SINGER W1466 User Manual

----:------ ;

You are now tte owner of a new zigzag sewing maciiine, the most

versatile machine of its type you can possess. Buttonholes, monogramming,

darning, overcasting and creative embroidery are done with ease and speed.

To aid you in obtaining the greatest performance from your machine

this book on its care and use has been written for you. Read the instruc

tions carefully as a thorough understanding will reward you with many

hours of trouble-free creative sewing.

Time-saving attachments such as rufflers, binders, edgestitchers

tr

c.

e-

%

cording feet, to complement the accessories furnished are available from

your dealer. .

INDEX

Page

Features and parts

...................................

2-3-4

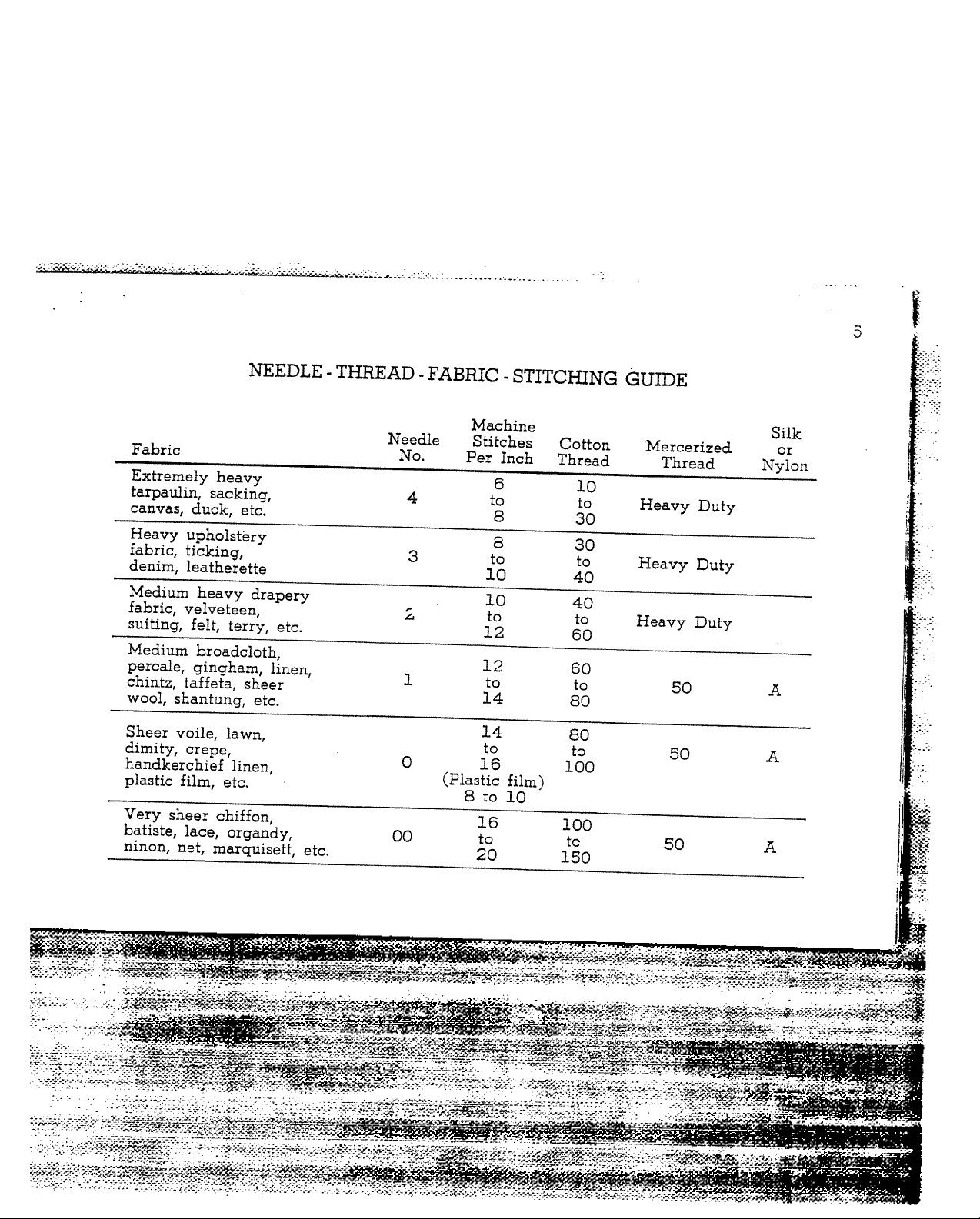

Needle and thread chart................................. 5

Setting the needle

..........................................

Winding the bobbin.................................... 6-7

Threading bobbin case

...................................

Placing bobbin case in shuttle ....................8

Upper threading

Straght stitching

Changing foot and plate

.........................................

..........................................

...........................

8-9

10

Setting the stitch length .............................. 11

Stitch length chart

Sewing in reverse

Adjusting the tensions

Adjusting pressure and feed

...................................

........................................

............................

...................

11-12

12-13

11

General sewing......................................... 13

1 ight weight fabrics..................................13

Preparing to sew

Removing the work

Creative embroidery

..........................................

....................'•...............

....................................

13

Satin stitch.................................................15

Adjusting stitch width

..............................

15

Embroidery Patterns .................................15

Samples of embroidery

................................

15

10

H

14

15

6

Page

Embroidering with a hoop

Making buttonholes....................................................17

Sewing on buttons

7

How to use accessories ...............................................20

Narrow hemmer ....................................................20

Lace trimmed hem ................................................20

Lace edge ...............................................................20

Seam gauge ............................................................20

Care and maintenance ..............................................21

Oiling .....................................................................22

Cleaning and oiling shuttle

Trouble chart

Accessories

Attachments ...............................................................29

Attachment foot ....................................................30

Edgestitcher ..................................................30

Binder ....................................................................

Ruffer

Cord and zipper foot.............................................33

Hemmers

Darning spring ..............................................34

.................................................................

..................................................................

....................................................

..................................................

.......................................................

.......................................

.......................................

23-24-25

16

19

22

26

...

32

34

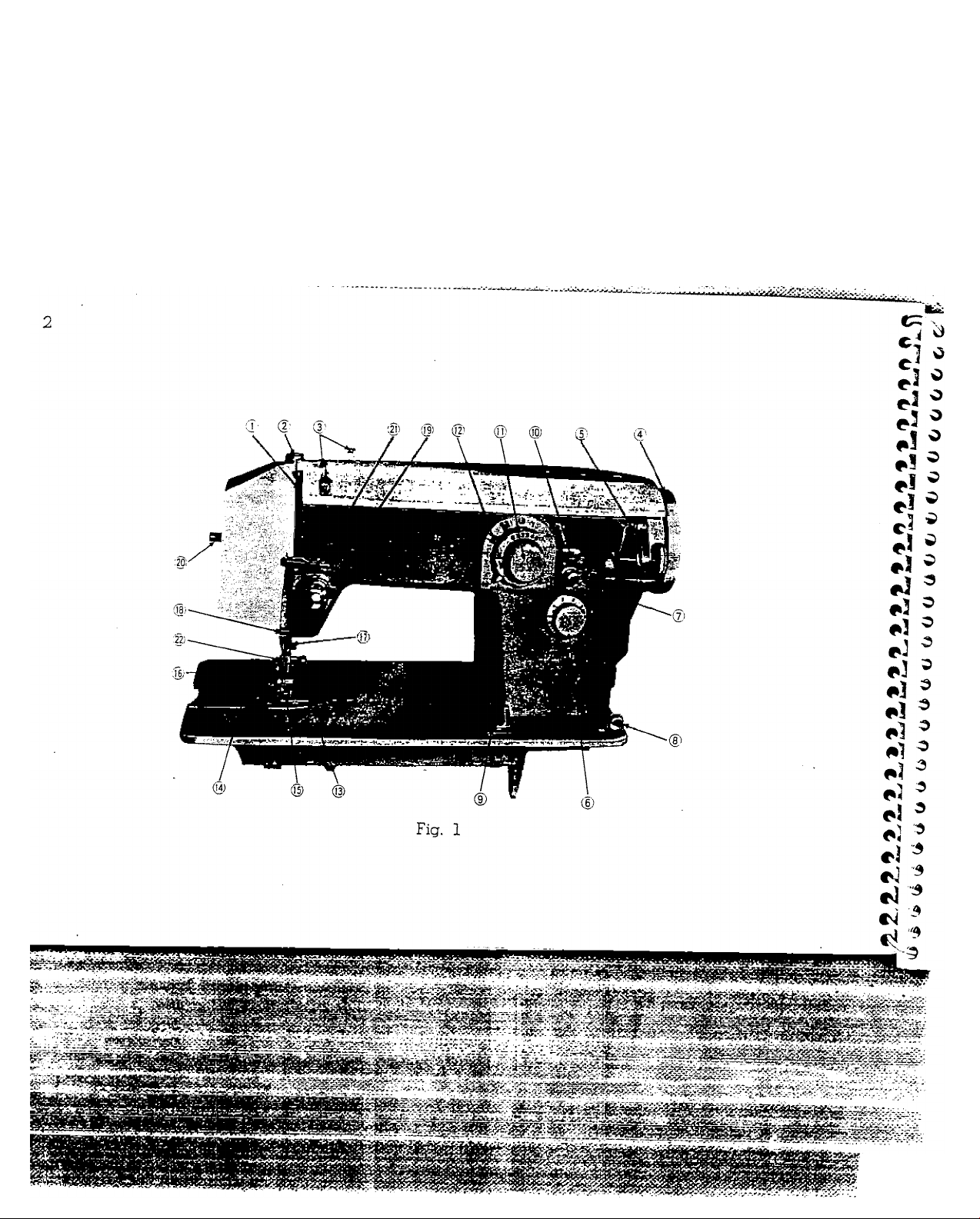

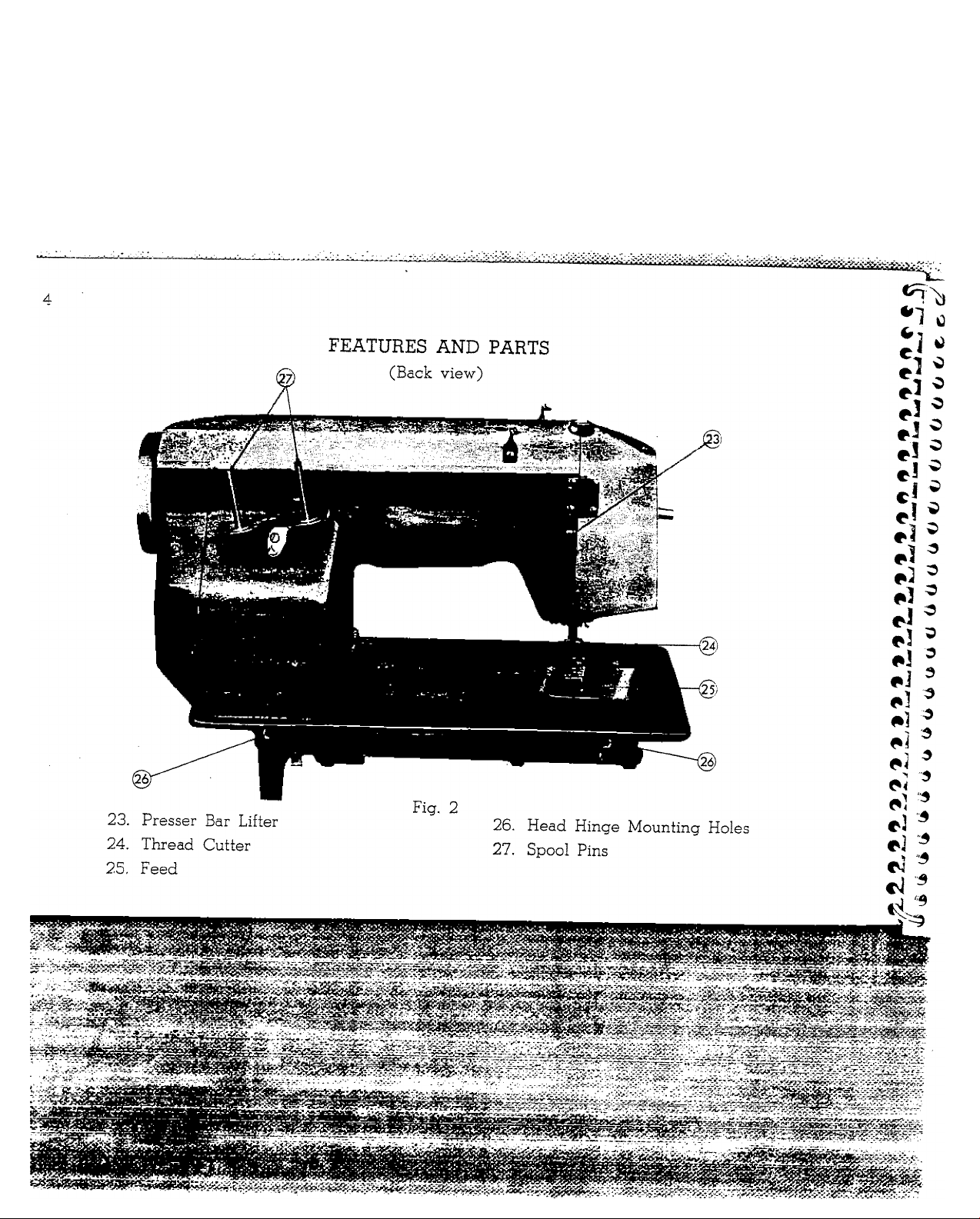

FEATURES AND PARTS

(Front view)

li

1. Take-up lever

2. Presser release-darner

3. Arm thread guide

4. Hand wheel

5. Bobbin winder

6. Stitch length dial

7. Push button reverse

8. Bobbin winding tension

9. Drop feed knob

10. Width lock

11. Zigzag width control knob

12. Buttonhole control knob

13. Needle plate

14. Cover plate

15. Presser foot

16. Presser foot thumb screw

17. Needle clamp

18. Thread guides

19. Tension

20. Light switch

21. Thread guide bar

^2. Needle bar thread guide

Fig. 3

Fig. 4

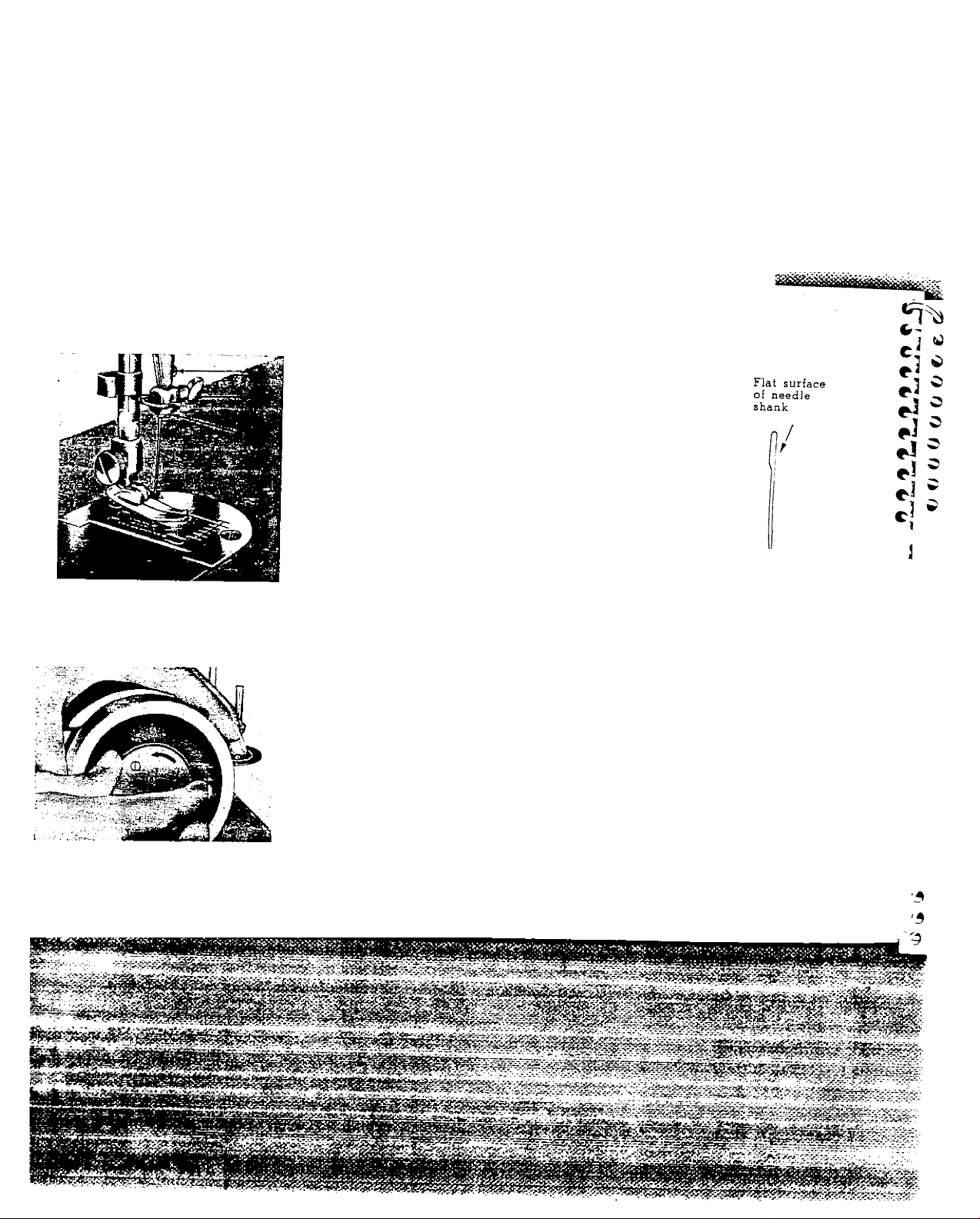

SETTING THE NEEDLE

See Fig. 3. Raise the needle bar A to its highest

point, turning wheel toward you by hand.

Then loosen the needle clamp screw B and the

needle ^ can be ^ inserted into clamp C. Place needle

_CR3ji_^ide^^^^to^^^^r^ght^ in the needle clamp and push it

upward ^ as far as it will go into the needle clamp

hole, tightening the needle clamp screw securely

with a screw driver.

After changing the needle make one com

plete revolution of the balance wheel by

hand to be sure the needle is in the correct

position.

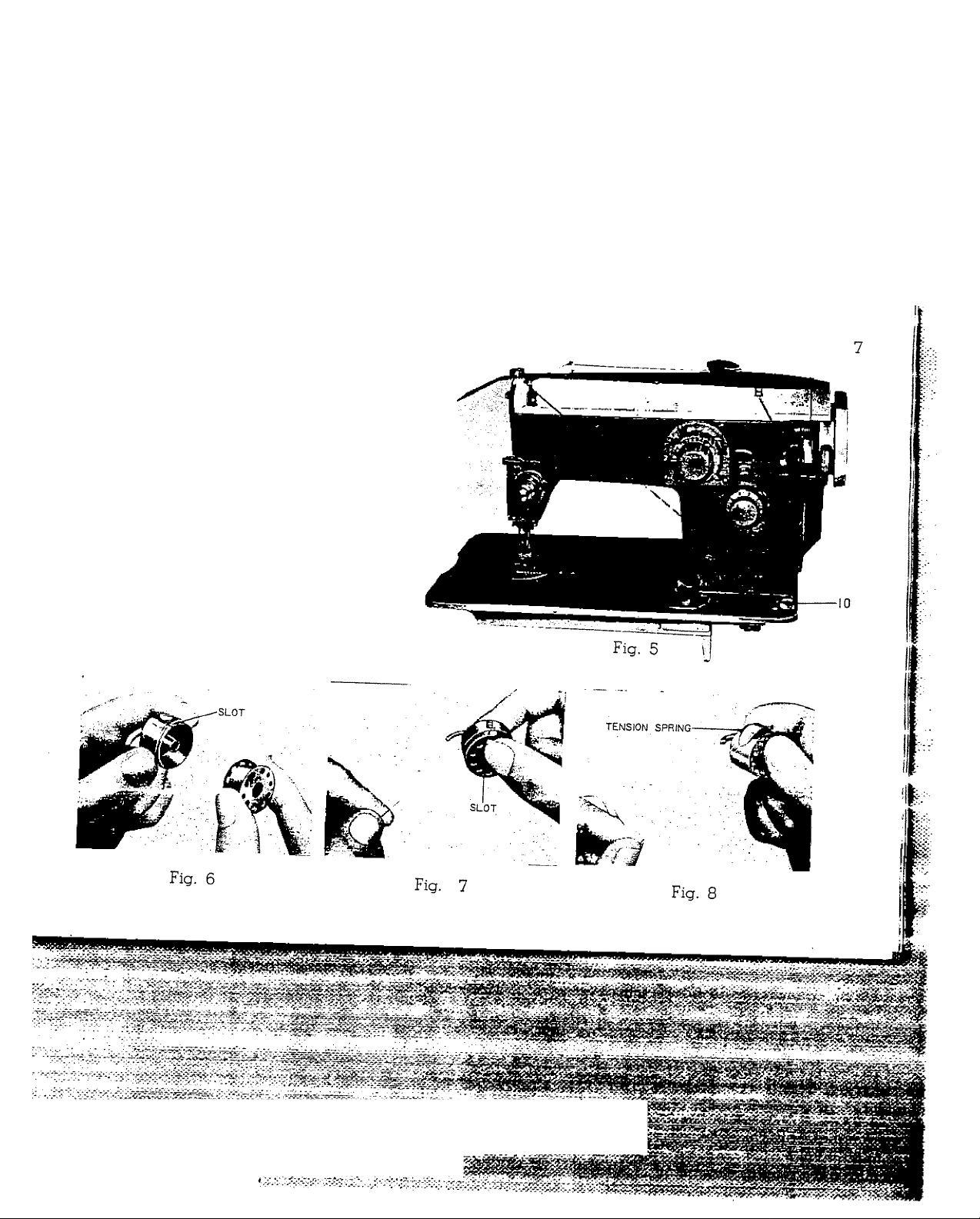

WINDING THE BOBBIN

Disengage the hand wheel (5, (Fig. 4) from the stitching

mechanism hy turning the clutch 6 toward you or counterclock

wise.

Place a spool of thread on one of the spool pins, lead thread

through the upper thread guides on the arm, and down through

the tension disc (10, (Fig. 5) at the base of the machine. Run

end of thread through a hole in the bobbin edge and place

bobbin B on spindle of bobbin winder 7, fitting the notch on

■bobbin over small pin on spindle. Push bobbin winder pulley

against hand wheel. Hold thread end loosely and start machine

slowly.

Bobbin will stop winding when it is filled. Turn clutch away

from you until sewing mechanism is again engaged so that

needle moves when you turn the hand wheel.

Break, off loose thread end used to start the winding.

cC

•N

e

o

a

a

a

a

a

a

a

a

a

a

a

a

a

a

! a

3

THREADING THE BOBBIN CASE

Step 1 (illustrated in Fig. 6). Hold

bobbin case between thumb and fore

finger of left hand, so that the slot in

the edge of the bobbin case is on top.

Take the bobbin between thumb and

forefinger of right hand so that the

thread on top leads from left to right.

Step 2. Insert bobbin into bobbin case,

pull the thread into the slot of the bob

bin case as shown in Fig. 7, and draw

it under the tension spring and into the

fork-shaped opening of the spring as

shown in Fig. 8

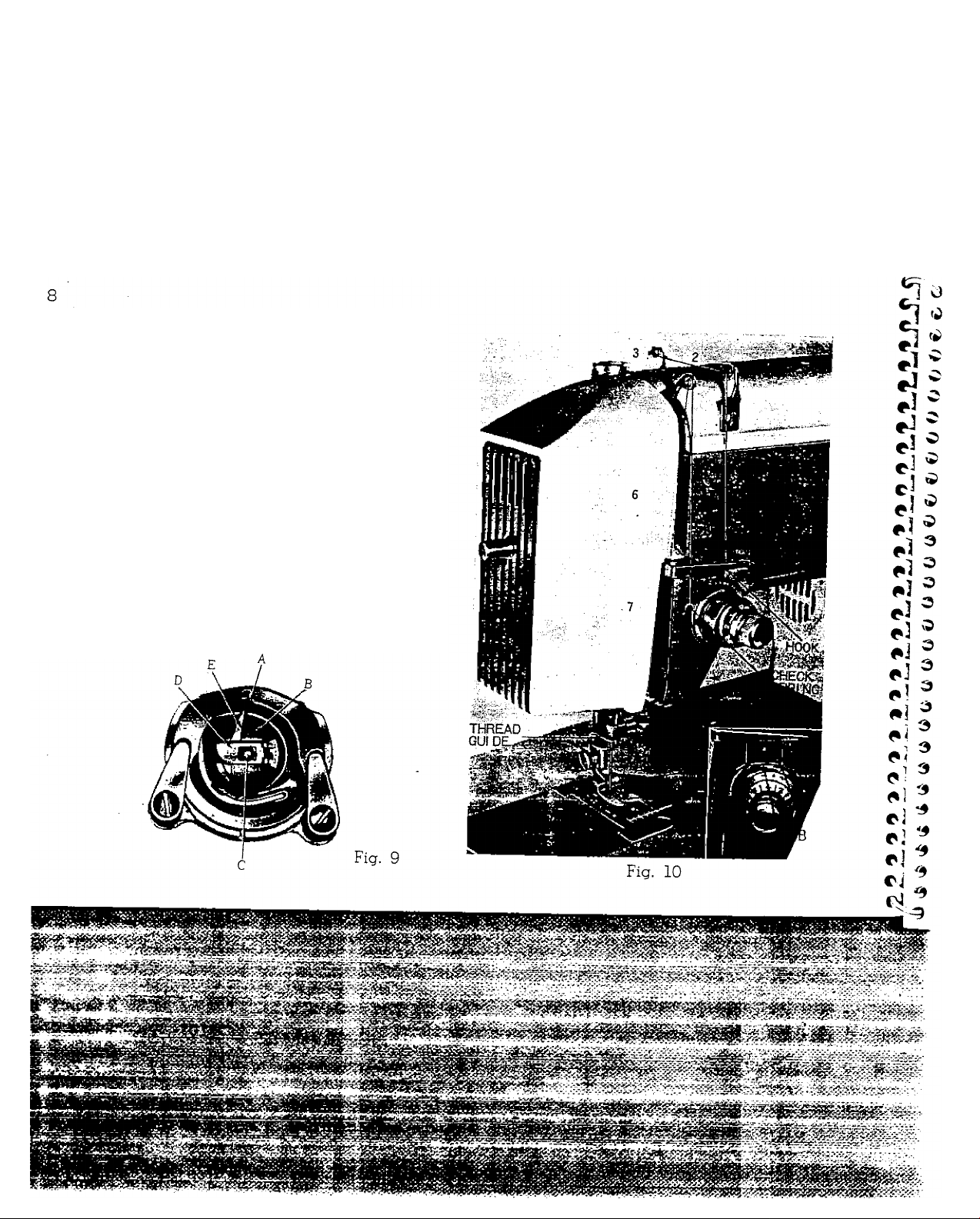

PLACING BOBBIN CASE IN SHUTTLE

Raise needle bar to highest position, and Slide

coyer plate to the left. See 14. Fig. 1 Hold the

boobin case latch, D, Fig. 9, between the thumb

and forefinger of the left hand, with at least

three inches of thread running from the top of

the bobbin case to the right. Insert and center

the bobbin case on the stud of the shuttle body,

(C) . Be sure the bobbin case finger, (E), is

opposite the shuttle race notch (A). Press the

bobbin case (B) into the shuttle as far as

possible until latch catche son the center post of

the shuttle. THEN release the bobbin case latch,

(D) . Press bobbin case again after latch has

been released to make sure the bobbin case is

locked securely in place. Close the cover plate.

UPPER THREADING

1. Turn the balance wheel toward you to raise the

take-up lever to its highest position.

2. Place a spool of thread on the spool pin.

3. Lead the thread through the upper arm thread

guides.

4. Run the thread through the thread guide bar to

the tension discs, then around and between

them from right to left.

5. Draw the thread up through the check spring

and with a slight tug into the hook. (See

Fig. 11

insert, Fig. 10)

6. Pass the thread under the bar and up through the eye of the take-up lever from right to

left.

7. Lead thread down through the face plate guides and then through the needle bar guide

from the back.

8. Thread needle FROM LEFT TO RIGHT, drawing it through about 3 or 4 inches. Hold the

end of upper thread loosely and turn hand wheel-toward you until the needle goes all the

way down and comes back up. A loop will be formed over the upper thread which then

can be pulled out straight. Place both thread ends under the slot of the presser foot and

draw toward the back of the machine, leaving both threads three or four inches long.

10

STRAIGHT STITCHING

For straight sewing on fine fabric or very soft mate

rial, you may want to.use the straight stitch presser foot

and the straight stitch needle plate which are included

in your accessory box. Both have narrow needle slots.

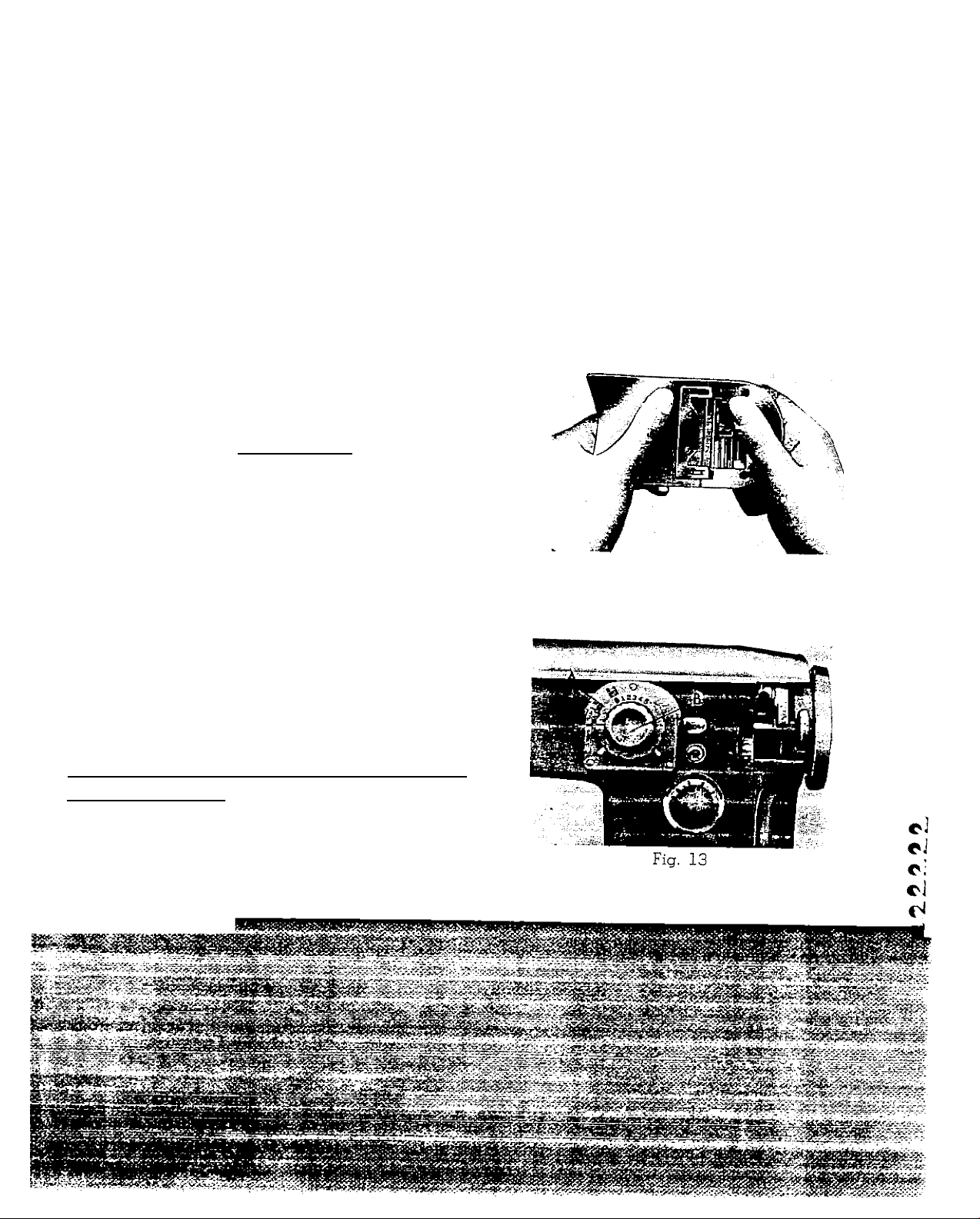

Q.h,anqinq the Foot and Plate. To change presser

foot. (15, Fig. 1) loosen thumb screw 16 and remove

zigzag foot. Replace with hinged narrow foot and

tighten screw securely.

To change needle plate (13, Fig. 1) remove screws

and lift off with cover plate 14 attached. Turn assembly

wrong side up. Hold needle plate with right hand and

cover plate with left. (-‘ig. 12)

Press corner of cover plate down slightly and pull

needle plate upward, slipping upper pin on needle plate

out of groove. Then slid lower pin out.

Attach cover plate to straight stitch plate by revers

ing the above procedure. Slip pin on lower side of

needle plate into grove on cover plate. Slide upper pin

under lip and into groove on cover plate. Put plates on

machine and fasten securely with needle plate screws.

Be sure the machine controls are set as follows or you '

will break the needle.

Fig. 12

ei

Cr'

(

e-’

el

e

*

1

(1) Buttonhole control knob A, set at 0 ^

(2) Zigzag Stitch Width control knob “B”, set at 0

Loading...

Loading...