Page 1

Blectric Sewing Machine

BUILT-IN STITCH

SELECTOR

Page 2

. . . welcome to the growing family of

happy owners of this fine, precision built

electric sewing machine.

You now have one of the finest full-size

sewing machines made, with all these won

derful features :

• BUILT-IN STITCH REGULATOR

• INSTANT REVERSE-SEWING by just

flicking a lever.

• DROP-FEED for embroidery and darn

ing.

• BUILT-IN DARNER.

• NUMBERED THREAD TENSION DIAL.

• AUTOMATIC BOBBIN WINDER. Self

adjusting.

• HINGED PRESSER FOOT that rides

over pins, seams, etc

• AUTOMATIC TENSION RELEASE.

• NOTCHED SHUHLE HOOK that pre

vents thread from tangling.

• SNAP-OUT RACE for convenience in

cleaning.

This machine is precision-built for o lifetime of sewing pleasure. It will

require a minimum amount of servicing, and will give the maximum in

satisfaction. Needles, bobbines and other parts are interchangeable with

those of other first class manufacturers.

This manual provides all the information needed to operate the machine

and to care for it properly. Hence, read through the book thoroughly so

that you may become familiar with beha-dor and operation of the machine

Foil ow all instructions closely.

Several seivice calls may be necessary to adjust this machine to your

Individual needs, and to eliminate any stiffiness which may be present in

a new machine. So do not hesitate to call on your Authorized Dealer for

any adjustment needed during the initial break-in period.

Page 3

!>o èasu

Keep the machihe clean and well oiled

Adjust tensions, etc. properly

Use proper size needles

WHEN PURCHASING NEEDLES FOR THIS MACHINE,

Enjoyable Sewing

NEVER ATTEMPT TO USE A BENT NEEDLE,

NOR ONE WITH A BLUNT POINT

ASK FOR 15x1 NEEDLES ONLY.

Sizes and !

Grades of

Needles i

; 11

i

1 (Medium1 Fine)

14

(Medium)

16

(LightHeavy)

Ì8

Medium '

Hea^'y)

1

I Nylon and Plastics.

Medium light-weight and

summertime fabrics.

For house dresses, children's

dresses, washable cotton dress

es, aprons, curtains.

Dress silks and cottons, light

weight woolens, draperies,

fabric furnishings.

Fot general household sewing,

fine men’s shirts, smocks, win

dow draperies and fabric

decorations.

Heavy cretonne^ madras, mus

; lin, brocades and quilts. |

For men's work shirts, sturdy I

smocks and aprons, heavy i

guilting and fabric furnishings. I

Heavy woven coating, light ^

weight canvas, bed ticking,

upholstery and awning mate

rials, slip-cover fabrics.

: For work or sports uniforms,

suits made of strong linen or

• cotton fabrics, awnings, slip

covers and mattresses.

Heavy woven suiting, coating,

duck, ticking, drilling, canvas

and sacking.

For heavy washing uniforms,

bedding supplies for hospi

tals, hotels and camps.

Type of Fabric

and

Work to be Done

Cotton

^ 80

to

100

60

to

80

40

to

60

24

to

30

: ^

1

; E

1 Twist

Silk

0

Twist

k & %

Twist

C

Twist

SIZE OF THREAD ji

Lii

1

__ 60

Ì to

1 80

Ir. general «wing, use the same size thread is the bobbin as js used on top.

Page 4

to Set the J^ecdk

FLAT

SIDE

m

Raise needle to its highest point by turn

ing the balance wheel toward you by hand.

Loosen the needle-clamp screw on the

right hand side of the needle bar. Remove

the old needle, and slide new needle up

(FLAT SIDE TOWARD BALANCE

WHEEL) until it hits the stop. Then

tighten the needle-clamp screw securely.

For best results, change needles frequently.

WtaUec

.y-7*

m

WHEN SEWING, WINDING BOBBINS, or

CHANGING NEEDLES ALWAYS TURN

THE BALANCE WHEEL TOWARDS YOU

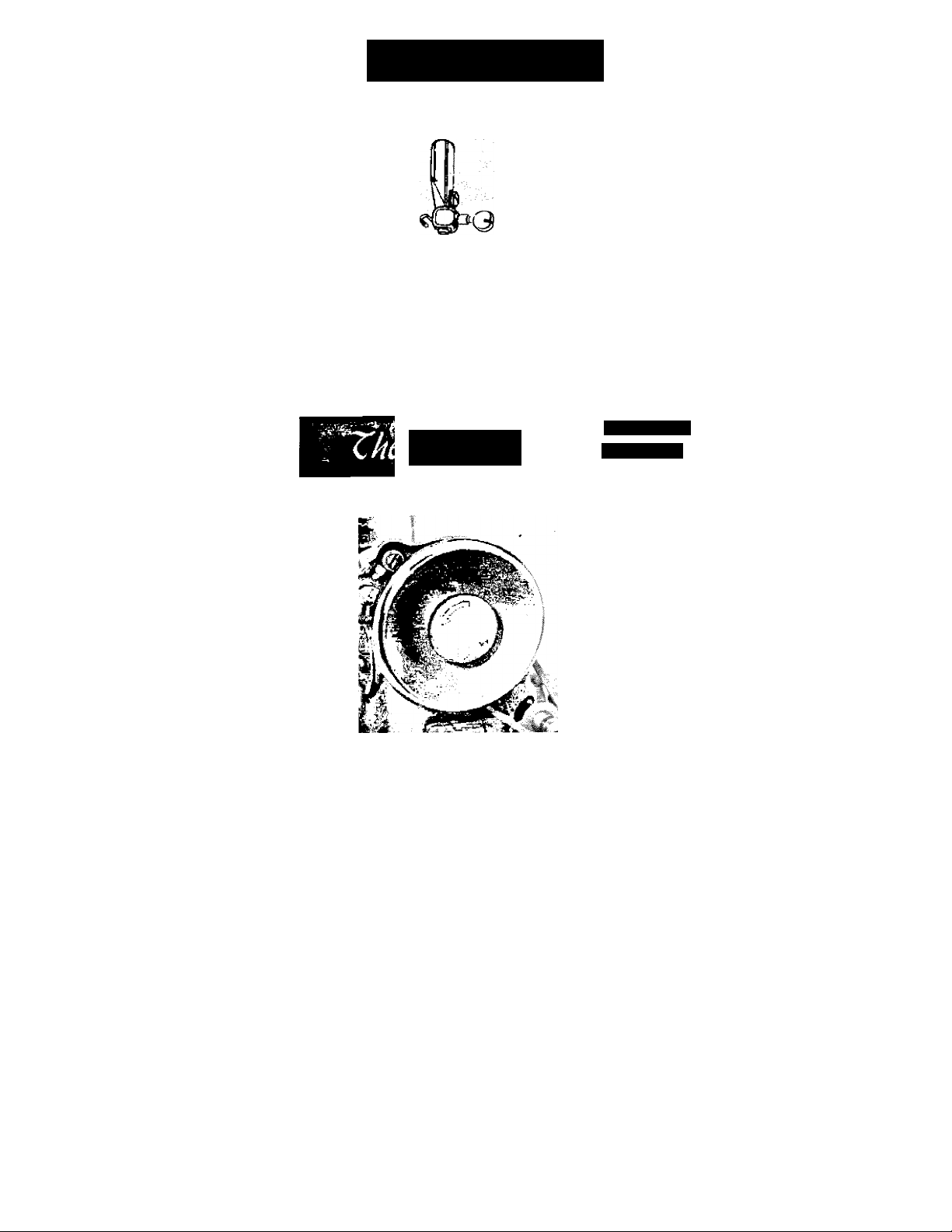

The balance wheel is provided with

a stop-motion device which allows the

balance wheel to run freely so that

bobbins may be wound without operat

ing the needle.

To loosen the wheel, hold it tightly

with the left hand, and with the right

hand, turn the stop-motion knob toward

you. See arrow.

To tighten the balance wheel, turn

stop-motion knob away from you.

Page 5

ii) Wind the Bobbin

First remove the bobbin case as Follows; Turn

the balance wheel toward you until the needle

bar is at its highest point. Hove the slide plate to

the left, and with two fingers grasp the hinged-

latch on the bobbin case and remove the case.

The bobbin will remain in the case as long as

you hold on to the hinged-latch. CloSe the latch

and the bobbin will fall out.

m

Loosen the balance wheel (as explained on Page 4.)

Place a spool of thread on the spool pin (A). Pass the thread through the tension

disc (B) at right corner of ti,e base of the machine. Wind the end of the thread

around an empty bobbin six or seven times and place the threaded Dobbin on the

spindle iC) of the bobbin winder. Press the bobbin onto the spindle making sure

that the PIN on the spindle fits into the SLOT in the bobbin winder. Push the bobbin

winder lever (D) down until the small.rubber wheel presses against the hub of the

balance wheeb and the clasp (E) falls between the sides of the boobin, holding it in

position.

Turn the balance wheel toward you, and press the knee control or Foot control (as

in sewing) to wind the bobbin completely. Run the machine slowly to wind the bobbin

evenly.

When the bobbin is full it will release automatically and come to a stop. Break off

the thread and remove the bobbin and reset the balance wheel for sewing.

Should the thread wind unevenly on the bobbin, adjust the tension discs (B) at the

bottom by loosening the screw and sliding the tension right or left as needed to chance

the tension.

Screw up the adjusting thumb screw (F) until the rubber ring gently touches the

balance wheeL

Note;—this machine uses standard 15 class bobbins—available at all sewing stores.

Page 6

ff- i.

Zh reading the Bobbin Case

Hold the bobbin case between the thumb and

forefinger of your left hand with the slot in the

edge facing up.

Hold the wound bobbin between the thumb and

two fingers of your right hand with the thread on

top leading away from you (see picture).

Insert the bobbin into the case, pull the thread

into the slot; then down under the spring, until it

enters the delivery eye.

i*»*'

ii?:-

(Be sure the needle is at its highest point.)

Hold the bobbin cose with your left hand

by the hinged-latch, with the metal finger

of the case pointing up and in line with the

notch at the top of the shuttle raceway.

Release the hinged-latch, and fitting the

centre of the bobbin over the center-pin

protruding from the racev./ay, press the bobbin

gently into position, being sure that the metal

finger fits into the notch of the raceway.

The 5 or 6 inches of thread hanging freely

from the case wii i be brought up later through

the hole in the centre of the ’needle plate.

Close the slide plate.

Page 7

Turn Balance Wheel

towards you until the

take-up lever is raised to

its highest point. Place

spool of thread on the

spool pin of the machine

arm ; pass thread over

and through the thread

guide Fig. 9 (A) at the

top corner of the face

plate, down and over the

back to front between

the tension-disc Fig. 9

(Bj up to thread guard

Fig. 9 (C), down into

the hook of take-up spr

ing Fig. 9 (D) and over

back to front through

hole in the end of the

thread take-up-lever Fig.

9 (E) down into the

eyelet of the face-plate,

Fig. 9 (F) into the lower }

wire-thread guide, Fig. 9

(G) Ihen from left to

FIGURE 9

right through eye of the

needle Fig. 9 (H j .

Draw about 2" of thread

through the eye of the

needle with which to commence sewing. Hold needle

thread in your left hand, turn balance wheal towards

you until needle moves up and down and up again to

its highest point, catching the bobbin thread, which will

be brought up that way through the hole in the thread

plate.

Page 8

Zo prepare for Sewing

Pick up the thread as follows : Holding

the loose end of the needle thread in your

left hand, turn the balance wheel toward

you by hand until the needle moves down

and up again to its highest point. Pull the

needle thread gently, and the bobbin thread

will come up with it in the form of a loop

through the needle hole. With your finger,

pull this loop until the end of the thread

appears. (If the bobbin thread does not rise,

check to see if at least 5 or 6 inches of

bobbin thread is hanging loosely from the

bobbin case.) Then draw both ends of the

thread back under the presser foot and

through the toes cf the presser foot.

Place the material to be sewn beneath

the presser foot, and lower the presser foot

lever. Insert needle into material by turning

the balance wheel toward you, from top

down, by hand. Regulate stitch to desired

size, and start sewing.

Do not trv to help the feeding of the

work by pulling the material, as this may

bend the needle and cause it to blunt or

break. As the machine feeds without any

assistance, it ir sufficient merely to guide

the fabric gently by hand in the direction

you want it to be sewn.

IT IS ADVISABLE TO TEST THE

TENSION AND THE STITCH LENGTH

ON TWO PLIES OF SCRAP MATERIAL

BEFORE STARTING TO SEW THE

ACTUAL GARMENT.

i c remove the work, stop the ma

chine with the needle at its highest

point ; raise the presser foot, and

draw the fabric back and to the left,

then pass the threads over the thread

cutter, and pul! down lightly to cut

them.

important

NOTICE

Never operate the

machine without

material under the

presser foot. If this

is not strictly ad

hered to, your ma

chine will lock, and

cannot be ope.ated

until the ra^d is

cleaned out of the

race.

Page 9

Kegulating the Stitch SormatioM^

For ordinary stitching; the tension on the upper and under threads should be equal,

and just sufficiently strong to lock both threads in the center of the work, as shown

above (A).

If the tension on the needle is too tight, or if that on the bobbin thread is too loose,

the needle thread will He straight along the upper surface of the material, thus mak

ing an imperfect stitch, as shown above (B).

If the tension of the bobbin thread is too tight, or if that on the needle is too loose,

the bobbin thread will be straight along the under side of the material, thus making

an Imperfect stitch, as shown above (C).

’ Regulating the Zension

A correct stitch can usually be obtained by

varying ^he tension on the needle thread.

AH adjustments should be made while the

presse” foot is down, since the automatic

release does not permit adjustments to be

made while the presser foot is up.

To increase the tension, turn the thumb nut

on the tension spring toward you. To lessen the

tension, turn the nut in the opposite direction.

The thumb nut should not be turned abruptly,

but regulated little by little, until the desired

tension is obtained.

The quality of sewing depends on the thread.

Hence, it is necessary for the user to become

fully familiar with the correct tensions, through

practice.

Page 10

CO Uegiilalc the jCeagth of thc^Stitchm^:^

r'|‘.

'To regulate length of

stitch, loosen thumb-screw

"A” and move it to the

bottom of the curved slot.

Now move stitch regulat

or lever “B” until its top

side is in line with the

number indicating the se

lected length of stitch.

Move thumb-screw “A”

until the regulator plate

touches the lever ”B”,

then tighten thumb-screw

"A”.

rf

Xo Reverse Sew

Loosen the thumb-screw "A” and move lever "B" above center line

towards position "R”.

can now adjust for desired reverse stitch. Tighten thumb-screw

A , so that it will lock the stitch. The machine will now sew in reverse.

NEVER SEW OR USE THE MACHINE with the Lever in

the NEUTRAL position.

To ADJUST THE BOBBIN TENSION.

All sewing machines are correctly adjusted before leaving the factory, and it is

therefore seldom necessary to alter the bobbin tension. '

Should it become necessaiy to do so, however, due to using certain hinds of materials,

the adjusting screw in the tension spring on the outside of the bobbin case can be

tightened so as to increase the tension, or loosened slightly in order to lessen the tension.

10

i

Page 11

m

ir

aa

This machine is fitted with both a dropfeed mechanism and a built-in darning de

vice which will enable you to darn, sew rips

and patches and Jo embroidery and applique

work.

TO WORK THE DROP-FEED, simply

turn the drop-feed button (at the right

bottom of the machine) to the right until

it stops—a quarter-turn. The feed dog is

then out of the way. For regular sewing

turn the button bock to its normal positio.'i.

It is adv isable that you practice carefully on scrap material before at

tempting any major repair so tliat you will learn to control the stitching

evenly. Be sure to keep the material constantly moving by pressure of

your fingers inasmuch as permitting the cloth to remairi in one place while

sewing may cause your thread to breaK.

Upon completion of your use of the Darner, simply press the device

down to its normal position. Also turn the drop-feed button hack to

regular sewing.

9or Darning and Smbraidcry^»

TO WORK THE BUILT-IN DARNER.

Place a finger of your left hand on the

mushroom-shaped cap (to cushion the sud

den rise of this cap when it is released).

Release this cap by pressing the Lever

(to which the other finge' is pointing)

with your right hand. Allow the cap to

rise all the way slowly.

Remove the presser foot, lower the

presser foot levar (to put the automatic

tension release out of operation) and you

are ready to darn or embroider.

Large repairs, fine materials, embroidery

and applique are best done with a hoop.

TO REGULATE PRESSURE OF THE PRESSER FOOT IN REGULAR SEWING’

Always maintain only enough pressure to keep the cloth moving and to permit the machine

to make a straight seam. When the cloth does not feed through the machine properly,

there may be too much pressure of the presser foot. Adjust by raising the darning

device a bit. Test this adjustment before sewing. If you wish, you can adjust the

machine for sewing heavier fabrics by adjusting the Drop-Feed instead.

11

Page 12

Use only a good grade of oil.

Inferior oils may cause the machine

to become sluggish.

Use only oil whose label spec

ifies “for Sewing Machines.”

If your machine is used continuously, it should be oiled every day ;

preferably when you are done using the machine for the day. If not

in constant use, oil the machine before using.

Use ONE drop of oil on bearings, and wherever one part rubs against

another, or turns within another part.

Some such parts are visible to the eye. Others are hidden inside tfie

castings. Hence look for all oil holes in the casting as indicated by arrows

in the picture. Insert the oil can nozzle well into the oil hole.

Before oiling the oil hole to the RIGHT of the spool-pin on top of the

machine, turn the balance wheel until the needle is DOWN at its lowest

point, and look into the oil hole to see that the oil receptacle on the shaft

is in position.

Also remove the face plate by loosening the screw near the top and

lifting the face plate up and off. Turn the balance wheel slowly by

hand and watch the mechanism under the face plate to see which parts

move and require oil.

o

u

Next, put three drops of oil in the bobbin raceway after the race has

been removed as described at the top of page 12.

The machine is also to be oiled from the back. Loosen the screw hold

ing the metal plate, move the plate out of the way, and tighten the screw

to hold it there. Turn the balance wheel slowly in order to see which

parts move and require oil.

Page 13

Lint, du5t and threads collecting In th»

machine will cause it to bacome alugglsh.

To dean th* machine^ first diBConnect the

alectric cord. Then remeve the needle,

presser foot, slide plate, and throat plate.

Also remove the bobbin ai>d bobbin cose

Brush the exposed parts thoroughly. I^e-

mova any packed lint with a toothpick*

Clean the inside oF the bobbin cast and

under the spring. Also dean th* raceway

as Instructed on Page 12. (Leave the ma

chine In this condition For oiling.)

Hte MACE ?N

p—.

Then tilt the machine back, and again turn the balance wheel slowly

to locate the bearings and ether movir.g parts. Here, too, you will find

some oil holes in the castings.

Wipe away all excess oil from ell parts cf the machine. Connect and

run the machine rapidly for a minute to allow the oil to penetrate into

the bearings.

Also sew some scrap material to be sure that no oil will dnp from

the needle bar on to your material.

13

Page 14

1. Turn the balance wheel by hand until needle is at its highest point.

2. Remove bobbin and bobbin case.

3. Turn knob (A) one ha!f turn toward you.

4. Turn knob ;B) one half turn away from you.

5. Remove retaining (C;, and hook (D) by grasping axle of hook 'D).

6. Remove accumulated lint and thread from retaining ring, hook and

race body.

7. Replace hook !,D.' m race body, with axle facing out, forming a

perfect circle with Driver E..

8. Replace retaining ring (C), polished side out, so that both grooves

are under knobs (A) and B).

9 LOCK retaing ring with knobs (A) and (Bj.

10. Replace bobbin and bobbin cace, and commence sewing.

DO NOT ATTEMPT TO FORCE ANY OF

THE ABOVE OPERATIONS.

14

Page 15

S?S?

^5H5E5S5S25Z51^S252S2S^iESH5£5^2STSZS2S25?ll

|pa j

This is to certify thac the sewing ma

chine listed on Slip Number dated

for twenty years for family sewing. Only

the best materials and the most skilled

labor enters into the construction of this

machine. Any part found defective and

returned, (transportation charges prepaid),

within twenty years from date shown

above, will be replaced, free of charge,

by the authorized sewing machine Dealer

named below, or affiliated branches.

The motor is guaranteed for one year.

Any motor proving defective will be re

placed, free of charge, if returned, (trans

portation charges prepaid), within one

year of the date shown above.

This guarantee is binding on all parts of

the machine, except bobbin case, bobbins,

needles, bulbs, cords and rheostat controls.

AUTHORIZED

SEWING MACHINE DEALER

by

•an t^ p

is hereby guaranteed

- - -

tfc!SZSKeS?SJSSS2S2SHSESESlSESZES|SKSS2S;^-2KgS='S

. ii-iA „

V"’

15

Page 16

SKIPPED STITCHES. May be caused by a bent or blunt

needle; or by incorrect setting the needle; or the wrong

size needle; or by a thread too heavy Рог the size of the

needle.

SEE THAT THE PRESSER TOOT is snug against the presser

bar and securely clamped by the screw so that the needle

will pass through the opening in the foot without any

interference,

BREAKIN6 NEEDLES. Usually due to pulling on the work,

causing the needle to get out of line and strike the throat

plate, thus breaking or bending the needle. May be due to

presser foot or attachments not being securely fastened to

presser bar. Be sure to use correct size needle and thread

for material.

BREAKINB THE UPPER THREAD. May be caused by:

(]) Incorrect threading.

(?) Not bringing up under thread correctly.

(3) Upper tension too tight.

(4) Needle imperfect, or set incorrectly.

(5) Needle rubbing against attachments or presser foot.

(6) Needle eye too small for thread.

(7) Starting the machine at full speed.

(8) Starting without take-up lever at highest point.

BREAKINB THE LOWER THREAD. May be caused by:

(1) Incorrect threading of bobbin case.

(2) Too tight a tension.

(3) Bobbin wound too full to revolve freely.

(4) Not bringing up under thread correctly.

(5) Mole -n the needle plate rough, caused by needle

striking the plate.

(6) Dust or lint in bobbin.

UNEVEN STITCHES. May be caused by :

Presser foot not resting evenly on material.

Feed not high enough.

Too short a stitch.

(3)

Pulling the cloth.

^4)

Too fine a needle with too coarse or poor a thread.

(5)

Distributed by

Printed in Tannn

Loading...

Loading...