Page 1

% *»^- 'k' í*t * "■ ”■ -vJ V ^

-, ' ■--; •■% ">/ , **r. > - • X -- £.’- ’- . ”> ,

Г' - '’i - > ^ -

*{,,■' .t

Page 2

IMPORTANT SAFETY INSTRUCTIONS”

‘*'Whea usiif an etectricaJ sewing machifl^ basic safety precautions should always be followed, includiEg the following,”

“Read all instructions before using this .sewing machine”

“This sewing machine is designed for household use.”

a

DANGER-To REDUCE RISK OF ELECTRIC

“A sewing machine should never be left alone when plugged in. Always disconnect this sewing machine from

the electrical outlet immediately after using and before cleaning.”

reduce the risk of burns, fire, electric shock or injury to persons,,.

1. “Do not allow to be used as a toy. Close attention is necessary when this sewing machine is used by or near children.”

2. “Use this sewing machine only for its intended use as described in this manual. Use only attachments

suggested by the manufacturer as contained in this manual.”

3 “Never operate this sewing machine if it has a damaged cord or plug, if it is not working properly, if it ha;

been dropped or damaged, or dropped into water. Return the sewing machine to the nearest authorized deale

or service center for examination, repair, electrical or mechanical adjustment.”

SHOCK:

4 “Never op-erate the sewing machine with any air openings blocked. Keep ventilation openings of the sewin

machine and foot control free from the accumulation of lint, dust, and loose cloth.”

Page 3

%yer drop or insert any object into any opening.”

T3o^noruse^oitdoorsf

0,

“Do not operate where aerosoi [spray] products are being used or where oxygen is being administered!’

7.

“To disconnect, turn all controls to the off [“0”] position, then remove plug from outlet!’

8

“Do not remove by pulling on cord. To remove plug, grasp the plug, not the cord!’

9.

A. Sewing Machines

10. “Keep fingers away from all moving parts. Special care is required around the sewing machine needle!’

11 “Always use the proper needle plate. The wrong plate can cause the needle to break!’

12 “Do not use bent needle!’

13. “Do not pull or push fabric while stitching. It may deflect the needle, causing it to break!’

14 “Switch the sewing machine off [“0”] when making any adjustments in the needle area, such as threading

needle, changing needle, threading bobbin, or changing presser foot and the like!’

15 “Always remove plug sewing machine from the electrical outlet when removing covers, lubricating, or when

making any other user servicing adjustments mentioned in the instruction manual”

16. “Always unplug before replacing bulb. Replace bulb with the same rated 15 watts!’

“SAVE THESE

INSTRUCTIONS”

Page 4

DO'S AND DONTS

1. Always be aware oi the up-and-down rnovemeot^of the needle and do not turn your attention from the_

machine while it is running,

2. When changing the needle, the presser foot, the bobbin or any other parts, always disconnect the machine by

Dulling the plug out of the wall socket

3 Do not place anything on the speed controller, otherwise the machine will start inadvertently, or the controller

or motor may burn out.

4 The maximum permissible power for the sewing lamp bulb is 15 watts.

5 When using your sewing machine for the first time, place a piece of waste fabric under the presser foot and run

the machine without thread for a few minutes. Wipe away any oil which may have appeared.

Page 5

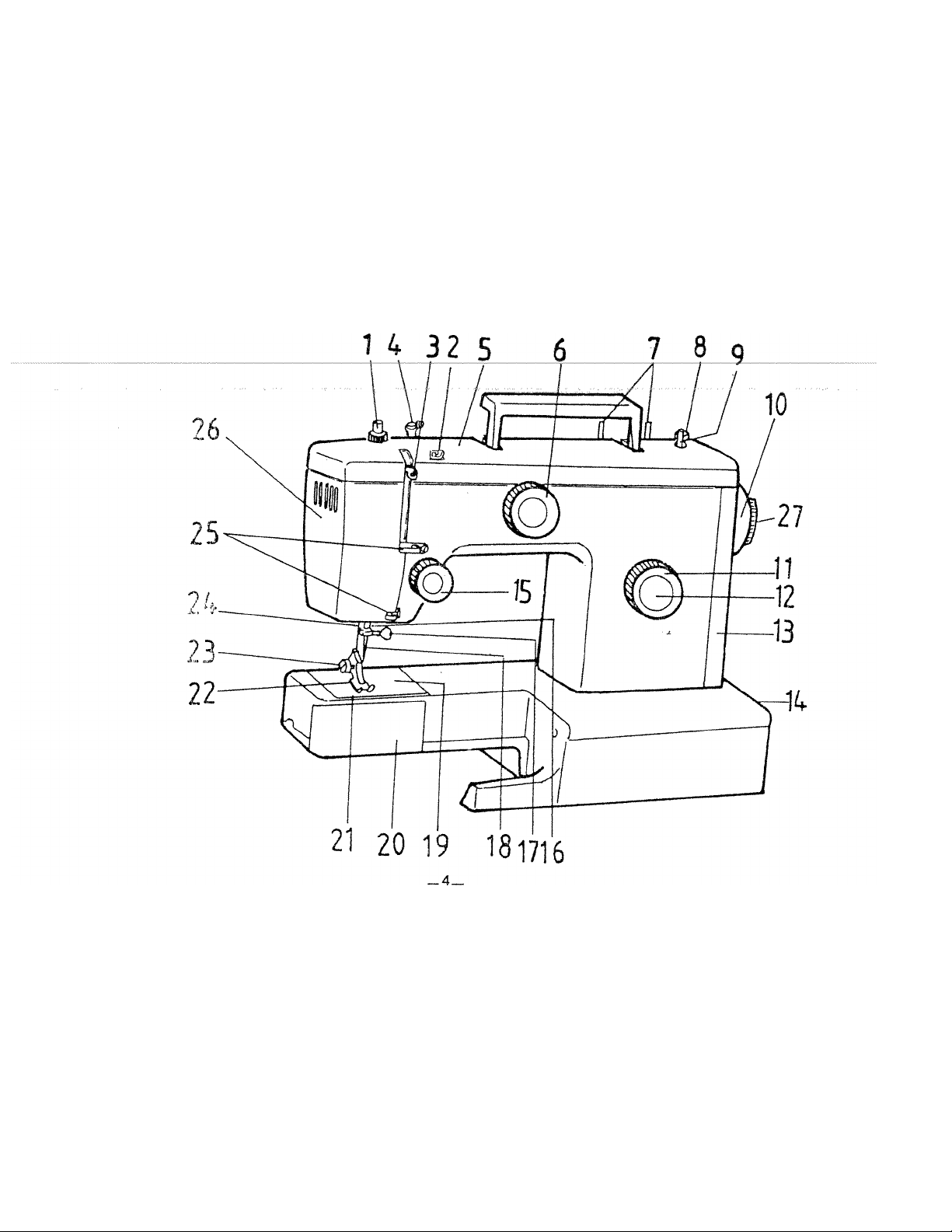

KNOWING YOUR SEWING MACHINE

Names of parts . . . /

............................................................

4-5

How to connect the machine to

the power supply.....................................................................6

How to use the speed controller

Sewing lamp............................................................................6

Thread and needle chart.........................................................7

Changing the needle

To select a suitable needle

Raising or dropping the presser foot.......................................9

..............................................................

.............................................

........................................■...........

Regulating the presser foot pressure {Patch-0-Matic)...9

Regulating the thread tension

Stitch length dial, reversing button and dropping the

feed dog

The pattern selector...............................................................12

* Selecting stretch stitch........................................................12

..............

'...........................................................11

Removing the bobbin case and bobbin

...............................................

..........................

10

13

Winding the bobbin

Threading the bobbin case

........................................................

.......................................... . 15

14

Threading the needle thread...........................................16

Drawing up the bobbin thread .............. 17

6

8

8

BASIC SEWING

Straight stitch and zig zag sewing

* Starting sewing.........................................................18

* Changing sewing directions

* Fastening seams

.....................................................

..................................

.....................................

18

19

19

UTILITY STITCHING

Sewing with a twin needles

.............................................

20

Page 6

Saving zippers .■................................................................

Buttonholes

Sewing on buttons

Hemming

................................................................

.........................................................

.......................................................................

24

25

Embroidery.................................................................... 26

To darn do the following

................................................

26

MACHINE CARE AND TROUBLE SHOOTING

How to oil the machine..........................................................27

Cleaning the feed dog

Cleaning the shuttle race.......................................................29

Free-arm sewing

Trouble shooting;

Causes and remedies

...........................................................

...................................................................

................................................

31-32

Accessories.....................................................................33

Polarized Plug Information....................................................34

91

28

30

_3_

Page 7

Page 8

Marn«i^ of Parts

...L...

Pcessua.iiiulaffl!’

2. Bobbin winder thread guide

.......................

3. Thread take-up lever

4. Thread guide

5. Top cover

6. Pattern selector dial

7. Spool pins

8. Bobbin winder stopper

9. Bobbin winder spindle

10. Balance wheel

11. Stitch length dial

12. Reverse button

13. Belt cover ■

14. Switch

15. Thread tertsion dial

16. ^ Needle bar ' '

17. Needle clamp and screw

18. Needle

19. Needle plate.

20. Shuttle cover

21. Feed dog

22. Presser foot

23. Presser foot thumb screw

24. Presser bar

25. Face plate thread guides

26. Face plate

27. Clutch knob

Page 9

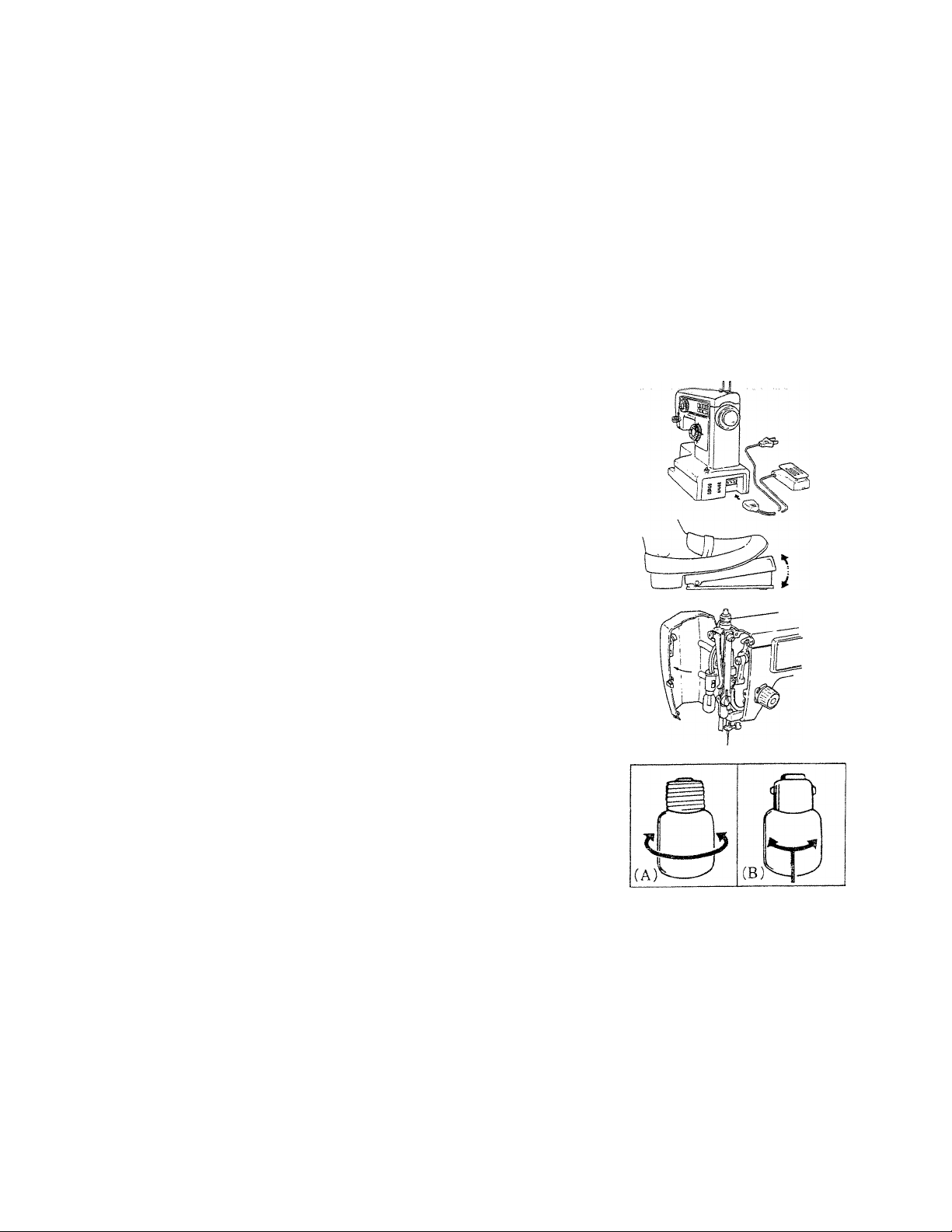

HOW,TQ. CONWeCI THE MACHINE TO THE POWER SUPPLY

1, Fit the machine plug into the machine.

2. Plug the machine to the power supply.

Note: ■'Before plugging in the machine, be sure'-that the voltage and

number of cycles indicated, is conformed to your electrical

power supply.

HOW TO USE THE SPEED CONTROLLER

Sewing speed can be varied by the spegd controller. The harder you

press on the controller, the faster the machine runs.

Note:*By releasing the controller, the machine stops running auto

matically.

'Before using the machine, practice controlling the speed

with-out threading,

SEWING LAMP

The sewing lamp is located behind the face plate.

Bulb type (A) : ® To remove ... Unscrew

® To replace ... Screw in

Bulb type {Bj : • To remove ... Push and twist out

»To replace ... Push and twist in

Note:'Before replacing a bulb. Remove plug from power supply,

power supply.

'Bulbs are available from sewing machine retailers. {Use a 15-

Watt bulb)

Caution!

Before leaving the machine, changing parts or doing any other work

on machine, always remove plug from power supply or wall socket.

Never place anything on the speed'controller, otherwise the machine

will start inadvertently or the controller or motor may burn out.

Page 10

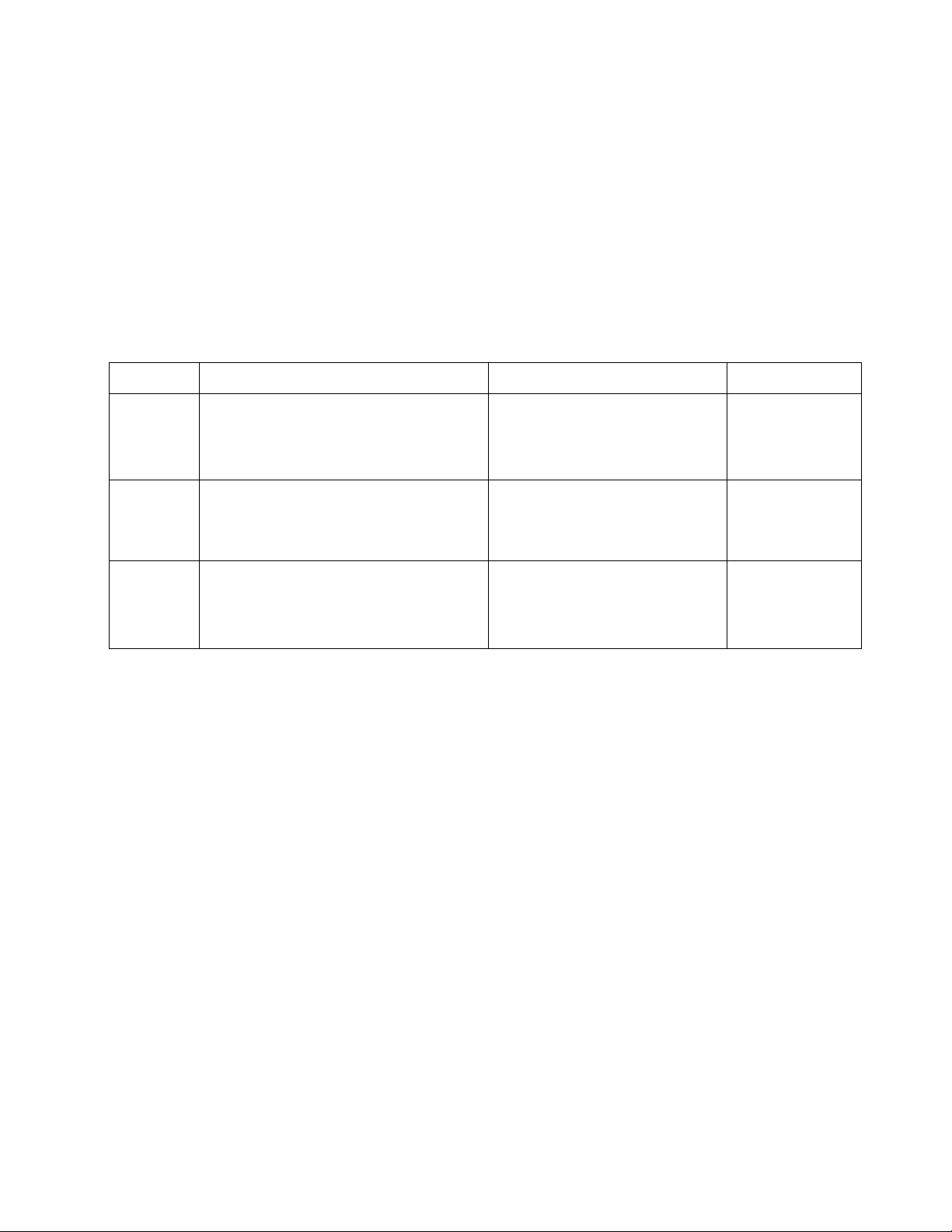

THR E A D AN D N EE D LE CHART

..............................FABRICS

THREADS

Fine Silk

LIGHT

WEIGHT

Crepe de Chine, Voile

Lawn, Organdy, Georgette, Tricot

Fine Cotton

Fine Synthetic

Fine Cotton Covered Polyester

50 silk

MEDIUM

WEIGHT

Linens, Cotton, Pique

Serge, Double Knits, Percale

50 to 80 Cotton ,

50 to 60 Synthetic

Cotton Covered Polyester

50 Silk

HEAVY

WEIGHT

Denim, Tweed, Gabardine,

Coating, Drapery and Upholstery Fabric

40 to 50 Cotton

40 to 50 Synthetic

Cotton Covered Polyester

Note: *ln general, fine threads and needles are used for sewing thin fabrics, and thicker threads and needles are

used for sewing heavy fabrics. Always test thread and needle size on a small piece of fabric which will

be used for actual sewing.

*Use the same thread for needle and bobbin,

*Wheri sewing stretch, very fine fabrics and synthetics, use a BLUE TIPPED needle. The blue tipped

needle effectively prevents skipped stitches.

*When sewing very fine fabrics, sew over a piece of paper to prevent thread distortion.

NEEDLE SIZE

9 or 11

11 or 14

14 or 16

Page 11

CH AN G IN G TH E NEEDLE

1. Turn the blance wheel towards you until the needle is at is

Highest position. ' ' '

.........................." .......

' ’ ’

2. Loosen the needle clamp screw by turning its top edge

towards you. Remove the needle from the clamp.

3. Place the new needle into the needle clamp with it's flat

side facing away from you.Push the needle up into needle

clamp as far as possible.

4. Tighten the needle clamp screw firmly.

TO SELECT A SUITABLE NEEDLE

A number Indicating the size

of needle is marked on the

Stem

stem.The higher the number,

the thicker the needle.

A BLUE TIPPED needle is

Blue tipped needle

supplied with the machine.

'Do not use any needle which

is bent or blunted.

Page 12

HA JS IN G on LOWERING THE PRESSER FOOT

............................

.

1. By raising or lowering the presser foot lifter, the presser foot / ti

goes up and down respectively.

2. For additional clearance, the foot lifter can be raised higher to inter ‘

sew on heavy fabrics.

REGULATING THE PRESSER FOOT PRESSURE

(Patch-O-Matic)

To release the pressure, push ring (A) downwards. This causes the

regulator to spring up to its highest position. The material is now

free from any pressure of the presser foot.

For sewing thin or light materials, push regulator (B) down just a

little to provide the light pressure required.

If you are sewing thick or heavy materials, push the regulator (B)

farther down to increase the pressure on the material.

...............

foof*

T

r

_9-

Page 13

;-:HGULAT1NG TH£ thread tension

GeneraHy, thread tension should be controlled by the thread tension dial. Bobbin thread tension has fv.n

trMd MslooXte°aS.d r,-Z '

read tension may be ad/usted by tightening or loosening theThread tension dial, if necessary.

Properly adjusted thread

tension for sewing

Ths nesdl« thread and

the bobbin thread shoutd

intsftock in the center of

two layers of fabric.

is —

The needle thread

is too light.

The bobbin

thread ap

pears on the

upper surface

of the fabrics.

The needle thread

is loo loose.

The needle

thread ap

pears on the

underside of

the fabrics.

....

.....

- _

Loosen the needle

thread tension by

moving the dial to

the lower number.

Tighlen the needle

thread tension by

moving the dial to

the higher number.

__________

*How to adjust the bobbin

thread tension

one fabric may not be correct for

fabric being sewn, as well as the type of stitch you are making, '

another. The required tension depends upon the stiffness of fabric thickness of the fabric numherc rsf i= r

It IS better to test the stitching on a scrap of the fabric you are using before starting to make a garment.

n 3S P66n

To increase tension

turn screw clockwise

To decrease tension

turn screw counter

clockwise.

10-

Page 14

STITCH LENGTH DIAL,REVERSING BUTTON AND DROPPING THE FEED

_11 _

Page 15

TH-E PATTERN SELECTOR

patterns shown on the panel «spectiveJy, «s follows; ^ ^ dial correspond,to the

^ ( CZ^ ) straiQht stitch, middle needle position

0 { Cfz) ) straight stitch, left needle position

1-5 i /Vww ) zigzag stitch with variable width

Note; Raise the needle to its highest position before

turning the pattern selector.

If you use a twin needle,

zigzag stitch width should

be in the range " = "

(zigzag width between

“0-2'')

-12 -

Page 16

2, Open the shuttle cover.

3. Open hinged latch of bobbin case and pull bobbin case out of

machine.

Release the latch and the bobbin will fall out. As long as you

hold the bobbin case latch open, the bobbin cannot drop

out.

_13 _

Page 17

WlNDJiNG TH£ BOeeiN

. Release dutch by turning clutch knob

toward you.

. Draw thread from spool through

bobbin winder tension disc as shown.

Pull end of thread through hole in

bobbin as shown.

Place bobbin onto bobbin winder

shaft with end of thread coming from

the top of the bobbin. Push bobbin

winder shaft to the right until it dicks.

Holding onto end of thread, start

machine. When bobbin is slightly

filled, clip off end of thread.

Wind thread until winder stops

Remove bobbin. Clip thread. '

Tighten clutch knob.

-14 -

Page 18

THñ E AD liS iG T H E BO B BI N CASE

Hold the bobbin between the thumb and forefinger of your right

hand and pull off about 15 cm (6 inches).of thread. ^ ^

1, Hold the bobbin case in your left hand as shown and place

the filled bobbin inside.

2. Pull the thread into the slot in the edge of .the bobbin case.

Now pull the thread under the tension spring and into the

thread eyelet.

To insert the bobbin case and bobbin ......

Make sure that about 15 cm or 6 inches of thread extends

out of bobbin. Hold the bobbin cáse so that the long

finger on the case points up. Open the latch of the bobbin case.

Slip the bobbin case over the center pin of hook and press in

place until long finger of the bobbin case enters notch.

Release latch and press down.

__

.

bobbtfv--G&seu

bobbin

^

long finger notch

.15 -

i- latch

Page 19

I'HHEADiWS THE .^JSeDLS

Ptace spool on spool pin as shown, with

%-he-thread-coiTiIrtg'from-ths^^ baek" of the

spool.

Draw thread through top thread guides.

Holding spool stationary with right hand,

pull the end of the thread between the

tension discs as shown above (^ .

Pull the end of,the thread taut with left

hand. This will puli the spring wire up

and past the end-of the hook. The thread

will then slip into the hook when the

spring is released as in (T) .

Release spool of thread and thread

machine throwh take-up lever (§) and

thread guide (s) as shown above. Thread

then passes through guides (?) and (I).

Thread needle @ from front to rear.

N

©

'! f /

, '

[® ^

1

k

V

i© ^

\

_________

_16_

1

\ 1

Page 20

DRAWING UP THE BOBBIN THREAD

hand until the needle goes down and comes up. Then stop

the balance wheel when the take-up lever is at its highest

position.

Lightly draw up the needle thread forming a loop with the

bobbin thread.

3. Pull about 15 cm or 6 inches of both threads away from you

under the presser foot.

,17 -

Page 21

STRAIGHT STITCH AMD ZIGZAG STITCH

Presser foot

Patter selector

Stitch length dial................

Starting Sewing

1 Be sure both the threads are drawn back under the presser foot

2. While holding the threads with your left hand, turn the blance

wheel toward you to bring the needle into the fabric where

you wish to start sewing.

3. Lower the presser foot, and press the speed controller gently,

then start sewing slowly.

"Sew a few reverse stitches by pushing the reverse button for

reinforcing the end of the seams

*Raise the needle to its highest position before turning the

pattern selector dial and stitch width dial.

.......................

...................

................zigzag foot

.......Ml cl

................0.3 ~4

....

) j or 0 1 dZD ) (for straight stitch)

1-5 (MiW ) (for zigzag stitch)

18-

Page 22

Changing Sewing Directions

^ tj-- and tunn rhp balance wheel towards you to

bring the needle down into the fabric. Raise the presser foot.

2. Pivot the fabric around the needle to change direction as

desired.

3. Lower the presser foot and continue the sewing.

Fastening Seams

1. For fastening the ends of seams, press down the- reversing

button and sew-several reverse stitches.

2. To remove the fabric, raise the presser foot and draw the

fabric away from you.

3. Cut threads on thread cutter at the rear of presser bar or

with a pair of scissors.

Leave about 15 cm or 6 inches of thread hanging from the

needle eye.

-19^

Page 23

sewing W!TH a twin needle

Pfstty colored patterns can be^^iflade'by ^sewing^ with a '

twin needle and different-colored threads.

Presser foot. ....................

Pattern selector

................

...............

0-2

(zigzag width

less than “ *= "

make)

Stitch length dial

......................

1. Set the pattern selector in the range of “ *= ",

otherwise the twin needle may hit the needle plate.

2. Insert the twin needle in the same way as a single

one (flat side away from you).

Place two spools of threads on the spool pins.

3. Pass both threads upto face plate thread guides as

for single needle stitching.

4. Separate the threads on needle bar thread guides and

needle eyes.

Note: *Be sure to place the two round felts provided in the accessories over

the spool pins. To turn a corner with a twin needle, you have to take

the needles out of the fabric, otherwise the twin needle will break or

bend.

-20-

Page 24

SEWING Z1PPEH3 -ZIPPER FOOT OPTIONAL

Presser foot

Pattern selector.

Stitch length diai

* *

Raise the foot and the needle to its highest position by turning

the balance wheel towards you. Replace the foot with the zipper

foot.

1. Pin or baste the zipper tape to the fabric and place the work

piece in position under the foot.

Attach snap on zipper foot so that the needle passes on its

left hand side.

* When starting to sew, both needle and bobbin threads ends

should be put away under the foot.

2. Sew on the right side of the zipper by guiding zipper teeth

as close as possible to the needle drop. Before the foot reaches

the slider on the zipper tape, raise the foot and open the

zipper by keeping the needle in the fabric.

Lower the foot and sew on the remaider of the seam.

3. To sew the left side of the zipper, change position of foot to bring

the foot to the left side of the needle. Sew on in the same way

as you did on the right side of zipper.

Elements

Zipper foot

\

Tape

Fig. 1

Slider

Element

.21.

Page 25

''¡ffOfiHOL^ SBVINS

"JYTONHOLE FOOT OPTIONAL

1. Remove the regular presser foot and attach the buttonhole foot, (optional)

2. Set the zigzag width knob between "1"and"2".

Set the ■stitch length regulator knob to obtain close stitches (satin stitch).

3. Mark with a pencil or chalk the position and exact length of the buttonhole on the fabric.

-22-

Page 26

4. Lower the needle carefully into the mark on the fabric indicating the start of the buttonhole. ■

........Lnwpr thf nres.ser foot and Start sewing the left row of the buttonhole until it reacha the end of the marking m

Stop the machine with needle on fabric at point A........................

..........

...........................................................................

5. Lift the presser foot and using the needle as a pivot, turn the fabric end for end to bring the buttonhole

to po.sition (D.

6. Raise needle from fabric and set the stitch length knob to ‘■‘0”.

7. Set Che zigzag width control knob at “5’’and sew three to four stitches to make bar-tack (D,

8. Now to sew the other row of the buttonhole, return the zigzag width control knob between ”1” and “2”(io its

original setting) and commence to sew until your stitching reaches the position shown in figure (j).

9. Raise needle from fabric, also set the stitch length knob to “0”, the zigzag width control knob at “5”,

10. To make the final bar-tack ©,

11. Return zigzag width to “0” and take two or three stitches to fasten bar threads and prevent ravelling.

12. Remove fabric from the machine and open the buttonhole with a buttonhole cutter or seam cutter.

0

*

..........

A

-23-

Page 27

3U7T0N SiWim

Fit the button sewing foot (optional) to the machine.

With the button sewing foot in a raised position, place a

button on fabric with holes in a horizontal line and the left

side hole underneath the needle, and lower the foot on it.

Set the stitch length dial to zero (O)

Set the zigzag width control knob in accordance with the

distance between the holes in the button, so that the needle

enters the right side hole.

Sew SIX or

seven stitches by turnig the balance wheel with

your right hand.

To lock the thread, set the zigzag width control knob at (0)

and make three or four stitches.

-24-

Page 28

HEiVIMIjyS -HEMMING FOOT OPTIONAL

„ ..^|eg.gg.0.|». .. ... ... ... ... ... . .. . .. . .. . ... ... ... ... ... ... . .. . .. . .. . .. . ... ... ... ... ... ... . .. . .. . .. . .

Pattern sslfctor .............. .M c!~l j

Stitch length dial...................................1-4

Raise the foot and the needle to its highest position. Replace the

foot with the hammer foot, (optional )

Fold over the fabric edge by about 3 mm (1/8 inches) and place it

under the foot. Secure the folded edge with a few stitches. Take

out the workpiece and draw the hem into the hemmer foot by

pulling on the threads.

Lower the foot and sew the hem.

During sewing, fold the fabric to the left a little and allow it to

run into the hemmer foot.

Make sure that the fabric does not move under the right half of

the foot. The fabric must be fed into the scroll of the hemmer

enough so that the workpiece edge runs freely through the

groove under the foot.

hemmer foot

-25-

Page 29

EMSROiDERY

Remove prssser foot

Pa ttern selector .......

Stitch length dial

Place the fabric with embrodidery hoop. Set the stitch length

dial at'' 0 Lower the presser foot lifter. Hold the embroidery

hoop firmly with you hand.

While sewing the desired pattern, move the emoroidery hoop

slowly and do not allow your fingers to get near the needle.

'Set the needle thread tension a little looser so that the bobbin

thread is not pulled through to the right side of fabric.

'It is recommended to mark the required embroidery pattern

on the right side of the fabric with a pencil or tailor's chalk.

..................

.............

..........

MlCp'5

0

TO DARN DO THE FOLLOWING

1. Turn the stitch length dial to zero.

2. Turn the zig zag to the desired width.

3. Release the pressure on the pressure foot.

-26-

Page 30

HOW TO OIL THE MACHINE

The oiling points are marksd with arrows on The illostrations. ^

Before oiling they should be wiped clean. Apply one or two

drops of a fine quality sewing machine oil. If the machine is in

constant use, this should be done every two or three days. If the

machine should not run well after being out of use for a long

period, apply a few drops of oil to the oiling points and run the

machine fast with all covers on for about one minute. Before

using the machine again oil it in the usual way.

*Do not forget to sew first on waste fabric, in order to soak up

any excess oil.

Page 31

CLEANJWC3 THc fEED DOG

It is ,necessary to keep, the feed dsg tatth always eleaned in order

to ensure smooth sewing.

Remove the needle and the presser foot.

Unscrew the needle plate set screws with a screw driver to take

off the needle plate from the machine.

With a brush, clean out dust and lint clogged on the feed dog

teeth.

Refit the needle plate.

-28-

Page 32

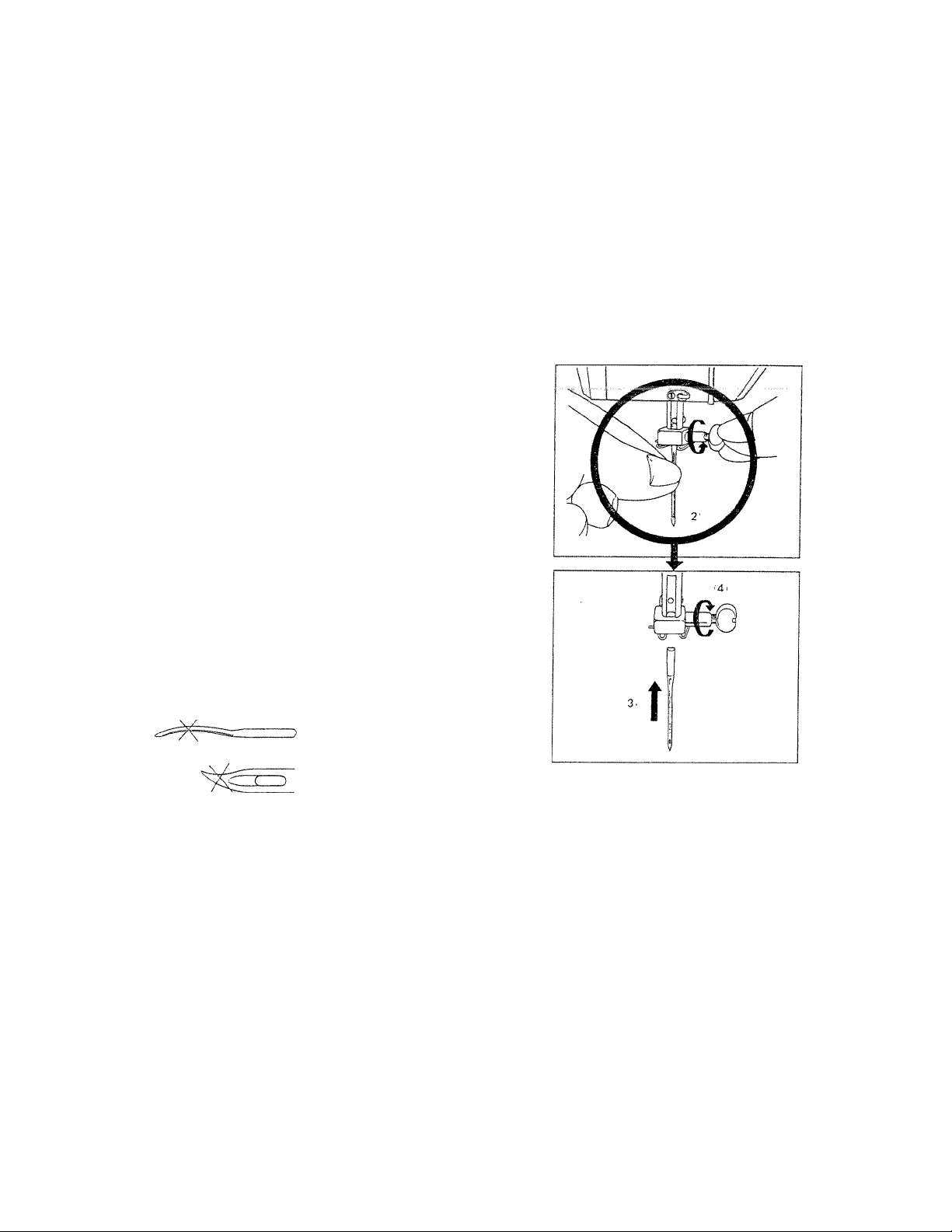

-cAN1 Nu r rtfc OTTu t f t-C

Remove plug from the power supply. .

To remove shuttle:

Raise needle to its highest position and remove bobbin case.

Turn levers away from shuttle and lift out retaining ring and

shuttle, by grasping center pin.

Clean the reverse side of feed dog with a small brush. Remove

lint .and thread from all parts of shuttle and wipe with a lightly

oiled cloth.

To reassemble;

Hold shuttle by center pin and fit carefully back into shuttle

race, forming perfect circle with shuttle driver.

Replace retaining ring polished side out, making sure the bottom

pin fits into notch .Lock retaining ring by turning levers back into

position. Put bobbin back in .bobbin case.

-29-

Page 33

'free-ARM

The tree arm enables you to sew tubular types of pieces more easily.

Just slip the sleeve or pants leg on the free arm as shown above.

You will find many uses for this free arm feature such as:

1 Mend elbows and knees of garments more easily.

....

sevVI'NG^^

2' Sew in sleeves more easily. This is especially true when sewing

smaller garments.

3. Applique, embroider or hem around edges of cuffs or pants legs.

4, Sewing in elastic casings in skirts or pants at the waistiline.

-30-

Page 34

■ROUBLE SHOOTING: CAUSES AND REMEDIES

IF needle THREAD BREAKS

CAUSE

Needle not properly threaded

Thread tension too tight

Sometning wrong with the needle

Thread it too heavy for needle

Thread check spring is broken

Needle not properly inserted

Needle plate, shuttle or foot bad

BOBBIN THREAD BREAKS

, REMEDY■

Thread properly

Loosen tension

Replace needle

Change

Have a new spring installed

Insert needle properly

Replace

Bobbin thread entangled because of incorrectly wound bobbin

Bobbin thread not under tension spring on bobbin case

Needle not properly fitted on needle bar

Needle is bent or blunt

Needle worn

Needle bent

Needle not properly fitted

Fabric too heavy or too hard

You are pulling on the fabric

Wind bobbin correctly

Thread bobbin correctly

STITCHES ARE LEFT OUT

Fit needle properly

Replace

Replace

NEEDLE BREAKS

Replace

Fit needle properly

Use needle of correct size

Do not pull

31-

Page 35

•H0U3LE SHOOTING: CAUSES AND REMEDIES

JF, THREAD FORMS LOOPS

CAUSE

Thread tension not properly adjusted

Needle thread and/or bobbin thread not threaded or wound properly

not properly wound

Thread size not working properly

Thread check spring not working properly

SHRINKING OR PUCKERING OF THE SEAM

Tension too tight

Sewing foot pressure too strong

Needle and bobbin threads of poor quality

Bobbin thread not wound correctly

MACHINE DOES NOT RUN FREELY AND MAKES A NOISE

Machine needs oiling

Dust and thread in shuttle

Wrong oil used, has now clogged machine

Drive belt tension too tight '

REMEDY

Read instructions for regulating needle-and bobbin thread tension

Thread machine properly and/or wind bobbin thread correctly

See "Size of needle and thread"

Have spring replaced

Read instructions for regulating needle-and bobbin thread tensions

Read instructions for regulating sewing foot pressure

IRREGULAR STITCHES

Use top quality threads

Re-wind bobbin

Read instructions on how to oil

Read instructions on how to clean shuttle race

Clean machine carefully and re-oil with top quality oil

Loosen tension of drive belt

-32-

Page 36

ACCESSORIES

Loading...

Loading...