Page 1

INSTRUCTION MANUAL

S16

SINGER and STUDIO are trademarks of The Singer Company Limited S.à.r.l. or its Affiliates.

©2014 The Singer Company Limited S.à.r.l. or its Affiliates. All rights reserved.

Page 2

IMPORTANT SAFETY INSTRUCTIONS

When using an electrical appliance, basic safety precautions should always be followed, including the

following:

This sewing machine is designed and manufactured for household use only.

Read all instructions before using this sewing machine.

To reduce the risk of electric shock:

DANGER

1. An appliance should never be left unattended when plugged in. Always unplug

this sewing machine from the electric outlet immediately after using and before

cleaning.

WARNING

1. Do not allow to be used as a toy. Close attention is necessary when this sewing machine is used

by or near children.

2. Use this appliance only for its intended use as described in this owner’s manual.

Use only attachments recommended by the manufacturer as contained in this owner’s manual.

3. Never operate this sewing machine if it has a damaged cord or plug, if it is not working properly, if

it has been dropped or damaged, or dropped into water.

Return this sewing machine to the nearest authorized dealer or service center for examination,

repair, electrical or mechanical adjustment.

4. Never operate the appliance with any air opening blocked. Keep ventilation openings of this

sewing machine and foot controller free from accumulation of lint, dust and loose cloth.

5. Never drop or insert any object into any opening.

6. Do not use outdoors.

7. Do not operate where aerosol (spray) products are being used or where oxygen is being

administered.

8. To disconnect, turn all controls to the off (“O”) position, then remove plug from outlet.

9. Do not unplug by pulling on cord. To unplug, grasp the plug, not the cord.

10. Keep fingers away from all moving parts. Special care is required around the sewing machine

needle and/or cutting blade.

11. Always use the proper needle plate. The wrong plate can cause the needle to break.

12. Do not use bent needles.

13. Do not pull or push fabric while stitching. It may deflect the needle causing it to break.

14. Switch this sewing machine off (“O”) when making any adjustment in the needle area, such as

threading the needle, changing the needle, threading the bobbin or changing the presser foot, and

the like.

15. Always unplug this sewing machine from the electrical outlet when removing covers, lubricating, or

when making any other adjustments mentioned in this owner’s manual.

—

—

To reduce the risk of burns, fire, electric shock, or injury to persons:

SAVE THESE INSTRUCTIONS

For Europe only:

This appliance can be used by children aged from 8 years and above and persons with reduced

physical, sensory or mental capabilities or lack of experience and knowledge if they have been given

supervision or instruction concerning use of the appliance in a safe way and understand the hazards

involved. Children shall not play with the appliance. Cleaning and user maintenance shall not be made

by children without supervision.

For outside Europe (except U.S.A and Canada):

This appliance is not intended for use by persons (including children) with reduced physical, sensory or

mental capabilities, or lack of experience and knowledge, unless they have been given supervision or

instruction concerning use of the appliance by a person responsible for their safety.

Children should be supervised to ensure that they do not play with the appliance.

Please note that on disposal, this product must be safely recycled in accordance with relevant

National legislation relating to electrical/electronic products. If in doubt please contact your

retailer for guidance. (European Union only)

2

Page 3

TABLE OF CONTENTS

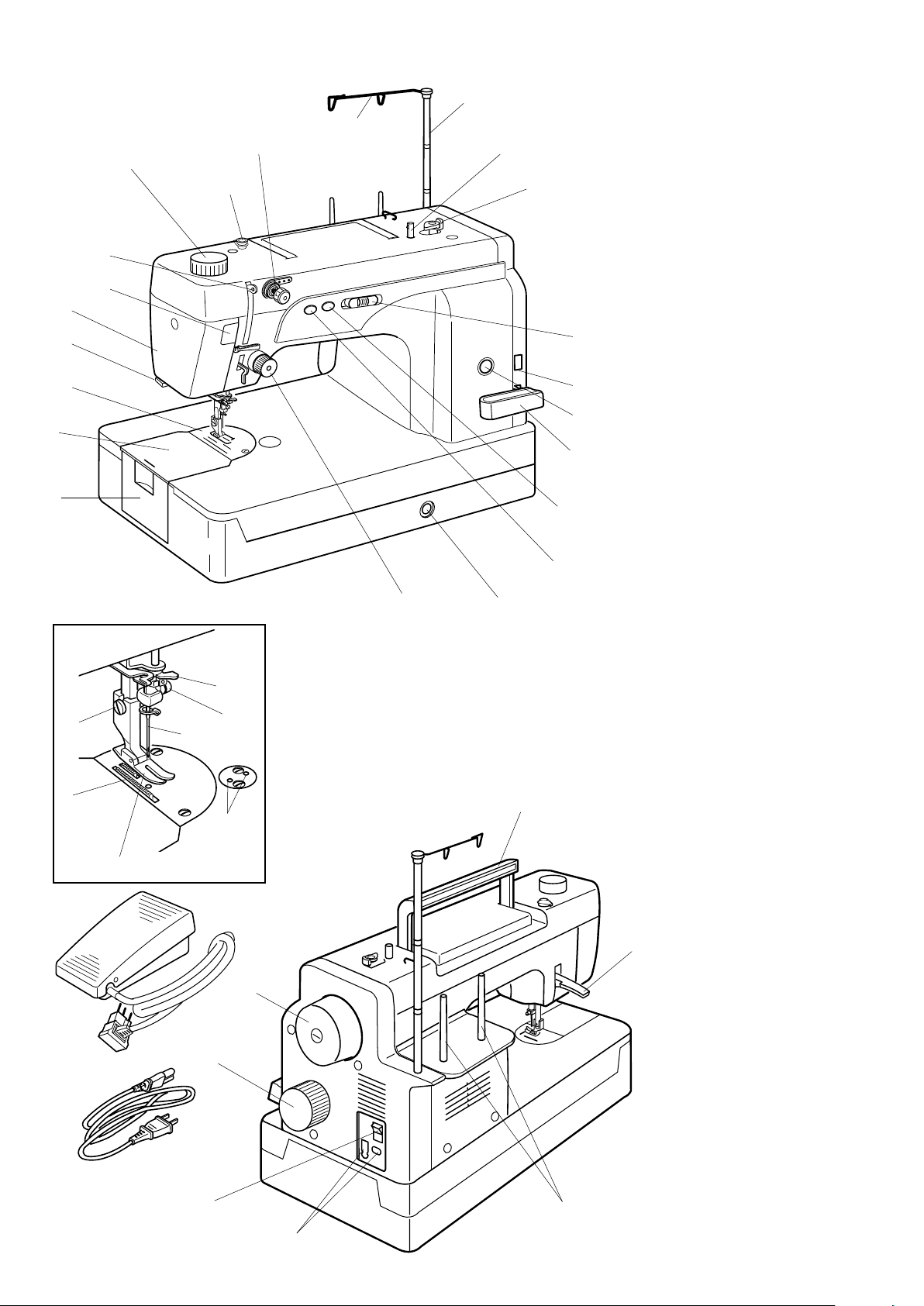

MACHINE IDENTIFICATION OF PARTS

Machine Identification ................................................................................................................... 4

Standard Accessories ................................................................................................................... 5

Attaching Knee Lifter ..................................................................................................................... 5

GETTING READY TO SEW

Connecting Machine to Power Supply ........................................................................................... 6

Controlling Sewing Speed ............................................................................................................. 6

Up/Down Needle Position Button .................................................................................................. 7

Bobbin Winding Button .................................................................................................................. 7

Thread Cutter Button ..................................................................................................................... 7

Stitch Length Adjustment Dial ....................................................................................................... 7

Reverse Stitch Lever ...................................................................................................................... 7

Presser Foot Lifter ......................................................................................................................... 8

Presser Foot Pressure Dial ........................................................................................................... 8

Attaching and Detaching Presser Foot .......................................................................................... 8

Removing Bobbin Case and Bobbin .............................................................................................. 9

Positioning Thread Spools ............................................................................................................. 9

Winding a Bobbin ........................................................................................................................ 10

Inserting a Bobbin ....................................................................................................................... 11

Inserting the Bobbin Case into the Hook ..................................................................................... 11

Threading the Needle Thread ...................................................................................................... 12

Using the Built-in Needle Threader .............................................................................................. 13

Bringing Up Bobbin Thread ......................................................................................................... 14

Changing the Needle ................................................................................................................... 15

How to Balance Thread Tension .................................................................................................. 16

Adjusting Bobbin Thread Tension ................................................................................................ 16

Adjusting Needle Thread Tension ................................................................................................ 16

HOW TO SEW

Test Stitching ............................................................................................................................... 17

Securing Seam ............................................................................................................................ 18

Pivoting a Corner ......................................................................................................................... 18

Using Fabric Guide ...................................................................................................................... 19

Using Narrow Hemmer Foot ........................................................................................................ 19

Using Darning / Embroidery Foot ............................................................................................... 20

Using Quarter Inch Foot with Guide ............................................................................................ 20

CARE & MAINTENANCE

Cleaning the Hook and Feed Dog Area ....................................................................................... 21

Oiling the Machine ....................................................................................................................... 21

Replacing the Light Bulb .............................................................................................................. 22

Replacing the Light Bulb on the Underside of the Sewing Arm ................................................... 22

Troubleshooting ........................................................................................................................... 23

3

Page 4

!5

!4

!8

!7

!6

@6

@7

@0

!9

q

@3

@1

@4

w

@2

#

e

7

#

8

r

t

!0

!1

!3

!2

@8

MACHINE IDENTIFICATION

Name of Parts

Presser foot pressure dial

q

Bobbin winding tension disc

w

Retractable thread guide

e

Bobbin winder spindle

r

Bobbin winder lever/stopper

t

Speed control lever

y

Stitch length display

u

Thread cutter button

i

Reverse stitch lever

o

Bobbin winding button

!0

Up/Down needle button

!1

y

Knee lifter socket

!2

Thread tension dial

!3

u

i

o

Bobbin case cover

!4

Bobbin case cover plate

!5

Needle plate

!6

External thread cutter

!7

Face cover

!8

Pressure foot pressure indicator

!9

Thread take-up lever

@0

Needle threader

@1

Needle clamp screw

@2

Needle

@3

Screw holes for attachments

@4

Presser foot

@5

Feed dog

@6

Setscrew

@7

Carrying handle

@8

Presser foot lifter

@9

Spool pins

#0

Power cord and foot control sockets

#1

Power switch

#2

Stitch length adjustment dial

#3

Handwheel

#4

Foot control

#5

Power supply cord

#6

7

Upper thread guide

#

8

Pre-tension disc and guide

#

@5

#6

#5

#2

@9

#4

#3

#0

#1

4

Page 5

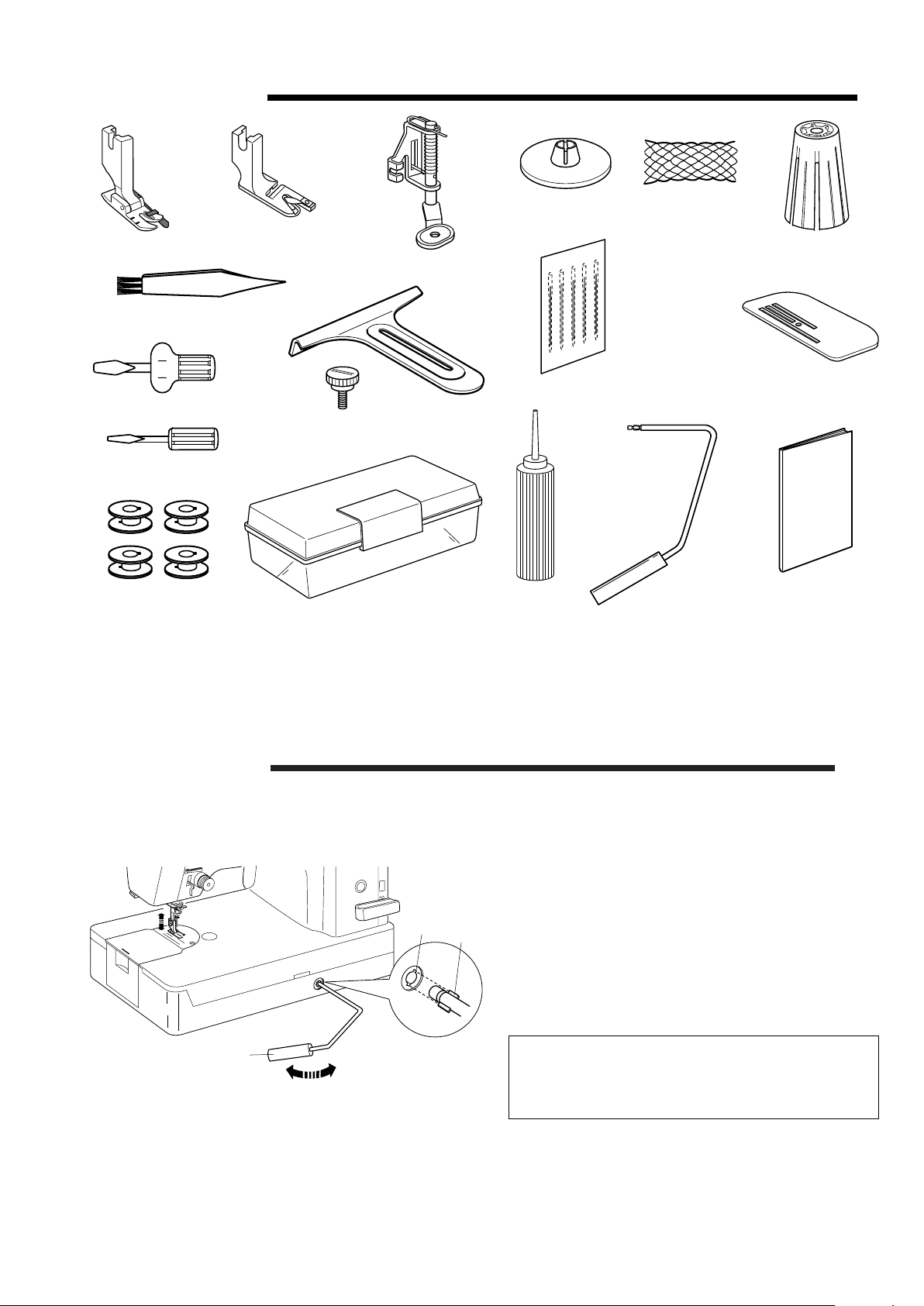

Standard Accessories

Quarter inch foot

Lint brush

Large screwdriver

Small screwdriver

Bobbins

Narrow hemmer

foot

Fabric guide and Setscrew

Darning / Embroidery foot

Accessory box

Spool cap

Oil

Thread spool net

HL x 5 –16 ... 1

HL x 5 –14 ... 1

HL x 5 –11 ... 2

HL x 5 –9 ..... 1

Needles

Knee lifter

Spool holder

Darning plate

Instruction book

Attatching Knee Lifter

q

e

w

The knee lifter is very helpful when quilting, sewing

appliques, or when working with larger projects because it allows you to keep both hands on the fabric

while your knee controls the presser foot.

Match the ribs on the knee lifter with the notches in

the knee lifter socket and insert the knee lifter.

Knee lifter

q

Ribs on Knee lifter

w

Notches on machine

e

Push the knee lifter with your knee to raise and lower

the presser foot.

NOTE

Keep leg away from lifter while sewing. Pressing on

knee lift while sewing will effect feeding of fabric and

the thread tension.

5

Page 6

GETTING READY TO SEW

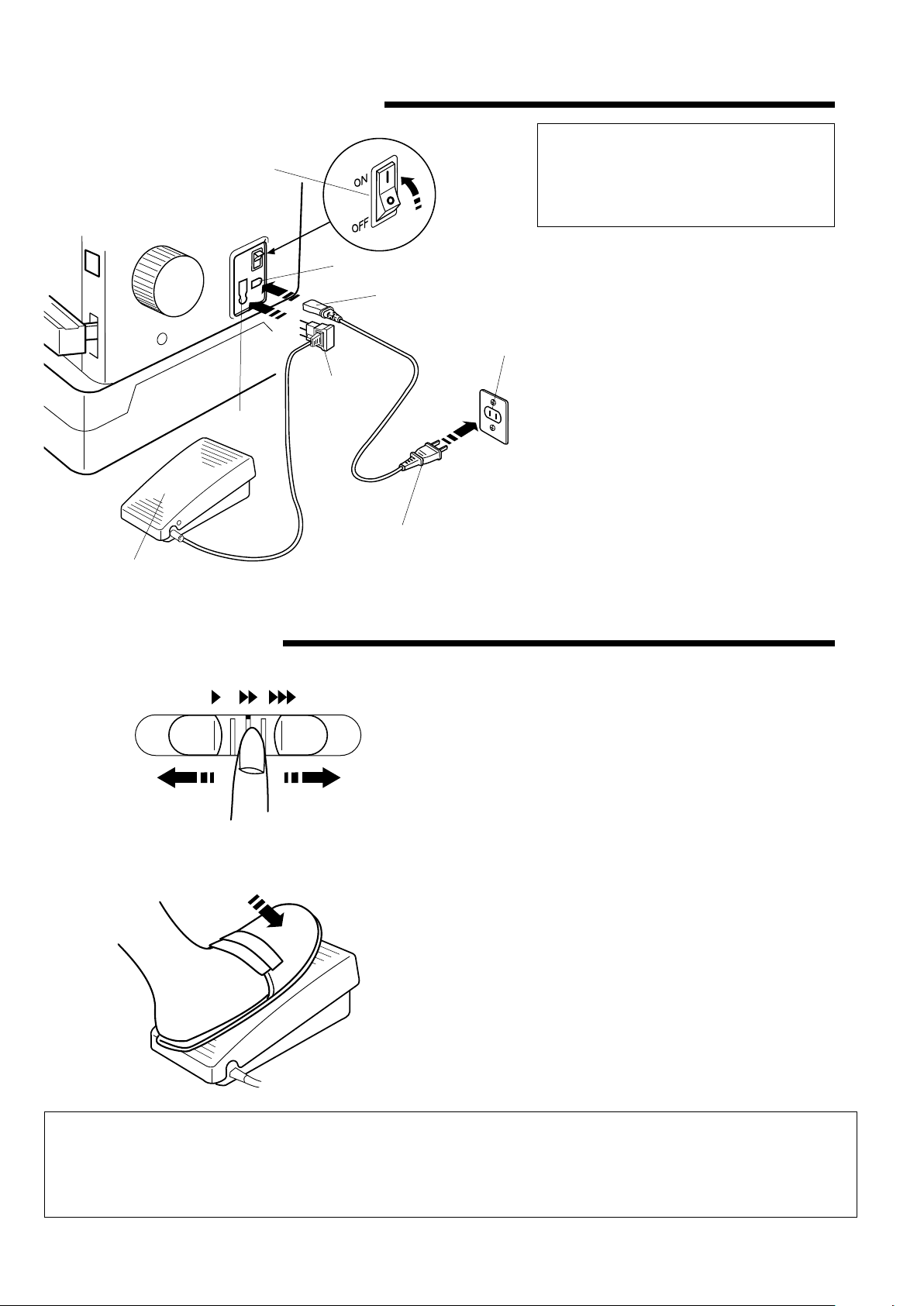

Connecting Machine to Power Supply

i

w

y

t

u

q

e

CAUTION

Always turn the power switch off and

unplug the sewing machine from the

electrical outlet when the machine is not

in use.

Machine power plug

q

Machine socket for power supply plug

w

Power supply plug

e

Wall outlet

r

Machine socket for foot control

t

Foot control plug

y

r

Foot control

u

Steps To Turning Machine Power

On

Turn off the power switch on the machine.

Insert the foot control plug y into the

machine socket t.

Insert the machine plug q into the

machine socket w.

Insert the power supply plug e into the

wall outlet r.

Turn on the power switch i.

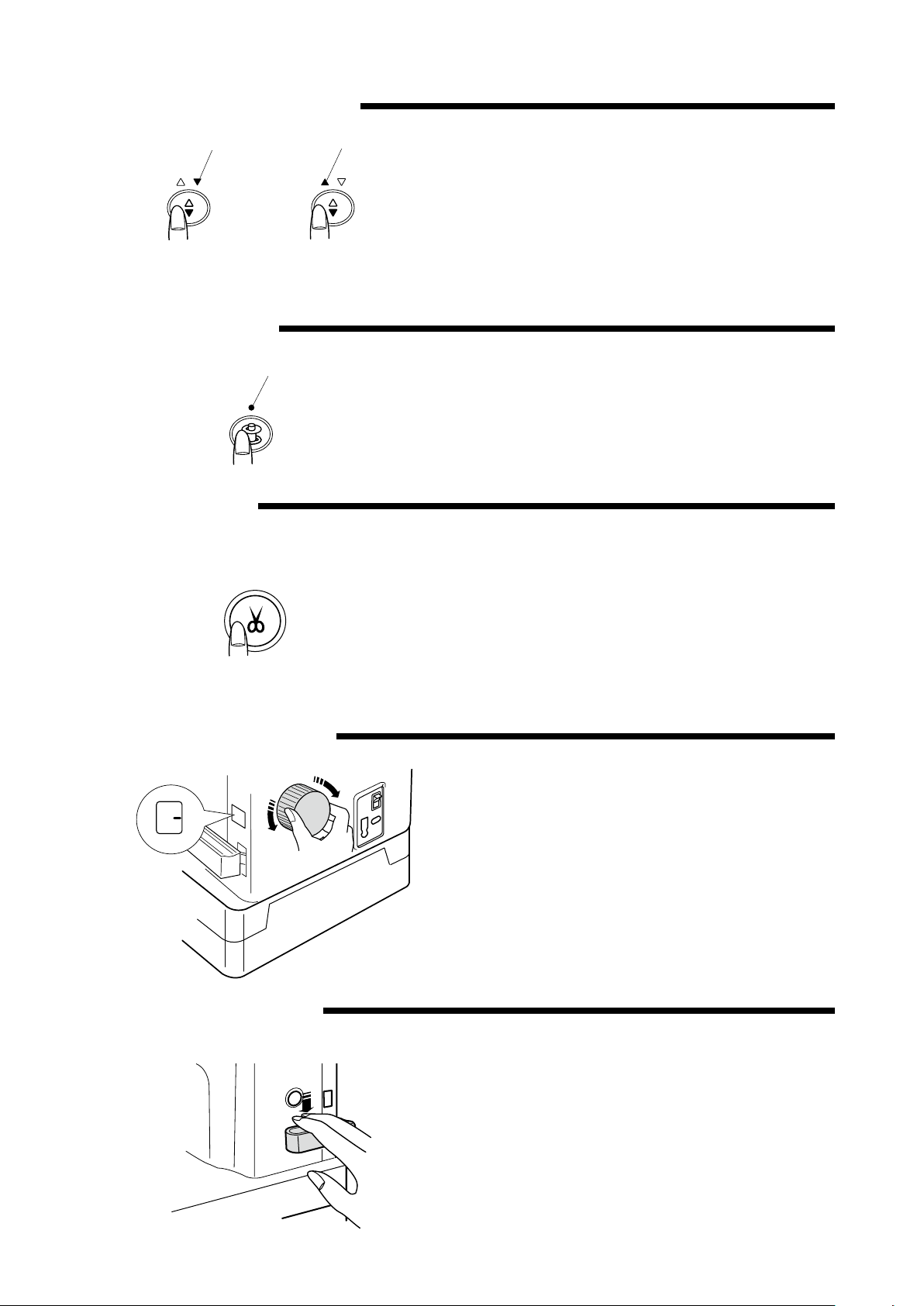

Controlling Sewing Speed

Speed Control Lever

Use the speed control lever to set the maximum

speed of the machine.

To increase sewing speed, slide it to the right.

To decrease sewing speed, slide it to the left.

Foot Control

Sewing speed is varied by the foot control and the

speed control lever. The heavier the foot presses

down on the controller the faster the machine runs.

The machine runs at the maximum speed set by the

speed control slider when the foot control is being

fully depressed.

Operating Instructions:

The symbol "O" on a switch indicates the "off" position of a switch.

For appliances with a polarized plug (one blade wider than the other): To reduce the risk of electric shock, this plug is

intended to fit in a polarized outlet only one way. If it does not fit fully in the outlet, reverse the plug. If it still does not

fit, contact a qualified electrician to install the proper outlet. Do not modify the plug in any way.

6

Page 7

Up/Down Needle Position Button

3

RED LED

Bobbin Winding Button

LED

Thread Cutter Button

GREEN LED

Press this button to bring the needle up or down.

The RED LED will light up when the needle is

down. The GREEN LED will light up when the

needle is up.

The machine will stop with the needle up or down

depending on the needle position determined by

this button.

The machine will always stop with the needle up

after auto thread cutting or buttonhole sewing.

Press this button to wind the bobbin.

The LED will light up when you shift the bobbin

winding lever toward the bobbin and press this

button.

The LED signal will turn off after bobbin winding is

finished.

Pressing this button after sewing will trim the

threads.

You can continue sewing without pulling the bobbin

thread up after using thread cutter.

Stitch Length Adjustment Dial

q

Reverse Stitch Lever

• Use the thread cutter on the face cover if the

thread is heavier than #30.

• The foot control and up/down needle position

button cannot be used while the machine is

trimming the threads.

You can adjust the stitch length from 0 to 6mm by

turning this dial. The stitch length chosen will be

shown on the stitch length display q.

The machine will sew in reverse while the reverse

stitch lever is pressed down. The machine will sew

forward when the lever is released.

Use the reverse stitch lever to secure the beginning

and end of a seam.

7

Page 8

Presser Foot Lifter

q

Presser foot lifter

q

Normal up position

w

Highest position

e

The presser foot lifter q raises and

lowers the presser foot.

You can raise it higher e than the

normal up position w to help you place

thick fabric under the foot.

e

w

Presser Foot Pressure Dial

q

w

When lifter is at highest position e the

lever will not lock in place w.

Presser foot pressure dial

q

Setting indicator

w

The presser foot pressure control dial

should be set at “3” for regular sewing.

Reduce the pressure for sewing on fine

synthetics and elastic fabrics.

Set the dial at “1” when sewing extra fine

fabrics.

NOTE

Do not reduce the foot pressure lower

than “0”.

Attaching and Detaching Presser Foot

q q

Setscrew

q

To change the presser foot, raise the

presser foot lifter. Turn the handwheel

toward you to raise the needle to its

highest position.

Loosen the setscrew q, choose the

proper foot and insert it from the bottom.

Tighten the setscrew q with the large

screwdriver to secure the foot.

8

Page 9

To Remove Bobbin Case and Bobbin

z

q

w

t

x

r

e

CAUTION

Turn the power switch off and unplug the sewing

machine from the electrical outlet.

Bobbin case cover plate

q

Bobbin case cover

w

Latch

e

Bobbin case

r

Bobbin

r

t

Step

z

Raise the needle and presser foot.

Remove the bobbin case cover plate q and open

the bobbin case cover w.

Step

x

Pull open the latch e of the bobbin case r. Take

the bobbin case straight out of the hook.

• To remove the bobbin from the bobbin case:

Release the latch, then drop the bobbin t out of

the bobbin case as illustrated.

Note: Spring in Bobbin Case

On close observation inside the bobbin case you will

see a thin metal spring at the back of the bobbin case.

(See illustration)

This spring allows the bobbin in the bobbin case to feed

smoothly at high speeds. When cleaning the inside of

the bobbin case area from lint, be careful to not dislodge

the spring.

If spring does come out simply push carefully back into

its original position.

Positioning Thread Spools

w

r

q

e

t

Spool of thread

q

Spool pin

w

Spool cap

e

Positioning thread spools:

Place a spool of thread q on the spool pin w

with the thread coming off the spool counter clockwise.

Attach the spool cap e, and press it snug against

the spool of thread.

Spool holder

r

Net

t

Positioning thread on spool cones:

Some threads are wound onto cones. Use the spool

holders to help prevent the thread cones from tipping

side to side. If the thread cone tips, the result could be

uneven feeding of the thread. Place the spool holder

on the spool pin, then place the thread cone on the

r

spool holder.

Cover the thread cone with the thread net t to help

prevent the thread from pooling around the bottom while

sewing.

9

Page 10

Winding a Bobbin

w

c

e

y

t

x

r

z

q

Pull the thread guide bar up as

far as it will go. Stoppers will

click when fully extended.

Thread guides

q

Bobbin winding tension disk

w

Bobbin hole

e

Notch

r

Spring

t

Bobbin winder spindle

y

Bobbin winder lever/stopper

u

Step z

Pass the thread through the thread

guides q from behind.

Stopper

v

b

n

u

i

Step x

Pass the thread under the bobbin winding

tension disk clockwise. w.

Step c

Thread through the hole e in the bobbin from

the inside to the outside.

Match the notch r with the spring t on the

bobbin winder spindle. Then insert the bobbin

on the bobbin winder spindle y.

Step v

Push the bobbin winder lever/stopper to

the left u.

Step

b

Hold the free end of the thread in your hand

and press the bobbin winding button i. Press

the bobbin winding button again to stop the

bobbin when it has made several turns, and cut

the thread close to the hole on top of the bobbin.

Step n

Press the bobbin winding button again. When

the bobbin is fully wound, the machine will stop

automatically. Return the bobbin winder

lever/stopper to its original position.

Cut the thread with a scissors. Remove

the bobbin from the bobbin winder spindle.

10

This machine has an independent motor

for bobbin winding. Bobbins can be wound

while sewing.

Page 11

Inserting a Bobbin

z

x

c

w

e

q

Step z

Place a bobbin in the bobbin case making sure the thread

winds clockwise on the bobbin as illustrated.

Step

x

Draw the thread through the slit q in the bobbin case.

q Slit

Step

c

Continue to pull the thread under the tension spring w

and through the opening e.

Pull out about 4˝ of thread.

The bobbin should spin clockwise when the thread is pulled

out of the bobbin case.

w Tension spring

e Opening

Inserting the Bobbin Case into the Hook

z

w

e

q

t

x

r

w

e

q

Step

z

Holding the latch q open, position the bobbin case into the

hook aligning the slot w with the notch e.

The bobbin case should lock into place when the latch is

released.

q Latch

w Slot

e Notch

Step

x

Close the bobbin case cover r and attach the bobbin case

cover plate t in this order.

r Bobbin case cover

t Bobbin case cover plate

11

Page 12

Threading the Needle Thread

q

z

v

!2

!1

(A)

w

e

r

!2

!1

!3

!4

!5

Pre-tension dial (side view)

x

u

!0

y

t

c

Step

z

Raise the presser foot lifter. Press the Up/Down

needle button twice to ensure that the needle is in

its highest position. Turn the power switch off.

Set a spool of thread on the spool pin.

Pass the thread through the guide q from behind.

Step

x

Pass the thread through the thread guide plate

, then draw the thread between the pre-tenison

w

disks e behind the pre-tension dial r.

Certain threads may twist or become loose

when sewing at high speeds. You may need to

thread through the three holes in the guide

plate as illustrated in fig.(A).

The standard setting of the pre-tension dial is

that the screw head t sinks about (1/8˝ to 3/16˝) y.

Turning the pre-tension dial clockwise will increase

the tension on the thread.

b

!4

!5

!3

!0

o

i

i

12

Step

c

Holding the thread with both hands, draw the

thread down and around the tension dial u from

right to left.

Pull the thread up to insert it between the tension

disks o and pass it over the tail of the check

u

spring i.

Step

v

Draw the thread under the thread guide !0,

behind guide !1 and through the eye of the

take-up lever !2.

Pass the thread through the thread guide !1

again. Hold the thread with both hands and slip the

thread into the thread guide !3 as shown.

u

Step

b

Draw the thread down to the needle bar thread

guide !4, and then pass the thread through the

needle eye on the left side of the needle !5.

Page 13

Using the Built in Needle Threader

z

x

c

w

q

Step

Step

Step

Lower the presser foot. Press the Up/Down needle

z

button twice to raise the needle to its highest

position. Turn the power switch off.

Push down the needle threader lever q as far as it

will go.

Turn the lever q in the direction of the arrow to

x

insert the hook into the needle eye.

The hook r comes out through the needle eye

as illustrated.

Holding the thread with both hands, draw the

c

thread along the thread path w.

Then hook the thread around the guide e.

v

b

r

e

Step

Step

Draw the thread under the hook r.

v

Hold the end of thread with your hand while pulling

up the thread lightly in the direction of arrow.

Turn the lever in the direction of the arrow as

b

shown, drawing the thread loop t through the

needle.

Release the threader lever slowly. Then pull the

thread loop t to the right.

t

13

Page 14

Bringing Up Bobbin Thread

z

x

q

q

Step

z

Hold the needle thread q lightly with your left

hand.

Step

x

Hold upper needle thread and rotate handwheel one

complete revolution q. The upper thread will bring

up the loop through the needle plate w. When the

power is on the machine you can push the Up/Down

needle button twice to bring up bobbin thread.

c

w

Step

c

Slide 4” of both threads to the rear under the presser

foot. You can use the external thread cutter on the

left side of machine. The cutter can be used to trim

threads to the proper length and to hold the threads

in place.

14

Page 15

Changing the Needle

z

x

q

CAUTION

Turn the power switch off and unplug the machine

before changing the needle.

Turn the power switch off. Lower the presser

z

foot. Turn the needle clamp screw q

counterclockwise with the large screwdriver.

Loosen the screw and remove the needle from

the needle clamp.

Needle clamp screw

q

Insert a new needle into the needle clamp w

x

with the flat side e to the right, pushing it up

as far as it will go.

Tighten the clamp screw q firmly.

Needle clamp

w

Flat side

e

w

e

To Check the Needle

Thread and Needle Chart

Fabrics

Light weight

Crepe de chine,

Voile, Lawn,

Organdy,

Georgette, Tricot

e

To determine if the needle is defective, place the flat side of needle

on something flat (a needle plate, piece of glass, etc.). The gap

between the needle and the flat surface should be consistent.

Never use a blunt or burred needle, as it may cause skipped

stitches or thread breakage. A defective needle can damage your

fabrics.

Thread

All-purpose thread

Silk thread

* Remember to use only Style HL x 5 needles in

your SINGER

Needle (HL x 5) size

9 or 11

®

Studio™ S16 sewing machine.

Medium

weight

Heavy weight

Linens, Cotton,

Pique, Double

Knits, Rayon

Denim, Tweed,

Gabardine,

Coating, Drapery

and Upholstery

Fabric

All-purpose thread

Polyester thread

All-purpose thread

Polyester thread

Topstitching thread

11 or 14

14, 16 or 18

15

Page 16

HOW TO BALANCE THREAD TENSIONS

Different threads and fabric types can cause irregular tension. Before making adjustments determine closely that the

machine is threaded correctly and the proper needle is being used.

Balanced Needle Thread Tension

The needle thread and bobbin thread should interlock in

the center of two layers of the fabric in straight seams.

Adjusting Bobbin Thread Tension

Test the bobbin thread tension by first holding the end of

the bobbin thread and suspending the bobbin case as

illustrated. Then, flick your wrist once or twice to check

the drop of the bobbin case.

Adjusting Needle Thread Tension

q

r

w

q

w

If the thread comes out of the bobbin case continuously,

and the bobbin case keeps falling, the bobbin thread

tension is too loose.

Make a slight adjustment by turning the screw clockwise

with the small screwdriver.

To tighten

q

If the thread does not come out of the bobbin case at all,

the bobbin thread tension is too tight.

Make a slight adjustment by turning the screw

counter clockwise with the small screwdriver.

To loosen

w

The bobbin tension is set correctly if the bobbin drops

but then stops.

Needle thread tension is too tight:

If the bobbin thread r shows through on

the right side of the fabric q and it feels

bumpy, loosen the needle thread tension

by turning the dial to the left.

q

w

e

16

Right side of the fabric

q

Wrong side of the fabric

w

Needle thread

e

Bobbin thread

r

Needle thread tension is too loose:

If the needle thread e loops on the wrong

side of the fabric w, tighten the needle

thread tension by turning the dial to the

right.

Page 17

HOW TO SEW

Test Stitching

Thread take-up

lever

z

q

Before starting your project always test the

compatibility of thread, needle and fabric together.

Also test stitch length and pressure foot pressure.

Step z

Turn the stitch length adjustment dial q to

adjust the stitch length to 3. Raise the thread

take up lever and slide the needle and bobbin

threads under the presser foot.

c

x

w

Step x

Turn the handwheel w toward you to lower the

needle into the fabric.

Step c

Lower the presser foot lifter e.

Set the speed control slider to a slower setting

until you get used to the sewing speed.

Press the foot control r to start sewing.

e

r

v

b

y

t

u

Step v

Check the sewing result and adjust the needle

thread tension t as necessary.

Step b

Press the auto thread cutter button y to trim

the threads. You can continue sewing without

pulling the bobbin thread up again through the

needle plate.

* Do not use the thread cutter u if the thread is

heavier than #30.

17

Page 18

Securing a Seam / Reverse Stitching

(1/4”)

(1/4”)

The machine will sew in reverse as long as the

reverse stitch lever is pressed.

Secure the beginning and end of a seam by sewing

in reverse for about 3/8”.

Securing a Seam / Knotting the Threads

Pivoting a Corner

Pull the bobbin thread to bring the needle thread to

the wrong side of fabric.

Tie the threads together. Trim the remaining

threads.

Stop the machine a few stitches before the end of

the seam.

Press the up/down needle button to sink needle in

place.

Leave the needle down in the fabric and raise the

presser foot.

Pivot the fabric around the needle to change the

sewing direction.

Lower the presser foot and continue sewing.

18

Page 19

Using Fabric Guide

Narrow Hemming Foot

q

e

w

w

q

Attach the cloth guide to the needle plate with the

setscrew q.

Adjust the position of the fabric guide for seam

allowance needed w and tighten the setscrew q.

Place the fabric with its edge e against the cloth

guide and sew.

Attach the narrow hemmer foot w to the presser

foot bar.

Tighten the setscrew q using the large

screwdriver.

Setscrew

q

Narrow hemmer foot

w

e

y

e

r

t

19

Pre-folding and trimming of fabric will help facilitate

an easier start with the Narrow Hemmer.

Fold the edge of the fabric over 1/8 inch twice for

a total of 1/4 inch. Finger press folded edge for 2

inches.

Open fold and trim fabric as seen in Diagram e.

by 1/4 inch t for easier insertion of the hem

r

into the foot.

Wrong side of the fabric

e

3/16˝

r

1/4˝

t

Spiral opening of the foot

y

Refold the fabric and position under the foot.

Insert the needle into the fold by rotating the

handwheel toward you and lower the presser foot.

Sew several stitches and raise the presser foot. If

needed hold onto tails of machine thread. Insert

the fabric fold into the spiral opening of the foot y.

Move fabric back and forth until the fold forms a

scroll shape.

Lower the presser foot and start sewing. Slowly

guide the raw edge of the fabric in front of the

narrow hemming foot. Guide fabric evenly into the

scroll of the foot.

Page 20

Using the Darning / Embroidery Foot

w

t

q

q

r

e

Darning and free motion sewing is used for

repairing holes or torn areas in cloth. Also the foot

allows you to do monograms and stipple quilting.

The darning plate covers the feed dog to prevent

the feed dogs from moving the fabric and allows

you to freely move the fabric.

Insert the 2 pins q on the darning plate w into the

holes of the needle plate.

Pin

q

Darning plate

w

Attach the darning foot e to the presser bar with

the lever over the needle clamp r.

Tighten the setscrew t using the large

screwdriver.

Darning foot

e

Lever

r

Setscrew

t

Using the Quarter Inch Foot with Guide

q

w

r

Draw the desired pattern on the fabric with

temporary markings. Set the fabric under the

presser foot and guide the fabric with your hands.

Move the quilt 1/8” or less per stitch.

The Quarter Inch Foot with guide provides a 1/4"

seam allowance. This helps provide accuracy for

quilting.

Attach the Quarter Inch Foot w to the presser foot

bar. Tighten the setscrew q using the large

screwdriver.

Setscrew

q

Quarter Inch Foot

w

e

To create a 1/4” seam, put 2 pieces of fabric with

right sides together.

Place the patchwork pieces under the foot so that

the edge of the fabric matches the guide on the

presser foot. To assure precise seaming be careful

not to push excess fabric towards the guide other

than 1/4”.

Edges of fabric

q

Guide on the Quarter Inch Foot

w

20

Page 21

CARE & MAINTENANCE

Cleaning the Hook and Feed Dog Area

r

w

e

q

u

y

CAUTION

Turn the power switch off and unplug the machine

before cleaning.

Remove the needle and presser foot.

z

Remove the bobbin case cover plate q and open the

x

bobbin case cover w.

Loosen the setscrews e and remove the needle

c

plate r.

Clean the hook t and feed dog area y with a lint

v

brush u.

After cleaning the machine, attach the needle

b

plate r, needle and presser foot.

Bobbin case cover plate

q

Bobbin case cover

w

Setscrew

e

Needle plate

r

Hook

t

Feed dog

y

Lint brush

u

Oiling the Machine

q

e

t

NOTE

Unplug the machine before oiling.

Oil the points as shown (q, w and e) with two or three

drops of oil. Use only SINGER® sewing machine oil for

this sewing machine.

If the machine is used up to 2-4 hours per day, it should

be oiled every 3 days. If the machine is used at least 8

hours per day, the machine must be oiled daily before

starting to use the machine.

Use a soft, dry cloth to remove excess oil.

Remove the bobbin case from the hook when you oil the

hook area.

After oiling, stitch a piece of scrap fabric to absorb

excess oil.

w

21

Page 22

Replacing the Light Bulb

w

q

e

CAUTION

Turn the power off before replacing the light bulb.

The bulb could be HOT, wait until it has cooled down

before touching it.

Setscrew

q

Face cover

w

Lamp socket

e

Light bulb

r

To remove:

Remove the setscrew q.

Remove the face cover w.

Pull bulb straight down r from the lamp socket e.

To replace:

Insert a new bulb into the opening of the socket e.

Attach the face cover w with the setscrew and cap.

Replace the bulb with the same type, rated 12 V, 5 W.

r

Replacing the Light Bulb on the Underside of the Sewing Arm

Lay the machine on its back.

Detach the lamp window q from the machine with the

q

screw driver as shown.

Pull out the light bulb e from the socket.

e

w

q

Insert a new bulb into the socket w.

Attach the lamp window q into the opening on the

machine.

Lamp window

q

Lamp socket

w

Light bulb

e

Replace the bulb with the same type, rated 12 V, 5 W.

22

Page 23

Troubleshooting

Condition

The needle thread

breaks

Cause

1. The needle thread is not threaded properly.

2. The needle thread tension is too tight.

3. The needle is bent or blunt.

4. The needle is incorrectly inserted.

5. The needle thread and the bobbin thread are not set under the

presser foot when starting to sew.

6. The thread is either too heavy or too fine for the needle.

7. The thread is feeding unevenly off the spool.

Reference

See page 10.

See page 14.

See pages 13.

See pages 13.

See page 12.

See pages 11, 13.

The bobbin thread

breaks

The needle breaks

Skipped stitches

Seam puckering

Fabric feeding problems

1. The bobbin thread is not threaded properly in the bobbin case.

2. Lint has collected in the hook area.

3. The bobbin is damaged and doesn't turn smoothly.

1. The needle is incorrectly inserted.

2. The needle clamp screw is loose.

3. The needle is too fine for the fabric being used.

1. The needle is incorrectly inserted, bent or blunt.

2. The needle and/or fabrics are not suitable for the work being sewn.

3. A ballpoint needle is not used when sewing stretch, very fine fabrics

or synthetics.

4. The needle thread is not threaded properly.

5. A poor quality and improper needle type is being used.

Use only HL x 5 needles.

1. The needle thread tension is too tight.

2. The needle thread is not threaded properly.

3. The needle is too heavy for the fabric being sewn.

4. The stitch length is too long for the fabric.

1. The feed dog is packed with lint.

2. The stitches are too fine.

See page 9.

See page 19.

Replace the bobbin.

See pages 13.

See pages 13.

See pages 13.

See pages 13.

See pages 11, 13.

See page 13.

See page 10.

Change the needle.

See page 14.

See page 10.

See pages 11, 13.

Make the stitch shorter.

See page 19.

Make the stitch longer.

Thread loops on

underside of fabric

Power is off to machine

Unusual noises made by

machine

1. The needle thread tension is too loose.

2. The needle is either too heavy or too fine for the thread.

3. Knee lifter is being lightly pressed by knee.

1. The machine is not plugged in.

2. Thread has been caught in the hook and bobbin case area.

1. Thread has been caught in the hook and bobbin case area.

2. Lint has built up in the hook area or bobbin case.

3. The machine needs oiling.

See page 14.

See pages 11, 13.

See page 4.

See page 19.

See page 19.

See page 19.

See page 19.

23

Loading...

Loading...