Page 1

Page 2

You are now the owner of a new straight stitch machine, the most versa

tile machine of its type you cam possess.

■'Hk

c. ^

‘'li

To aid you in obtaining the greatest achievement from your machine

this book on its care and use has been written for you. Read the instruc

tions carefully as a thorough understanding will reward you with many

hours of trouble-free sewing.

Time-saving attachments such as rufflers, binders, buttonholes, edge-

stitchers cording feet, decorators and so forth to complement the acce

ssories, are available from your dealer.

J!

I

y

c

c

a

c

K

Page 3

INDEX

i arts warranty

Service policy ... „

„ ........................................... 3

reatures and parla

Needle and thread chart

Winding the bobbin

Threading bobbin case .......................................... g

Placing bobbin case in shuttle

...........................

...............................................

2

...........................................

.....................................

...........................

g g

Upper threading ..................................................... Ц

Setting the stitch length

Stitch length chart

Sew in reverse

...................................

Adjusting the tensions

Adjusting pressure and feed

General sewing

Light weight fabrics

Darning and mending

Preparing to sew

...............

..............................

.................................

...............................

......................

..............................

............................

....................

"

22

2g

22 13

24

23

23

24

Page

456

^

ю

Removing the work .............................. .

/—»__ , _

>^are and mainteriance

Accessories

^7“' ....................................... 18-19.20

At achmenb ,. 22.23-24.2S.26.27-2S-29-30

Attachment foot .................................................... 23

Edgestitcher

Binder

Huffier

Cording and zipper foot

Hemmers ....

Darning spring

Buttonholes

Button sew-on .

............

...........................

.............

.........................

..................................

..................................................... 17

...............

....................................

........................................................

.....................................................

..............................

.....................................................

............................................

..............................................

.

............

15-16 17

-i-T’-xO

28

Decorator .............................................

Blind stitch hemmer

.........................................

Installing Head in cabinet ..................... g >

Head in Portable case

..................................

3q.3{

25

27

Page 4

18 17

с

e

fe;

С !ч

с N

L)

С

с N

- к

^ I '

- :■ <

1^'

! ¥

^ i¡

с •<

сЧ

Л

сН

с1

^ Fig. 1

"г

с 'í

ci.

с Í

.t

ft

?.

Page 5

Hand wheal

],

Bobbin winder

2.

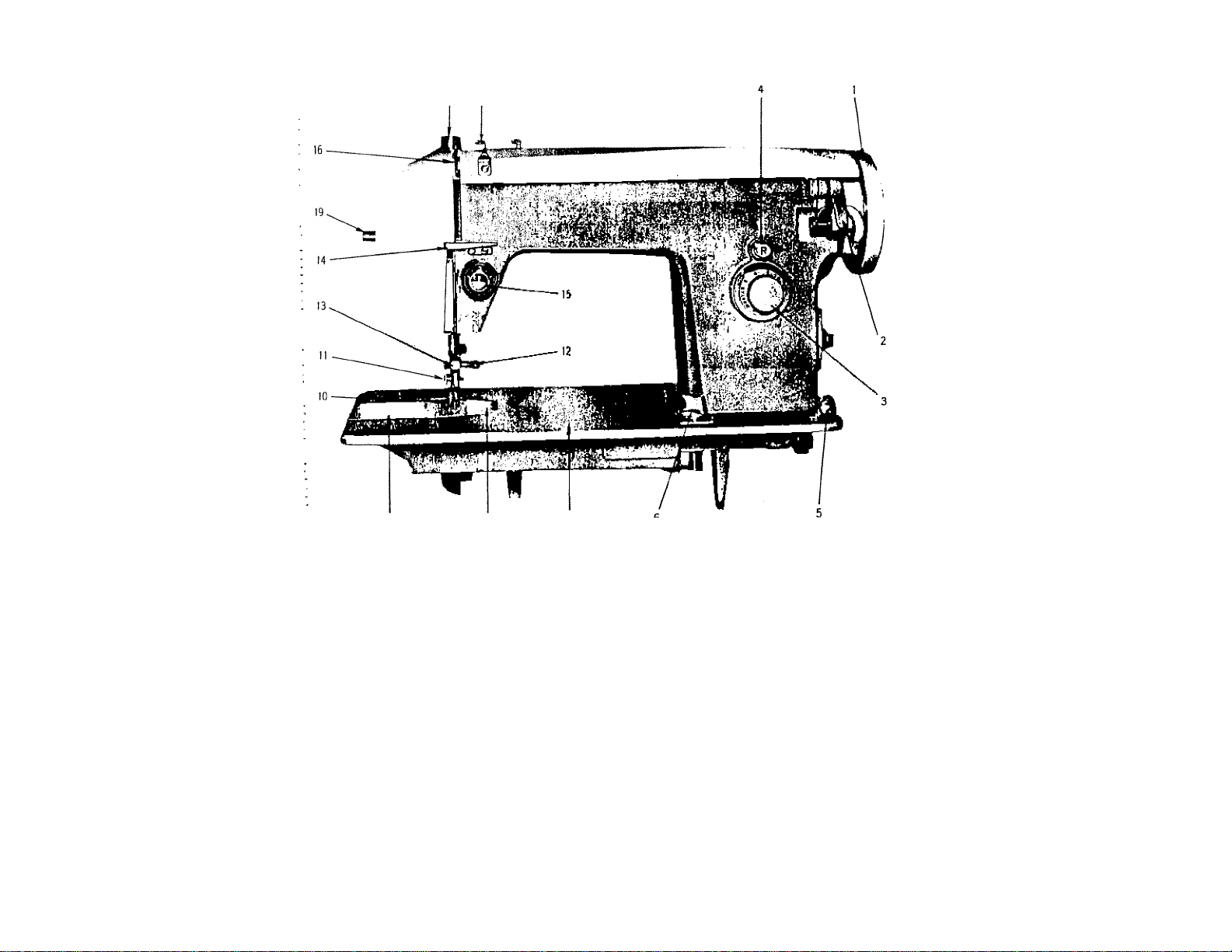

FEATURES AND PARTS

11.

12.

Attachment and foot thumb screw

Needle clamp and screw

*jr

-

►

W

Stitch length dial

3,

Push button reverse

4.

Bobbin winding tension

5,

Drop feed knob

6.

Bed

7.

Needle plate-seam guide 18.

8.

Cover plate

9.

Presser foot

10.

Needle bar thread guide

13.

14. Thread guide bar

Tension regulator

15.

Take-up lever

16.

17. Thread guides

Presser release-darner

Light switch

19.

Page 6

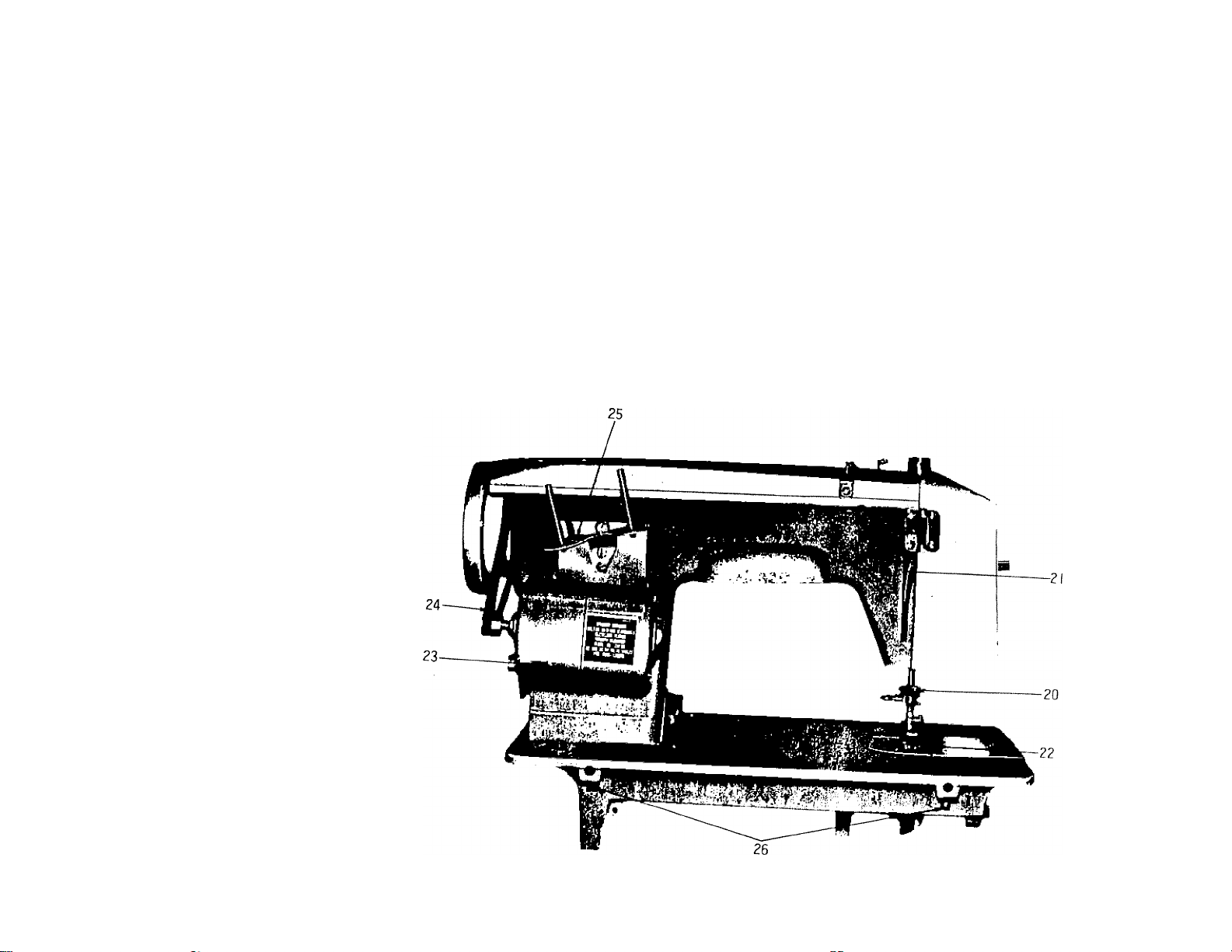

features and parts

(Back view)

■ ais:

20. Thread Cutter

21. Presser Bar Lifter

reed

23. Motor

24. Belt

25. Spool pin

Fig 2

26. 1 inge Screv/s

Page 7

NEEDLE - THREAD - FABRIC - STITCHING GUIDE

ii

y

u

u

u

J

J

A

y

y

Fabric

Extremely heavy

tarpaulin, sacking,

canvas, duck, etc.

Heavy upholstery

fabric, ticking,

denim, leatherette

Medium heavy drapery

fabric, velveteen,

suiting, felt, terry, etc.

Medium broadcloth,

percale, gingham, linen,

chintz, taffeta, sheer

wool, shantung, etc.

Sheer voile, lawn,

dimity, crepe,

handkerchief linen,

plastic film, etc.

Very sheer chiffon,

batiste, lace, organdy,

ninon, net, marquisett, etc.

Needle

No.

4

3

1

0

00

Machine

Stitches

Per Inch

6

to

8

8

to

10

10

to

12

12

to

14

14

to

16

(Plastic film^

8 to 10

16

to

20

Cotton

Thread

10

to

30

30

to

40

40

to

60

60

to

80

80

to

100

1

100

to

150

Mercerized

Thread

Heavy Duty

Heavy Duty

Heavy Duty

50

50

50 A

Silk

or

Nylon

A

A

Page 8

SETTING THE NEEDLE

Fig. 3

Fig 4

See Fig. 3. Raise the needle bar A to its highest

point, turning wheel toward you by hand.

Then loosen the needle clamp screw B and the

needle can be inserted into clamp C. Place needle

(flat side to right) in the needle clamp and push it

upward as far as it

hole, tightening the

with a screw driver.

After changing the needle make one com

plete revolution of the balance wheel by

hand to be sure the needle is in the correct

position.

will go into the needle clamp

needle clamp screw securely

Flat surface

of needle

shank

WINDING THE BOBBIN

Disengage the hand wheel (5, (Fig. 4) from the stitching

mechanism by turning the clutch 6 toward you or counterclock

wise.

Place a spool of thread on one of the spool pins, lead thread

through the upper thread guides on the arm, and down through

the tension disc (10, (Fig. 5) at the base of the machine. Run

end of thread through a hole in the bobbin edge and place

bobbin B on spindle of bobbin winder 7, fitting the notch on

bobbin over small pin on spindle. Push bobbin winder pulley

against hand wheel. Hold thread end loosely and start machine

slowly.

Bobbin will stop winding when it is filled. Turn clutch away

from you until sewing mechanism is again engaged so that

needle moves when you turn the hand wheel.

Break off loose thread end used to start the winding.

It*

:

A;

h;

c ii

c ^

r I

it 6

Page 9

, M

M

u

J

J

J

J ■

i"

I -

THREADING THE BOBBIN CASE

k ^ «"illustrated in Fia R)

bobbm case between thunlb ?

Rnger of left hand, so that the f

edge of the bobbin case is o^f °

the bobbin between thumb and

of right hand so that the fh^ ^“^efinger

leads from left to right Step^ T

bobbin into bobbin case Jli J'

into the slot of the bobh',,f ^^

■» Kg. 7, a„d d,:„

spring and into the fork-sh. tension

of the spring as shown in Fig.^8

Fig. 6

Fig. 7

rtMilOM SPR|^4(; .

' a

Fig. 8

Page 10

10

PLACING BOBBIN CASE IN SHUTTLE

Raise needle bar to high

est position, and lift hinged

cover plate. (See 10, Fig

1.) Hold the bobbin case

latch, ( D), Fig. 9, between

the thumb and forefinger

of the left hand, with at

least three inches of thread

running from the top of the bobbin case to the right.

Insert and center the bobbin case on the stud of the

shuttle body, (C). Be sure the bobbin case finger,

(E), is opposite the shuttle race notch, CA).

the bobbin case (B) into the shuttle as far as possible

until latch catches on the center post of the shuttle.

THEN release the bobbin case latch, (D). Press

bobbin case again after latch has been released to

make sure the bobbin case is locked securely in place.

Close the cover plate.

UPPER THREADING (Fig. 10)

THRE

QUID

1. Turn the balance wheel toward you to raise

the take-up lever to its highest position.

2. Place a spool of thread on the spool pin.

3. Lead the thread through the upper arm thread

guides.

Page 11

■1 Hun ll.e Uiread tlirough the thread guide bar to the

tenuion discs, then around and between them from

rigtil lo left.

!i. Draw llie thread up through the check spring and

with a slight lug into the hook. (See insert, Fig. 10}

6. I ass ttie thread under the bar and up through the eye

of the take-up lever from right to left.

7. I.ead tfiread down under bar, tlirough the face plate

guides and then through the needle bar guide.

8. Thread needle FROM LEFT TO RIGHT, drawing it

through about 3 or 4 inches. Hold the end of upper

thiead loosely and turn hand wheel toward you until

the needle goes all the way down and comes back up.

A loop ( Fig. 11) will be formed over the upper thread

which then can be pulled out straight. Place both

thread ends under the slot of the presser foot and

draw toward the back of the machine, leaving both

threads three of four inches long.

SETTING THE STITCH LENGTH

The length of the stitch is regulated by the dial, shown

in Fig. 12. Near 0 is the shortest stitch and 5 is the long

est, but the dial may be set at any spot between the mark

ings or a variety of lengths. Turn the dial to the right to

length and to the left to shorten the stitch. The number

stitch length you choose is indicated by the triangular pointer.

11

Fig. 11

Fig. 12

-'i

Page 12

Figures on indicator

Number of stiches per inch

SEWlNCdi ilN

adjusting THE TENSIONS

Always adjust the upper tension with P ^ ^3^ to

released when il is raised. To increase e ensio number on the dial the lighter

,„e right, or dochw.se. To decrease ° is threaded properly,

the tension. Before adiusting lower tension be sure that tn

When necessary to change the bobbin tens,or., turn sma

screw (Fig, 14) on side of the bobbin case clockw.se

lighten, counterclockwise to loosen. Uy^lanred

When the upper and under tensions

a perlecl st.loh will be formed with both threads interlockmg

in fabric (Fig. 15). ic.

When the upper tension is too light, the lower

pulled up over the upper thread which is lying flat on

i • nh the nresser foot down, as the tension is na u

' I?

c h

c ^

y

ij

'"'’"when Ihl^ upper tension is too loose the “PP“

terms loops over the lower thread lying ilal under the

(Fig. 17).

Page 13

Fig.

15

Rg. 16

Rg. !7

Fig. 18

ADJUSTING PRESSURE AND FEEDING OF FABRIC

GENERAL SEWING. Usually for straight sewing, the pressure bar cap or darner release Fig

18, IS at Its lowest position and the feed at its highest level-with the drop feed dial knob turned

to the positon marked "NORM" Fig. 19 P e aiai icnob turned

SEWING THIN OR LIGHT WEIGHT FABRICS

When lighter pressure is required to sew satisfactorily on thin

silk or filmy material, the pressure cap should be about halfway

own. Release all the way by pressing the snap lock. A, Fig.

8, and then press cap B down again to half-way spot. Lower

13

"" 19) to the point

marked SILK"

Fig. 19

Page 14

14

l^e'crp rcompletelY by pressing down on

sure cap to left marReo

Fia 20. turn dial knob t,ng-

!S,er *CH a.ps .He .eea »eu He.ew he neea.e

To return feed to normal, turn the drop teeo

position marked "NORM"

Fig. 20

preparing to sew ^ ^

He,e .he-op .e,e. e. H.pHes. po.n. He,o,e ^ ,J,

h, pulling the malerlel ns this mny aellecl the needle n

NEVER run machine without passer loot and lower the presses tool. You

Place nra.erinl and threads m y^Hp^t poinl, it is not necessary o

are now ready to begin sewing. By a»i 3peed ol Ihe

n —dX iXa“— the aJoun. o. pressure eserted on the coniroi,

machine is regulated oy

removing the work

1 d 1 lovfor and needle bar are al the higher

Be sure to stop the machine when the thread iahe-up lever

^^rrmV

Now raise the presser foot and draw

foot and draw the labric back and to the lell. Fid- 21-A and It, nud

Page 15

’

is"

.’I

Vi:

i'i

15

-1 ^

•i ^

V

51"

‘1'

.'5i

Fig. 2!A £-. _,„

1

r

pass the threads over the thread cutter.

We ae"

Leave the ends of thread under the presser foot.

Fig. 21B Pig 22

CARE AND MAINTENANCE OF YOUR MACHINE

HOW TO OIL YOUR MACHINE

Your machine should be oiled occasionally to keep

it operating smoothly-how often depends on the amount

of sewing you do.

Fig. 23

Page 16

■ f;

lOv* •

16

Before oiling the tipper part of the sewing unit at points indicated by arrows in Fig. 22 turn

hand wheel toward you until the take-up lever is at its lowest point.

Avoid over-oiling-only a drop is needed at each point.

To oil parts under the bed of the machine, tip the unit back on its hinges and apply a drop

of oil at each point indicated in Fig. 23.

CLEANING AND OILING THE SHUTTLE

(See Fig. 24 and 25)

The stitch forming mechanism occasionally becomes

clogged with loose threads and lint. This will interfere

with the efficient operation of the machine. Cleaning

and removal of the lint will safeguard the performance.

To remove the shuttle assembly, proceed as follows;

1. Turn the balance wheel until the needle reaches its

highest position. Tilt head back on its hinges

2. Remove bobbin case (A)' Fig. 24.

3. Turn the two shuttle race cover clamps (B) downward

and remove the shuttle race cover (D) and shuttle

Fig. 24

body (D).

Page 17

r

fii 3

*11

ii}^

?11"

if ’

'i ^

i;

*%i ^

>i 3

4. Clean the shuttle race, the shuttle, and

cover by removing all threads, lint etc.

5. Apply a drop of oil with finger tip to

of shuttle.

When the cleaning has been completed, proceed

follows to replace the shuttle assembly;

Turn the balance wheel until the needle reaches its

highesj: position.

Place shuttle body, (D), in race against shuttle driver.

Replace shuttle race cover, iC), over hinge pin at lower edge and lock into position with

s u e race cover clamps, (B) making certain the clamps have been snapped securely into

position.

4.

Put bobbin into bobbin case.

5.

Put the bobbin case into the shuttle race, fitting tongue into notch E of race cover.

shuttle race

outer edge

as

ACCESSORIES

1.

Plastic Oiler

(Sealed and filled)

2.

Package of Needles (5:

3.

Large Screw Driver

4.

Small screw Driver

5.

Felt washers (2)

(For spool pins)

Bobbins (3)

o

5

o

17

K

Page 18

If Machines

Binds

BOBBIN

CASE

LATCH

BOBBIN

CLAMPS

2— Turn clamps outward and remove race cover.

3— Remove hook. . • i j

4— Clean thread and lint from all parts, includ

ing race.

5— Run a drop of oil along rim of hook.

6— Replace hook, then race cover. Snap clamps

into place. 1,1 j

7_Grasp threaded bobbin case by latch and re

place, fitting tongue into notch of race cover.

RAC:

Page 19

19

Skipping

Stitches

Irregular

Stitches

Uneven

Stitches

Trouble

! Probable Cause

Bent needle

i

Needle place iri-

1 correctly in clamp

I Too fine a needle

j for thread being used

Upper thread tension

too loose

1 Improper threading

Bobbin not wound

even

Pulling or holding

material

Not enough tension

on upper thread

Poor quality thread

Needle too fine for

thread being used

Correction

Discard and replace.

See instruction page No. 8.

See needle and thread chart, page No. 7.

Tighten upper tension.

See threading instruction, page No. 10.

Rewind bobbin.

Avoid puling or holding material, just guide it.

Increase tension.

Try different thread.

See needle and thread chart, page No. 7.

Page 20

20

ly

Trouble

Upper Thread

Breaking

Material

Puckering

Probable Cause

Improperly threaded

Too much tension

Starting with take-up

in incorrect position

Improper setting of

needle

Bent or eye of needle

too sharp

Bent or blunt needle

Tensions too tight

"

...............

Dull needle

Stitch length too long

Correction

Refer to threading instructions see page No. 10

and rethread machine

Loosen tension on upper thread by turning

thread tension knob to lower number

Always start sewing with take-up lever in

highest position

Refer to needle setting instruction see page No. 8

Try a new needle

Discard all blunt or bent needles and replace

with new

See tension adjustment page No. 13 and 12

Change needle

Reduce stitch length

. r

.J

Page 21

Il

ì’-:. O

• <!

i ■ D

.•fi

ì ■ D

■ 1

■l ^

;i ^

Tour sewing machine comes equipped with the basic set of accessories

described earlier in this book.

The following pages illustrate additional time saving attachments that have

been designed specifically for your machine. They are available at modest

cost from your dealer. If your dealer cannot supply you with these items,

ask him to order them for you by part number. Then you will be assured

of receiving the genuine part designed for best performance with your

machine.

If a sewing machine dealer is not available mail your inquiry directly to :

'i ’

'-I ^

'.4

-3

h ^

j o

WHITE SEWING MACHINE COMPANY

11750 Berea Road

CLEVELAND, OHIO 44111

' ^

In Canada :

WHITE SEWING MACHINES

1470 BIRCHMOUNT ROAD

o

SCARBOROUGH, ONTARIO, CANADA

Page 22

22

SOME OF THE ATTACHMENTS AVAILABLE FOR YOUR MACHINE

il

O fO

RUFFLER

PART# 1403

ATTACHMENT

FOOT

PART#74I74

PART#76553

DARNING

SPRING

PART #2146'

BINDER

PART#74I59

HEMMERS

PART #76552

J

PART #76551

S '

CORDING &.

ZIPPER FOOT

PART#I873

edgestitcher

PART#76554

PART #76550

-I

-I

-I

Ì

A

_ n

ci'

. ^

a

r k

^ k

-1

.1

" I:

on

■jf

Page 23

F,9- 26

23

ATTACHMENT FOOT

In order to attach the binder, edgestitcher and the

hemmers, it is necessary to remove the presser foot and

replace it with the attachment foot. Fig. 26.

Mount binder, edgestitcher or hemmers sliding the

attachment to the left as far as possible and tighten screw.

The mounting slot enables you to sew as close to or

as far away from the edge as desired. Just move the

attachment to the correct position before tightening the

mounting screw.

I =

i’.

THE EDGESTITCHES

The edgestitcher is used in making

lace insertions, edgings and pipings.

The slots serve as guides. To sew lace

edging to fabric, place the material you

want on top in slot. 1 (Fig. 27) and the

other piece in slot 4. (Fig. 28)

To trim with a wide piping, place Fig. 27 28

the fabric in slot 4, and the fold of the .. -i ¡. o rho folded edge of

p.pmg to the left in slot 3, ior a narrow piping, place the fabric rn slot 2 and the folded edge

the piping to the right in slot 3.

Slot 5 may be used as a guide in stitching a french seam.

Page 24

24

BINDER

This attachment sSts‘‘o„"''smoÎ ol the

edge oi material m widths oi commençai fo ec

binder are for corresponding

bias binding. used for unfolde

The open mouth of bmae

15 16 inch wide.

folded BINDING ,pp„psiate

Cut a point ‘f “^„^^■„tàm'binde. «i* strong pin^

,lpt. Draw through edge, Adinst by

Test strtching to be sure . s

sliding binder to right or l^tt.

TWO.TONE BINDING - Fjg^ 29^^

Two bindings can be se™ ^hip one siue be-

c- When two are used, aiway

operation^ When ^^^e slot,

tween Widths, inserting (Fig. 30)

hand-cut ® in half for a couple

Cut 15.16 inch ‘>‘«1"“^' ® ie„e,d end, almost to

oi inches. Cut bindm, dragona y Draw back until

fold. Slip fold mto end ol scroll. Test

out opens and brndm« none „ „.oessary.

Stitching to be sure it

P-'

r'

r, f

Fig. 25*

Fig- 30

Page 25

A

25

R U F F L E R

0

\

ii

■1

<1

;i

f .

V1

’1

:i

♦i

<1

%

^il

Fig. 31 Fig. 32 Fig. 33

The ruffler will produce yards of delicate ruffling or precision pleating.

Ruffling can also be done and sewn to another piece of fabric at the same time.

This highly versatile attachment despite its wide range of use, is simple to use.

Use the ruffler for making aprons, curtains, pleating a skirt, adding fullness to the bodice ot

a dress and etc.

o

3

3

3

n

Page 26

28

THE ADJUSTABLE CORDING

AND ZIPPER FOOT

- V

This attachment is used to make

and insert covered cording, and to

sew in zippers. Loosen thumb screw

to slide foot to either right or left

of needle.

CORDING. Fold bias strip of

fabric over cord. Loosen thumb

screw and set foot so needle is cen

tered in needle hole. Machine taste

cord in place (Fig. 34 )

TO sir covered ooid to material, reset adjustable loot so ueedle stitches closer to cord, and

on edge of base fabric.

SEWING IN ZIPPER

Loosen thumb screw and slide foot so needle

enters center of needle hole. Guide metal of zipper

along edge of foot (Fig. 35). Stitching should be

close to zipper to allow easy opening and closing.

Adjust to sew from either right or left side, which

ever is more convenient.

-I

-li

Fig. 34

rP.

^ %

•

Fig. 35

Page 27

Is 3

%

U 3

! J'

’ •i ~

o

o

Before attaching any of the hemmers. Be sure

bobbin thread is pulled up. Then, with hemmer in

place, hold top thread loosely and turn hand wheel one

full turn toward you, making a loop under hemmer.

thread will catch loop and carry upper thread to back

of hemmer.

THE SET OF HEMMERS

Grasp bobbin thread with both hands and slip

horizontally under hemmer toward back. Bobbin

■J.,

■■■ -’k I.':--;;»

27

'ii

u I

3

Ni’

;1-

'^1*’

Fold material to suit for two inches along edge,

hold at each end of fold. Slip fold into guide and

up over spoon (Fig. 36). Fold hem in material back of hemmer. Draw forward to

and fasten with point of needle. Pnll on threads gently as you start st.tohing.

Fig. ;i6

DARNING SPRING

HOW TO ATTACH

Remove presser foot, unthread needle, place darner

spring, on needle and slip hook up over needle clamp.

Fig. 37

end of hem

Page 28

28

Fig. 38

BUTTON SEW - ON

(Fig. 39)

This is a time saving attachment which will

convert your machine to a unit that will sew

buttons of various size on any item you care

BUTTONHOLE ATTACHMENT

(Fig. 38)

Perfect buttonholes every time--all uniform m

size when you let the Butionholer take over for

you. Once it's on the machine you do not even

guide the fabric--the buttonholer thinks for it

self It comes with live different size keys for

buttonholes rangings in length from 5/16 to

1-1/16" in both the straight and keyhole type.

Once you have used this Buttonholer you

will realize there's no greater timesaving acces

sory for your sewing machine.

Keys for other size button holes are also

available.

-H

-li

' H

'A

ri

p

c

^

^"^"^'just place the button under the foot of the

attachment let the machine take over and sew

it to the material quickly, easily and m a neat

appearing manner.

T %

* ^

Fig- 39

•I

VOV-

Page 29

■ai’

o

U

3

•*1

ft"

'

¡ì;

1’

'i-.

H

H '

>i

With the wonderful new decorator your machine

converts to a master-controlled performer of

embroidery magic. It's so simple, too. Just remove

the presser foot, attach the "A.D." and you're ready

to make eight different decorative patterns.

Each pattern of course, has many variations in

PART 4176022

Fig. 40

BLIND STITCH HEMMER

(Fig. 41)

With the use of this attachment you are able to

quickly produce invisible stitched hems on dresses,

skirts, draperies and etc. Also save many tedious

hours of hand work and give your sewing that pro

fessional look.

Just fold your material and let the attachment

take over.

width and length. All designs are built right into the

decorator, reducing your effort to a minimum and

you use ordinary thread, standard needles.

29

DECORATOR ATTACHMENT

(Fig. 40)

Fig. 41

-i

K

Loading...

Loading...