SINGER W150-FL User Manual

INTRODUCTION

CONTENTS

name of each part

SPECIAL FEATURES

TO SET THE NEEDLE . TO WIND THE BOBBIN

TO THREAD THE BOBBIN CASE

TO REPLACE AND REMOVE THE BOBBIN CASE TO CLEAN SNAP OPEN R.rr

-HREAOTHT«..,,^, ™Eo"““LenCESEW,NO

- ™ ««ATE THE STITCH LENOTH

TO REGULATE THE PRESSURE OF THE PRESSER FOOT

BUILT-IN LIGHT

NEEDLE AND THREAD SIZEs"

....

' ■ '

TO OIL SEWING MACHINE

i?AU||f JOrcUMMUN UII-HUWLIItS i:

TO USE THE DROP FEED DIAL

..............

- -

..............

...........

-

MAIN PLANT

INmOI>UCTION

lis booklet is your guide to sewing pleasure with your new machine,

contains the names of the major parts and identifies them for ready reference,

le special features of this machine are explained and detailed instructions for its

iccessful operation are set forth. The booklet also lists the various items of maintenance

icessary to avoid wear or damage and explains how to diagnose or discover errors

nd possible trouble.

our new machine is a smart, well-built machine with two tone color made by a reliable

■m with over seventy years of experience. It was designed to be attractive, accurate

id easily regulated.

lis machine is the first non-commercial machine to incorporate an automatic lubricating

evice as a convenience to the user.

is o precise and highly efficient machine capable of producing the desired stitches

ther backward or forward, regardless of material weight, with a minimum of effort by

e operator. Prior to leaving the factory this machine was subjected to a rigid test

I a special sound-levelling apparatus which reduces noise and vibration to a minimum.

3U may well take pride in your selection of this attractive, precise and efficient

ochine. Its quiet operation, unique features and reasonable price will provide you

fh more satisfying sewing hours per dollar than any other selections you might have

□ de.

INTRODUCTION

CONTENTS

INTRODUCTION

NAME OF EACH PART ...................................................................................

SPECIAL FEATURES .....................................................................................

1. TO SET THE NEEDLE

2. TO WIND THE BOBBIN ................................................

3. TO THREAD THE BOBBIN CASE .................................

i. TO REPLACE AND REMOVE THE BOBBIN CASE ..

5. TO CLEAN SNAP-OPEN RACE

6. TO THREAD THE MACHINE & NEEDLE ...............................................

7. TO PREPARE FOR SEWING

8. TO COMMENCE SEWING ......................................................................

9. TO REMOVE THE WORK

10. TO REGULATE THE THREAD TENSION ..............................................

11. TO REGULATE THE STITCH LENGTH .................................................

12. TO REGULATE THE PRESSURE OF THE PRESSER FOOT

13. TO USE THE DROP FEED DIAL

14. BUILT-IN LIGHT

15. TO OIL SEWING MACHINE

16. SOME USEFUL SEWING HINTS .................................

17. CAUSES OF COMMON DIFFICULTIES

......................................................................

.......................................................

...................................................... ..

........................................

................................

...............................................................

........................................

.................

NEEDLE & THREAD SIZES ...........................................................................

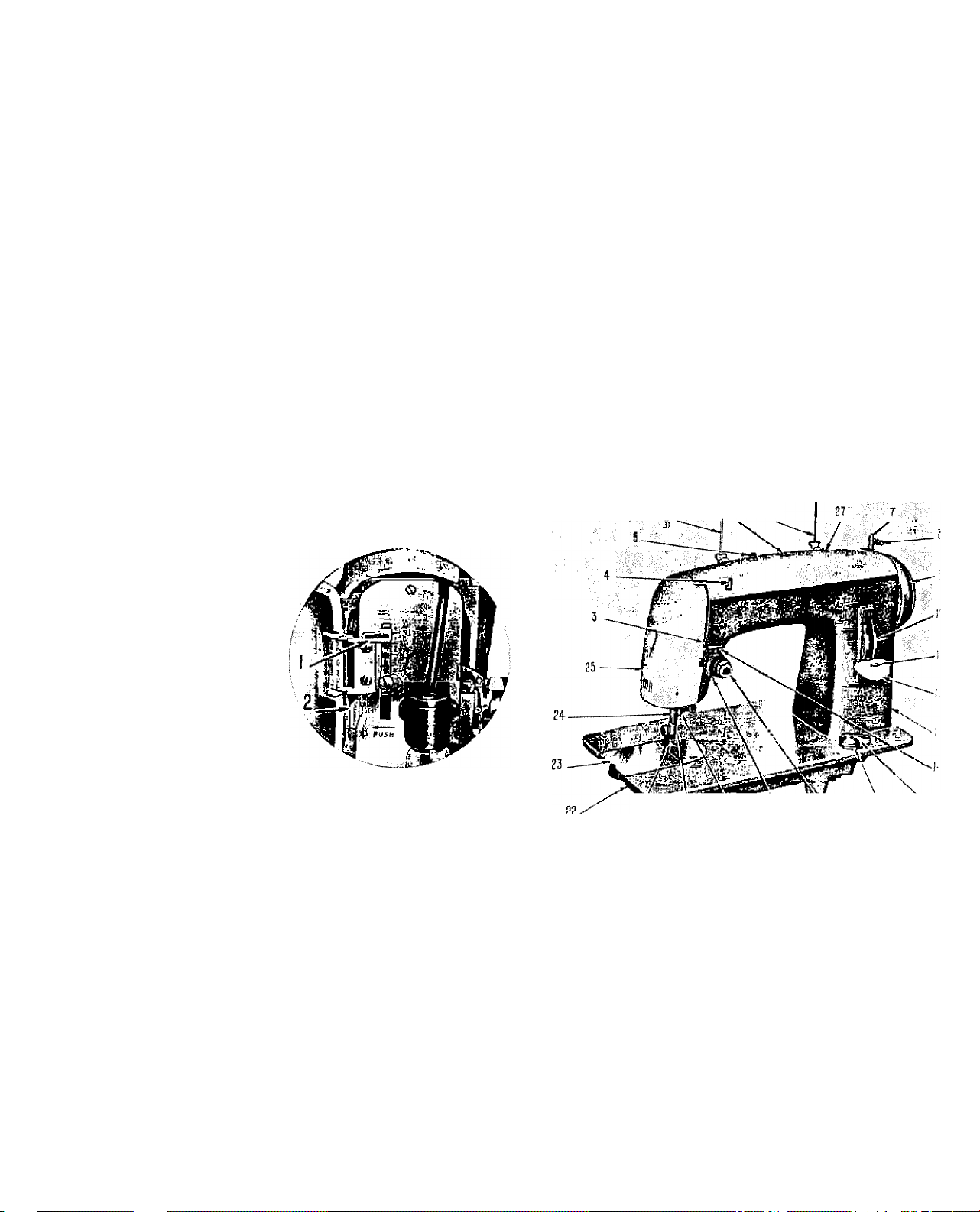

MÁME OF EACH PART

/21 Í2ÍI \|3 \|8 \t?

28 B

1. Built-in darner (Regulating plate)

2. Built-in darner (Release lever)

3. Thread take-up lever

4. Arm thread guide

5. Bobbin winder thread guide

6. 6’. Spool pin

7. Bobbin winder spindle

8. Bobbin winder stop latch

9. Balance wheel

10. Graduation plate

11. Feed regulating lever stop screw

12. Feed regulating lever

13. Light switch

nnUTFMTC UáUC nr mru DADT

14. Thread guide

1 5. Drop feed indicator

16. Drop feed dial

17. Calibrated upper thread tension régulât

18. Thread take-up spring

19. Needle bar

20. Needle

21. Presser foot

22. Shuttle race

23 Slide plate

24. Presser bar

25. Presser foot lifter

26. Oiling button

27. Plastic viewer

SPECIAL FEATURES

iUILT-lN DARNER - is the first of, its kind. It enables you to dial the exact

ssure you desire according to the kind of material you are sewing. The

bers on the graduator tell you how much pressure you have. -

5TITCH REGULATOR - not only regulates your stitch length, but also controls

,vard and backward sewing. It helps you to select your stitch size with ease

I accuracy.

5U1LT-1N AUTOMATIC BOBBIN WINDER - winds your bobbin and stops auto-

ically when your bobbin is filled. Its mechanism is built inside the arm to

[form with the manufacturer's wish to present you with a machine of the

irtesf design.

lALlBRATED UPPER THREAD TENSION REGULATOR - allows the tension of

upper thread to fce easily and accurately adjusted according to thread and

erial weight differences.

)ROP FEED DIAL - regulates the position of your feed dog for embroidering

darning and for different weights of fabrics.

5U1LT-IN LIGHT - illuminates your work for better and efficient sewing with-

glare. Light bulb is easily changed.

.NAP-OUT RACE - is so constructed that cleaning it or eliminating any

Dlications arising within it is made very simple and quick.

LOATING PRESSER FOOT - glides over pins and bastings or any other ir-

ularity in your work, so you will be able to sew over these as smoothly

if they were not there.

dJTOMATlC LUBRICATING DEVICE - applies the oil to the vital parts auto-

ically. - ; • ■ ■

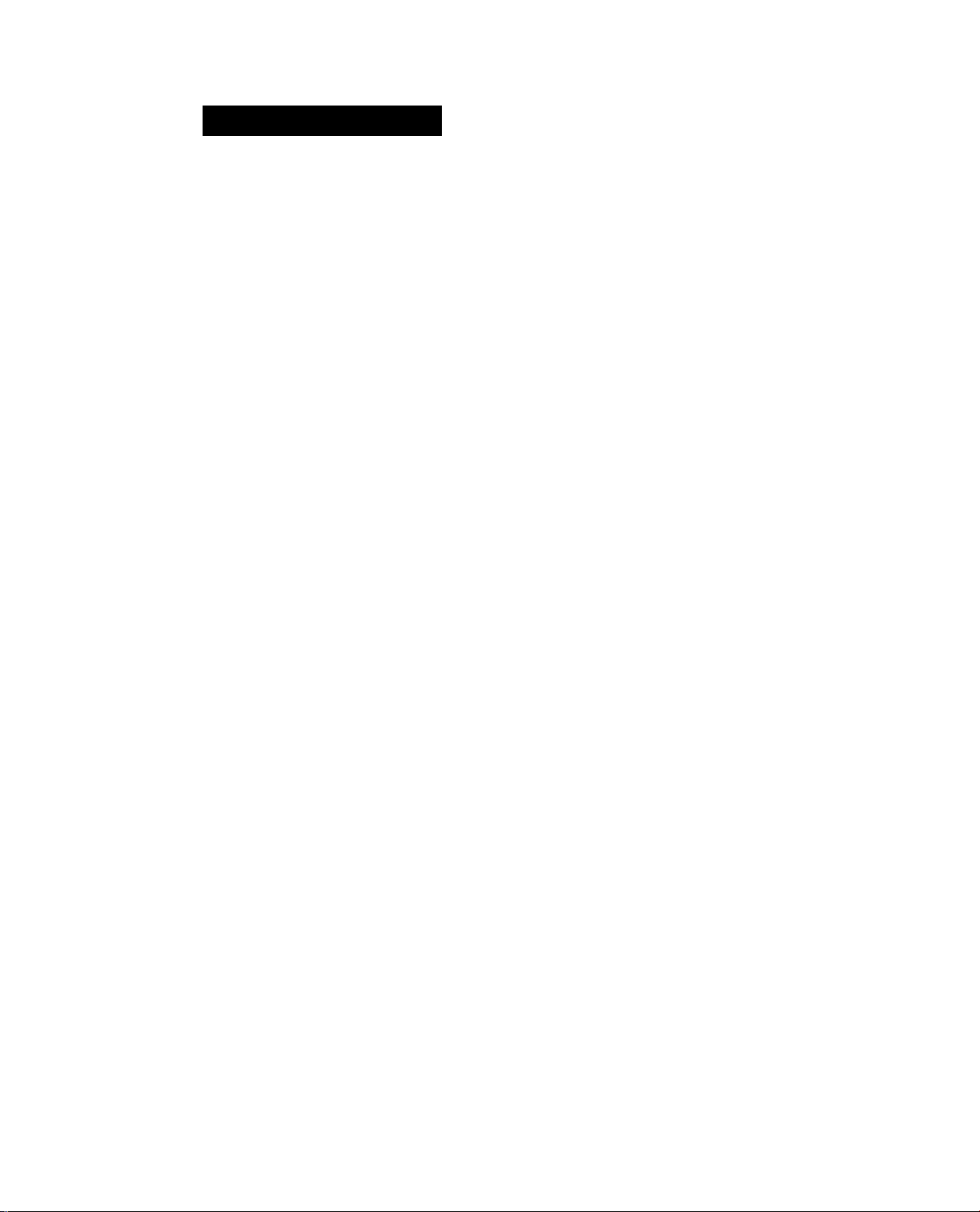

1. TO SET THE NEEDLE

NEEDLE

FLAT

■SURFACE

(1) Turn fhe Balance wheel toward you,

raising needle bar to its highest point,

and loosen the needle clamp screw.

(2) Hold the needle in the left hand with

the point down, and insert the needle

clamp as far as it will go, with its flat

surface to the right; then retighten the

clamp screw (Fig I)

2. TO WIND THE BOBBIN

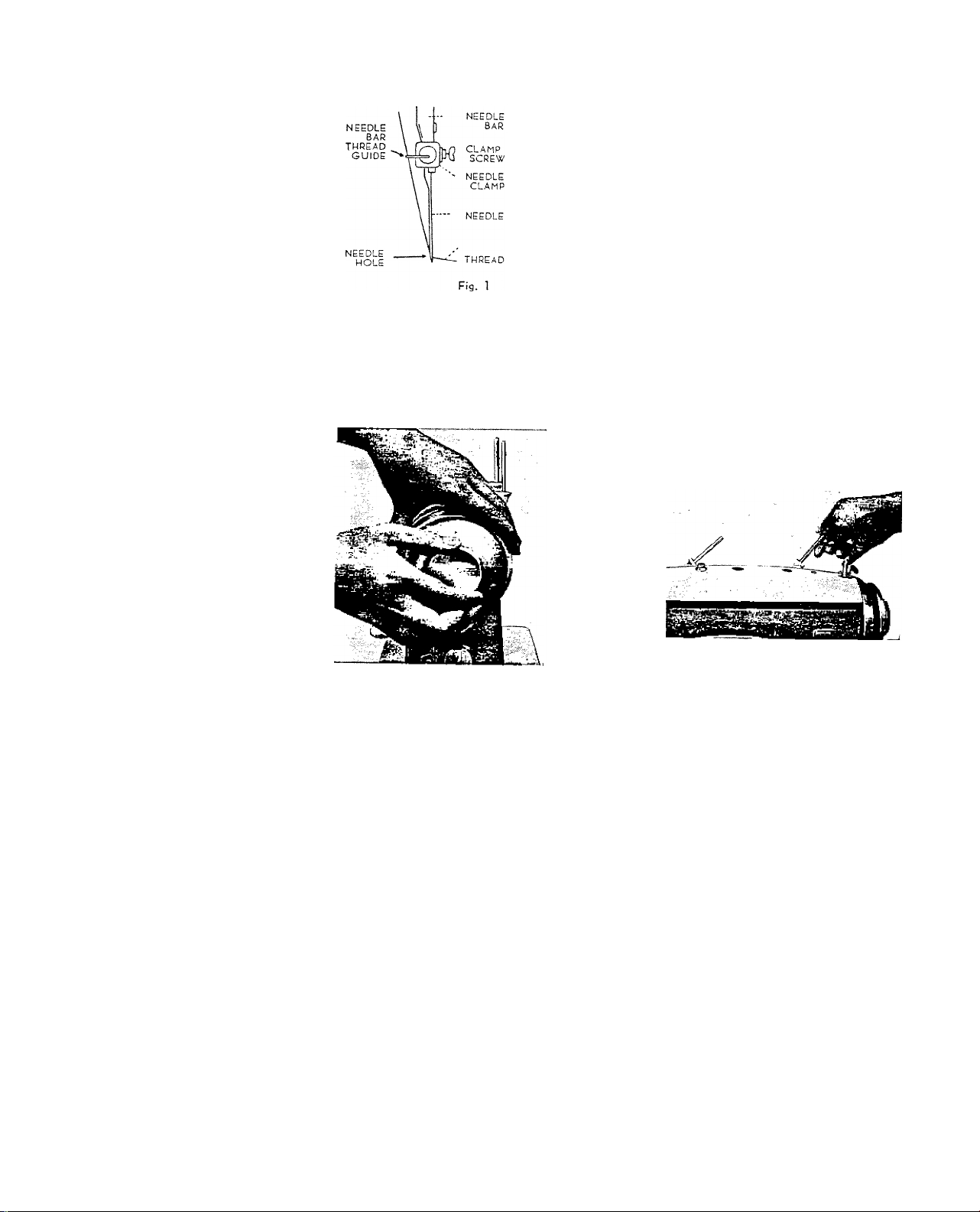

0) Disconnect the balance wheel from the stitching mechanism by holding the balance

wheel with your left bond- and turning fhe sfopmotion knob COUNTERCLOCKWISE

with your right hand. - (Fig. 2)

(2) Raise the folded spool pin (6) and place a

spool of thread on it. (Fig. 3)

Fig 2

Fig. 3

SPECIAL FEATURES

TO SET THE NEEDLE • TO WIND THE BOBBIN

TO THREAD THE BOBBIN CASE

TO REPLACE AND REMOVE THE BOBBIN CASE TO CLEAN SNAP-OPEN RACE

TO THREAD THE MACHINE & NEEDLE TO PREPARE FOR SEWING • TO COMMENCE SEWING

TO REMOVE THE WORK • TO REGULATE THE THREAD TENSION • TO REGULATE THE STITCH LENGTH

TO REGULATE THE PRESSURE OF THE PRESSER FOOT TO USE THE DROP FEED DIAL

BUILT-IN LIGHT TO OIL SEWING MACHINE

SOME USEFUL SEWING HINTS CAUSES OF COMMON DlFFrCULTlES

'NEEDLEliND^HREAD^SiZES ^ ^ ^

Loading...

Loading...