Page 1

5 STITCH. Attachments

BOOK 12

ik0.fl

DIRECTIONS

iBii

F@r Usiog tlia

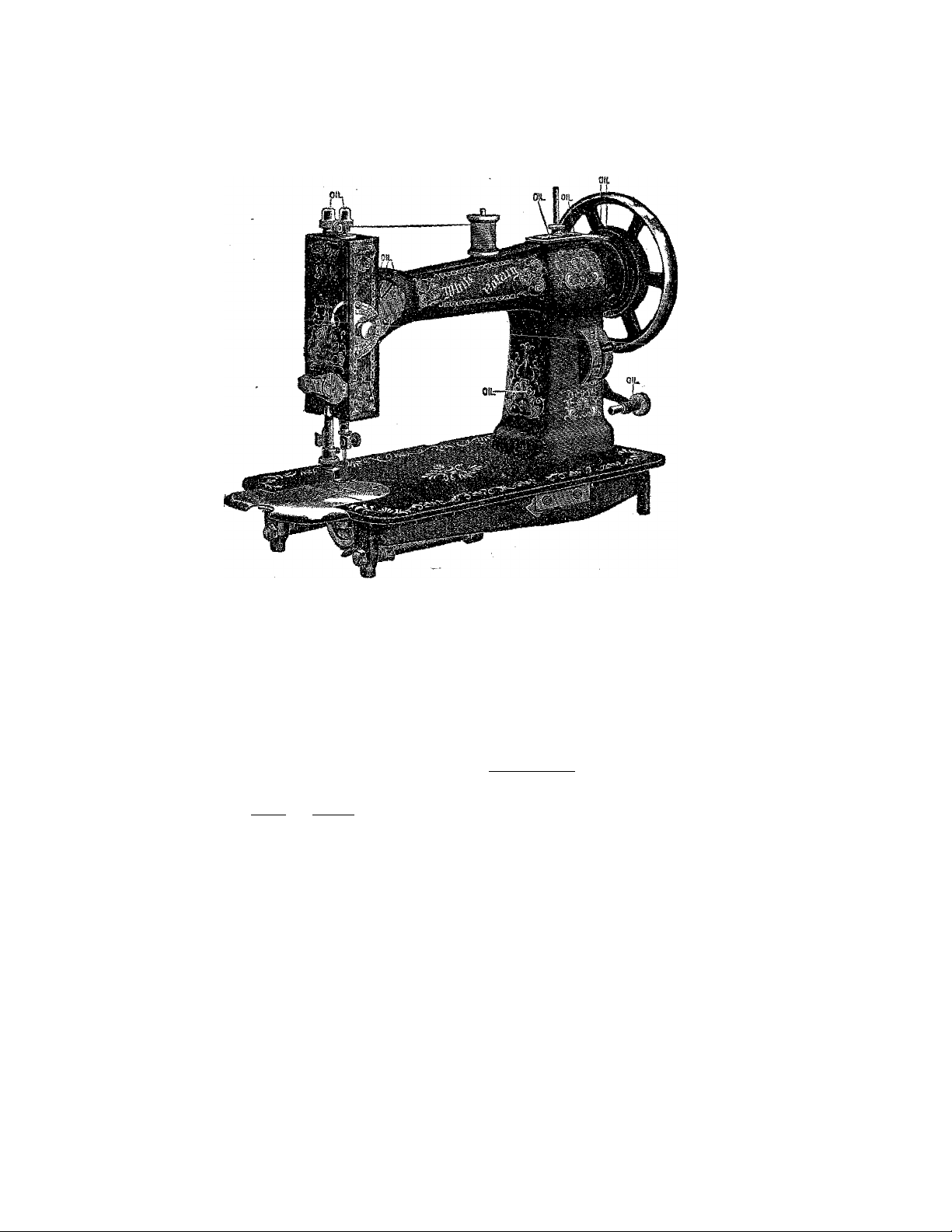

White Rotary Sewing ;

Machine

10 M 6-20

.

MANUFACTURE© BY

W'Mte Sewing Machine Company

Cleveland, Ohio, U. S. A.

Page 2

Any needle offered for sale or use in

yyjfti'iia'aij

,eOI.D SWAGESi

IT'OlMACHiNE/

iraVJVEEDLES/f

Fae-sTmife of genuine

Trade Mark Label,

trade mark registration on the outside label. Accept no other.

fit

fit

box, and the express or freight charges Prepaid.

per to write and mail us a letter upon the same day he sends the

machine, and inform us how, and by what line he ships; also.'write

full particulars as to the trouble with the machine, and give us the

Machines Returned to Us for Repairs

ShoGd have the name and address of the shipper inside of the

|n addition to putting the address in the box, we want the ship

White sewing machines, without the name

WHITE F.R. stamped on the shank is "bogus” .

Many of them will cause the machine to

skip stitches, break thread, injure your ma

chine, and invalidates the guarantee for free

repairs. ''Genuine White” needles have the

name “White F. R.” stamped on the

ahank. They are put up and sold only in

packages with notice of the United States

PLATE NUMBER, Found On Bed Under Bobbin Winder,

Close To Arm.

Be sure and give 'explicit directions how and where to return the

machine.

il-

*

m

Page 3

INSTRUCTIONS

for using the

White Rotary Sewing Machine

Never run Machine with needle threaded without goods

under presser-foot. Run Machine so that upper side of hand

wheel moves from gou.

TO SET NEEDLE

Raise the needle-bar to its highest point; loosen the thumb

screw and press it to the left to permit the shank of the needle

to pass up between the clamp and needle-bar as far as it will go,

flat side to the right—the needle being flattened on one side so

it will set itself perfectly, then fasten securely by tightening

thumb-screw.

To avoid loosening of the needle, always use a screw driver

to fasten the same, the needle nut being slotted for that purpose.

The needle, when descending, should pass central in the

needle hole from front to rear, but close to the right side of the

hole, as it prevents the needle from glancing into the race and

being caught by the shuttle.

NEEDLES AND THREAD TO BE USED

The MOST IMPORTANT consideration is to buy and use perfect

needles—not bent, nor blunt points.

When ordering needles for this machine, be sure to ask for

the genuine White Rotary flat shank needles which are stamped

on the shank “White F. R.” Imitation or “just as good” needles

will cause trouble. Get the genuine White.

Cut of White Rotary flat shank needle

The size of the needle should conform to the size of the

thread and both be suitable to the material sewed. Use as fine a

needle as will permit the thread to pass freely through the eye.

The following index will show the size of needle, thread and

silk to be used.

For colored thread use needles one size larger than given

in index above.

showing exact length.

COTTON THREAD.

150 to 800

90 to ISO

70 to 90 0

50 to 70

SO to 50 C

20 to 30

SILK THREAD

000

00 0

A & Б

D

3

NO. OP NEEDLE

00

1

2

3

4

Page 4

;

;

I:

l-.iv

-

^r\ t^t^KJKrwrr* rtr\T3TJll^1 A Of?

IV/ iNjc-mv^ V Ka

FROM SHUTTLE

Eaise the take-up to its highest

point. With the thumb and sec

ond finger of left hand clasp bob

bin case as shown in cut, then lift

latch S with the third finger, when

bobbin case may be readily with

drawn from shuttle F. See page 5.

TO REMOVE SHUTTLE FROM SHUTTLE RACE

First remove the bobbin case. Turn the machine back on its

hinges, then, turn the machine in the same direction as in sewing

until the point of the needle just enters the needle plate hole;

push on rear end of latch G and at the same time pull shuttle

race cover away from shuttle and toward latch G from under pin

H; the shuttle can now be removed.

When shuttle has been removed from race be sure to clean

both and oil the race slightly before replacing. Occasionally oil

slightly in hole on race cap marked V above and pin W in

shuttle, see page 5, fig. 9.

4

Page 5

TO REPLACE THE SHUTTLE

Turn the machine in direction for sewing until the point of the

needle just enters the needle plate hole: take the shuttle by the center

JV with the left hand and place it in the race, so that point of

pin

shuttle will be from you and over arrow on thread cast off, so that

the holes in the shuttle will drop on. to the driving pins in race, then

^ replace the shuttle race coven

I DO NOT FORCE the shuttle into race. It will enter readily

when in proper position

Should the machine at any time act badly in sewing or running

it would be well to remove shuttle and dean it and the race, which

is but a moments work.

To replace the bobbin case, it need not be held as when remov

ing. but simply slip it on the pin in shuttle, with the tension project

ing upward, and push it into shuttle as far as it will go, when the

spring latch will pass over and retain it in that position.

The thread should be allowed to project about one inch from

bobbin case tension.

TO WIND THE BOBBIN

Place spool oa spool pin, pass the thread dovn. through

the rear hole in axm of cover plate, then to the left under and

over the arm down through front hole. Put the end of thread

through hole U in bobbin from inside out, place bobbin on

bobbin winder spindle, raise winder so p

belt will drive it, loosen thumb screw in

Fig, 7 Bobbin hand wheel, run the machine as in sew

ing. holding on to the end of thread until winding is started'

then break off thread and finish winding.

LOWER TENSION

Fig. 8 represents the bobbin case. To regulate the lower

tension, t-urn the screw T to the right to tighten, and to me

left to loosen the same. Fig. 3 Bobbin Case

TO THREAD BOBBIN CASE TENSION

Place bobbin in case so that thread will come from bc^hin on

same side as hole B in. bobbin case: pass thread throusii slot A to

hole B thence across opening, drawing it down under h'P C then pull

it up until thread passes out under tension spring R-

. The tension on bob

bin case should be the

same as the upper ten

sion.

0 1

if ■

Fif. 9 Shuttle

Fig. 10 Shuttle Race Cover

Page 6

DIRECTIONS FOR THREADING

Place the spool on spool pin, take the thread in your left

hand holding it taut with the right during the whole threading

operation. Pass

thread from

spool over check

spring K at top

of face and down

under point L;

now pull thread

upward until it

passes through

the eye of spring

N and into notch

O, then into end

of t a k e-u p P,

then down

through slot R in

end of needle bar

and through eye

of needle from

left to right, al

lowing about 3"

of thread when

take-up is at its highest point.

To draw up the lower thread,

raise the presser-foot, take hold

of end of upper thread and turn

the hand-wheel once around,

(moving upper side of wheel from

you) which will draw the lower

thread up through needle hole.

Pass the ends of both threads

under the presser-foot and you

will be ready to sew.

Note.—Do not run the machine with

the presser-foot down on the feed withoat cloth under it. Do not pull cloth to

or from you in such a manner as to bend

needle.

THE TENSION

The illustration above represents the

Tension Regulator and Indicator for the

upper thread, an entirely new and useful

device. The half circle is marked with a

scale running from 1 to 8, with the word

Fig. IZ

"loose” at fig. 1 and "tight” at 8,1 being

the slack and 8 the tightest tension.

6

Page 7

OIL PLACES AS INDICATED BELOW

V

The regulator is located at the right end of machine on the front side of arm,

TO SHORTEN stitch move the lever down. TO LENGTHEN stitch move lever up

No. 1 indicates the shortest, and No. 7 the longest stitch.

TO CHANGE THE LENGTH OF STITCH

w

TO REGULATE THE TENSION

To loosen the tension, turn the thumbscre'W on the dial to the

left which will move the pointer toward figure 1. To tighten it, turn

to the right, moving the pointer toward No. 8. By this means the

same tension can always be duplicated, thus obviating the necessity

of experimental trials, as is the case with other machines. If a tight

tension is desired, both upper and under threads must necessarily be

tight. If the upper thread is tight and the lower thread loose, tiie

upper thread will be drawn to the top thus If the low

er thread is too tight, it will be drawn straight on the bottom of goods,

thus; ' When you desire the goods to look alike on

both sides, and be elastic, balance the tension thus;

3

The tension releaser is operated by the presser-bar lifter. By

means of it, all tension is taken off the upper thread when the

presser-foot is raised, and the work can be taken out without pulling

the thread down by hand.

PARTICULAR NOTICE—The tenshn cannot is regulated when the lifter is up

because the Releaser is operated by the presser-bar lifter,

THE TENSION RELEASER

7

IB

¡!i S

;f:

m

B

fi®

I :: :

li

li

if

Page 8

TO COMMENCE WORK

In threading^ the needle and bobbin case respectively, you

should leave an end of thread about two inches in length to each.

Hold the end of the upper thread loosely in the left hand, and

with the right hand gently revolve the hand-wheel until the

needle passes to its lowest point and returns, a loop will be

formed through which the shuttle will pass, and, as the needle

ascends it will draw up the lower or shuttle thread, and the

machine is ready for practical operation.

TO REMOVE VfORK

Stop the machine with the take-up at its highest point; raise

the presser-foot with the lifter which slackens the upper thread;

then take hold of your work with your left hand and pull it di

rectly from you, keeping the top thread in the slot of the presserfoot, which will prevent bending the needle. Now raise the work

and draw the threads into the thread cutter on the presser-bar

and pull downward, which will cut the threads the proper length

to commence work again.

EXPLANATION OF DIFFICULTIES THAT SOMETIMES

OCCUR WITH BEGINNERS

If the upper thread breaks, it may be caused by the needle

not being properly set, or the machine not threaded correctly, or

the upper tension too tight, or the thread uneven and the needle

too small for it, or the needle eye too sharp, or the presser-foot

attached to the machine so that the needle rubs it in passing.

If the under thread breaks, it may be caused by the bobbin

case being improperly threaded, or too much tension upon it, or

by the bobbin being wound too full so that the thread slips over

the ends of the bobbin in the bobbin case.

If the needle breaks, it is more than likely your owii fault

caused by pulling the goods to or from you in such a manner that

the needle strikes the throat plate and is bound to break. The

needle may, however, break in trying to sew extraordinary heavy

seams when the pressure on the presser-foot is not heavy enough.

To create more pressure upon the' goods turn the presserbar nut on top of the presser-bar to the right; to decrease the

pressure turn it to the left.

If it makes loop stitches, it is most sure to be caused by too

loose tension both top and bottom.

If the machine skips stitches, the needle is either bent or not

in right position.

If the stitches are not even, it may be caused by the presserfoot not resting evenly upon the fabric sewed, or by the feed not

being high enough, or by the stitch being too short, or Dy pulling

the cloth or by using too fine a needle with too coarse or uneven

thread.

If the machine should be run without sewing and thread get

in the shuttle race making the machine run heavy, take out

bobbin case and run the machine in the wrong direction; it will

cut the thread out.

Notice.—The leather band should always be tight enough not to slip. If it

slips, or does not force the needle through thick goods, cut off a very short piece

and re-adjust the ends. The belt should not be so tight as to prevent an easy

motion of the machine.

8

Page 9

DIRECTIONS FOR USING THE ATTACHMENTS

I'M

I

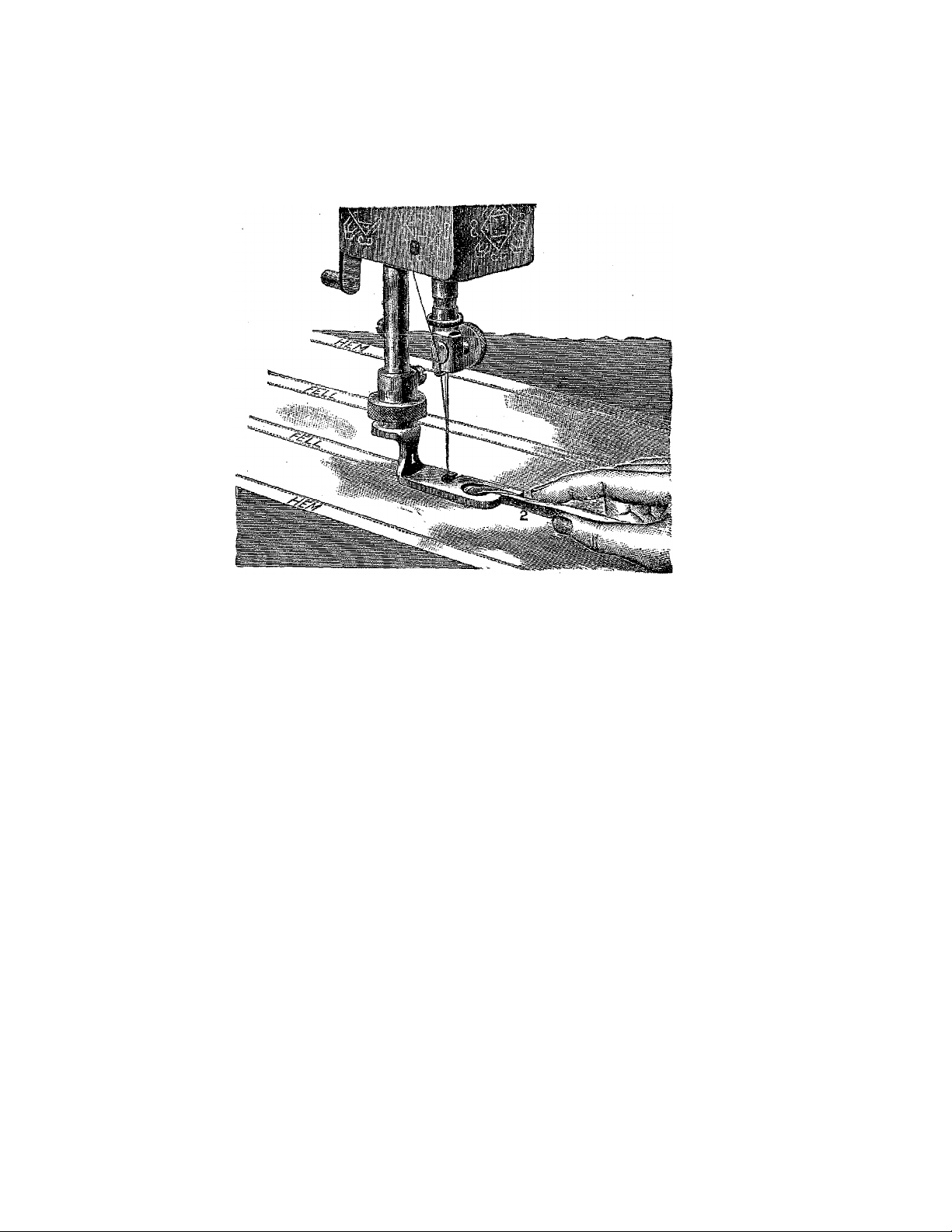

Hemming

Eaise the take-up to its highest point, remove the presserfoot and in its place attach the hemmer. Trim the edge of cloth

on a curve and insert in hemmer far enough to permit the needle

to enter the cloth at its extreme edge (See Fig. 2 above), then

proceed to sew, keeping the edge turned as it feeds through.

Felling

The hemmer is also the feller. Sew together two pieces of

cloth with the under edge projecting between % and inch

beyond the upper edge y then trim the edges if necessary and

open the work flat wrong side up, and fold the wider edge,

toward the left, over the narrow edge, and then pass the folded

edge into the feller the same as in ordinary hemming.

Illustration above represents an operator in the act of com

pleting a fell.

m

iii

iH

iS

: H

Page 10

& ^ & 1ÌI

10

)

7Se, 5S4 Sl3

i

Page 11

No

140 Tabe аг roller etud

141 Take up roller

300 Take up screw ior aeedle bar bnsnrag 379

6prÌEg . . . . M ^ t Ш

204 Screw to fasten attacbment holder 342 to

presser bar T75

306 Screw to fasten rear feed rock arm. 723

to rock shaft 724 and thread pull off

rock arm 755 to roek shaft 756 and

guide 7S0 to presser bar 775 and to

connect 714 with 723

207 Screw for head of main connection 747- .

208 Screw to bind screw 760 in shuttle race

209 Screw to fasten 866 to bed 613

210 Screw to fasten face. .... *

215 Screw to fasten presser bar lifter block

779 »....................

233 Quilter . . . .. ^ ..............................................

234 Screw to fasten quilter and thread cutter

237 Cinteh latch screw.

245 Gnage screw............................................................

271 Presser bar lifter washer

278 Screw to fasten 833 to face........................................

279 ¿ieedle bar bushing

280 I7eedle screw and clamp.

281 Needle screw nut

841 'Washer for 738.......................................................

842 Attachment holder complete.....................................

343 Presser foot

345 Hemmer

847 Presaer bar lifter and releaser cam

348 Presser bar lifter screw

355 Tension indicator complete

357 Tension disc ........................................................

858 Tension spring on inside of face. .......

359 Screw and nut to connect 358 and 735- .

860 Guide pin and slot of tension plate 785. .

363 Screw to adjust lower end of face.

366 Thread cutter .

869 Needle bar

519 Nut for 797.................................................................../

536 Lock nut for 758

538 Take up collar screw.. ..4 ........... -

540 Screw to fasten 767 in arm.

548 Foot gatherer

593 Stud for revolving spool standard

694 Sleeve for revolving spool standard

595 Screw to fasten 593 in arm

617 Bobbin winder pulley....................................................

701 Screw to bind needle bar link screw 784

in take up cam 762

• 702 Screw to fasten feed cam 763 and to

locate take up cam 762..........................................

703 Screw to tighten take up cam 762 on

shaft 761 and to fasten 842 in arm, . ,

704 Screw to fasten main connection stud

751 in arm....................

705 Center for feed rock shaft 724 and thread

pull off rock shaft 756.

706 Nuts for 705

707 Screw to connect 754 with 756 and to

fasten bobbin winder to arm.

703 Nut for 707 and 721.......................................................

710 Bin in feed fork shifting block 711............................

711 SuiftiUs block In feed connection 714,-.

714 Feed connection ........................................ • .............

715 Feed connection link.

716 Pin. for feed connection link 715

717 Stitch adjtjstiag lever...............................................-

718 Stitch adjusting stud

719 Friction washer for 717

720 Sleeve for 713

.....................................................

..........................

303 Screw to iastea etitch iodlcator plate

732 take up plate 79Э oheot spring

bracket 794 screw to iasteu 886 latcb

................................................ •

....................................-..................

........................................................

..........

.......................................*...............

.......................................................................

864 Screw to clamp feed bar centers 726 in

feed rock shaft 724................

............

...................................................................

...........................................................

................................................................

.................................................................

.......

...................................

..

.

.........

.

............

....

............-.............

................................

.....................................

..

..............................................

...................................................

.........

................................

...............................*...............

.........................

...........

.........

.............................................

............................

..........................................

................

...............................

............................

...................................

....................................

.................

............

.......................

...............

........................................

...............................

..............................................

* ■ * •

..

......................

..

..

..............

No*

721 Screw to connect 71S to 717 to take np

rear bearing of shuttle shaft 808

722 Stitch indicator plate

723 Bock arm on rear end of feed rock shaft

724

724 Feed rock shaft.

725 Feed bar ....................... . . ....

726 Centers for feed bar 725.

727 Feed

728 Screw to fasten feed 727 to feed bar 725

729 Spring washer for bobbin winder frame, .

730 Shuttle race .................................................................

731 Latch to hold shuttle race cover S34 on

732 Spring for 731..............................................................

733 Fin for 731

734 Spring pin to hold shuttle race cyover 834

735 ^ring for 734.......

786 Washer on 734

738 Thread guide plate on 834...........................

739 Screw to fasten 7S8 to 834

744 Bobbins

746 Crank on rear end of shuttle shaft SOS.,

■ .

747 Main connection complete.......................................

748 Main eonneetton roll, ................................................

749 Screw to adjust-main connection to elide

750 Main connection sUd© block.

751 Main connection stud

..

752 Feed raising and thread pull off cam. ., .

753 Screw to fasten 752 to 808. ...........

734 Fccenti'ic connection for thread pull off.,

755 Thread puH off rock arm. ^

756 Thread pull off rock shaft.

757 Thread pull off................................................

758 Screw to connect 757 to 765..........

739 Thread ргг11 off slide block. ............

760 Screw to connect 759 to shuttle race 730

761 Tipper shaft

762 Take up cam,

763 Feed cam

764 Screw to go in rear end of 761...................................

765 Forward bushing for upper shaft.

766 Screw to fasten 765 in arm 814 and T83

767 Rear bushing for upper shaft 761. .: ...

779 Needle plate . . - .

771 Screw to fasten 770

..

772 Bobbin winder complete.

775 Presser bar

776 Presser screw

'

777 Needle bar cap1

778 Presser bar spring

779 Presser bar lifter block

780 Presser bar guide.

781 Needle bar link.............................................................

782 Needle bar block.......................................................-

784 Screw to connect 781 to take up cam 762

785 Tension plate...............................................................

786 Auxiliary spring

787 Adjusting washer for 786

789 Screw to connect 839 to 834 and to inside

. -

792 Spring for latch 839..

793 Take up cover plate.....................................................

794 Check spring bracket

795 Bear spool standard

796 Bear cover plate

797 Table hinge complete

799 washer for 7Э7..............................................................

802 Screw to locate needle bar block 732, . . .

804 Screw to clamp shuttle race 730...................................

807 Guage .......................................................^

808 Shuttle shaft driver and thread cast off

..

809 Screw to adjust auxiliary spring 736.,,

...... .................................. ...............

.....

........................................................................

race 730

on race 730...............................................

...........................

block 750 ....................................................

to 369

.....

of face 815

complete

..................................................

........

.................................................

....................................

.............

......................................

..................................................................

...........

.......

......

.................................................................

..........................................................

.....

{Continued on next page)

...........................................

.............................................

.........................................

..

.............................................

....................................

.............................................

........

......................................................

.............................................................

.............

...................................

.............................................

......................................

..............................................................

.......................................................

..................................

.........

............................................

........................................................

...........................................

...............................................................

..................

...................

....................................................

.........................................................

..................................................

...........................................................

..........................

.......

..............................

..

..

..

..

..

..

..

..

- - -

..............

..

.....

.........................

..............

..

...............

..

..

..

- *

..

11

Page 12

No,

Bed

.................................................................

Atm

’^ 315 Face

820 Screw to fasten fceaaioti indicator

821 Waslier ou ausiljar7 spring T36

S22 Washer imder iatch S39.............................................

323 Sfcad for lower end of main connection

324 Screw to fasten crank 746 on rear end

826 Plate for 725. ., .

827 Short rivet for 826...................................................

828 I#oug rivet for 336.................................................

829 Screw to fasten bed to arm

830 Hand hole cover complete

831 Latch for cover 830

S33 Spring for iatoh 831....

833 Catch on lower end of face to retain

834 Shuttle race cover

333 Shuttle ..........................................................................

838 Bobbin case complete

837 Bobbin case tension spring

8S8 Bobbin case tension serew

839 Latch to retain bobbin case 836.

840 Anxiiiar? cam

841 Feed fork and stud complete...................................

842 Bearing for feed fork stud

843 Screw ia end of food fork stud.

852 Screw to fasten radial ciatch to upper

................................................................

...

.................................

to 315.....................................................................

747

......................................................................

of shuttle shaft 808 and to fasten 842

in. arm .

......

................................... ..................

..........

cover 830 when raised

..........................................................

shaft

.....

.....................................

..................... .

..........................

............................................

.........................

.......................................

...............................................

.......................................

...........

..........

..............................

..........................................

..............................................

.................................

..........................

....................................

..

.............................

..

..

Numbers preceded by a star (*> are not illustrated

355

..

..

..

..

..

No.

855 Bobbin winder center

863 Sliding head latch,..................................................

866 Cover lor 865

867 Spring for 865.............................

86S Separating washer for 865 and 868.

877 TTake up stud.

STS Take up collar, .........

8S1 Take up

SS5 Clutch

S88 Latch spring for radial clutch.

887 Latch for radial clutch...........................................

*888 Hand wheel

.................................................................

......

...........................................

........

.....................................

..........

........................................ ,

....................................... . .

.............................................................

......................................

..

.............................

..

,. .

■fe'--

-f

DIRECTIONS FOR USING THE FOOT GATHERER

Remove the presser-foot and replace with the Gathering Foot.

TO GATHER, FUFF OR SHIRR

Place the goods under the foot the sanie as in ordinary sewing

For fine gather use s short stitch. To increase the fullness lengthen

the stitch. For greater fullness tighten tension.

12

i

I

i

Page 13

f

HEMMING AND SEWING ON LACE

ONE OPERATION

Our hemmer and feller which accompanies each machine, is

now made with a slot—6. (See illustration above.) In this slot place

the edge of the lace and sew it on at the same time as in ordinary

hemming.

WIDE HEMMING

Any width hem can be made with the hemmer and feller upon

thin fabrics by simply folding the goods the desired width of hem

and then passing the edge through as in narrow hemming.

13

Page 14

‘■'-i

'■ i

TUCKING

Loosen the thumb-nut A and remove presser-foot, adjusting the

tucker on holder, after which tighten A.

To regulate the size of tuck, loosen screw D and place gauge for

any desired width, moving to the right for wide and to the left for

narrow tucL

To regulate the space between tucks, loosen screw D and move

the marker to the left for a wide space and to the right for narrow

The figures on the back of cap show the width of tuck, and those

on the front the width of space.

By adjusting gauge and marker so that the indicators will point

to the'same figures, the tucks will meet

To Commence tucking, fold the cloth for the first tuck and place it

beneath the creaser and lip E. with folded edge against the guide;

drop the presser-foot and sew as usual

The edge of the .last tuck made should always pass under the

spur placed immediately in front of the marking blade. This will

prevent the finished tuck from passing over the marker and will

greatly assist in guiding the work.

To tuck without marking, throw the lever B up.

14

Page 15

QUILTING

Pass the quilter through hole 2 in presser-bar, adjust the quilter

guide to the right of the needle according to the desired space between

seams, and high enough to allow' the goods to pass freely under it,

and then fasten the quilter securely by screw 3.

In starting to quilt use the outer edge of the cloth for the first

guide, or else crease the cloth on the right and let the quilter guide

follow the crease, quilt the remainder by keeping the guide in a line

and over the last seam stitched

Large quilts should be made in squares or sections and

then sewed together. In quilting squares or diamonds the seams

should be on equal bias.

15

i

Page 16

i'S

The New Improved Five Stitch Ruiiler is a rufiler which makes a

gather or pleat either at every stitch or oace in every five stitches

as the operator may choose.

RUFFLING

Loosen thumb screw I. remove presser foot and place the ruffler

in holder, at the same time setting the ruffler arm fork 2 on needle

clamp screw 3, then tighten nut 1.

The goods to be ruffled must be placed between the two blue

blades and then in gauge 12. Gauge 12 should be adjusted to the

right or left to get the desired distance from the edge. The goods will

guide itself.

To make a fine ruffle, shorten stitch of machine and move ad

justing nut 5 upwards.

To make a heavy ruffle lengthen the stitch of machine and move

adjusting nut 5 downward. Ruffling can always be duplicated by re

membering the numbers on scale of ruffler arm, tension and stitch

regulator.

TO RUFFLE ON BAND. Place band under both springs next to

feed and over lip 9. If facing is required, place facing above both ‘

springs and under foot Place the goods to be ruffled same as in

plain ruffling.

TO RUFFLE WITH A HEADING. Place the goods to be ruffled

between the springs with heading to the right and adjust gauge 10

for desired heading.

TO MAKE SCALLOP RUFFLING. Remove gauge 12; cut Lonsdale

cambric in strips one inch wide lengthwise of the goods. Fold in the

center and press the folded edge down smooth, adjust the goods with

folded edge to the left and between the springs. When sewing move

the goods to the right and left alternately. Adjust fullness, bands,

facing, etc, same as regular ruffling.

16

Page 17

SHIRRING

Remove hand hole cover, in

sert ear of shirring plate into

gauge screw hole in needle

plate, and holding down the

shirring plate replace hand

hole cover over ear X on shiring plate.

Loosen screw 4, shown in

illustration on page 16 and re

move separator, placing the

goods to be shirred between the blades, and shirr at any desired

distance.

Be careful not to use ruSler without the separator or shirring

blade and cloth above, for in so doing the rufiler teeth will be broken

or injured.

To PUT RUFFLING ON A BAND EDGE, STITCHED, WITH OK WITHOUT PIPING,

take striped calico or plain colored goods; cut on the bias in strips

full one half inch wide, folding in center. Place the piping in guide

7 with folded edge to the right, then take the band and turn down on

edge a quarter of an inch and place in guide 6 having both ends

down under foot. The guide can be adjusted to right or left by

loosening screw 11. Place the ruffling to the right between the blades

and in guide 13; if wider ruffling is desired remove separator and use

shirring slide. To use facing with shirring slide place facing under

shirring blade 1 and in guides 2 and 4,

m

TO ADJUST RUFFLER FOR THE S TO I STITCH

The ruffler as shown in cut is set for the regular one gather to

each stitch. To change so as to make a pleat every fifth stitch, turn

screw “C" to the right as far as it will go. This will bring the lever

marked 5 St, in action and will produce a wide pleat without length

ening the stitch.

In placing the goods iii ruffler to be pleated or if you wish to use

bands, piping, eta follow same directions as in regular ruffling, in

heavy pleating the adjusting nut 5 should be turned entirely down,

the longer the stitch the farther apart the pleats will be.

TO ADJUST RUFFLER BACK FOR

REGULAR RUFFLING

Turn the screw “C” to the left as far as It will go.

17

i

Page 18

■

The following cuts show a few of the many varieties of work

done on the five stitch ruffler. It does not require an expert: with a

little care and patience in following directions, you can produce a

great variety of work with ease and satisfaction.

r

Band Edge stitched with piping

Page 19

HEMMING

We furnish with each machine

' ur assorted widths of hemmersSelect the width desired’and substitute

it for the presser-foot. Take the cloth

in both hands, the right hand in front

of the hemmer and the left behind.

Place the edge of the cloth in the hem

mer drawing it back and forth until the hem is formed, stopping

with the end under the needle. Drop presser-foot and commence to

sew. Guide the cloth so as to keep the hemmer full. To change

stitching near or far from edge, loosen thumb screw and move hem

mer to right or left as desired and tighten screw,

BINDING

Remove the presser-foot and sub

stitute the binder. Cut the binding

inch wide (on the bias if convenient).

Pass the binding through the scrolls

of the binder and under the presserfoot. Place the edge of the goods to

be bound between the scrolls of the

binder, drop presser-foot, guide the

cloth with the left hand, and let the binding glide easily through the

fingers of the right. To change the stitching near or far from the

edge, move binder lug A to right or left as desired.

Using No. 6 Folded Tape with Binder

Cut the end of the tape bias and thread it through the outside

slot in the scroll of the binder. The seam or edge to be bound is then

inserted in the binder in the regular way. Folded tape can be pur

chased in any department store in a variety of colors.

UNDER BRAIDER

Substitute the under braider foot

(which is found in the box of attach

ments) for the regular presser-foot.

Place under braider on machine same

as the shirring plate; draw the braid

)

under and through the tube and a lit

tle past the needle. The pattern to be

braided should be stamped on the

wrong side of the cloth. Place the goods under the presser-foot same

as in regular sewing, following pattern carefully. This stitches the

braid on the cloth from the underside.

19

i m

j i

■

Page 20

Page 21

Parts for White Sewing Machines may be

Secured Anywhere

list of Stand Parts for Ball Bearing Stands, White Возе Top, White Automatic Swing

Drop# Nos, 70, 74. 7o« 7d, 77. SO and S5 and CabinotsNoa. 72. 73 and 78

Stud in dress guard for balance wheel

206 Screw to fasten link No, 621 to plate

No. 630

207 Adjusting screw in lower end of pitman

209 Screw to fasten stud in treadle, treadle

211 Screw to fasten dress guard and brace to

223 Stand caster

224 Pin in stand caster,..............

226 Wood screw to fasten swing drawer to

221 Stud in treadle, for pitman

309 Felt head tack^

364 Set screw to tighten balance wheel cone

379 Balls for balance wheel and pitman, per

*384 Brace for T)OX too

*385 Dress guard for box top

**389 Rest pin in table lor box top.....................................

487 Brace for Nos. 74, 75, 76 and SS drops. .

513 Pin in head carrier for slotted stop

616 Screw to connect cable to Ud.

517 Screw to connect cable to lever..................................

619 Nut for adjusting stud.........................................

*530 Drip pan for Nos. 70, 74, 75, 76, 77,

531 Spring for awing bottom,

532 Eyelet for 531 ............................................................

*533 Drip pan for Nos, 72, 73 and 78..................................

544 Latch plate for vibrator bead carrier ....

*550 Treadle for.No. 80 drop

*552 Treadle support for No. SO drop

553 Caster for No. 80 drop

563 Treadle support for Noa. 74, 75, 76 and

564 Screw to fasten treadle support to leg, ..

665 Treadle for Noa, 72, 73, 74, 75, 76, 77.

566 Treadle center

567 Pitman for Nos. 70, 74, 75, 76, SO and

588 Balance wheel for Nos, 70, 73, 73, 74, 75,

569 Dress guard for Nos. 70, 72, 74, 75,

..................................................................

centers in treadle support and crank

pin In ualance wheel

leg ..........................................................................

table

......................................................................

573 and crank pin cone S77

100 .........................................................................

SO and 85

85

...................................................

rro

_____

J OK

1 Oi miu

.

86 drops

76, 77, 78, 80 and So

76, 77, 78, SO and So

............

...............................

............................

........

.....................................................

.....

.................................................

...............

.......

............................................................

-...

....

........................

..........................

........................................

.......................................

................................

......................................

....................................

.........................................

.................................... .. .

...........................

..

....................................................

............................

.............................................

..

....

...........................

..............

................

....................

............

—

..

..

..

Numbers preceded by a star (*) are not iilustrated.

Where the parts such as pitman, treadle rod, etc. are ordered to be sent by mail,

postage will be charged thereon.

570

568

Nut to fasten stud 570

671

Rear cone for balance wheel stud 570. ..

572

Front cone for balance wheel stud 570..

573

Ball race in balance wheel hub............................

674

Bail retainer for bail race 574

575

Crank pin in balance wheel, for pitman

676

(including rear cone)

Front cone for crank pin 576

577

Ball cage for crank pin balls, with balls

578

Pitman for No. 77........................................

*579

*5S0

Treadle support for No. 77............ .

Bight leg for No, 77

*581

*582

Left leg for No. 77

Pitman for box top

*5S3

Treadle support for box top

!о84

Right leg for box top,,,.'

*583

*5S6

Left leg for box top

Balance wheel for box top.

*5S7

Stud in leg for balance wheel 587

*5SS

Treadle support for Nos. 72, 7S and

589

cabinets

Pitman for Nos. 72, 73. 78 cabinets.

*590

Treadle for box top....................................................

*592

Wire bail for belt grip

699

Clip for 509

600

Spring for 599........................

601

Treadle for No. 70...... — ..........

*603

Treadle supoort for No. 70

*604

*605

Brace for No. 70

619

Cable adjusting lever

Adjusting stud and plate for cable lever.

620

Link to connect swing front to head

621

Cable (20 in. long) for Nos. 70, 72,

632

Cable guide

623

Right leg for Nos. 70, 74, 75, 76 and 85.

625

Left leg for Nos. 70. 74, 75, 76 and S5..

626

Brace for No. 77

627

Support for cable adjusting lever No. 619

*630

631

Head carrier hinge ......

632

534

*636

Treadle support for No. 73 cabinet-.

869

.....

carrier

....

74, 75, 76, 77, 78, SO and 85

Pin for head carrier hinge No. 631

Swing cover for comer of bead carrier.,

Latch plate on head carrier for 865,-

..............................................

..................................

.................................

.................................................

......................................................

.........

..................

.............................. ...

............................

...................................................

...........

...........................................................

...............................

.............................

.......................................

........................................................

......................

...................................................

.......

.................................

.................................-.............. • ■ •

.............................

..

..

..

..

...........................

............................

..

.................................

.................

..

..

..

................................

..

..

..........................

................

..

..

m

instructions for opf^r.4

ting the WHITE supplied in English, Ger

man, Spanish, Portuguese, French, Bohemian, Swedish, Danish, Dutch.

Italian. Polish, Finnish and Hungarian.

When writing for information regarding parts or anything per

taining to your machine.be sttre to mention style of machine whether

Vibrator or Rotary shuttle, also give the plate No. which is stamped

on bed of machine at foot of arm.

By giving full information it will save time and expense.

21

m

I

■

Page 22

UST one more time saver which the busy user will eagerly wel

J

come—a Scissors Gauge with which one can easily and accurately

cut bands of various widths, either straight or on the bias.

It’s an attachment, the value of which will be grasped on sight

by every sewer and highly appreciated for its thorough utility.

This attachment is included free with the attachments supplied

with this machine,

THE SCISSORS GAUGE

The Scissors Gauge is for cutting bands of various widths, either

straignt or bias. The sliding scale is adjustable for the w^idths of

band desired.

Place the gauge upon the scissors, as shown in the illustration,

slip the edge of the cloth in the gauge and proceed to cut the band.

The tape of the binder should always be cut on the bias, also the

piping which is used with the ruffier.

The letter F indicates the proper width for a

bias fold, which is to be one-half of an inch wide

The Scissors Gasge

bands which are used with the binder.

C is for corded or plain piping. The piping is cut bias and folded

double to use with the ruffler.

when finished.

The letter B indicates the width for cutting bias

With the aid of this gauge any

number of folds may be cut of

exactly the same width. Those

who have tried know the diffi

culty of doing this with the scis

sors alone. Everyone who uses

a bias gauge is delighted with it.

Buy a yard of 44 inch lawn.

Cut it into bias strips?^ to 15-16

of an inch wide. Roll it on card

board and keep it in the machine

drawer. It will furnish the bind

ing for the inside seams of the

white sewing for months to come.

22

Cutting a Bias Band with the help

of the Gauge.

Page 23

THE EDGE-STITCHER

A Combiised Edge-Stitchiag, Lace-Joinini and Piping Attachment

HE EDGE-STITCHING ATTACHMENT is fastened to

machine in the same manner as the Presser-Foot. The (Efferent

T

slots which are ntimberéd frarn 1 to 5 in the illmtratiosi serve as

guides'for sewing together laces, insertions, embroideries, sevring in po-

i. sition folded or hemmed edges, bias-folded mateiiai or piping, etc.

This Attacnment is very useful in trimming such articles of cloth

ing as aprons, women’s and children’s dresses and underwear, shirt

waists, silk blouses, boys’ rompers and suits, or for articles for household

decoration such as fine bureau scarfs and thin curtains, baby carriage covers and doilHes.

I

Veiy beautiful effects may be ob

tained in yokes, gtiimpes, sleeves,

collar and cuff sets, vestees, fichus,

lace waists, camisoies, etc. by joining

rows of lace insertion, alternate rows

of lace and embroidery insertions, or

alternate rows of tucking and lace in

sertions.

The folded tape, which may be

purchased in any department store in

all colors, quaEties and widths, is in

dispensable to use with this attach

ment. The folded piping, which may

also be purchased ready turned, will

exactly fit the piping slot in this at

tachment.

How to Adjust the Edge-Stitcher

To adjust, move the lug .A. I llustration) at the left of the attachment to the right

or left until the desired adjustment is obtained. When sewing two pieces of lace together,

it is very necessary that the attachment is adjusted to stitch exactly on the edge, so that the

edges will not fold over when laundered.

.When sewing laces or soft materials together, it is better to hold the edges slightly

overlapped. This will prevent the lace from feeding away from the guide.

When the attachment is properly adjusted, the most inexperienced operator may sew

yards of lace or material together with no difficulty.

Practical Uses of the Edge-Stitcher

1. Sewing lace and insertion together.

2. Sewing lace and embroidery insertions together.

3. Piping plaits and belts for children’s clothes.

4. Sewing tape to top of stocking to prevent “runners” (patented).

5. Sewing insertion on material—afterward cutting material away and turning edges back.

6. Sewing lace on edge of hem.

7. Setting in insertion with edges edge-stitched. ,

S. Sewing lace and ribbpn together.

9. Covering seams with bias bands or finishing braids.

10. Sewing braid on heavy suits and dresses,

11, Sewing on bias bands for trimming—straight or curved.

12, French seaming.

23

■

Page 24

PRACTICAL SUGGEimON&

12 3 "45

III. 1 shows rcws of insertion sewn together. Slots Nos. I and 4 are used for this kind of work. In joining insertions of different

patterns the piece with the neatest edge should be placed in slot No. 1 and this will be the upper edge when the work is finished.

111. 2 shows alternate rows of Insertion and embroidery sewn together. Slots No. 1 and 4 are used for tfils purpose, the embroidery

being placed in slot No. 1 and the lace in slot No, 4, If the embroidery used has a heavy edge it may be found more convenient to uae

slot No. 2 for the embroidery as this gives a wider over-lap,

111. 3 shows pieces of tucking put together with rows of insertion. The edge of the material is folded and placed in slot No. I and the

lace is placed in slot No. 4.

111. 4 shows ribbon and lace sewn together. The ribbon is placed in slot No. 1 and the lace in slot No. 4. This sort of work is very

popular for making camisoles and trimming underwear.

111. 5 shows a band of embroidery finished on edge with lace, edging. The embroidery is placed in, slot No. 1 and the lace in slot 4.

111,. 6 shows lace insertion used as trimming, The insertion is placed in slot No. 1 and the material underneath the Attachment, The

free edge of the insertion is then sewn in position with the proaser-foot. The material is then cut away from the under side and the edges

turned back and a second row of stitchi^ added for finish and strength.

11!, 7 shows braid sewn to the garment to be used in trimming. Braid, ribbon Of velvet may be used in this manner and is inserted in

slot No. 1 with the garment uuderneath the Attachment. Itis best to make a crayon mark or fold to Indicate where the stitching is to come,

III. 8 shows bias-folded material sewn to the édge of a garment to be used as a finish and trimming. This sort of trimmingis used for

aprons and children's clothes. The bias-folded material is inserted in slot No. 1 and the edge of the garment in slot No. 5 with the garment

wrong side up, then fold the bias material back on the right side and stitch in position with the presscr-foot.

6

s

Page 25

PRACTICAL SUGGESTIONS

Ш. 9 sho-ws folded bias tape sewn on the top of a hem for a finish. The foM^ tape is inserted in slot No. 1 and the edge of the hem

in slot No. S. Then turn hettH and sew other edge in povsition with the Presser-foot,

111. 10 shows a box plait piped. Insert the piping in slot No, 3, and the edge of the plate in slot No. 4 for the wdde piping effect. If a

narrow piping is desif^ insert thé piping in slot No;i 3 and edge Of plait in No. 1.

Til. И shows bias-folded material used té cover a seam. Thé folded strip is placed in slot No. 1 and the material underneath the At

tachment. Care must be taken to keep, thè row of stitching as Close to the seam stitching as possible. The free edge of the bias strip is

then sewn in position with the Presser-foot.

111. 12 shows bias-folded material used to finish a curved edge. This finish Is practical for underclothes. Insert the bias-folded material

in slot No. 1 and the gariment in OlOt No. 5. Turn the bias strip back and add a second row of stitching with the Presser-foot,

lit. 13 shows a French seam stitched with thé Edge-slitching Attachment. After the seam is stitched with the Presser-foot and the

materia! turned on the wrong side ready for the fi nishing, it is inserted in síéí NO, 5 and adjusted to the proper distánée. .This is especially

practical for fine work where the seam shows through the garment.

Ш. 14 show's bias-.foldcd material sewn in position. To be used for boning or as a stay for children’s underwaists, or for brassieres. The

.folded tapé is inserted in slot No. 1 and the garment underneath the Attachment.

Ill, 15 shows bias-folded material used as a trimming. It is quite easy to turn corners using the Edge-Stitching Attachment. To turn

the outside curve stop the machine where the corner is to be turned and fold the proper amount ofmaterial over, then insert it in the At

tachment and stitch until another corner Is reached. : It is not necessary to remove the material from the Attachment to turn the inside"

curve. Slot No. 1 is used for this kind of work and the garment is placed underneath the Attachment

.ю

;

Page 26

Practical Buttonholes made with the Binder and Hemmer

It is the desire of every women to understand the art of making fine button

holes, but many women do not have the time to spend working them, even though

"they are skilled in the art.

Good practical buttonholes can be made on the sewing machine with the help

of the Binder and Hemmer. ' These buttonholes are strong and durable and will

wear as long as the garment. They are neat and good looking and a dozen can be

made in a fraction of the time it takes to make one by hand. These buttonholes

arc especially practical for children’s underclothes, rompers, dresses and for the

backs of Princess slips.

Directions for Making

If the buttonholes are to be two inches apart, take a strip of material two inches

wide and bind it as shown in B. The marks show this _strip divided into sections.

Each section is one-half inch wider than the button. If your button is one-half inch

across add one-half inch, thus cutting your strip into pieces 1 inch wide. If the

button is three-quarters of an inch wide, add one-half inch and cut strip into sec

tions one and one-quarter inches wide.

B

Aftftr ’V'rtiii* -Qtr-irt ie

------J-----

the presser-foot. Bind the edges with bias binding as shown in D, This makes a

finished strip of buttonholes which are strong and practical for children's clothes.

E shows the same idea worked out with finer materials; the Foot Hemmer in

stead of the Binder is used to finish the first strip, in order to get an effect dainty

enough to use with dimity, batiste, etc,

E also shows the edges sewn to another piece of cloth, which in the case of

practical sewing would be the garment. This is done when they are in the stage as

shown in C, binding the edge of the garment in with the row of buttonholes, then

stitching the free edge of the binding flat on. the garment, using the presser-foot.

------

J- W«»,

pieces together as shwwn in C, using

£

26

Page 27

OIL PLACES INDICATED BELOW

r «?i5* i?''^*Sia^” •¿'’■''‘^’L''? L '*■ J" SRb^ - "JiLL-T* i. -i," ' ” ’A" *3 A^ T. -+i.'^'‘^

I |,^:-i. \jX';" ■.^:

______

'?'■' --:-K

KEEP MACHINE WELL OILED

Oil in all the places indicated on page 7. To oil the under

side of machine, slip the belt off the balance wheel and turn the

machine back on its hinges and oil in places indicated above.

THE IRON STAND

Oil occasionally the treadle centers, upper and lower end of pit

man and the balance wheel hub bearings. Whenever you oil the

machine work it a little to distribute the oil. After standing a'few

moments take a soft cloth and clean the superfluous oil from the

Japansd parts of machine.

■

TO CLEAN MACHINE

If the machine is dirty or gummed up with poor oil. oil thorough

ly in places indicated above and on page 7.using Kerosene (coal oil)

run the machine for a short time, wipe dry and oil with good sewing

machine oiL

Loading...

Loading...