Page 1

1 1 J .TiZì^.

117.812

117.813

1 17.560

PART NO. 2903

PRiNTEO IN U. 6. A.

Page 2

The Object of This Book

Certificate of guarantee

We guarantee to the original purchaser the sew

ing head of this machine when used for normal

family use to be free from defects in material

and workmanship for a period of twenty years

from date of purchase. In the event that %vorking

parts prove to be defective in material or woi-kmanship, they will be replaced free of charge if

the machine is returned to the nearest Sears

or Simpsons-Sears retail or mail order store. In

returning to a mail order store, be sure and pack

securely. (Needles, belts, bobbins, shuttles, bulbs,

or parts which wear out from natural use are ex

cluded from the guarantee.)

We further guarantee all electrical equipment to

be free from defects for a period of one year from

date of purchase. • ‘

When referring to this guarantee or when writ

ing us about your machine, always mention the

model number.

We do not authorize any person or representative

to make any other guarantee or to assume for us

any liability in connection with the sale of this

sewing machine other than those contained here

in. Any agreements outside or contradictory to

the foregoing shall be void and of no effect.

For ready reference record the number of your

machine on this page.

Model No.

Cabinet Model No.

Head Serial No.

Date Delivered

SEARS. ROEBUCK AND CO.

and SIMPSONS-SEARS LIMITED

_

is Lo provide you with complete directions for

operating this sewing machine. We are extremely

anxious that your investment in this machine re

turns the utmost in satisfactory service. Therefore

you arc urged to read this book carefully ami thor

oughly ill order to familiarize yourself with the

operation of this sowing machine, even though you

may be accustomed to using some other make.

To Install Sewing Machine Head

On Cabinet

Place the head on top of open cabinet and slide

iiead hinge lug holes (Fig. 2) over round shanks of

the two hinges attached to back of cut-out in top of

cabinet. Tip head back and tighten head hinge set

screws (Fig. 2) securely.

Pull bushing up on motor cord as near to the

motor as possible and slip motor cord into slot at

edge of bed plate and push bushing back into hole

in bed plate (see Fig. 9). Unwind the extension

cord inside the cabinet, plug into any base plug

outlet, and the machine is ready for operation.

If machine is treadle operated, merely place

leather belt around hand wheel drive pulley as of

course there is no motor or electrical connections.

IMPORTANT

GIVE PARTICULAR ATTENTION TO IMPOR

TANT INFORMATION ON PAGES 11 AND 12.

One

Page 3

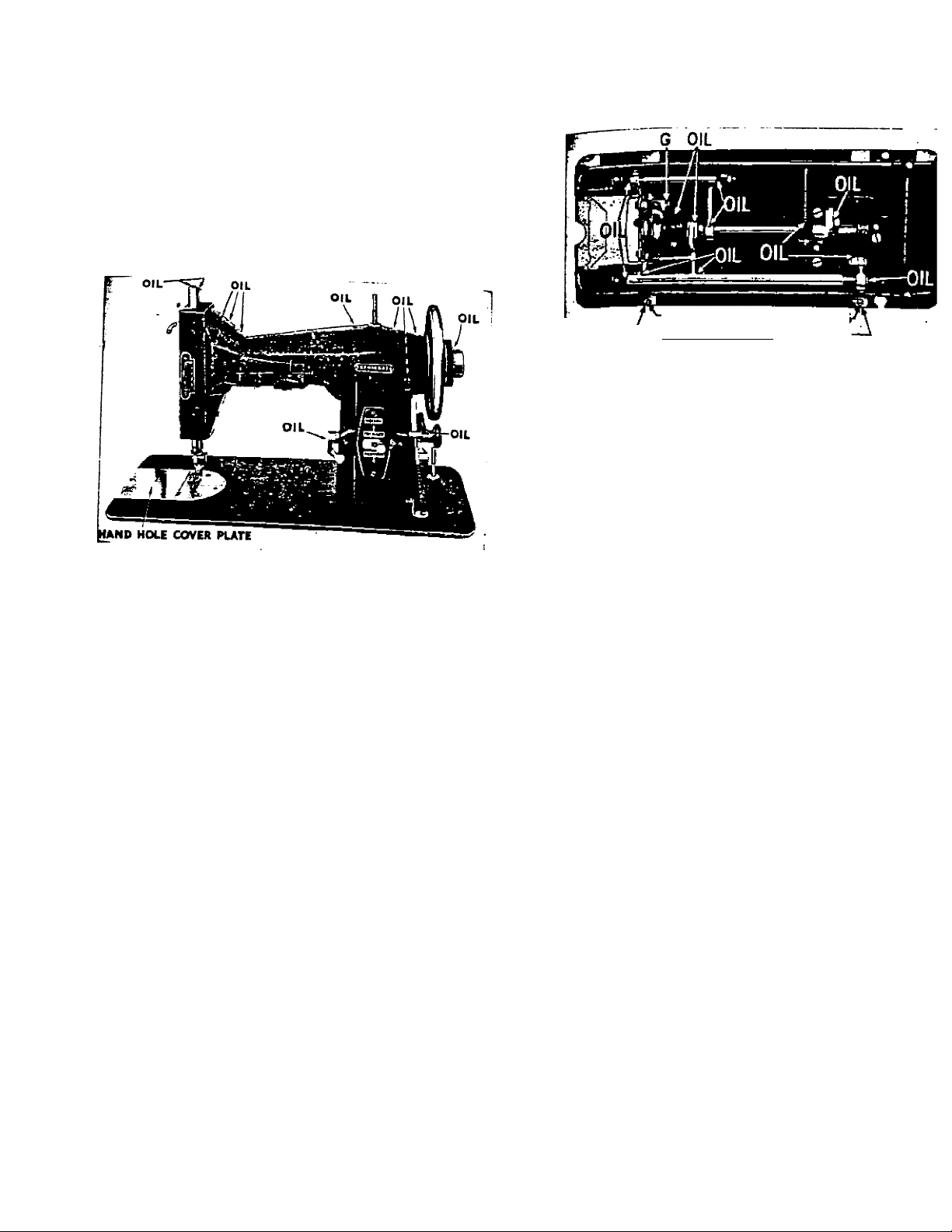

Oiling

A sewing machine, like every other piece of mach'

needs oiling to insure easy running and to prevent un

sary wear of the parts which bear upon each other.

Oil holes are provided in the arm of the machine for

which cannot be directly reached.

Depending on how frequently the machine is used d t»

mines the oiling requirements. Moderate use requires o \

occasional drop of oil at the points indicated on the"-n

trations shown. ®

To ofl the works underneath the bedplate, turn the 1

hack and apply oil to points as shown in Figure 2.

On automatic lift machines the thumb screw on the

late near the base of the arm must be taken out before

head can be turned back.

-HEAD HINGE SET SCREWS

-HEAP HINGE LUG HOLES-

FigTir» 2

Cleaning Machine

IF THE MACHINE RUNS HARD it is due to lack

proper oiling of some bearings. Should the machine beco

rammed from long standing or poor oil, apply kerosene to

the bearings to remove the gum; then run the machine ti

Idly, wipe clean and OIL THOROUGHLY WITH GOi

SEWING MACHINE OIL before beginning to sew.

Occasionally place one drop of oil on tip of finger i

apply around outer rim of shuttle, race, and center

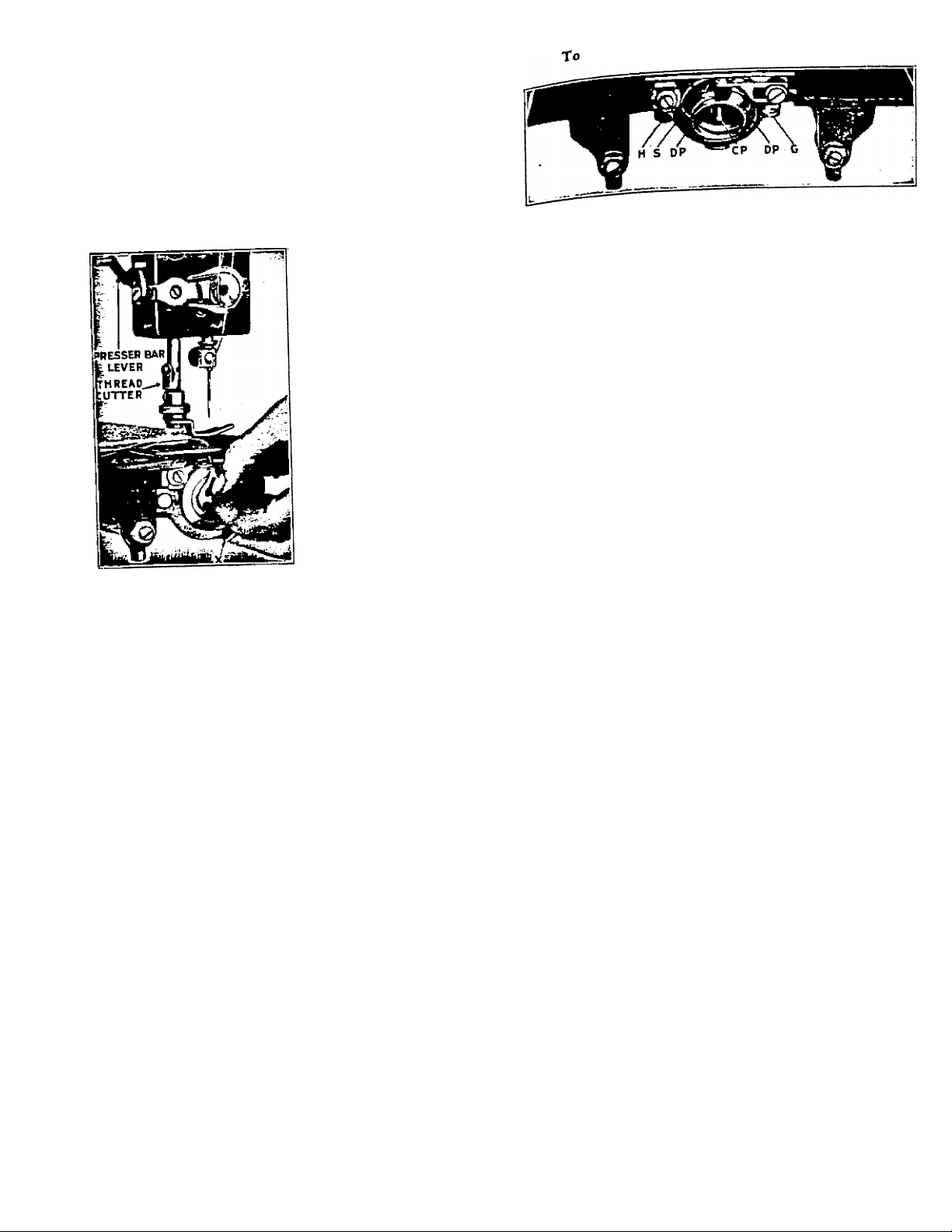

(C.P.) fig- 6-

Fisrur* 1

Two

Be sure to use ONLY Eenmore Sewing Machine <

Three

Page 4

PRESSER BAR CAP

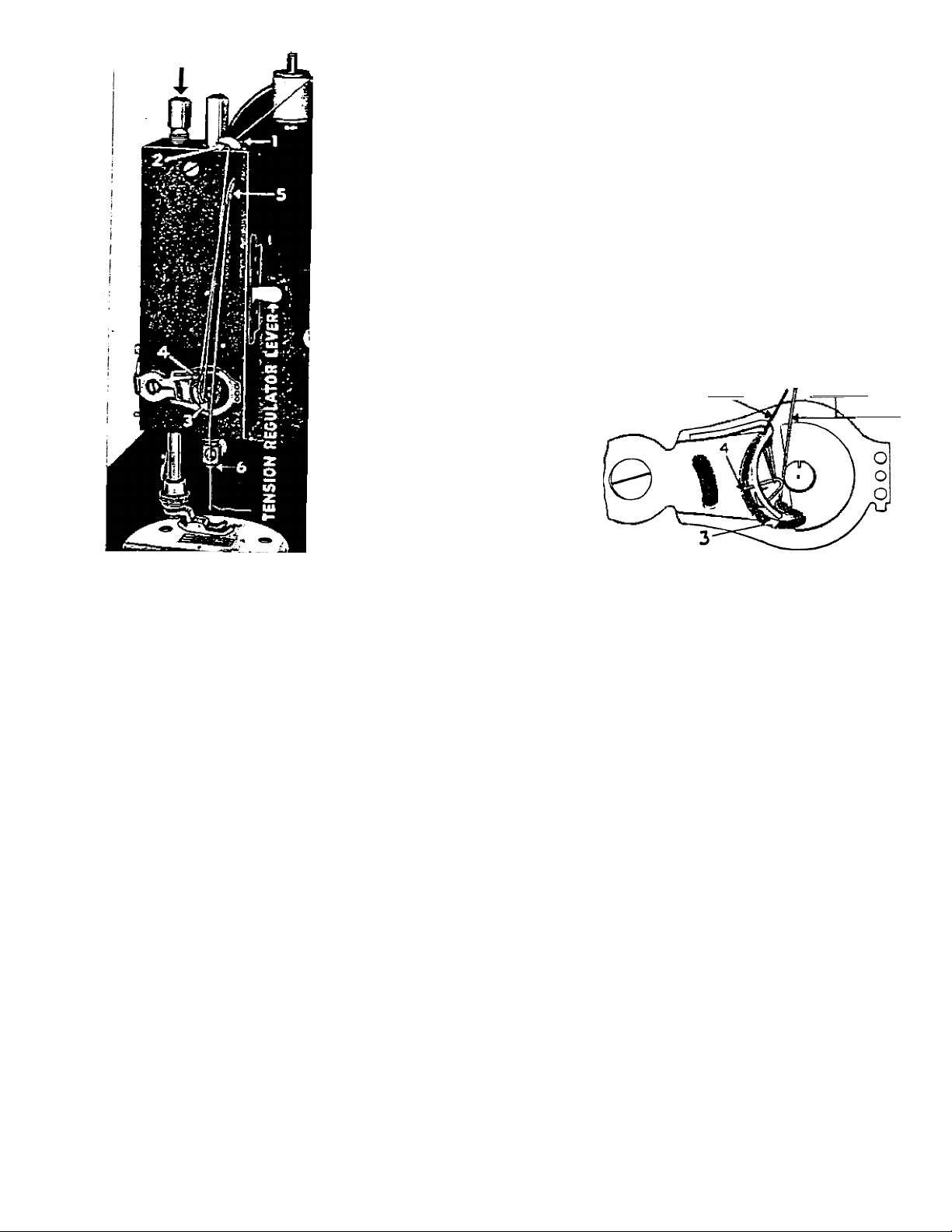

Threading

The Machine,

Upper Thread

(See Fig.

Your machine should h» •

proper position for thl.f- ®

by turning the hand !

(the top of the

from you) so that

up (5,.Fii 3) Tatit^ take.

est pomt., *ugh.

Place a spool of thread n

the spool pm on top^f

fhSnd Of the

thread in the left ®

tween the first fineer**

thumb, then use t^e

hand (first finger and thumbi

threat"^ "

Next, the thread should

pss under and in front of

hook one (1), then under aid

in back of hook two (2) “

Next, downward and hook

to bTck.°^"*

Next, pull the thread un

ward until it hooks into

spring eyelet No. 4.

Next, continue upward in

to the hole in the take-up

lever (5) from back to front

Next, downward and hook

thread into needle damn

thread guide 6 from back to

front. ,

Next, into the eye of needle

Figure 3 **i«vjA4*4c

(See enlarged view of tension assembly on page S)

from left to nght as you face

the machine.

Four

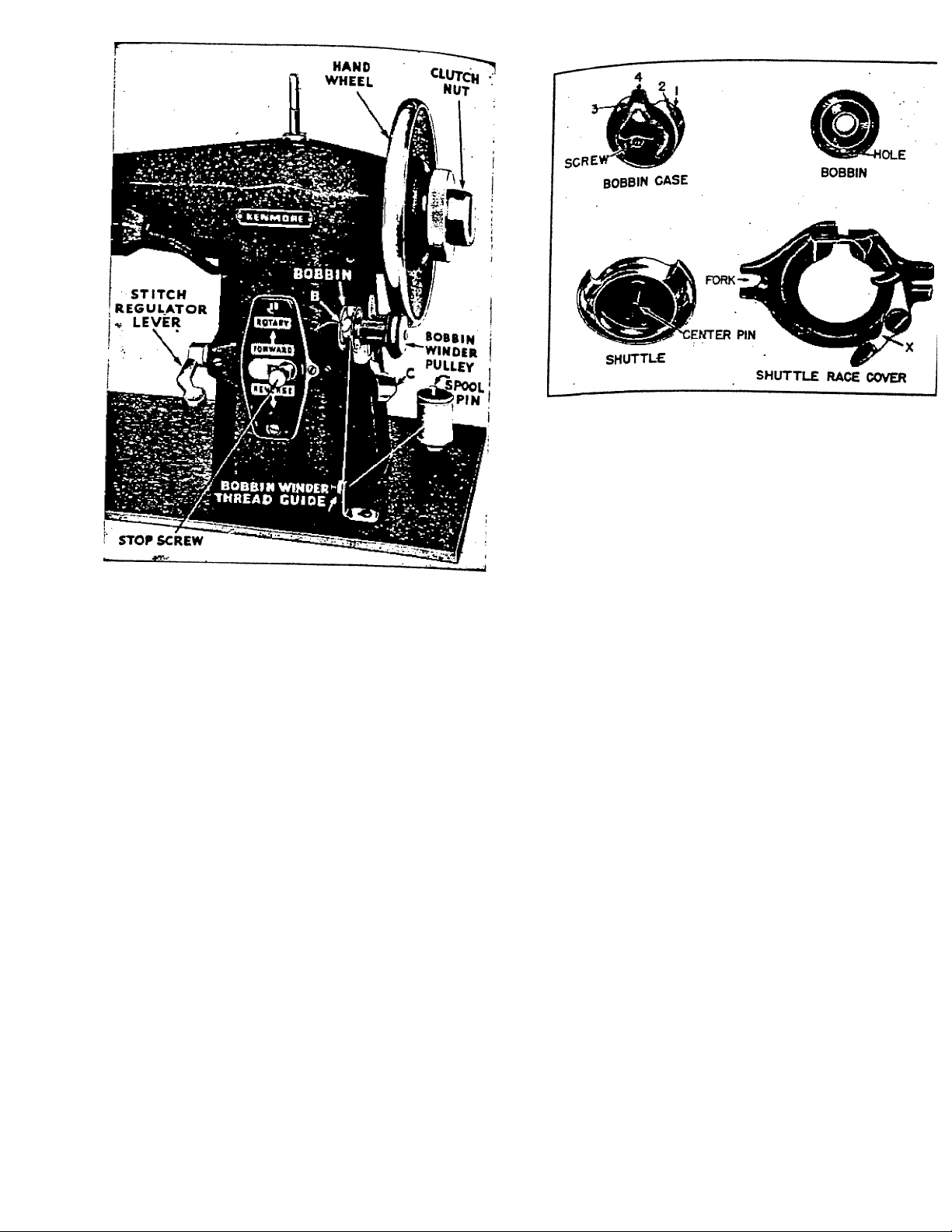

To Wind a Bobbin

(See Figure S Page 6)

, = the bobbin on bobbin winder spindle as sho’

tht hand wheel with the left hand and turn the top

Hold tne towards you. This will release the sew

th® of the machine. Next, place a spool of thr<

„lechanis located on bed of machine directly be!

on wheel. Next, take the end of the thread and p

the n^ the tension plates on bobbin winder thread gui

it b®two , j upward into eye of guide, then run end

fhfea'd through hole “B” in bobbin.

ir„,rocrp the bobbin-winder pulley with the hand wheel

k" O' lever “C” downward. Hold end of thread until y

pushing „chine sufficiently to wind the thread around i

boDDin machine and bobbin winder will automatica

contin proper amount of thread is wound. '

^^'^'iTfter the bobbin is wound and removed; tighten

?he hand ^h'eel with your left hand.

Five

several times: then break thread off at hole “B” a

. i k niit bv turning the top of it from you while holdi

‘ r>n non-electric machines proceed in the same mann

cept that power for operation is furnished by foot treat

TP *5

Enlarged view of tension assembly showing thread

ing of auxiliary spring, as described on page i.

FROM*I

AND*2

Page 5

nsoT* I

Six

F1*u« t

Threading the Bobbin Case

Hold bobbin case with thumb and first finger of lef

hand, with tension tongue (4) upright. Then place fillei

bobbin in case, starting thread into slot (1). Continue pull

ing thread up to end of slot (2); then across to bottom o:

slot (8) and upward until thread comes out at top of tensioi

tongue (4). Leave about two inches of thread projecting.

Caution —Note carefully the way the bobbin case ii

threaded before removing bobbin or unthreading.

Seven

Page 6

To Draw Up Lower Thread

While holding loosely in the left hand, the end of th

thread extending through eye of needle (three or fo„*

inches), turn the top of hand wheel from you (clockwUe\

with the right hand, until the needle goes all the way down

and comes hack up. The lower thread will form a loop over

the thread you are holding and come up through the needle

hole. Lead the ends of both threads back under the presser '

foot, keeping the upper thread in presser foot slot.

Remove Shuttle from the Shuttle Race

Flffur* 8

To Remove the Bobbin Case from Shuttle ’

Turn hand wheel (dock-

wise) until take-up (5^ pig

3) is at its highest point,

Then remove the hand hole

cover plate permitting you to

reach down to bobbin.

Clasp the bobbin case with

the thumb and first finger of

your left hand as shown in

Fig. 7. Then with the second

finger lift up on latch "X"

and the- bobbin case can be

readily removed.

Follow the same procedure

in replacing the bobbin case

in shuttle.

The hole in the center

spindle inside the bottom case

fits over the center pin of the

Usar« 1

shuttle, as shown in Fig. 6.

Eight

First remo ^ remove bobbin case as already ex

„move the hand hole cover plate and tip head

back on ite hi (clockwise) until the

plained. is just entering needle plate hole. Then .

point of the neM jp pig. g. This will release

press rear en readily removed

the shuttle ra the center pm m

from under p ^ readily removed WITH-

shuttlc (Cp/ '

OUT FORCE.

To Replace the Shuttle

m ... the hand wheel untU the point of the needle a just

entering the v shuttle by the center pin

■f*®;a!h other in the outer edge of the shuttle, are

oppMite each o^her pips (dP). When properly

lined up. the ou imperative that the

°i®L.n^L*nrooerly placed in the race, and it must never be

^,°®^!Sttìe rS cover by slipping the fork at left side

thè SHARP point of shuttle will be almost directiy

fnto^ position. When the shuttle is in position re-

the needle plate hole. With the thumb and first

entering tM n ^. ... the shuttle by the center pm

SS p“» (H) b.ck .«r Llpk (G)

whiS will snap back to its holding position.

Nine

Page 7

Regulating the Tensions

Upper:

When the presser foot lifter lever (Pig. 3) .

tension on the upper thread is automatically released

fore, the presser foot must always be lowered when ad‘

ing the upper tension. The tension regulator lever is f

on the face of machine (Fig. 3). To increase tension°'^*^^^

lever downward. To decrease tension push lever unJ*-

The most satisfactory tension for ordinary sewing is '

with pointer on this lever set between figures 2 and ^

numbered gauge.

Lower:

The small screw in center of the bobbin case (Pig B\

regulates the tension on the lower thread. To increase ten

sion tighten the screw; to decrease tension, loosen it. in

either event only turn this screw a little bit at a time.

Tension should be in balance to get best results

fiexible, accurate stitching. Experiment until your stitching

is balanced as follows: ■

If the upper thread is too tight, the upper thread will be

drawn straight on the top of the material, thus:

If the lower thread is too tight, the lower thread will be

drawn straight on the bottom of the material, thus:

When tensions are properly adjusted the stitching on

materials will look the same on both aides, thus:

________

neat

Ten

To Regulate Stitch Length

(Forward and Backward With Stops)

mu stitch regulator lever (Fig. 5, page 6) controls th

’J’116 . ,_onrl woirciwcii

’itengTfor both forward and" reverse:

st’mhi positioning of the stop screw (Fig. 5, page 6) regi

he

^length of the stitch, forward and reverse, by li

lates the down of the stitch regulator level

i„g the mu _ T

8PP.f ¿omes to rest.

“"a long as the stop screw is not turned the length o

lengtn gjj j.jjg stop screw and set the stitch regulator U

®u Hpsired longer stitch as shown in the window in the plat«

mh ” same longer stitch will now result both forward and

revise, except that number 4 is the longest reverse stitch

length. .

hpfore attempting to remove the work. Failure to do this will

° in breaking the thread and unthreading the needle.

ffc highest point, raise the presser foot with presser foot lever

snd DRAW THE FABRIC BACK about three inches in a

straight line, pass both threads over the thread cutter on the

nresser bar. After the material has been removed and the

threads cut, do not run the machine accidentally or other

wise without material under the presser foot. (See following

in the window then turn the stop screw to the righ

. u will remain the same.

T sew in reverse, move the lever down until it stops.

1° sew forward, move the lever up again until it stops.

Tf the lever and stop have been set for a short stitcl

th such as No. 2, and the operator wishes to use a longei

titrhten the stop screw as before until it comes to rest

The take-up (5, Fig. 3) must be at its HIGHEST POINT

Turn the hand wheel until the take-up (5, Pig. 3) is at

To Set the Stitch Length:

^jje stitch regulator lever until the desired nunibe

To Remove the Work

__

-----

^L.

limil

paragraph.)

IMPORTANT—When the machine is threaded, do not

operate it without having material

under the presser foot.

Failure to observe this instruction will cause thread to

lodge in the shuttle mechanism and prevent machine from

Eleven

Page 8

running properly. To correct, take out bobbin case and run

the machine in the wrong direction, turning wheel by hand

and it will cut thread out; or better still remove shuttle and

clean the race and driving pins.

To Avoid Breaking^ Needles

Never pull the work, causing needle to strike the needle

plate. A needle may also be broken by sewing heavy seams

oT* very thiclc goods without sufficient pressuie on the presser

foot for such heavy work. To increase this pressure, turn the

thumb screw on top of the presser bar.

To Set the Needle

The needle bar should be raised to its highest point.

Loosen the thumu screw of the needle clamp and press it to

the left This will permit the shank of the needle to pass up

Kofween the clamp and the needle bar as far as it will go

tfth the flat side of the the

needle clamp screw securely. Use a screw driver.

tL needle when descending should pass in the center

of the needle plate hole from front to rear, but close to

right side of needle hole. If it does not the needle is either

bent or improperly set

Proper Needles and Thread

It is important to use perfect needles that are not bent

nor blunted! When ordering needles for this machine men

the name and give the head number. For ordinary fam-

S sewing!”se needle size No. 1. This will carry thread No.

60 to No. 90.

Needle Sizes

0

For plastic film, use No. 0 needle and mercerized thread.

Needle and Thread Sizes

Cotton Thread

80 to 100

60 to 80

40 to 60

30 to 40

Heavy Duty Mercerized

Heavy Duty Mercerized

Other Threads

Mercerized

Nylon A

Silk A

Mercerized

Mercerized

Twelve

The Narrow Hemmer

ilfure »

. ■ h«« ever equaled the dainty finishing that it h

Nothing h« ever Narrow Hemmer.

iTofaifd^ifdes" ^ to"tor"n “Stcia^tr

row hem m Serial in Hemmer crease over % incl

Before i"®®’^^^"f;^nce of about 2 inches, insert edge ii

of its edge for a ^he scroll, folded edge on top

Hemmer guiding .. jg under needle; lower presse

draw to stitch. Should stitching appear too far fror

bar and begin push Hemmer slightly toward the right

turned edf too close to edge, or not catching a

iriovi toward th. Lit.

Guide and uneven hems; neither too little, nc

iLwing^for"l second turning, thus leaving a raw edge. Th

tcroTl Xuld be kept just full.

Thirteen

foyial so that neither too much feeds into th

Page 9

Hemming and Sewing on Lace in One Operation

With the Foot Hemmer

. Figxm 10

The Narrow Hemmer is designed with a slot at the right

into which the edge of lace, rick-rack braid or any finished

edge can be inserted and stitched to garment while it is being

hemmed.

Proceed to make a hem in the same manner described on

previous page. Insert edge of lace or trimming right side

down in slot at right of hemmer and see that the needle

pierces it close to the edge Just above turned edge of hem.

Commence to stitch guiding the lace edge into the slot of

hemmer with the right hand while guiding material to be

hemmed into the scroll of Hemmer with the left hand.

Applying lace in what is termed the French manner also

requires the use of the Narrow Hemmer. Enter the fabric to

be hemmed as for plain hemming, enter laces from the left,

right side down, on top of the fabric; allow edge of lace to

enter hemmer and meet material just as it is being turned,

thus the hem will enclose lace edge in one stitching. Press

hem back on wrong side of fabric and no visible stitching

will mar this dainty finish.

■ Fourteen

A FcU.d S.a» F““'

Fleur« 11

A felled seam is generally used where double strength

J with a nice flat finish.

th. mo pioooo of to b. .»».d t^.tb

Place the t J section to extend about

with righ other Place goods under the Foot Hemm

inch beyond th presser foot, keeping narrow si

Just as though hemmer

of seam “PP®™ ’ After stitching is completed op

“ goWe 'ruCtndIr foof hemmer with right side of ma

seams end p machine and the widest half of sei

^dThe right. This widest portion of seams edge is tk

toward the r g of hemmer (See Fig. 11) and if seam 1

entered ^ ^he % inch or widest half of seam v

S.-” d ot» ¿0 A look >” •

Fifteen

Page 10

Wide Hemmen

Cutting Gauge

biarSnL

a binding: or narrow

for y®®ither straight or bxas to

bands f*"®facings, pipings,

' FipJ« U

An assortment of wide hemmers is furnished with

Sewing Machine.

Attach the desired size of Hemmer to machine in place

of the presser foot; crease over 14 inch of material to be

hemmed for about two inches before inserting edge of goods

Enter material and guide it around scroll of hemmer using

both hands to draw it back and forth a few times, while

gradually feeding the cloth into the hemmer so as to fill the

scroll completely. Draw material back so that creased edge

fits around edge of scroll in hemmer and selvedge edges meet

Hold both under and upper threads and proceed to stitch. '

Should the stitching appear too far from turned edge of

hem loosen thumb screw and move hemmer toward the right.

If it appears dangerously close to turned edge of hem move

hemmer toward the left.

As material is stitched through the large hemmers the

turn at edge of hem is visible. Allow the hem to ride freely

through the hemmer, never drawing on the edge being turned,

but gently retarding the material under the hemmer, using

the left hand.

your

Sixteen

The inch and fractions thereof, d

ienated on the cutting gauge, enab.

one to cut material of any te.\ture pi

fectly for use with the binder.

%linch of hi-inch is correct for firn

woven nriaterials.

1-inch to IV*-inch IS correct for rx

terials that stretch more readily. T

gauge slide is adjustable and can

moved to the left or right. -

Figure 15

Attach cuttingsg^an^ove

gauge siiqe material

• “ in he used with the

bin%r be cut on a

evenly.

Seventeen

slide to width of band

betwLn the blades

if toportant that bind-

Figure 14

Fleur* IS

Page 11

The Multiple Slot Binder

The popidariiy ior bindings that do double dntv «

dinnnishea. Bindings are frequently used to finish

of fabric as well as furnishing a garment’s onW ®

-- , Th. MulUpl. Slot bM “ST

irAbV.ri SX““#?

making of dainty garrmfr,*

caU for narrow binding wln^thl

SfSSL"' “> \

each designed to carry binding oi

their width. Size 1-2-3-4-B. ^ ”

Commercial single fold bindine

must U used and fed into th!

slots of same size as illustrated

The familmr % inch or H inch

bias cut binding which every

t^nough the open mouth of the

The Binder is adjustable side

Fisur. 17 erly close to the edge of binding

wise to bring the stitching pron-

SstLl; ^

« entered

Exclusive Bindings with the

Multiple Slot Binder ^

Remove the presser foot, attach Binder in its place. «

As shown in Fig. 18 the Multiple Slot Binder can be used S

for attractive combination trimmings so much in vogue on

jabots and frilled accessories.

Our illustration shows a tricolored trim using com

mercial single fold bindings sizes 1—3 and B. Sizes 5 and 3

act as two tone pipings while size 1 binds the edge enclosing

the fabric in the double piping all in one single stitching.

This trimming is just as effective on the reverse side of fabric

making it a desirable accomplishment for any dainty cascade.

Eighteen

Fisur» 18

riin bindings to a decided point and enter each width

•t respective slot helping it beyond the needle with the i

f a large needle or pin and starting with the narrow,

•dth The edge to be bound is inserted in the center of i

¡l^chment between the scroll and held in as far as possil

without crowding.

Manv lovely double binding combinations are possible

sevCTal different sizes; 1 and 3; 2 and 4; or 3 and 6.

Binding with Bias Cut Binding

Binding that has been cut and prepared for Bind

should be cut to a long point, inserted into the scrolls

Binder and helped forward beyond the needle by the aid of

large pin. Lower presser bar and stitch to ascertain whe

stitching line appears on binding.

.Nineteen

Page 12

Fignr# 19

The Binder is adjustable and can be moved to left or

right, until line of stitching appears safely close to edge of

binding.

In binding scallops it is necessary to hold the edge to be

bound well into the fold between scroll of Binder as fabric

nears the needle, at this point only is binding being stitched

and if care is exercised no stretch will appear on this curved

edge. Illustration of bound scallops (Fig. 19) clearly shows

this operation.

Additional rows of binding can be applied as a trimming

by placing garment to be trimmed under the Binder and guid

ing the spaces between rows by thé edge of Binder Frame.

Twenty

Quilting

Figvre 20

much depends upon the accuracy in stitching espe<

V. ^ =i?rcessive rows are used for trimming. The quiltei

^.t"as aTawurate guide for any stitching that is sj

»V, than the presser foot allows.

'^’'^For“ genuine quilting over wadding the Quilter C

i the Ouilter Foot has no equal. Place as i

liicknlsSsli wadding over the wrong side ^

thicknesses u cheese cloth over the who

as P pucker so desirable on comfortables or q

the 5i?ead cutter screw at back of presser

Free tne quilter wire to fit into the screw

®A'!r‘^lt”ouilter Guide the distance from needle desired

wh enough from bed of machine so that material can

high en B . gjj tighten screw.

“”‘^let tte machine stitch fairly long and keep the w

®*^For exteemSv^thkk'padding release the pre^ure on

Quifter Foot by turning the Pre.«ser Bar Cap. (Fig. 3).

Twenty-one

Page 13

RufBer

A. Slots to space

fullness at number

of stitches.

B. Slide lever to

regulate depth oi

pleat.

Attach Kuffler by Pjf

the foot “C” on |ttachment

holder and the ®

astride the needle clamp

screw. •

See that needle goes do\ro

in center of needle hole in

Ruffler.

Ruffling

Enter material to

between blue blades.

material is guided into ”

“everal slots or adjustable

guides provided for different

widths of seam allowance or

headings, as shown in these

pictures.

At point “A”, set pin in No.

1 opening for f^the| at every

stitch. At point B loosen

screw and set lever

gather. No. 1 makes the finest

father. Length of stitch

ing machine varies amount of

fullness.

Pleating can be pleats, spaced cJ

At P°'”p„ing for pleat

№• ® °fixth ftitch. At

every s'i, loosen screw,

point 15 fiown to deepen

fength of stitch on sewing

machine.

Ko"^M opentog

every „ loosen screw,

Prifp lever down to deepen

slide lever ce pi^^tg by

fenfto of stitch on sewing

machine.

Rhoff P^Sied" to make first group of pleats. Stop sewi

^ At point “A” set pin in

ftoi. Stitch without plea^

pre'rillsVeatingposttiom

Twenty-two fuoenty-three

V #„™ed in a wide range of effects. '

Six-Stitch Pleating

“A” set pin in

Twelve-Stitch Pleating

“A” set pin in

twelfth stitch. At

Group Pleating

C ' V 1I^^:

Rix-stitch or twelve-stitch pleating,

Page 14

Shirring

The Shirring Plate is used to

make wide ruffles, deep headings

on ruffles, and for continuous rows

of shirring.

To Use Shirring Plate:

1 Remove handhole cover. Put Shirring Plate on machine

0 Remove lower blade and heading guide by loosening

3. Put Ruffler on machine as before.

4. Set attachment

Doint “YY” in screw hole of needle plate. Point

eoes in squared opening of needle plate, and is held

in'place with handhole cover, replaced at this point.

fmSl screw on right side of Ruffler. and slipping for

ward. Tighten small screw.

for ruffling. For

several rows of

shirring, it helps

to use the Quilt

ing Guide for

spacing.

Piping »nd Edgestitching to Ruffle

Shirring Plate. Enter material to 1

Use Huffier right. Guide into seam-allowan<

ruffled be^een piping through

slot of Shirring ^ fabric. Guide folded edg

on left- Fold "tnd above blades. To adjust the guu

into slot above pipi 8 screw behind needle ho

needle sews on veijf

Twenty-four

Twenty-five

Page 15

Combinatioo Edge-Stitcher, Tucking Guide and

Top-Braider

The Edge-Stitching Attachment is

fastened to the machine in the same

manner as the Presser-Foot. There are

five different slots, which are shown in

the illustration, serving as guides for

sewing together laces, insertions, em

broideries, sewing in position folded or

hemmed edges, bias-folded material or

piping, etc.

How to Adjust the Edge-Stitcher

To adjust, move the lug “A” ^he right or Mt until the

desired adjustment is obtained. When semng two pieces of

lacf together, it is very necessaij that the a^chment is

adjusted to stitch exactly on the edge, so that the edges will

not fold over when laundered.

When sewing laces or soft materials together, it is “®tter

to hold the edges, slightly overlapped, This will prevent the

lace from feeding away from the guide. ^

When the attachment is properly adjusted, the most inexnerienced operator may sew yards of lace or material

tolether with no difficulty.

Tucking

The numbers 2 to 6 inclusive stamped on the back edge

of the sliding guide represent the width of tuck in eighths

of an inch. After folding the material for the first tuck, put

the folded edge into the guide slot which is nearest the needle.

When the left edge of the friction spring “H” coincides with

the number 2 on the scale a tuck results

In like manner, set the guide at 3 for ® tuck.

In like manner, set the guide at 4 for a % tuck.

In like manner, set the guide at 5 for a %" tuck.

In like manner, set the guide at 6 for a tuck.

For tucks narrower than U" move the guide "G” as far

as desired to the left.

fwenty~$ix

■ Braidmg

Move the 8^ . . with the needle hole of the atts

hole “K” »s fifiM^to be braided should be plainly mar^d

«ent. The right side of the fabric. Start

stamped hole “K” and stitch along desi^, be

soutache feeding freely into hole

sure that turn a comer, stop the machine v

without twisting. TO gjjggt comer of

the preswr-bar just enough to permit the to

design, the p^ the desired direction, lower the press

“G” to the right until the braiding gr

bar^nd proceed as before.

Twenty-seven

Page 16

The Shirring Foot

Figure 26

One of the very newest and well liked Se^ng Machine

triiSfngf i thelinty smocking obtained when nsxng the

^“Mr2rshows rows of shirring held firmly by a row of

Fig. 26 snows . hole of Shirnng Foot

and “ I shirring are broken by a diagonal shirring

Th^rX: atSTttractive puffing for a smocked effect

The Shirring Foot replaces the presser-foot for this work

and ihe amoUt of fullness obtainable is ^he

^ * machine stitch and tension. For fine shirring set

riu'rA.” iuita- >.»»«■» “•

and tighten the upper tension. •

cJeMly C.U. i.b* » ,i‘ >»"=

material feeds to the needle singly.

Twenty-exgKt

Tk. Combi»»““ Adjos“bk Zippor

A«»»bi»s »»d Coodms Foot

This attachment is designed s<

can be adjusted for stitching eii

left or right side of cording in a s

or for stitching right or left

when attaching a slide fastener,

just by loosening thumb screw-

sliding foot to desired position on

Inserting Cording

FlfUM II

■Remove the re^iar p place. Loosen the tl

Mb Combination move the foot to the rig

iilw on the attachment and move ^t^^^

S;%ordinj is^ >%^uttr%f the needle hole before tig

,i=c Tiresser foot and attach the Ad

fnltL^thumb. screw

Fold a strip of bias q+itch along close to the

place under Adjustable Attachment b|mg u»

Fig. 2] ®^Hoin it to a fabric edge in one atitehing

Bar^djusting Cap Screw^.^E^^^^^ Combination Attachi

more freely unuc»

Twenty-nine

Page 17

Attaching a SUde Fastener

. Fifure 28

Remove the regular presser foot and attach the Com*

bination Attachment in its place. Loosen the thumb screw

on the attachment and move the foot to the right or left as

desired. See that the needle goes down in center of the

needle hole before tightening the thumb screw.

The needle holes on either side are cut deep enough to

allow sufficient space between the metal of tiie slide fastener

and the line of stitching so the fabric wiU not catch in the

slide pull as it is being opened and closed.

Fig. 28 shows a slide fastener being stitched in a gar

ment with the Combination Adjustable Zipper Attaching and

Cording Foot positioned to the right of the needle.

Thirty

To InstaU Sewing Machine Head on Cabinet

°f-jt\ead binge

and 2)

‘“®.\ound shanks

°Tthl two hinges

attached to^ of cab-

■'"It Tip head back

to back of

tighten head

set screws

(Fig® 2) securely.

^to^iS'ariea?

r°the motor as pos-

a?d slip motor

cord into slot at edge

f bed plate and

nush bushing back

fnto hole in bed p|a j ^

(see Fig. 9); y“ ^ord inside the cabinet, plug into an

wind the ef^f"®*and the machine is ready for operation,

base plug ' trehdle operated, merely place leather bel

“ Thind wheel drive pulley as of course there is no moto

^electrical connections. _ .

Motor Lubrication

/rtTic at either end of the motor shaft) provid

Two ““Purgation. Unscrew the caps and fill with petro

occasionally, depending upon the use of the ma

chine ^Sproximateiy every six months.

’ Speed Control and Current

„.v .loeired sewing speed is obtained by pressing th^

The pressure from the knee lever auto

knee lever. Rem g ^e used on eithe

Tr or DC, no on IIB volts up to 75 cycles.

^ Motor Pulley

Ra sure the motor pulley (Fig. 9) is adjusted so i1

centers on the disc wheel of the machine.

Thirty-one

Page 18

SIMPLE CORRECTIONS FOR

MINOR DIFFICULTIES

This sewing machine was carefully adjusted and tested

before being delivered, and with proper care and attention

according to the directions in this book should give you no

trouble. To be sure of getting the proper supplies for it, such

as needles, oil and bobbins we recommend that you buy them

from us, always giving the name of your machine and its

serial number.

If your machine should actually need replacernent parts

or repair service we suggest that you get in touch with us.

Do not permit just anybody who comes along to tamper with

or attempt to fix your machine. Unskilled agents and un

trained repair men often do far more harm than good in

attempting to adjust a sewing machine.

For the most part sewing machine troubles can be reme

died by minor adjustments easy to perform. Should your

machine start misbehaving, check over the following list of

minor difficulties and simple corr_ections for them, before

calling for help.

If It Skips Stitches

The trouble may be caused by— ■

1. Crooked Needle: i ■ ■

May be hardly perceptible yet sufficient to cause skipping.

Unthread the needle, remove presser foot, turn machine

bv hand. Needle should maintain a constant position in

relation to the needle hole as the needle passes down

through the needle plate hole. ■ .i,- •

Replace with a new needle and make certain this is not

the cause of trouble.

2. Incorrect Needle—or too fine a needle: „

It is very important that you have the correct needle. Be

certain to follow the table in this instruction book in

selecting the proper size needle for size of thread and

material being used. .

3. Needle incorrectly set: . .

The needle must be pushed up as far as it will go into

the needle clamp with the flat side of the shank to the

right and fastened securely with thumb screw.

Thirty-two

w pdle rubs Presser Foot:

^ . „.-»«.ipr foot holder on the presser bar so th:

Adjust pres «r cubbing, the right side of tV

needle i® „rake this adjustment, loosen the sma

presser to presser foot holder to presser ba

screw rna proper position and finuly tightc

sMlVf the foot.

jf It Breaks Thread

The trouble may be caused by—

■a7w,ntr Needle being used: _

1^/fs Important before trying anything else to put in i

new straight ■tieedle, proper kind and size.

table elsewhere in this instruction book.

, pr-ie in the Needle Plate Choked with Stray Threads:

P 11 threads from the tcnderside of needle plate witl

screw driver or long needle, or better remove plate anc

clean. , . .

A Machine Improperly Threaded:

rheck over carefully the instructions on threading the

«^arhine and observe especially the threading of the

Sieck spring on top of the face plate.

Refe^to'1n°s*tr^tionf elsewhere in this book on the proper

adjustment—both upper and lower tensions.

R Needle too Close to Presser Foot:

Adjust foot as described “Needle Rubs on Presser Foot”

under “Skips Stitches",

7 Examine needle hole in needle plate. If it has become

' rough or burred from needle striking it, needle plate

should be replaced with a new one.

If It Breaks Needles

The trouble may be caused by—

1 Pulling of the material when sewing will break needles.

Guide the material only—do not pull.

Thirty-three

The Se should be a trifle closer to the rigb

the proper needle and thread according to thi

Page 19

' '-i

---■i

%

-'

■

2. Wrong Needle being used: ,

Be sure you are using the correct needle for this machine.

3. Needle incorrectly set—too low:

- See instructions elsewhere in this book on how to prop,

erly set needle and follow instructions carefully.

Needle Rubs on Presser Foot:

4.

Adjust foot as described “Needle rubs on Presser Foot"

under “Skips Stitches”.

Needle not firmly set:

5.

After being certain needle is properly set be sure it is

held tight by needle clamp screw—use a screw driver.

If Puckers On Ordinary Material

The trouble may be caused by—

1. Tensions NOT in balance:

Reduce the'tension on upper thread by- moving indicator

towards No. 1. Do some testing. If this fails, examine

lower tension on bobbin case for proper adjustment and

proceed to balance the tensions. See instructions else

where in this book on tension adjustment.

Blunt Needle—Replace with a new straight needle—ex

2.

amine needle point.

1/

The trouble may be caused by—

Both tensions may be too tight: ^

1.

Adjust upper and lower tensions—must be in balance.

For chiffon and other very light materials, best results

are obtained with upper tension set at % and the lower

tension in balance with that. However, sufficient tension

must be maintained to raise the small auxiliary spring

(No. 4 in Fig. 3) when machine is in operation.

Presser foot loose in holder:

2.

Tighten knurled thumb screw.

Blunt Needle:

3.

Replace with new straight needle—examine needle point.

Thirty-four

Needle Plate:

1, in this plate might be slightly bent down. N.

hole might be rough from needle striking it

eifhir «.se a new needle plate is required.

Loose Stitching

The trouble may be caused by—

Tension too loose—either top, bottom or both:

1.

gee instruction.-» elsewhere on tension adjustment

balance.

Upper Tension fails to Operate Satisfactorily:

2.

T int or stray threads lodged between tension plate Nc

n ¡L the presser foot lifter (see illustration). Set

fension regulator at figure No. 1, next cut a piece of 1

down a few times which will remove any bits of thread i

lint from between tension plate No. 1 and washer No.

Thirty-five

_ cloth to a point and di

this strip of cloth thrm

and under tension pi

No. 1 and close to sci

No. 3 on the side from »

as shown in illustrati

This cloth should be dra

down through tension ph

No. 1 and washer No. 2 i

shown in illustration), t

can be accomplished

holding tension plate (T

1) and washer (No.

apart with a small sen

driver. Be careful to dri

the cloth between pis

No. 1 and washer No.

When you have this do

in place, drop the press

bar lifter, move the te

sion regulator toward N

8 and pull the cloth up ai

Page 20

Loading...

Loading...