IMPORIANT SAFETY INSTRUCTIONS

When using an electrical sewing machine, basic safety precautions should always be followed, including the following.

Read all instructions before using this sewing machine.

This sewing machine is designed for household use

DANGERto REDUCE RISK OF ELECTRIC SHOCK:

A sewing machine should never be left unattended when plugged in. Always unplug this sewing machine from

the electrical outlet immediately after using and before cleaning.

WEming-To reduce the risk of burns, fire, electric shock or injury to persons...

1. Do not allow to be used as a toy. Close attention is necessary when this sewing machine is used by or near children.

2. Use this sewing machine only for its intended use as described in this manual. Use only attachments

recommended by the manufacturer as contained in this manual.

3 Never operafe this sewing machine if it has a damaged cord or plug, if it is not working properly, if it has

been dropped or damaged, or dropped into water. Return the sewing machine to the nearest authorized dealer

or service center for examination, repair, electrical or mechanical adjustment.

4 Never operate the sewing machine with any air openings blocked. Keep ventilation openings of the sewing

machine and foot control free from the accumulation of lint, dust, and loose cloth.

5 Never drop or insert any object into any opening.

6. Do not use outdoors.

7. Do not operate where aerosol [spray] products are being used or where oxygen is being administered.

8 To disconnect, turn all controls to the off [“0”] position, then remove plug from outlet.

9. Do not unplug by pulling on cord. To unplug, grasp the plug, not the cord.

Keep fingers away from all moving parts. Special care is required around the sewing machine needle.

10.

Always use the proper needle plate. The wrong plate can cause the needle to break.

11

Do not use bent needle.

12

Do not pull or push fabric while stitching. It may deflect the needle, causing it to break.

13.

Switch the sewing machine off [“0”] when making any adjustments in the needle area, such as threading

14

needle, changing needle, threading bobbin, or changing presser foot and the like.

Always unplug sewing machine from the electrical outlet when removing covers, lubricating, or when making

15

any other user servicing adjustments mentioned in the instruction manual.

16. Always unplug before reclamping. Replace bulb with the same rated 15 watts.

SAVE THESE

INSTRUCTIONS

DO'S AND DONTS

1. Always be aware of the up-and-down movement of the needle and do not turn your attention from the

machine while it is running.

2. When changing the needle, the presser foot, the bobbin or any other parts, always disconnect the machine by

pulling the plug out of the wall socket.

3 Do not place anything on the speed controller, otherwise the machine will start inadvertently, or the controller

or motor may burn out.

4. The maximum permissible power for the sewing lamp bulb is 15 watts.

5. When using your sewing machine for the first time, place a piece of waste fabric under the presser foot and run

the machine without thread for a few minutes. Wipe away any oil which may have appeared.

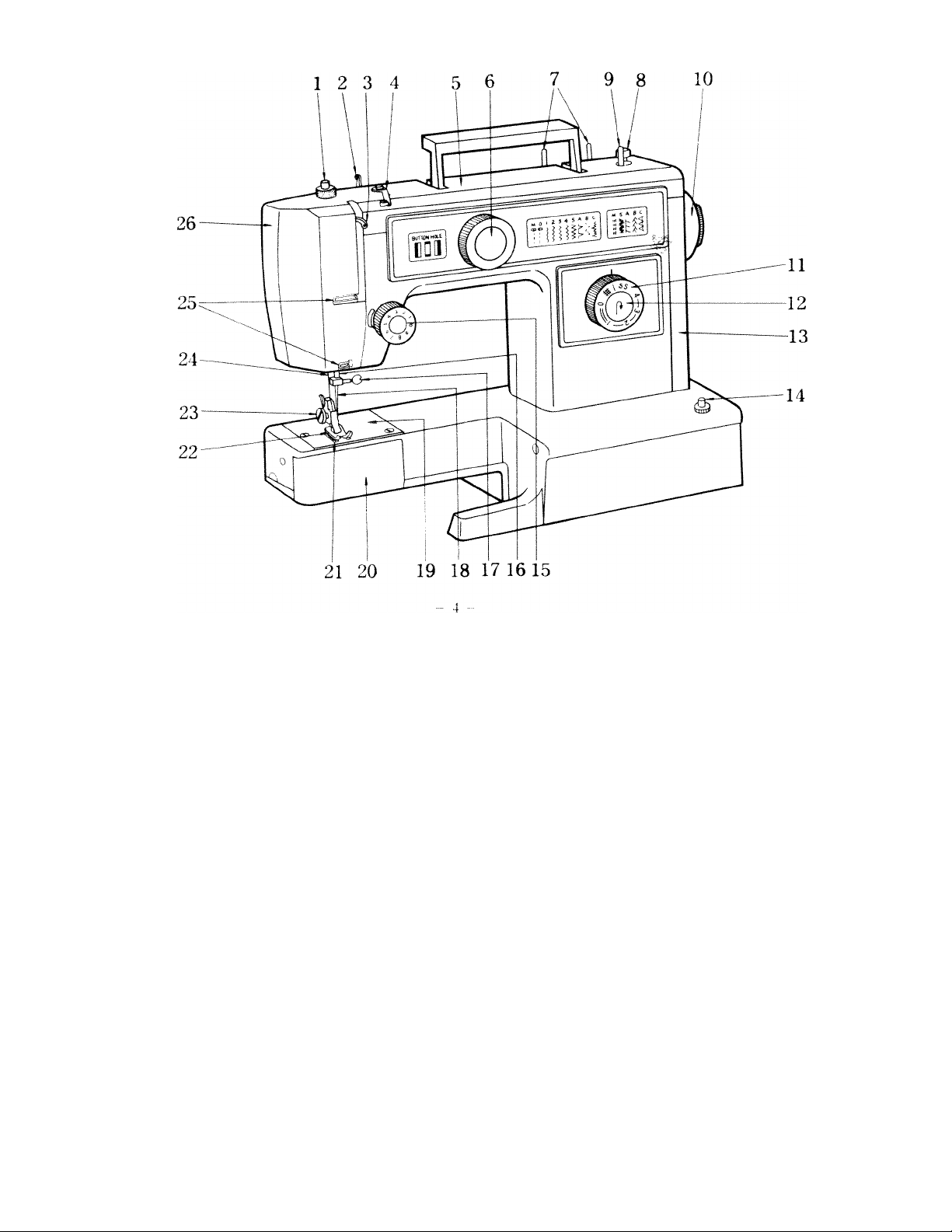

KNOWING YOUR SEWING MACHINE

Names of parts

How to connect the machine to

the power supply........................................................................6

How to use the speed controller

Sewing lamp...............................................................................®

Thread and needle chart............................................................7

Changing the needle

To select a suitable needle........................................................8

Raising or lowering the presser foot

Regulating the presser foot pressure

(PATCH-O-Matic)........................................................................9

Removing and attaching the presser foot.............................10

Removing or attaching the foot holder

Regulating the thread tension

Stitch length dial, reversing button

and dropping the feed dog......................................................13

The pattern selector

* Selecting stretch stitch.........................................................14

Removing the bobbin case and bobbin

......................................................................

..............................................

..................................................................

.......................................

..................................

................................................

.................................................................

................................

4-5

12

14

11

15

Winding the bobbin..................................................................16

Threading the bobbin case

Threading the needle thread......................................................18

Drawing up the bobbin thread................................................19

6

8

9

BASIC SEWING

Straight stitch and zigzag stitch

* Starting sewing...................................................................20

* Changing sewing directions.................................................21

* Fastening seams..................................................................21

.....................................................

.............................................

17

20

UTILITY STITCHING

Sewing with a twin needle.......................................................22

Triple stretch stitch..................................................................23

* Triple straight stretch stitch..................................................23

* Triple zigzag stretch stitch

Tricot zigzag stitch

Feather stitch...........................................................................24

Overlock stitch.........................................................................25

.....................................................................

...............................................

23

24

Sewing buttonholes............................................................26-27

Sewing zippers.........................................................................28

Hemming...................................................................................29

Sewing blind hems...................................................................30

Embroidery...............................................................................31

MACHINE CARE AND TROUBLE SHOOTING

How to oil the machine............................................................32

Cleaning the feed dog

Cleaning the shuttle race

Free-arm sewing

Trouble shooting;

Causes and remedies.........................................................36-37

Polarized plug information......................................................38

.............................................................

........................................................

......................................................................

33

34

35

1. Pressure regulator (Patch^O^Matic)

2. Thread guide

3. Thread take-up lever

4. Bobbin winder thread guide

5. Top cover

6. Pattern selector dial 19. Needle plate

7. Spool pins

8. Bobbin winder stopper

9. Bobbin winder spindle

10. Balance wheel

11. Stitch length dial

12. Reversing button

13. Belt cover

14. Switch

15. Thread tension dial

16. Needle bar

17. Needle clamp and screw

18. Needle

20. Shuttle cover

21. Feed dog

22. Presser foot

23. Presser foot thumb screw

24. Presser bar

25. Face plate thread guides

26. Face plate

HOW TO CONNECT THE MACHINE TO THE POWER SUPPLY

1. Fit the machine plug into the machine.

2. Plug the machine to the power supply.

Note:‘Before plugging in the machine, ensure that the voltage and

number of cycles indicated, is conformed to your electrical

power supply.

HOW TO USE THE SPEED CONTROLLER

Sewing speed can be varied by the speed controller. The harder you

press on the controller, the faster the machine runs.

Note:*By releasing the controller, the machine stops running auto

matically.

‘Before using the machine, practice controlling the speed

with-out threading.

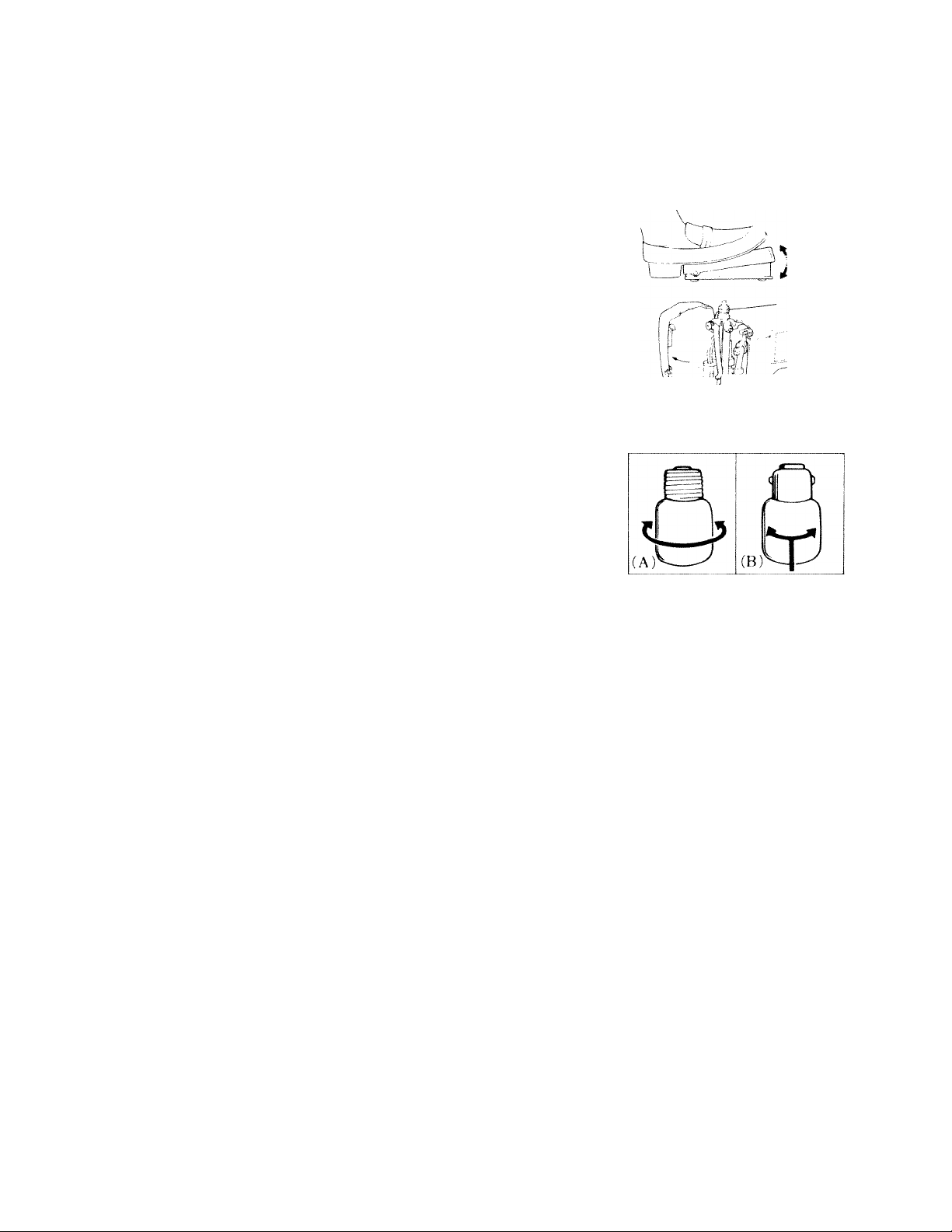

SEWING LAMP

The sewing lamp is located behind the face plate.

Bulb type (A) : • To remove ... Unscrew

• To replace ... Screw

Bulb type (B) : • To remove ... Push and twist counter-clockwise

• To replace ... Push and twist clockwise

Note:‘Before replacing a bulb, disconnect the machine from the

power supply.

‘Bulbs are available from sewing machine retailers. (Use a 15-

Watt bulb)

--------------------------------------------------Caution!------------------------------------------------------

Before leaving the machine, changing parts or doing any other work

on it, always disconnect the plug from the wall socket.

Never place anything on the speed controller, otherwise the machine

will start inadvertently or the .controller or motor may burn out.

-----

iM-v

. if

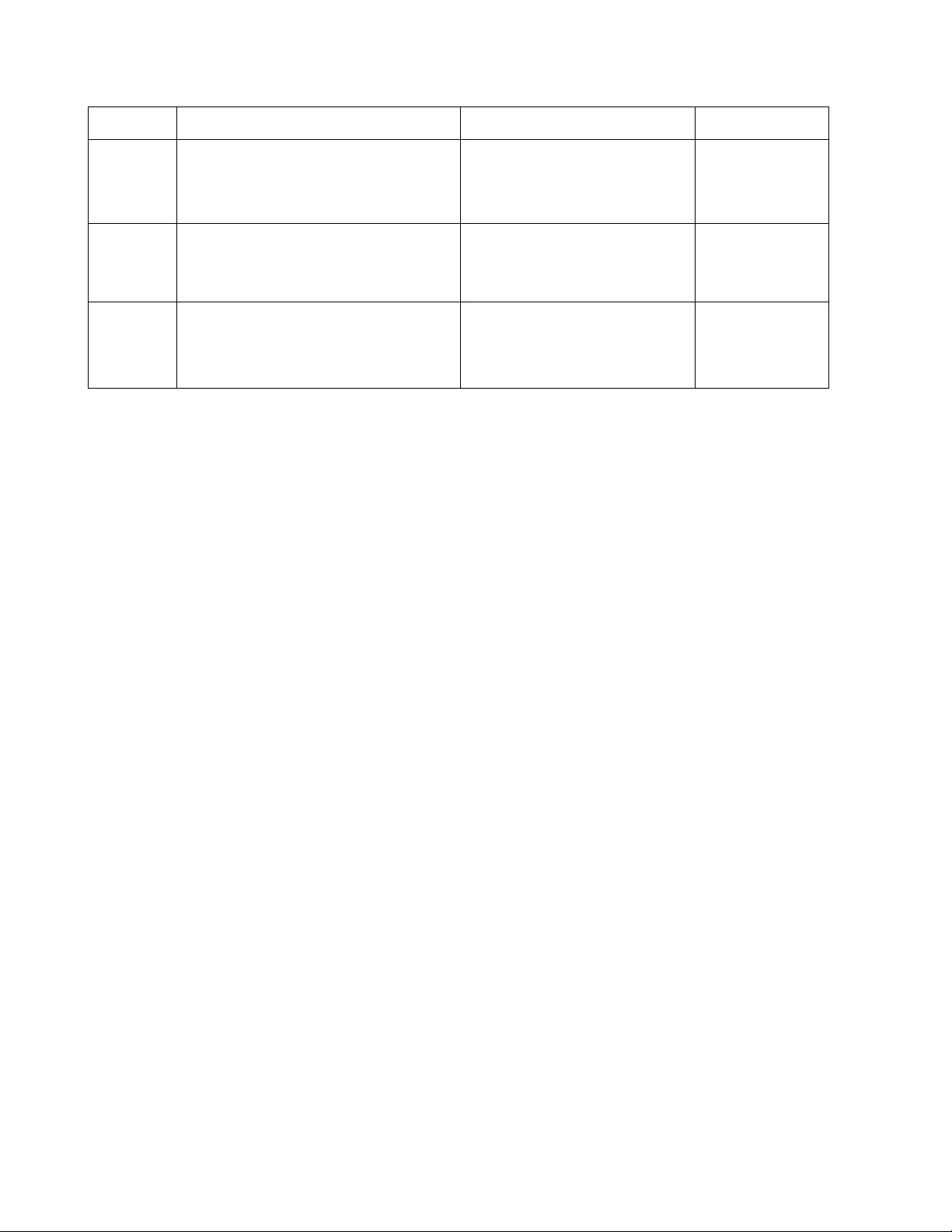

THREAD AND NEEDLE CHART

FABRICS

Fine Silk

LIGHT

WEIGHT

MEDIUM

WEIGHT

HEAVY

WEIGHT

Note; *ln general, fine threads and needles are used for sewing thin fabrics, and thicker threads and needles are

Crepe de Chine, Voile

Lawn, Organdy, Georgette, Tricot

Linens, Cotton, Pique

Serge, Double Knits, Percale

Denim, Tweed, Gabardine,

Coating, Drapery and Upholstery Fabric

used for sewing heavy fabrics. Always test thread and needle size on a small piece of fabric which will

be used for actual sewing.

*Use the same thread for needle and bobbin.

*When sewing stretch, very fine fabrics and synthetics, use a BLUE TIPPED needle. The blue tipped

needle e,ffectively prevents skipped stitches.

*When sewing very fine fabrics, sew over a piece of paper to prevent thread distortion.

Fine Cotton

Fine Synthetic

Fine Cotton Covered Polyester

50 silk

50 to 80 Cotton

50 to 60 Synthetic

Cotton Covered Polyester

50 Silk

40 to 50 Cotton

40 to 50 Synthetic

Cotton Covered Polyester

THREADS

NEEDLE SIZE

9 or 11

11 or 14

14 or 16

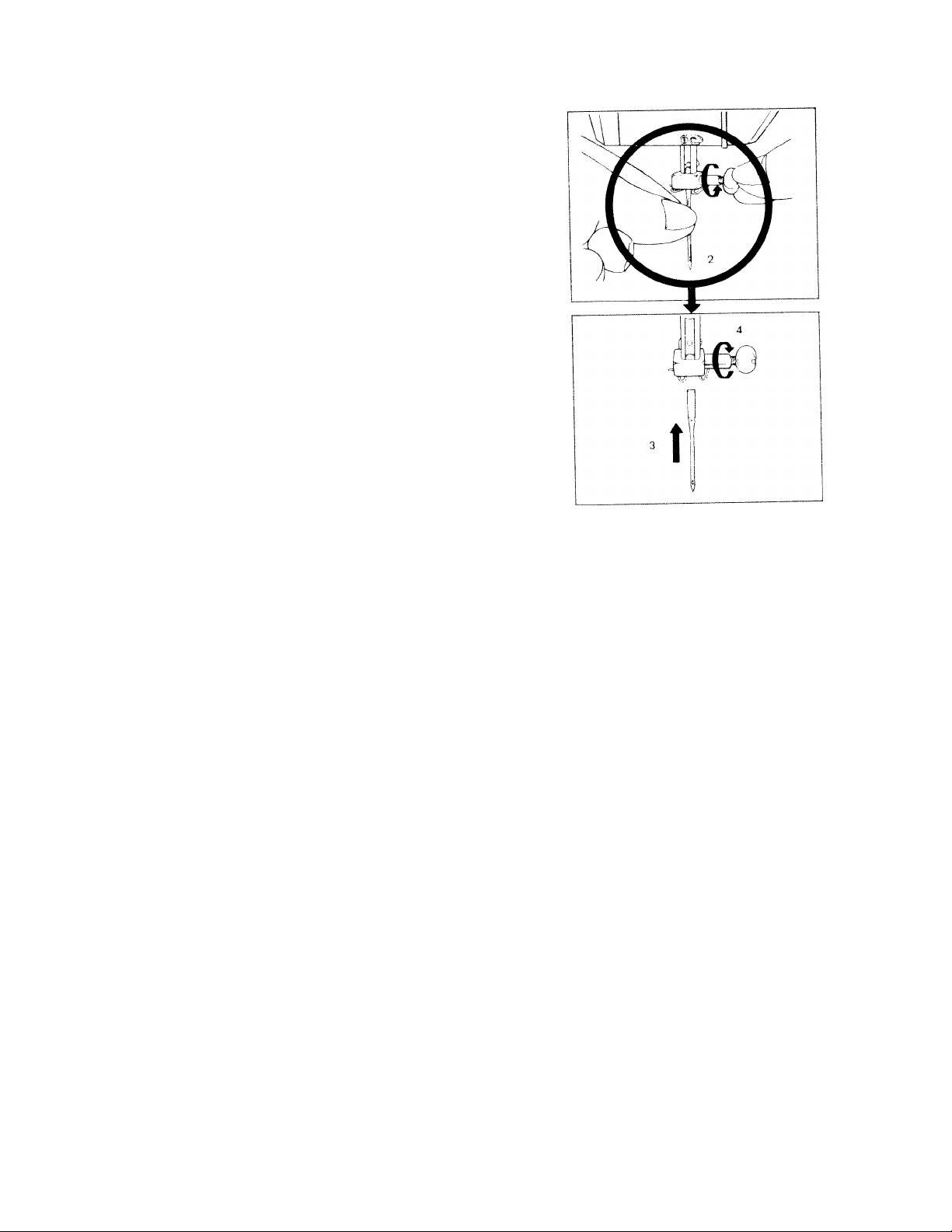

CHANGING THE NEEDLE

1. Turn the balance wheel towards you until the needle is at is

highest position.

2. Loosen the needle clamp screw by turning its top edge

towards you. Remove the needle from the damp.

3. Place the new needle into the needle clamp with its flat

side facing away from you.Push the needle up into needle

clamp as far as possible.

4. Tighten the needle clamp screw firmly.

TO SELECT A SUITABLE NEEDLE

A number indicating the size

of needle is marked on the

Stem

Blue tipped needle

stem.The higher the number,

the thicker the needle.

A BLUE TIPPED needle is

supplied with the machine.

• Do not use any needle which

is bent or blunted.

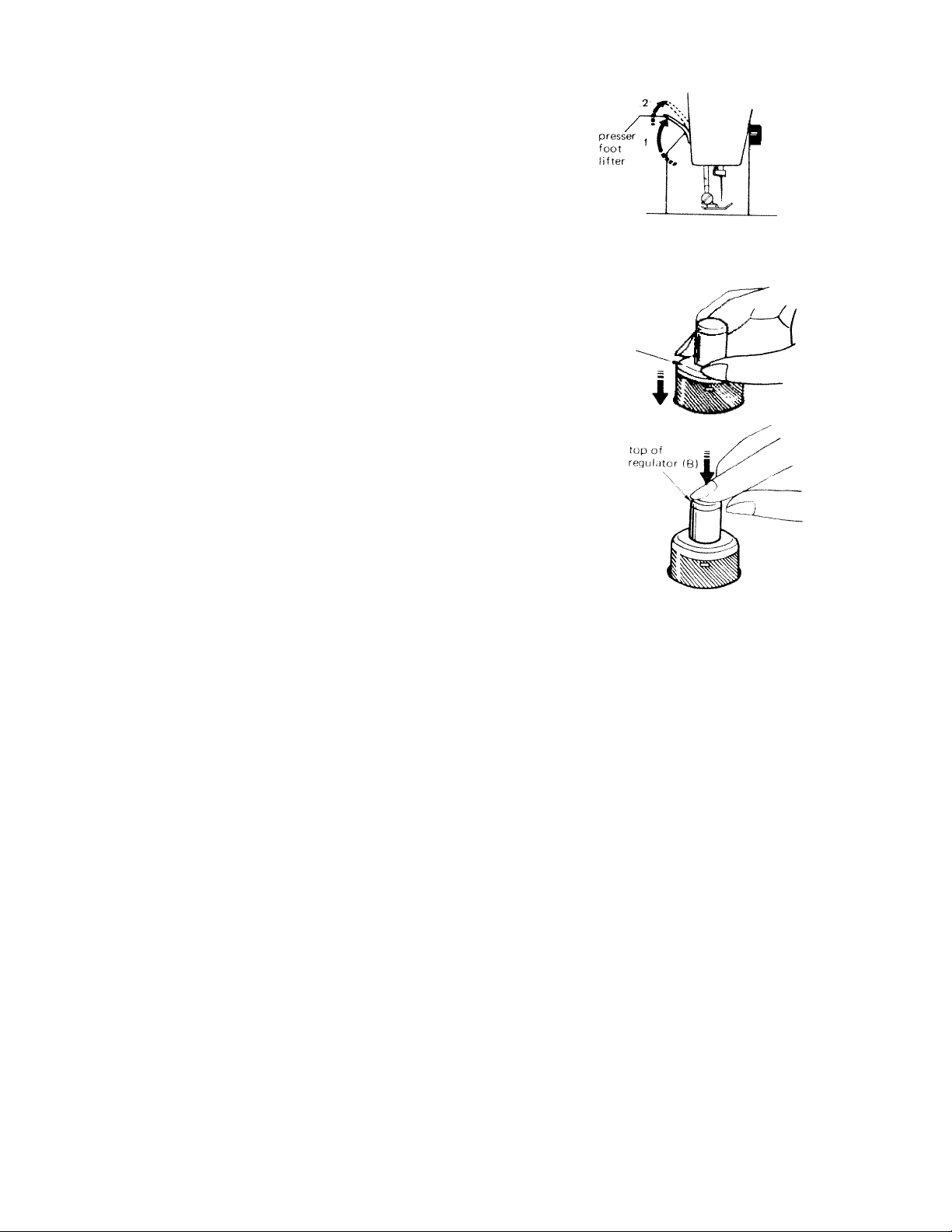

RAISING OR LOWERING THE PRESSER FOOT

1. By raising or lowering the presser foot lifter, the presser foot

goes up and down respectively.

2. For additional clearance, the foot lifter can be raised higher to

sew on heavy fabrics.

REGULATING THE PRESSER FOOT PRESSURE (Patch-O-Matic)

To release the pressure, push ring |A) downwards. This causes the

regulator to spring up to its highest position. The material is now

free from any pressure of the presser foot.

For sewing thin or light materials, push regulator |B) down just a

little to provide the light pressure required.

If you are sewing thick or heavy materials, push the regulator |B)

farther down to increase the pressure on the material.

ring (A)

REMOVING AND ATTACHING THE PRESSER FOOT

To Remove: .

1 Turn the balance wheel towards you until the needle is at its highest position.

Raise the presser foot by lifting the presser foot lifter.

2 By lifting the lever on the back of the foot holder, the presser foot will drop off.

Note: *Do not force the presser foot to remove it.

To Attach:

1 Place the presser foot so that the pin on the foot lies just under the groove of the

foot holder. Lower the foot holder.

2 When the presser foot lifter is raised you'll find the presser foot is locked in place.

REMOVING OR ATTACHING THE FOOT HOLDER

It is not necessary to remove the foot holder unless you use blind stitch hem guide or

to allow clearance when you clean the feed dog.

To Remove;

Raise the needle to its highest position by turning the balance wheel towards you, and

lift the presser foot.

Remove the foot from the foot holder and loosen the foot holder screw with a screw

driver.

To Attach:

Raise the needle to its highest position by turning the balance wheel towards you, and

lift the presser foot lifter.

When attaching the foot holder to the presser bar, push it up as far as it will go and

tighten .the screw firmly with a screwdriver.

regulating the thread tension

Generally thread tension should be controlled by the thread tension dial. Bobbin thread tension has teen

adiusted^at the factory and readjustment is scarecely needed except for special stitch, thread and fabric. Bobbin

thread tension is just right when you can pull the thread from bobbin case easily with a little resistance.

Thread tension may be adjusted by tightening or loosening the thread tension dial, if necessary.

liic ni'cilk' Mia-.ul .itul !lic hohhin !hrc.n!

Properly adjusted thread

tension for straight sewing

------K ^

......

- -

..............

^ .

...

jT

........................................

shoiilil in!crl(Kk in tire i,cn!croI !wt) Ijycrs ol Idhru

—

*How to adjust the bobbin

thread tension

L.oosen the needle thread tcnsfnn bv

moving the dial to the Utwer number

The needle thread is too

loose

’There are many reasons for having to reset your tension. The best tension for one fabric may not be correct for

another. The required tension depends upon the stiffness of fabric, thickness of the fabric, numbers of layers o

fabric being sewn, as well as the type of stitch you are making.

*lt is better to test the stitching on a scrap of the fabric you are using before starting to make a garment.

STITCH LENGTH DIAL REVERSING BUTTON AND DROPPING THE FEED

To change the length of the stitches proceed as follows:

Turn the dial so that the number for the required stitch

length Is at setting mark. The numbers indicate the ap

proximate stitch lengths in mm. The lower the number,

the shorter the stitch.

REVERSE STITCH:

Press center of the stitch length dial (reversing button) and

hold for reverse stitching. Fabric will immediately start

feeding backwards. Release button and machine will

resume normal forward sewing.

Very useful for fastening ends of seams and darts without

having to tie threads, and for strengthening seams.

DROPPING THE FEED DOG:

Embroidering and darning are best carried out with the

feed mechanism disengaged. This is done by setting the

stitch length dial at , which drops the feed and allows

the material to be moved freely under the needle.

The feed starts its normal function again as soon as you

turn the stitch length dial to "0" or beyond it.

1 if -

THE PATTERN SELECTOR

The desired pattern can be selected by turning the pattern selector dial. The marks on the dial correspond to the

patterns shown on the panel respectively, as follows;

. 1 .-.I,.

M( CX^ ) straight stitch, middle needle position

rj—) ) straight stitch, left needle position

15

0

A/.AA^'

A

zigzag stitch with variable width

reverse blind stitch

B ( 'zj ) tricot stitch

C ( ) stretch blind stitch

U - ^ + [1 ^ automatic buttonhole sewing

If you use a twin needle,

zigzag stitch width should

Selecting Stretch Stitch:

When sewing stretch stitch, set the stitch length dial at

"S.S.". ^

be in the range " ^ “

(zigzag width between

"0-2"

When you release the "S.S." engagement on the dial, the

stretch stitch mechanism will be off automatically.

M i dlD ) triple straight stretch stitch, middle needle

position.

¿Id ) triple straight stretch stitch, left needle

0

position.

,A,'v\-v. ) triple zigzag stretch stitch or ric-rac stitch

1-5

t; ) overlock stitch

A

B

C

) feather stitch

) fancy stretch stitch or blanket stitch

Note: * Raise the needle »to its highest position before

turning the pattern selector. j i

REMOVING THE BOBBIN CASE AND BOBBIN

1. Raise the presser foot and turn the balance wheel towards

you until the thread take-up lever is at its highest position.

2. Open the shuttle cover,

3. Open hinged latch of bobbin case and pull bobbin case out of

machine.

Release the latch and the bobbin will fall out. As long as you

hold the bobbin case latch open, the bobbin cannot drop

out.

1.5-

WINDING THE BOBBIN

1. Release clutch by turning clutch knob

toward you.

2. Draw thread from spool through

bobbin winder tension disc as shown.

3. Pull end of thread through hole in

bobbin as shown.

4. Place bobbin onto bobbin winder

shaft with end of thread coming from

the top of the bobbin. Push bobbin

winder shaft to the right until it clicks.

Holding onto end of thread, start

machine. When bobbin is slightly

filled, snip off end of thread.

5. Wind thread until winder stops.

Remove bobbin. Clip thread.

6. Tighten clutch knob.

THREADING THE BOBBIN CASE

Hold the bobbin between the thumb and forefinger of your right

hand and pull off about 15 cm (6 inches),of thread.

1. Hold the bobbin case in your left hand as shown and place

the filled bobbin inside.

2. Pull the thread into the slot in the edge of the bobbin case.

3. Now puli the thread under the tension spring and into the

thread eyelet.

To insert the bobbin case and bobbin

Ensure that about 15 cm (6 inches) of thread extends

out of bobbin. Hold the bobbin case so that long

finger on case points up. Open the latch of bobbin

case. Slip the bobbin case over the center pin of

hook and press in place until long finger of the

bobbin case enters notch. Release latch and press

down.

....................

THREADING THE NEEDLE THREAD

Place spool on spool pin as shown, with

thread coming from the back of the

spool.

Draw thread through top thread guides.

Holding spool stationary with right hand,

pull the end of the thread between the

tension discs as shown above ^^3 ■.

Pull the end of the thread taut with left

hand. This will pull the spring wire up

and past the end of the hook. The thread

will then slip into the Jiook when the

spring IS released as in .

Release spool of thread and ^hread

machine through takemp lever ^5/ and

thiead guide ,6 as shown above. Thread

then passes through guides .^7 and ^8 •

Thread needle ,9 from front to rear.

-- ! 8

DRAWING UP THE BOBBIN THREAD

1. Hold the end of the needle thread with your left hand.

2. Turn the balance wheel slowly towards you with your right

hand until the needle goes down and comes up. Then stop

the balance wheel when the take-up lever is at its highest

position.

Lightly draw up the needle thread forming a loop with the

bobbin thread.

3. Pull about 15 cm ¡6 inches) of both threads away from you

under the presser foot.

19-

STRAIGHT STITCH AND ZIGZAG STITCH

. . . .zigzag foot

Patter selector

Stitch length dial.....................

Starting Sewing

1 Be sure both the threads are drawn back under the presser foot

2. While holding the threads with your left hand, turn the blance

wheel toward you to bring the needle into the fabric where

you wish to start sewing.

3, Lower the presser foot, and press the speed controller gently,

then start sewing slowly.

*Sew a few reverse stitches by pushing reverse button for rein

forcing the end of seams.

•Raise the needle to its highest position before turning the

pattern selector dial and stitch width dial.

........................

1-5 (Wwv- Ì (for zigzag stitch)

............

0.3 ~4

IVI { c±31 or 0 {dZD Ì (for straight stitchl

Changing Sewing Directions

1. Stop the machine, and turn the balance wheel towards you to

bring the needle down into the fabric. Raise the presser foot.

2. Pivot the fabric around the needle to change direction as

desired.

3. Lower the presser foot and continue the sewing.

Fastening Seams

1. For fastening the ends of seams, press down the reversing

button and sew several reverse stitches.

2. To remove the fabric, raise the presser foot and draw the

fabric away from you.

3. Sever threads on thread cutter at the rear of presser bar or

with a pair of scissors.

Leave about 15 cm (6 inches) of thread hanging from the

needle eye.

SEWING WITH A TWIN NEEDLE

Pretty colored patterns can be made by sewing with a

twin needle and differenLcolored threads.

Presserfoot

Pattern selector............................................0 2

Stitch length dial

1. Set the pattern selector in the range of " ,

otherwise a needle may hit the needle plate.

2. Insert the twin needle in the same way as a single

one (flat side away from you).

Place two spools of threads on the spool pins.

3. Pass both threads upto face plate thread guides as

for single needle stitching.

4. Separate the threads on needle bar thread guides and

needle eyes.

Note: *Be sure to place the two round felts provided in the accessories over

..................................................

..................................................

the spool pins. To turn a corner with a twin needle, you have to take

the needles out of the fabric, otherwise the twin needle will break or

bend.

zigzag foot

(zigzag width

less than " •=

make)

TRIPLE STRETCH STITCH

If you wish to sew stretch fabrics, this is the right stitch to avoid thread breaking. This is also very suitable

for seams that need great strength, e.g. crotch seams or pocket seams.

TRIPLE STRAIGHT STRETCH STITCH

Presser foot..............................

pattern selector

Stitch length dial

.......................

...................

...............

...............

Note: 'Use a BLUE TIPPED needle.

TRIPLE ZIGZAG STRETCH STITCH

zigzag foot

Presser foot...............................................zigzag foot

Pattern selector

S.S.

Stitch length dial........................................S.S.

The blue tipped needle effectively prevents

skipped stitches.

-23-

........................................

5

TRICOT ZIGZAG STITCH

FEATHERS STITCH

This stitch is very suitable for darning tears. It can

also be used for reinforcing stretch materials and

sewing on fabric parts.

Presser foot

Pattern selector

Stitch length dial

.............................................

.......................................

......................................

Note: *Use a BLUE TIPPED needle.

zigzag foot

B { )

0.3 to 4

The blue tipped needle effectively prevents

With this type of sewing, seams are elastic and fabrics

can be joined firmly. Use the feather stitch to sew

bathing suits, mend girdles and bras and as a deco

rative top stitch.

Presser foot.............................................zigzag foot

Pattern selector.......................................B ( ^ )

Stitch length dial......................................S-S-

OVERLOOK STITCH

With this seam it is possible to provide raw edges, especially on easily fraying fabrics, with a good-locking and

lasting edge finish.

Presserfoot

Pattern selector

Stitch length dial

Place the fabric under the presser foot so that the stitches are made

over the edge.

The overlook stitches are formed correctly when the needle sews

to the right and it just misses the fabric edge.

..............................................

.......................................

......................................

Lower the presser foot and start sewing.

Guide the material lightly as shown.

Sew on a piece of waste fabric to check the machine setting.

Note: *Use a BLUE TIPPED needle.

The blue tipped needle effectively prevents skipped stitches.

zigzag foot

A{ ^ )

S.S.

SEWING BUTTONHOLES

The buttonhole mechanism built-in this machine makes it possible to sew

button holes in a short time without turning the material.

Presser foot

.............................

Pattern selector

Stitch length dial

.......................

.....................

...............

...............

...............

buttonhole

c ^

0.3 to 1

foot

1 -m

Raise the foot and the needle to its highest position. Replace the foot with

the transparent buttonhole foot for sewing buttonholes.

Mark the location and the desired length of buttonhole on the fabric by using a

pencil or tailor's chalk.

Note:*To find the most suitable

stitch length, it is better

to sew a sample buttonhole

on a piece of waste fabric.

‘When sewing very fine

fabrics and synthetics, de

‘The mark on the stitch

length dial shows a range of

buttonhole sewing. An

adjustment can be made

by setting the mark, as

shown.

crease the pressure of foot

and sew over a piece of

paper to prevent thread dis

tortion.

stitcnes

for heavy

fabrics

dense

stitches

^ I for tight

i 1 fabrics

(CONTINUED)

SEWING BUTTONHOLES (continued)

1. Set the pattern selector at " B Then pass the needle thread

through the opening in the buttonhole foot and draw both needle and

bobbin threads to the left side. Turn the balance wheel towards you

until the needle comes to the point (1).

2 Lower the foot and sew slowly until a desired length is sewn,

then stop the machine at (2).

3. Raise the needle and set the selector at '' HI "■ Then sew

several stitches of bar tack until the needle is at point (3).

4. Raise the needle and set the selector at " Cl ", then sew the

right side of buttonhole just as the same length as the left side

of buttonhole. Stop the machine at (4).

5. Raise needle and set the selector at " □ ", then sew several

stitches of final bar tack. Stop the machine with the needle

at point (5). To lock threads, set the pattern selector at "B

(zero point of zigzag width)" and sew a few stitches.

6. Cut the buttonhole open carefully using a seam ripper, taking

care not to damage the bar tacks.

Note: * To make a heavier buttonhole, sew twice by repeating the

same procedure.

c

]

SEWING ZIPPERS

Presserfoot

.............................................

zipper foot

Pattern selector.........................................M ( CjD )

Stitch length dial

.......................................

1 to 4

* *

Raise the foot and the needle to its highest position by turning

the balance wheel towards you. Replace the foot with the zipper

foot.

1. Pin or baste the zipper tape to the fabric and place the work

piece in position under the foot.

Attach snap on zipper foot so that the needle passes on its

left hand side.

* When starting to sew, both needle and bobbin threads ends should

be put under the foot.

2. Sew on the right side of the zipper by guiding zipper teeth

as close as possible to the needle drop. Before the foot reaches

the slider on the zipper tape, raise the foot and open the

zipper by keeping the needle in the fabric.

Lower the foot and sew on theremaider of the seam.

3. To sew the left side zipper change position of foot for bring

the foot to the left side of the needle. Sew on in the same

way as you did on the right side of zipper.

-28-

Fig. 3

HEMMING

............

hemmer foot

Pattern selector

Stitch length disi

Raise the foot and the needle to its highest position. Replace the

foot with the hemmer foot.

Fold over the fabric edge by about 3 mm (1/8 inches) and place it

under the foot. Secure the folded edge with a few stitches. Take

out the workpiece and draw the hem into the hemmer foot by

pulling on the threads.

Lower the foot and sew the hem.

During sewing, fold the fabric to the left a little and allow it to

run into the hemmer foot.

Make sure that the fabric does not move under the right half of

the foot. The fabric must be fed into the scroll of the hemmer

sufficiently so that the workpiece edge runs freely through the

groove under the foot.

....................

..................

...............

...............

M( cb Ì

1 to 4

- 2 9 -

SEWING BLIND HEMS

presser foot

Pattern selector

Stitch length dial

Turn up the hem with the desired width and press. (Fig. 1)

1.

Fold hem back against the right side of the garment with

2.

top edge of hem extending about 4 mm (1/6 inches) to the

right side of the garment folded. (Fig.2)

Place the garment under the foot so that double-folded edge

3.

runs along the hem|guide and lower the foot.

Sew slowly for better control, marking sure the narrow

zigzag stitches will fall on the hem edge and wide zigzag

stitches will just catch one thread of folded edge. (Fig. 3)

Unfold the fabric and you will have a blind stitch hem

4.

(Fig. 4)

...........................................

....................................

..................................

C( )

1 to 3

,30-

(Fig. 4)

EMBROIDERY

Remove presser foot

Pattern selector

Stitch length dial

Place the fabric with embroidery hoop. Set the stitch length

dial at " # Lower the presser foot lifter. Hold the embroidery

hoop firmly with you hand'

While sewing the desired pattern, move the emoroidery hoop

slowly and do not allow your fingers to get near the needle.

*Set the needle thread tension a little looser so that the bobbin

thread is not pulled through to the right side of fabric.

*lt is recommended to mark the required embroidery pattern

on the right side of the fabric with a pencil or tailor's chalk.

............................

...........................

.........

............

m

CLEANING THE FEED DOG

It is necessary to keep the feed dog teeth always cleaned in order

to ensure smooth sewing.

Remove the needle and the presser foot.

Unscrew the needle plate set screws with a screw driver to take

off the needle plate from the machine.

With a brush, clean out dust and lint clogged on the feed dog

teeth.

Refit the needle plate.

-33-

CLEANING THE SHUTTLE RACE

Unplug the machine from the power supply.

Rgi^^ee^e to its highest position and remove bobbin case.

T::::^rs Iv from Shume and lift out retaining ring and

d», , ,™.i b... r.™,.

lin, ,„d thread from all p..a of »buttle and »ipe with a luhtv

oiled cloth.

To reassemble: carefully back into shuttle

Hold shuttle by center pm and fit caretuiiy o

race, forming perfect circle with shuttle driver.

Replace retaining ring poldhed .ide out, making .ure »be tot

pin fit» into notch .Lock retaining ring bv turning le.er. back into

position. Refit bobbin case with bobbin.

34 -

FREE-ARM SEWING

This sewing machine can be used like a flat bed machine, but easily

converts to free arm machine by removing the extension table.

The free arm enables you to sew tubular types of pieces more easily.

Just slip the sleeve or pants leg on the free arm as shown above.

You will find many uses for this free arm feature such as:

1 Mend elbows and knees of garments more easily.

2. Sew m'sleeves more easily. This is especially true when sewing

smaller garments.

3. Applique, embroider or hem around edges of cuffs or pants legs.

4. Sewing in elastic casings in skirts or pants at the waistline.

-35-

TROUBLE SHOOTING: CAUSES AND REMEDIES

NEEDLE THREAD BREAKS

CAUSE

Needle not properly threaded

Thread tension too tight

Something wrong with the needle

Thread it too heavy for needle

Thread check spring is broken

Needle not properly inserted

Needle plate, shuttle or sewing foot damaged

BOBBIN THREAD BREAKS

REMEDY

Thread properly

Loosen tension

Replace needle

Change

Have a new spring fitted

Insert needle properly

Replace

Bobbin thread entangled because of incorrectly wound bobbin

Bobbin thread not under tension spring on bobbin case

Needle not properly fitted on needle bar

Needle bent or blunt

Needle worn

Needle bent

Needle not properly fitted

Fabric too heavy or too hard

You are pulling on the fabric

Wind bobbin correctly

Thread bobbin correctly

stitches: ARE LEFT OUT

Fit needle properly

Replace

Replace

NEEDLE BREAKS

Replace

Fit needle properly

Use needle of correct size

Do not pull

-36-

TROUBLE SHOOTING: CAUSES AND REMEDIES

THREAD FORMS LOOPS

CAUSE

Thread tension not properly regulated

Needle thread not properly threaded and/or bobbin thread

not properly wound

Thread size not suited to fabric

Thread check spring not working properly

SHRINKING OR PUCKERING OF THE SEAM

Tension too tight

Sewing foot pressure too strong

REMEDY

Read instructions for regulating needle-and bobbin thread tension

Thread machine properly and/or wind bobbin thread correctly

See "Size of needle and thread"

Have spring replaced

Read instructions for regulating needle-and bobbin thread tensions

Read instructions for regulating sewing foot pressure

IRREGULAR STITCHES

Needle and bobbin threads of poor quality

Bobbin thread unevenly wound

....... .......

Machine needs oiling

Dust and thread in shuttle

Wrong oil used, has now clogged machine

Drive belt tension too tight

MACHINE DOES NOT RUN FREELY AND MAKES A NOISE

Use top quality threads

Re wind bobbin

Read instructions on how to oil

Read instructions on how to clean shuttle race

Clean machine carefully and re-oil with top quality oil

Loosen tension of drive belt

POLARIZED PLUG INFORMATION

This product is equipped with a polarized alternating current line plug (a plug having

one blade wider than the other). This plug will fit into the power outlet only one way.

This is a safety feature. ,

If you are unable to insert the plug fully into the outlet, try reversing the plug. If the

plug should still fail to fit, contact an electrician to replace the obsolete outlet. Do not

defeat the safety purpose of the polarized plug.

38^

Loading...

Loading...