Page 1

tit

<19

INSTRUCTION

,0« SE..0

Page 2

CONTENTS

Name of parts

1.

Turning of light

2.

Winding the bobbin............................................................. 3

3.

Inserting of the needle

4.

How to thread the needle

5.

How to remove the bobbin case................................................. 6

6.

How to insert the bobbin case................................................ 6

7.

How to thread the bobbin case................................................. 7

8.

How to sew straight stitches.................................................. 8

9.

Adjustment of stitches and reverse Sewing

10.

Use drop feed device

11.

Adjustment of pressure to cloth............................................... 12

12.

Regulating width of zigzag stitch

13.

Manual zigzag sewing

14.

How to keep the machine in good repair...

15.

How to make button holes

16.

Darning and embroidery

17.

Sewing on buttons

18.

Narrow hemming

19.

Sewing in a zipper

20.

Installing sewing heads in cabinet or portable base

21.

Blind hems................................................................................................................................................................................. 24

22.

.................................................................

..............................................................

.......................................................

.....................................................

.....................................

..........................................................

............................................

.........................................................

....................................

.....................................................

.......................................................

............................................................

...............................................................

...........................................................

.........................

1

2

^

5

11

H

13

14

15

16

18

19

20

21

22

.1'"

Page 3

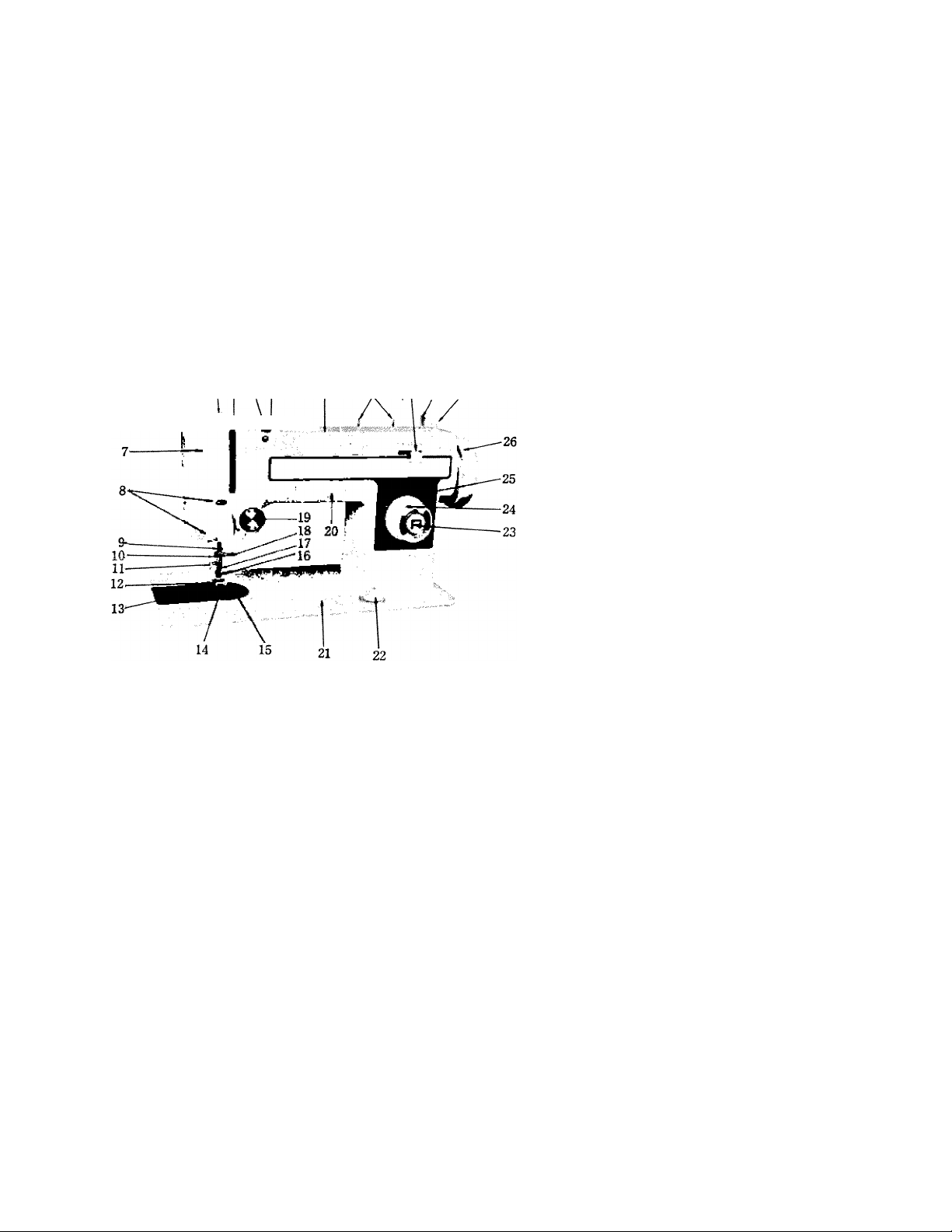

1. NAME OF PARTS

^ ? 29 1 2 28 27

ni A*

1. Spool pin

2. Zigzag width control knob

3. Bobbin winder thread guide

4. Top cover thread guide

5. Thread take-up lever

6. Patchomatic darner

7. Face plate

8. Thread guides

9. Needle bar

10. Needle bar thread guide

11. Presser foot thumb screw

12. Presser foot

13. Shuttle cover slide plate

14. Feed teeth

15. Needle plate

16. Needle

17. Pres ser bar

18. Needle clamp

19. Thread tension regulator

20. Arm

21. Bed plate

22. Drop feed knob

23. Reverse button

24. Stitch length regulator knob

25. Stitch indicator window

26. Balance wheel

27. Bobbin winder latch

28. Bobbin winder spindle

29. Top cover

Page 4

2. TUENING ON LIGHT

The lamp housing is enclosed in the face plate (Fig 2).

The switch for operating the light is beneath the face plate (Fig 3).

Changing bulb:

Be sure to first unplug your sewing machine. With your left hand, open the face

plate and the bulb is easily replaced.

I ^

l!

Fig. 2

Fig. -3

Page 5

3. WINDING THE BOBBIN

The bobbin is easily wound by the fol

lowing method.

(a) Turn the stop motion knob (1) toward

you while holding the balance wheel

(2) with the left hand, loosening it

so the wheel will run free without

operating the sewing mechanism.

(b) Place the Spool on the Spool.pin (3).

Pass the end of the thread through the

Arm Thread Guide (4). Also pass it

between the discs of the tension brack

et (5). Wind the thread around the

Bobbin (6) seven or eight times, and

place the bobbin on the Bobbin winder

spindle (7). The bobbin winder auto

matically disengages when the bobbin

is about 907o full.

5 4

3 8 7 6 2

Fig. 4

Page 6

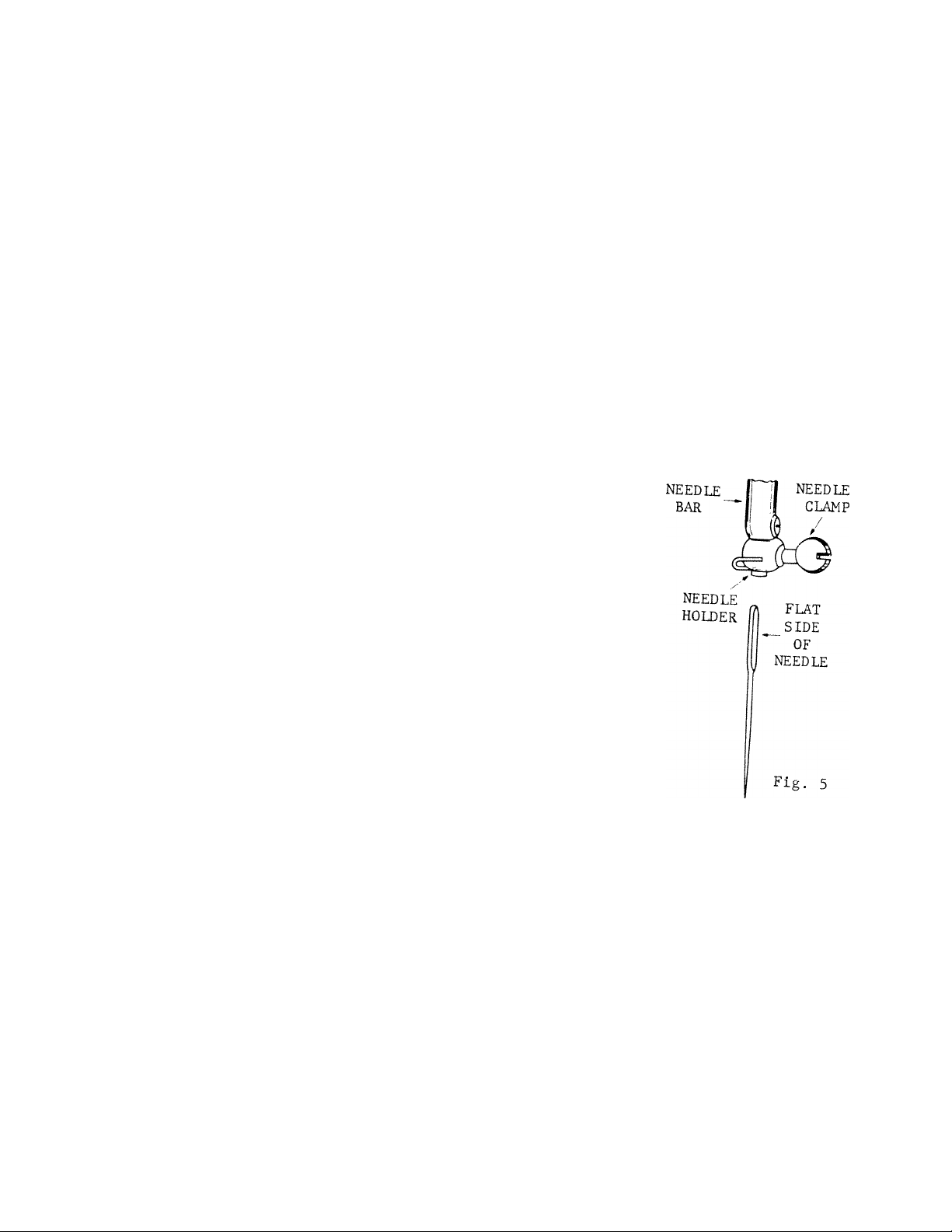

4. INSERTING OF THE NEEDLE

(a) Loosen the needle clamp with your right hand

and hold needle so that the flat side is to

your right. Then insert the upper part of the

needle until it hits the closed end of the

clamp,

(b) Tighten the needle clamp with your right hand.

(c) As the picture indicates, turn the needle

clamp to the left to loosen it, and turn it to

the right to tighten it.

(d) Always make sure that the long groove in the

needle is toward the left.

Page 7

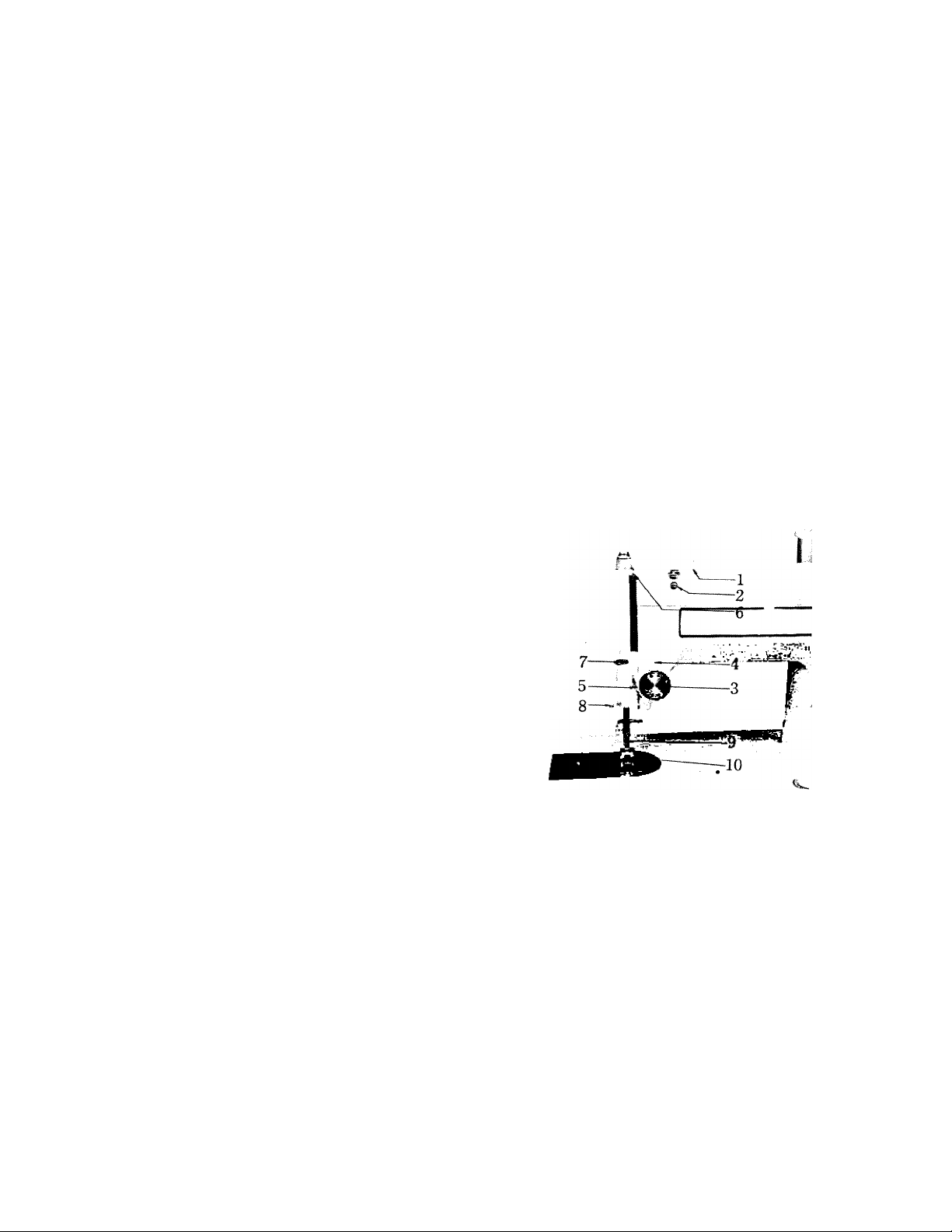

5. HOW TO THREAD THE NEEDLE

(a) Raise the needle bar to its highest point.

(b) Thread the needle by following the numbers indicated in the picture.

(1) Arm Thread Guide

(2) Tension Bracket

(3) Tension Disc

(4) Tension Thread Guide

(5) The Take-up Spring

(6) Thread Take -up Lever

(7) Arm Thread Guide

(8) Arm Thread Guide

(9) Needle Clamp Thread Guide

(10) Needle

Fig. 6

Page 8

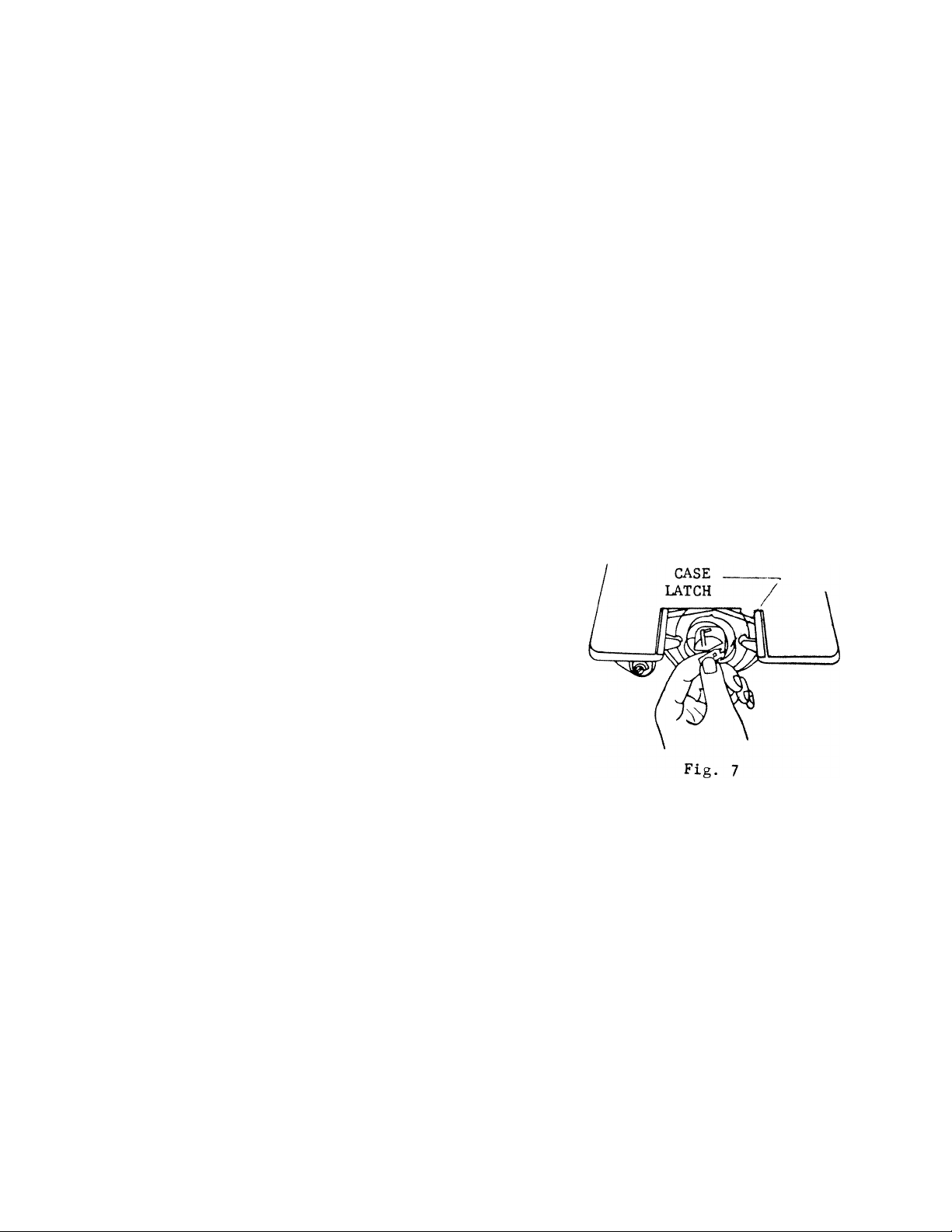

6. HOW TO REMOVE THE BOBBIN CASE

(a) Raise the needle bar to its highest point by

turning the balance wheel.

(b) Open the bobbin case cover.

(c) Open the latch of the bobbin case and take it

out.

(d) Close the latch of the bobbin case thus taken

out, and turn it with the open side downward.

The bobbin will drop out.

7. HOW TO INSERT THE

BOBBIN CASE

(a) Open the latch and insert the bobbin case on the

shuttle race pin. Be sure that the horn goes

into the slot in the shuttle race.

(b) Close the latch when the bobbin case has been

inserted.

(c) Be careful not to remove or insert the bobbin

case when the needle bar is lowered. The shuttle

body and the shuttle race will be damaged if

BOBBIN

this warning is ignored. — 6 —

Page 9

8. HOW TO THREAD THE BOBBIN CASE

(a) Hold the bobbin in your right hand, pull out the thread about 5 inches, and

insertin the bobbin case. (Fig. A)

(b) Pull the thread through the slot in the bobbin case as indicated in Figure B,

and pull the thread under the tension spring.

(c) Pull out the thread, and it will come out to the position indicated in Figure C.

Page 10

9. HOW TO SEW STRAIGHT STITCHES

(1) Prepare for Sewing as Follows:

(a) Set the zigzag width regulating knob to "0" (zero po

sition). Now you can sew straight sewing.

(b) Hold the upper thread lightly in your left hand.

(c) Turn the balance wheel toward you gently with your

right hand, until needle enters needle plate & re

turns to highest point.

(d) When the needle bar with the thread inserted into the

needle has been raised, pull the upper thread, and

the lower thread will come out of the needle hole

picked up by the upper thread.

(e) Put both the upper and the lower thread beneath the

presser foot and pul] the ends to the back.

(2) Actual Sewing:

(a) Place the cloth to be sewn beneath the presser foot,

making one stitch by turning the balance wheel, and

lower the presser foot.

(b) Start sewing.

(c) Do not pull on the material. This often causes the

needle to break.

(3) How to Change the Direction of Sewing:

- 8 -

Page 11

(a) Stop sewing with the needle in the cloth

(c! L»:: 2 izz

(4) How to Remove the Cloth:

(a) When the needle bar has reached its highest noint cr. •

(b) Raise the presser foot and ^ sewing.

(5) Adjustment of the Upper and Lower Thread Tension,

( } Satisfactory seams can be produced by

being sure the upper thread and the lower

thread are knotted right in the middle of

the two pieces of material being sewn. See

Figure C.

(b) When too much tension is applied to the

upper thread, the result shown in Figure A

is produced.

(c) When too much tension is applied to the

lower thread, the result shown in Figure B

presser root and resume sewing,

presser toot and pull the material out to the left.

Fig. 13

Page 12

is produced, (looping on the bottom)

(6) How to Adjust the Tension of the Upper Thread

(b) Turn the tension disc to the right to increase the tension.

(c) j-urn it to the left to loosen the tension

(7)

111 Z- ‘Z°ZZ

(7) How to Adjust the Tension of the Lower Thread

(a) Ordinarily it is unnecessary to change the

tension of the lower thread, but there are

some fabrics that require a change.

(b) Turn the screw to the right in order

tighten the tension.

(c) Turn the screw to the left in order

loosen the tension.

(d) As it depends entirely upon the tension

whether or not you sew well, it is highly

important that you learn how to adjust the

tension as soon as possible.

(e) Use the small screw driver in your acces

sory kit to make these adjustments.

““ -“p »p pt»ippp<i.

to

to

-10-

Page 13

10. ADJUSTMENT OF STITCHES

AND REVERSE SEWING

(a) The figures on the indicating plate (3)

show the stitch length.

(b) Turn the knob (1) setting the desired

length of the stitch to the black-mark

on the knob (2).

(c) For reverse sewing, push the push button

reverse (4) until it stops.

11. TO USE DROP FEED DEVICE

Darning and embroidering is facilitated by means of the drop feed knob on the right

hand corner of the bed.

When this knob is set at "0", the feed teeth drop below the surface of the needle

plate so that it will not interfere with

the free movement of the cloth.

The feed teeth will return and resume their

normal operation when the knob is set at "2".

For sewing light materials like silk, it may

be set at "1" position in order to avoid

puckering the material.

-11-

Page 14

12. ADJUSTMENT OF PRESSURE TO CLOTH

(a) In the case of ordinary cloth, it is seldom

necessary to adjust the pressure, but when

sewing thin or delicate materials the pressure

must be so adjusted that the cloth gets the

proper pressure. For instance, too much pres

sure will cause the material to pucker.

(b) Press down the patch-o-matic darner (A) and

the presser bar will jump up and the pressure

will release. Press down the presser bar (B)

and the pressure will become strong.

(c) You can easily adjust the pressure. In the

case of embroidering, the presser bar should

be raised to its highest point.

12-

Page 15

13. REGULATING WIDTH OF ZIGZAG STITCH

The width of tlgtag stitch Is regulated by the zigsae width ,

rigtag width lever to desire zlzzae stlth "Idth lever. By moving the

straight stitch, and to "5" mar zigzag stitch. Instance, to "O" as

Zigzag stitch accordinelv s

Fig. 9

13-

Page 16

14. MANUAL ZIGZAG SEWING

By manually adjusting Che stitch length, zigzag width while running the machine, a variety of omamental stitches are

sewn.

following are some examples of manually sewn omamental stitches:

Patterns

—

I-«"’«""!-»

Stitch Length

any length

short

any length

"

long and short

(repeat)

any length

"

14-

Width

0

5

1-5

••

any width

5-2-5

"

Page 17

IS. HOW TO KEEP THE MACH/NP

Oiling CHINE IN GOOD repair

IS SQ important that if

ot only shorten the ^ should be neaT

nT , roachine'Q '^^gligent in •

; ° al3„ "

Oo not use fnn cause it p

°° »11. I, PP P'PC.O„

(2) Where to Oil

<p)

to be oiled. PPPPP

Just one drop at a ti

<P^ «^PU you dare „ned “

'"pppppuj. run the „aed;:;

WhxX0 Q l r^т T i-OE 3.

slowly so that the oil

penetrate and ^

The Quali,, Of tb T'"'

Oil of nn Used

the ^ quality will not n 1

the machine to run u ^ause

will cause wear and

°nly good quality'"'' °f

- -Wing machines "

^ “""Pcessary ,

"Py sta,„ „

BOTTOM

-15-

Big. 22

Page 18

HOW TO MAKE BUTTON HOLES

Place a marking needle

across the cutting

space to protect the

stitching.

1. Kemove the regular presser foot and attach t-ho k

2. Set the zig-zae wiHrh i v attach the buttonhole foot.

3. Mark witr^pLcIfor IhS^^tL^poLi° "Pitches (stain stitch),

the fabric. -“-^ngth of the buttonhole on

zigzag width lever between "1" and "2"

Stop the machine with needle on fabric at point A.

16-

Page 19

end to brine thp к ^s^ng the needlp я

-7 ■ feed tep^ь u

'• the eigeag width J drop f„d t

taok. (2) ** ® at '4., P faed k„

8- Raise teedle e " ^°"t stitches t

at „g,, -«P fabric, siao taise deed te th K

»P» to sew the other row g '*’'* “-P feed кос

"ееа 1" g^d "2" (to 1оГ dettonhole ret

stltchiog reaches he p„sit°"""‘' ’a» со ‘ 1*-^ be

“• To „ske the iidal bar-t.l «*“- (3, ““ datli Д

bar-tack. (4) ^gain setting the d. '

11- Return zigzag -a u ^ at "П" a

thread. 5 ® to "0" a^d r.u the

Re„o;:^r,fP"P stitches to is t

« -- -ebioe sod open the hott h

C) P bottoohoie cott

Pr*esser foot апи •

■17-

Page 20

17. DARNING AND EMBROIDERY

Raise the presser bar lifter and remove the presBei. foot. Then lower the presser

bar lifter to ensure the thread tension device is set correctly.

Set the drop feed knob at "O",

Now your machine is ready for embroidery and darning.

Embroidery will be done most successfully when the fabric is stretched and fixed in

an embroidery hoop. Hold the hoop closely on the machine bed with both hands, press

the material with your left forefinger in the vicinity of the needle.

This will help in holding down the material and will prevent the machine from

making skipped stitches. Manipulate work carefully and be sure to keep fingers out

of the path of the needle.

Adjust thread tensions for the best appearance of embroidery work and slightly in

crease the bobbin thread tension to avoid the lower thread from being pulled up.

18-

Page 21

18. SEWING ON BUTTONS

(b)

)-op.,..,

(c) Place the button under th^ k

fcot. Get both holes c r

foot evenly. centered under the

(<i) Turn the balance wheel tn

ybur bpttop eyes, and fl* eh

''"»b at the propen „„ ■ "“‘b

\^) Run the marsK,-

proper position.

machine at medium speed •

wneei to set the .c

‘■bout 5 or 6 stitches.

<0 Set the Zigzag width knob maklne e

straight stitches In the sas,e h„^ “

zigzag stitch. lock

■19-

fig. 25

Page 22

19. NARROW HEMMING

Turn balance wheel towards you until needle

reaches its highest point. Raise presser bar

and remove the regular presser foot. At

tach hemmer foot (Fig. 27).

1. Fold over edge of material approximately

wide, then fold it over again in the

same way for a length of about 2". Insert

this folded end from beneath into spiral

formed opening (scroll) or hemmer foot.

Move material back and forth until the

hem forms itself in the scroll.

2. Pull material towards you until the beof the hem is just below the

needle.

3. Lower presser foot and begin to sew.

Guide material into hemmer foot while

sewing (Fig. 27).

NOTE: Do not crowd material into scroll and do not leave scroll

by material.

Feed just enough material into the hemmer foot to fill out the scroll.

Instead of a straight stitch, you can also use a zigzag stitch for this hemming

operation. Be sure however, to adjust the width of the zigzag stitch to be as

wide as the hem itself. Using a very long stitch and tight tensions will pro

duce a shell stitch.

-20-

Fig. 27

only partly filled

Page 23

20. SEWING IN A ZIPPER

The Zipper foot included in the arrpce^ •

rlc. accessories enables you to attach a tipper „„ feb-

Remove the regular presser foot and attach thp •

the machine. zipper foot to the presser bar of

First open out the tipper and place fab

ric in the position under the needle.

Set the machine for straight stitching.

Loosen the thumb screw (A) to set the

foot on the left side of the needle and

saw the left-side zipper as sho™.

To sew the right-side zipper, bring the

foot to the right side of the needle.

21-

Page 24

21. INSTALLING SEWING HEAD IN CABINET

OR PORTABLE BASE

1. Back off both head hinge set screws

until head hinge hole is clear.

2. Tilt head hinge tongues up and back

as far as they will go.

3. Carefully slip head onto head

(1) CABINET

Hi HEAD HINGE

HOLES

hinges-making sure tongues are in

serted as far as they can go into

head hinge holes.

4. Allow the head to rest in its

tiltedback position.

5. Tighten boht set screws securely

with screw driver.

6. Plug electrical leads into sockets

located inside cabinet. Cord iden

tified with "motor" tag must be

into socket marked "motor".

Untagged cord gees to "light"

- socket.

^22

Page 25

(2) PORTABLE BASE

■ 23-

Page 26

22. BLIND HEMS

1. Usfe blind stitch cam. NO. 8

2. Use standard zigzag presser foot

3. Set needle position lever in right notch marked

4. Set zigzag stitch width control knob at ”o”

5. Set stitch length control dial between “2” and “3”.

Prepare the garment in the same manner as for hand hemming.

Step 1. If hem with folded edge is used make first fold 3/8” deep.

Step 2. Turn hem the depth desired and baste 1/4 from upper edge.

Press into place. __

◄ R

Step 3. Fold hem back toward right side of garment leaving 1/4 extended.

Step 4. Place material under presser foot and sew blind hem automatically.

Loading...

Loading...