Page 1

Page 2

Table of Contents page

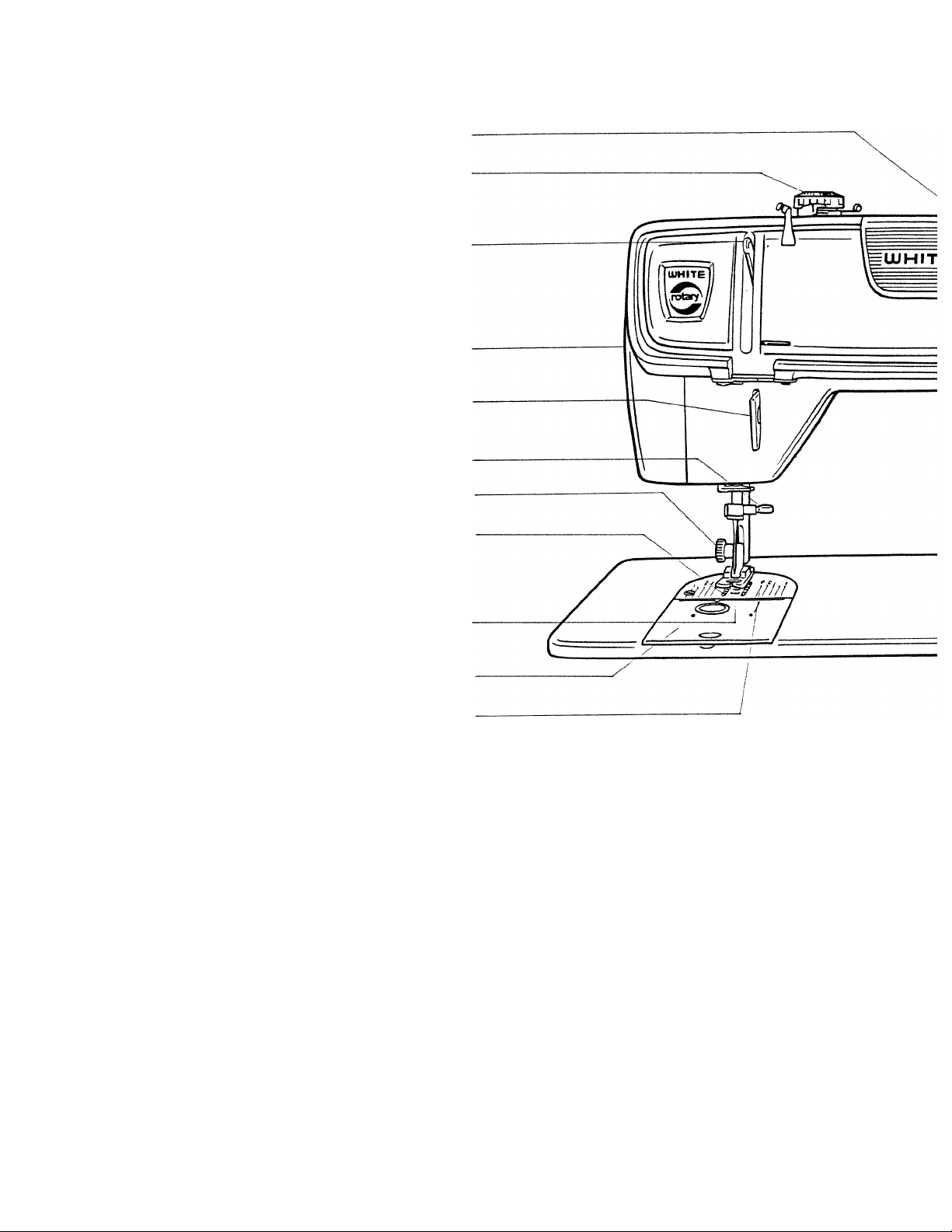

1. Features and Parts

Principle Parts.............................................................1-2

Accessories

U. Installation of Machine Head

Portable Case................................................................. 4

Cabinet

..........................................................................

III. Preparing Machine to Sew

Winding the Bobbin...................................................... 5

Lower Threading

Upper Threading........................................................... 6

rv. Choosing the Right Needle ........................................7 — 9

Types of Needles .......................................................... 3

Needle — Thread — Fabric Chart

Changing the Needle..................................................... 9

Changing the Needle Plate

V. Getting to Know Your Sewing Machine. . . iQ-14

Adjusting the Stitch

Stitch Length Dial

Reverse Button

Stitch Width Lever

Relating Stitch Length to

Stitch Width .......................................................10

Pattern Selector

Needle Position

Adjusting for the Fabric.......................................12—13

Feed Dog Control

Pressure Control

Tension Dial ......................................................13

Adjusting the Tension

The Proper Presser Foot ..............................................14

Changing the Foot

The All Purpose Foot

The Straight Stitch Foot......................................14

The Embroidery Foot

The Buttonhole Foot ..........................................14

VI. How to Sew

Pinning ........................................................................15

Placement of Fabric/Starting a Seam....................15

Guiding the Fabric ......................................................15

Etched Seam Guide............................................15

Cloth Guide .......................................................15

Presser Foot as a Guide......................................15

Holding the Fabric ......................................................15

Turning Comers...........................................................16

Curved Seams .............................................................16

Sewing Across Heavy Seams

Ending a Seam/Removal of Fabric

VII. Applications of the Straight Stitch

Seams ..........................................................................12

Basting/Topstitching....................................................17

Darning........................................................................17

Elastic Thread Shirring................................................17

VIII. Applications of the Zigzag Stitch

Overcasting..................................................................18

Seaming Knits

Sewing on Buttons ......................................................18

Forming a Thread Shank

Satin Stitching .............................................................19

Tanerins ......................................................................19

............................................ 1 - 3

.................................................................

.........................................

.........................................

..........................................................

..............................

......

....................................

............................................

..............................................

...................................................

.............................................

..................................................

..................................................

..............................................

................................................

........................................

..............................................

........................................

.........................................

........................................................

.....................................

..............................

.............................

.........................

.............................................................

.............................................

5 — 6

10—11

15—16

3

10

10

10

11

11

12

18-21

Manual Embroidery Designs

Freehand Monogramming

Applique............................................................................20

4

4

5

8

9

12

13

14

14

14

16

16

17

18

18

Gathering Over a Cord.....................................'................21

Lace Application

Flutter Hem ......................................................................21

DC. Buttonholes

Preparation........................................................................22

Built-in Buttonhole...........................................................22

Tum-around Buttonhole

Corded Buttonhole............................................................24

Stretch Buttonhole............................................................24

X. Applications of the Blind Hem Stitch

Hemming .........................................................................25

Shell Tuck.........................................................................26

Decorative Effects

XI. Applications of the Multiple Stitch Zigzag. . .27-28

Overcasting.......................................................................27

Patching............................................................................27

Mending a Tear/Daming

Elastic Application ..........................................................28

Understitching Facings .................................................. 28

Decorative Effects............................................................28

XII. Applications of the Overlock Stitch .........................29—30

Seams

...........................................................................

Nylon Tricot Seams..........................................................29

Applying Elastic ..............................................................29

Ladder Stitch

Hemstitching

Topstitching ................................................................... 30

XIII. Applications of the Straight Stretch

Stitch................................................................................31

Seams ..............................................................................31

Topstitching .....................................................................31

XiV- Applications of tne oiira Siretcn Stucn

Seams

..............................................................................

Elastic Application ..........................................................31

XV. Use of the Accessories

Twin Needle Sewing Effects ...........................................32

Pin Tucks

Decorative Designs ................................................32

Yam and Cord Sewing.....................................................33

Zipper Foot/Zippers/Cording ..........................................33

Quilting Guide

;AA. ..c.iaumoZpcc:;.: ..c.cs .....................................................34

Roller Foot

Overcast Foot

Blind Hem Foot................................................................34

Rolled Hem Foot .............................................................34

Fringe Foot.......................................................................34

XVn. Care and Maintenance of Your

Sewing Machine

Changing Needles ...........................................................35

Cleaning...........................................................................35

Procedure for Oiling

Changing the Light Bulb

XVin. Minor Problems and Their Solutions................................37

..............................................................

..............................................................

............................................................

....................................................................

....................................................................

...............................................................

.................................................................

.......................................................................

...................................................................

......................................................

............................................

................................................

...................................................

......................

.................................................

...........................

.............................................

........................................................

......

..........................................

page

19

20

21

22—24

23

25—26

26

27

29

30

30

31

31

32—33

32

33

34

34

35—36

35

36

Page 3

I. Feattires and Parts

Principle Parts

Picture Window

pictures the stitches and allows for easy selection.

regulates the amount of tension on the needle

thread.

regulates the flow of thread throu^ the needle.

It has an open-slot to simplify threading. The take

up lever should always be in its highest position

when beginning or ending sewing.

Descriptive Tension Dial

Take-Up Lever

opens to the left. Allows easy changing of the

light bulb.

helps control the flow of thread through the

needle.

Needle Clamp Screw

holds the needle in place.

holds presser foot in place.

Diamond Point Feed Dog

moves the fabric after each stitch is formed. The

diamond points give a gentle feed for delicate

fabrics as well as an accurate feed for heavy

fabrics.

holds the fabric in place for sewing. Various feet

are given in the accessory box.

slides open for changing the bobbin.

has guide lines on the left and right for greater

sewing accuracy.

Face Plate

Check Spring

Thumb Screw

Presser Foot

Slide Plate

Needle Plate

controls the raising and lowering of the presser

foot. It has an extra lift for the placement of

heavy fabrics.

is located on the back of the presser bar for

convenience.

hold aU types of spools effectively and eliminates

over-spin of lightweight spools.

Presser F oot Lever -

Thread Cutter-

Spool Pins and Caps

Page 4

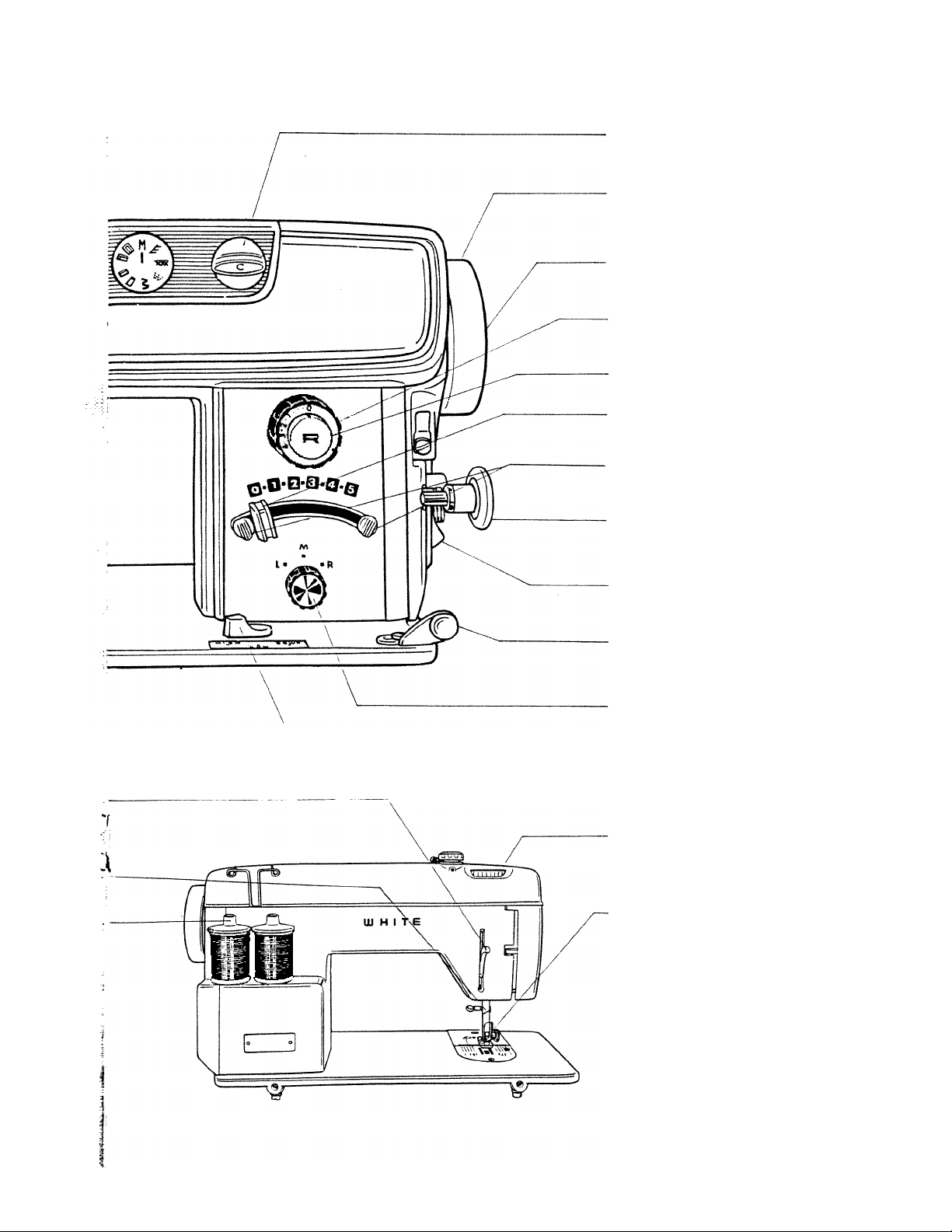

Pattern Selector

selects the stitch shown above the indicator in the

picture window.

Hand Wheel

controls the up and down movement of the needle

bar. Always turn it toward you.

Coupling Wheel

releases the movement of the needle bar in order

to wind a bobbin.

Stitch Length Dial

allows for precise adjustment of stitch length from

very fine to very long.

Push Button Reverse

allows for easy backtacking to lock thread ends.

Stitch Width Lever

allows for precise adjustment of zigzag stitch

width as well as tapering.

Zigzag Width Lever Stops

left lock determines the minimum width stitch,

while right lock controls the maximum.

Bobbin Winder

automatically disengages from hand wheel when

bobbin is filled to the proper level.

Power Switch

turns on both the motor and light simultaneously.

Allows selection of high or low speed.

Bobbin Winder Tension Disk

controls the tension on the thread as the bobbin

is being wound.

Needle Position Dial

is variable and may be set in any position from the

left to the right.

ecu iyog ^oiUiO.

adjusts the height of the feed dog for special

sewing applications.

Pressure Control

controls the amount of pressure on the fabric. It is

numbered to make adjustment easier. Normal

pressure is # 5.

Foot Holder

holds the foot. It is easy to exchange the sole.

Page 5

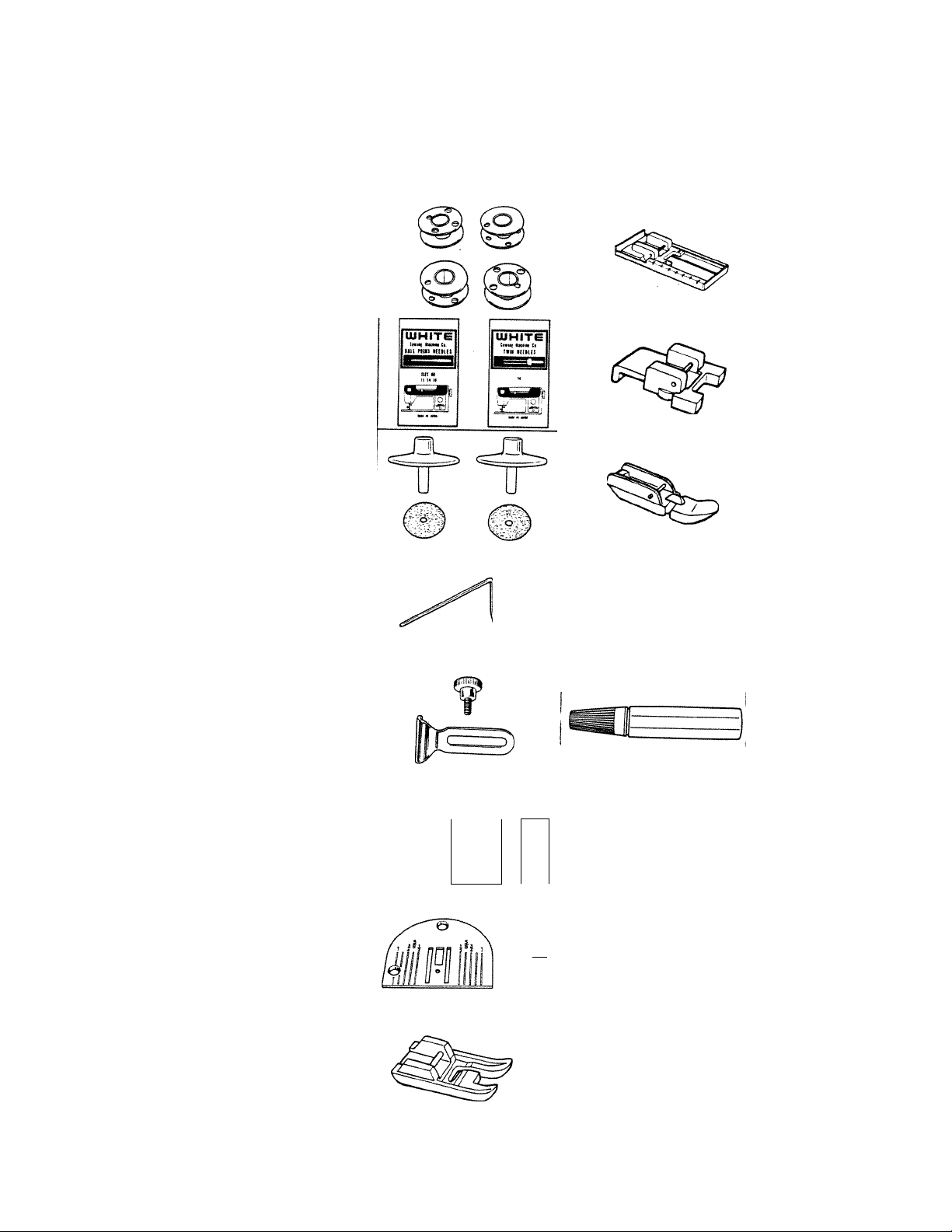

Accessories

Your new White Rotary sewing machine comes equipped

with the following set of accessories to make your sewing

easier.

Four Metal Bobbins

The bobbins have holes in

one side for convenient bobb

in placement.

Needles

light ball point needles, two

each of sizes 11, 14 and 16

are provided. Two twin need

les are also included.

TSvo Felt Washers and Spool

Caps

Place felt washers on spool

pins under the spools and

place caps over the spools

tightly for best stitching re

sults.

(jilting Guide

Helps make parallel rows of

stitching.

Buttonhole Foot

Is adjustable and regulates

proper buttonhole length

every time.

Button Sewing Foot

To hold button in place for

stitching.

Cording and Zipper Foot

For stitching very close to the

edge of a cord or zipper.

Screw Drivers

Small one for use on bobbin

tension. Large one for use

on thumb screw, needle clamp

screw, etc.

Qoth Guide with Screw

Aids in creating straight

seams.

AU Purpose Foot & Zigzag

Needle Plate

For all utility sewing.

Straight Stitch Foot and

Straight Needle Plate

For straight stitching on

sheer or , very lightweight

materials where extra control

is needed.

Embroidery Foot

Has a wide groove on the

bottom which allows the foot

to pass over dense stitches,

such as satin stitches or other

decorative stitches. Do not

use this foot for normal

sewing of lightweight fabrics.

O

1** A

111

b=c

X

* —^

Tubed Oiler

For use in oiling the machine.

See page 34.

Seam Ripper

For cutting the openings in

buttonholes and for removing

stitches.

Bobbin Extractor

For easy removal of bobbin

from the bobbin case.

Lint Brush

For removing all lint.

Page 6

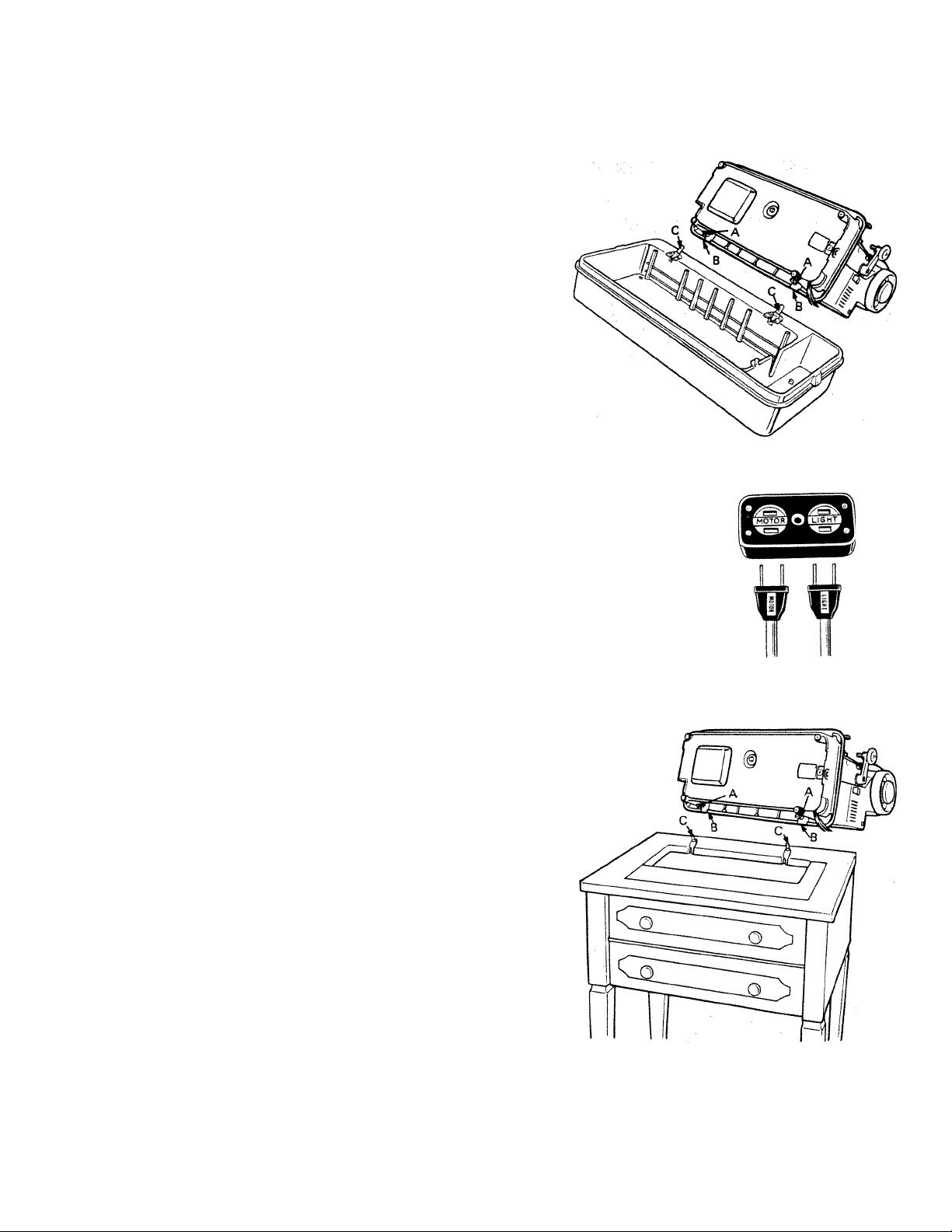

n. Installation of Machine Head

Portable Case

Lay the sewing machine unit face down on a

table. On the underside of the back of the

sewing machine are two clamping screws (A).

These enter the head hinge holes (B). Release

the clamping screws.

On the base of the portable case are two head

hinges (C). Lower the sewing machine onto

the base, fitting the hinges (C) into the holes

(B). Tighten the clamping screws securely

with a screw driver. Place machine in an

upright sewing position. Machine will snap

under portable case clamp securing it in

correct position.

Draw the two electrical leads through the slot

in the base. Plug cord labeled motor into the

receptacle marked motor on the block attach

ed to the outer section of the base. Insert the

other cord into the receptacle marked light.

Insert plug into a wall outlet. (110-115 volts)

Cabinet

Lay the sewing machine unit face down on a

table. On the underside of the back of the

sewing machine are two clamping screws (A).

These enter the head hinge holes (B). Release

the clamping screws.

On the cabinet are two head hinges (C). Tilt

them up and back as far as they will go.

(Hint: Stretch a rubber band across the two

hinges to help hold them upright while

mounting the sewing machine unit.)

Carefully lower sewing machine onto the

head hinges, making sure to insert the hinges

as far into the hinge holes as they will go.

With the sewing machine in its tilted position,

tighten both clamping screws securely with a

screw driver.

Plug the electrical leads into the sockets

located inside the cabinet. Plug the cord

labeled motor into the receptacle marked

motor on the block attached to the inside of

the cabinet. Insert the other cord into the

receptacle marked light. Insert plug into a

wall outlet. (110-115 volts)

NOTE: Where three wire grounding is

provided connect the plug from the sewing

machine to the connection leading from the

control. One prong is larger than the other

three, eliminating the possibility of error.

Insert plug into wall outlet. (110-115 volts)

Page 7

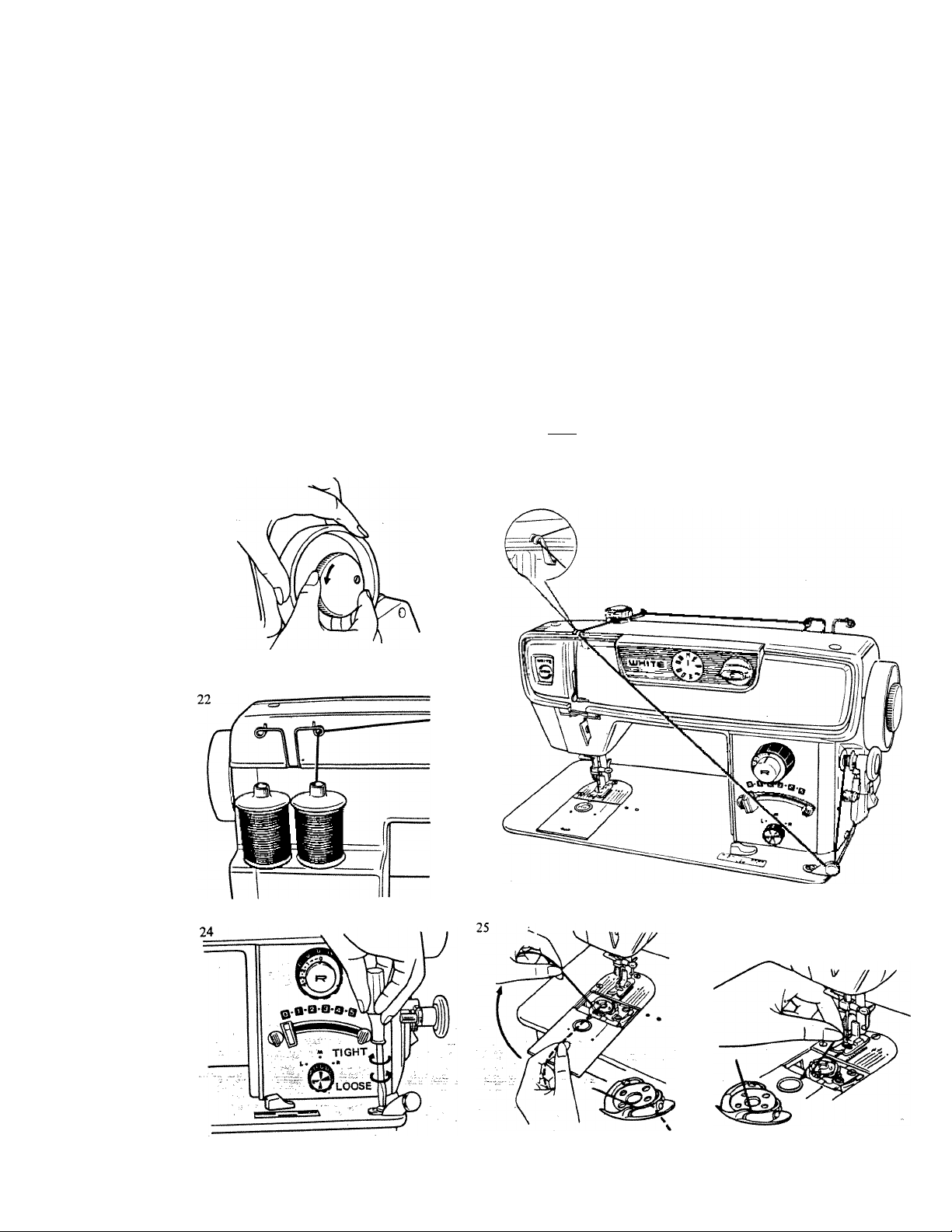

Ш. Preparing Machine to Sew

Winding the Bobbin

Disengage the hand wheel by holding it

tightly with your left hand and turning the

coupling wheel toward you with your right

hand. (Fig.21) Place spool on spool pin,

leaving about one foot of thread free, then

place spool cap over spool as shown (Fig. 22)

until it holds the spool in place. Lead thread

as illustrated. (Fig. 23) Run the end of the

thread through the single hole on one side of

the bobbin, and place bobbin on spindle of

bobbin winder with the four holes of the

bobbin facing to the right. Turn the bobbin

until it clicks into place.

Lift bobbin winder until it makes contact

with the hand wheel. Hold thread end

securely and run machine slowly. Bobbin will

stop turning when filled. Always break off

loose thread end used to start the winding.

Tighten the coupling wheel by turning it away

from you as you hold the hand wheel in

21

...........

■ 23

place. The needle should now move when you

turn the hand wheel.

Note: If the bobbin winds unevenly, adjust

bobbin winding tension disc to the right or

left by loosening the screw and sliding it.

When disc is in proper position, tighten screw.

(Fig.24)

Lower Tlireading

Drop the bobbin, with four holes on top, into

the hook and be sure the bobbin rotates

counter clockwise. Draw the thread through

the slot and toward the left into the clearance

between hook and spring. (Fig. 25) Put the

thread through the notch at the end of the

spring and leave the thread about three or

four inches long. Close the slide plate

allowing the thread to emerge through the

notch above the window. Thread should cross

from the left across the top of the bobbin.

Note: For satin stitching, drop the feed dogs

to down and slip the thread into the clip at

the back of the hook. (Fig.26)

26

Page 8

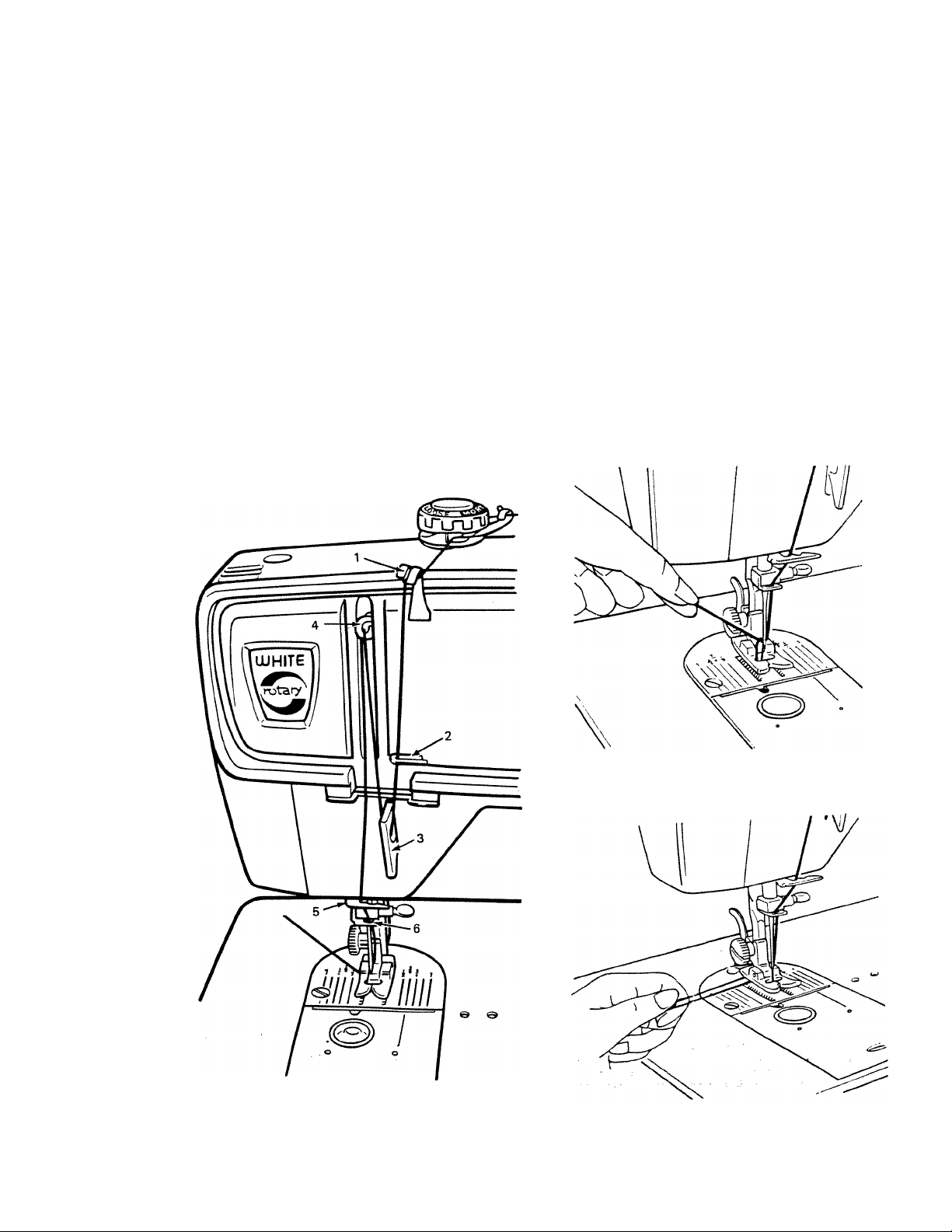

Upper Threading

1. Turn hand wheel toward you to raise the

take-up lever to its highest position. Presser

foot should be in the raised position.

2. Lead thread from the spool as illustrated,

(Fig. 22) being sure to place the spool cap

so that it holds the spool securely. Draw

the thread between the tension discs and

around toward the right until it emerges

under the finger like projection. Bring the

thread through the succeeding points as

illustrated. Thread the needle from front to

back and leave the thread about three or

four inches long. (Fig. 27)

3. Hold upper thread down on slide plate and

turn hand wheel toward you one complete

revolution. Pull the loop which has been

formed through to the upper surface. (Fig.

28)

Place both thread ends under the presser

foot and draw them toward either the right

or left leaving both threads about four

inches long. (Fig.29)

27

r

28

29

Page 9

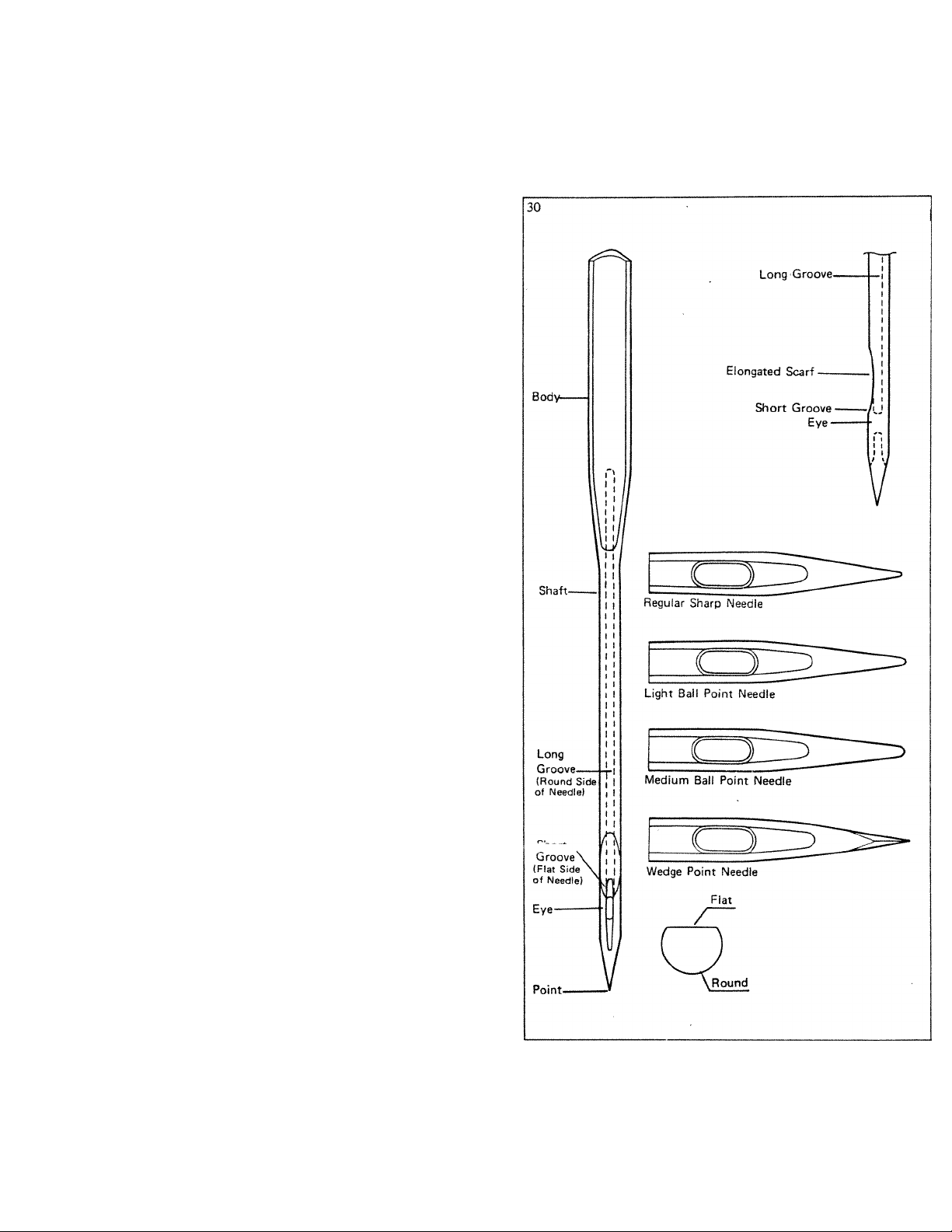

rv. Choosing the Right Needle

Types of Needles

The correct selection of needle to suit the

thread and fabric being sewn gives the best

stitching results. Fine fabrics should be sewn

with fine needles, heavier fabrics with heavier

needles. For best results, sewing machine

needles should be replaced when they become

even slightly dull or bent or at the completion

of every other garment.

A regular needle is suggested for use with

woven fabrics. Needles, style 15x1, (Euro

pean equivalent System 705) are used on the

majority of household sewing machines. They

range in sizes from 8 to 20 with the lower

number indicating the finer needle. The most

commonly used sizes are 11 and 14.

A ball point needle is recommended for use

with tricots, jerseys, lingerie and power nets.

Unlike sharp, pointed needles, which pierce

fibers of knit fabrics, destroying elasticity, the

ball point sUps between fibers, preventing

damage to fabric and skipped stitches. These

are available in fine, medium, and heavy ball

points.

A wedge point needle is recommended for use

with leather and leather-look vinyls. A wedge

cutting point pierces leather more easily than

ordinary sewing machine needles, resulting in

more satisfactory stitching.

An all purpose needle is designed to handle

knits as well as woven fabrics. It eliminates

skipped stitches and the slight ball will not

damage delicate fabrics. This is the needle

provided with your sewing machine and will

be used for most of your sewing. A larger ball

point may still be necessary for certain knits,

such as bathing suit fabric or power net.

Page 10

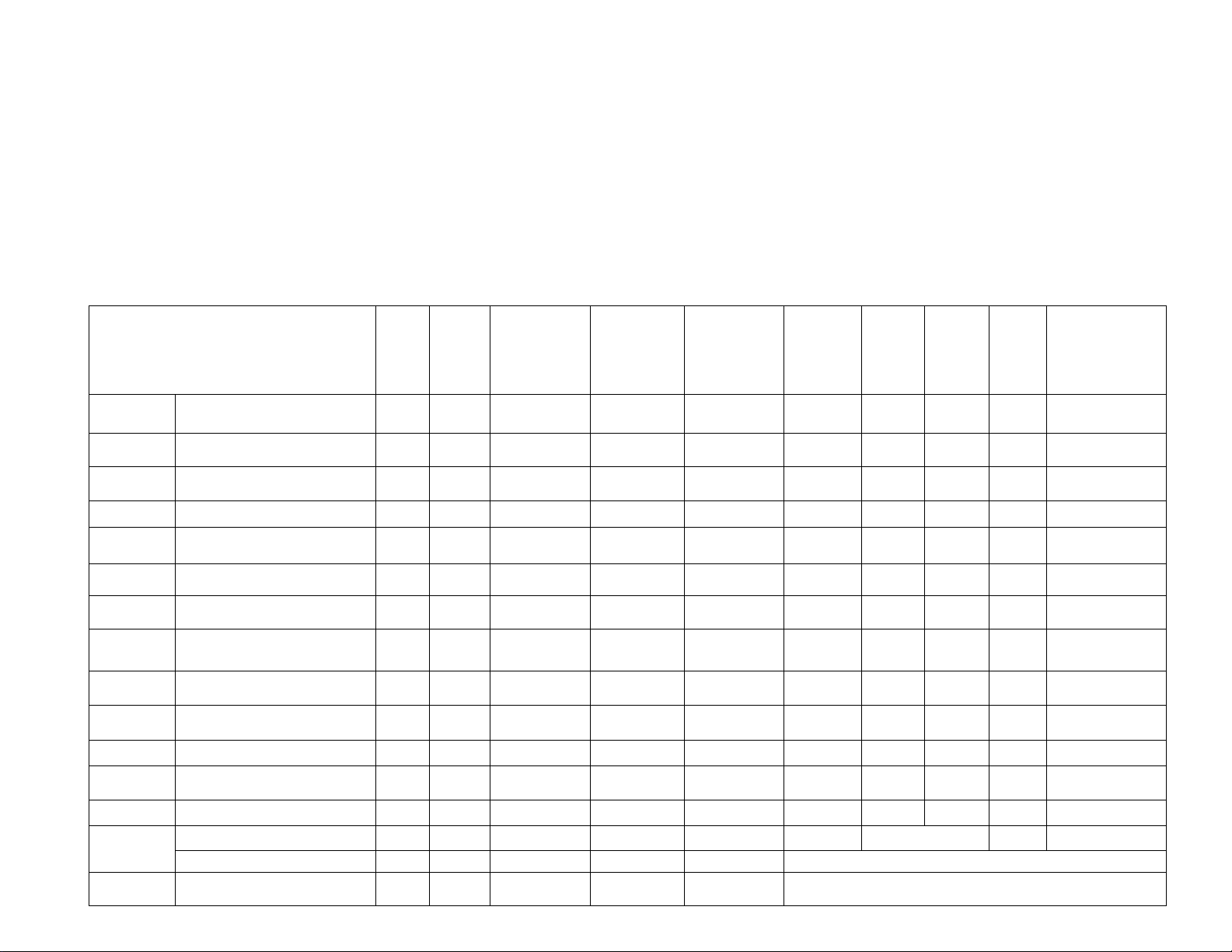

Needle

Stitdiing

Guide

The correct selection of needle and thread to suit the

fabric will result in more satisfactory stitching. Fine

fabrics should be stitched with fine needles, fine thread

and short stitches.

For best results on heavier fabrics, use coarser needles,

heavier threads and longer stitches. Replace the

machine needle when it becomes even slightly dull or bent.

Consult

this chan whi'iiever

a difjereiit /17«'

of fai)rw

is lo he stili heil.

Thread

and needle .sizes

for various

kinds and weights

of fabrics.

KNITS

WOVEN

LEATHER

DECORATIVE

STITCHING

type of fabric

LIGHT WEIGHT

Tricot, Power Net

MEDIUM WEIGHT

Jersey, Double Knit, Power Net

HEAVY WEIGHT

Double Knit, Power Net

FAKE FURS ^VELOURS

VERY SHEER

Lace, Net, Chiffon, Voile

SHEER

Lawn, Taffeta, Blouse Crepe, Organdy

DRESS WEIGHT

Crepe, Wool, Brocade, Velvet

MEDIUM

Wool, Silk, Linen, Pique,

Faille. Velveteen, Terrycloth

HEAVY

Denim, Duck, Sailcloth

EXTRA HEAVY

Canvas, Upholstery, Awning

VINYLS-ITLMS

LIGHT TO MEDIUM WEIGHT

Leathers & Suedes

HEAVY LEATHER

MACHINE EMBROIDERY

TOP STITCHING

METALLIC EMBROIDERY

mchine i

U.S. Size

European

15x1

9

9-10

11-14 80-90

14-16

9-11

11 80

16

19

14-16

16-18

9-11

16-18 100-110

70-80

90-100

9 70

9

14 90

90-100

100-110 Leather (Wedge)

11 80

705

70

70

70-80

100

120

60-80

cedles

Point Style

Light Ball

Light Ball to

Medium Ball

Medium Ball to

Heavy Ball

Ball or Sharp

Sharp

Sharp

Sharp

Sharp

Sharp

Sharp

Leather (Wedge)

Leather (Wedge)

approxiuiate

straight

stitches

per inch

20

12

10-14

10

16-18 10

14-16

12

12

10

8

10

8

6-8 3

hand

needles

10

9

4-5

4-5

10

9

7-8

6-7

3 4

7-8 50

3-4

ihrcac

i

Mercerized

Cotton

60

50

50

Heavy Duty 30

60

60

50

50

Heavy Duty

Heavy Duty 30 YES

50

Heavy Duty

Cotton Embr<

Silk Buttonhole Twist Size D

Metallic Thread

European

Cotton

50-70

50-70

>idery Thread Size 50-70

Polyester

NO

30 YES

30

70

30 NO

30 NO

30 YES

30

30 YES NO

30

YES

YES

NO

NO

YES

YES NO

Siìk

Nylon

A-Silk

Nylon

A-Silk

Nylon

A Silk

Nylon

NO

A-Silk

Nylon

A-Sìlk

Nylon

A-Silk

A-Silk

NO

NO

NO

attachments

Roller Foot

Roller Foot

Roller Foot

Roller Foot

Roller Foot

Roller Foot

Roller Foot

Page 11

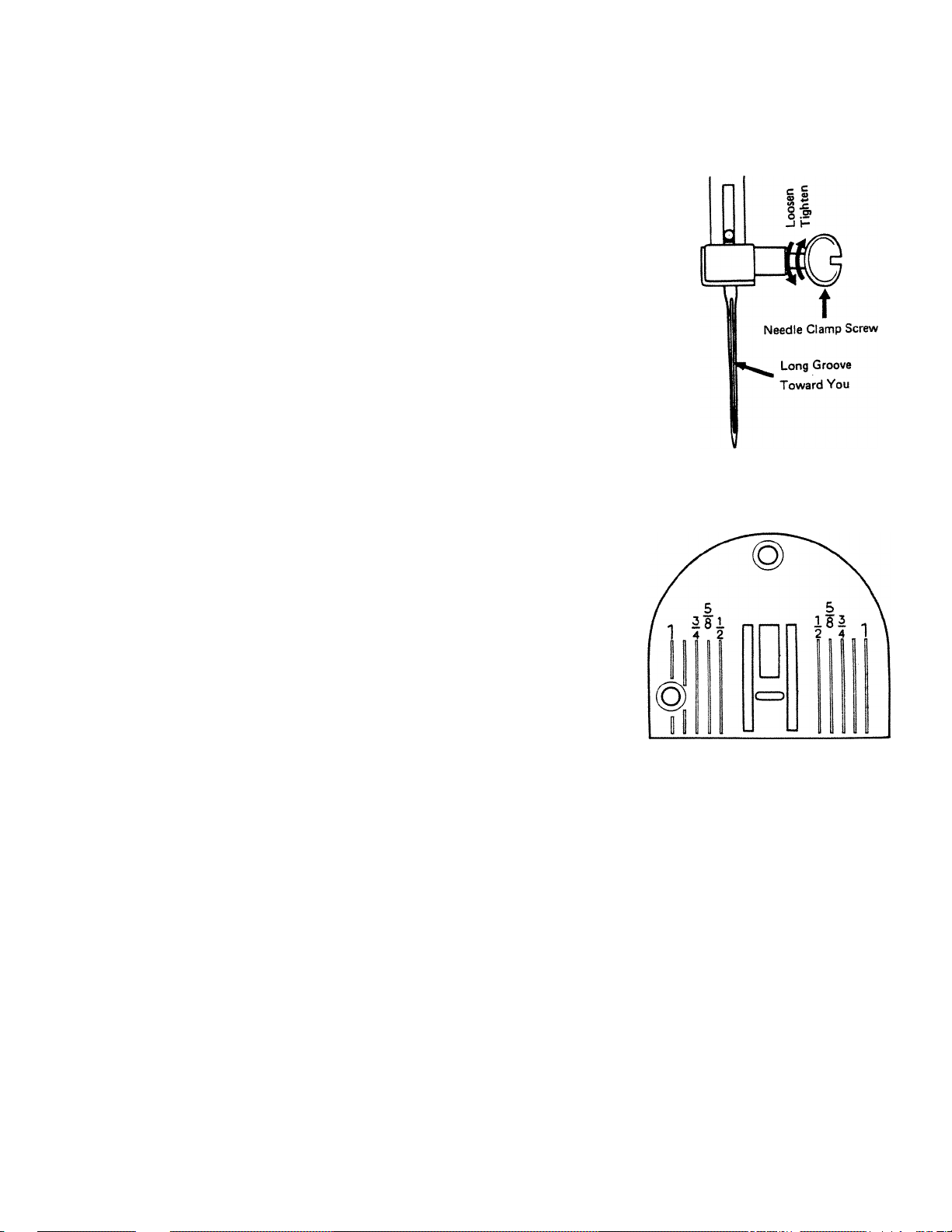

Qianging the Needle

Always change the needle after every other

garment especially when sewing on polyester

and nylon fabrics which dull needles much

faster. When needles are dull or bent, they

damage both your fabric and the machine.

A general rule when replacing sewing

machine needles is that the flat side of the

needle is placed to the back of the machine,

when the bobbin is put in from the front. If

the needle is inserted incorrectly, the

stitches will not form.

To change the needle

1. Raise the needle bar to its highest

position by turning the hand wheel

toward you.

2. Loosen needle clamp screw to remove

the needle. (Fig.31)

3. Place needle (flat side to the back and

long groove toward you) (Fig.31) in the

needle clamp and push it upward as far as

it will go, tighten clamp screw.

4. After changing the needle, make one

complete revolution of the hand wheel

by hand to be sure the needle is clearing

the needle plate.

31

32

Changing the Needle Plate

To change the needle plate, simply slide the

cover plate toward you. Remove the needle

and the presser foot. Remove the two screws

holding the needle plate in place, lift the

needle plate. Replace the needle plate.

The needle plate is removed for cleaning the

lint which may pile up between the needle

plate and the feed dop. The straight stitch

needle plate is used for sewing very fine or

soft materials. The zigzag needle plate can be

used for almost all of the normal sewing.

Page 12

V. Getting to Know Your Sewing Machine

Adjusting the Stitch

33

35

Reverse Button

1 2 3 4 5

34

Stop Lever

Pattern - M

Length - 0-4

Width - 0

Needle Position - M

Feed Dog - High

Pressure — 5

Foot - All Purpose

Pattern — M

Length - 2

Width - 0-5

Needle Position - M

Feed Dog - High

Pt-essiire - 5

Foot - All Purpose

Stop

Stitch Length Dial

This dial (Fig.33) controls the forward

feeding of the fabric. At 0, the fabric does

not feed at all. As the numbers increase so

does the length of the stitch. Turn the blue

dial so that the desired number is above the

blue line on the white button.

Reverse Button

The white button in the middle of the stitch

length dial (Fig.33) will cause the feed dog

to feed the fabric backwards. This button

may be used at the beginning and end of

sewing to lock the threads.

To backstitch, simply push the button in

and hold for the desired number of stitches.

It is advisable to tie thread ends instead of

backstitching on soft sheer fabrics to avoid

puckering.

Stitch Width Lever

This lever (Fig.34) controls the swing of the

needle from left to right for various width

of stitches. At 0 the needle does not swing,

therefore a straight line of sewing results no

matter which pattern is selected.

At 1, the needle takes a narrow swing

resulting in a narrow column of stitching. At

5, the needle takes a large swing resulting in

a’wide column of stitches. (Fig.35)

Slide the blue lever to the desired number

then push in the left hand stop (Fig. 34)

and slide it over to the blue lever. The stop

will hold the lever in place.

36

Pattern - M

Length - 0-4

Width - 5

Needle Position - M

Feed Dog - High

Pressure - 5

Foot - All Purpose

Relating Stitch Length to Suich Width

When the width lever is engaged at one

particular width (such as 5), the stitch length

dial will now control how close those stitches

come together. At length 0, the fabric does

not move, resulting in a ball of stitches

formed one on top of the other, as is used

in button sewing. At about length 14, the

feed pulls the fabric through slowly, resulting

in a dense column of stitches called a satin

stitch. At length 4, a very long open zigzag

results. (Fig.36)

10

Page 13

Pattern Selector

This dial (Fig. 37) selects the stitch pattern

to be made according to the pictures shown

at the blue indicator. Turn the silver selector

dial to the right and the picture of the stitch

to be formed will be shown in the top

position. The stitches shown are as follows:

1. M stands for manual position which

gives the standard straight stitch when

the width is at 0 and the standard zigzag

when the width is engaged.

2. Black boxes - indicate buttonhole steps

for four step buttonholes to be explain

ed on page 22.

3. Blindhem ( $ ) - stitches forward then a

zigzag bite to the left for use in

hemming, shell tucking, and other ap

plications. See page 25. Width 0 will

give a straight stitch, all other widths

will give the blind hem stitch.

4. Multiple stitch zigzag ( iS ) - takes three

stitches from side to side for use in

overcasting, applying elastics and mend

ing as shown on pages 27. Width 0 will

give a straight stitch, width 5 is the best

choice for use of the multiple stitch

zigzag. _

5. Overlock stitch ( e ) - takes one stitch

to the left, one stitch backwards and then

one stitch to the right to form a straight

seam and overcast all in one operation.

This is excellent on both knits and

wovens for Vi inch seams on width 5,

and for the straight stretch stitch at

width 0. See page 29. Straight stretch

stitch is discussed on page 31.

6. Ultra stretch stitch { } - takes stitches

then back on a diagonal. This stitch has

the greatest strength and elasticity and is

excellent for loose or bulky knits, such

as sweater knits, bathing suit, and

cotton knits. Use it at width 5 for

completed V* inch seams on knits. This

stitch is never used on width 0. See page

31.

Pattern -

Length - 2

Width - 5

Needle Position - M

Feed Dog - High

Pressure - 5

Foot - All Purpose

37

38

M

M

O' U O'

M

Needle Position

This dial controls the location of the needle

in relation to the presser foot. (Fig. 38)

Never move the needle position dial while

the needle is in the fabric because it will

bend or break the needle.

The needle may be used in any position

between the left and right even though only

three positions are labeled. L -Left M -

Middle R - Right

The etched guide lines on the needle plate

are measured from the needle in the middle

position.

Pattern - M

Length - 2

Width - 0-2

Needle Position - L, M, R

Feed Dog - High

Prcbiuic - D

Foot - All Purpose

Page 14

When straight stitching with the all purpose

foot, the needle may be moved to get closer

to an edge or to make guiding of the fabric

more convenient, as in topstitching. The

needle can also be moved in relation to the

zipper foot in order to take full advantage

of the feed dog.

Caution: When using the straight stitch foot

use the M position of the needle only.

39

40

Pattern - M

Length - 2

Width - 5

Feed Dog -

Pressure - 5

Foot - All Purpose

Adjusting for the Fabric

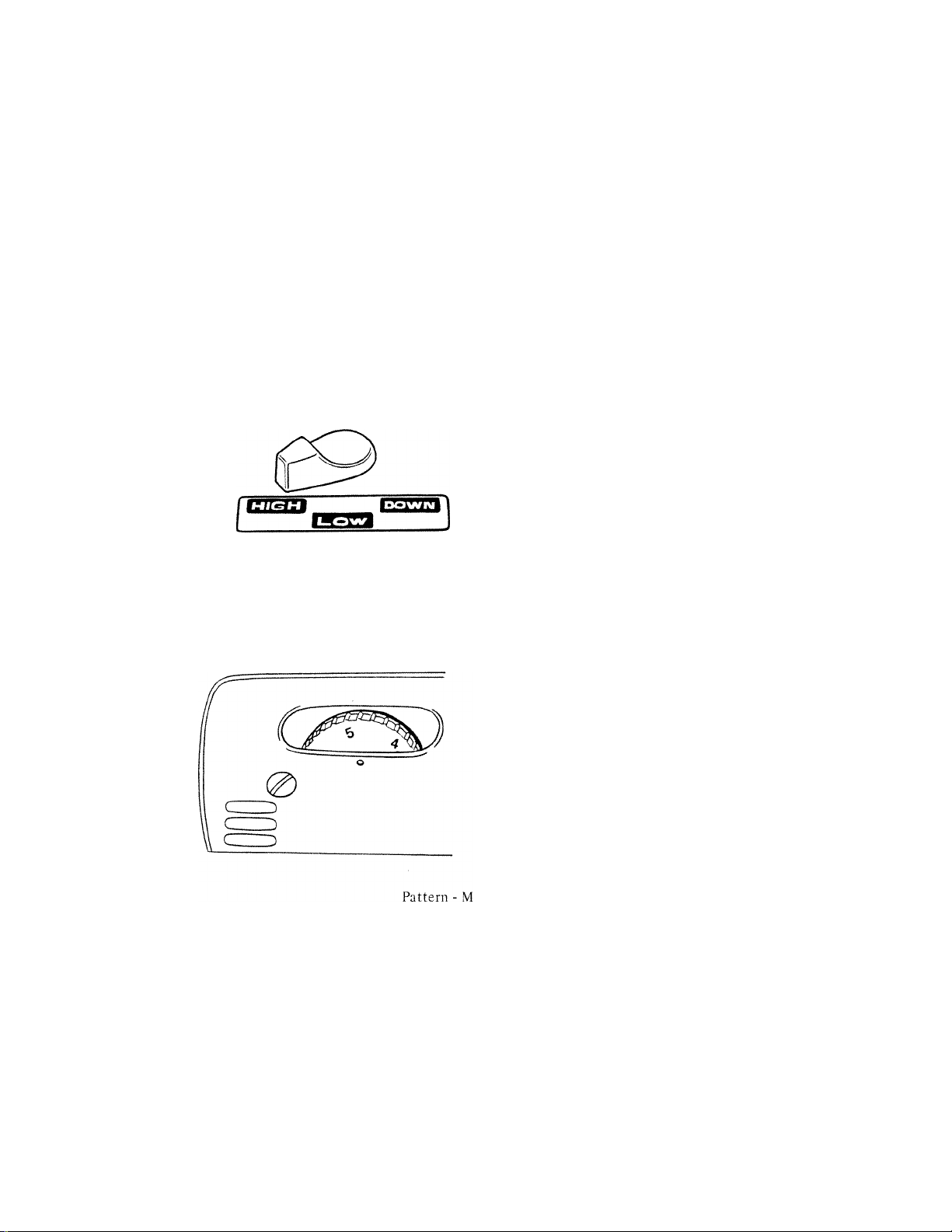

Feed Dog Control

This lever (Fig. 39) will raise or lower the feed

dog as indicated. Since the feed dog carries

the fabric through the machine, this lever

allows the feed to be regulated for various

materials and types of sewing.

High: For the greatest height of the feed dog

and best grip on the fabric. This is the

position used for most sewing.

Low: For less height of the feed dog and

more gentle hold on the fabric. This position

is used for sewing delicate fabrics.

Down: In this position, the feed dog is

completely below the needle plate surface and

therefore does not move the fabric at all.

Length - 2

Width - 0

Needle Position - .M

Feed Dog - High

Pressure -

Foot - All Purpose

Pressure Control

This control (Fig. 40) regulates how heavily

the presser foot rests upon the fabric. It is

numbered from 0-5 with .stops at the half-way

points as well. The higher the number the

heavier the pressure. The lower numbers give

lighter pressure. Zero gives no pressure.

Lighter weight fabrics need more pressure for

better hold against the feed, whereas heavier,

bulkier fabrics require less pressure to

eliminate pushing on the top layer of fabric.

Normal pressure is 5.

12

Page 15

Tension Dial

The top tension (Fig.41) consists of discs

between which the thread passes. The

descriptive tension dial regulates how tightly

the thread is being held. When necessary,

adjust the top tension in relation to the red

line, turning toward “loose” or “tight” as

needed. The top tension is engaged only when

the presser foot is down for sewing.

The bobbin thread tension is controlled by

the left small screw on the front edge of the

bobbin case. (Fig.42) This screw may be

turned with the small screw driver resting in

the notch of the slide plate. Turn to the right

to tighten and to the left to loosen.

Adjusting the Tension

The tensions may have to be adjusted for

certain fabrics. Before adjusting your tension

make sure that the machine is properly

threaded with identical thread on both

top and bobbin. Use a new needle the correct

size for the thread and fabric being sewn. (See

chart page 8.)

41

Pattern - M

Length - 2-3

Width - 0

Needle Position - M

Feed Dog - High

Pressure - 5

Foot - All Purpose

42

It is best to test the tension on a scrap of the

fabric you are using for construction. Always

use a double thickness and always sew on the

bias when testing tension.

The tensions are correct when the upper

thread and lower thread interlock between

the two layers of fabric with the loops not

showing on top or bottom. (Fig. 43)

Adjust as follows;

If the seam is puckered both top and

1.

bobbin tensions are too tight. Loosen

both tensions slightly. (Fig.43)

If top thread lays on the fabric with

2.

bottom thread looping over it, the top

tension is too tight. (Fig. 44) Loosen the

top tension slightly.

If the bottom thread lays on the fabric

3.

with the upper thread looping over U, top

tension is too loose. (Fig. 45) Tighten

top tension slightly.

43

Page 16

The Proper Presser Foot

46

Changing the sole

Pull presser foot shank lever toward you, to

remove the sole. (Fig.46 Step 1) Place desired

sole under shank and lower presser foot

lever onto the sole. (Fig.46 Step 2) Sole

will be locked in automatically. (Fig.46 Step

3)

Step 1

Step 2

The All Purpose Foot

This foot (Fig.47) is flat on the bottom and

has a wide hole to accommodate wide

stitches. This foot should be used for all of

your normal sewing so that you can use any

stitch without changing the foot. This foot is

fine for straight stitching. (If fabric is pulled

down with the needle, use left needle position

for more control.)

The Embroidery Foot

This foot (Fig.48) has a wide groove carved

out on the bottom. This groove allows the

foot to pass over dense stitches such as the

satin stitch without catching on the stitch.

It is transparent to make stitch placement

easier. Do not use this foot for normal sewing

of lightweight fabrics. Since it is grooved, it

will not hold the fabric taut enough to

produce a good stitch.

The Straight Stitch Foot

This foot (Fig.49) is flat on the bottom and

has only a narrow hole to accommodate only

straight stitching. It may be used on sheer or

soft fabrics for more control when the all

purpose foot allows the fabric to be pulled

with needle. When using this foot, the needle

position should always be on “M”, and

the width on “O” to avoid hitting the foot

and breaking the needle.

49

50

The Buttonhole Foot

This foot (Fig.50) has a frame. This frame

holds the fabrics taut enough to produce a

good buttonhole.

14

Page 17

VI. How to Sew

Pinning may be used as a time saver instead of

hand basting. Place your pins at right angles

to the edge of the fabric with the pin head at

the raw edge. It is possible to sew over pins,

but for best results it is recommended that

the pins be removed as you approach the

presser foot. Sewing over pins can result in

damaged needles.

Placement of Fabric/Starting a Seam

Before placing fabrics under the presser foot,

make sure that the take-up lever is at its

highest position. Place your fabric so that

its raw edge is even with the back edge of

the presser foot.

When placing a heavy, bulky fabric under the

foot push up on the presser foot lever for

extra lift while you are positioning the fabric.

(Fig.51) Place the thread ends, which are

3-4 inches long, under the presser foot and

either to the left or to the right. Be sure that

both thread ends are under the presser foot.

Always lower presser foot before sewing.

Press in the reverse button so that the

machine sews a few stitches backwards to the

edge of the fabric to backtack, then release

the button allowing the machine to continue

sewing forward.

Guiding the Fabric

Etched Seam Guide

The etched seam guides on the needle plate

are graduated in 1 /8 inch divisions measured

from the middle needle position. In order to

use the etched guides effectively, let the edge

of the fabric follow the line selected for the

seam. Therefore, for a 5/8 inch seam, place

the raw edge of the fabric on the line marked

“5/8”. (Fig.52) In order to sew a straight

line, let your eye follow the etched lines, not

the needle.

Cloth Guide

This guide may be placed on the machine for

extra help in keeping seams straight. It will

allow you to guide seams from 1/4 inch to

1-1/2 inch in width, so that it is useful for

seams of unusual widths. (Fig.53)

Presser Foot as a Guide

Straight Stitch Foot - for a 1/4 inch seam,

guide fabric using the first etched mark on

the right side of feet. (Fig.54)

All Purpose Foot - for a 1/4 inch seam, use

the left needle position and guide the fabric

along the right side of the needle hole. (Fig.55)

All Purpose Foot - for a 1/8 inch seam, use

the middle needle position and guide the

fabric along the right side of the needle hole.

(Fig.56)

Holding the Fabric

For most fabrics, it is not necessary to hold

the fabric in both front and back. Merely

guide the fabric with one hand from the

front.

Page 18

57

For the fine delicate fabrics, such as chiffon,

georgette, and tricot, the best results will be

attained by holding the fabnc in front and

back of the needle without pulling on it.

Turning Corners

To pivot at a comer, (Fig.57) leave the needle

in the fabric while on the upswing so that the

stitch is almost completed, thus preventing

the possibility of skipped stitches m the

comer. Lift the presser foot and pivot the

fabric. Then, lower the presser foot and

continue sewing.

Curved Seams

On a curved seam (Fig. 5 8) use a slightly

shorter stitch length than you are using for

the rest of the seams. For example, if length 2

is being used for the seams, a 1-1/2 stitch

length would be preferred for curves. A

smaller stitch length will add strength and

elasticity to the seam.

When guiding the fabric, keep your fabnc

edge on the etched seam guide line directly

across from the needle rather than on the

forward part of the line. The seam guide may

be used on an angle as shown.

Sewing Across Heavy Seams

When approaching a heavy seam, (Fig.sy)

hold the fabric upwards on an angle so that

the heavy seam falls under the upward curve

of the foot. This will help feed the heavy

seam through the machine.

Ending Seam/Removal of Fabric.

Stitch to the edge of the fabric, then hold m

the reverse button and backstitch for a few

stitches to reinforce the end of the seam.

Turn the hand wheel until the take up lever is

in its highest position so that the «titc i

completed and the threads will P^ll freely^

Lift the presser foot and

by drawing the threads to the left and back

kLping them under the foot so as to not

bend the needle. Cut the threads with the

thread cutter on the back of the presser bar.

Leave the thread ends three to four inches

long.

16

Page 19

Vn. Applications of the Straight Stitch

Seams

The normal stitch length for most fabrics is 2,

but the length chosen should depend on. the

fabric and area of usage. Usually, heavier

fabrics require longer stitches, and lighter

weight fabrics require shorter stitches. For

curved seams and bias cut areas use a shorter

stitch length to add strength and elasticity to

the seam.

basting/ lopstitching

Sewing a seam with a longer stitch is useful

for temporary seams prior to fitting. Basting

stitches also may be used when gathering in

fullness.

Topstitching can be done very effectively

with the long straight stitch. For a bolder

stitch, two threads of the same type can be

threaded through one needle (size 14 or 16).

A heavier thread such as buttonhole twist

may be used for topstitching, but be sure to

use a larger needle (size 16 or 18). (Fig.60)

Darning

Worn spots or small holes can be darned very

easily. Use of an embroidery hoop is optional

depending on the fabric. (Fig.61) A fine

thread is recommended so that the fabric

and thread will blend together invisibly. When

you use a fine thread, loosen upper thread

tension slightly.

Trim the ragged edges from the area to be

darned. Hold the threads to start, then move

the fabric slowly backwards and forwards

while running the machine very fast to fill the

area. More professional results will be attained

by moving the fabric in a figure eight pattern

while sewing. After filling in the area

lengthwise, reweave with crosswise stUches in

the same manner.

Elastic Thread Shirring

Wind elastic thread onto bobbin, (Fig.62) as

shown, letting the thread pass through your

fingers. The thread should be wound smooth

ly without stretching. Place bobbin in case as

usual, being sure that the elastic is drawn

through the tension. Use regular thread on

the top of the machine. Do a trial run on the

chosen fabric to test length of stitch. Lay a

piece of paper under the fabric to keep it

from gathering up as you sew. This will

enable you to sew many parallel rows of

stitching without difficulty. Afterwards tear

out the paper and the fabric will be gathered.

(Fig.63)

Pattern - M

Length - 1 -3

Width - 0

Needle Position - M

Feed Dog — High or Low

Pressure - 3-5

Foot - Straight Stitch or

,411 Purpose

Pattern - M

Length - 4

Width - 0

Needle Position - L or M

Feed Dug — Highi or Low

Pressure - 3 — 5

Foot - All Purpose

Pattern - M

Length - 0

Width - 0

Needle Position - M

Feed Dog - Low

Pressure - 0

Foot - All Purpose or

Embroidery

Pattern - .M

Length 2

Width - 0

Needle Position - M

Feed Dog - nign

Pressure - 5

Foot - .411 Purpose

...........

a

60

62

1

.......

.....■....

63

...

17

Page 20

Vin. Applications of the Zigzag Stitch

66

64

65

Pattern - M

Length - I-3

Width — 5

Needle Position — M

Feed Dog - High

Pressure — 5

Foot - All Purpose

Pattern - M

Length - 1

Width - 1

Needle Position - M

Feed Dog - High

Pressure — 5

Foot - All Purpose

Pattern - M

Length - 0

Width 2-5

Needle Position - L

Feed Dog — Down

Pressure - 5

Foot - Button Sewing

Overcasting

Place the e^dge of the material underneath the

opening of the sewing foot and guide raw

edge along the center groove of the foot,

allowing stitch to form half on and half off

the fabric. (Fig.64)

The multiple stitch zigzag is a wiser choice for

most fabrics. See page 27.

Seaming Knits

The narrow zigzag can be used in seams of

firm knits for added strength. After sewing,

open seam and press flat. Tiny zigzag stitches

can hardly be seen and the seam will give

when stretched. (Fig.65)

Sewing on Buttons

Zigzag stitching is a very easy and convenient

method of sewing on buttons without a

shank. (Fig. 66)

Place the button so its left hole comes

directly under the needle, then gently lower

the button sewing foot. Take a stitch into

the hole.

Raise the needle from the left hole, and move

zigzag width lever to the right until the needle

comes down exactly over the right hole in the

button.

Note: Be sure the needle clears the holes of

the button by moving the wheel by hand

before running the machine fast.

67

Usually 6 to 8 stitches are adequate for

securing a button in place. Stop with the

needle in the left hole. To lock the threads,

set the stitch width at 0, and take a few

stitches in the left hand hole.

Forming a Thread Shank

Buttons* sewn on coats or jackets should have

a thread shank to make them stand away

from the fabric. (Fig.67) To form a thread

shank, sew over the blade of a regular sewing

machine needle. Insert needle into hole on

the front side of foot.

After stitching the button to the fabric,

remove work from under the presser foot

leaving threads about six inches from fabric.

Remove needle. Pull the threads to back of

button and form a shank between button and

fabric by winding threads tightly around the

attaching stitches. Pull threads to back of the

fabric and tie thread ends securely. (Fig.67)

Page 21

Satin Stitching

This is useful for decoration such as tapering,

manual designed embroidery, monogramming,

and applique. (Fig.68)

The satin stitch, which is really just a very

close zigzag stitch, is obtained by setting the

stitch length as near to “0” as possible

without stopping the feeding action. The

setting will vary for different fabrics. It may

be desirable to loosen the upper tension

slightly to cause the threads to lock under

neath, in order to make the top surface look

especially smooth. For lightweight fabrics,

place paper underneath the fabric while

sewing for best results.

Tapering

Tapering is done by gradually increasing and

decreasing the stitch width while sewing.

(Fig.69) By this method, tapered monograms

and other interesting designs can be created.

(Fig.70) For tapered monogram run the

machine fast while sliding the width dial lever

slowly from narrow to wide and from wide

to narrow.

Pattern - M

Length - ‘4

Width - 1^5

Needle Position ^ M

Feed Dog — High

Pressure 5

Foot -- Emhroiderv

,'n

Length

Width - 0

Needle P'o

Feed Dog

root — tr

0-L

Hiuh

troidi

69

First, learn this stroke by letting the fabric

guide straight and trying different needle

positions. Then, learn to pivot the fabric as

you are tapering by holding the fabric at one

point. Various strokes can be combined to

form letters and designs. Variegated thread

can give attractive results.

Manual iimoroiGer

Desiiins

Different designs can be made by sliding the

stitch width lever control (disengaging both

stops) between 0 and 5. By running the

machine at a constant speed and sliding the

lever in a definite rhythm, various designs

can be created. (Fig.71)

Pattern - M

Leneth - O-M

Width ^0^5

70

A M

W ^

. %

1 i

f \

71

1

1

Feed Dog — High

Pressure - 5

Foot - Embroidery

Page 22

72

Pattern — M

Length - 0

Width - 1-5

Needle Position - M

Feed Dog - Low

Pressure — 0

Foot - Embroidery or

All Purpose

Step 1

Pattern — M

Length — 1

Width - 0-1

Needle Position - M

Feed Dog - High

Pressure - 5

Foot - Embroider^'

Step 2 ,

Pattern - M

Length - '/4—'/2

Width - 2-4

Needle Position - M

Feed Dog - High

Pressure - 5

Foot - Embroidery

Freehand Monogramming

For giving garments and linens a personalized

touch, first transfer the design to the right

side of the fabric. An embroidery hoop is

recommended especially for soft fabrics and

toweling. (Fig.72) When you monogram

loosen upper thread tension slightly.

In order to monogram, you must move the

fabric slowly and run the machine rapidly.

Monogramming is like writing by moving the

paper under a stationary pen. Guide the fabric

slowly so that the zigzag falls close together

like a satin stitch, but be careful that the

stitches do not pile up. When guiding from

side to side, move fabric slightly faster to

avoid a heavy area.

Practice by forming loops. Once this is

accomplished any letter is easy.

Sometimes the use of paper or non-woven

interfacing under the fabric may make guiding

the fabric easier. The paper or interfacing may

be tom or cut away at the completion of the

monogram. When monogramming towels,

plastic film placed on the top will help cover

loops and make the monogram smooth. Pull

or cut away remaining plastic film when

finished.

Applique

Applying decorative shapes of fabric scraps to

household articles and colthing is a very

interesting way of trimming an otherwise

plain article. First, trace the design on fabric

to be appliqued, then pin or baste it securely

in place on garment. With a small straight

or L

stitch or narrow zigzag, sew around the

transferred design. (Fig.73)

After excess fabric is trimmed away, sew

around the applique with a satin stitch. For a

smooth curve, stop frequently at the inside

edge of the curve to pivot the fabric slightly.

Corners look much better when the point is

stitched by pivoting rather than just turned.

As with all decorative stitches, paper may be

used to give more body to the fabric when

stitching and can be torn away when the

applique is completed. (Fig.74)

Note: Bobbin thread should be placed

through the clip for all operations described

on page 19 and 20.

Page 23

Gathering Over a Cord

Ordinary gathering with a basting stitch often

breaks while pulling in fullness. A small zigzag

across a cord such as crochet thread or carpet

thread, gives a much stronger cord for

gathering fullness into fabrics. (Fig.75) Once

the gathers have been stitched in place, the

cord can be pulled out in order to eliminate

bulk. (Fig.76)

Pattern - M

75

Length - 2

Width 3—4

Needle Position - M

Feed Dog - High

Pressure - 5

Foot - Embroidery

Lace Application

.Attaching laces or trims adds a special touch

to lingerie, dresses, or linens. Pin or baste lace

in place easing or mitering comers where

necessary.

A straight edged lace or braid has a

convenient line to follow when sewing.

(Fig.77) When using a scalloped edged lace

follow the design of the lace for an almost

invisible application. (Fig.78)

Lettuce Hem

An unusual way of hemming or finishing

edges of tricot or soft knits is by a lettuce

edge. (Fig.79) Hemming in this manner is just

like overcasting an edge, but the fabric is

stretched in back and in front of the needle

as you sew. For best results, pull the fabric

equally, making sure the needle goes over the

edge. (Fig.80) When you stop to reposition

your hands, keep the needle in the fabric.

Pattern - M

Lenath —

'/2

— 1

Width -1-2

Needle Position. - M

Feed Dog - High

Pressure - 5

Foot - .A.I1 Purpose

77

Fatte

M

78

80

Page 24

81

85-1

Step 1

Step 2

Pattern - UlL_

Length — '/4

—/'2

Width — 3 — 5

Needle Position - M

Feed Dog - High

Pressure - 5

Foot - Buttonhole

Built-in Buttonhole

This buttonhole eliminates the need or

pivoting the fabric. It is used most often on

light and medium woven fabrics.

1 Set pattern selector dial for the first

’ buttonhole position. Lower needle into

the mark at the end of buttonhole. Lower

presser foot and take a few stitches to

bartack. (Fig.85-1 Step 1)

5 With needle out of the fabric, turn pattern

“■ selector dial to second picture. Sew up

left side of buttonhole until the white

nylon slide runs into the back of lip of

the foot. At this position, the machine is

feeding in reverse. (Fig.85-1 Step 2)

IX. Buttonholes

Various fabrics require various methods of

sewing buttonholes. Four different methods

are given below, with suggested uses. If you

are in doubt as to which method is best for

vour fabric, test the methods in question and

choose the best according to the finished

appearance. ,

preparation

For the best results, a good quality

mercerized cotton thread should be used.

Polyester threads often result in puckered or

heavy unattractive buttonholes. The tiner

your fabric is, the finer your cotton thread

should be.

An interfacing should be used under the

buttonholes to give body, to strengthen, and

to help them withstand wear.

To establish the correct length of the

buttonhole, add the diameter of the button

(A) plus the thickness of the button (B), plus

l/g’inch for the bartacks. (Fig. 81) The length

may be marked on the garment with a basting

stitch, tailor’s chalk, or transparent tape.

Another way to make sure that all button

holes will be the same size is to cut a piece

of cardboard as wide as the buttonhole foot

and long enough to make the distance

between the toe of the white slide and the

cardboard the size buttonhole needed. (Fig.

82) This method works for buttonholes up

to 1 1/8 inches long. Horizontal buttonholes

should extend 1/8 inch beyond the center line

of the garment. (Fig. 83) Vertical buttonholes

are placed so that the cutting space of the

buttonhole is directly on the center line.

(Fig. 84)

Always make a practice buttonhole on a scrap

of the garment fabric before making any

buttonholes on your garment. On your test

sample, duplicate the thicknesses found in

the garment and be sure to include the

interfacing. The test sample should help

determine the length needed for the button to

pass through the hole easily, as well as the

stitch length needed for the particular fabric.

As with the satin stitch, the stitches should be

close together, but not so close that they pile

up. Be sure to use the buttonhole foot.

01

Page 25

3. With the needle up select the third

buttonhole picture on the pattern selector

dial. Sew a few stitches to bartack. (rig.

85-1 Step 3) . , . .

4 With the needle out of the fabric, turn

' to the final buttonhole picture on the

pattern selector dial and complete he

riaht side of the buttonhole. White nylon

slide will run into cardboard so you

cannot go beyond first bar tack. (Fig.so

1 Step 4)

5. To lock the stitches, make sure the needle

is out of the fabric and set width at 0.

Then take a few stitches.

6. Score the buttonhole with the back edge

of the seam ripper several times. To

prevent cutting through the bartack,

insert a straight pin through the bartack.

Cut buttonhole open with the seam

ripper. (Fig.85—2)

Turn-around Buttonhole

Turning the fabric for buttonholes gives

better results in certain situations. This memod

may be desirable for making the top button

hole at the neck or waistband near thick

enclosed seam allowances. It is also excellent

to use when repairing worn buttonholes on

ready-made garments, or

the stitches have been cut accidently when

cutting open the buttonhole. When using tlus

method over a buttonhole which has already

been slit, be sure to hold the buttonhole open

and allow the needle to go off the edp of the

fabric at the right. On soft or stretch fabrics,

use paper underneath.

1 Set the needle position to the left. With

■ zigzag width at 2V2, start at the end of

the buttonhole marking. Sew down the

left side of buttonhole until you reach the

end marking. Leave the needle m fabnc

at the right side of the stitches. Lift the

presser foot and pivot the fabric around

until the first row of stitching is directly

in front of the presser foot. (Fig.86)

Slide buttonhole foot up to the end of

foot, so the other side of buttonhole

can be made.

2. Lower presser foot and raise the needle.

Move width to 5 and take several stitches

on top of one another to bartack. Hold

the fabric to prevent feeding. Stop needle

in fabric at the left side of stitches. (Fig.

87) . .

3. Raise the needle and return zigzag to in

width. Complete second side of button

hole, stopping the needle in the tabnc

at the left of the end marking, or when

the nylon slide runs into cardboard insert.

(Fig.88) .

4. With needle up, move width to 5 again

and take several stitches while holding the

fabric to prevent feeding. (Fig.89)

5. Lock threads by stitching a few stitches

at 0 width. Cut buttonhole as indicated

93 previously, (page 23)

85-1

Step 3

Pattern — M

Length — Vi—’/2 _

Width -2Vi-5-2y2-5-0

Needle Position - L

Feed Dog - High

Pressure - 5

Pool - Buttonhole

85-2

Page 26

90

I’attcrn - M

Lcnuth - '4 -'4

Width -- 2'2-5-2'2-5Needle Position — L

Feed Dog ^ High

Pressure — 5

Foot — Buttonhole

Pattern -

Leneth — 4—0Width - 2H-5-2'

Needle Position Feed Dog - High

Pressure — 5

Foot — Buttonhoit

-0-0

-5-0

L Uli i iOiilUhC

Cording gives a reinforced raised buttonhole.

It is excellent for use on bulky, woven fabric,

or knits in which the stitching often gets

buried and makes cutting difficult. On knits,

a corded buttonhole will help keep the fabric

from stretching out of shape.

Choose a heavy cotton crochet thread or

buttonhole twist to use for cording. Proceed

as for the built-in buttonhole (Page 22) - Loop cord around the front prong and under

the presser foot in such a way that the zigzag

stitch covers the cord.

At the completion of the buttonhole snip the

excess cord close to the bartack on woven

fabrics. For knitted garments, always pull the

cords to the wrong side by using a darning

needle or needle threader and knot the cord

ends before clipping.

Stretch Buttonhole

This buttonhole is used on knit fabrics when

it is desirable to omit interfacing or cording.

This buttonhole will stretch and return to

shape unlike an ordinary zigzag buttonhole.

The ifisX pattern of the stitch makes the bu

ttonholes nearly invisible when using match

ing thread. It is excellent to use on jerseys,

double knits, and sweater fabrics. (Fig.91)

I I

Set the needle position to the left. With

the width at 2'/2, start at the end of the

buttonhole marking. Sew down the left

side of buttonhole until you reach the

end marking or cardboard insert. Leave

needle in fabric at the right side of the

stitches, lift the presser foot. Pivot the

fabric and slide sole up to the end of foot

so the other side of buttonhole can be

made. -

Lower the presser foot and raise the

needle. Move the stitch length to 0 and

the width to 5. Sew several stitches to

bartack. Stop the needle in fabric at the

right side of stitches.

3.

With the needle up, move the stitch

length back to 4 and the width to IVi.

Complete the second half of the button

hole, stopping the needle in fabric at the

left of the end marking.

4.

With the needle out of the fabric, move

the stitch length to 0 and the width to 5.

Bartack several stitches.

5,

With the needle up, slide the stitch width

to 0 and take several stitches to lock the

threads. Cut buttonholes as indicated

previously (page 23).

24

Page 27

X. Applications of the Blind Hem Stitch

Hemming

The blind hem stitch provides a durable hem

finish that is almost invisible on garments

drapes, and curtains. It is done easily with

straight or slightly curved hems, ^ith a littk

practice it will be a very quick and easy hem

application and the hem will never need

repairing.

Procedure; .

(1) Prepare raw edge of hem “ desired

manner, such as overcast, 1/4 men

stitched under, pinked, hem tape, or just

plain. (Fig.92-Stepl)

Fold hem up desired length.

Baste or pin 1/2 inch from upper edge.

Press in place. (Fig.92—Step2) ,, , .

(3) Fold hem back toward right side of fabric

leaving about 1/4 inch extended.

(Fig.92-Step3)

(4) Adjust your stitch width and neeuie

position (Fig.93) so that the zigzag i e

of the stitch comes just slightly to the lett

of the center cut of the presser foot

Then the fold of the fabne may be guided

into the center cut of the presser foot tor

a perfect hem. The straight stitches

should be formed on the single thickness

of fabric, and the zigzag bite should catch

just barely into the fold of the fabric at

Pattern - <1

Length - 2

Width - 2-3

Needle Position - M

Feed Dog - High

Pressure - 5

Foot - All Purpose

92

(S') When stitching is completed, (Fig.94)

remove fabric from machine and turn to

right side. Press completed hem.

When hemming an A-line skirt, p ace a

machine basting stitch along the raw edge

the hem. At an ironing board, fold up the

hem, matching the seams. Ease in the excess

fabric by pulling on basting thread. Press with

steam, then apply hem tape. Baste or pin hem

1/2 inch from taped edge, then continue in о

step 3.

93

94

i

; >

(C

r

Page 28

Pattern -

Length - ‘/2-I

Width ^ 5

Needle Position — M

Feed Dog High

Pressure — 5

Foot — All Purpose

96

Shell Tuck

The blind hem stitch gives a very effective and

easy way to make a shell tuck for lingerie,

pillowcases, and decorative finishes. (Fig.95)

This works well on knits or on the bias of

soft, woven fabrics. A single folded bias tape

may be tucked in this manner, and then

applied under a fold for a decorative hem on

pillowcases or applied with the facings at the

neckline or armhole for a decorative finish.

Fold under the edge where the shell tuck is

to be created. Place the bulk of the fabric to

the right of the needle with the folded edge

to the left. Place the fabric so that the folded

edge will be guiding into the center cut of

the foot. The straight stitches will form on

the fabric, and the zigzag bite will swing to

the left off of the folded edge. (Fig.95) The

shell edge is created as the needle swings

back onto the fabric. The size of the “shell”

can be varied by changing the stitch length.

1 j

; ;

><

' ;

:

i <<

> i

!

> !

I

—

-4>

: <

t- _

H

> i

i

> i

r'

1 ;

: <

> i

; <

S ;

/T “ * F

V _ - i.

\ ■

r "

'=1

Needle Positicn - .M

Feed Dog ^ High

Pressure ^ 5

Foot ^ All Purpose

Decorati"? Effe-''

By sewing two adjacent rows of blind hem

stitching on lace or ribbon attractive decora

tions are created. (Fig.96) The stitch may be

pivoted when the zigzag bite swings to the left

and the points matched in the second row.

Another variation alternates the zigzag bites

in the center of the straight stitched segment.

The stitch may also be pivoted after three

straight stitches to form a snowflake-like

pattern.

A flower design can be created by starting at

the center of the zigzag bite, then pivoting at

the end of each petal as shown. Four more

petals can be added if desired.

26

Page 29

. f-f-. .o \j t Htc iviuitLIpiC OtiLUIl ¿LiyZdy

Overcasting

The multiple stitch zigzag is an excellent

choice for overcasting. (Fig.97) It keeps the

fabric flat and prevents raveling. For most

fabrics, this stitch is better than the zigzag

stitch for overcasting.

The stitch should fall right at the raw edge of

the fabric. Feed the fabric under the presser

foot by guiding the raw edge along the right

hand side of the hole in the presser foot.

97

Pattern - 7:

Length - '/;-l

Width - 5

Needle Position ^ M

Feed Dog - High

Pressure - 5

Foot - All Purpose

Patching

The multiple stitch zigzag is an excellent

stitch for patching. It is stronger than the

zigzag and the tiny stitches bury into the

fabric to make an almost invisible stitch when

using matching thread.

Place the patch over the right side of the worn

or damaged area. Sew around the patch with

the multiple stitch zigzag letting the last stitch

to the right overcast the edge of the patch.

(Fig.98) When turning comers leave the needle

in the fabric at the comer. (Fig.99) Usually

this will be the furthest stitch to the right or

left. In this way, the eomers are doubly

stitched and very strong. When the patch is

stitched in place, trim away the excess worn

fabric on the wrong side of the patch. (Fig.

100)

Mending a Tear or Instant Darning

The multiple stitch zigzag provides a strong

and easy repair for tom garments. It gives an

almost invisible mend, especially when a fine

darning thread is used.

To mend a tear, hold the tom edges close

together and stitch down the middle. (Fig.

101) If the tear is guided under the slot in the

middle of the presser foot, stitching will be

equal on both sides. If necessary, sew again on

either side of the first row of stitching making

sure the needle catches the stitch in the

center. With very worn or frayed fabric,

place a piece of lightweight interfacing or

cotton batiste under the tear for reinforce

ment.

Pattern - ‘A

Length Width - 5

Needle Position - M

Feed Dog - High

Pressure - 5

Foot ^ All Purpose

99

Pattern - Lp

Length

Width - 5

Needle Position M

Feed Dog - High

Pressure - 5

Foot - All Purpose

101

27

Page 30

■^1 '

102

f ■ - ■ r-is. Vi^.

104

'j.' -t,'

/.V-'i '■ 'r^";

rail cm ' . .

Length - m - 1

Width — 5

Needle Position ^ M

Feed Dog ^ High

Pressure — 5

Foot - All Purpose

103

■:

Applying elastic to lingerie or soft knit fabrics

is easy when using the multiple stitch zigzag.

Cut the elastic 2 inches smaller than your

waist measurement. Overlap the raw ends to

form a circle and stitch with a tiny zigzag to

form a box as shown. Fold the elastic into

quarters or eighths and mark with pins. Do

the same with the waistline of the garment.

(Fig. 102) Place the elastic about Id inch from

the top edge of the fabric, matching the pins.

Place under the presser foot and begin stitch

ing. As you stitch, place the forefinger of each

hand on the fabric at either side of the presser

foot. (Fig. 103) Stretch the fabric exactly at

the point where the needle is sewing over the

elastic and the fabric. This will ease your

fabric and elastic together as you sew. The

amount of ease is dependent on how much

you stretch the fabric. In this way you never

need to stretch the elastic, which can be

damaged and stretched out of shape. Trim

off excess fabric above elastic near the stiches.

n

» s

■t«

105^

/ \

< >

\ /

X

< >

\ r

X

/ N

< >

\ /

X

r \

< >

\ /

X

/ \

< >

\ /

NT

/ / / / /

/ / / / /

<<<<<

\ S \ \ N

>>>>>

/ / / / /

<<<<<

\ N \ \\

>>>>>

/ / / / /

<<<<< <

S N N \N

> >>>>

/ / / / /

<<<<<

\ N S S \

>>>>>

/ / / / /

<<<<<

s \ N s \

\ \ \ \ s

A

i \

< >

< >

\ /

V

Pattern — m

Length 1

Width ^ 5

Needle Position -- M

Feed Dog High

Pressure ^ 5

Foot - All Purpose

Pattern W:

Length — 1^2

Width ^3-5

Needle Position ^ M

Feed Dog High

Pressure — 5

Foot - All Purpose

Understitching Facings

The multiple stitch zigzag is an excellent

choice for understitching and eliminating bulk

in facing seam allowances. (Fig. 104) After

attaching the facing to the garment, trim and

clip the seam allowance as usual. Press the

seam allowances toward the facing and use

the multiple stitch zigzag close to the seam,

stitching through the facing and the seam

allowances. Using a matching thread, the

stitch will blend into the fabric and prevent

excess bulk. This is much more successful

than a straight stitch for understitching. It

really helps to keep the facinp from rolling.

Decorative Effects

As with the blind hem stitch, the multiple

stitch zigzag can be used for many decorative

combinations. (Fig. 105) If the stitch is

pivoted when the needle reaches the far left

or right of its swing, and the points are

carefully matched, a tracery diamond shape

results.

On the other hand, if rows of the multiple

stitch zigzag are sewn with the points falling

directly under each other, a wavy pattern is

produced.

Flowers may also be produced. Start in

center; pivot at points shown. Add four more

petals if desired.

28

Page 31

Seams

This stitch gives a finished % inch seam in one

step. For knits, it gives strength and elasticity

to the seams and prevents the curling of the

fabric that often occurs with 5/8 inch opened

seams. It is most applicable to soft, thin knits

such as nylon or acetate knits, but may be

used on other fabrics as well. Always make

test seams with this stitch and with the Ultra

Stretch Stitch and choose between the two

according to performance on the particular

fabric.

For woven fabric, the overlock stitch gives

strength and prevents raveling. It can be used

on woven goods to replace flat felled or

French seams.

For patterns with ’A inch seams: (Fig. 106)

Place the raw edge of the fabric under the

presser foot so that as the needle swings to

the right, it comes down at the raw edge. This

will result in an enclosed seam allowance.

For patterns with 5/8 inch seams: (Fig. 107)

The seam allowances may be trimmed to 14

inch either before or after sewing. If trimming

before sewing, proceed as above. Otherwise,

sew the seam with the raw edge of the fabric

on the etched guide line “14”. (Any time you

use the full width of a particular stitch, you

should readjust the raw edge of the fabric

1/8 inch to the left.) Afterward, trim the

excess fabric near the stitching. This method

is actually easier than the overedge method

for fabrics that curl.

Note: On soft, loose knits, the fabric may

seem to wave or ripple. If this occurs, reduce

the pressure (Page 12).

Pattern —

Length - 4

Width - 5

Needle Position -- M

Feed Dog - High

Pressure — 4 or 5

Foot - .4.11 Purpose

107

Nylon Tricot Seams

The overlock stitch is excellent for use on

fine fabrics such as nylon tricot. Lingerie or

tricot seams should only be about 1/8 inch

finished width. Use size *11 needle for better

seams.

If your pattern has wide seams, trim them

down to /4 inch while cutting out the pattern.

Guide the raw edges of the fabric into the

center slot of the presser foot. On the right,

the needle will stitch over the edge resulting

in a finished rolled seam of 1/8 inch. If a

pucker results when stitching, a looser tension

is needed.

Stitching in this manner can also be used to

form a rolled hem on the raw edge of a scarf.

.Applying Elastic

The overlook stitch gives a very finished

appearance to elastic application. (Fig. 108)

See instructions for elastic application on

Page 28, but use this stitch instead of the

multiple stitch zigzag.

29

Pattern -

Length Width - ;

Needle Po

Feed Dog

4

i

.Nitiuil -

- High

Pressure -

Foot - A

nose