

Page 5

Page 6

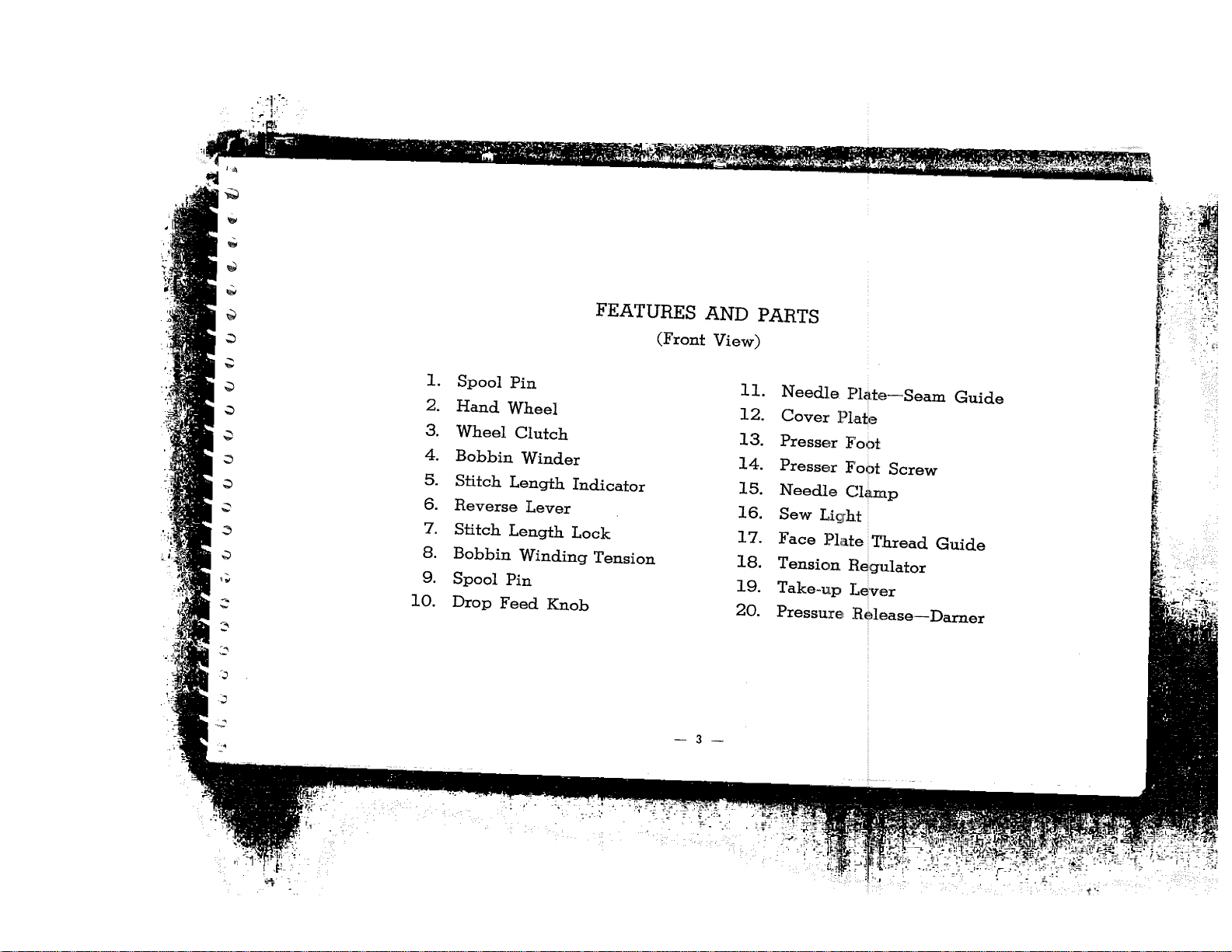

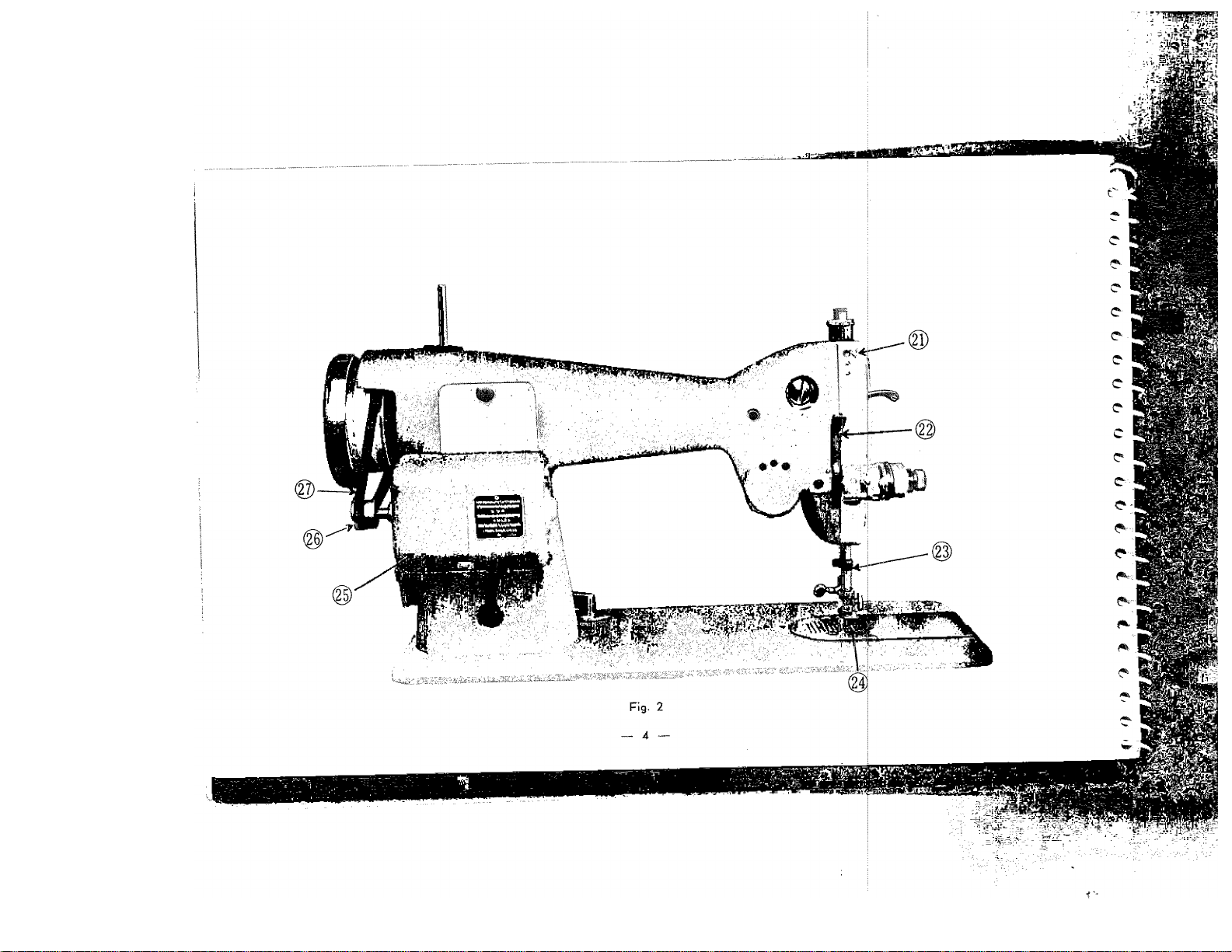

FEATURES AND PARTS

(Back View)

21. Arm Tkread Guide

22. Presser Bar Lifter

23. Thread Cutter

24. Feed

25. Motor

26. Motor Pulley-

27. Belt 1

Page 7

Page 8

tte following fnble will show the ei.e of needles generally used with v„ious sizes of tineed.

NEEDLE-THREAD-FABRIC-STITCHING GUIDE

"fi.

V^iii'

Fabric

ExtrsmBly iiBavy

tarpaulin, sacking,

canvas, duck, etc.

Heavy uphoistery

fabric, ticking,

denim, iBatherettB

Medium heavy

drapery fabric, velveteen,

suiting, felt, terry, etc.

MediunTbroadc^

percale, gingham, linen,

chintz, tafieta, sheer

wool, shantung, etc.

Sheer voile, lawn,

dimity, crepe,

handkerchief linen,

plastic film, etc.

NbbcIIb

No.

MachiuB

StitchBs

Psr Inch.

6

to

8

Cotton

Thread

10

to

30

rtercerized or

Silk

Lread Nylon

I^avy Duty

Hjeavy Duty

Page 9

HOW TO WIND THE BOBBIN

Turn the clutch in the center of the hand, wheel (Fig. 4)

toward you to disengage the sewing mechanism. Place

a spool of thread on the spool pin on the bed of the

machine (Fig. 5). Pass thread through tension disc A.

Insert thread through a hole on edge of bobbin and

^ace bobbin on spindle (B) of winder. Be sure that

the notch in the bobbin fits over the small pin on the

spindle. Place pulley (C) against hand wheel by press

ing lever (D) and

set machine in

motion. When

the bobbin is

fully wound, the

action of the

winder stops

automatically.

Remove from

spindle and cut

off loose thread

end used to start

winding.

If the bobbin winds unevenly, ad

ing tension disc (A) to the right

the screw. When the disc is in

tighten screw. Before starting

clutch by turning it away from

'!KrnaiLi^mrig[W№;!W!W-.-ry.:j:

Page 10

HOW TO THREAD THE BOBBIN CASE|

Refer to Figs. 6, 7 and 8 to familiarize yourself with the procedure. Hold the bobbin

case in your left hand with the tongue pointing up. Let about two inches of thread

hang free from the bobbin, and insert bobbin into case so that tljiread will be rotating

counter-clockwise.

Guide the thread end through the slot on the side of the case aid under the tension

spring until it enters the small notch on the edge of the spring.

.. -:i

■■'I

-.■m

^W'

Fig. 6

Fig. 7

Fig. 8

Page 11

PLACING BOBBIN CASE IN SHUTTLE

Raise needle bar to highest position, hnd. lift hinged

cover plate. Hold the bobbin case latch, (D), Fig.

9, between the thumb and forefinger of the left

hand, with at least three inches of thread running

from the top of the bobbin case to thfe right. Insert

and center the bobbin case on th

shuttle body, (C). Be sure the bobfiin. case finger,

(E), is opposite the shuttle race notcir, (A). Press

the bobbin case (B) into the shuttle

sible until latch catches on the ceni

Fig. 9

shuttle. THEN release the bobbin case latch, (D).

Press bobbin case again after latch has

to make sure the bobbin case is lo

in place. Close the cover plate.

10

Page 12

■ '■ ->.- r 'V';''

1) Place spool of tliread on spool pin.

2) Lead thread through upper thread

guide A on back of face plate

3) down and around tension discs B

from back to front

4) into check spring C

5) then tug on thread to pull it into

hook D Cs®® insert, Pig. 10)

6) up into take-up lever E from back

to front

7) down into thread guide F on face

Tii. ¿i*

n

plate

8) through the needle bar thread

guide G

9) and into needle from left to right.

Pull three or four inches of thread

through needle.

Fig. 10

Page 13

Hold the end of upper thread loosely and turn hand wheel toward

you until the needle goes all the way down and comes back up.

A loop ^^Fig. 11) will be formed over the upper thread which

then can be pulled out straight. Place both thread ends under the

slot of the presser foot and draw toward the back of the machine,

leaving both threads three or four inches long.

SETTING THE

STITCH LENGTH

The length of the stitch

and reverse sewing are

both regulated by the

lever A, Fig. 12.

Button B locks the stitch

length for both forward

and reverse.

To adjust stitch length,

turn button B to the left,

then move lever A past

the zero mark until bar

C is opposite the num

ber stitch length re

quired. (4 is the longest

stitch, near 0 the

Fig. 11

stitch length. Then push lever A down against bar D. To sew in

reverse push lever A upward against bar C.

shortest.) Turn button

B to the right to lock the

12

V

I r

;r-

Page 14

ADJUSTING THE TENSIONS

Always adjust tlie upper tension, with, the presser

foot down, as the tension is automatically released

when it is raised. To increase the tension on the

upper thread, turn dial (iigj 13) clockwise, or

toward you. To decrease, turn iaway from you. The

higher the number on the dial the tighter the ten

sion.

Before adjusting lower tension be sure that the ma

chine is threaded properly. When necessary to

change the bobbin tension, tum small screw (Fig.

14) on side of the bobbin case clockwise to tighten

counter-clockwise to loosen. ’

When the upper and under tensions are properly

balanced, a perfect stitch will be formed with both

threads interlocking in fabric (|Fig. 15).

When the upper tension is too ti^ht, the lower thread

is pulled up over the upper thread which is lying

flat on the fabric.

When the under tension is too tifht, the upper thread

forms loops over the lower thread lying flat on the

fabric.

1

'Salii:

Upper thread tension too tight

Fig. 15

13 ^

Under thread tension too tight

Page 15

HOW TO USE THE DARNER, ADJUST PRESSURE

To release the pressure from the presser foot so the material

can. be moved freely for darning and mending, press down

snap lock (A, Fig. 16) and cap B will pop up.

To return pressure to normal, push darner cap B all the way

down again.

For a slighter pressure when sewing thin materials, push

darner only part way down. Test for correct position on a

scrap of fabric.

DROP FEED ADJUSTMENT

The height of the feed can be adjusted to suit the fabric or

type of work being done. Turn knob A, Fig. 17, to SILK

position to sew on thin materials, or all the way to DARN

position for darning. Turn dial to the right to return feed

to NORM, or normal. Consult the following chart to deter

mine the level of the feed and darner for various t3/pes of

sewing.

Type of Sewing

Sewing thin material

Darning

Sewing thick material

Page 16

PREPARING TO SEW

Have take-up lever at higiiest point before starting to sew. Aft^r threading, NEVER run

machine without material between presser foot and feed.

Place material and threads in position under presser foot and low^ the presser foot. Turn

the hand wheel toward you until the needle is at its highest poinf. You are now ready to

begin sewing.

The speed of the machine is regulated by increasing or decreasing the amount of pressure

exerted on the control.

REMOVING THE WORK

Be sure to stop the machine when the thread take-up lever and needle bar are located at

the highest position. Now raise the presser foot and draw the fabric back and to the left,

and pass the threads over the thread cutter. Pull down slightly, holding thread in both

hands, so as not to bend the needle. Leave the ends of thread under the presser foot.

CARE AND MAINTENANCE OF YOUR MACHINE

HOW TO OIL YOUR MACHINE

Your machine should be oiled occasionally to keep it operating smoothly—how often de

pends on the amount of sewing you do.

Oil the upper part of the sewing unit at points indicated by anlows in Fig. 18. Avoid

overoiling—only a drop is needed at each point.

— 15 —

Page 17

Fig. 18

Fig. 19

Ki^

■V'.i

IviCK,

Fig, 20 ^

thema-

and ar^rF bact; on its hinges

inicSSii n^^lt °“ *‘

DlLte^Lv°I“^^i ihside the face

reSoVri^a? ®ly tequire oiling,

¿ce ltti *n-i°i of the

Fig. 20 * indicated in

— 16

Page 18

CLEANING AND OILING THE SHUTTLE

The stitch forming mechanism occasionally

becomes clogged with loose threads and lint.

This will interfere with the efficient operation

of the machine. Cleaning and removal of the

lint will safeguard the performance. To remove

shuttle:

1. Turn the balance wheel until the needle

reaches its highest position. Tilt head

back on its hinges.

2.

Remove bobbin case (Ä), Fig. 21.

3.

Turn shuttle race cover clamps B down

ward and pull hinged shuttle race cover,

C, down and remove shuttle D.

4.

Clean the shuttle race, the shuttle, and

shuttle race cover by removing all threads,'

lint, etc.

5.

Apply a drop of oil with finger tip to Pig.

outer edge of shuttle.

21

When the cleamng has been completed, proceed as follows to replac# Üie shuttle assembly ;

. lum the balance wheel until the needle reaches its highest position.

. shuttle JD, Fig. 21, agamst shuttle driver and adjust iatol position.

A. p hinge bracket, replace with polished side out.

4. Fut bobbin into bobbin case A.

position by turning clamps B upward

5. Put the bobbin case into shuttle race, fitting tongue into notch E of race cover.

_ 17 _

■ÖfaiF:

Page 19

Page 20

CHECK UP FOR SMOOTH SEWIN0

Although your sewtng uraohin, is designed for nraxtoun. efficienoy, should any of the

followrug diflioulties occur they o«r be remedied with minor adjustments.

Upper Tiiread. Breaks

Be sure needle is inserted properly.

Ckeck on correct way to thread machine.

Use correct needle size for thread.

Do not have upper tension too tight.

Lower Thread Breaks

Check correct method of threading bobbin case.

Be sure lower tension is not too tight.

Needle Breaks

not tug or pull on the fabric while sewing as this will

break the needle.

Be sure presser foot is firmly attached to bar.

19

bend and eventually

Loading...

Loading...