SINGER W130 User Manual

Hc»w^ То^-

, •*;, *,►■■►—, 441*'. К,'

Zigzag Sewing Machine

¡i 1Й->'i.*v. ••■• ■ 1 • ':*5» •••’■• -•îÿ’-'Vÿ» ^, '¿-r*'

л> • u . t ■ ^ Î-'

....................

.....

. M: \ MODEL 130

r *TT—• * « V*

CONTENTS

MACHINE A.ND FEATURES.........(Front)

BELT ADJUSTMENT

...................................................................

REPLACING NEEDLE ..................................................................

RE.MOVING BOBBIN CASE .......................................................

WINDING BOBBIN .......................................................................

ADJUSTING BOBBIN WINDER ..................................................

THREADING BOBBIN CASE

......................................................

REPLACING BOBBIN CASE .......................................................

THREADING MACHINE

PREPARING TO SEW

..............................................................

..................................................................

ADJUSTING UPPER THREAD TENSION ..................................

ADJUSTING BOBBIN THREAD TENSION

13

ADJUSTING FABRIC FEEDERS

14

ADJUSTING PRESSURE OF THE PRESSER FOOT

15

REGULATING STITCH LENGTH

16

ZIG Z.AG SEWING

.................................................

Regulating Width of Stitch

Locking Zig Zag Regulating Lever

Making Patterns

.....................................................

CLEANING SHUTTLE AND RACE ASSEMBLY .'

18.

OILING MACHINE ........................................................................

BUILT IN LIGHT

19,

ACCESSORIES ..............................................................................

20.

.......................................................................

A. Needle Plate & Presser Foot for Straight Sewing

B. Cloth Guide ...............................................................................

C. Zipper Foot ................................................................................

D. Buttonhole Foot .........................................................................

21

BLIND HEMMING .........................................................................

nn

APPLIQUEING

23

EMBROIDERING AND MONOGRAMMING ............................

25

SEWING ON BUTTONS

26

NEEDLE SIZES ....................................................................

27

CAUSES OF COMMON DIFFICULTIES ...........................

28

MEMO ...............................

..............................................................

.....................................................

...............

..................................

(Back)

................................

................................

..............................................

..............................................

.................................

.................

13 &

....................

.....................

.

Pase

j>

"i

o

4

5

5

6

6

9

9

10

14

15

16

..

16

17

18

18

18

19

20

20

21

22

3&

24

25

26

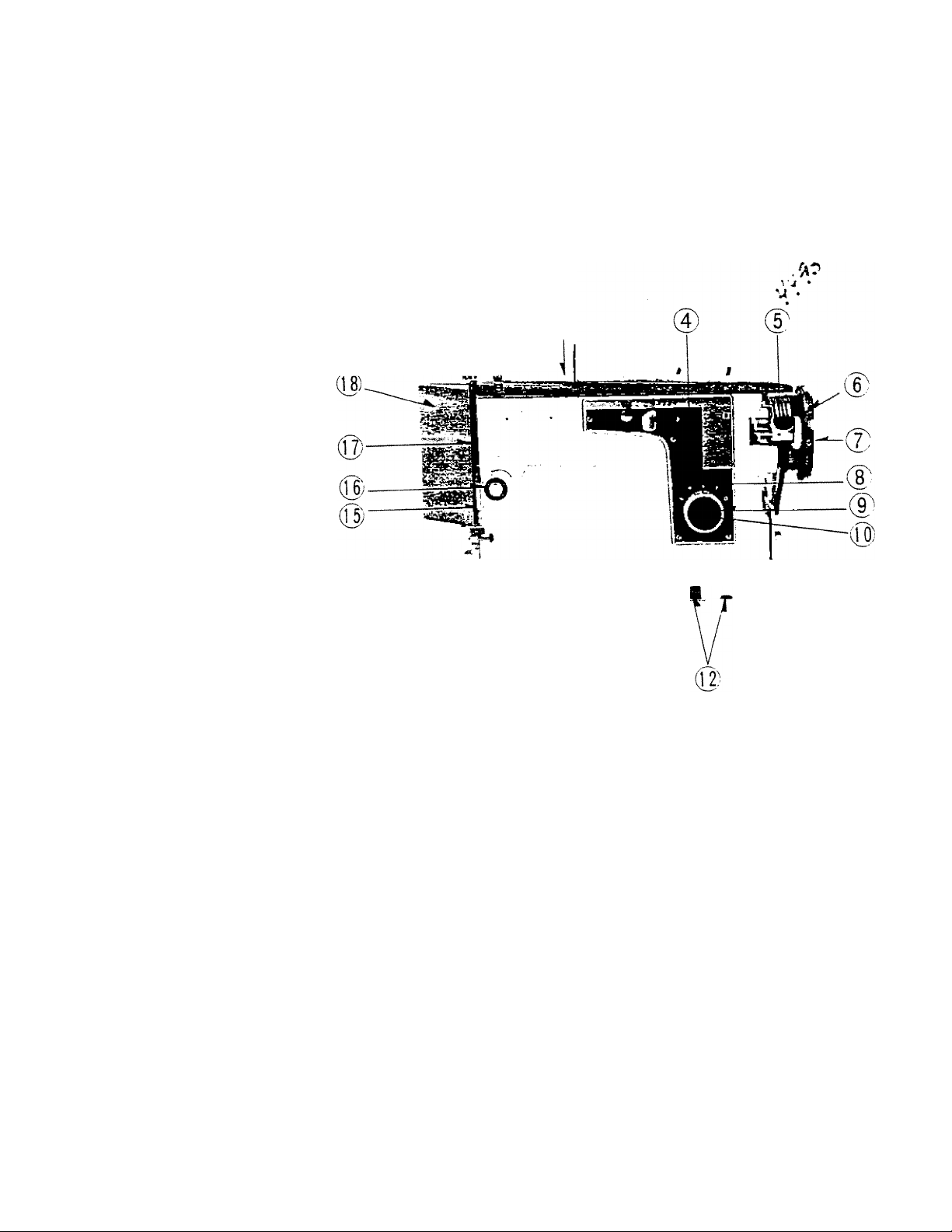

1. MA CH I NE A ND F EA TU RE S

®(D (D

U

•M-v

0 ®

Fic. 1

FRONT

Pressure release (darning)

1.

2.

Thread guide for top cover

Top cover 12.

3.

Zigzag indicator

4,

Bobbin winder

5.

Fly wheel

6.

Clutch nut

7.

Stitch length indicator

8.

Stitch length control dial

9.

10.

Reverse button

Bobbin winder tension

11.

Drop feed buttons

Needle plate

13.

Cover plate (Slide plate

14.

Thread guide

15.

Tension

16.

Take up

17.

Face plate

18.

Fig. 2

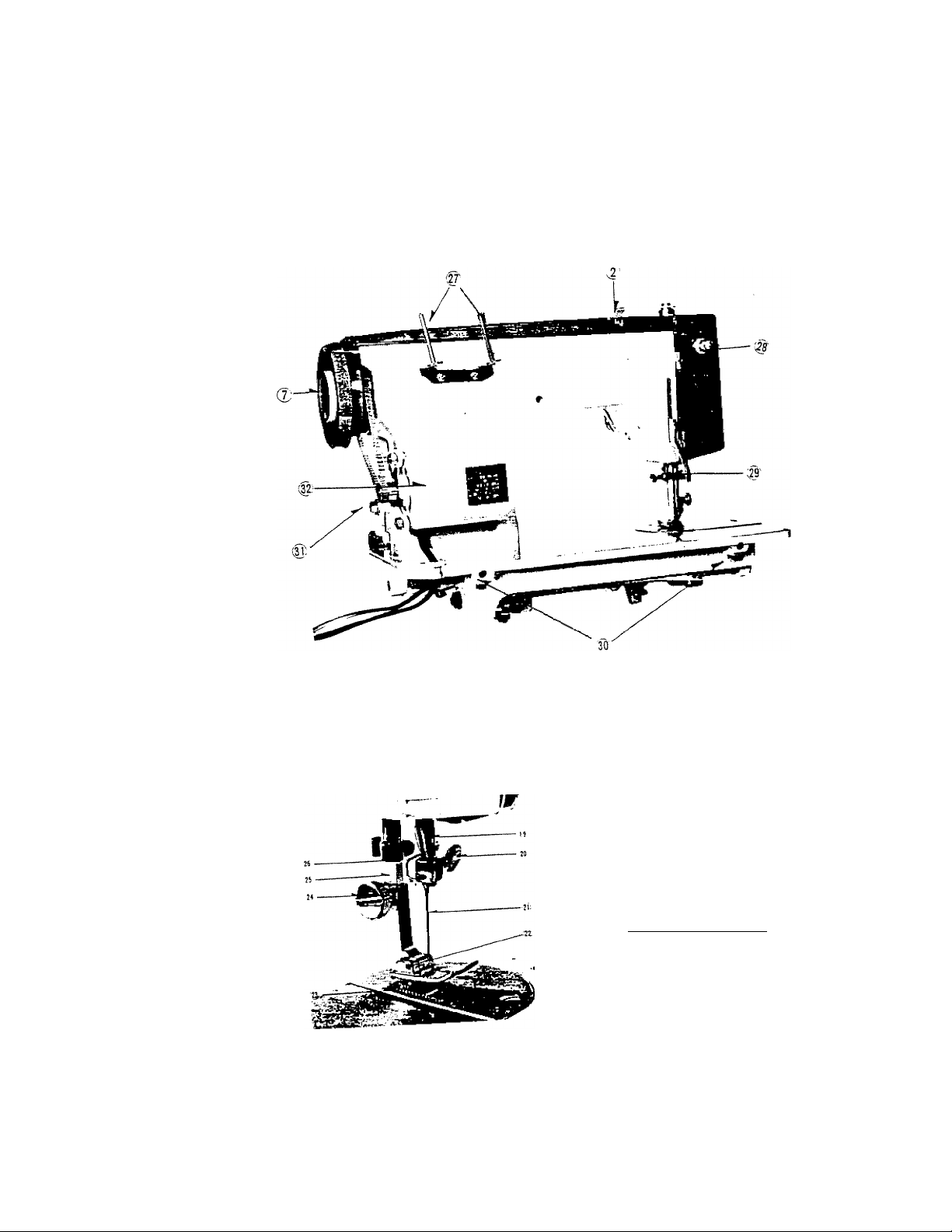

Fig. 3

Fie.

19. Needle bar

20- Needle clamp

21. Needle

22. Presser foot

23. Fabric feeders

24. Presser fool clamp screw

25. Presser bar

26. Thread cutter

RACK (Fig. 3)

27. Spool pins

28. Li#U switch

29. Presser bar lifter

30. Head hinge mounting holes

31. Motor set screw

32. Motor

___

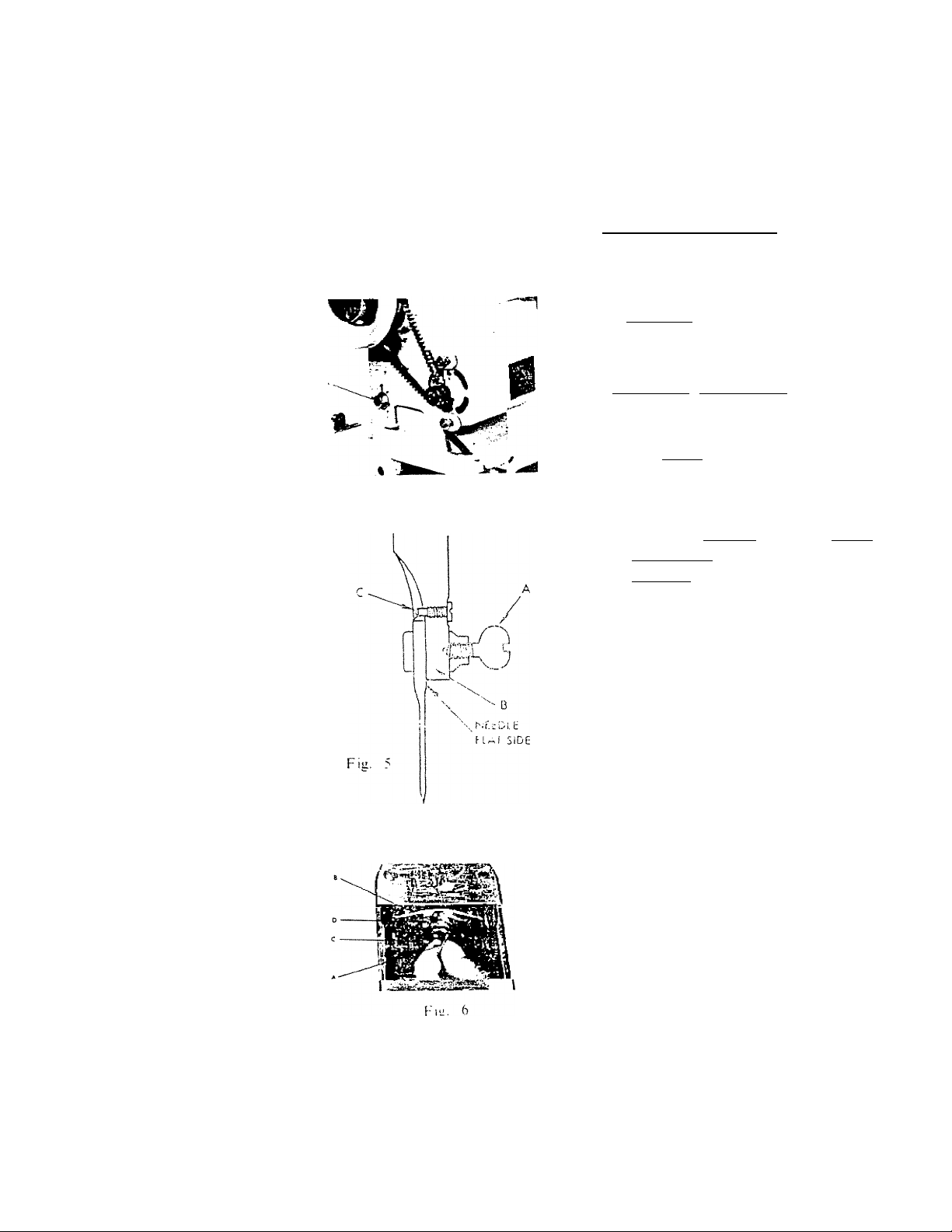

Fia. 4

2. BE LT A DJ US T ME NT

Loosen motor bracket screw (A).

Slide motor bracket down to tighten

- up to loosen.

CAUTION : Do not tighten belt

too tight.

3. RE PL AC IN 8 N EE DL E

1. Raise the needle bar to its highest

position. (Turn the fly wheel by

hand toward you.)

2. Loosen needle clamp screw (A) and

remove old needle.

3. Insert the needle into needle bar (B)

with the flat side of the needle toward

the fly wheel.

C.AUTION ; Be sure the needle is

all the way up. It should rest against

the needle stop pin (C).

4. Tighten the needle clamp screw se

curely with screw driver.

C.AUTION ; Check needle and make

sure it is not bent or dull.

4

. m]mm

Raise ihe needle bar to its highest

position. (Turn the fly wheel toward

you b}' hand.)

thumb and forefinger, open the latch

(A) of the bobbin case (B).

Remove bobbin case from the spindle

post (C). (Pull to the left.)

NOTE : With the latch held open,'

the biihbin is locked inside the

bobbin case. To remove bobbin from

the bobbin case, release the latch.

b ob bi n c as e

Open slide plate. With the left

Fig. 8

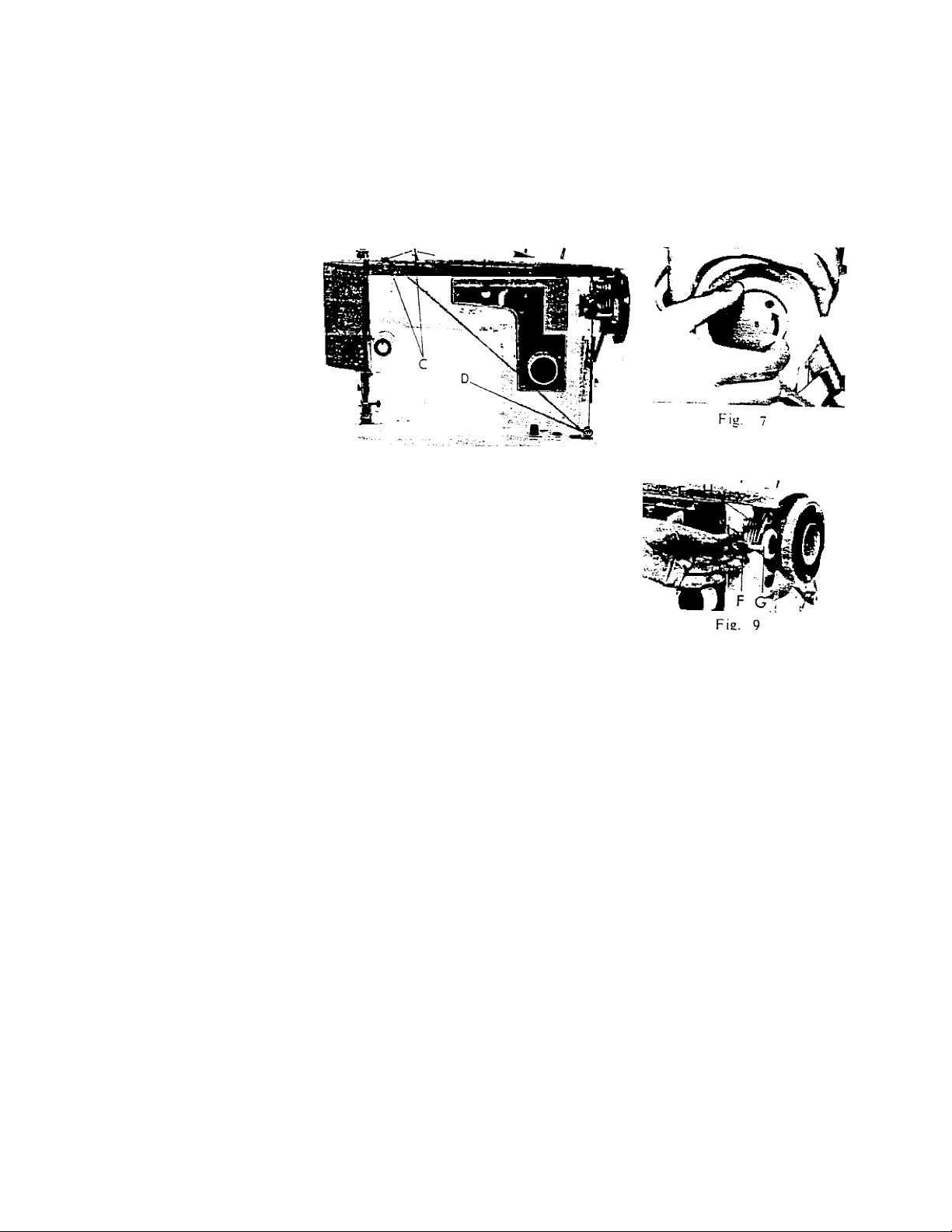

5. W IN DI NG B OB BI N

1. Hold the fly wheel (A) Fig. 7 with the left

hand and turn the cluch (B) Fig. 7 toward

you to release the clutch. By doing this, the

fly wheel turns freely.

note : If the needle moves, the dutch is

not completely released.

2. Place thread on the spool pm and guide the thread through the upper thread

guide (C) Fig. 8. Then bring the thread across the machine and under the

bobbin winder thread guide (D) Fig. 8.

3. Wind the thread several times on the bobbin (E) Fig. 9. Now place the bobbin

on the spindle (F) Fig. 9 of the bobbin winder.

I^OTE : The lock spring on the spindle must fit into the slot in the bobbir

This IS done by holding the rubber ring (G) Fig. 9. with the right hand and

turning the bobbin with the left hand until the lock spring slips into the slot

ot the bobbin.

4. Pu.sh the cover fH) Fig. 9. of the bobbin winder down until the rubber ring

(G) Fig. 9 is brought in contact with the fly wheel.

5. Turn the fly wheel slowly, tov^ you; then operate the machine as in sewing

when the bobbin is full, it will stop,

6. Remove the bobbin from the spindle, then reengage the machine by holding

e fly wheel with the left hand and with the right hand turn the clutch away

irom you.

NOTE : Make sure you tighten firmly.

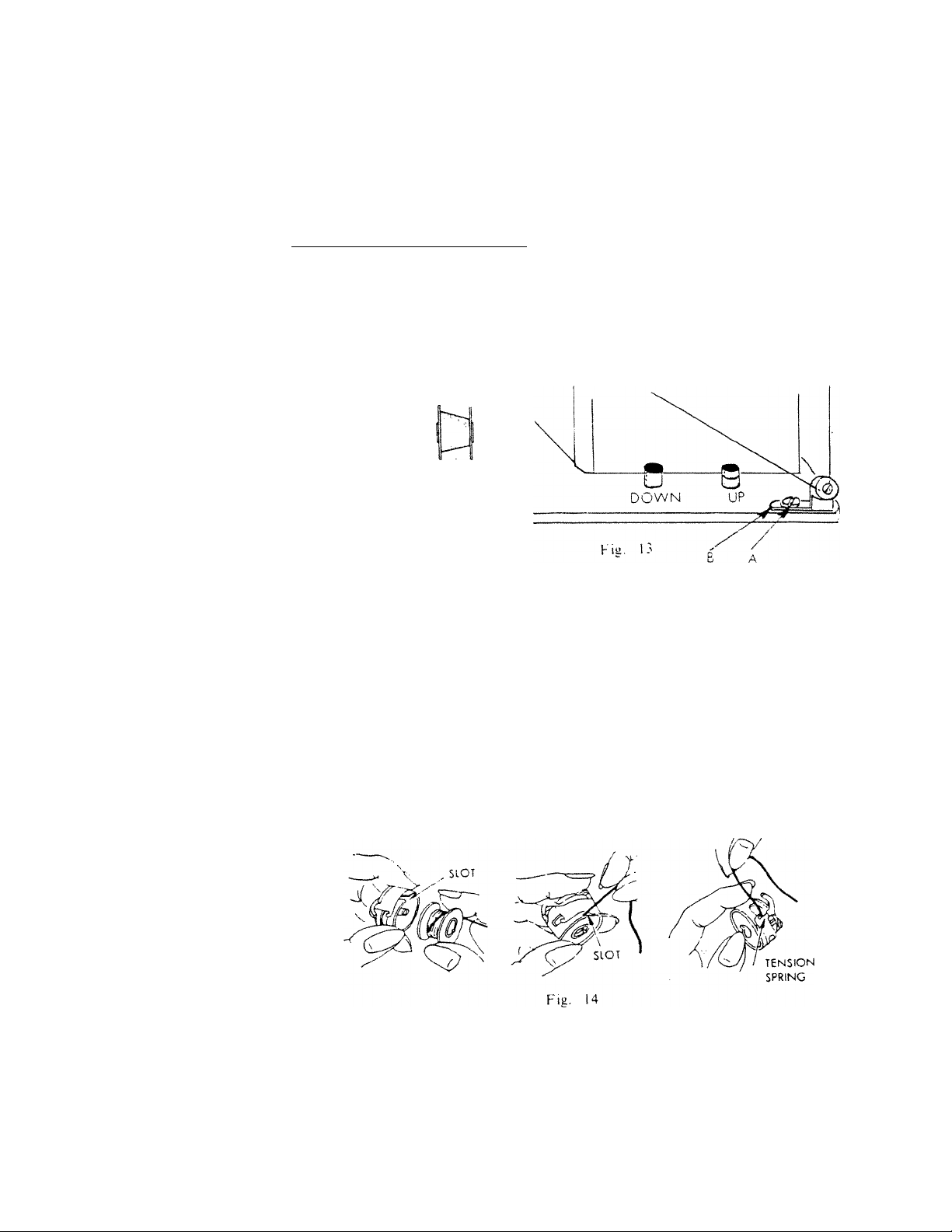

6. ftP iU ST IN G B OB BI N WI ND ER ,

1. If the thread winds unevenly on the bobbin as'shovvn in Fig. 11 and 12, loosen

screw (A) Fig. 13 and adjust the bobbin winder thread guide bracket (B) Fig. 13.

2. If the thread winds as in Fig. 11, move the bracket slightly to the left. If the

thread winds as in Fig. 12, move the bracket slightly to the right.

Fig. JO Fig. 11 Fig. 12

?. T HR EA D IN G BO BB IN C AS E

1. Hold the bobbin case between the left thumb and forefinger with the slot up.

With 5 or 6 inches of thread trailing in the palm, hold the bobbin between

the thumb and first two fingers of right hand.

2. Insert the bobbin into the bobbin case, then pull the trailing thread into the

slot, up to the loft until it enters the delivery eye under the tension spring.

There should be a slight tension on the thread as it pulls through the delivery eye.

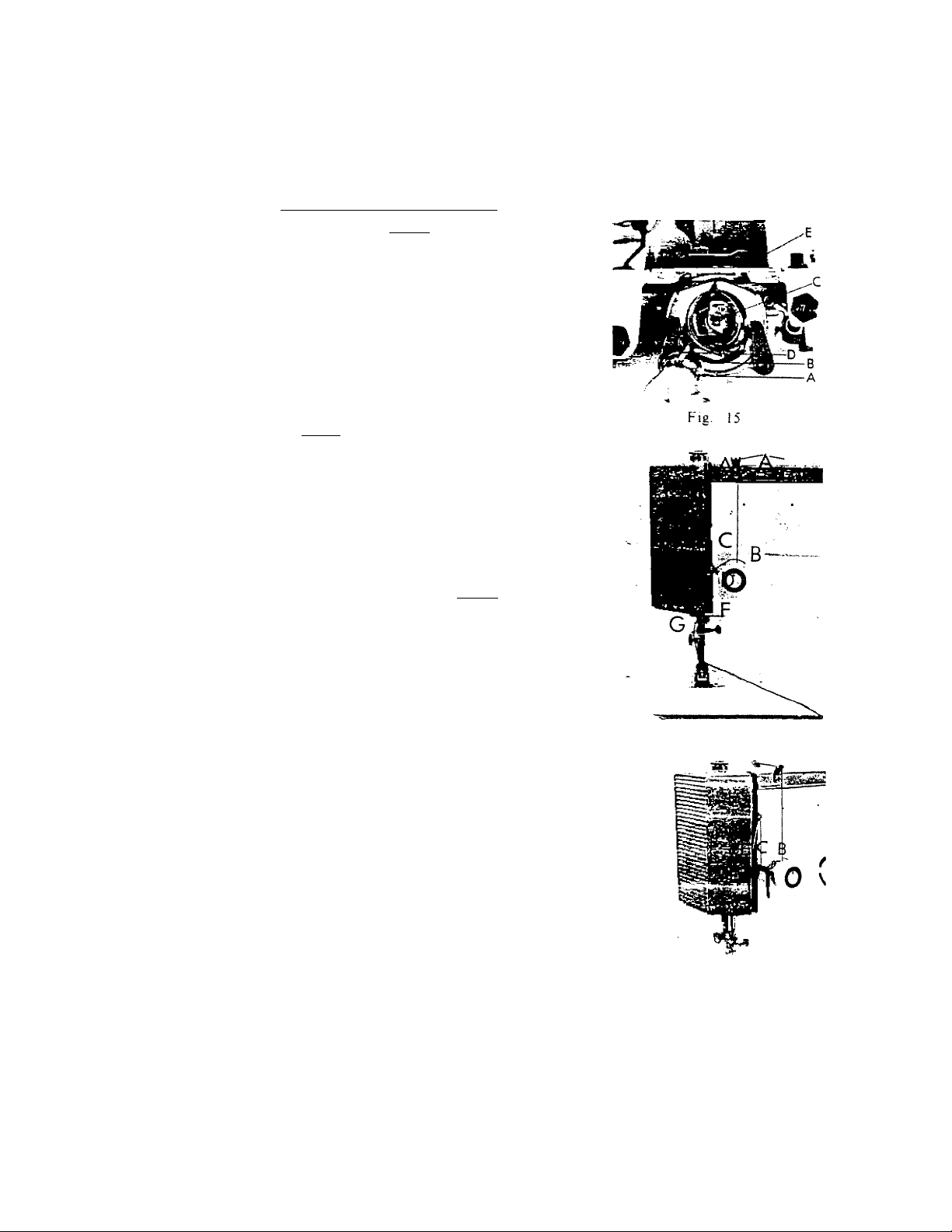

8. RE PL AC IN G BO BB IN CA SE

1. Turn fly wheel toward you by hand

until the needle bar is at its highest •

position, and open the slide plate.

Draw about 3 inches of thread from

the bobbin and let it hang loosely

from the bobbin case.

2. With the left thumb and forefinger,

hold the latch (A) of tlie bobbin case

(B) and place it on the spindle post

(C) . (Fig. 6)

NOTE : The protruding finger (D)

must slide into the delivery eye (E)

at the top of the shuttle.

3. Release the latch and press the bobbin

case to the right until it catches the

groove on the spindle post.

9. THREADING MACHINE

1. Turn the fly wheel toward you and

raise the take up lever (E) to its highest

position. Place thread on the spool pin

and bring the thread through the upper

thread guide (A).

2. Bring the thread down through the

thread guide to the tension disc (B)

from right to left and up. Then pull

the thread up through the thread take

up spring (C).

3. Bring the thread under the thread

tension guide (D) and thread the take

up lever (E) from right to left.

4. Bring thread down througli the thread

guide (F) at the opening in the face

plate, and through the needle bar

thread guide (G) from behind. Thread

the needle from left to right, leaving

about 5 or 6 inches of thread.

Fig. 16

F ig. 17

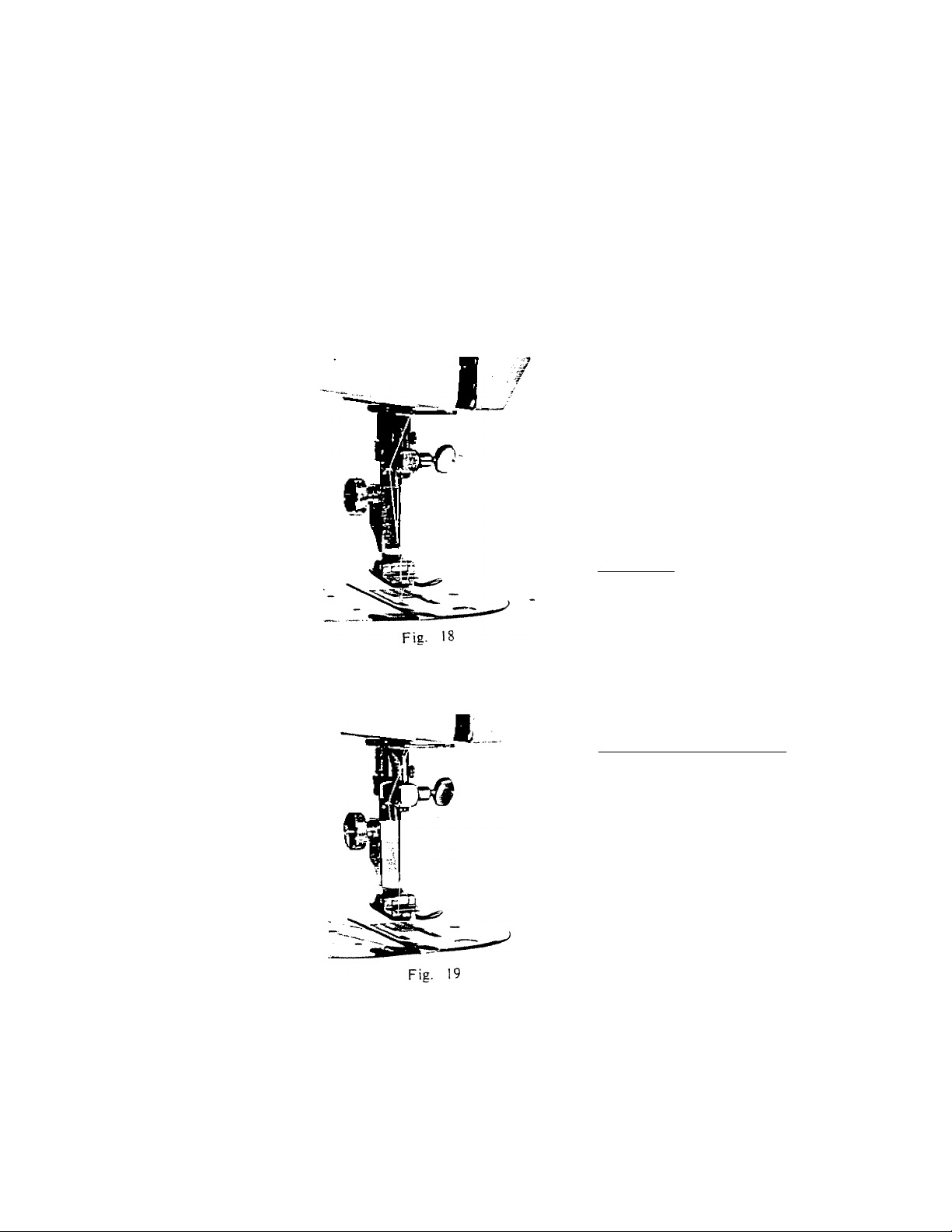

10 . P R EP AB iN G TO S EW

1. Hold the loose end of the needle thread

in your left hand, and turn the tly

wheel toward you by hand until the

needle moves down through the needle

plate and up again to its highest position.

Pull the needle thread gently, and the

bobbin thread will come up with it

through the hole in the needle plate.

Then place both ends of the thread

back between the toes of the presser foot.

NOTE : It the bobbin thread does

not rise, check to see if there is at

least 3 or 4 inches of bobbin thread

hanging loosely from the bobbin case.

2. Pull the two threads at least 5 inches

behind the presser foot. Place material

under presser foot, and lower the foot

with the presser bar lifter. Regulate

the stitch to the desired size and sew.

TO REMOVE MATERIAL, raise the

needle to its highest position and raise

the foot with the presser bar lifter, then

pul! the fabric back and to the left.

Cut the thread with the thread cuitcr

behind presser bar, leaving a few indies

of thread behind the presser foot.

Loading...

Loading...