Page 1

Page 2

Page 3

FORM 71OT.

£iu)>ei«6d«B Form 7C0C«

July 7, 18BL

DIRECTIONS

FOR USING THE

InPl^OVRD PaAIET

SHEER SEWING MACHINE.

I .

The Sihger Manufacturing Co.,

NEW YORK.

1891.

Page 4

Fio. 1,

to

Tbrcmd T»ka Vp Com

i’VoMiier Bar Tliuuib Sctuk

iteedio Bar Connoctlon Link..

K{>ed1« Bar--

Thread TaJio Vp

ftoemr Bar Siiriiui,’.

ргоФаот Шг^.

Feed HegulmLor Thuisb Screw.

Feed Cam Forked ConnecUoa ) \

Feed Bar

SbnCtV

Shuttle Driver

PHANTOM HF-ЛП OF IMPROVED FAMILY WACHiNE.

Feed lie njUtor I

Feed Cats

Fwd Bock Shaft

OeciLiaUbfi Shaft

Belt Cover

Bitasce Wlieel

wAiiicmiatlc Dobhhi ^l&der Spindle

..ATitomatie ВоЪЫс Winder Spring

AQ Coma lie Bobbin Winder Spool Bracket

Antomatic Bobbin Winder Spool Bracket Diece

Crank Oortiuicting Hod

■OecClatlttii IlJ>ck Shaft

ЧМсШаВпе Shaft Ornbk

PS

rt

n

H

о

cn

о

a

5

a

I'

* -f. it

r- Vr

► r* r

Page 5

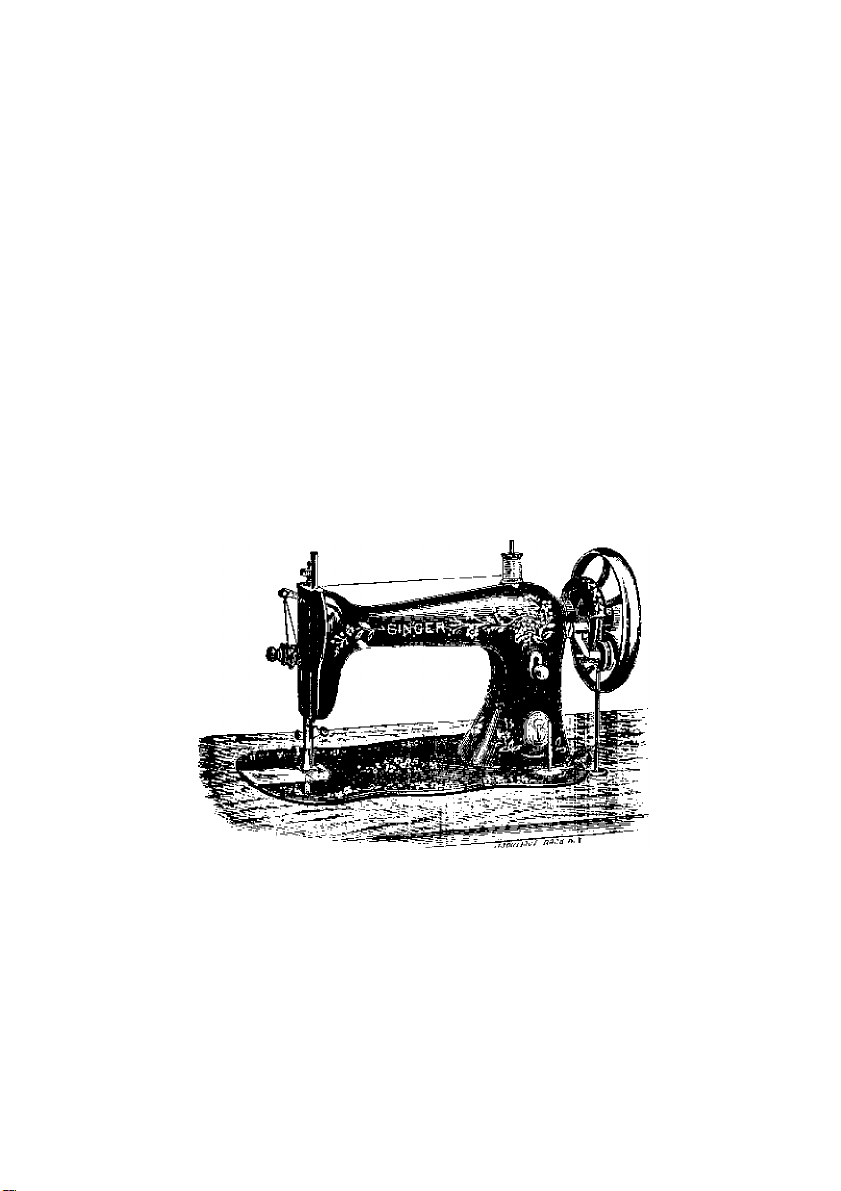

THE IMiHOVED FAMILY SINGER.

Bto. a

lipool Hn

TeDfttbid Thumb Sara^_k-. q

i^WiiiHer-PoatiLiftflrZ-^.

Pr6»t86i>$^oht . ..

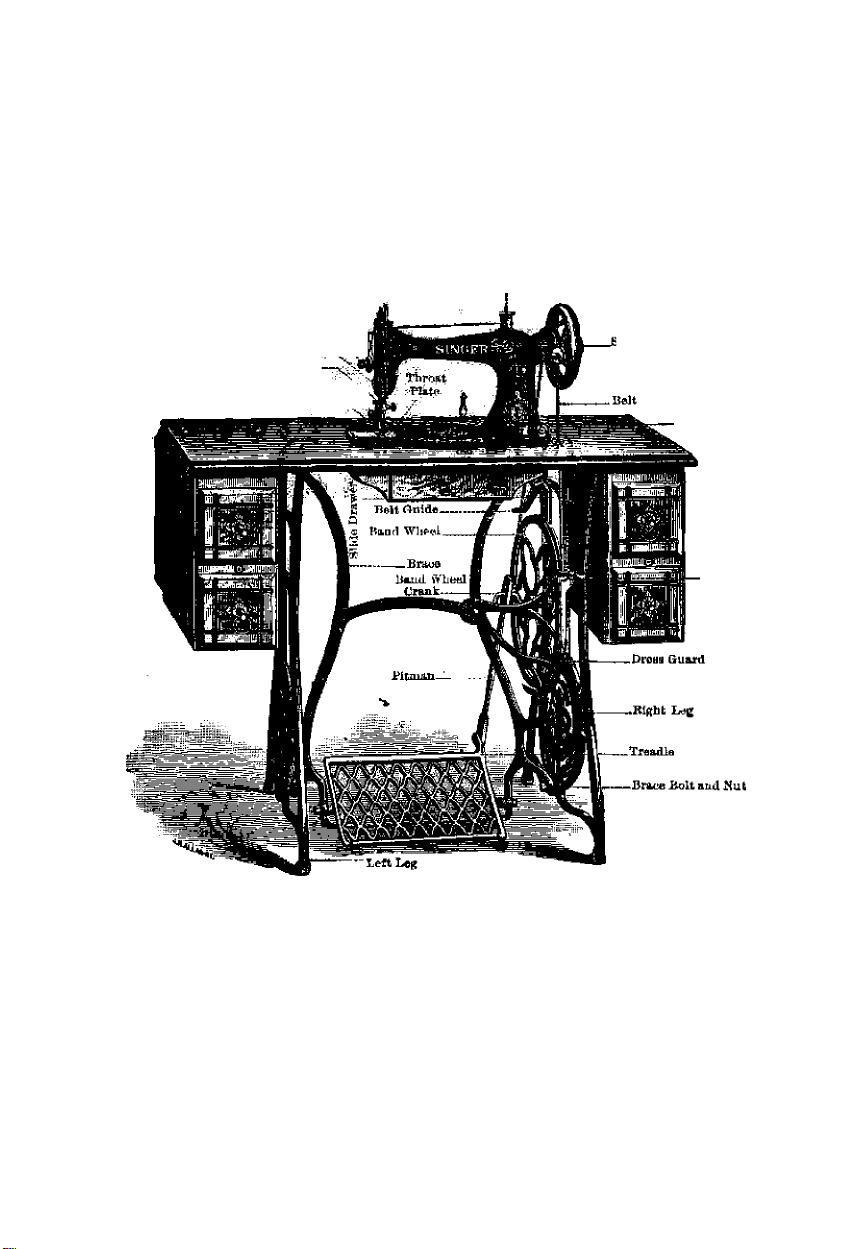

IMFSOVED FAMILY UACHlS^y WITH STANU

Ltop Uotlnn

Top

BaltiSbiftW'

Page 6

DIRECTIONS FOR USING

Fig. 3.

Fig, 4.

't-

Page 7

1^1 RECT IONS

FOR USING THE

Trppí-oV^cí РагртТу Aiach^nS-

~—->Ф<—'

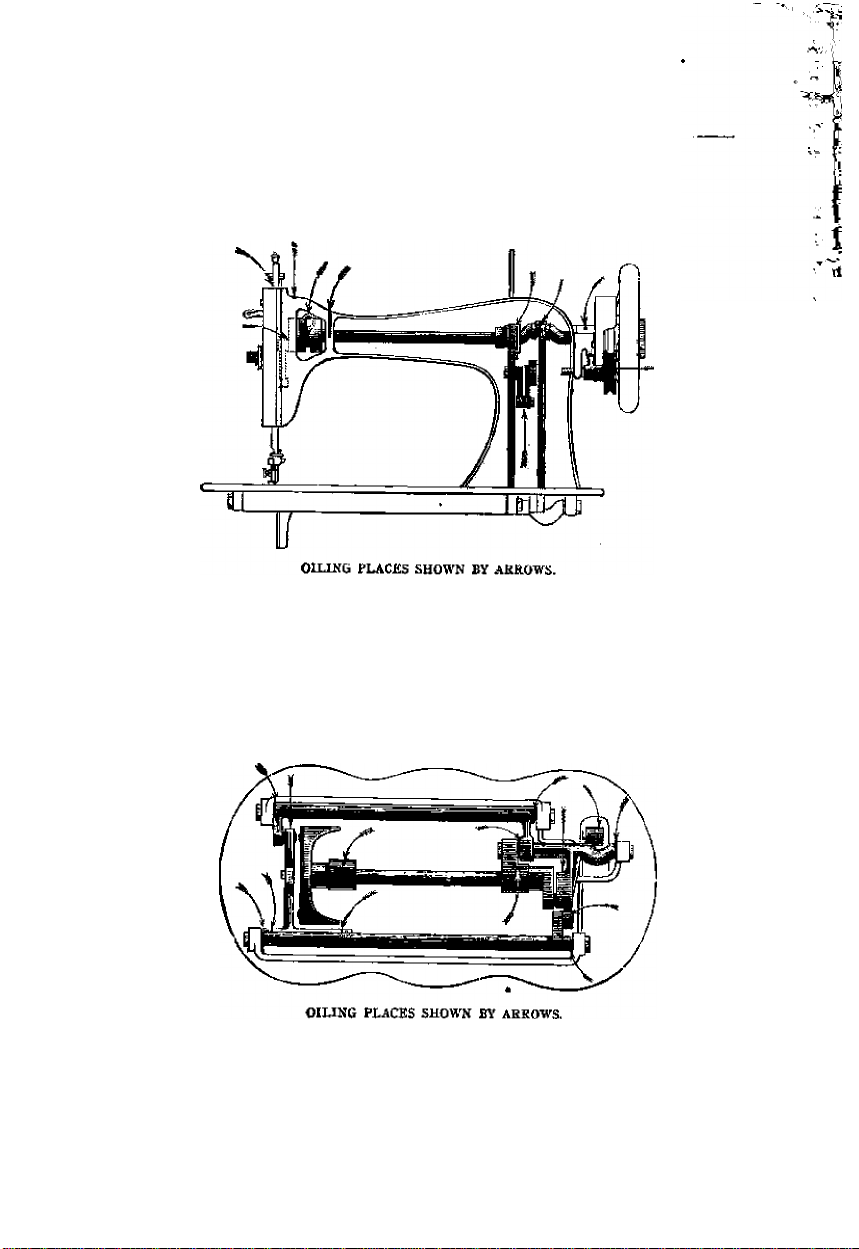

To Oil the Machine.

Be sure that every part is dean before you cominence to sew. ¡/ ¡hi

machine runs hard at any time, it is с екта in that some piare has not been oiled.

Oil holes will be found ftir all bearings whidi cannot be reached without

them. Each place reipiiring oil is indicated by an arrow head in the

cuts on the opposite page. The shuttle should be oiled sparingly, but

often, if the machine is in constant use; always be careful to use no

more oil than is needed, a single drop bdng sufficient at any point, If

the machine runs hard after standing idle for some time, use a little kero

sene oil or henainc on the wearing points, run rapidly, ivipe dean, and

then oil with the best .\perm oil, which should always be used. To make

sure of gettiHg good oil, buy it at at any of the Company’s offices or from

its auihori/ed representatives. The genuine oil is f>ut up in bottles which

have 'I'he Singer Manufacturing Company’s "trade-mark" blown in their

panel, and bear the Company's label

The Stop Motion.

The object of the slop motion is to enable the operator to wind a

bobbin by running the balance-wheel without running the macliine, which

not only saves labor but permits the re-winding of a bobbin w hen a seam

is partially sewed, without removing the goods from tlic machine or

interfering with tlic upper or needle thread.

■ ’'Го operate the stop-motion turn the friction-screw outside of the

balance-wffieel over towards you to release the balancc-wh^l, and in the

opposite direction to clamp it.

To Operate the Treadle and Machine.

Release the balance-wheel as explained, (see ‘ ‘ slop motion ”) place

your feet upon the treadle with the instep directly over its center, turn the

balance-wheel over towards you with the right hand and continue with

the feet (giving an alternate pressure with the heel and toe) the motion

thus commenced until a regular motion is obtained. Next clamp the

balance-wheel to the machine, (see “stop motion’’) see that the presser

foot does not rest on the feeding surface, and operate the treadle as before.

Page 8

DIRECTIONS FOR USING

Finally place some goods in the machine, loosen the presser-foot

upon them and again operate the traadle.

Do not attempt to sew until you are sufficiently familiar

Caution 1. -

Caution

Caution

Caution

Caution

with the treadle motion to be able to start the machine

without turning it backwards, to run it with a regular

and steady motion, and to guide the goods,

i Never run the machine with the presser-foot resting on the

2.

I feed and no cloth between.

i Practice upon strips of cloth, and do not attempt pratical

I sewing until you can guide the material and produc a

3-

' regular motion of the machine,

’ Do not try to help the machine by pulling the fabric, lest

you bend the needle; the machine feeds without any

4.

' assistance,

(Never mn the machine with both shuttle and needle

5-

I threaded, except while you are sewing.

To Set the Needle.

Hold the needle in the left hand with the flat side of the shank

towards the arm of the machine ; raise the needle-bar to its highest point,

put the needle up in the clamp as far as it will go, and tighten the

thumb-screw.

Relative Sizes of Needles and Thread.

Bound Porsi' Nkkduss fob Cloth.

O...

B.. .

...............

...........

f lOO, 150 Cotton.

1 000 Silk.

f 80, 100 Cotton.

100, 0 Silk.

j 60, 80 Cotton.

...............

1 A Silk.

j 40, 60 Cotton.

г...

...............

...............

|b, C Silk.

f 24, 40 Cotton.

1 D, E Silk.

{20, 24 Cotton.

.........

[ 60, 00 Linen.

4...

' " ' 1 very coarse Cotton.

J 40, 60 Linen, or

5-..

Wbihje and Twist Points fob

Lkattbb Wobk.

.....................

0.

.....................

B.

.....................

I ,

...................

2 .

.....................

3-

’ 1 EE Silk.

000, 0 Silk.

A, В Silk,

C, D Silk.

j40 to 60 Cotton.

1D, E Silk,

j 40, 60 Linen,

35> 40 Linen.

4.

Page 9

THE IMmOVED FAMILY SINGER.

Fig. 5.

Place ihe spool of thread on the spool pin, and draw the thread from

the BjK)o] through the eyelet i, on the side of the arm, downward between

the tension discs a from the back toward you, up behind and over the

staple 3, through the hook of the lake up spring 4, up and through the

eyelet in th; end of the take-up lever S from the back toward you, down

through the eyelet 6 in the face plate, under the hook 7 on the needle

bar, and from left to right through the eye 8 of the needle. Enough

thread should he drawn through the needle to leave an end two inches

long when the take up is at its highest point, w hich should be caught

up behind tlie thread cutter 9.

Page 10

DIRECTIONS FOR USING

Pia.

e.

Fia. 7.

THE SHUTTLE CONTAINING BOBBIN.

Fio. 8.

THE BOBBIN WINDER (with latch down).

Palmil’d.

THE BOBBIN,

The Bobbin Winder.

To prepare for winding^, release the balance-wheel (see "Stop

Motion ”) press the bobbin on the spindle of the bobbin-winder until it

reaches the shoulder, then press the arm of the latch down between the

./

Page 11

THE IMPROVED FAMILY SINGER.

flanges of the bobbin until it catches, to bring the pulley in contact with

the driving-belt

To wind the bobbin, place the spool of thread on the spool-pin at

the base of the arm. draw to the right between the retainer discs, pass the

end about an inch through the slot in the outer end of the bobbin from the

inside (this must be done before the bobbin is placed on the spindle) and

“Operate the Treadle " the same as in sewing until the bobbin is filled,

when it will stop automatically.

The free end of the thread must be held with the hand until a few

coils are wound, and should then be broken off.

To Remove the Bobbin.

Tto. 9.

Open the slide on the

beil of the machine, and

bring the shuttle into

position by turning the

balance-wheel toward

you until the needle-bar

reaches its lowest ¡joint;

then with your left hand

under the table, remove

the bobbin, by ¡>lacing

your thumb against the

cap, on outside of the

shuttle (as shown in Fig.

9) and press it outward

as far as it will go; the

cap will then remain

o|Jen and allow the bob

bin to drop out into

your hand.

Page 12

10

DIRECTIONS FOR USING

To Replace the Bobbin and Thread the Shuttle.

Fig. 10.

Talte the bobbin between the thumb

and forefinger of the left hand with

threat! drawn tightly across the finger

(as shown in Fig. lo).

Pw, n.

Pass the hand un

der the table and

place the bobbin in

the cap of the shut

tle and with the same

movement press the

thread which passes

over the finger into

the slot of the deliv

ery eye (as shown in

Fig. ii).

Page 13

THE IMPROVED FAMII.V SINGER.

Ehj, J3.

Withdraw the thumb

gently, allowing the

shuttle to close; then

draw the thread behind

the delivery-eye-guard

or hook, (as shown in

*3)f leaving an end

two inches long, with

which to commence

ewing.

Page 14

12

DIRECTIONS FOR USING

To Commence Sewing.

With the left hand, taVe hold of the needle thread (leaving it slack

between the hand and the needle), turn the balance-wheel over toward

you until the needle moves down and up again to its highest point, thus

catching the shuttle thread ; draw up the needle thread, and the shuttle

thread will appear ; then draw the shuttle thread up through the hole in

the throat-plate, lay both threads back across the feed points, and catch

them behind the thread-cutter, place the material beneath the needle,

lower the presser-foot upon it, and commence to sew, turning, the wheel

over toward you.

TO TURN A CORNER,

stop the machine without raising the needle more than half way out of

the goods. Raise the presser-foot and turn the work in the manner

desired, the needle as a pivot.

FOR SEWING FLANNEL OR BIAS SEAMS,

use a fine stitch and as light a tension as possible so as to leave the

thread loose enough to stand the strain of stretching the goods,

A STII'CH 'rO RAVEL EASILY

can he had, if desired, by leaving the upper tension so light that the

under ihreail w ill not draw into the goods, hut lie straigliL

To Remove the Work.

Let the take up rest at its highest point; take hold of the upper thread

between the take up lever and the eyelet on the face-plate and draw down

about two inches of slack ; then raise the presser-foot, and draw the

fabric to the left, about two inches, and cut the threads by drawing them

behind and then down across the knife-edge of the thread-cnttcr, leaving

the ends caught behind the same.

I^This ingenious but simple device saves " hunting-up the

scissors” every few minutes, and is a highly-valued addition to the special

aitadiments of the Singer machine. ”

To Regulate the Tensions.

The tension on the shuttle-thread is regulated by the small screw

near the delivery eye—turn toward you to increase, and from you to

diminish; when once properly adjusted, it will seldom require to be

changed for any kind of thread commonly used, as a perfect stitch can

usually be obtained by regulating the tensions on tlie upper or needle

Page 15

THE IMPROVED FAMILY SINGER.

thread. To regulate tlie upper tension, turn the ^mall thumb-screw in

front of the tension discs, over toward you to increase the tension, and

from you to diminish it. A loose tension is best for sewing cotton or

linen fabrics, to prevent fullness after the goods have been washed.

If there are loops or a straight Uiread on the under side of the fabric,

as in Fig, 14,

Fig. 14.

it shows that the upper or needle tension is too loose.

If loops or a straight thread appear on the upper side of the goods, as

in Fig. 15,

Fig. 10.

it ^ows that the upper tension is too tight, and it should be diminished

sufficiently to bnng the lock m the centre of the fabric, as in Fig. 16,

Fig. 10.

To Alter the Length of Stitch.

^ On the right side of the operator, and at the front of the arm, there

is a thumb-screw working in a slot. Loosen this, and move it downwards

to lengthen, or upwards to shorten the stitch. When you get the length

of stitch you require, tighten the thumb-screw.

To Change the Pressure on Material.

Turn the large thumb-screw on the top of the head of the machine,

to the rig^ht to increase, and to the left to diminish the foot-bar pressure;

When properly set, this need never be changed for any ordinary work.

Page 16

14

DIRECTIUNS FOR USINO

The Belt.

The leather belt, which gives motion to the machine, should always

be tight enough not to slip, and no tighter—not so tight as to prevent the

easy motion of the machine. If the belt is too long, uncouple and cut

to the desired length.

Twist, Linen and Cotton Thread and Needles.

Do not use poor thread or needles. Any good thread will worjt well,

but you must not expect to make a smooth even stitch with poor rough

thread, r.or can you expect a machine to work well with a cheap grade of

needles made in imitation of ours. As our interest is to maintain the

reputation of the Tinuhine, it is evident that we will always supply the besL

Persons living at a distance from an agency, can send by mail, enclosing

us the money, and we will fill orders promptly by mail or express.

■t

Page 17

THE IMPROVED FAMILY SINGER.

Fid. 17.

DROP CABINET (closed).

To open the cabinet turn over the leaf which covers the machine,

release the platform upon which the machine is fastened by pressing- the

button at the right of the operator near the bottom of the centre doors,

first taking hold of the arm of the machine with the left hand to steady it

as it rises, and when entirely up push back the centre doors which then

become a firm support for the platform, liee page i6.

Page 18

16

DIRECTIONS FOR USING

Fig. 18.

.a

....

DROP cabinet (open).

To close the cabinet, bring the small doors to the front, as shown

on page 15, A slight pressure upon the machine will then force it down

beneath the top of the cabinet, and after the platform is latched the leaf

is folded over the apierture, completely enclosing the machine.

The cabinet, when closed, forms a handsome piece of furniture.

A

Page 19

THE IME'KOVF.D FAMIFV SI MGER.

Fro. 10-

SINGER DROP CABINET (read-v for oiling).

Fig. 19 represents the Drop Cabinet with the machine turned back

and the driving mechanism exposed^ ready for oiling. In order to turn

the machine back, pull open the door at the right of the operator, and

Iwith the machine in motion) turn the belt-shifter handle to tlie left, to

throw the belt off the band-wheel. To reach the oiling points in the

driving mechanism, open the door at the end of the cabinet. After

oiling, turn the machine up again, and operate the treadle as in sewing,

which will automatically replace the belt on the band-wheel.

Page 20

18

DIRECTIONS EOR USING

Fib. 20.

Fig. zo shows our Stand

Brace, carrying the entire

driving mechanism.

Both the baiui-wheel and

treadle work upon adjust

able centres, which admit

of accurate adjustment

with a minimum amount

of friction.

This distinctive feature

renders ours the lightest

running of any sewing

machine stand yet con

structed, and is a matter

of great importance to the

health and comfort of the

operator.

THE NEW SINGER STAND RKACE (WITH BELT

THROWN ofe).—PatiTticd,

Tills invention simplifies and makes

easy the often-irritatingp task of throwing

off and replacing the belt. To throw

off the belt, press the small lever St the

top of the dress guard to the left wiih

the forefinger, keeping up the motion

of the treadle meanwhile. To put on

the belt, allow the lever to spring back

in its place, and operate the treadle as

in sewing (%vith the w'heel turning toward

you), w^hen a single revolution of the

wheel will bring the belt back in place.

Pio. 31,

THE NEW singer bf.i.t shifter.

Paienkd.

Page 21

I

I

I ^

r*

I ■

Fig. Ua.

THE IMPROVED FAMILY SINGER.

Fig.

22

block which forms one-half of the journal is adjust

ed to the crank or pin by means of the screw,

shown at the top of the cut.

Wheti^ taking up lost motion, be careful not to

make the journal so close as to prevent the free

motion of the band wheel.

shows ogt hew adjustable pitman. The

I 2

I

■i

THE NEW SINGER

pitman.

We send with each machine a full set of Attachments in a neat

case, and an Attachment Instruction Book.

The Singer Manufacturing Co. use and recommend exclusively the

“Willimantic 6 Cord Spool Cotton.”

if

Page 22

Loading...

Loading...