SINGER W1266 User Manual

^ ' í'i •r-.’":.cjL:-L : . - nr^- • - ,*, •

' ÍC. . .-■>'i. - . ‘. :,. Г-- ‘;’'

^■£

: ; '■ ■ f 'Ж->

■ ■■.■ :■ ¿ ;-Iti-- b'■■: ' f ^ ,r '. '^;-‘

f rí^v-Síá'-' '

‘ ''b

I 1 ' ' '1

<i <> O

' .1,' .- - -’’ -il-'^,;' .-U/S r'í.í * É

• <- ,’ ■-- ■■ '^iirbh

^ ' _^. ---..'¿Л'¿ít' ' •

ч=¥г^:

-i

' -А’Ч-

I’’-'”' i 'ifii и

, S' '

INDEX

Accessories

How to Use

Hemmers

Seam Gauge or Cloth Guide

Quilting Guide

Attachments

Adjustable Cord and Zipper Foot

Attachment Foot

Binder

Edgestitcher

Hemmers

Rüffler

Blind Hem

Bobbin

Placing in Shuttle

Threading

Winding

Buttonholes

Bound

Buttons Sew - On

Charts

Needle-Thread-Fabric-Stitching 4

Stitch Length 9

Trouble 30-31-32.

Pages

23

24

25

26

26

34

40

35

37

35

38

42

16

7

6

5

20

47

22

Pages

Darning and Mending 11

Embroidery

Creative 18

Hoop 19

Features and Parts (Front View) 2

(Back View) 3

Installation - Head in Cabinet 50

Head in Portable case 48

Maintenance and Care 27

Cleaning and Oiling the Shuttle 28

Needle Setting ' 6

Pressure and Feeding of Fabric 11

Thin and Lightweight Fabrics 11

Reverse Sewing 9

Sewing Preparation 12

Sewing Tips 44

Straight Stitching 13

Tension Adjustment 10

Threading-Upper 8

J

м.

Thread Take-up Laver

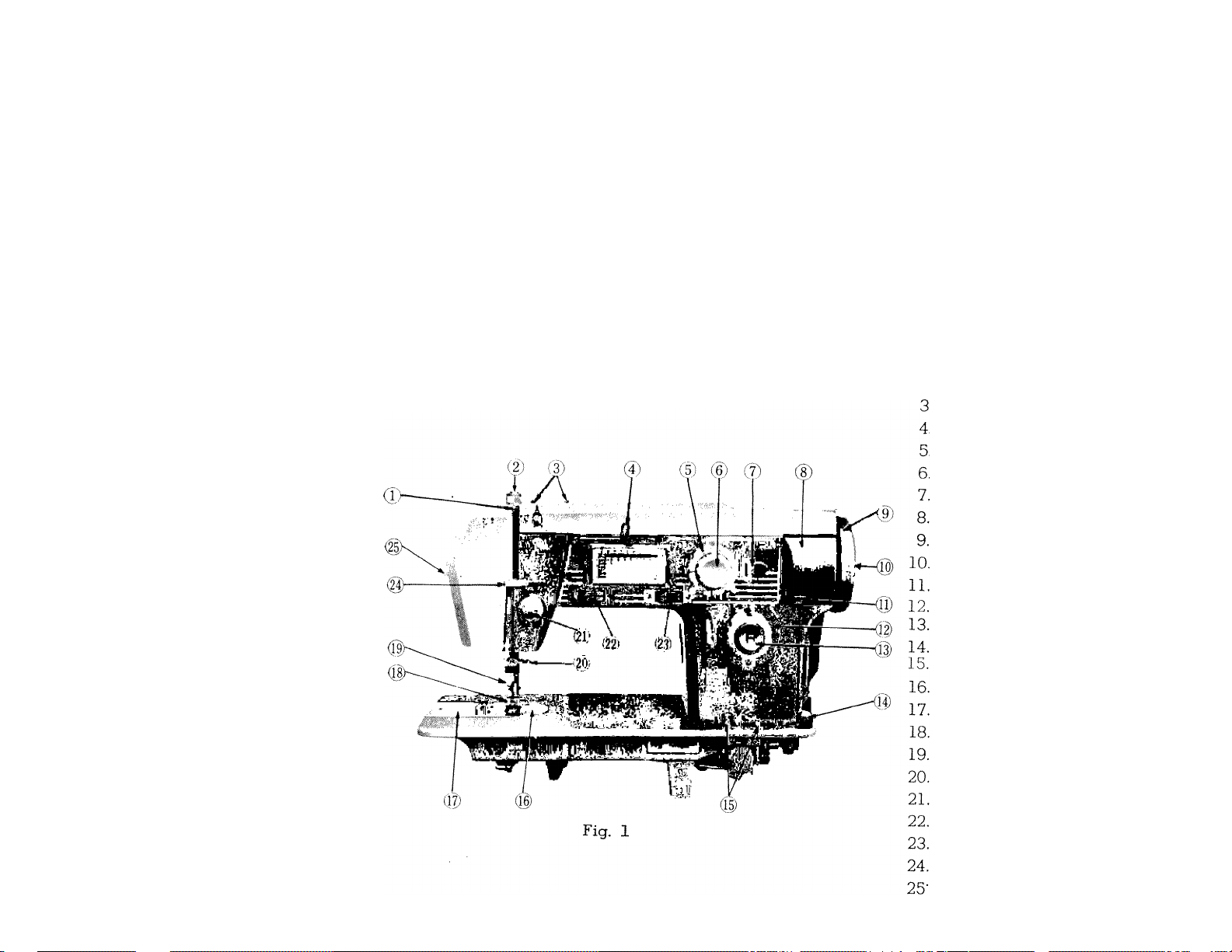

FEATURES AND PARTS

(Front View)

■

Pressure. Release

(Darning)

Arm Thread Guides.

Mechanism Releasing Lever.

Buttonhole Control Knob.

Zigzag Width Control Knob

Zigzag Stitch Width Stop

Bobbin Winder Cover Door

Hand Wheel

Clutch

Cover Release Button

Stitch Length Control

Push Button Reverse

Bobbin Winding Tension

Drop Feed Buttons

Needle Plate

Cover Plate

Presser Foot

Presser Foot Thumb Screw

Needle Clamp

Tension

Pattern Selector Control 1 to 8

Pattern Selector Control A to J

Thread Bar and Face Latch

Sew Lite Switch

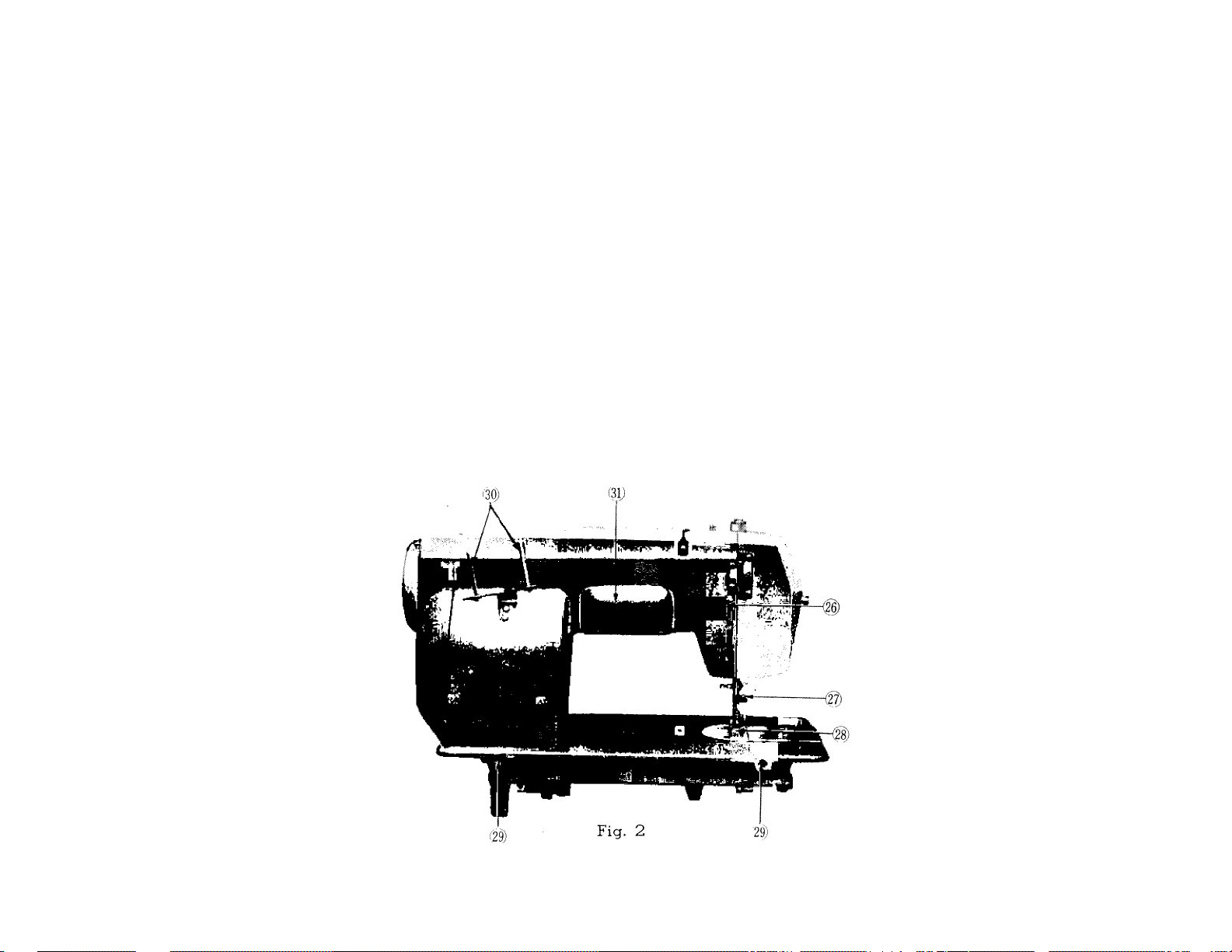

FEATURES AND PARTS

(Back View)

Presser Bar Lifter

26.

Thread Cutter

27.

Feed

28.

29.

Head Hinge Mounting

Holes

30.

Spool Pins

31.

Handle

NEEDLE - THREAD - FABRIC - STITCHING GUIDE

Fabric

Extremely heavy

tarpaulin, sacking,

canvas, duck, etc.

Heavy upholstery

fabric, ticking,

denim, leatherette

Medium heavy drapery

fabric, velveteen,

suiting, felt, terry, etc.

Medium broadcloth.

percale, gingham, linen.

chintz, taffeta, sheer

wool, shantung, etc.

Sheer voile, lawn.

dimity, crepe.

handkerchief linen.

plastic film, etc.

Very sheer chiffon.

batiste, lace, organdy.

ninon, net, marquisett, etc.

Needle

No.

4

3

1

0

00

Machine

Stitches

Per Inch

6

to

8

8

to

10

10

to

12

12

to

14

14

to

16

(Plastic film)

8 to 10

16

to

20

Cotton

Thread

10

to

30

30

to

40

40

to

60

60

to

80

80

to

lOO

100

tc

150

Mercerized

Thread

Heavy Duty

Heavy Duty

Heavy Duty

50

50

50

Silk

or

Nylon

A

A

A

/1, 3

^^■=9515*

Fig. 3

Fig. 4

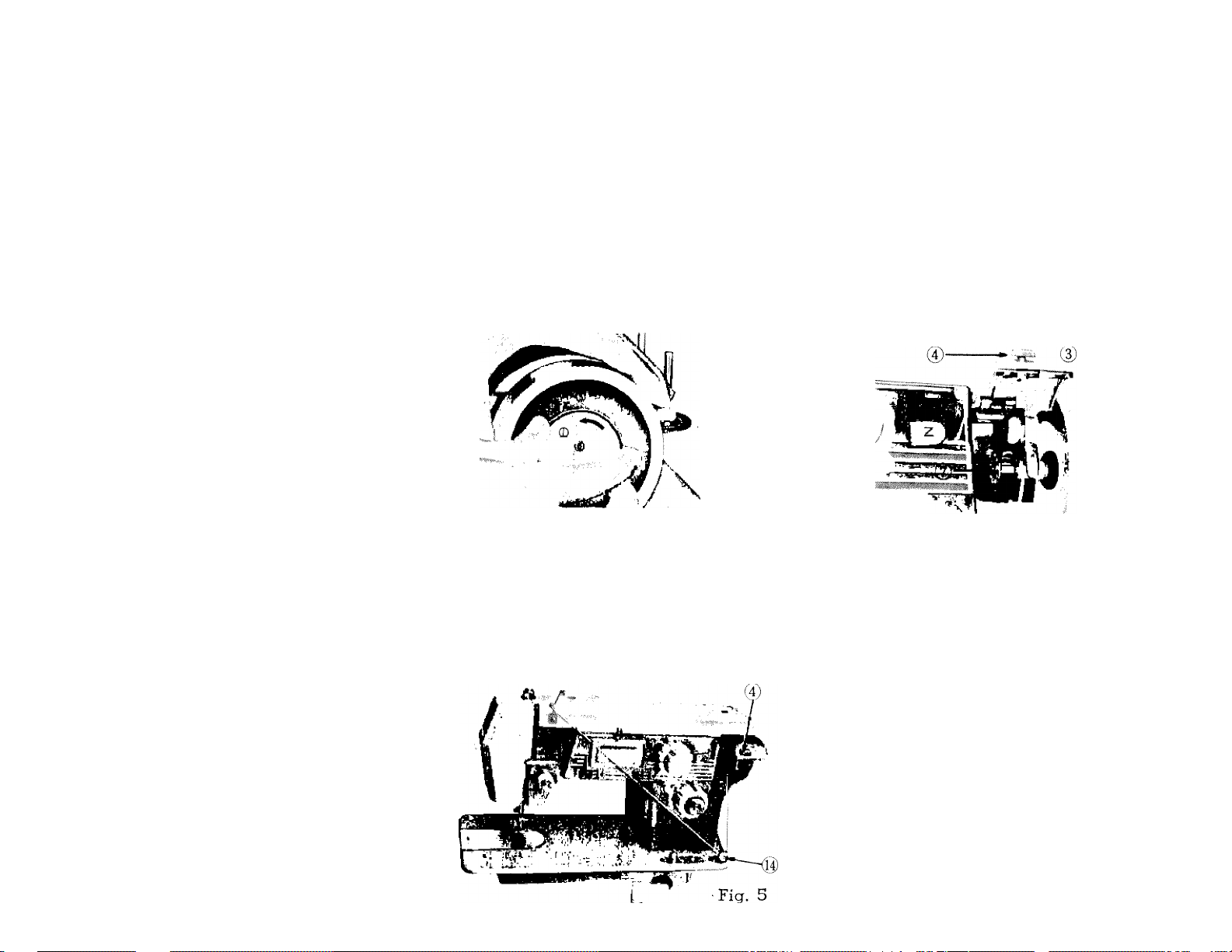

WINDING THE BOBBIN

yo„°rc”„''u^Lr'‘otciw!si.'^ ^ by turning clutch 6 toward

“Slide latch 4 to the right (Fig. 4) to spring open cover 3 of the recessed winder”

Place a yool of thread on one of the spool pins, lead thread through the upper thread guide

on arm and down through terision disc 14 Fig. 5 at base of machine. Run end of thread throuS

a hole in bobbin edge < left flange and from inside out) and place bobbin B on spindle of bobbin

winder 7 Fig. 4 fitting the notch bobbin

over small pm on Spindle. Push bobbin

winder against hand wheel. Hold thread

end loosely and start machine slowly

Bobbin will stop winding when it is

filled. Turn clutch away from you until

sewing mechanism is again engaged so

that needle moves when you turn the

hand wheel.

Break off loose thread end used to

start the winding and thread bobbin as

stated on Page 6.

6

SETTING THE NEEDLE

See Fig. S. Reise the needle bar A to its highest

point, turning wheel toward you by hand.

Then loosen the needle clamp screw B and the

Flat surface

of needle

shank

needle can be inserted into clamp C. Place needle

(flat side to right) m the needle clamp and push it

upward as far as it will go into the needle clamp

xiole, tig'htening' the needle clamp screw securely

with a screw driver.

After changing the needle make one com

plete revolution of the balance wheel by

hand to be sure the needle is in the correct

position.

Fig. 7

Fig. 6

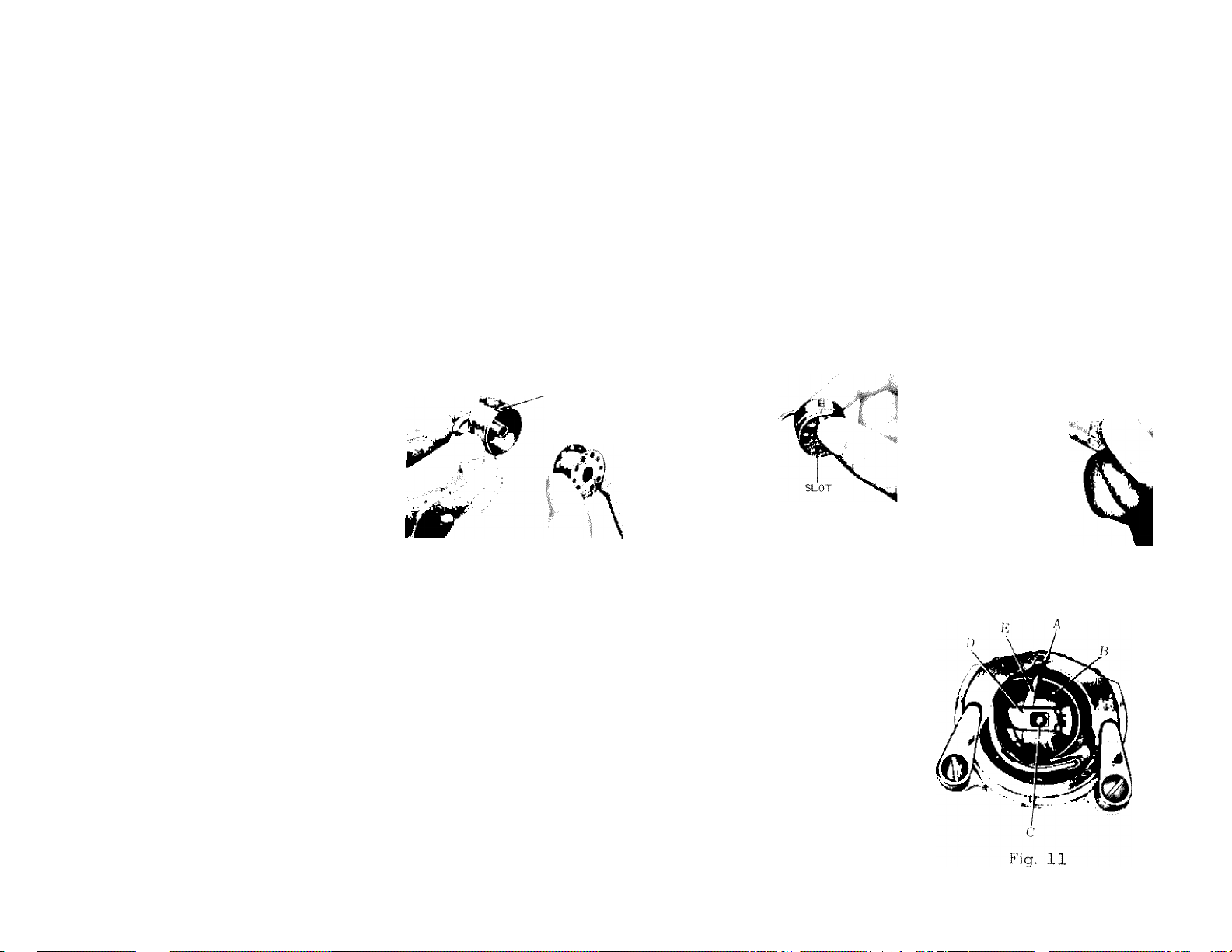

THREADING THE BOBBIN CASE

p illustrated in Fig. 8;. Hold bobbin case between thumb and forefinger of left hand,

so that the slot in the edge of the bobbin case is on top. Take the bobbin between thumb and

orefinger of right hand so that the thread on top leads from left to right.

Step 2 Insert bobbin into bobbin case, pull the thread into the slot of the bobbin case as

shown m Fig. 9, and draw it under tension spring and into the fork-shaped opening of the spring

as shown in Fig. 10,

7

SLOT

Fig. 8

Fig. 9

PLACING BOBBIN CASE IN SHUTTLE

Raise needle bar to highest position, and Slide cover plate to

the left, (See 17, Fig. 1) Hold the bobbin case latch, (D),

Fig. 11, between the thumb and forefinger of the left hand,

with at least three inches of thread running from the top of

the bobbin case to the right. Insert and center the bobbin

case on the stud of the shuttle body, (Cj. Be sure the

bobbin case finger, (E), is opposite the shuttle race notch (A).

Press the bobbin case (B) into the shuttle as far as possible

until latch catches on the center post of the shuttle. THE.N

release the bobbin case latch, (D). Press bobbin case again

after latch has been released to make sure the bobbin case

is locked securely in place. Close the cover plate.

TENSION SPRING

Fig. 10

-----------------

3^

■iff.

8

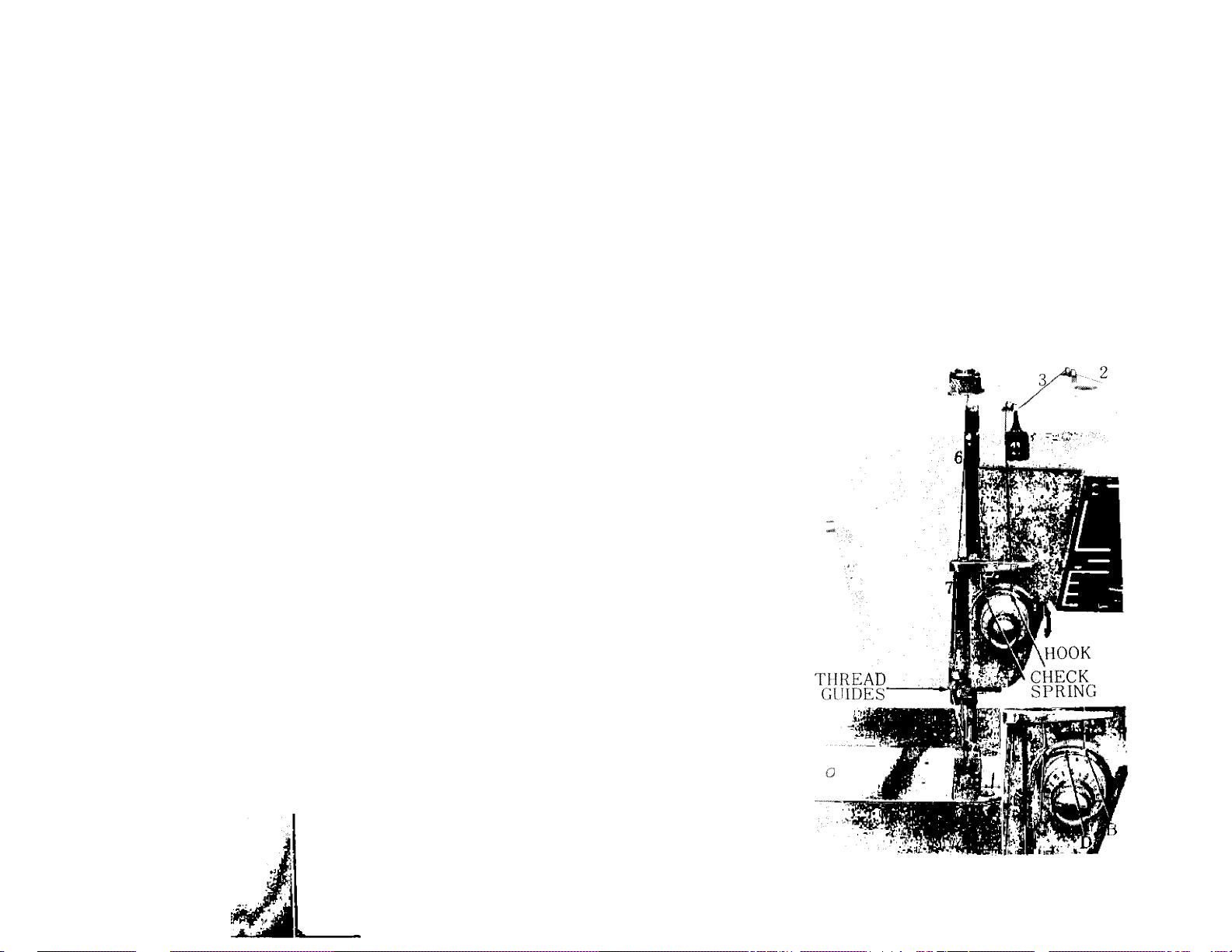

UPPER THREADING

1. Turn the balance wheel toward you to raise

the take-up lever to its highest position.

2. Place a spool of thread on the spool pin.

3. Lead the thread through the upper arm thread

guides.

4. Run the thread through the thread guide bar

to the tension discs, then around and be

tween them from right to left.

5. Draw the thread up through the check spring

and with a slight tug into the hook. (See

insert, Fig. 12)

6. Pass the thread under the bar and up through

the eye of the take-up lever from right to

left.

7. Lead thread down under bar, through the

face plate guide and then through the needle

bar guide from the back.

8. Thread needle FROM LEFT TO RIGHT,

drawing it through about 3 or 4 inches.

Hold the end of upper thread loosely and

turn hand wheel toward you until the needle

goes all the way down and comes back up.

A loop (Fig. 13) will be formed over the

upper thread which then can be pulled out

straight. Place both thread ends under the

slot of the presser foot and draw toward the

back of the machine, leaving both threads

three or four inches long.

Fig. 12

, «Jfcl

'-"I

1

.1 ’

*

.4 •

4 •

,1 -

4 *

I 5

/1 •>

/■* *

,i ;

,1 ;

<! »

4 ;

9

r ■,

9

9

Fig. 13 Fig. 14

SETTING THE STITCH LENGTH

The length of the stitch is regulated by the dial, shown in Fig. 14. Near 0 is the shortest

stitch and 5 is the longest, but the dial may be set at any spot between the markings for a

variety of lengths. Turn the dial to the right to lengthen and to the left to shorten the stitch.

The number stitch length you choose is indicated by the pointer.

STITCH LENGTH CHART (APPROXIMATE)

Figures on indicator

Number of stitches per inch

0

No Feeding

^30

1

2

25

3

15 8

5

6

1 '

i:

SEWING IN REVERSE

When you wish to sew backward to tie the threads at the beginning or end of a seam, press

in the button R, Fig. 14, as far as it will go.

The machine will sew backward as long as the

button is held in.

10

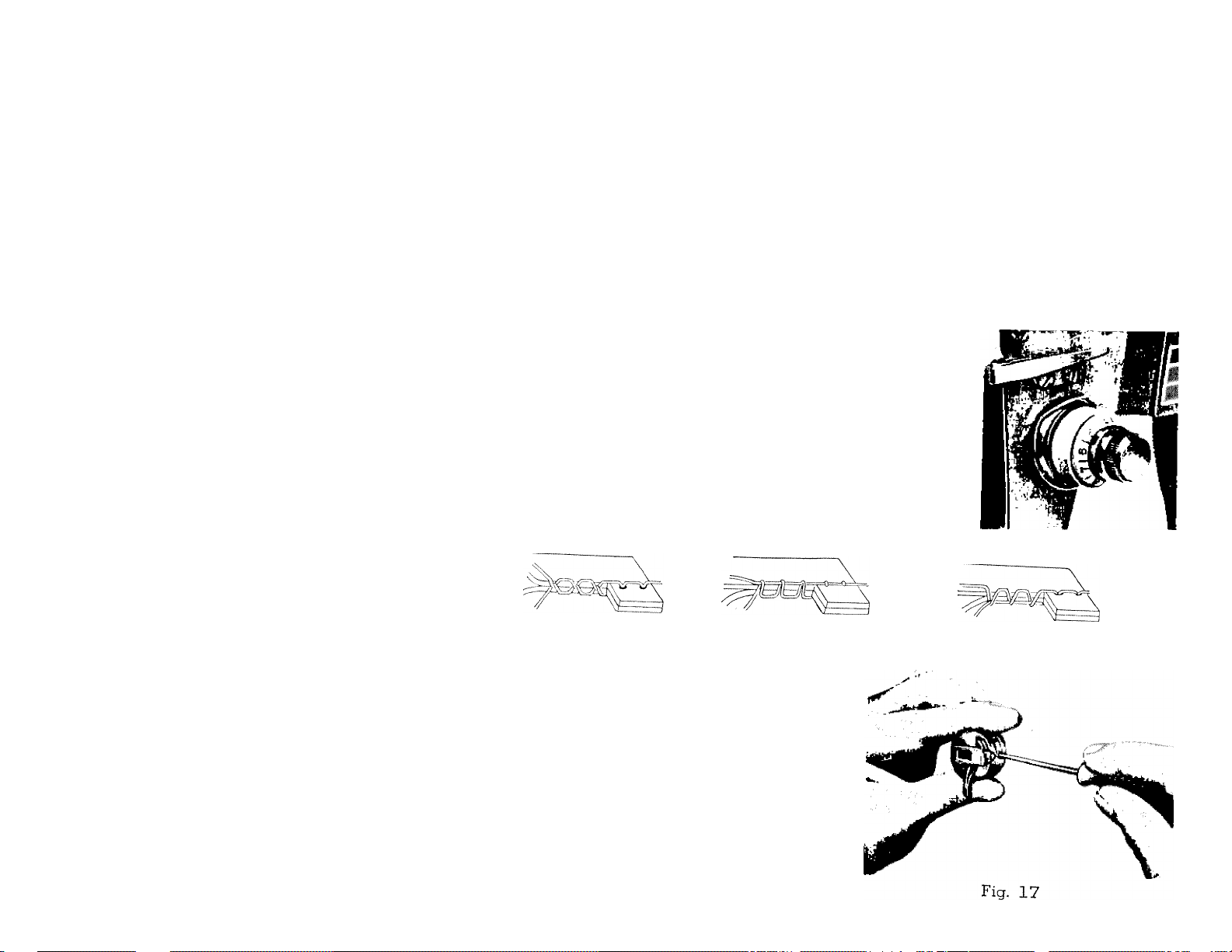

ADJUSTING THE TENSIONS

Always adjust the upper tension with the presser foot down,

as the tension is automatically released when it is raised. To

increase the tension on the upper thread, turn dial (Fig. 15 ) to

the right, or clockwise. To decrease, turn to the left. The higher

the number on the dial the tighter the tension. Before adjusting

lower tension be sure that the machine is threaded properly.

When necessary to change the bobbin tension, turn small

screw (Fig. 17) on side of the bobbin case clockwise to tighten,

counterclockwise to loosen.

Fig. 15

Fig. 16A Fig. 16B

When the upper and under tensions are properly

balanced, a perfect stitch will be formed with both

threads interlocking in fabric (Fig. 16-A).

When the upper tension is too tight, the lower

thread is pulled up over the upper thread which is

lying flat on the fabric (Fig. 16-B).

When the upper tension is too loose the upper

thread forms loops over the lower thread lying flat

on the fabric (Fig. 16-C).

Fig. 16C

,i

/f

,,..l

i

■ ■ 1

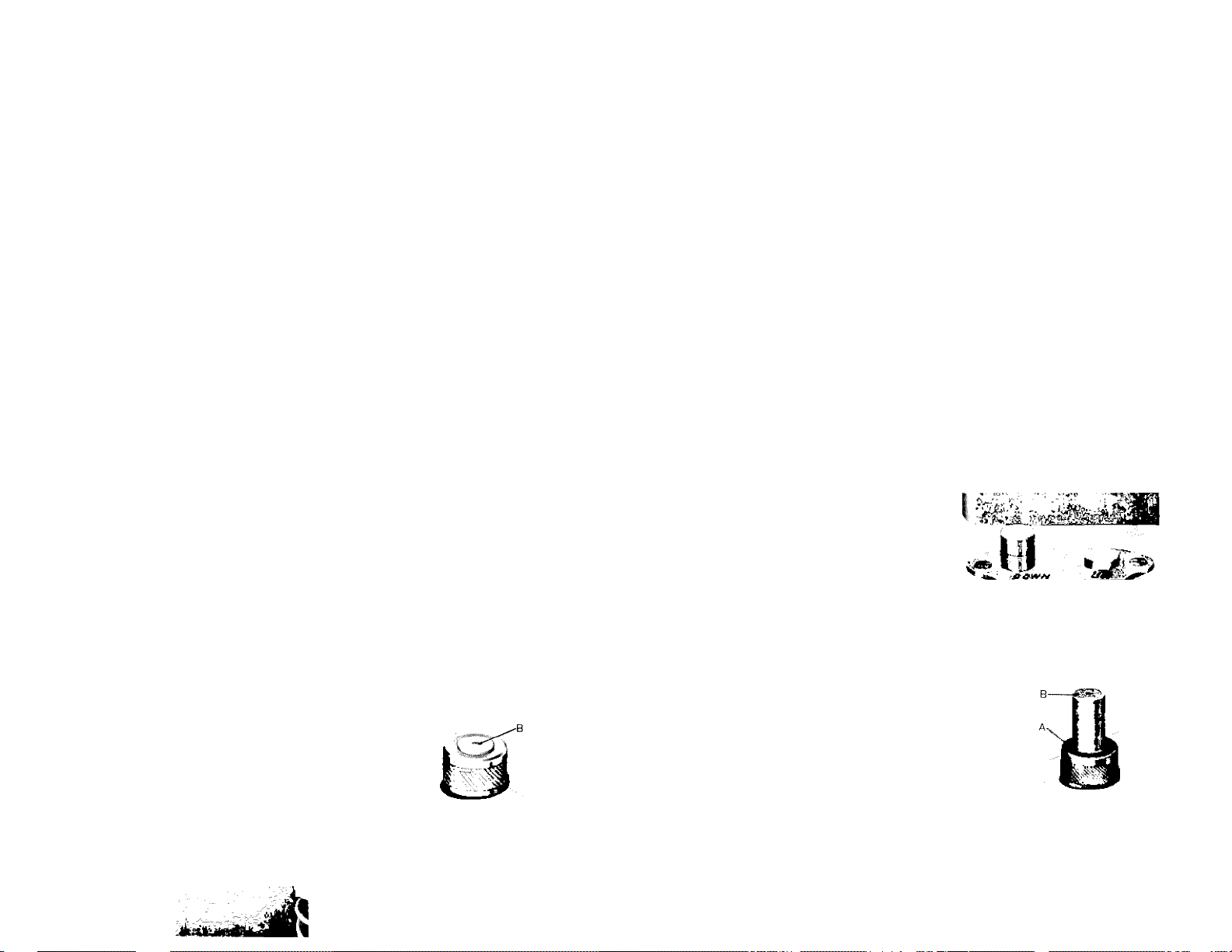

ADJUSTING PRESSURE AND FEEDING OF FABRIC

GENERAL SEWING. Usually for straight sewing and various embroidery work, the pressure

bar cap or darning release Fig. 19 is at its lowest position and the feed at its highest level-with

the drop feed button marked UP pressed all the way down. Fig. 18.

SEWING THIN OR LIGHT WEIGHT FABRICS

When lighter pressure is required to sew satisfactorily on thin

silk or filmy material, the pressure cap should be about halfway

down. Release all the way by pressing the snap lock. A, Fig.

20, and then press cap B down again to half-way spot. Lower

the feed slightly by pressing the down button (Fig. 18) to the

Fig. 18

red line.

DARNING AND MENDING

11

/!

In order to move the fabric freely in any

direction for darning and mending, release

1

the pressure cap B completely by pressing

down on the snap lock. A, Fig. 20. Press

down button (Fig. 18) all the way down,

which drops the feed well below the needle

Fig. 19

A

plate. To return feed to normal, press the

up button all the way down.

Fig. 20

12

PREPARING TO SEW

Have take-up lever at highest point before starting to sew. Do not try to help the feeding

by pulling the material as this may deflect the needle and cause it to break.

NEVER run machine without material under presser foot.

Place material and threads in position under the presser foot and lower the ptesser foot. You

are now ready to begin sewing. By having the needle at its highest point, it is not necessary

to touch the hand wheel to start the machine. You merely press the control. The speed of the

machine is regulated by increasing or decreasing the amount of pressure exerted on the control.

REMOVING THE WORK

Be sure to stop the machine

when the thread take-up lever

and needle bar are at the highest

position.

Now raise the presser foot

and draw the fabric back and to

the left, Fig. 21 A and B, and pass

the threads over the thread cutter.

Pull down slightly, holding

thread in both hands, so as not

to bend the needle.

Leave the ends of thread un

der the presser foot.

' . , ).P,' .

Fig. 21B

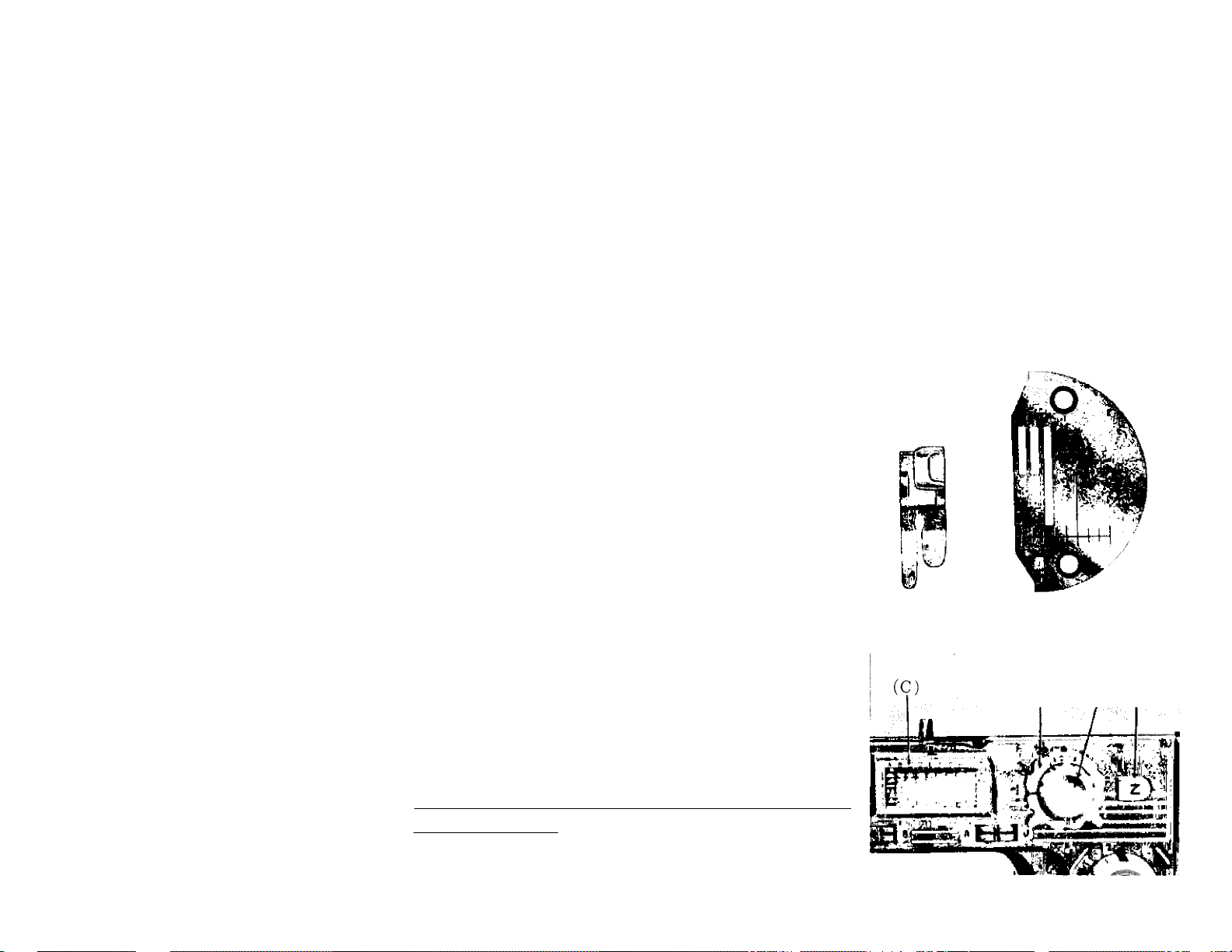

STRAIGHT STITCHING

For straight sewing on fine fabric or very soft ma

terial, you may want to use the straight stitch presser

foot and the straight stitch needle plate which are in

cluded in your accessory box. Both have narrow needle

slots.

Changing the Presser Foot and Needle Plate:

Cl) Presser Foot

(A) Loosen thumb screw 19, Fig. 1, and remove

zigzag presser foot.

(B) Replace with straight stitch presser foot,

Fig. 22A.

(2) Needle Plate

(A) Slide cover plate 17, Fig. 1, to the left as

far as possible.

(B) Remove screws holding needle plate 16,

Fig. 1, to bed plate.

(C) Remove zigzag needle plate.

(D) Replace with straight stitch needle plate

22B.

Be sure the machine controls are set as follows or you

will break the needle.

Fig. 22A

13

Fig. 22B

(A) iB),:.(Z)

^ 1

(1) Buttonhole control knob A, set at 0

3

(2) Zigzag Stitch Width control knob “B”, set at 0

(3) Decorative Stitch Design Dial at 'A-l’

Fig. 23

14

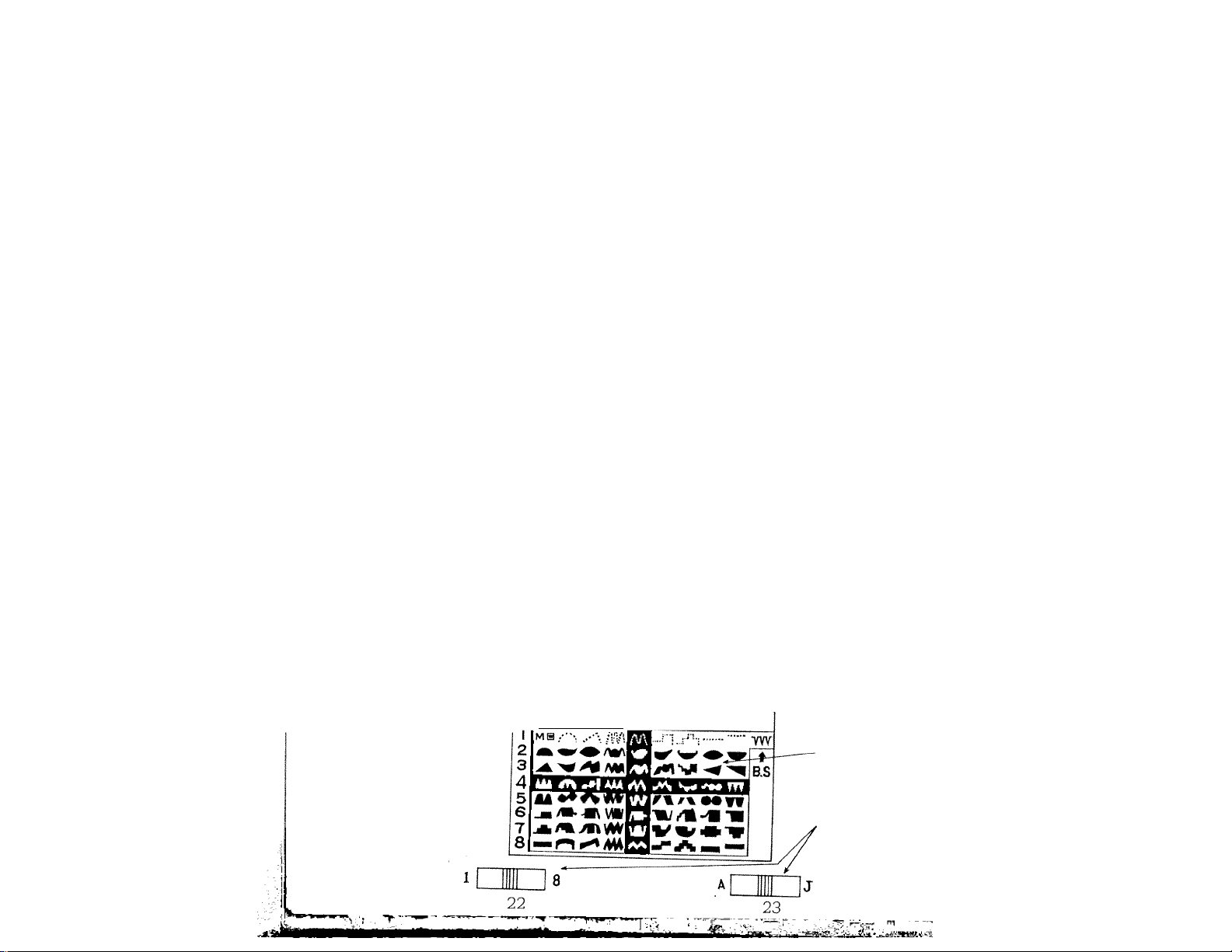

AUTOMTIC EMBROIDERY SEWING

Any one of the stitch designs illustrated on the Decorative Stitch Dial (32 Fig.

24) can be made automatically. The pattern located in the black area where the

two lines cross is the one produced.

To select a pattern,

(1) move mechanism release lever to the right

as far as it will go

(2) turn pattern selector control 22 to place

horizontal black line over pattern desired

(3) turn pattern selector control 23 to place

vertical black line over pattern desired

(4) release mechanism lever by raising it slightly so it wll spring back to its left

hand position

(5) set buttonhole control knob A at 0 (Fig^23)

(6) set zigzag width control knob B at 0 (Fig-23)

(7) Set stitch length control as close to 0 as possible without stopping the feeding

for a very compact design. By increasing the feed the design will be longer

but not quite so compact.

A B C D E F G H I J

n_T

- Release lever

Decorative stitch dial plate 32

Pattern selector control Knob

Fig. 24

JÈtSSi

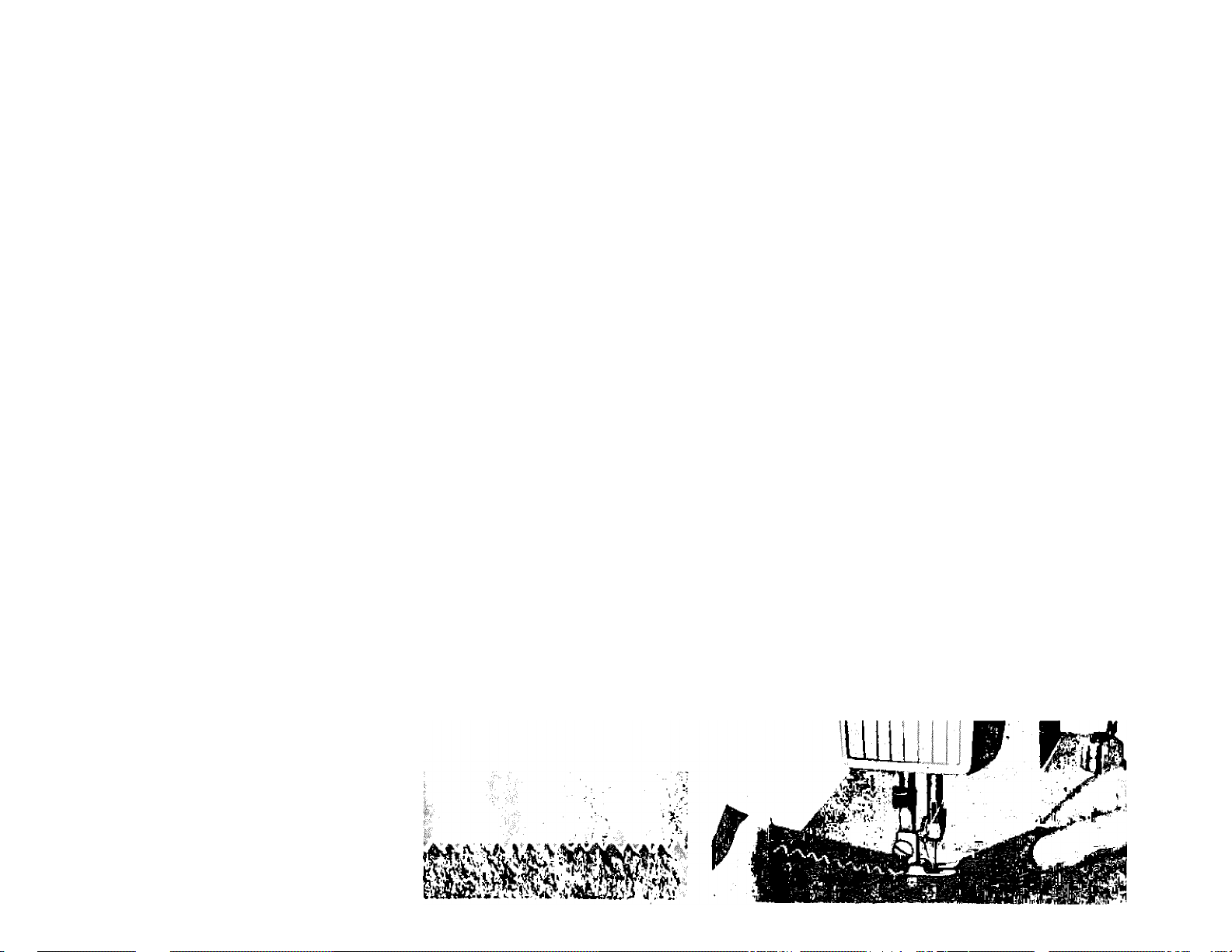

ELASTIC STITCH

Two types available on your machine. One the multiple zigzag stitch and the

other the serpentine stitch. Use the one most suited for the type of material and

work you are doing.

For multiple zigzag stitch set your machine for decorative stitch design number

D-1, for the serpentine stitch E-1 and zigzag stitch width and buttonhole control knobs

at 0 and stitch lenght to suit.

Use these stitch designs for :

(1) When applying elastic waist bands to skirts and dresses being sure to

stretch the elastic as it is applied to insure fullenss required in the garment.

(2) When replacing worn blanket bindings as they afford both a decorative

and durable finish,

C3) When sewing on jersey or any material that has a tendency to stretch,

C4) Many other iems which you will encounter in your sewing projects.

15

M »

Fig. 25

Fig. 26

Loading...

Loading...