Singer EM200 Instruction Manual

INSTRUCTION MANUAL

EM200

IMPORTANT SAFETY INSTRUCTIONS

This household embroidery machine is designed to comply with IEC/EN 60335-2-28 and UL

1594.

IMPORTANT SAFETY INSTRUCTIONS

When using an electrical appliance, basic safety precautions should always be followed,

including the following:

Read all instructions before using this household embroidery machine. Keep these instructions

conveniently near the machine. Make sure to hand them over if the machine is given to a third

party.

DANGER

To reduce the risk of electric shock:

An embroidery machine should never be left unattended when plugged in. Always unplug

this embroidery machine from the electric outlet immediately after using and before cleaning,

removing covers or when making any other user servicing adjustments mentioned in the

instruction manual.

WARNING

To reduce the risk of burns, fi re, electric shock, or injury to persons:

• Do not allow to be used as a toy. Close attention is necessary when this embroidery machine

is used by or near children.

• Use this embroidery machine only for its intended use as described in this manual. Use only

attachments recommended by the manufacturer as contained in this manual.

• Never operate this embroidery machine if it has a damaged cord or plug, if it is not working

properly, if it has been dropped or damaged, or dropped into water. Return the embroidery

machine to the nearest authorized service center for examination, repair, electrical or

mechanical adjustment.

• Never operate the embroidery machine with any air openings blocked. Keep ventilation

openings of the embroidery machine free from the accumulation of lint, dust, and loose fabric.

• Keep fi ngers away from all moving parts. Special care is required around the embroidery

machine needle.

• Always use the proper needle plate. The wrong plate can cause the needle to break.

• Do not use bent needles.

• Do not pull or push fabric while stitching. It may defl ect the needle causing it to break.

• Wear safety glasses.

• Switch the embroidery machine off (“0”) when making any adjustment in the needle area,

such as threading needle, changing needle, threading bobbin, changing presser foot, etc.

• Never drop or insert any object into any opening.

• Do not use outdoors.

• Do not operate where aerosol (spray) products are being used or where oxygen is being

administered.

• To disconnect, turn all controls to the off (“0”) position, then remove plug from outlet.

• Do not unplug by pulling on cord. To unplug, grasp the plug, not the cord.

• Do not use the machine if it is wet.

• If the LED lamp is damaged or broken, it must be replaced by the manufacturer or its service

agent or a similarly qualifi ed person, in order to avoid a hazard.

2

• This embroidery machine is provided with double insulation. Use only identical replacement

parts. See instructions for Servicing of Double-Insulated Appliances.

SAVE THESE INSTRUCTIONS

Servicing should be performed by an authorized service representative.

FOR EUROPE ONLY:

This appliance can be used by children aged from 8 years and above and persons with reduced

physical, sensory or mental capabilities or lack of experience and knowledge if they have been

given supervision or instruction concerning use of the appliance in a safe way and understand

the hazards involved. Children shall not play with the appliance. Cleaning and user maintenance

shall not be made by children without supervision.

The noise level under normal operating conditions is less than 70db.

FOR OUTSIDE EUROPE:

This embroidery machine is not intended for use by persons (including children) with reduced

physical, sensory or mental capabilities, or lack of experience and knowledge, unless they have

been given supervision or instruction concerning use of the embroidery machine by a person

responsible for their safety. Children should be supervised to ensure that they do not play with

the embroidery machine.

The noise level under normal operating conditions is less than 70db.

SERVICING OF DOUBLE INSULATED PRODUCTS

In a double-insulated product, two systems of insulation are provided instead of grounding. No

ground means is provided on a double-insulated product, nor should a means for grounding

be added to the product. Servicing of a double-insulated product requires extreme care and

knowledge of the system and should be done only by qualifi ed service personnel. Replacement

parts for a double-insulated product must be identical to those parts in the product. A doubleinsulated product is marked with the words ‘DOUBLE INSULATION’ or ‘DOUBLE INSULATED’.

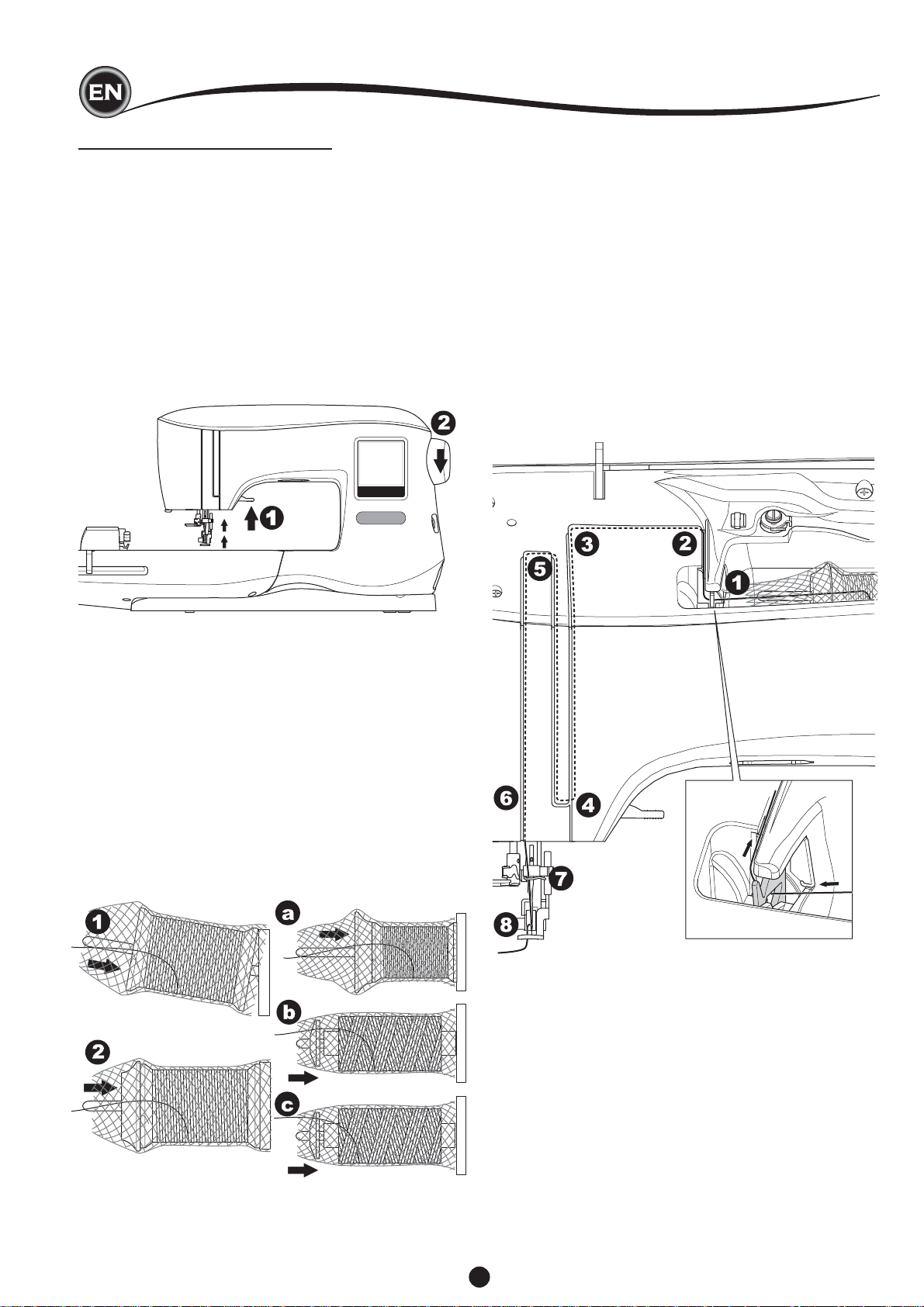

SETTING UP THE MACHINETHREADING THE MACHINE

EMBROIDERY PREPARATION

PREFACE

Thank you for your purchase of this embroidery machine.

This machine intended for household use will provide you with excellent performance in sewing

embroidery designs and lettering.

Please refer to this booklet for proper use and optimum performance. To get the most out of

your embroidery machine, read the entire instruction manual before attempting to operate the

machine. Then familiarize yourself with the machine by following the instruction manual page by

page.

To ensure that you are always provided with the most modern embroidery capabilities, the

manufacturer reserves the right to change the appearance, design or accessories of this

embroidery machine when considered necessary without notifi cation or obligation.

SINGER® is the exclusive trademark of The SINGER® Company Limited S.à.r.l. or its Affi liates.

©2015 The SINGER® Company Limited S.à.r.l. or its Affi liates. All rights reserved.

3

EMBROIDERYMAINTENANCE

TABLE OF CONTENTS

MAIN PARTS

ACCESSORIES

NEEDLES

REMOVING & INSERTING THE NEEDLE ...........................7

SELECTING NEEDLE & THREAD ........................................ 7

SETTING UP THE MACHINE

CONNECTING THE EMBROIDERY UNIT ............................ 8

REMOVING THE EMBROIDERY UNIT ................................ 8

ELECTRICAL CONNECTION ............................................... 8

MESSAGES AT START UP ...................................................9

MACHINE CONTROL FUNCTIONS .....................................9

START/STOP BUTTON ..................................................9

SPEED CONTROL BUTTONS .......................................9

THREAD CUTTER BUTTON .........................................10

TOP COVER ..................................................................10

HAND WHEEL ............................................................... 10

PRESSER FOOT LIFTER .............................................10

THREAD CUTTER ........................................................ 10

MOUNTING MACHINE IN SEWING CABINET .............10

SOFTWARE INFORMATION

USB EMBROIDERY STICK ................................................11

CONNECTING USB STICK ........................................... 11

DESIGN BOOK .............................................................. 11

INDIVIDUAL DESIGN INFORMATION .......................... 11

EMBROIDERY SOFTWARE .......................................... 11

UPDATING YOUR MACHINE ........................................ 11

THREADING THE MACHINE

BOBBIN SETTING ..............................................................12

REMOVING THE BOBBIN............................................. 12

SETTING SPOOL OF THREAD ON SPOOL PIN ..........12

WINDING THE BOBBIN ................................................12

WINDING BOBBIN INDEPENDENTLY .........................13

INSERTING THE BOBBIN .............................................13

THREADING THE NEEDLE ................................................ 14

PREPARING T O THREAD MACHINE ...........................14

SETTING SPOOL OF THREAD ON SPOOL PIN ..........14

THREADING THE UPPER THREAD ............................14

THREADING THE NEEDLE EYE .................................. 15

DRAWING UP THE BOBBIN THREAD .........................15

EMBROIDERY PREPARATION

HOME SCREEN/HOME BUTTON ...................................... 16

EMBROIDERY MACHINE SETTINGS ................................16

SETTING BUTTON ........................................................ 16

THREAD TENSION .......................................................16

STOP FOR CUT ............................................................17

AUDIBLE BEEP ............................................................. 17

CONTRAST OF SCREEN .............................................17

CALIBRATION SCREEN ...............................................17

SOFTWARE VERSION .................................................17

........................................................................5

....................................................................6

..............................................................................7

...............................................8

.............................................. 11

.............................................12

..........................................16

USING FABRIC AND STABILIZER .....................................18

SECURING FABRIC IN THE EMBROIDERY HOOP ..........19

A TTACHING THE EMBROIDERY HOOP TO THE MACHINE .

REMOVING THE HOOP FROM THE MACHINE ..........19

SELECTING DESIGNS

HOME SCREEN ..................................................................20

EMBROIDERY COLLECTION .......................................20

SELECTING A DESIGN ......................................................20

TO SELECT A BUILT-IN DESIGN ..................................20

TO SELECT A USB DESIGN ......................................... 20

EDITING THE DESIGN

EMBROIDERY PLACEMENT SCREEN..............................21

EMBROIDERY ROTATION AND MIRRORING SCREEN ...21

EMBROIDERY SCALING SCREEN .................................... 21

EMBROIDERY OPTION SCREEN ...................................... 22

HOOP OPTION AND SELECTION ................................22

HOOP OPTION - MOVING HOOP POSITION .............. 22

HOOP SELECTION ....................................................... 22

TRACING .......................................................................23

BASTING .......................................................................23

MONOCHROME ............................................................23

SEWING DESIGN

SEWING SCREEN .............................................................. 24

ST AR T T O SEW ..................................................................24

EMBROIDERY LETTERS

SELECTING EMBROIDERY LETTERS ..............................25

EDITING EMBROIDERY LETTERS .................................... 25

SEWING EMBROIDERY LETTERS .................................... 25

POP-UP MESSAGES

UPPER THREAD BREAKAGE ..................................... 26

CONNECT USB ............................................................26

THREAD JAM ................................................................ 26

WRONG HOOP TYPE ...................................................26

DATA ON THE USB STICK CANNOT BE READ...........26

REMOVE THE HOOP ....................................................26

EMBROIDERY TOO LARGE .........................................26

STOP COMMAND IN DESIGN ......................................26

MAIN MOTOR OVERLOAD ...........................................26

CORRUPTED DATA ......................................................26

MAINTENANCE

REMOVING THE EMBROIDERY FOOT ............................. 27

ATTACHING THE EMBROIDERY FOOT ......................27

CLEANING ..........................................................................27

BOBBIN HOLDER .........................................................27

HOOK RACE & FEED DOG ..........................................27

HELPFUL HINTS

EMBROIDERY QUICK REFERENCE CHART

TECHNICAL SPECIFICATION

DESIGN BOOK

.......................................................20

.......................................................21

...............................................................24

...................................................25

.........................................................26

..................................................................27

................................................................28

...................29

...........................................30

19

4

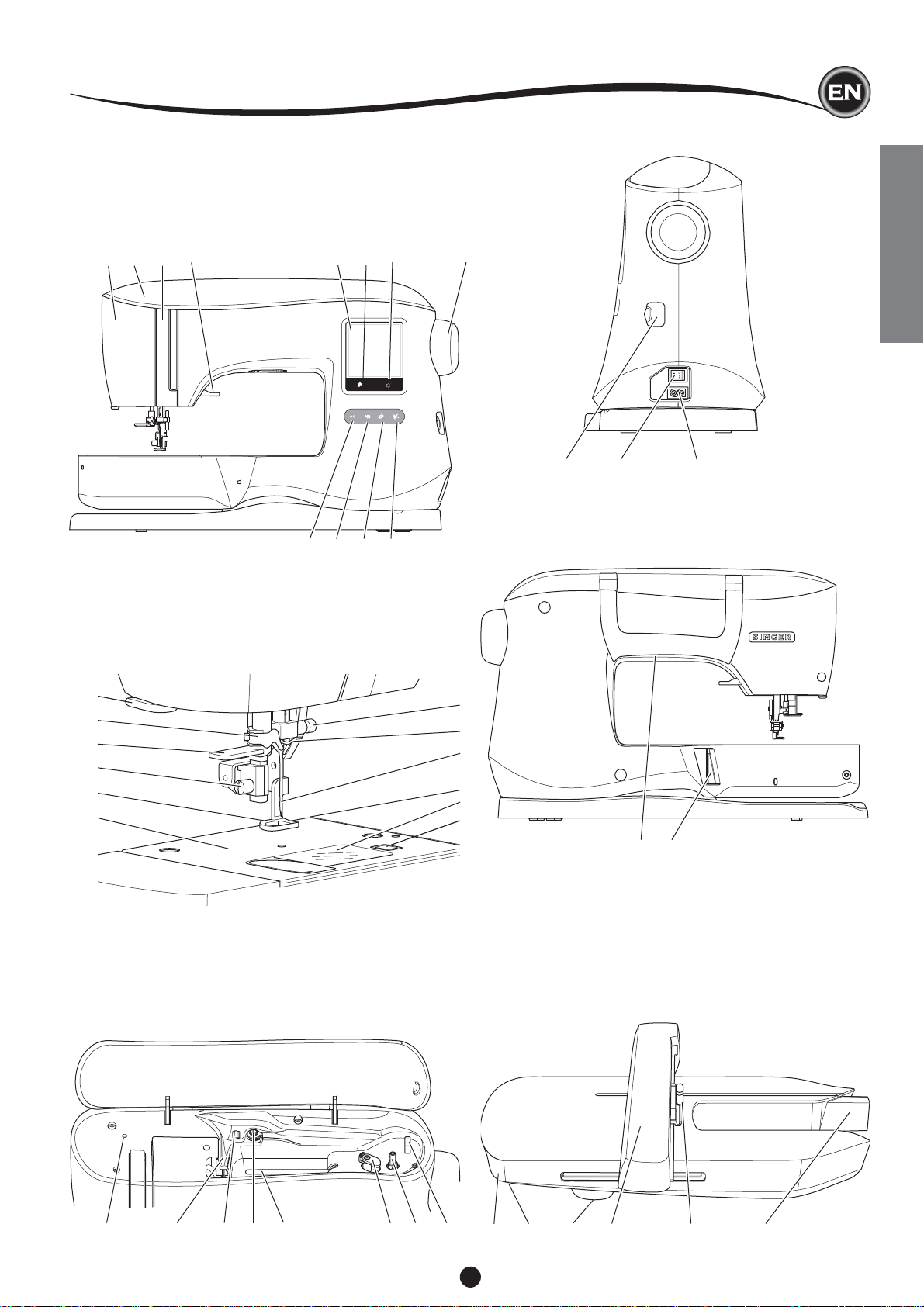

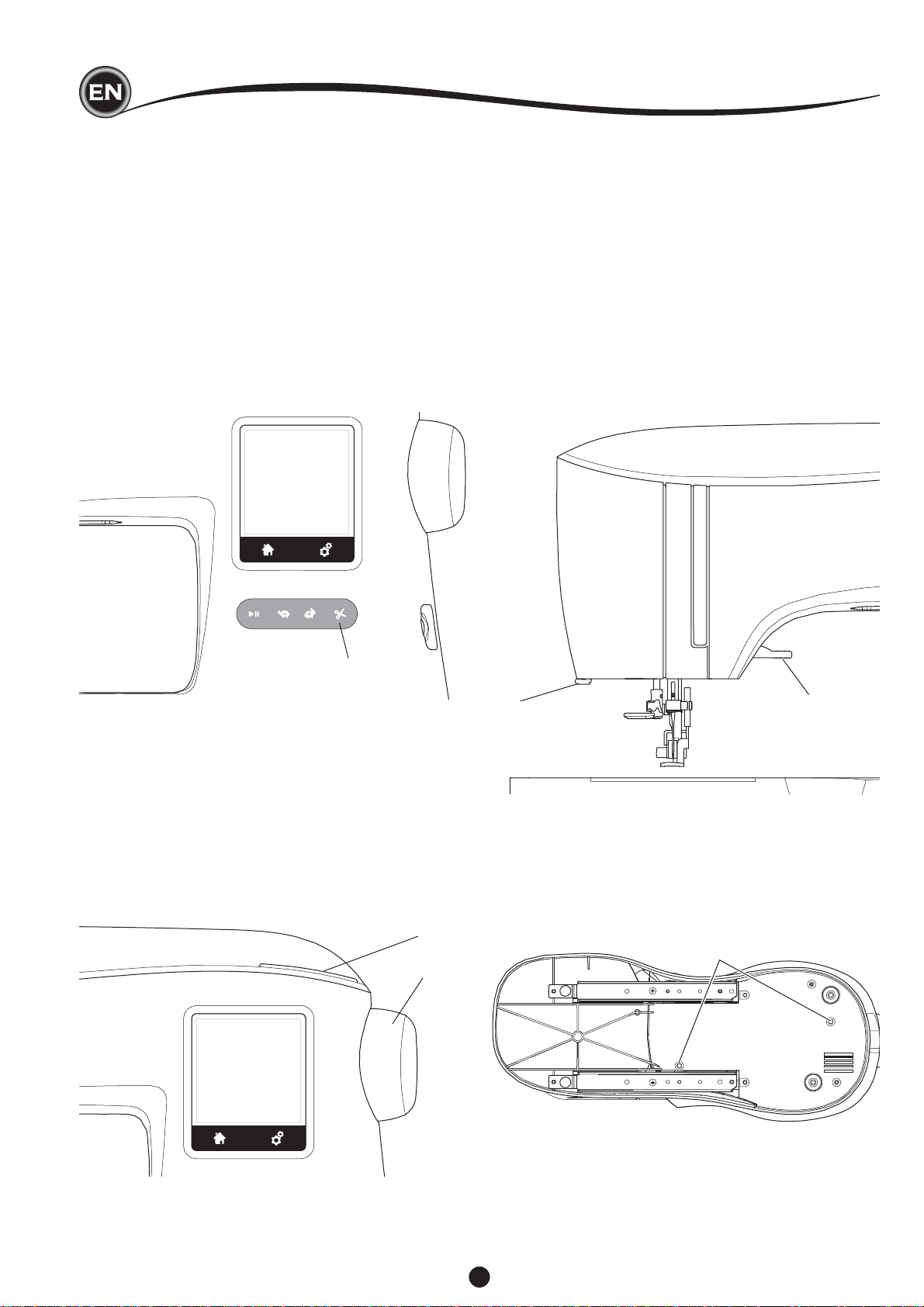

MAIN PARTS

1. Face Plate

2. Top Cover

3. Thread Take-Up Lever

(Inside)

4. Presser Foot Lifter

5. Touch Panel LCD

6. Home Button

1 2 3 4 5 6 9 7 8

13. Thread Cutter

14. Needle Threader

15. Needle Threader Lever

16. Presser Foot Screw

17. Embroidery Presser Foot

18. Needle Plate

7. Setting Button

8. Hand Wheel

9. Start/Stop Button

10. Slow Button

11. Fast Button

12. Thread Cutter Button

10 11 12

19. Needle Clamp Screw

20. Needle Thread Guide

21. Needle

22. Bobbin Cover

23. Bobbin Cover Latch

32. USB Embroidery

Stick Socket

33. Power Switch

34. Connector for

Power Cord

32 33 34

35. Handle

36. Embroidery Unit Connection Socket

SETTING UP THE MACHINE

13

14

15

16

17

18

24. Auxiliary Spool Pin

Holder

25. Thread Guide

26. Extra Thread Guide

27. Bobbin Winding Tension

Disc

28. Spool Pin

29. Bobbin Winder Stop

30. Bobbin Winder Shaft

31. Bobbin Winder Thread

Cutter

19

20

21

22

23

37. Accessory Tray

38. Embroidery Unit

Release Lever (Under

Accessory Tray)

39. Level Adjusting Feet

(Bottom of Unit)

35 36

40. Embroidery Hoop

Carriage

41. Embroidery Hoop

Connection Assembly

42. Embroidery Unit

Socket

24 25 26 27 28 29 30 31

37 39 40 41 42

38

5

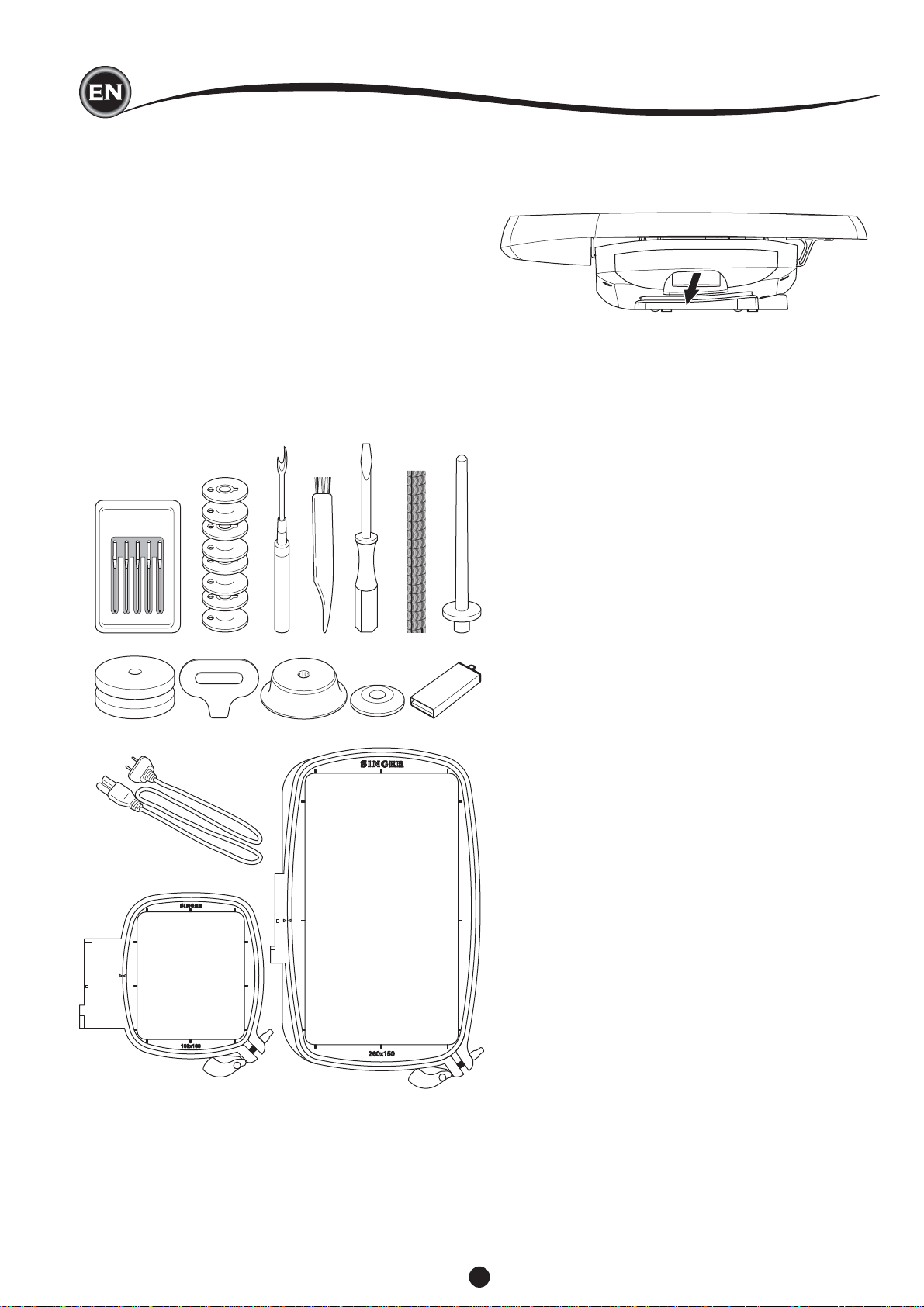

ACCESSORIES

ACCESSORIES

Some accessories are stored in the accessory tray.

1. Needle Pack

2. 5 SINGER® Class 15 transparent bobbins

( 1 is in the machine)

3. Seam Ripper

4. Brush

5. Screw Driver

6. Thread Net

7. Auxiliary Spool Pin

8. 2 Felt Washers

9. Screwdriver for Needle Plate

10. Spool Cap

11. Small Thread Cap

12. USB Embroidery Stick

13. Power Line Cord

14. Embroidery Hoop 100mm x 100mm (4” x 4”)

15. Embroidery Hoop 260mm x 150mm (10 1/4” x 6”)

ACCESSORY TRAY

The accessory tray is located on the left side of the embroidery

unit. Pull to open.

1 2 3 4 5 6 7

8 9 10 11 12

13

14

15

6

NEEDLES

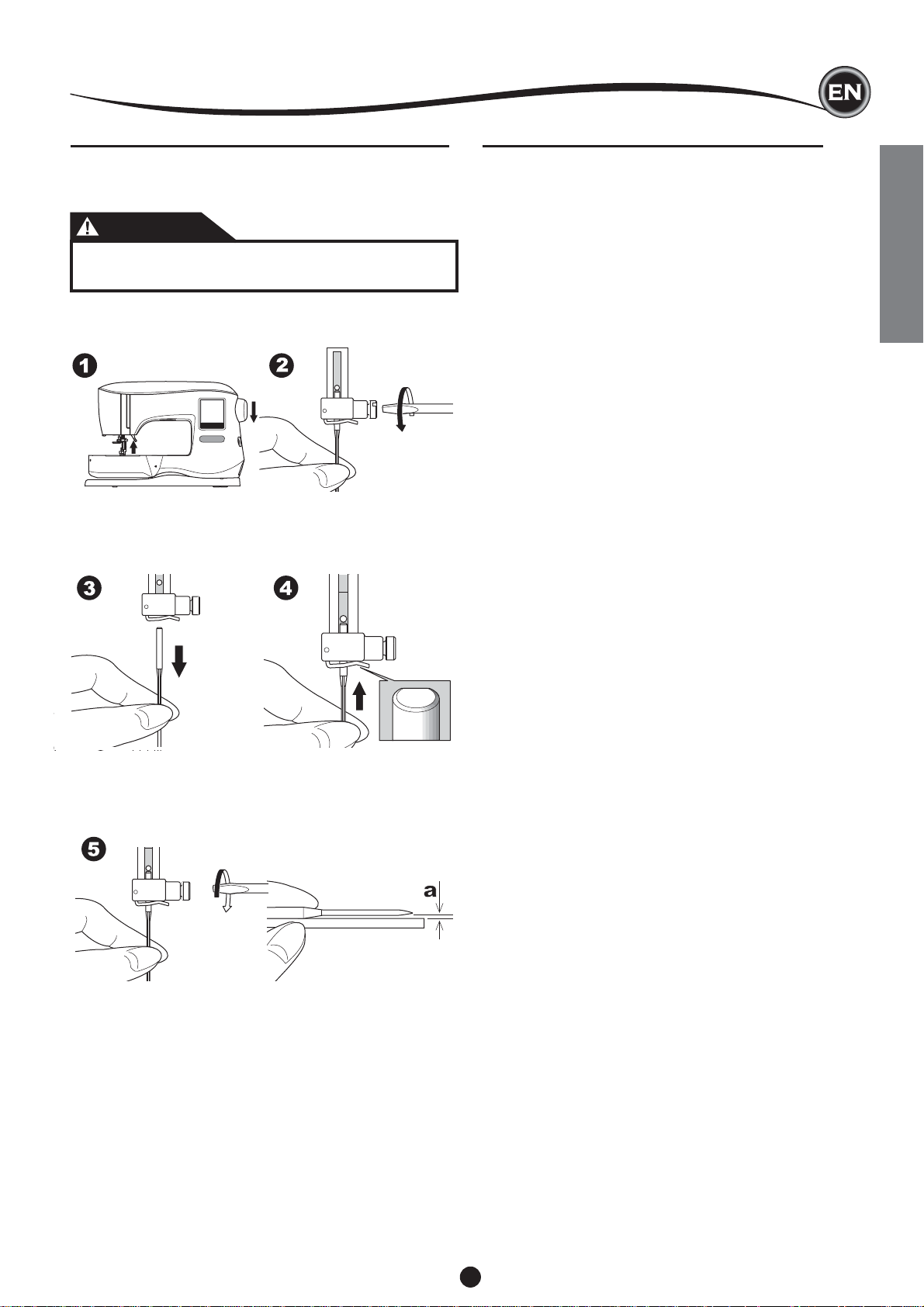

REMOVING & INSERTING THE NEEDLE

Select a needle of the appropriate style and size for the fabric

to be embroidered.

CAUTION

To prevent accidents:

Turn off the power before removing the needle.

1. Turn the hand wheel toward you until the needle is at its

highest position.

2. Loosen the needle clamp screw.

3. Remove the needle.

4. Insert new needle into needle clamp with the fl at side to the

back and push it up as far as it will go.

SELECTING NEEDLE AND THREAD

For good quality results, it is important to use the appropriate

style and size of needle for the fabric that will be embroidered.

For help with determining which needle to use, refer to the

Embroidery Quick Reference Chart on page 29.

NEEDLE

1. For light weight woven fabrics, use SINGER® Style 2000,

Size 11/80 needle.

2. For medium to heavier weight woven fabrics, use SINGER®

Style 2000, Size 14/90 needle.

3. For light weight stretch fabrics, use SINGER® Style 2001,

Size 11/80 needle.

4. For medium to heavier weight stretch fabrics, use

SINGER® Style 2001, Size 14/90 needle.

It is possible to substitute SINGER® Style 2020 needles for

the 2000 Style, in either the 11/80 or 14/90 sizes.

It is possible to substitute SINGER® Style 2045 needles for

the 2001 Style, in either the 11/80 or 14/90 sizes.

It is recommended to use SINGER® needles in your SINGER®

embroidery machine.

THREAD

Machine embroidery is most often done using rayon or

polyester thread in the needle.

A lighter weight thread, referred to as bobbinfi ll, is

recommended for the bobbin. This helps create less density on

the back side of the embroidery design.

NOTE: In addition to the correct needle and thread, it is also

important to use the appropriate stabilizer for the fabric to be

embroidered. (See pages 18 and 29 for more information.)

SETTING UP THE MACHINE

5. Tighten the needle clamp screw securely.

Do not use a bent or blunt needle (a). Place needle on a

fl at surface to check its straightness.

7

SETTING UP THE MACHINE

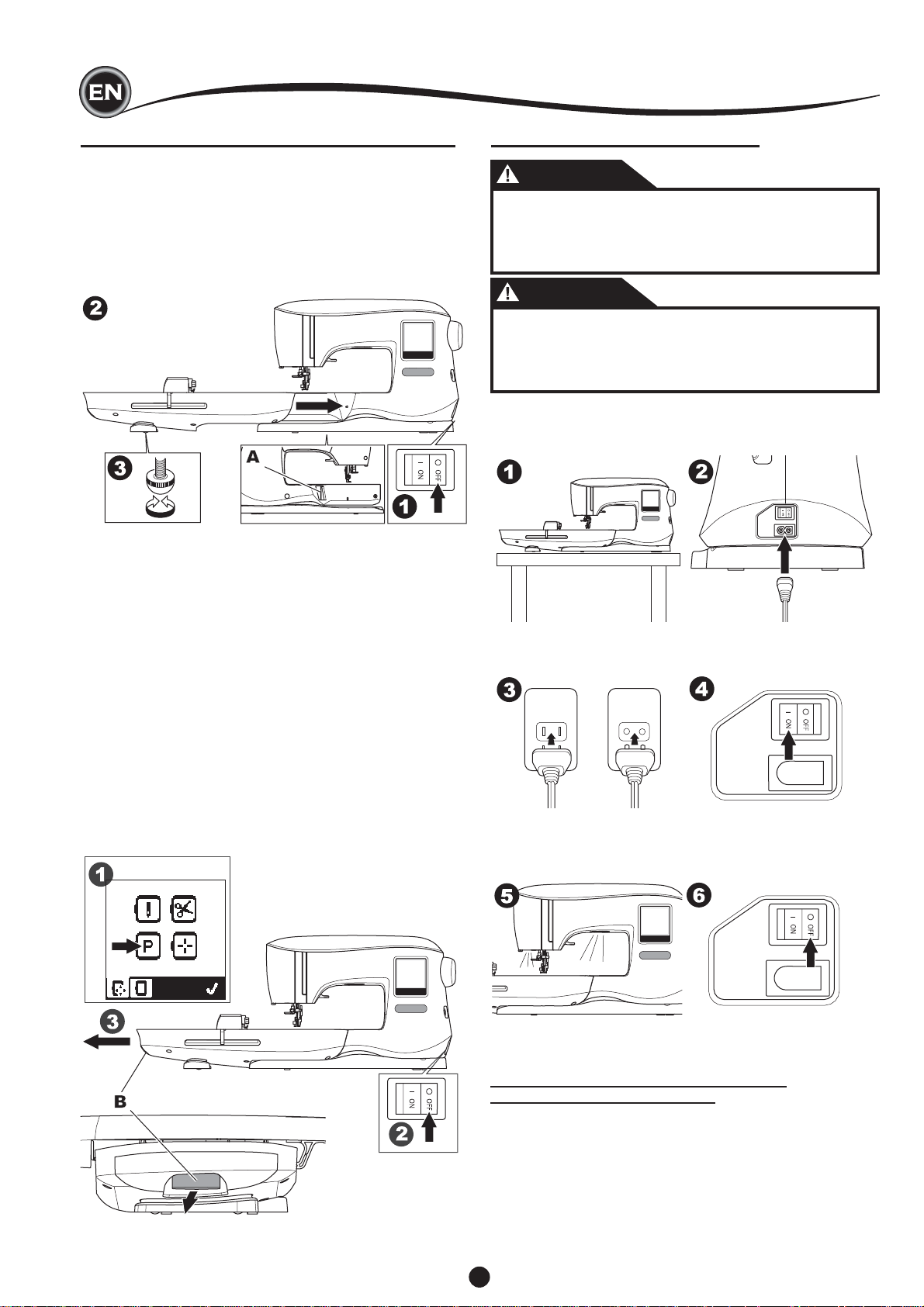

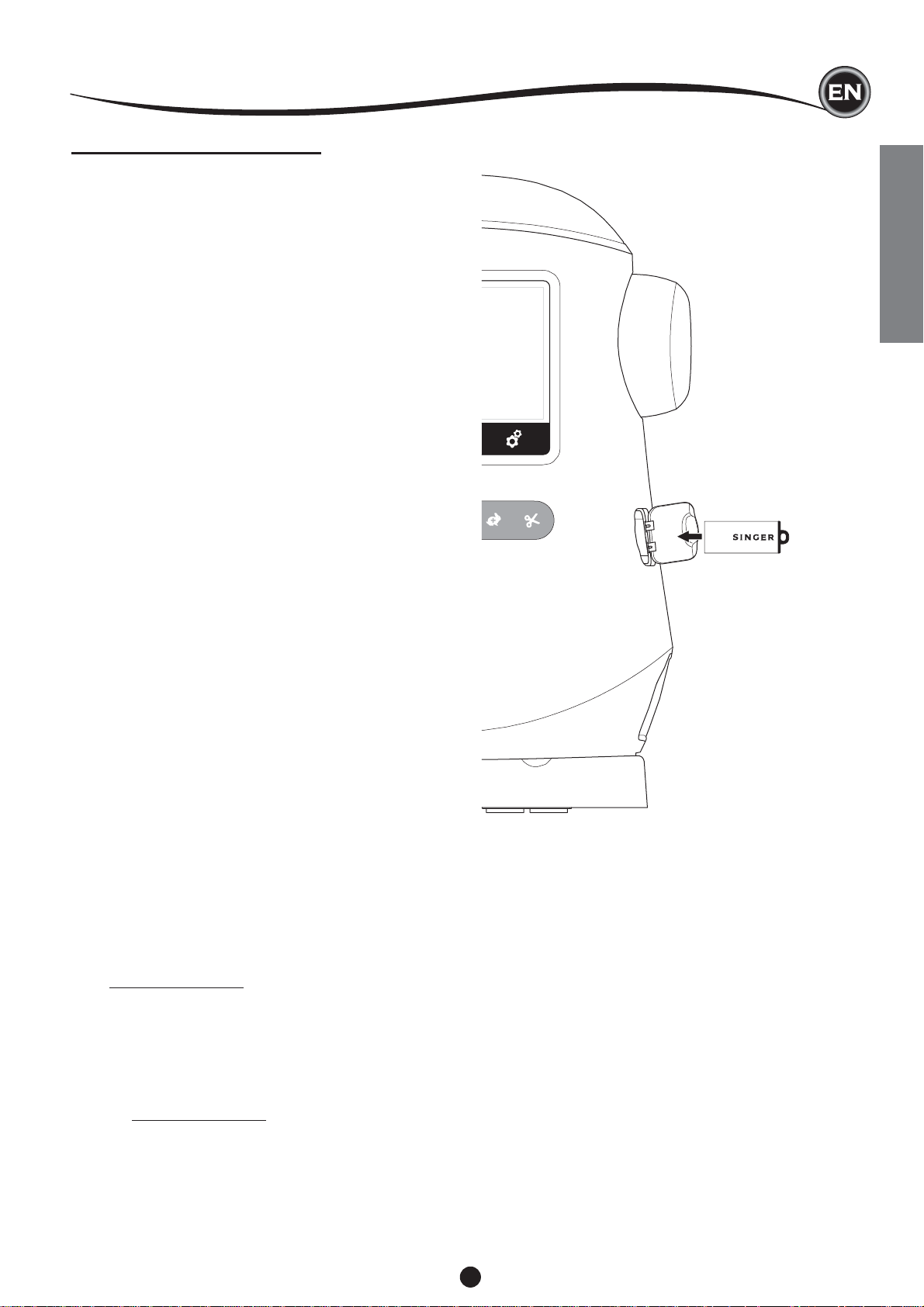

CONNECTING THE EMBROIDERY UNIT

There is a covered socket (A) behind the machine. The cover

will open automatically when connecting the embroidery unit.

1. Turn the machine off before connecting the embroidery unit.

2. Slide the embroidery unit onto the arm of the machine until

it plugs fi rmly into the socket.

3. If needed, use the level adjusting feet so that the machine

and embroidery unit are even with one another.

ELECTRICAL CONNECTION

DANGER

To reduce the risk of electric shock:

Never leave unattended when plugged in. Always

unplug this machine from the electric outlet

immediately after using and before maintenance.

WARNING

To reduce the risk of burns, fi re, electric shock, or

injury to persons:

Do not unplug by pulling on cord. To unplug, grasp

the plug, not the cord.

1. Place machine on stable surface.

2. Connect the power line cord to the machine by inserting

the 2-hole plug into the power cord connector.

TO REMOVE THE EMBROIDERY UNIT

Remove the hoop from the machine. (See Page 19)

1. To store the embroidery unit into the box, move the carriage

to park position by selecting Park Position in the Hoop

Option.(See page 22)

2. Turn off the machine.

3. Pull the lever (B) at the left, underneath the embroidery unit

and slide the unit to the left to remove it.

The cover of the socket closes automatically.

4. Store the embroidery unit in the original packing material.

3. Connect the power line plug to the electric outlet.

4. Turn on the power switch.

5. The lamps will light up when switch is turned on (symbol I).

6. To disconnect, turn the power switch to the off position (symbol

O), then remove plug from outlet.

FOR UNITED STATES AND CANADA USERS:

POLARIZED PLUG INFORMATION

This appliance has a polarized plug (one blade wider than the

other). To reduce the risk of electric shock, this plug is intended

to fi t in a polarized outlet only one way. If the plug does not fi t

fully in the outlet, reverse the plug. If it still does not fi t, contact

a qualifi ed electrician to install the proper outlet. Do not modify

the plug in any way.

8

SETTING UP THE MACHINE

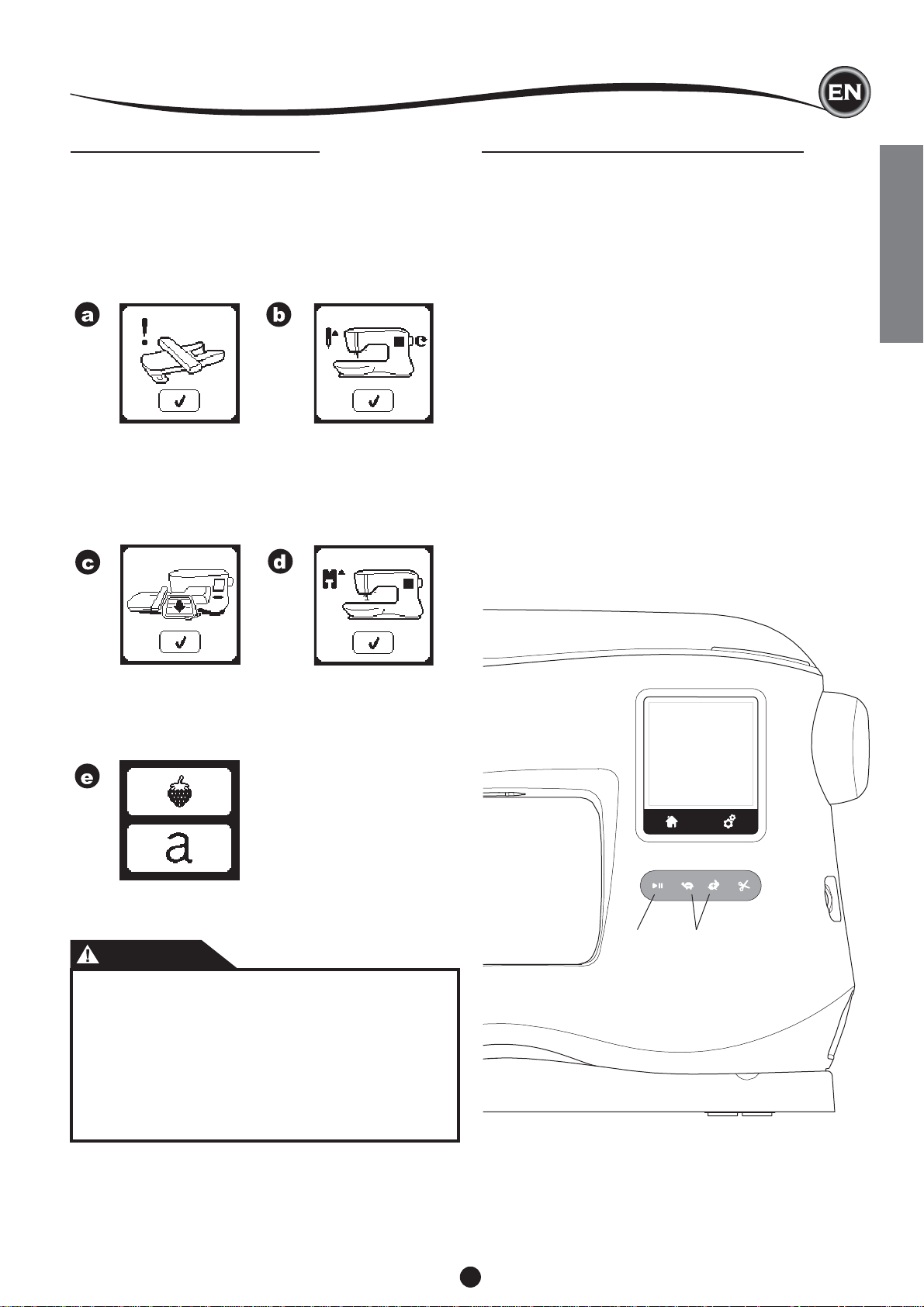

MESSAGES AT START UP

When you turn the machine on, a series of messages will

appear on the screen.

a. If the embroidery unit is not attached, this message will

appear. Attach the unit correctly. (See previous page.)

b. If the needle is not in its highest position, this message

will appear. Turn the hand wheel toward you to raise the

needle to its highest position and then press the “✓” button.

c. If this message appears, remove the hoop (if attached),

clear the embroidery area and press the “✓” button.

d. If presser foot is lowered, this message will appear. Raise

the presser foot lifter and press the “✓” button.

(See next page)

MACHINE CONTROL FUNCTIONS

TART/STOP BUTTON (A)

S

The machine will start running when Start/Stop button is

pressed and will stop when pressed the second time. The

machine will ramp up slowly at start of sewing.

NOTE:

1. Machine will not start if you don’t select an embroidery

design or letter.

2. Bobbin winding function is independent from this button. (See

page 12)

SPEED CONTROL BUTTONS (B)

The sewing speed is controlled by the machine.

You can change the maximum speed by pressing these

buttons.

Press the left button to decrease the speed.

Press the right button to increase the speed.

NOTE:

If you use a specialty thread, such as metallic thread, you

should reduce the the maximum speed to help prevent thread

breakage.

SETTING UP THE MACHINE

When the messages a-d have cleared the screen, the carriage

will move to start point.

e. The Home Screen will appear.

(For more information on the Home Screen, see page 16.)

CAUTION

To prevent accidents:

1. Do not carry the machine when embroidery unit is

attached. It may fall off.

2. Do not push nor pull the carriage forcefully. It may

break.

3. Do not hold the carriage to move the machine.

4. Do not press the screen too hard and do not use

sharp objects to touch it. Doing so can damage the

screen. Touch the screen with your fi nger only.

A B

9

SETTING UP THE MACHINE

THREAD CUTTER BUTTON (C)

By pressing this button, machine will cut both threads

automatically.

NOTE:

The machine will cut threads automatically between color

changes and when an embroidery design has been completed.

CAUTION:

1. Do not press this button when there is no fabric under the

presser foot or no need to cut the threads. The thread may

tangle, resulting in damage.

2. Do not use this button when cutting thread thicker than

#30, nylon thread or other speciality threads.

In this case, use the thread cutter (G).

PRESSER FOOT LIFTER (F)

The presser foot is raised or lowered by this lever.

You can raise and hold the presser foot lifter to an extra-high

position, which can help make it easier to install the embroidery

hoop.

NOTE:

Machine will not start when the presser foot is raised (except

for bobbin winding).

THREAD CUTTER (G)

Use this cutter if the Thread Cutter button is not used.

1. Raise the presser foot and bring threads toward the back.

2. Hook the threads to the thread cutter from back to front.

3. Pull threads to cut them.

C

TOP COVER (D)

To open the top cover, lift up the front right side of the cover.

HAND WHEEL (E)

By turning the hand wheel, the needle will raise or lower. You

should always turn hand wheel toward you.

D

E

FG

MOUNTING MACHINE IN SEWING CABINET (H)

There are two holes on the underside of the machine designed

for mounting the machine into a sewing cabinet. Align the

holes (indicated in the picture) with the corresponding holes in

the cabinet base. Attach the machine with screws. (Screws not

included)

H

10

SOFTWARE INFORMATION

USB EMBROIDERY STICK

Your machine comes with a USB stick. This stick contains the

following:

a. Design Data (embroidery designs)

b. Design Book (PDF fi le displaying images of included

embroidery designs and fonts, viewed on PC)

c. Individual Design Information (PDF fi le displaying details

on individual designs, viewed on PC)

CONNECTING USB STICK

Your machine has a USB socket to read embroidery data from

the USB embroidery stick.

Open the cover and insert the USB embroidery stick in the

socket. The USB plug can only be inserted one way - do not

force it into the socket.

To remove, carefully pull the USB embroidery stick out straight.

NOTE:

Do not remove the USB embroidery stick while operating the

machine or stitching the embroidery, as this can damage the

fi les on your USB embroidery stick.

DESIGN BOOK

A Design Book is provided, which displays an overview of the

included embroidery designs and fonts that come with your

machine. You can see an images of the designs, as well as

the dimensions and stitch count of the designs.

This book is a PDF fi le, which can be accessed from the USB

stick when placed in your PC. Your PC will need to have

Adobe Acrobat Reader installed in order to view the Design

Book. If your PC doesn’t have Acrobat Reader, access the

Adobe website to install it.

SETTING UP THE MACHINE

INDIVIDUAL DESIGN INFORMATION

This is a PDF fi le that contains more specifi c information

about each individual embroidery design that comes with your

machine, such as the order of thread colors, suggested thread

colors and more.

This book is a PDF fi le, which can be accessed from the USB

stick when placed in your PC. Your PC will need to have

Adobe Acrobat Reader installed in order to view the Design

Book. If your PC doesn’t have Acrobat Reader, access the

Adobe website to install it.

EMBROIDERY SOFTWARE

Embroidery software is available for your machine, which will

allow you to use designs from other sources, such as design

CD’s and designs from the internet.

Go to singer.mysewnet.com for information on how to

download this software to your PC.

UPDATING YOUR MACHINE

Periodically, updates may be made available for your machine.

Your machine is updated via your USB stick.

1. Go to singer.mysewnet.com for information about available

updates for your machine.

2. Follow the instructions for how to update your machine.

11

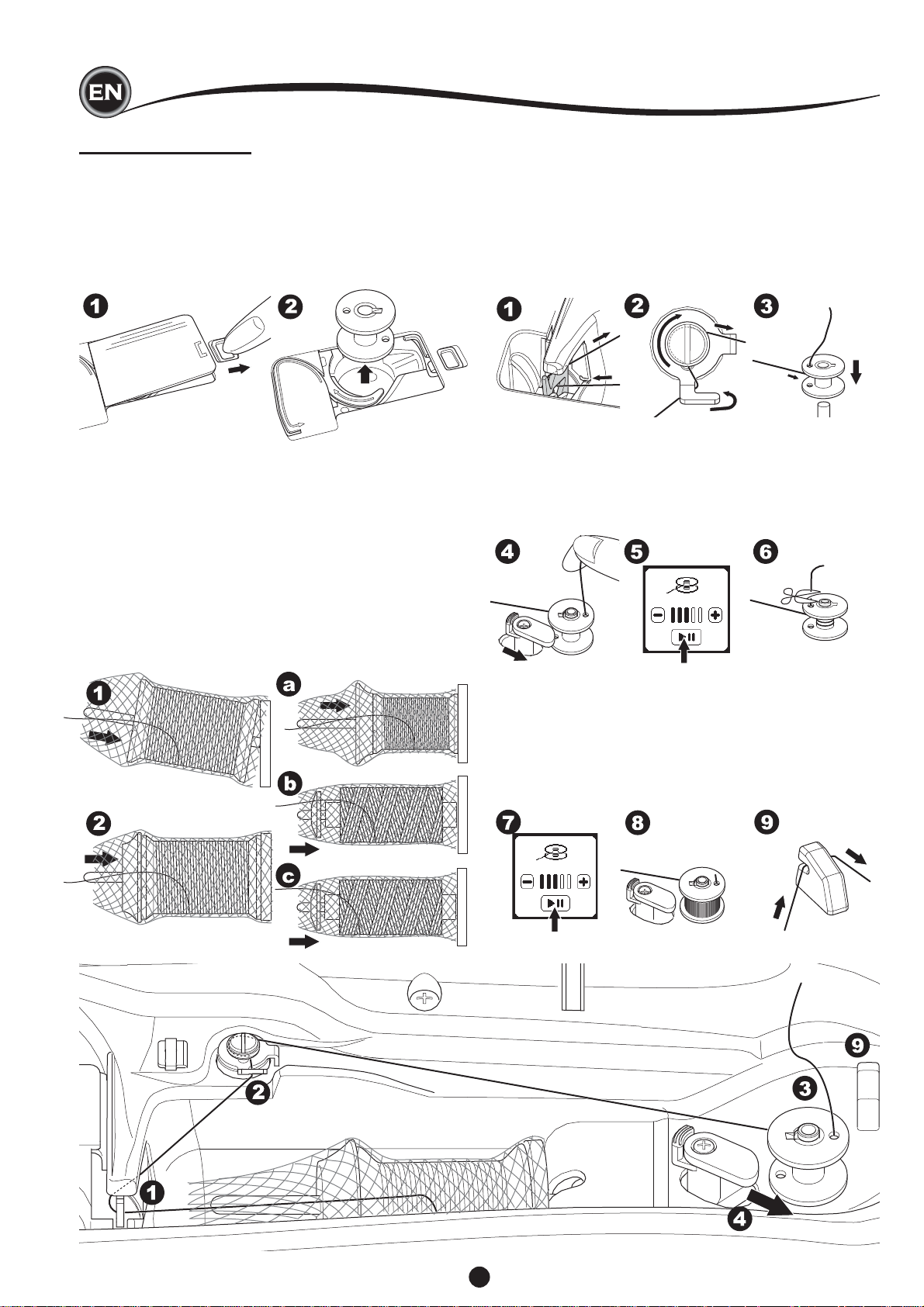

THREADING THE MACHINE

BOBBIN SETTING

Be sure to use only SINGER® Class 15 transparent bobbins in

this machine.

REMOVING THE BOBBIN

1. Pull the bobbin cover latch to the right and remove the

bobbin cover.

2. Lift up the bobbin from the machine.

SETTING SPOOL OF THREAD ON SPOOL PIN

1. Pull up the left end of spool pin and set the felt washer and

the spool of thread on spool pin so that the thread unrolls

from the front of the spool.

2. Set the spool cap on spool pin as far as it will go.

a. The spool cap can be reversed in order to better

accommodate the size of smaller thread spools.

b. Use the small spool cap when you use cross wound

thread. Leave small opening between cap and spool as

illustrated.

c. Set the thread net over the spool if thread unrolls too

easily.

WINDING THE BOBBIN

1. Hold thread in both hands and hook thread to the guide

from front opening.

2. Bring thread to the right and pass it through the thread

guide from the back side. Pass thread under the tension

disc in a clockwise direction.

3. Insert thread through hole in bobbin and place the bobbin

on bobbin winder spindle.

4. Hold the end of the thread and push bobbin stopper to the

right. When the bobbin winding screen appears, press the

Start/Stop button on the screen to start winding.

5. After the bobbin winds a few turns, stop the machine by

pressing the Start/Stop button on the screen.

6. Cut the thread near the hole, as illustrated.

7. Start the machine again.

You can adjust winding speed by pressing “+” (faster) or “-”

(slower) button on the screen.

8. When the bobbin is wound fully, the bobbin stopper will

return to the left and stop winding.

9. Remove the bobbin from the spindle and cut thread with

the thread cutter.

12

THREADING THE MACHINE

WINDING BOBBIN INDEPENDENTLY

You can wind the bobbin independently while embroidery

stitching.

1. Insert the auxiliary spool pin into the hole at the left side on

the top of the machine.

2. Place the felt washer and spool of thread onto the auxiliary

spool pin.

3. Bring thread to the right and hook the thread to the thread

guide from rear opening.

4. Follow the normal winding procedure from Steps 2 to 9 (on

page 12).

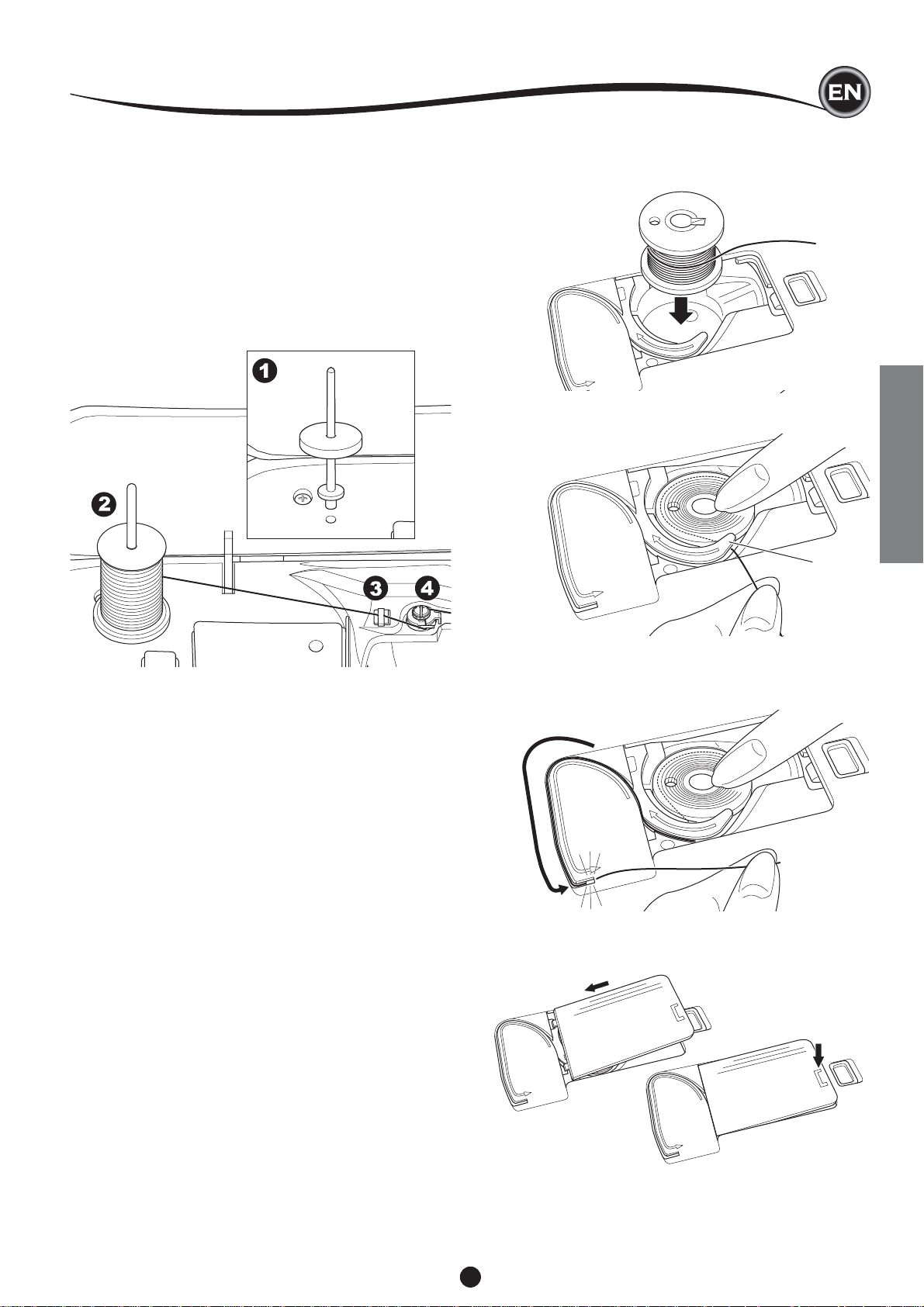

INSERTING THE BOBBIN

1. Place bobbin into bobbin holder, making sure the bobbin

turns in a counter clockwise direction.

2. Draw thread into notch (a) while holding the bobbin.

a

THREADING THE MACHINE

3. Pull thread along the groove, up and around the top, to the

left, then down.

While lightly holding the bobbin in place with your fi nger,

pull the thread to the right to cut the thread.

4. Replace the bobbin cover. Set the left tabs into the holes in

needle plate and push the right side of bobbin cover down

until it clicks into place.

NOTE:

This machine can start to sew without manually drawing up the

bobbin thread.

If you want to draw up the bobbin thread manually, see page

15.

Be sure to use only SINGER® Class 15 transparent bobbins in

this machine.

13

THREADING THE NEEDLE

THREADING THE MACHINE

REPARING TO THREAD MACHINE

P

1. RAISE THE PRESSER FOOT LIFTER. It is very important

to raise the presser foot lifter before you proceed to thread

the machine to ensure proper thread tension.

2. Raise the needle to its highest position by turning the

handwheel toward you.

(Keep this position for threading the eye of the needle.)

NOTE:

It is very important to raise the presser foot lifter before you

thread the machine. Not doing so will likely result in poor

stitch quality, or excessive thread loops on the underside of

the fabric. Always raise the presser foot lifter before you begin

threading the machine.

THREADING THE UPPER THREAD

1. Hold thread in both hands and pass thread into the guide

from front opening.

2. Bring thread backward and pass through the slit from right

to left.

3. Bring thread to the left and pull thread down toward you

along the slit.

4. Pull the thread around the U-turn, then bring it back up.

5. To thread the take-up lever, draw thread up and bring

thread back down again from right to left along the slit.

6. Pull thread downward along the slit.

7. Draw thread through thread guide from right side opening.

8. Pass through needle eye from front to back.

Refer to next page for instructions on how to use the built-

in needle threader.

SETTING SPOOL OF THREAD ON SPOOL PIN

1. Pull up the left end of spool pin and set the felt washer and

the spool of thread on spool pin so that the thread unrolls

from the front of the spool.

Set the spool cap on spool pin as far as it will go.

2.

a. The spool cap can be reversed in order to better

accommodate the size of smaller thread spools.

b. Use the small spool cap when you use cross wound

thread. Leave small opening between cap and spool as

illustrated.

c. Set the thread net over the spool if thread unrolls too

easily.

14

THREADING THE MACHINE

THREADING THE NEEDLE EYE

CAUTION

To prevent accidents:

1. Keep fi ngers away from all moving parts. Special care

is required around the needle.

2. Do not lower the threader lever while machine is

operating.

NOTE:

The needle threader is used for needle sizes 11/80 and 14/90.

1. Lower the presser foot.

2. Check that the needle is raised to its highest position. If it is

not, raise needle by turning the handwheel toward you.

3. Lower the threader slowly and draw thread through thread

guide (a) and pull toward the right.

DRAWING UP THE BOBBIN THREAD

This machine can start to sew without drawing up the bobbin

thread. If you want to start sewing with longer bobbin thread,

draw up the bobbin thread as follows.

1. Insert the bobbin into the bobbin holder as shown on page

13, but do not cut thread.

2. Raise the presser foot.

3. Hold upper thread loosely and turn hand wheel toward you

one complete revolution.

4. Lower the lever as far as it will go. The threader will turn

and the hook pin will go through the needle eye.

5. Draw the thread into the guide, ensuring that the thread is

under the hook pin.

6. Hold thread loosely and release the lever.

As the threader rotates back, the hook pin will pass through

the needle eye, forming a loop of thread.

7. Pull thread out about 10 cm (4 inches) through the needle

eye.

THREADING THE MACHINE

4. Pull upper thread lightly. Bobbin thread will come up in a

loop.

5. Pull both upper and bobbin threads about 10 cm (4 inches)

toward the back of presser foot.

6. Replace the bobbin cover. (See page 13)

15

EMBROIDERY PREPARATION

HOME SCREEN / HOME BUTTON

OME SCREEN (A)

H

When you have attached the embroidery unit correctly, the

Home Screen will appear.

You can start selecting and editing embroidery from this

screen.

HOME BUTTON (B)

You can go back to the Home Screen from anywhere by

pressing the Home Button.

At this time, all selected designs or letters and editing for

embroidery will be cleared.

A

B

THREAD TENSION (D)

This embroidery machine adjusts thread tension automatically.

However, depending on the thread or fabric being used, it

may be necessary to modify the tension setting to achieve the

desired results.

To obtain the desired thread tension, adjust as follows.

i. CORRECT THREAD TENSION

Upper thread appears slightly on the bottom side of fabric.

ii. UPPER THREAD TOO TIGHT

Bobbin thread appears on the top side of fabric.

Decrease the upper thread tension by pressing the “-”

button.

iii. UPPER THREAD TOO LOOSE

Upper thread is loose or makes loops.

Increase the upper thread tension by pressing the “+”

button.

TOP SIDE BOTTOM SIDE

EMBROIDERY MACHINE SETTINGS

ETTING BUTTON (C)

S

Before or during the embroidery process, you can adjust the

machine settings by pressing the Setting Button.

The Setting Screen will appear. (a)

This screen is scrolled by pressing the right side arrow buttons.

Pressing the Setting Button again, machine will return to

previous screen.

NOTE:

All settings except for thread tension will remain until you

change them. Thread tension will return to pre-set when you

change the design.

(a)

D

i

ii

iii

When thread tension is changed from the default (pre-set)

setting, the number will be highlighted.

NOTE:

If the bobbin has been threaded or inserted incorrectly, or if

the upper thread has not been threaded correctly, good thread

tension cannot be achieved. Check to make sure that the

bobbin and upper thread are correctly threaded before making

any adjustments.

C

16

EMBROIDERY PREPARATION

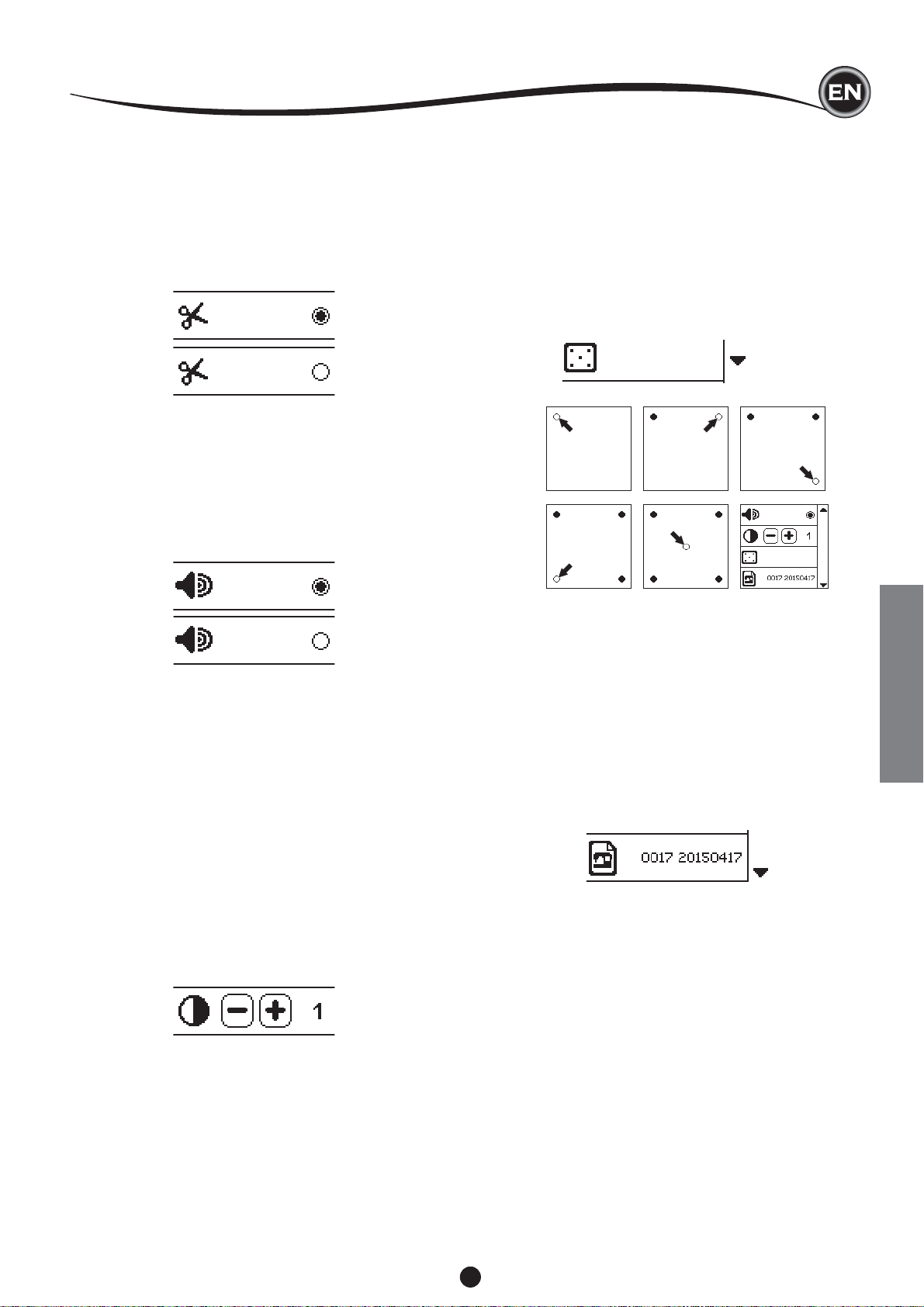

STOP FOR CUT

When starting to embroider, the machine can be set so that it

will stop after a few stitches, allowing you the opportunity to cut

the thread tail.

You can select or deselect this function, as follows:

i. Stop for Cut is activated.

ii. Stop for Cut is deactivated.

i

ii

AUDIBLE BEEP

You can turn the audible beep on or off by pressing this button.

i. Audible Beep is on.

ii. Audible Beep is off.

i

CALIBRATION SCREEN

If the icons on the screen (in relationship to where you touch

the screen) seem misaligned, the screen may need calibrating,

as follows:

1. Scroll down and press calibration screen button.

2. Press the each “O” mark indicated on the screen 5

positions. (4 corners and center)

When calibration is completed, setting screen will appear

again.

1

2

5

3

4

6

ii

CONTRAST OF SCREEN

You can adjust the contrast of the LCD screen.

By pressing “+” or “–” button, contrast will increase or

decrease.

SOFTWARE VERSION

Software version of this embroidery machine will be indicated

at the bottom of this screen.

You can update the software by using the USB embroidery

stick.

(See page 11)

(example)

EMBROIDERY PREPARATION

17

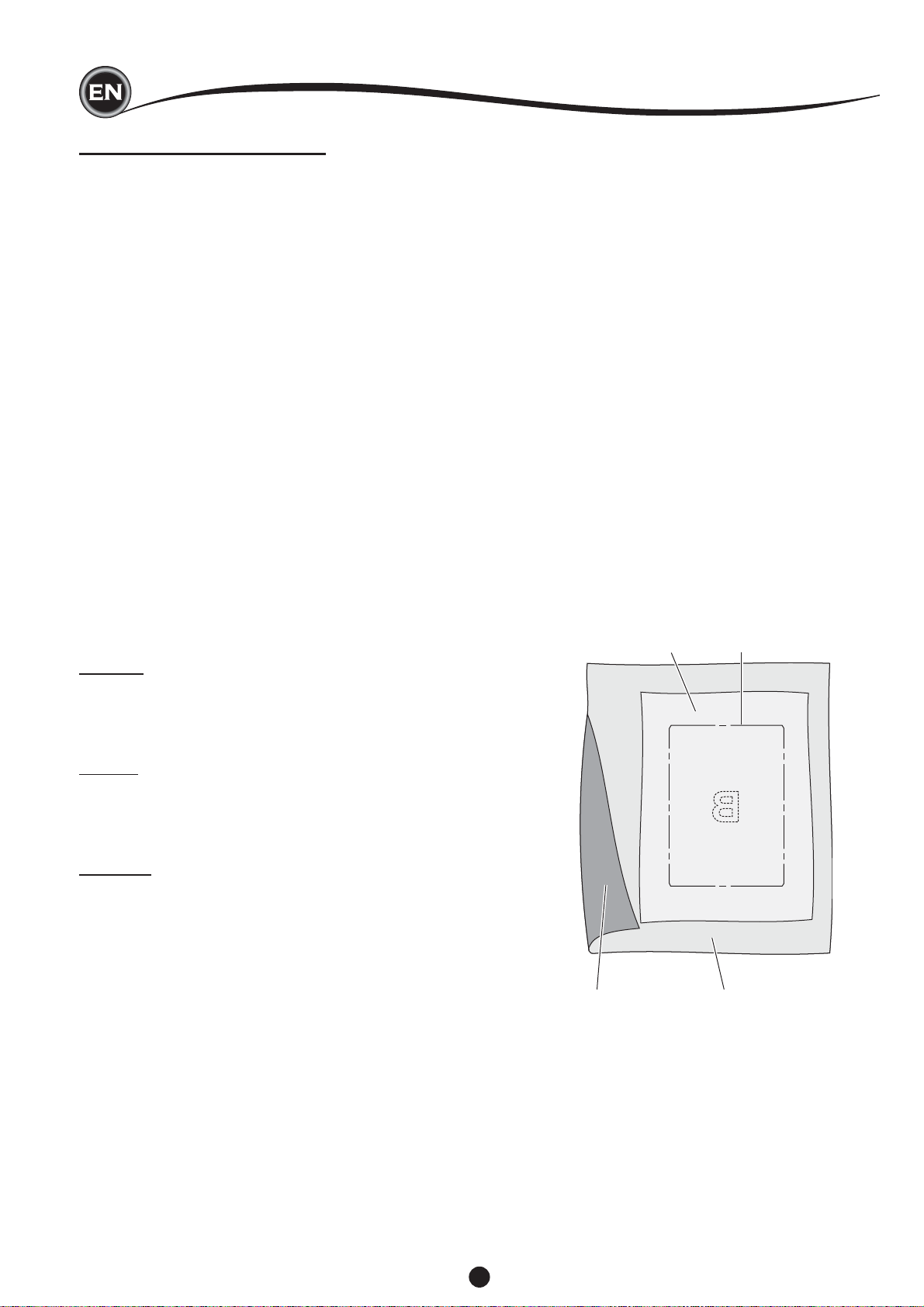

F ABRIC AND ST ABILIZER

Embroidery can be applied to many different types of

fabrics. Regardless of the fabric, it will be necessary to use

an appropriate type of stabilizer. (See page 29 for more

information)

Stabilizer serves as a foundation, holding fabric securely while

the embroidery machine stitches out the design, eliminating

distortion in the fabric and the design.

Different fabrics will require different types of stabilizer,

depending on the nature of the fabric and the density of the

design being embroidered. But most embroidery designs will

stitch out looking their best if the fabric is properly stabilized.

Stabilizer is mainly used as a backing, but at times, a stabilizer

is used on the top of the project as well.

A “Backing” goes on the back side of the area to be

embroidered. It may be hooped along with the fabric or hooped

alone, depending on the fabric and project.

A “Topper” means that an additional stabilizer is placed on the

top of the fabric, either hooped with the fabric or secured in

another manner. Its function is to ensure that the texture or loft

of the fabric is held down, providing a smooth surface for the

embroidery.

Though there are many types of stabilizers available, the most

common types are tear-away, wash away, and cut away.

Stabilizers come in different weights as well. After selecting the

best type of stabilizer for the project, choose the appropriate

weight. A good general rule is that the weight of the stabilizer

be compatible with the fabric.

Tear-away stabilizers are temporary, so once the excess is

removed after embroidering, the fabric itself must be able to

support the design on its own.

Tear-away stabilizers are usually recommended for woven

fabrics.

EMBROIDERY PREPARATION

Generally, the stabilizer should be larger in size than the hoop

with which it is being used. When embroidery is completed,

use a fi ne point scissor to carefully remove any excess

stabilizer from the embroidery area.

a. Stabilizer

b. Hoop position

c. Fabric (Under side)

d. Embroidery surface (Top side)

a

b

Cut-away stabilizers are permanent, and therefore a better

choice for supporting embroidery on unstable fabrics, to

prevent distortion. Simply trim away the excess from around

the design. Even after frequent laundering, the embroidery

design will stay intact.

Wash-away stabilizers rinse away from the embroidered area.

Though they are a good choice when sewing very light weight

fabrics, they can also be used as a topping. After removing the

main excess stabilizer, the rest is simply rinsed away.

There are also fusible and non-fusible version of stabilizer

available. Fusible stabilizers can be ironed onto the back of

the area to be embroidered, preventing distortion of the fabric

while hooping.

However, for fabrics that may be more sensitive to ironing,

the non-fusible stabilizers are used. In these cases, another

helpful tool is a temporary fabric spray adhesive. Use this to

temporarily ‘hold’ the fabrics and stabilizer while hooping and

embroidering, to prevent the fabrics from shifting during the

embroidery process.

Knowing how to properly stabilize involves a little trial and error

at fi rst. Follow the stabilizer manufacturer’s recommendations,

for best results.

cd

18

EMBROIDERY PREPARATION

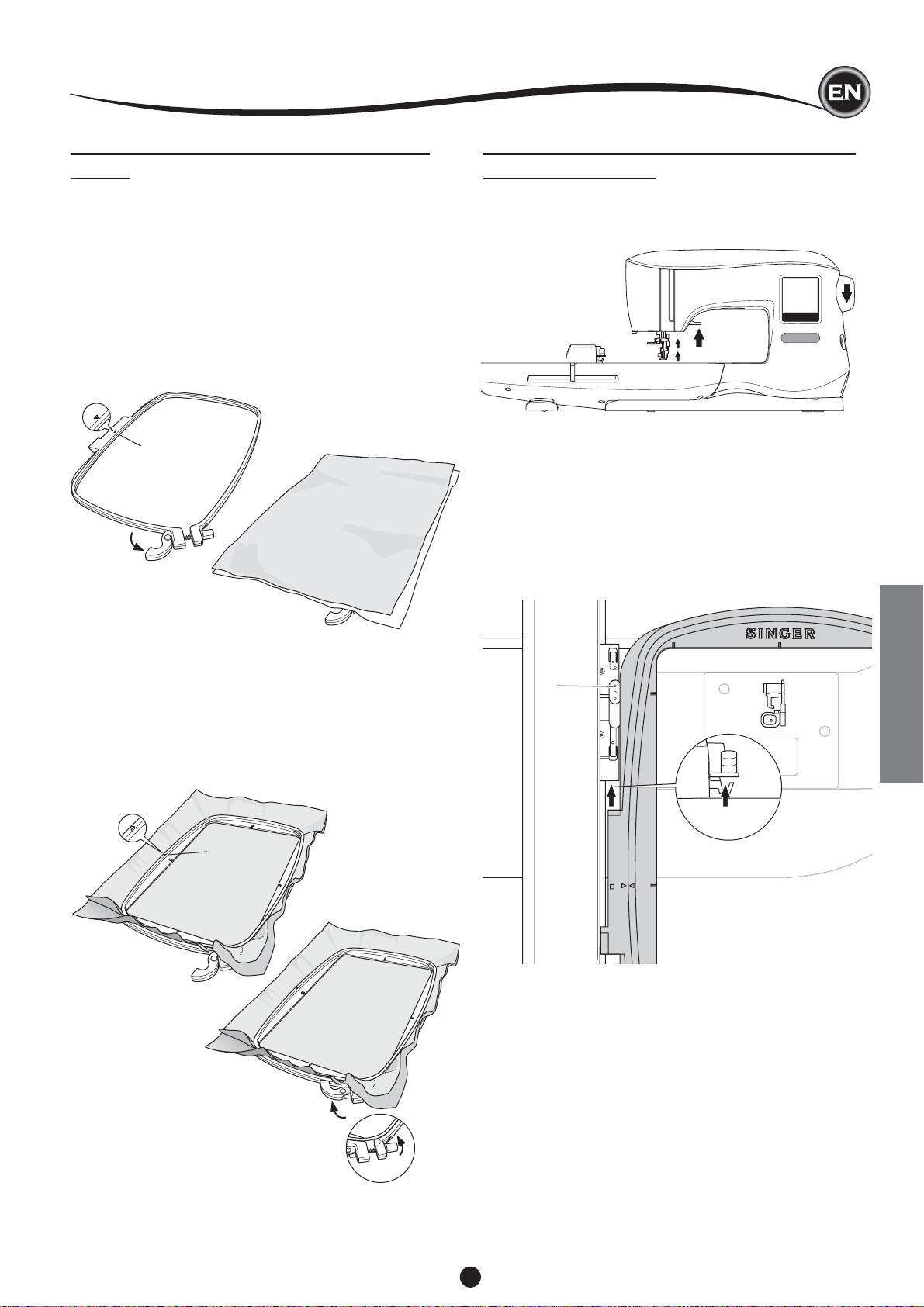

SECURING FABRIC IN EMBROIDERY

HOOP

For the best embroidery results, place a layer of stabilizer

beneath the fabric. When hooping stabilizer and fabric make

sure that they are smooth and securely hooped.

1. Open the quick release lever on the outer hoop and remove

the inner hoop.

2. Place the outer hoop on a fi rm fl at surface with the screw

on the lower right. There is a small arrow in the center of

the left edge of the outer hoop which will line up with a

small arrow on the inner hoop.

3. Place stabilizer and the fabric, with the right sides facing

up, on top of the outer hoop.

2

3

1

ATTACHING THE EMBROIDERY HOOP

TO THE MACHINE

1. Raise the presser foot. Raise the needle to its highest

position by turning the hand wheel toward you.

2. Slide the hoop onto the embroidery unit from front to back

until it clicks into place.

NOTE:

Presser foot lever can be raised and held in a higher position

to help passing the hoop under the foot.

4. Place the inner hoop on top of the fabric with the small

arrow at the left edge and push fi rmly into the outer hoop.

5. Close the quick release lever. Don’t force the quick release

lever. If it seems as though it doesn’t want close, loosen the

retaining screw fi rst and then try closing the quick release

lever again.

6. Adjust the pressure of the outer hoop by turning the

retaining screw. The fabric should be taut in the hoop for

the best results.

4

a

EMBROIDERY PREPARATION

REMOVING THE HOOP FROM THE MACHINE

Press and hold the release lever (a) on the hoop connection

assembly, then slide the hoop toward you.

5

NOTE:

When embroidering additional designs on the same fabric,

open the quick release lever, move the hoop to the new

position on the fabric and close the quick release lever. When

changing type of fabric, you might need to adjust the pressure

using the retaining screw. Do not force the quick release lever.

6

19

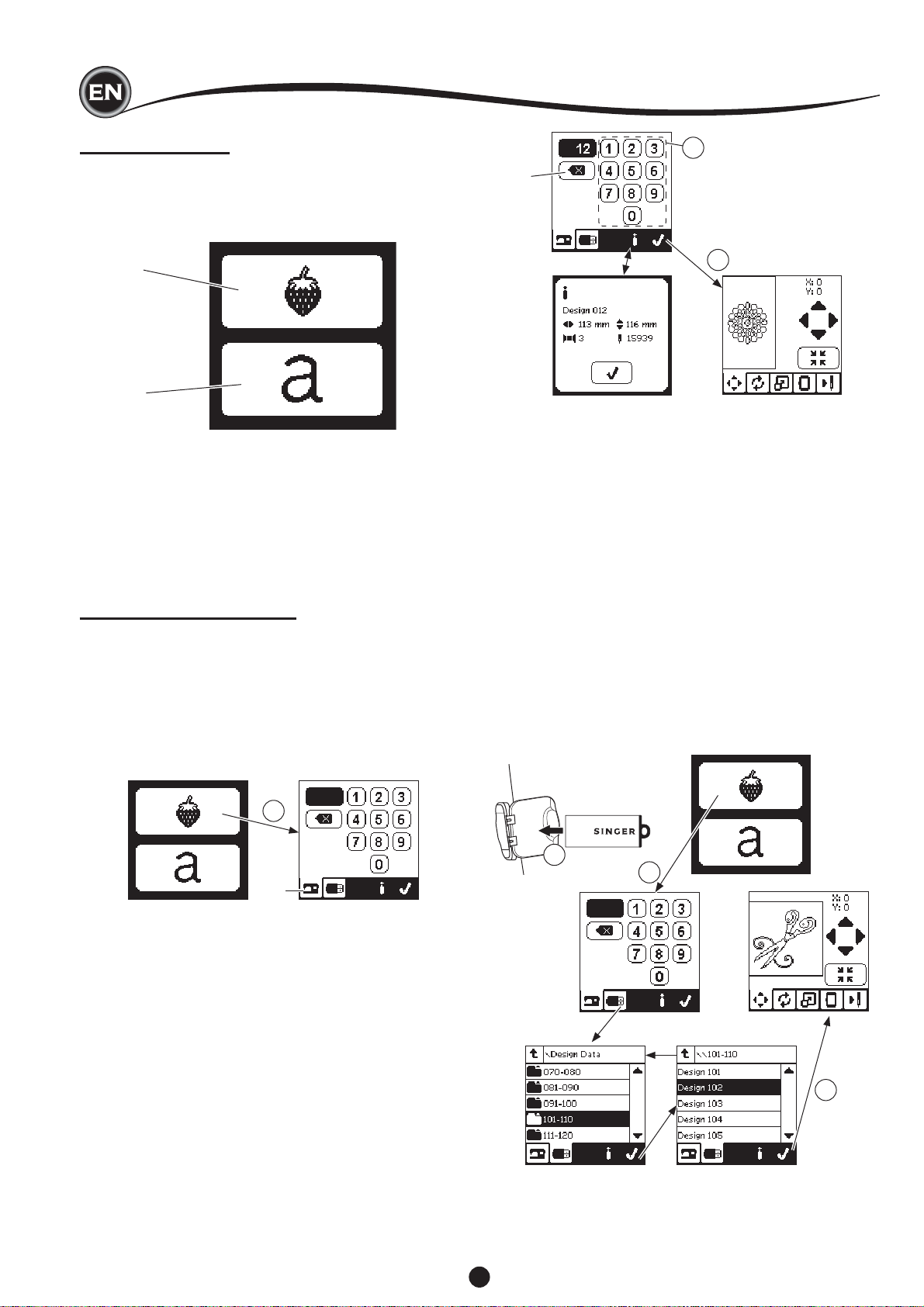

SELECTING DESIGNS

HOME SCREEN

Selecting designs to embroider begins with the Home Screen.

The Home Screen has two main selections.

a. Selecting a design, editing and stitching.

b. Programming letters, editing and stitching.

a

b

EMBROIDERY COLLECTION

Your machine comes with 200 embroidery designs, as well as

embroidery fonts. You will fi nd 69 of these designs, plus the

fonts, built-in to the machine. The remainder of the designs

are on the USB stick.

The USB stick also has 2 PDF fi les with information about the

designs. For more information about this, see page 11.

SELECTING A DESIGN

O SELECT A BUILT-IN DESIGN

T

Your machine has 69 built-in embroidery designs.

1. Press the Design button on the Home Screen.

A ten-key screen will appear.

NOTE:

Press the Machine tab (c) if USB tab is activated.

2

d

e

3

TO SELECT A USB DESIGN

Your machine can read “.xxx” and “.dst” embroidery data

stored in the USB embroidery stick.

1. Insert the USB embroidery stick into the USB socket.

2. Press the design button on the Home Screen and then

press the USB tab (f).

Data list will appear in the screen.

Press the fi le or folder to select or open and press the “✓”

button.

When folder is opened, the list of designs included in that

folder will appear (g).

To go back, press the arrow button on the top line (h).

Press the info button for more information about the

selected design.

NOTE:

If the USB stick or a folder is empty or if readable fi le is not

included, empty mark will appear.

3. When fi le is selected, embroidery placement screen will

appear.

1

c

2. Select the design from the Embroidery Collection and press

the design number on the ten-key screen.

Selected number will appear in the top left of LCD.

To delete a number, press the Delete button (d).

If you want to know about selected design, press the info

button (e). The following information is indicated on the

screen.

i. Design name

ii. Design width & height

iii. Total number of colors

iv. Total number of stitches

By pressing “✓” button, the information will disappear and

ten-key screen will appear again.

3. Press the “✓” button at ten-key screen.

The design is selected and Embroidery Placement screen

will appear.

1

2

f

h

3

g

20

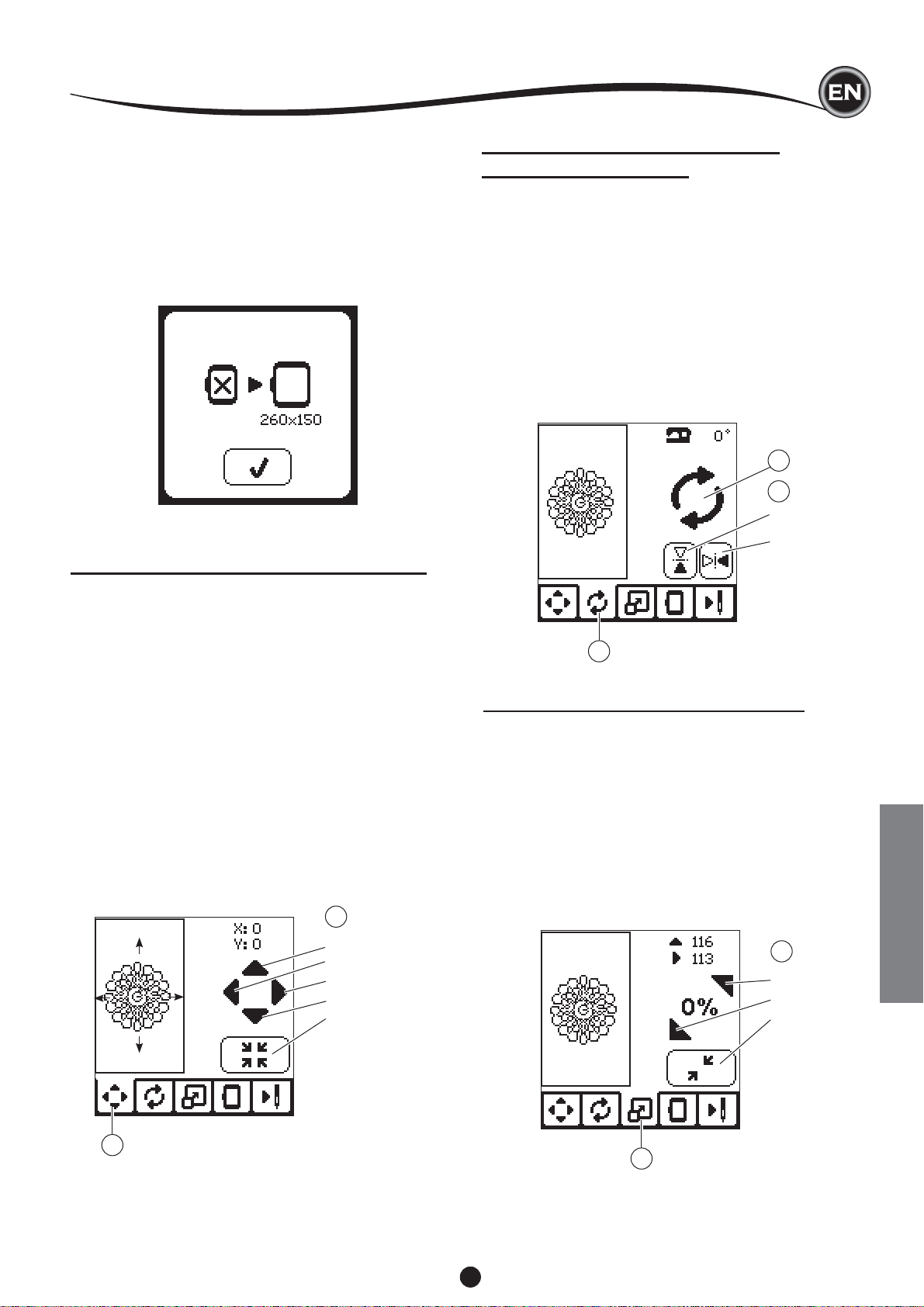

EDITING THE DESIGN

Before you begin embroidering, you can edit designs, as

shown below, using the Edit tabs.

NOTE:

The pop up message may appear if you did not attach the

correct hoop.

Press “✓” button and attach the hoop indicated in this message

or change hoop size setting at the Embroidery Option screen

(Next page).

EMBROIDERY PLACEMENT SCREEN

You can move the placement or position of the selected

embroidery design, as follows:

1. Press the Embroidery Placement tab.

(When you have selected the design, this screen will

appear fi rst.)

2. Press the four arrow buttons to move the position.

a: up, b: left, c: right, d: down

The hoop will move according to the direction selected.

Each time the button is touched, the hoop will move. If the

button is touched and held, the movement will occur in

larger increments.

The values (X:Y:) near the top of the screen indicate

distance from center position.

NOTE:

The left side of screen is indicating embroidery fi eld and

relative design position and size.

When you edit the design, this fi eld will redraw according to

your editing.

EMBROIDERY ROTATION AND

MIRRORING SCREEN

1. Press the Embroidery Rotate and Mirroring tab.

2. Press the Rotate button. By pressing this button, the design

will rotate 90 degrees clockwise. If the design is too wide or

too high to rotate 90 degrees, it will rotate 180 degrees.

The total rotation value will be indicated at the top right of

the LCD screen. Located to the left of the rotation value is

a ‘machine icon’, which will rotate as the rotation value is

changed.

3. Press the Mirror buttons.

a. Mirror from top to bottom

b. Mirror from side to side

The ‘machine icon’ (located near the top of the LCD screen)

will invert according to the selections made, indicating the

new orientation of the embroidery design.

2

3

a

b

1

EMBROIDERY SCALING SCREEN

1. Press the Embroidery Scaling tab.

2. To increase the scale, press the upper arrow button (a).

To decrease the scale, press the lower arrow button (b).

The design will be scaled 5 percent each pressing on a

button.

The maximum scaling is +/- 20 percent.

If scaling is over the hoop size, it cannot be selected.

To return to original size, press the button (c).

The value of scale is indicated between the buttons, and

size of scaled design is indicated on the top line of screen.

2

a

b

c

d

e

1

1

21

2

a

b

c

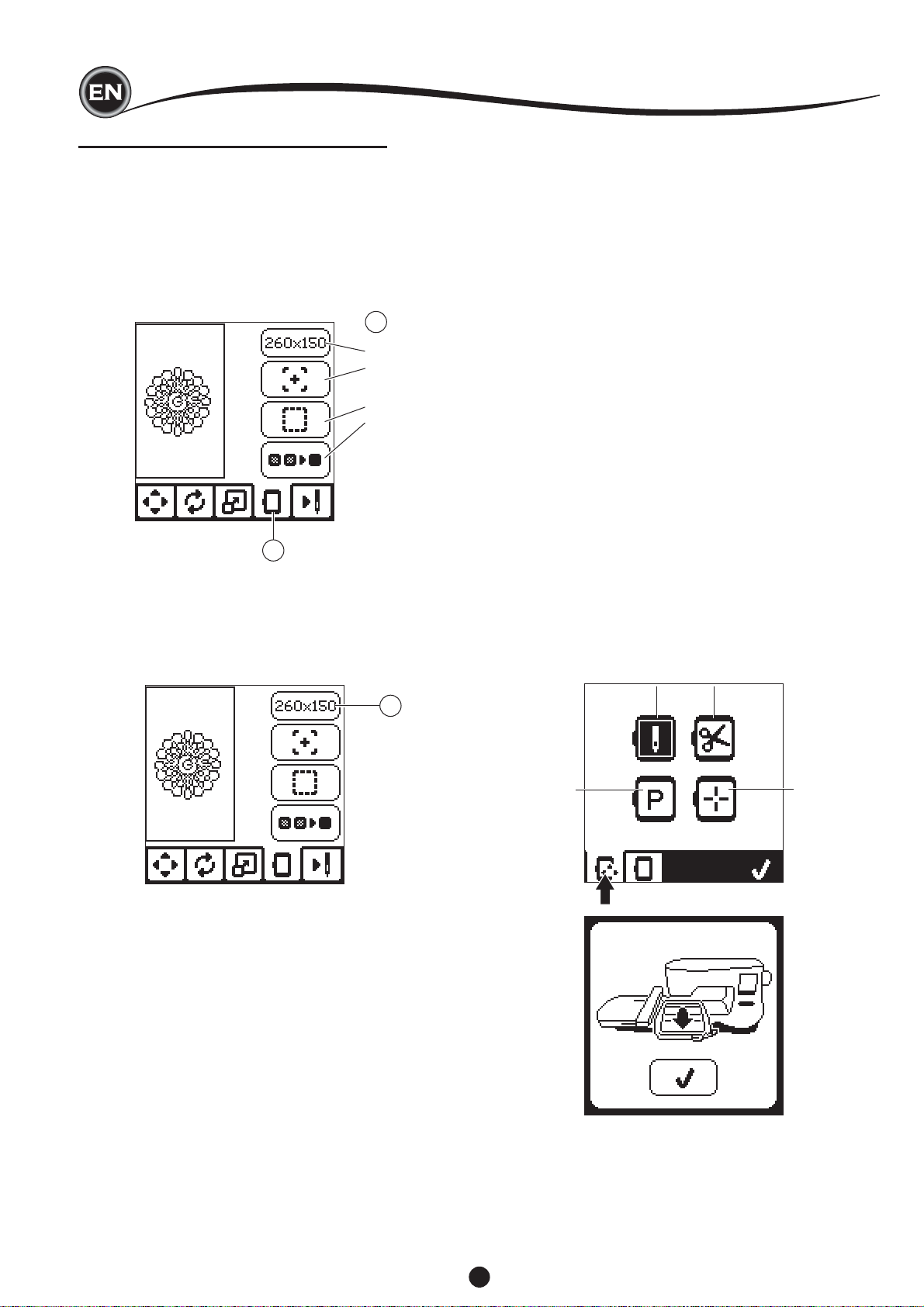

EMBROIDERY

EDITING THE DESIGN

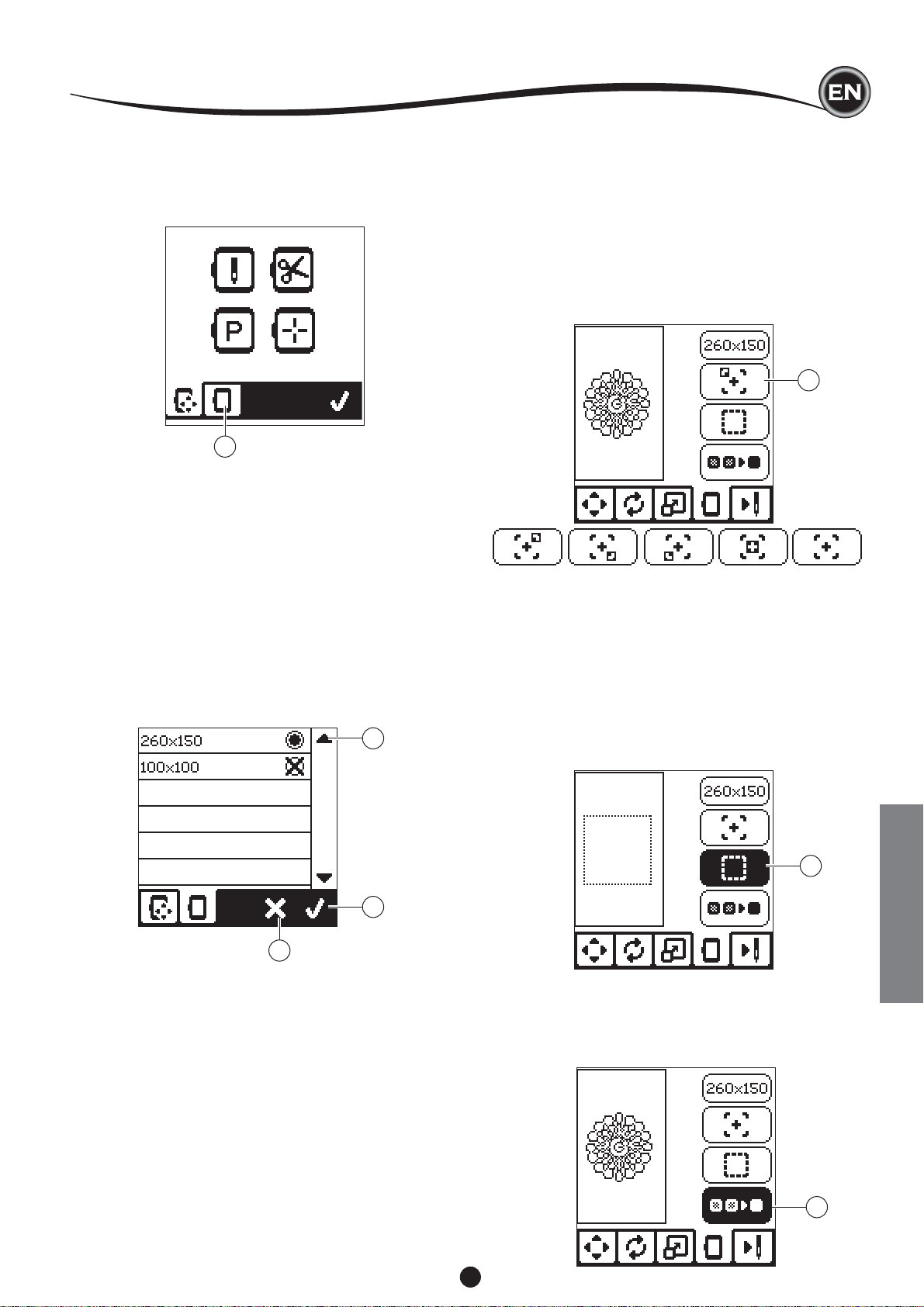

EMBROIDERY OPTION SCREEN

1. Press the Embroidery Option tab.

2. You can access embroidery options by pressing the

buttons, as shown below:

A. Hoop Option and Selection

B. Tracing

C. Basting

D. Monochrome

2

A

B

C

D

1

HOOP OPTION AND SELECTION (A)

The top right button indicates the hoop size selected. Press

this button to move the hoop position or to change the hoop

size.

HOOP OPTION - MOVING HOOP POSITION

When you press the Hoop Option and Selection button, the

Hoop Option screen will appear fi rst.

You can move the hoop position as follows:

i. Current Position:

When you want to return to the current stitch and start

embroidering again where the embroidery was interrupted,

press this button.

Hoop will move to current positon and return to embroidery

option screen.

NOTE:

You can also press the “✓” button to return to current

positon and embroidery option screen.

ii. Cut Position:

By pressing this button, move the hoop towards you,

making it easier to trim fabric when embroidering an

appliqué.

iii. Park Position:

When your embroidery is fi nished and you want to store

your machine, it will be necessary to move the hoop

carriage to Park position. Press the Park position button.

When the pop-up message (v) appears, remove the hoop

and press the “✓” button. The carriage will then move to

the correct position for storage.

Then, turn off the power switch and remove the unit.

NOTE:

It is very important that the hoop is removed, otherwise it

may be damaged.

iv. Center Position:

If you want to check where the center position of the hoop

will be placed on the fabric, press this button.

i

ii

A

iii

v

NOTE:

When hoop is not attached, buttons “ ii, iv “ will not activate.

iv

22

EDITING THE DESIGN

HOOP SELECTION

When you select the design, machine will select most suitable

hoop automatically.

1. To change the hoop, press the second tab to open the hoop

list.

1

2. Select the hoop you want to use.

The hoop list can be scrolled by pressing the right side

arrow buttons.

Only hoops that are big enough for the selected design will

be possible to select.

Hoops that are too small are marked with an X and cannot

be selected.

Selected hoop is marked with a black dot.

✓

3. Press the ”

embroidery option screen will appear.

At this time, all edits (rotation, mirroring and scaling) will be

reset. If you don’t want this, press the “X” button (e). Hoop

size and edits will not change and return to the Embroidery

Option Screen.

” button. Hoop size will change and the

2

TRACING (B)

The Tracing function can be used to trace around the design

area. Press the second button to move the hoop so the needle

is placed in the upper left corner of where the design will be

embroidered. Each press of the button will move the hoop to

view all corners of the design.

On the fi fth press, the hoop will move to the center position

of the design and on the sixth press it will move back to its

original position.

The Tracing button will indicate the position by highlighting

mark.

B

BASTING (C)

By pressing the third button and pressing the Start/Stop button,

machine will sew a basting stitch around the design area as a

box.

Basting enables you to secure your fabric to a stabilizer placed

beneath it, especially when the fabric to be embroidered

cannot be hooped. Basting can also provide added support,

especially for unstable fabrics.

NOTE:

During basting, the design box will be indicated with a dashed

line and basting button will be highlighted.

3

e

NOTE:

If the hoop you have selected is not the same as the hoop

attached to the embroidery unit, a pop-up will appear to inform

you of this. Attach the correct hoop or select another hoop

from the list.

Hoops 260x150 and 100x100 are provided with this machine.

C

EMBROIDERY

MONOCHROME (D)

Press the fourth button to activate monochrome embroidery.

The machine will not stop for color block changes. Press the

button again to deactivate monochrome embroidery.

When monochrome is activated, this button will be highlighted.

D

23

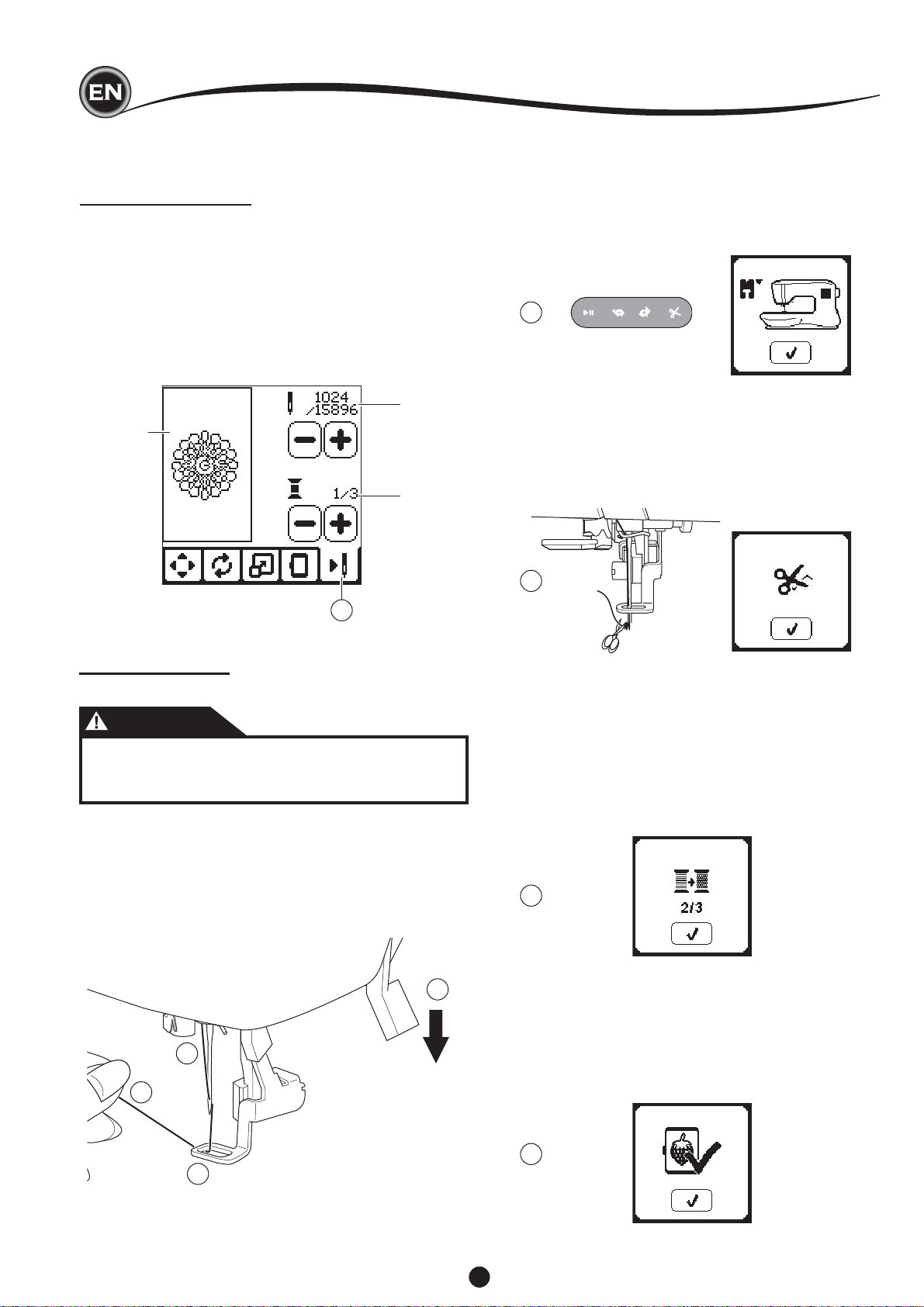

SEWING DESIGN

When you complete editing the design, press the Stitch Out

tab to start sewing.

SEWING SCREEN

When you press the Stitch Out tab (A), the Sewing Screen will

appear.

a. Embroidery fi eld and position

b. Stitches left in color block / Total number of stitches left in

design.

By pressing -/+ buttons, stitch will go backward/forward.

c. Current color / Total number of colors

By pressing -/+ buttons, color block will go backward/

forward.

b

a

c

6. Press the Start/Stop button.

The machine will start embroidering the fi rst color of the

design.

NOTE:

If presser foot lifter is raised at this time, the pop up

message will appear. Lower the foot and press the “✓”

button.

6

7. When Stop for Cut setting is on, machine stops

automatically after few stitches for cut thread end. A pop up

appears asking you to cut thread end. Cut thread end and

press the “✓” button. Continue embroidering by pressing

Start/Stop button.

7

A

START TO SEW

1. Thread the upper thread with the fi rst color.

CAUTION

To avoid injury:

Special care is needed for the needle when changing

the upper thread.

2. Pass the upper thread through the hole of the Embroidery

Foot from the top side.

3. Lower the presser foot lifter.

4. Hold the upper thread.

5. Clear suffi cient space to accommodate movement of the

carriage and the hoop.

3

1

4

8. When embroidering is completed, machine will stop

automatically and cut upper thread.

A pop up will appears asking you to change color. Re-

thread with the next color and press “✓” button. Continue

embroidering by pressing Start/Stop button.

Each color segment is tied of at the end and the upper and

bobbin threads are cut.

8

9. When the embroidery is completed, your machine cuts both

threads and stops.

A pop-up informs you that your embroidery is fi nished.

Then press “✓ button.

Raise the presser foot and remove the hoop.

9

2

24

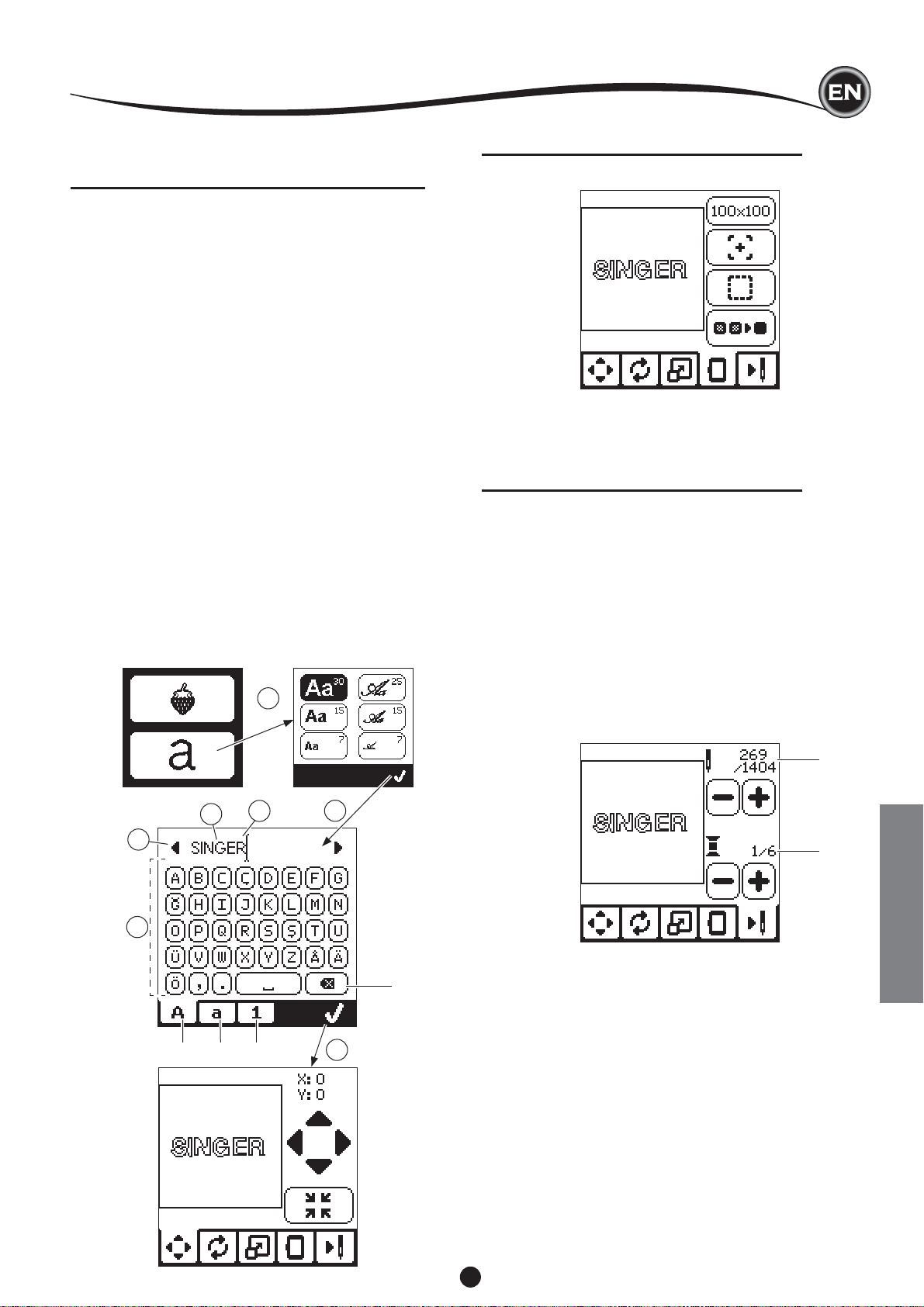

EMBROIDERY LETTERS

You can select from 2 different font styles.

SELECTING EMBROIDERY LETTERS

1. Press the Font button on the Home Screen.

The Font Selection screen will appear.

2. This machine has 2 fonts and each font has 3 sizes.

Press the button for the font you want to sew, and then

press the “✓” button.

The uppercase letter screen will appear.

3. Select the letters you want to embroider.

To change to different types of characters, press the

tab that contains the desired characters, as follows:

a. Uppercase letters

b. Lowercase letters

c. Numeric letters and special letters

4. Selected letter will be added to the top line.

5. The arrow buttons on top line will move the cursor.

6. To insert the letter, move the cursor to the inserting point

and select letter.

To delete the letter, move the cursor to the right side of the

letter to be deleted, then press the delete button (d).

7. When sequence of letters is completed, press the "✓" mark.

The Sewing Screen will appear.

NOTE:

If no letters are selected, the Home Screen will appear.

✓

You can return to letter selecting mode after pressing "

by pressing home button.

You can add letters until largest hoop height (If width of

letters exceeds maximum width of hoop, 90 degree rotate

automatically).

1

" mark

EDITING EMBROIDERY LETTERS

Lettering can be edited, similar to the way designs can be

edited.

SEWING EMBROIDERY LETTERS

Sewing embroidery letters works in the same way as sewing a

design.

When stitching lettering, the values appear on screen.

a. Stitches left in current letter / Total number of stitches left

all letters

b. Current letter / Total number of all letters

The machine will stitch each letter, cutting the threads between

each letter.

NOTE: If desired, you can select the Monochrome function (see

page 23) so that all letters will sew without cutting between

each letter, cutting only at the end.

5

3

abc

a

4

6

2

b

EMBROIDERY

d

7

25

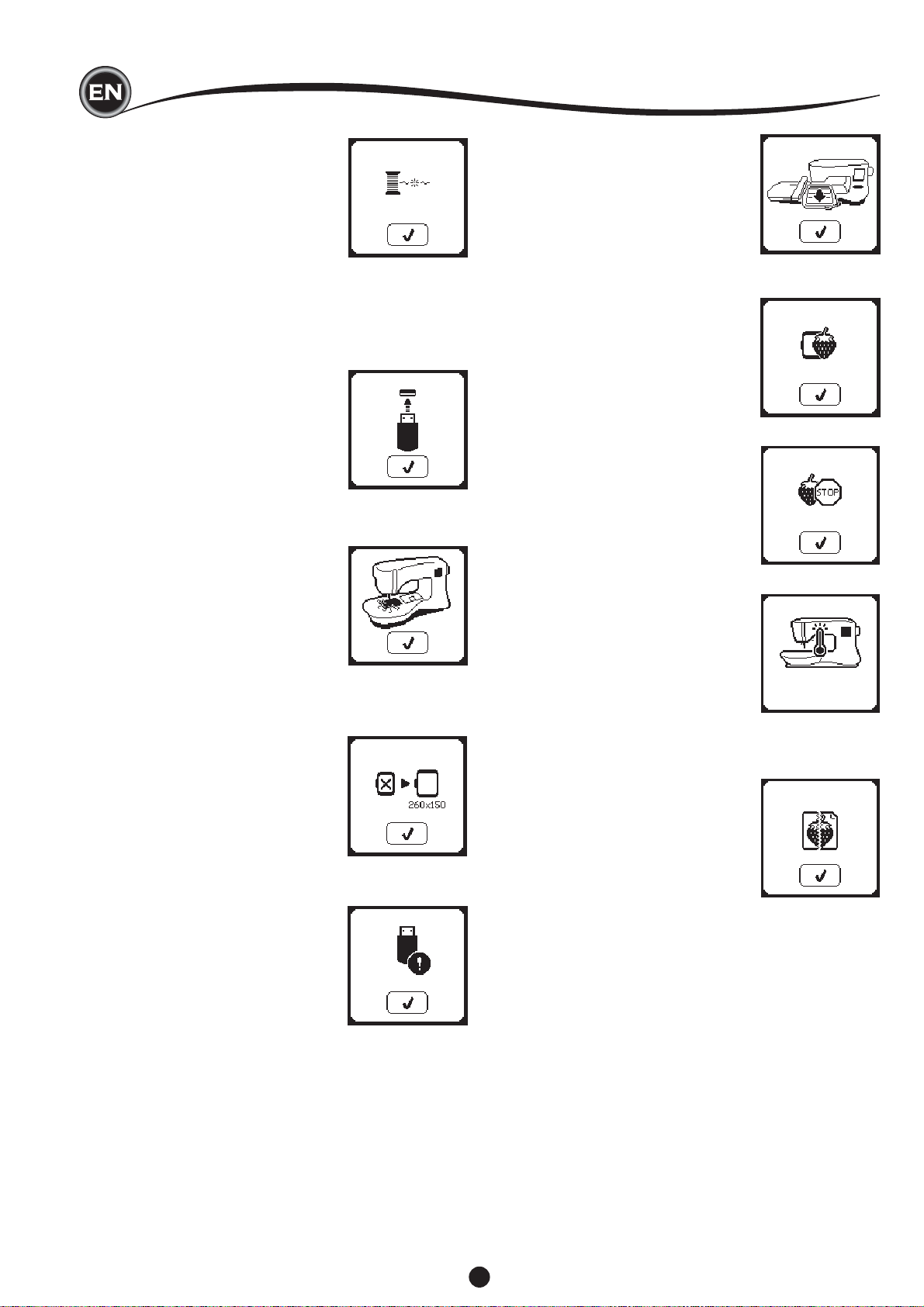

POP-UP MESSAGES

UPPER THREAD BREAKAGE

When the upper thread breaks or

runs out, this pop-up will appear

and sewing will stop.

Re-thread the upper thread and

press “✓” button.

Go back 3-4 stitches backward

from broken point by pressing “-”

at sewing screen.

Press the Start/Stop button to

restart sewing.

CONNECT USB

This pop-up will appear if the USB

button is pressed without any

USB stick connected or if the USB

stick is removed during browsing

of the stick or removed when

embroidering.

Connect USB stick and press the

“✓” button.

THREAD JAM

If upper or bobbin thread is

jammed under the needle plate,

machine will stop and pop-up this

message.

Remove the hoop and needle

plate (see next page) Remove the

thread jam and reset needle plate.

Press the “✓” button.

WRONG HOOP TYPE

This pop-up will appear when

the selected hoop in the hoop

selection list is not the same

as the hoop attached to the

embroidery unit. Attach the correct

hoop type and press the “✓”

button.

REMOVE THE HOOP

This pop-up will appear when a

function has been chosen that the

forces the embroidery unit to move

outside the limits for the attached

hoop. In order for the carriage to

move freely, remove the hoop and

then press the “✓” button.

EMBROIDERY TOO LARGE

This pop-up will appear if a design

is too large for this machine to

read from USB stick.

STOP COMMAND IN DESIGN

This pop-up will appear when

there is a programmed stop in

the design. The machine will

stop. Press “✓” button to continue

embroidering.

MAIN MOTOR OVERLOAD

If you are sewing on very heavy

fabric or if the machine is blocked

when sewing, the main motor can

get overloaded and the machine

will stop sewing. The pop-up

message will close when the

main motor and power supply are

secure.

CORRUPTED DATA

This pop-up will appear when

the content of the USB memory

is corrupted and cannot be read

correctly.

THE DATA ON THE USB

STICK CANNOT BE READ

This pop-up will appear when

your embroidery machine cannot

access the information on the

USB stick. This can be caused

by wrong fi le formats on the USB

stick, the USB stick could be

damaged or you might be using a

USB stick that is non-compatible

with this machine.

26

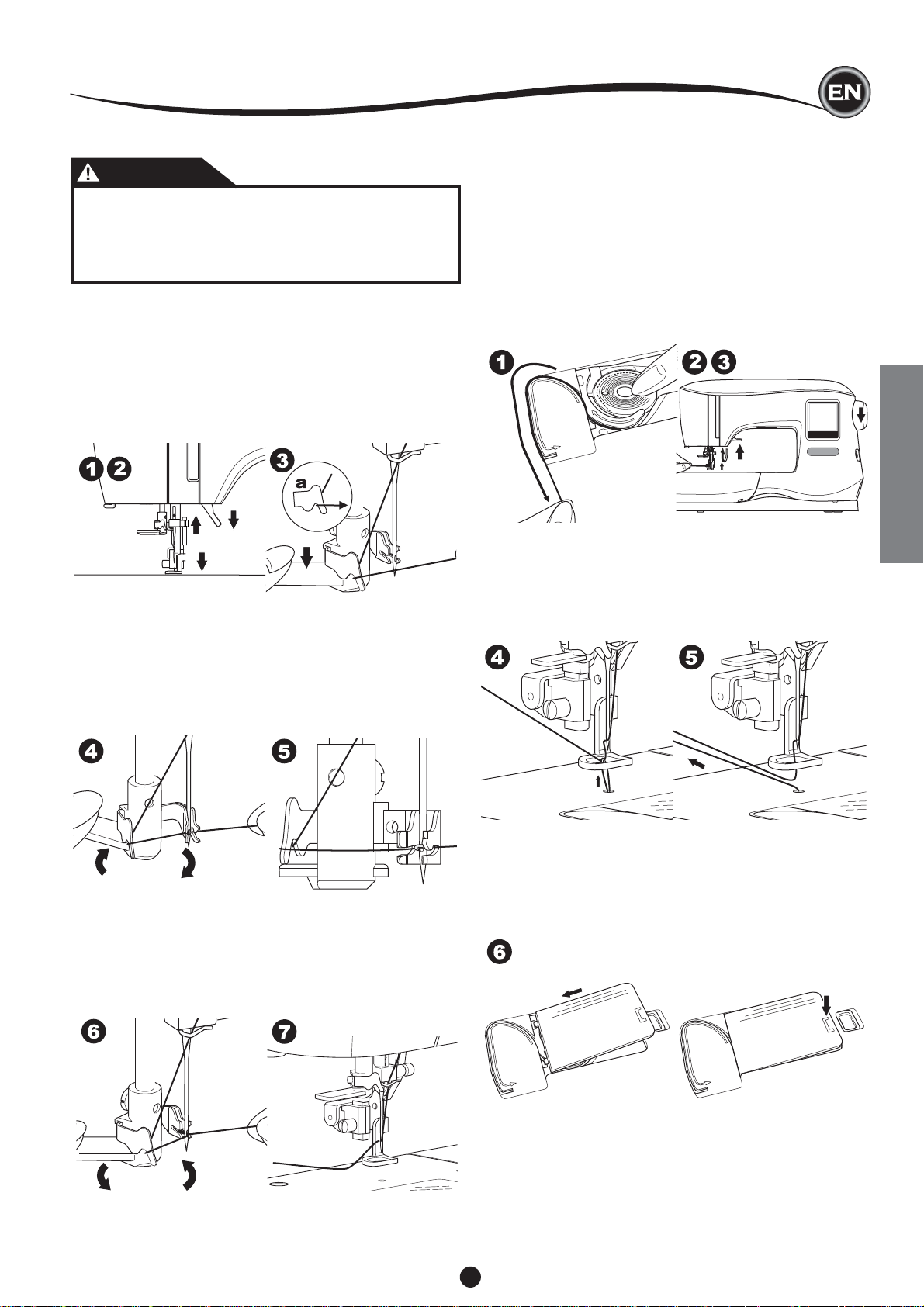

MAINTENANCE

CAUTION

To reduce the risk of electric shock, disconnect the

power line plug from the electric outlet before carrying

out any maintenance.

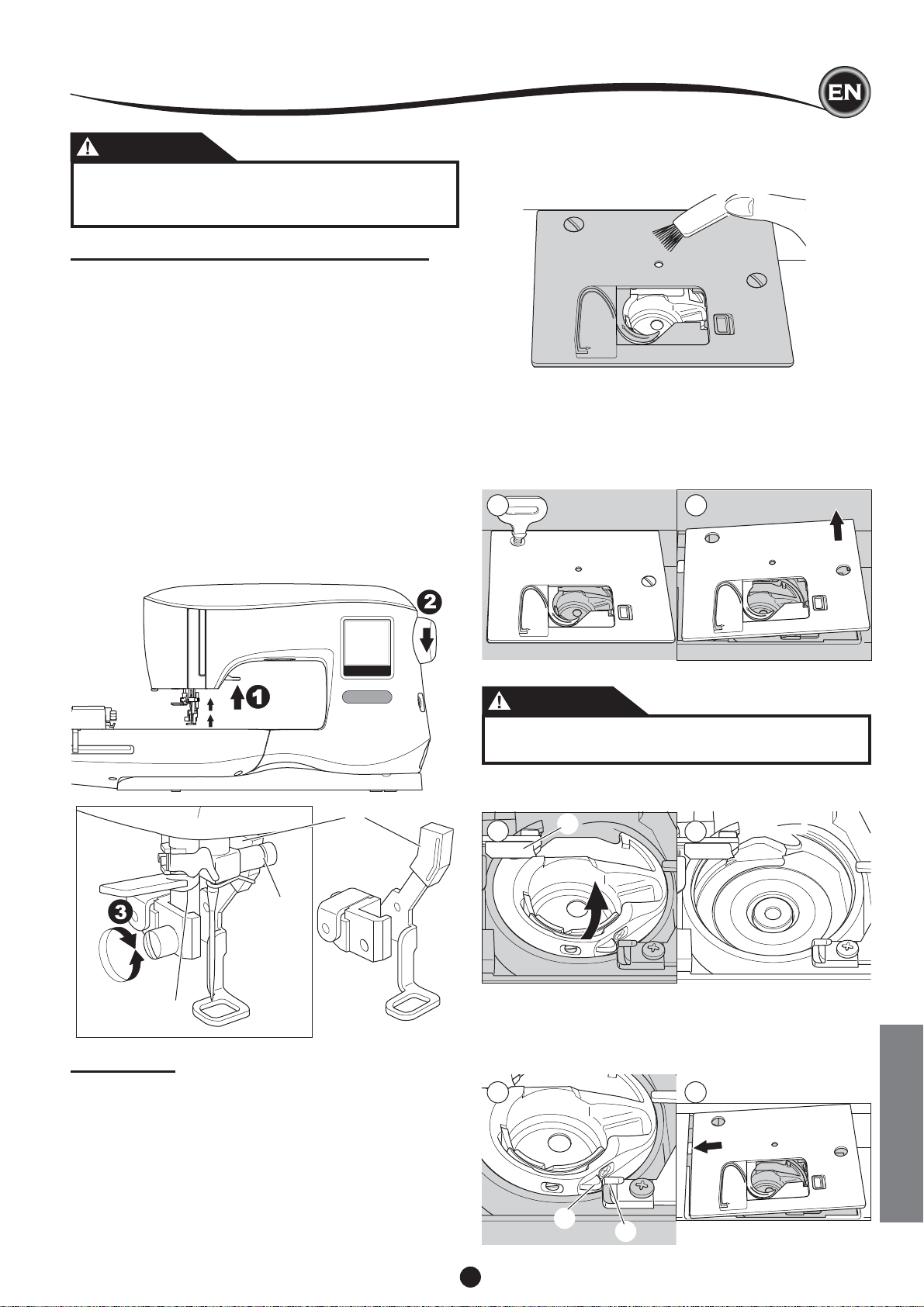

REMOVING THE EMBROIDERY FOOT

When cleaning the machine, you should remove the

embroidery foot.

1. Turn the hand wheel toward you until the needle is at its

highest position.

2. Raise the presser foot lifter.

3. Remove the presser foot screw and remove the embroidery

presser foot.

ATTACHING THE EMBROIDERY FOOT

1. Turn the hand wheel toward you until the needle is at its

highest position.

2. Raise the presser foot lifter.

3. Attach the embroidery foot to the presser bar (a) so that the

arm (b) of foot rest securely on the shaft (c) of the needle

clamp.

Attach the presser foot screw and tighten it.

(It may be helpful to lower the needle slightly when

attaching the presser foot and presser foot screw.)

BOBBIN HOLDER

Remove the bobbin cover and bobbin.

Clean the bobbin holder with a brush.

HOOK RACE AND FEED DOG

1. Remove the needle, presser foot and holder. Remove the

bobbin cover and bobbin. Remove the screws holding the

needle plate.

2. Remove the needle plate by lifting up the right side of the

plate.

1 2

b

c

a

CLEANING

If lint and bits of thread accumulate in the hook, this will

interfere with the smooth operation of the machine. Check

regularly and clean the stitching mechanism as needed.

3. Lift up the bobbin holder and remove it.

CAUTION

To prevent accidents, do not touch the thread cutter

unit (a).

4. Clean the hook race, feed dogs and bobbin holder with a

brush. Also clean them, using a soft, dry cloth.

3

5. Replace the bobbin holder into the hook race so that the tip

(b) fi ts to the stopper (c) as shown.

6. Replace the needle plate inserting the hook into the

machine.

Replace the screws and tighten.

5 6

a

4

NOTE:

* An LED lamp is used to illuminate the stitching area. It does

not require replacement. In the unlikely event it does not

light up, call your authorized SINGER® retailer for service.

* There is no need to lubricate this machine.

MAINTENANCE

b

c

27

HELPFUL HINTS

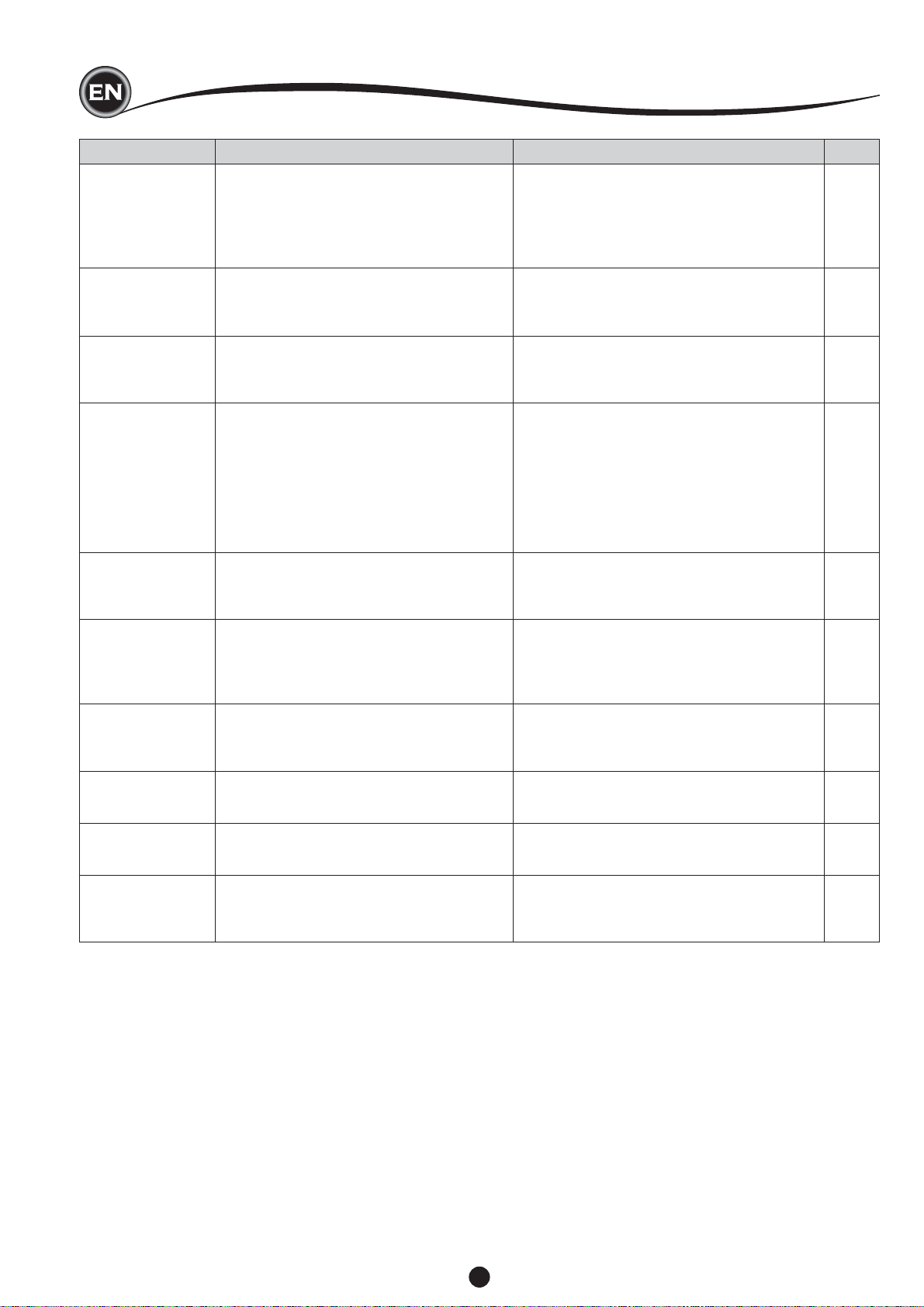

PROBLEM

Upper thread

breaks

Lower thread

breaks

Machine skips

stitches

Fabric puckers

Machine makes

loose stitches or

loops

CAUSE

Machine not properly threaded.

Thread entwined around bobbin.

Needle inserted incorrectly.

Thread tension too tight.

Thread of incorrect size or poor quality.

Bobbin threaded incorrectly.

Bobbin wound unevenly or too full.

Dirt or lint in the bobbin holder.

Needle inserted incorrectly.

Bent or blunt needle.

Incorrect size of needle.

Machine not properly threaded.

Bobbin threaded incorrectly.

Blunt needle.

Thread tension too tight.

Design too dense for fabric being

embroidered.

Insuffi cient stabilizer.

Bobbin threaded incorrectly.

Machine not properly threaded.

Tension not adjusted properly.

CORRECTION

Re-thread machine.

Remove entwined thread.

Re-insert needle.

Readjust thread tension.

Choose correct thread.

Re-thread the bobbin.

Rewind the bobbin.

Clean the holder.

Re-insert needle.

Insert new needle.

Choose correct size needle for fabric.

Re-thread machine.

Re-thread the bobbin.

Insert new needle.

Readjust thread tension.

Select less dense design for fabric, or change

fabric type.

Use proper stabilizer for fabric being

embroidered.

Re-thread the bobbin.

Re-thread machine.

Readjust thread tension.

Page

14

13

7

16

7

13

12

27

7

7

7

14

13

7

16

20

18

13

14

16

Stitch pattern is

distorted

Threader does not

thread to needle

eye

Needle breaks

Machine runs with

diffi culty

Machine will not

run

Hoop or carriage is interferred.

Thread tension is not balanced.

Insuffi cient stabilizer.

Needle is not raised to highest position.

Needle inserted incorrectly.

Bent needle.

Needle inserted incorrectly.

Incorrect size needle or thread for fabric.

Dirt or lint accumulated in the hook race.

Cord not plugged into electrical outlet.

Power switch is not turned on.

Presser foot is not lowered.

Remove obstruction.

Adjust the thread tension.

Use proper stabilizer for fabric being

embroidered.

Raise the needle.

Re-insert needle.

Insert new needle.

Re-insert needle.

Choose correct size needle and thread.

Remove the needle plate and bobbin holder

and clean the hook race.

Insert plug fully into outlet.

Turn on the switch.

Lower the foot.

24

16

18

15

7

7

7

7

27

8

8

10

28

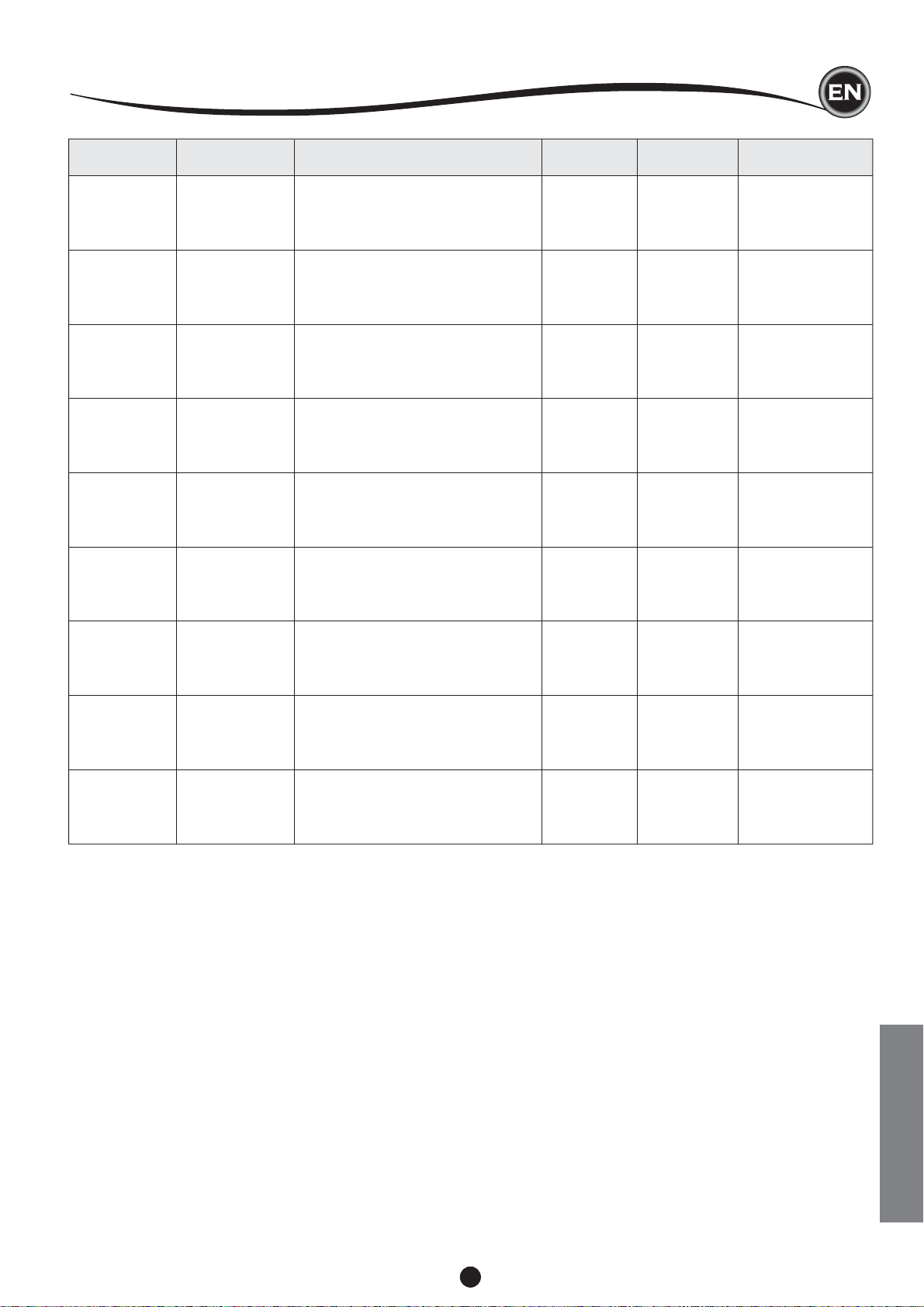

HELPFUL HINTS

PROJECT STABILIZER HOOPING NEEDLE

SINGER

T-Sh irts

Soft Mesh

Cut-Away

Hoop fabric and stabilizer together.

Chromium

Size 11/80

SINGER

Chromium

Size 14/90

Fleece

Cut-Away and

Topper

Hoop cut-away stabilizer. Pin topper

and fleece to the hooped cut-away

stabilizer.

SINGER

Towe ls

Topper and

Tear-Away

Hoop tear-away stabilizer. Pin topper

and towel to the hooped tear-away.

Chromium

S

SINGER

Chromium

Size 14/90

Sweater Knits

Cut-Away

Stabilizer

Hoop cut-away stabilizer. Pin topper

and sweater to the hooped cut-away

stabilizer.

SINGER

Light Weight

Fabrics

Water-Soluble,

Light Tear-Away

Hoop fabric & stabilizer together.

Chromium

Size 11/80

Medium to

Heavy Woven

Fabrics

Medium to Heavy

Weight Tear-Away

Hoop fabric and stabilizer together.

SINGER

Chromium

Size 14/90

SINGER

Denim

Medium to Heavy

Weight Cut-Away

Hoop fabric and stabilizer together.

Chromium

Size 14/90

Medium to Heavy

Napped Fabrics

Weight Cut-Away

and Topper

Vinyl & Leather Cut-Away

Hoop cut-away stabilizer. Pin topper

and fabric to the hooped cut-away

stabilizer.

Hoop cut-away stabilizer. Secure

fabric to the hooped cut-away

stabilizer.

SINGER

Chromium

Size 1

SINGER

Chromium

Size 14/90

#2001

#2001

#2000

ize 14/90

#2001

#2000

#2000

#2000

#2000

4/90

#2000

BOBBIN

THREAD

®

NEEDLE THREAD

Bobbinfill Polyester or Rayon

®

Bobbinfill Polyester or Rayon

®

Same color as

needle thread

®

or towel

recommended

Bobbinfill Polyester or Rayon

®

Bobbinfill

®

Rayon is most often

Bobbinfill Polyester or Rayon

®

Bobbinfill Polyester or Rayon

®

Bobbinfill Polyester or Rayon

®

Bobbinfill Polyester or Rayon

Polyester is

used

NOTE:

Though the SINGER® Chromium needles are recommended for machine embroidery, it is possible to substitute, as follows:

In place of SINGER® Chromium 2000 needles, use SINGER® Regular Point needles for woven fabrics.

In place of SINGER® Chromium 2001 needles, use SINGER® Ball Point needles for stretch knit fabrics.

Follow the guidelines in the chart above regarding the size of needle, depending on the fabric to be embroidered.

29

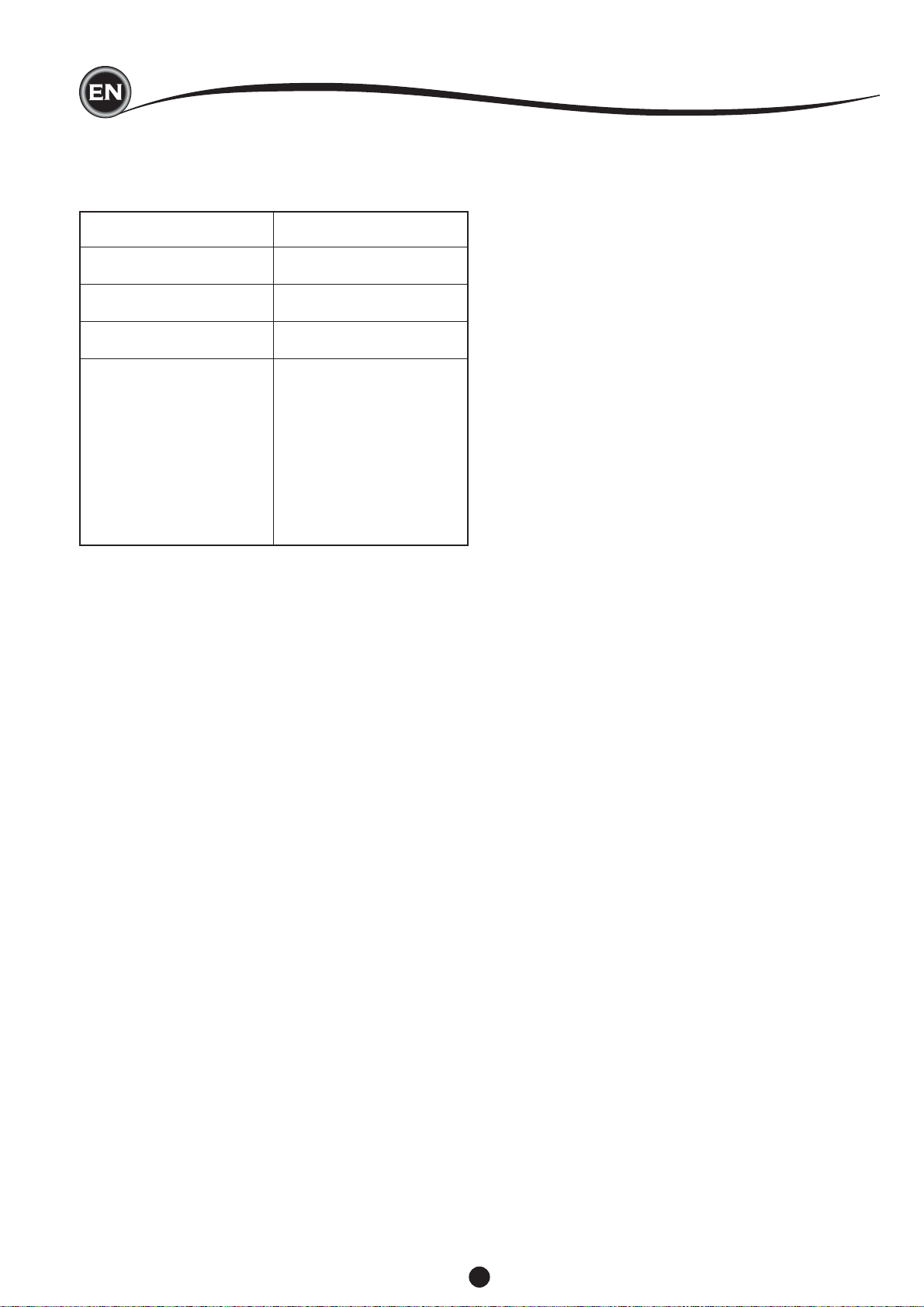

MAINTENANCE

Rated voltage 100–240V ~ 50–60Hz

Nominal consumption 55W

Light LED

Sewing speed 700 rpm maximum

Machine dimensions:

Length (mm) 470

Width (mm) 750

Height (mm) 315

Net weight (kg) 10.2

TECHNICAL SPECIFICATION

• The technical specifi cations and this Instruction manual can be changed without prior notice.

30

Loading...

Loading...