Page 1

гп Cti

Page 2

To the Owner:

We wish you many years of satisfying and successful sewing with your new Domestic

sewing machine. Because of its functional design and simple controls it is easy to handle,

easy to use and easy to keep in perfect condition.

This book, written to acquaint you with the performance you can expect from your new

Domestic should be read carefully and kept with your machine for future reference.

Time-saving accessories to fit this model such as buttonholers, rufflers, automatic

decorators and binders are available from your dealer or the store where you purchased

the machine.

WHITE SEWING MACHINE CORPORATION

CLEVELAND 11, OHIO

WHITE SEWING MACHINE PRODUCTS LTD.

Toronto 16, Ontario, Canada

_ £

Page 3

INDEX

Features and Parts ................................................. 2~4

Needle and Thread Chart

Setting the Needle............................................... 5

Winding the Bobbin ................................................ 6

Threading Bobbin Case............................................. 7

Placing Bobbin Case in Shuttle ........................... 8

Threading ................................................................. 0

Setting the Stitch Length

Stitch Length Chart

Sewing in Reverse

Adjusting the Tensions

Adjusting Pressure and Feed.................................. H

..................................................

..................................

........................................

............................................

.........................................

5

10

10

10

Page

9

General Sewing .................................................. n

Light Weight Fabrics ......................................... n

Darning and Mending

Preparing to Sew .................................................... 12

Removing the Work .............................................. 12

Care and Maintenance ........................................... 13

Oiling .........................................................

Replacing Light Bulb

How to Replace Belt

Cleaning and Oiling Shuttle ................................. 15

Check up for Smooth Sewing ............................... 17

Accessories.............................................................. jg

....................................................... 13

........................................

........................................

.........................................

14

15

Page

12

Page 4

Л

J

»I

<»•

Л

Л

r

,1

Fig. 1

0

e

Page 5

i5

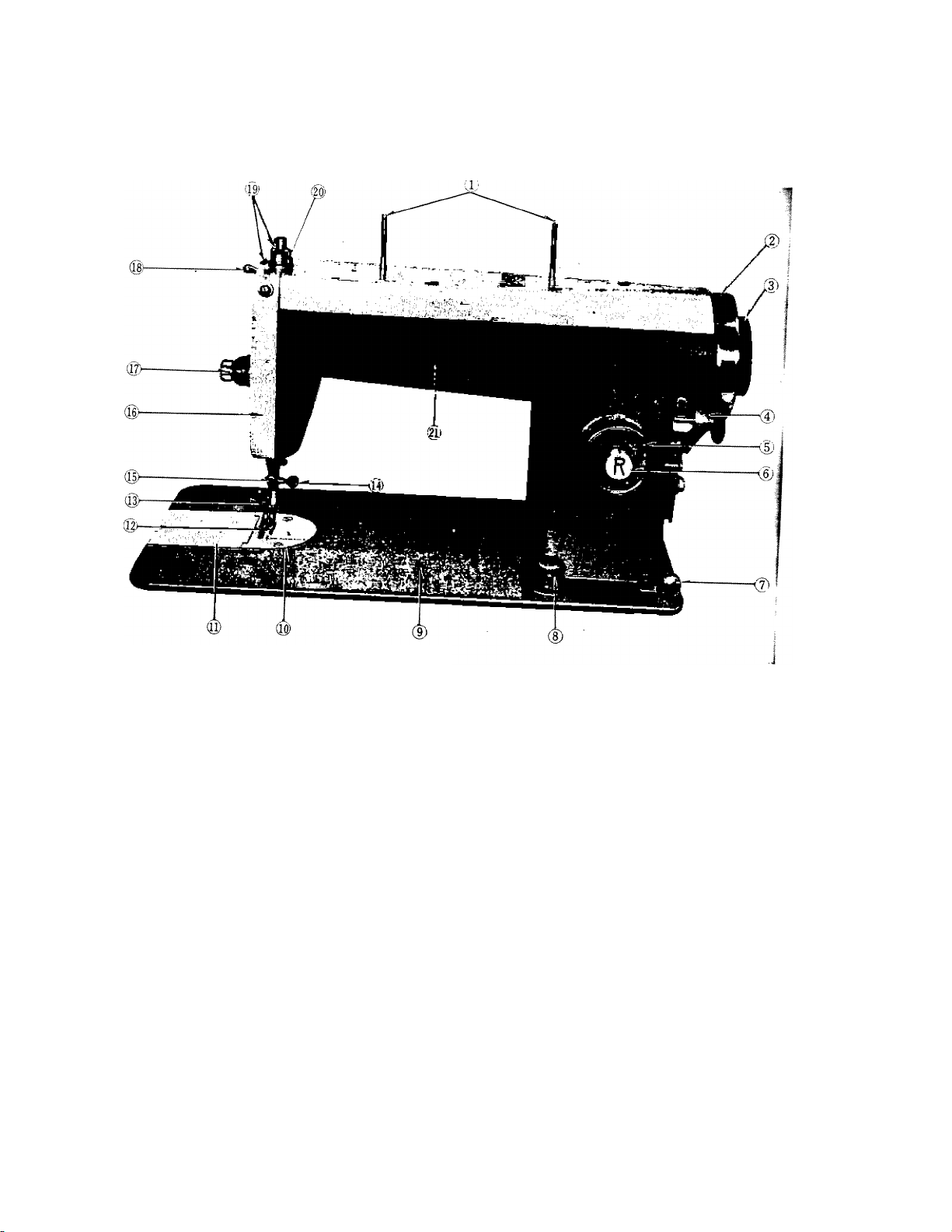

FEATURES AND PARTS

(Front View)

1. Spool Pins

3

9

d

)

2. Hand Wheel

3. Wheel Clutch

4. Bobbin Winder

5. Stitch Length Dial

6. Push Button Reverse

7. Bobbin Winding Tension

8. Drop Feed Knob

9. Bed

10. Needle Plate - Seam Guide

11. Cover Plate

12. Presser Foot

13. Attachment and Foot Thumb Screw

14. Needle Clamp and Screw

15. Needle Bar Thread Guide

16. Face Plate Thread Guide

17. Tension Regulator

18. Take-up Lever

19. Thread Guides

20. Pressure Release-Darner

21. Light Assembly

Page 6

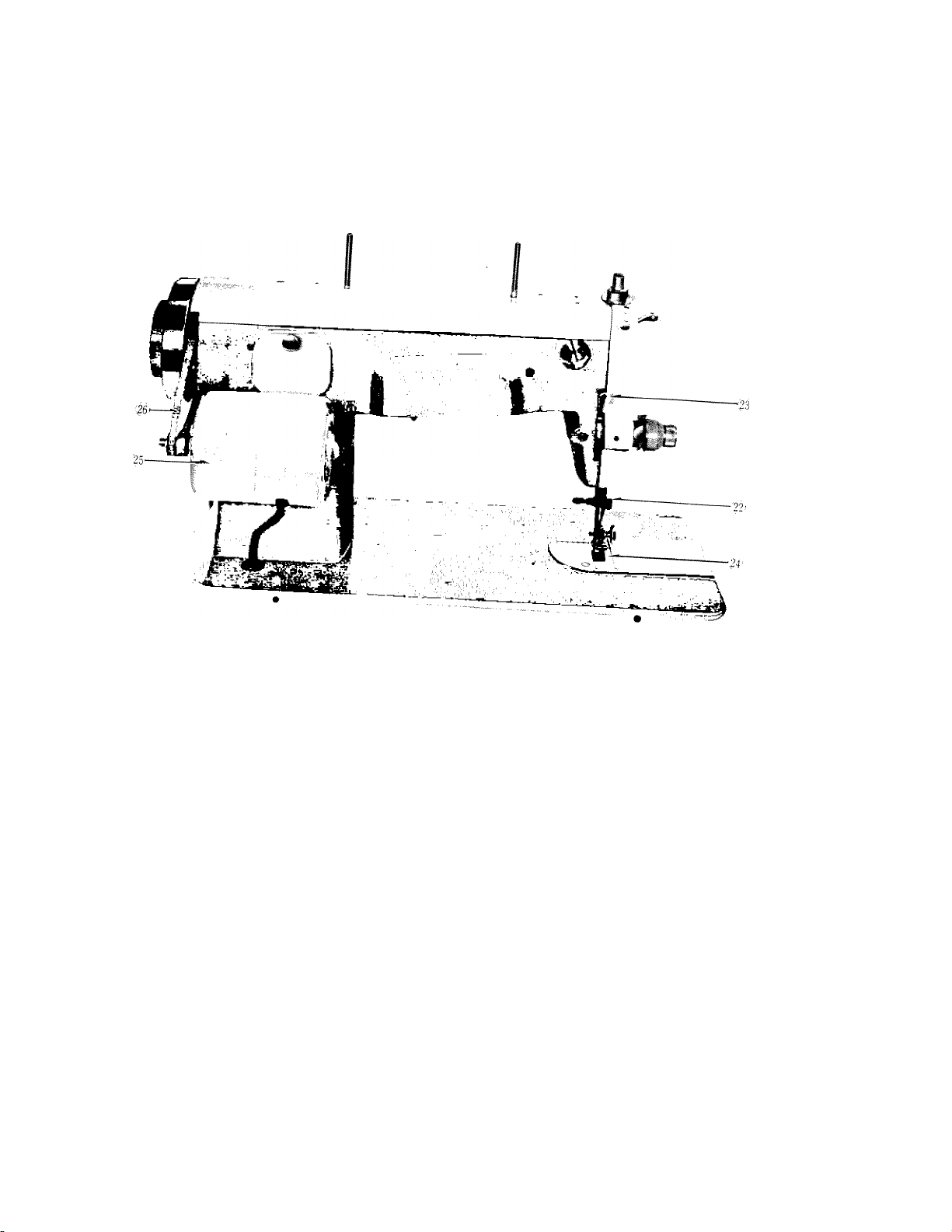

features and parts

(Back View,

c f

r

I

22. Thread Cutter

23. Presser Bar Lifter

Fig. 2

24. Feed

25. Motor

26. Belt

^ i

I-'

g

I

Page 7

NEEDLE - THREAD - FABRIC - STITCHING GUIDE

Machine

Fabric

Needle

No

Stitches

Per Inch

Extremely heavy

tarpaulin, sacking,

4 to

canvas, duck, etc.

Heavy upholstery

fabric, ticking.

3 to

denim, leatherette

Medium heavy drapery

fabric, velveteen.

2

suiting, felt, terry, etc.

Medium broadcloth.

percale, gingham, linen.

chintz, taffeta, sheer

1

X to

wool, shantung, etc.

Sheer voile, lawn. 14

dimity, crepe.

handkerchief linen.

plastic film, etc.

Very sheer chiffon.

batiste, lace, organdy.

ninon, net, marquisette, etc.

0

16

(Plastic film)

8 to 10

16

00 to

20

10

10

12

12

14

to

to

Cotton

Thread

6

10

to

8

8

30

30

to

Mercerized

Thread

Heavy Duty

Heavy Duty

or

Nylon

40

40

Silk

to

Heavy Duty

60

60

to

50

80

80

to

100

100

to

50

50

A

A

150

Page 8

Fig. 4

SETTING THE NEEDLE

tJZ Seel' toSLSu bStT'a

peJtrCSTallfrflfSrtlSS*

fastening the needle olanip securely with TscrL

WINDING THE BOBBIN

Disengage the hand wheel (3 Firr c ui

mechanism by turning the clutch 6 M ^ I™“ stitching

=t°ohw.se. Place a sp’oercftrSd on oTeSre ” “T“*"'-

lead thread through the front thread guide oShfaS '"“d

0^

s^.n‘ .™tn‘tT:rt:relTS's- ^ ‘SS:nf tS

edge and Pl.oe“hthtf ret t°„7lt Sholj.“

bohlun „tnder pullet tSntTauTSetT “oir.S d""1

loosely and start machine slowly. Bobbin tdl be S “t

automatically when it is filled. ^ released

Turn clutch away from you until sewinrr m

agajn engaged so that needle moves when you tur^ Tlld

Break off loose thread end used to start the winding.

x, ■

0^

^

€

Page 9

THREADING THE

BOBBIN CASE

Step 1 (illustrated in Fig. 6).

Hold bobbin case between tbumb

and forefinger of left hand, so that

the slot in the edge of the bobbin

case is on top. Take the bobbin

between thumb and forefinger of

right hand so that the thread on

top leads from left to right. Step

2. Insert bobbin into bobbin case,

pull the thread into the slot of the

bobbin case as shown in Fig. 7, and

draw it under the tension spring

and into the fork-shaped opening

of tile spring as shown in Fig. 8.

Fig. 5

TENSION SPRING

Fig. 6

Fig. 7

i

Fig. 8

Page 10

PLACING BOBBIN

CASE IN SHUTTLE

Raise needle bar to

higbest position, and lift

hinged cover plate. (See

11, Fig. 1.) Hold the bob

bin case latch, (D), Fig. 9,

between the thumb and

forefinger of the left hand,

Fig. 9

the top of the bobbin case to the right. Insert and

center the bobbin case on the stud of the shuttle

body, (C). Be sure the bobbin case finger, (E), is

opposite the shuttle race notch, (A). Press the bobbin

case (B) into the shuttle as far as possible until latch

catches on the center post of the shuttle. THEN

release the bobbin case latch, (D). Press bobbin

case again after latch has been released to make

sure the bobbin case is locked securely in place.

Close the cover plate.

with at least three inches

of thread running from

UPPER THREADING (Fig. 10 ■

1) Place spool of thread on spool pin nearer the

needle

2) lead thread through upper thread guide A on

back of face plate

3) down and around tension discs B from back to

front

Fig. 10

:r

u

C f

Page 11

4) into check spring C

5) then tug on thread to pull it into hook^D (see~insert,

Fig. 10)

6) up into take-up lever E from back to front

7) down into thread guide F on face plate

8) through the needle bar thread guide G

9) and into needle from left to right. Pull three or four

inches of thread through needle.

Hold the end of upper thread loosely and turn hand

wheel toward you until the needle goes all the way down

and comes back up. A loop (Fig. 11) will be formed over

the upper thread which then can be pulled out straight.

Place both thread ends under the slot of the presser foot

and draw toward the back of the machine, leaving both

threads three or four inches long.

SETTING THE STITCH LENGTH

The length of the stitch is regulated by the dial, 5,

shown in Fig. 12. Near 0 is the shortest stitch and 4 is

the longest, but the dial may be set at any spot between

markings for a variety of lengths. Turn the dial to the

left to lengthen and to the right to shorten the stitch.

The number stitch length you choose appears above the

center line on the reverse button R.

Fig. 11

Page 12

10

„ f

______________

Figures on indicator ~ ———

Number of stitches per inch No Feeding 30 o ^

When you wish to sew backward to tie the ttirc^arle =.+ 4-1. u ■ ■

press in the button R, Fig.

as the button is held in 9 ■ he machine will sew backward as long

to the right, or olookwise. To decrease "I

the number on the dial the tighter the tension. ® ® ■ “ «"ta. from you. The higher

thr

^fT

‘e-af°o be sure that the machine is

turn smilf'°'’° “°®asary to change the bobbin tension,

io Lhln T i"' , ' “ clockwise

to tighten, counterclockwise to loosen.

a perfect” stteh'’‘’y “°nej tensions are properly balanced,

in fabtc (Fto 15 “‘«locking

STITCH LENGTH CHART (Approximate)

-------------

SEWING IN REVERSE

12,

as far as it will ao TK l^eginmng or end of a seam,

ADJUSTING THE TENSIONS

T

“ *°° “®1“' n*«» lower thread is

--

-—an.

ii

I

i g. 16). When the upper tension is too loose, the upper thread

rms loops over the lower thread lying flat on the fabric^Fig 17 p. ^3

?

Page 13

11

Fig. 15

BBS

Fig. 16

Fig. 17

------c

Fig. 14

ADJUSTING PRESSURE AND FEEDING OF FABRIC

General Sewing. Usually for normal sewing the pressure bar

cap or darner release, 20, Fig. 18, is at its lowest position and the

drop feed knob is turned to "HI" position. Fig. 19.

Sewing Thin or Light Weight Fabrics. When lighter pressure

is required to sew satisfactorily on thin silk or filmy material, the

pressure cap should be about halfway down. Release all the way

by pressing the snap lock. A, Fig. 20, and then press cap B down

again to halfway spot. Lower the feed slightly by turning the

black dot on the knob to "LO" position.

........

)

k. i

1

1

-------

J

----

c

Fig. 18

Fig. 19

Page 14

12

a°d Mendina In order to move the fabric freely in

any drreobon for darning and mending, release the pressure cap

B completely by pressing down on the snap look, A Fig 20

Turn the knob to -DN" position, which drops 'the feed well

to °HI" ° * '”'**'* feed to normal, return knob

PREPARING TO SEW

Do n“tT ‘f ‘r: -w-

del:

aeilect the needle and cause it to break.

ready to begin sewing. By haying the neel IL hl' f ““ ““

the hand wheel to start the machine. Yon merely 1"

is regulated by increasing or decreasing the amounTrf °°°*” 1

Z

: 1 « *1>‘3 may

never run machine without material under the presser loot

Tult“ 1“ rd yrrtiiT'

g e amount of pressure exerted on the control.

Fig. 20

REMOVING THE WORK

Be sure to stop the machine when the thread taVm . i i

highest position. Now raise the nre i + j j ^ needle bar are at the

NOW ra.se the presser foot and draw the fabric back and to the left.

Page 15

13

Fig. 21-A

Fig. 21-A and B, and pass the threads over the thread

cutter. Pull down slightly, holding thread in both hands,

so as not to bend the needle. Leave the ends of thread

under the presser foot.

Fig. 21-B

CARE AND MAINTENANCE OF YOUR MACHINE

HOW TO OIL YOUR MACHINE

Your machine should be oiled occasionally to keep

Fig. 22

Fig. 23

Page 16

14

it operating smoothly-how often depends on th . x

>.PPer pan of the se„i„, „oft at points indicated “>■ >

yon until the take-up lever is at its lowest point ^ wheel toward

Avoid over. Oiling, only a drop is needed at each point

To oil parts under the bed of thfo rr,= t,- n- , '

drop of oil at each point indicated in Fig ^ ^ ^

HOW TO REPLACE LIGHT BULB

under light bulb, Un?ol!‘iL‘’rdlptrwdhtliw '“’"h“'’ “

your sewing machine dealer. which is available from

r

c

Fig. 25

Fig. 26

1

Page 17

V'

3

3

3

3

?

3

»

»

>

HOW TO CHANGE THE BELT

If It should ever become necessary to replace the Kelt .

must first be loosened and moved out. machine, the hand wheel

To do this, follow these instructions:

1. Ke„ove dutch nut A iu center of wheel by taldno out th

2. Bdo'"' -- « -n Be Itfteror

the clutch nu! * n maTfdi oui ”T

. 1 hand wheel away from the machine carefully. Fig 26 Pull it ' K

.He grooyed aecbon which holds the belt accessible

5 siidl °''' °°

5. Slide new belt into grooved section and over motor pulley.

• ush hand wheel back against the machine.

7. If washer C has fallen off, replace so that the lips D arf^ ■ f

8. Replace nut and tighten screw securely.

15

After doing this, turn the clutch toward vnn A- ,

needle still moves up and down as you turn the hanrwTeeT aglin If the

Give the washer a half turn and replace the nut, '

Page 18

16

CLEANING AND OILING THE SHUTTLE

(See Figs. 27 and 28)

The stitch forming mechanism occasionally becomes

clogged with loose threads and lint. This will interfere

with the efficient operation of the machine. Cleaning

and removal of the lint will safeguard the performance.

To remove the shuttle assembly, proceed as follows:

1. Turn the balance wheel until the needle reaches its

highest position. Tilt head back on its hinges.

2. Remove bobbin case (A), Fig. 27.

3. Turn the two shuttle race cover clamps (B) downward

and remove the shuttle race cover (Cj and shuttle

4. SeJn the shuttle race, the shuttle, and shuttle race cover by removing all threads, lint, etc.

5 Apply a drop of oil with finger tip to outer edge of shuttle.

When the cleaning has been completed, proceed as follows to replace the shuttle assembly :

Turn the balance wheel until the needle reaches its highest

1.

position.

Place shuttle body, >D), against shuttle driver and adjust

into position.

Replace shuttle race cover, (C), fitting pin at lower edge

3.

into notch, and lock into position with shuttle race cover

clamps, (B), making certain the clamps have been snapped

securely into position.

Page 19

xV

V

4. Put bobbin into bobbin case.

3

9

3

5. Put tbe bobbin case into tbe shuttle race, fitting tongue into notch E of race cover.

CHECK UP FOR SMOOTH SEWING

17

3

3

3

3

3

3

3

3

3

3

3

3

>

>

5

Although your sewing machine is designed for maximum efficiency, should any of the

following difficulties occur they can be remedied with minor adjustments.

Upper Thread Breaks

Be sure needle is inserted properly.

Check on correct way to thread machine.

Use correct needle size for thread.

Do not have upper tension too tight.

Lower Thread Breaks

Check correct method of threading bobbin case.

Be sure lower tension is not too tight.

Needle Breaks

Do not tug or pull on the fabric while sewing as this will bend and eventually break

the needle.

Be sure presser foot is firmly attached to bar.

Skipped Stitches

Do not use a blunt or bent needle.

Insert needle correctly.

Page 20

18

Use correct needle size for thread.

Be sure pressure on foot is sufficient when sewing heavy fabrics.

Stitches Loop

Make sure tensions are properly balanced and that machine is threaded correctly

Machine Binds

Clean thread, dust and lint from hook, shuttle and race.

If condition continues, it may be that the machine is gummy with oil. Apply kerosene to

oil holes, run rapidly for a while, and wipe dry. Then lubricate again with fine sewing

machine oil.

w» t

i»'

Page 21

9

ACCESSORIES

5

19

1. Plastic Oiler

(Sealed and filled)

2. Package of Needles (5)

3. Large Screw Driver

4. Small Screw Driver

5. Felt Washers (2)

e

(for spool pins)

6. Bobbins (3)

Loading...

Loading...