Page 1

SINGER

414

Page 2

Instructions for using SINGER

Form 30-008 G (1264) engl. Printed in Western Germany

* Trademark of THE SINGER COMPANY

Page 3

the new 414... the finest straight stitch sewing machine ever built!

Page 4

THE SINGER 414 ...

. . . represents the ultimate in design and styling! With the

purchase of the new SINGER 414 you can take pride in own

ing the finest straight stitch sewing machine ever built. You'll

marvel at its almost unbelievable ease of operation . , . the

remarkable services it performs. You'll delight in its perfect,

beautiful stitching.

Distinct features include —

• SLANT NEEDLE for greater visibility.

• HINGED FACE PLATE with built-in threading chart.

• HANDY "DROP-IN" BOBBIN in front of needle.

• ALL MECHANISM completely enclosed.

• CLAMP TYPE fastened calibrated throat plate, easily

removable.

• GEAR DRIVEN rotary sewing hook (with built-in motor

on Electric Models).

TO GET THE MOST ENJOYMENT FROM YOUR SINGER

Take advantage of the free sewing lessons to which you are

entitled. Skilled, SINGER-trained teachers will give you per

sonal guidance and assist you in learning the fundamentals

of home sewing.

Copyright 1964 by The Singer Company

Page 5

SINGER SERVICE

Wherever you go you will find expert, dependable SINGER*

Service close at hand. SINGER is interested in helping yuu

keep your SINGER Sewing Machine in top running condition.

That is why you should always call your SINGER SEWING

CENTRE if our machine ever requires adjustment or repair.

Only from your SINGER SEWING CENTRE can you obtain

the services of a trained SINGER repairman and warranted

SINGER* parts.

II

EVERYTHING FOR THE WOMAN WHO SEWS

The answer to your sewing needs is at your SINGER

SEWING CENTRE. There you will find a wide choice of

sewing aids, notions, sewing instructions and services. Look

for the famous red "S" and SINGER trademarks on your

SINGER SEWING CENTRE and the ever ready SINGER Ser

vice Car. See phone book under SINGER SEWING MACHINE

COMPANY for address nearest you.

3

Page 6

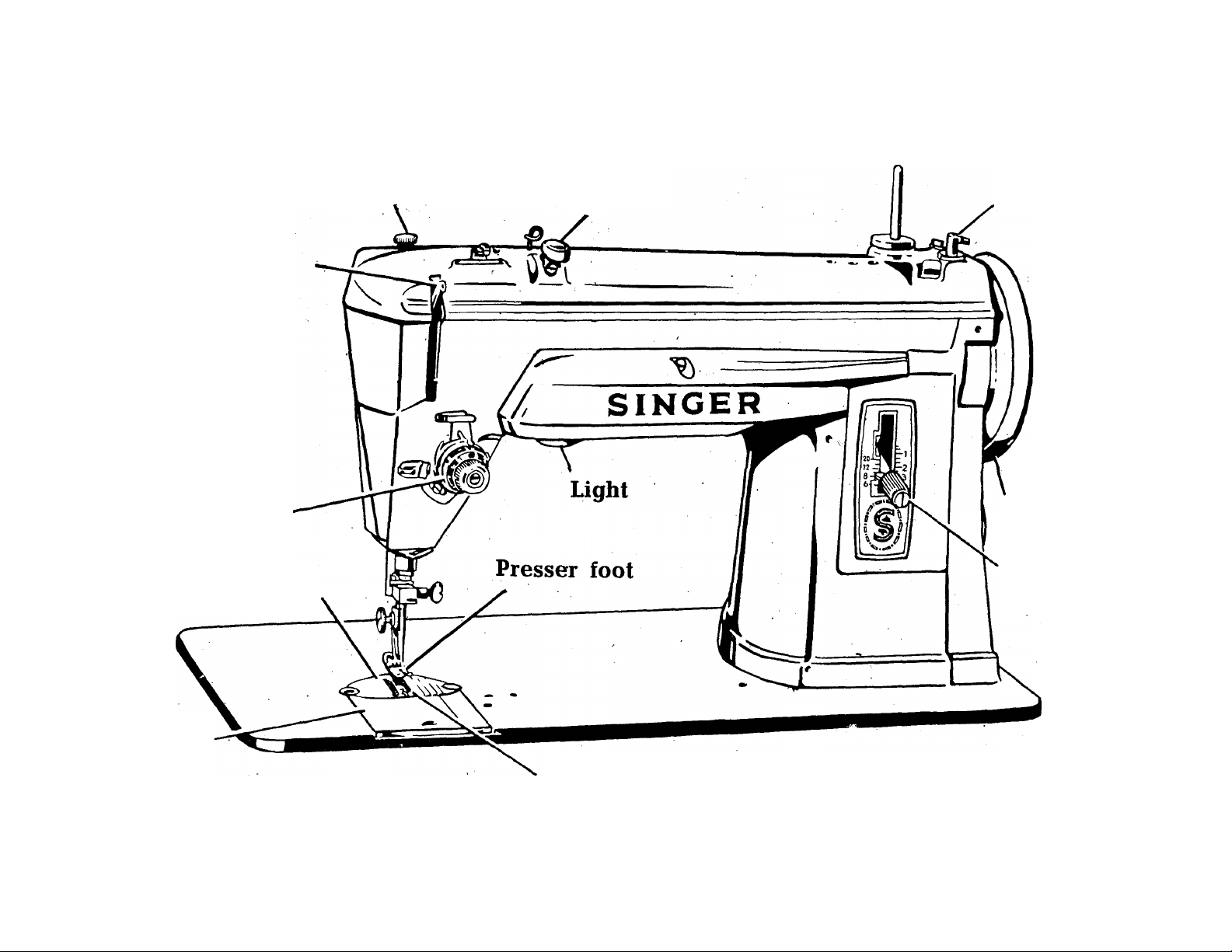

PRINCIPAL PARTS OF MACHINE 414

Pressure regulating Bobbin winder

thumb screw tension

Take-up

lever

Needle thread

tension

Throat plate

Bobbin

winder

Hand

wheel

Stitch

regulator

Slide

plate

Feed

Page 7

NEEDLE AND THREAD SELECTION

The selection of thread should be based on the fabric to be stitched. The thread should

♦

blend with the fabric in colour, fibre and size.

Silk and wool fabrics should be stitched with silk thread; cotton fabrics should be

stitched with cotton or cotton mercerised thread, etc. The thread must be of a size that

will imbed itself into the texture of the fabric. Thread that is too heavy for the fabric

will remain on the surface and become weakened by friction and abrasion when worn.

The selection of the needle should be based on both the fabric and thread being used.

The eye of the needle must be large enough for the thread to pass freely through it. The

blade of the needle must be fine enough not to mar the fabric with too large a puncture,

yet heavy enough to pierce the fabric without binding or deflecting.

You will obtain best stitching results from your Sewing Machine if it is fitted, with a

SINGER" Needle.

Page 8

NEEDLES AND THREAD

This machine uses a Cat. No. 2020

needle (15 X 1).

Sizes 9, 11, 14, 16 and 18.

For perfect stitching, select correct

needle and thread to correspond with

fabric. Be sure to use like threads for

both needle and bobbin.

NEEDLE INSERTION

Raise needle bar to highest point by

turning hand wheel toward you.

Loosen needle clamp screw.

Insert needle upward into clamp as far

as it will go, with flat side of needle to

back and long groove toward you.

Tighten needle clamp screw.

6

Long groove

toward you

Page 9

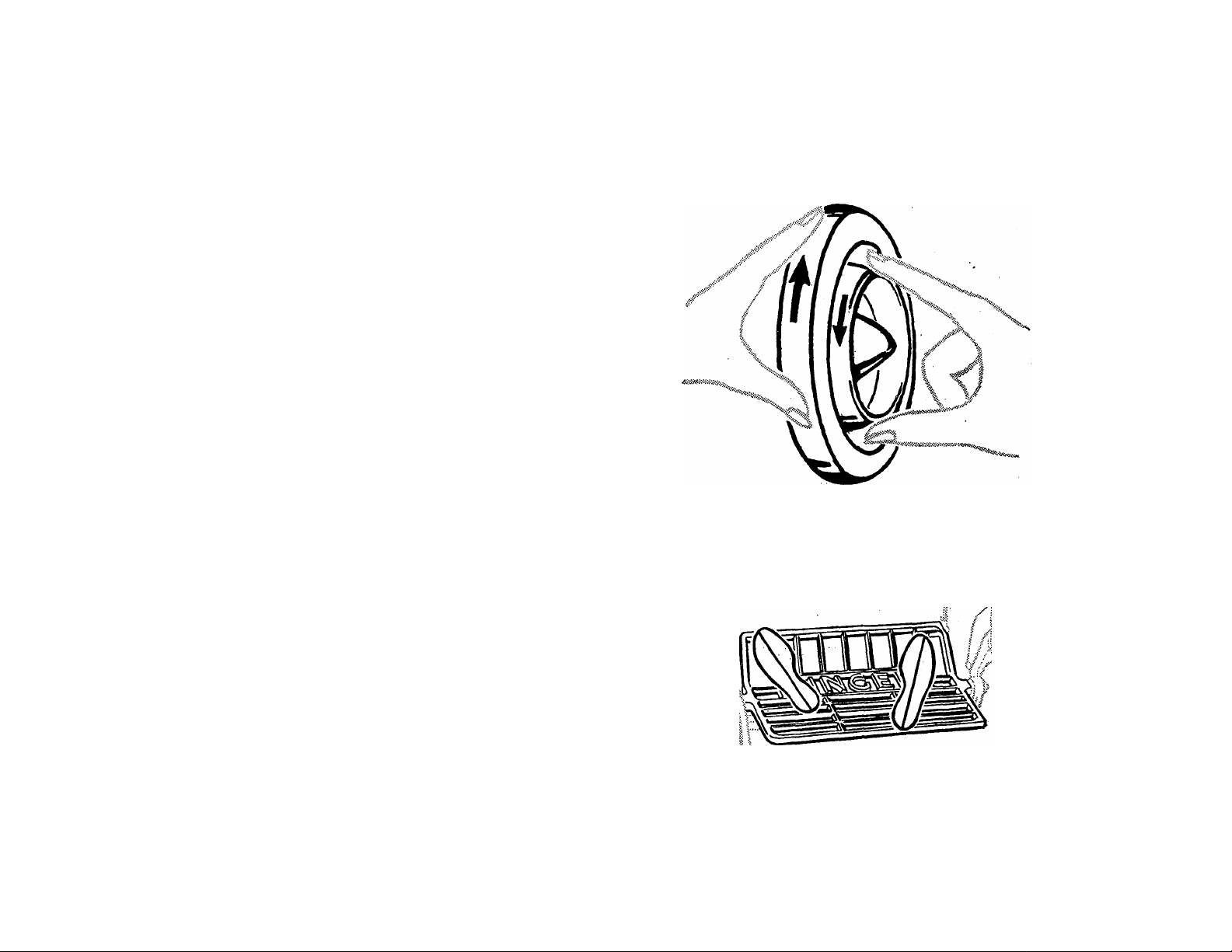

TO OPERATE THE MACHINE

Electric Drive —

• Raise presser foot.

Place material under presser foot and

lower the presser bar.

Connect plug to electric outlet (see

page 56).

Start machine by pressing controller.

If installed as knee controller, press

knee lever to right.

If installed as foot controller, press

Treadle Drive —

Loosen stop motion screw.

r^^/' in

down on foot pedal.

Practice operating machine (without

thread) until you become accustomed

to guiding material and regulating

machine speed.

\ II

i '

Place both feet on treadle.

Page 10

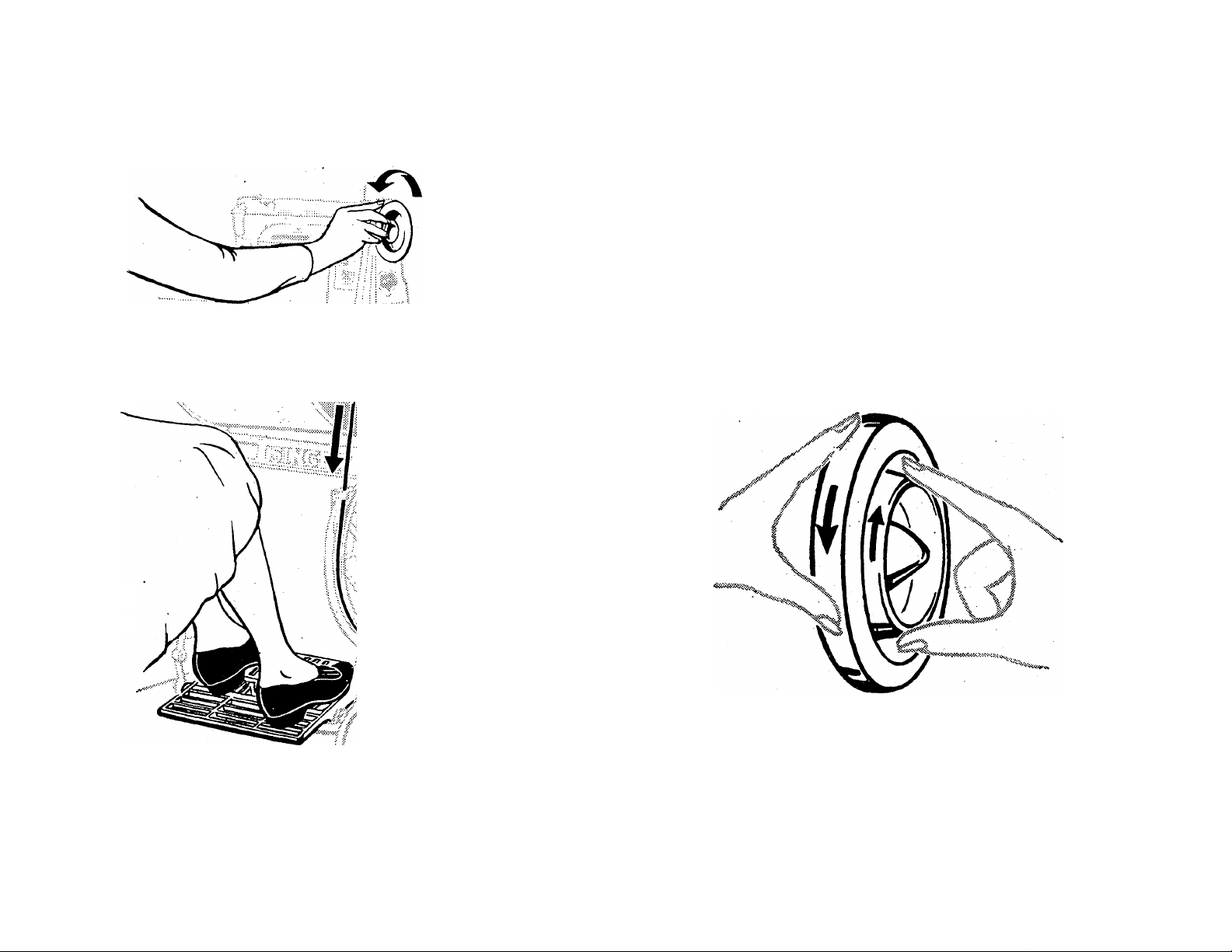

TO OPERATE THE MACHINE

Treadle Drive (Cont'd)

Turn hand wheel over toward you and

allow feet to move freely and lightly

with motion of treadle.

Practice this motion until you are able

to re-start machine with hand wheel

turning over toward you.

Tighten stop motion screw.

8

Page 11

TO OPERATE THE MACHINE

Belt Shifter -

Place material under presser foot and

lower the presser bar.

Operate machine (without thread) until

you become accustomed to guiding the

material.

NOTE: Tension on belt should be only heavy enough to keep belt from slipping.

To disengage belt, operate treadle and

move belt shifter as shown.

To engage belt, work treadle slowly

with band wheel turning over toward

you.

y

Page 12

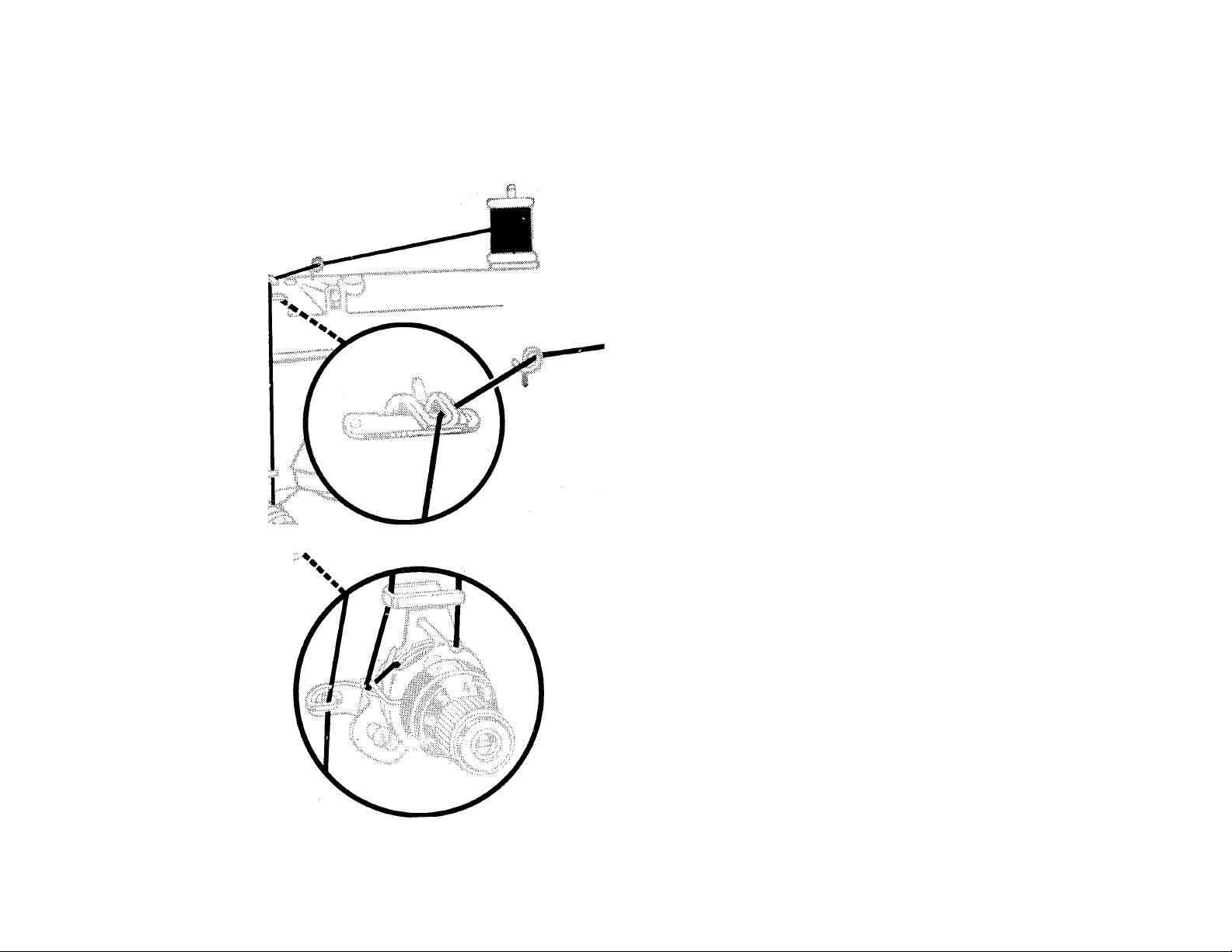

UPPER THREADING

Raise take-up lever to highest point.

Lead thread through threading points

shown.

Thread needle from front to back.

Draw sufficient thread through eye of

needle with which to start sewing.

I

10

Page 13

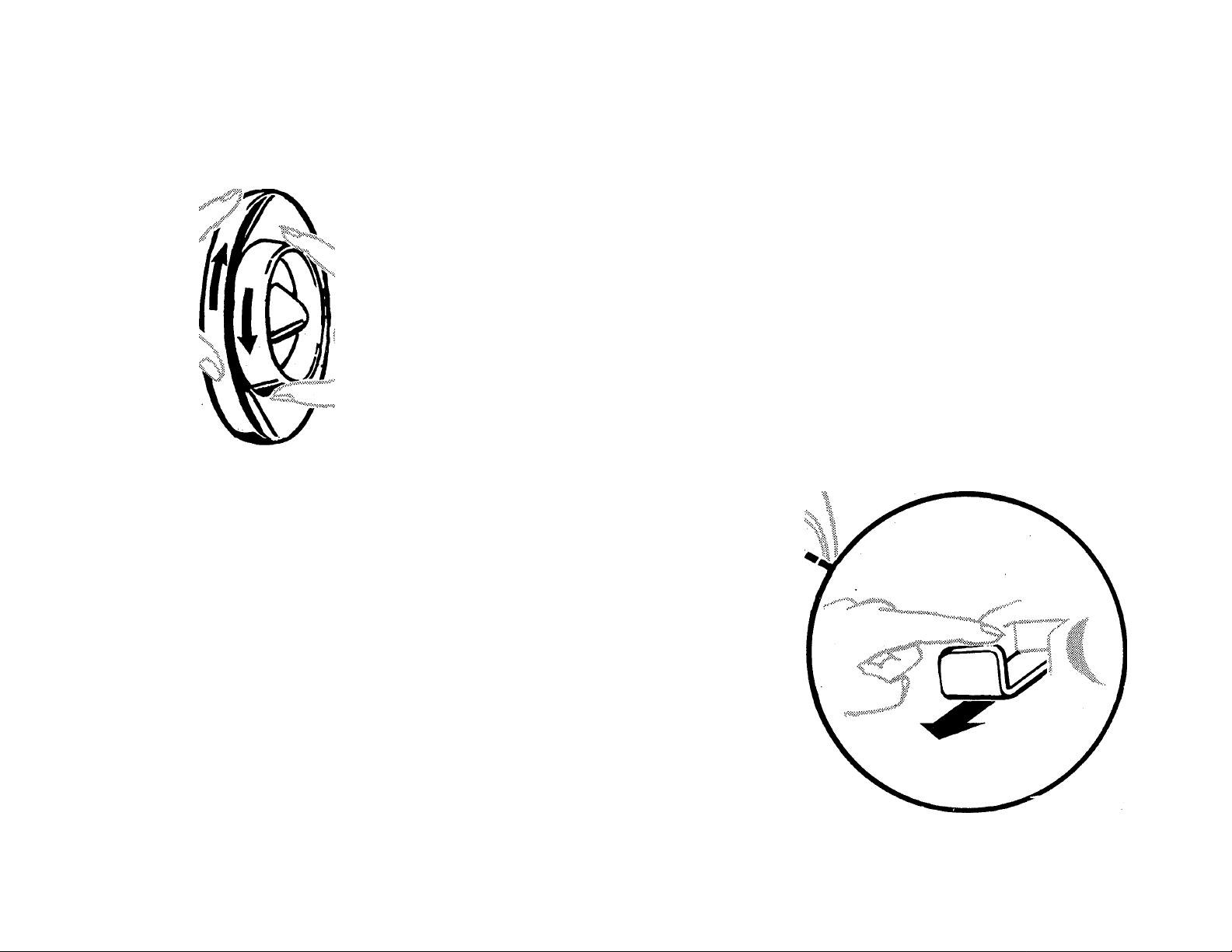

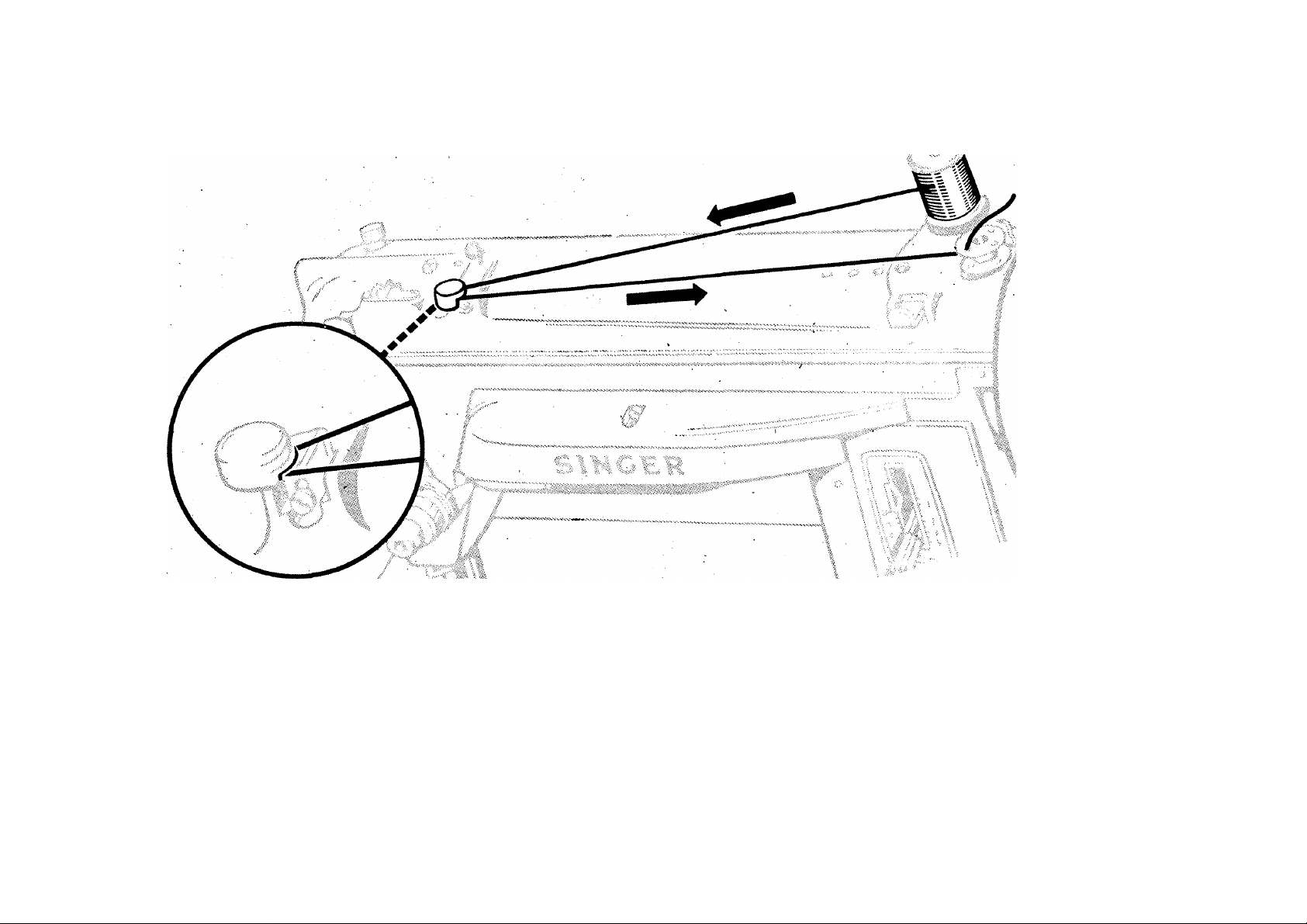

WIND THE BOBBIN

4-

A

Loosen stop motion screw.

Place bobbin on spindle.

Pull out bobbin winder engaging slide.

II

Page 14

eoe««"

\г

^Vca

itv'

/

/

/

itvA

o\

^ otv

/

sp®

3cvVt^e

■fCV^^’

as

Page 15

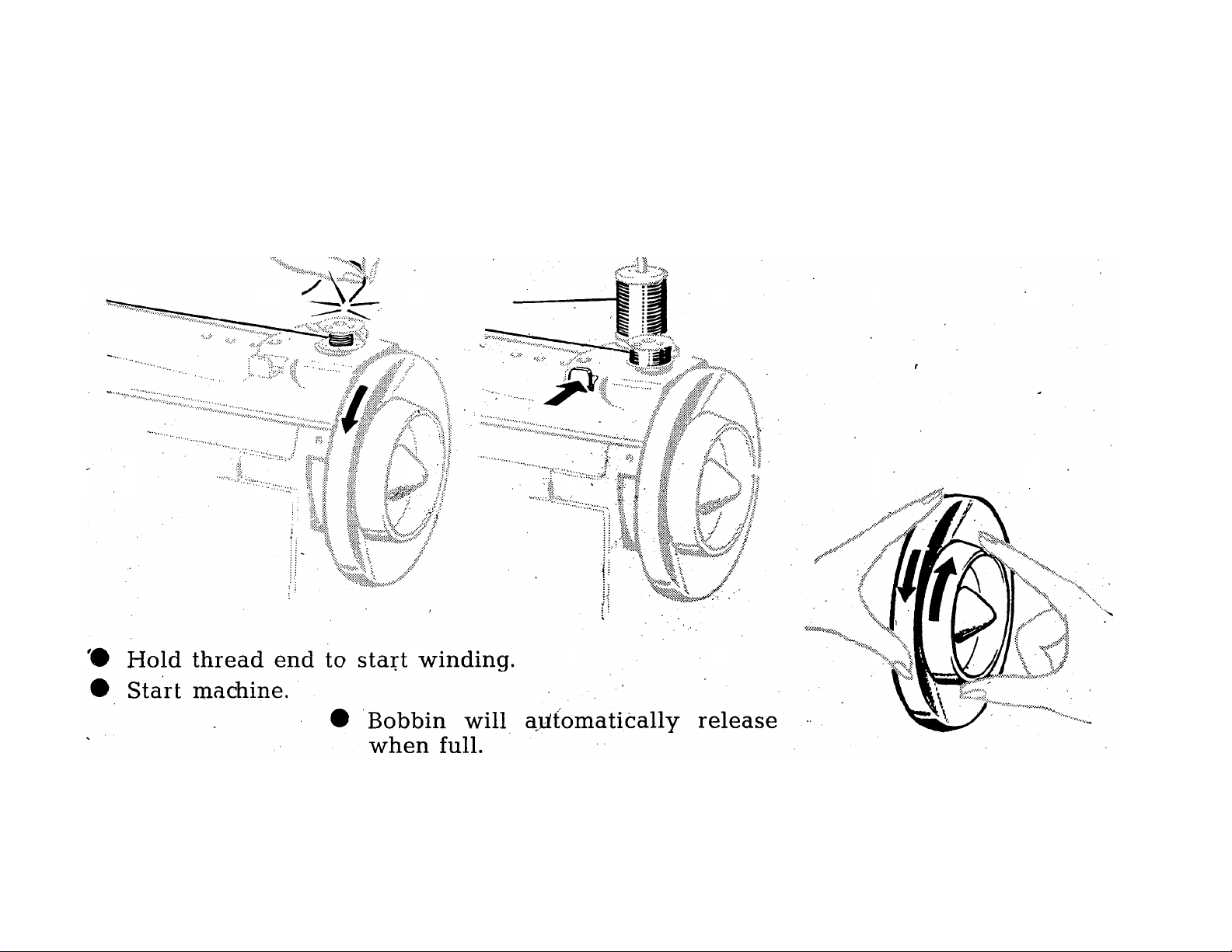

WIND THE BOBBIN (Cont'd)

Push in bobbin disengaging slide.

Tighten stop motion screw.

13

Page 16

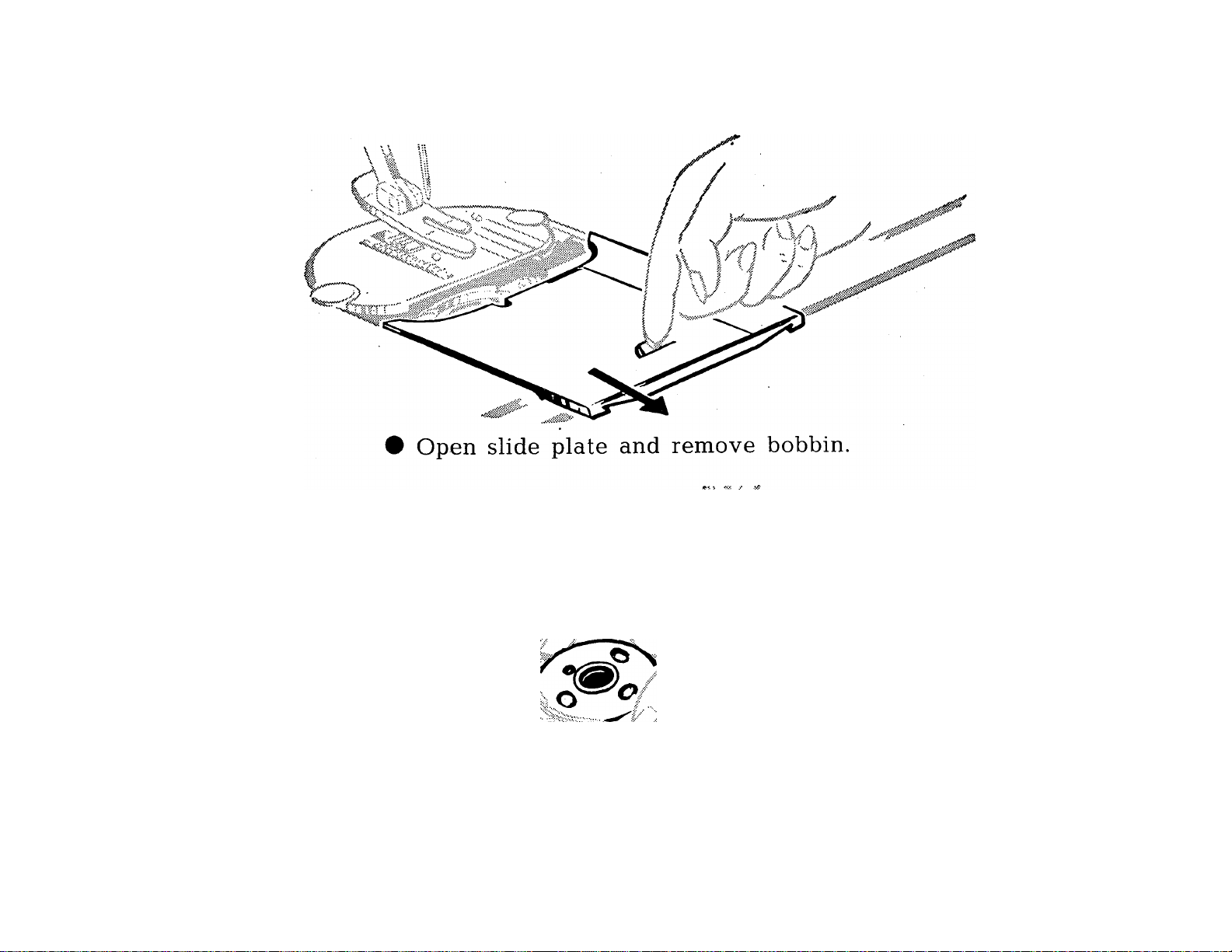

REMOVE THE BOBBIN

14

Page 17

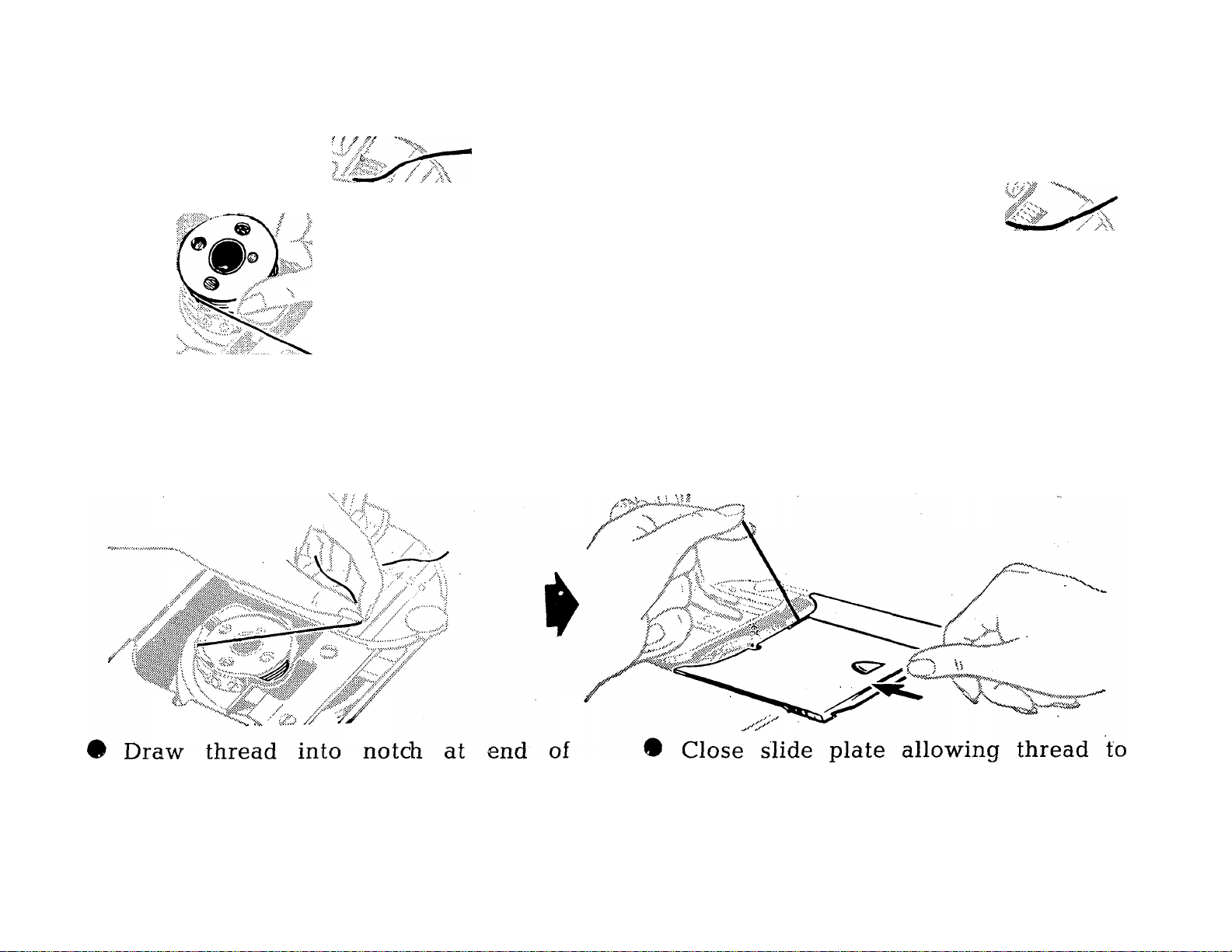

THREADING THE BOBBIN CASE

1

,

I

■' y 1

/

\

Hold bobbin so that thread leads off in

direction shown.

spring; pull about 3 inches of thread

across bobbin.

• Place bobbin in case.

• Lead thread into slot and under spring.

enter notch.

15

Page 18

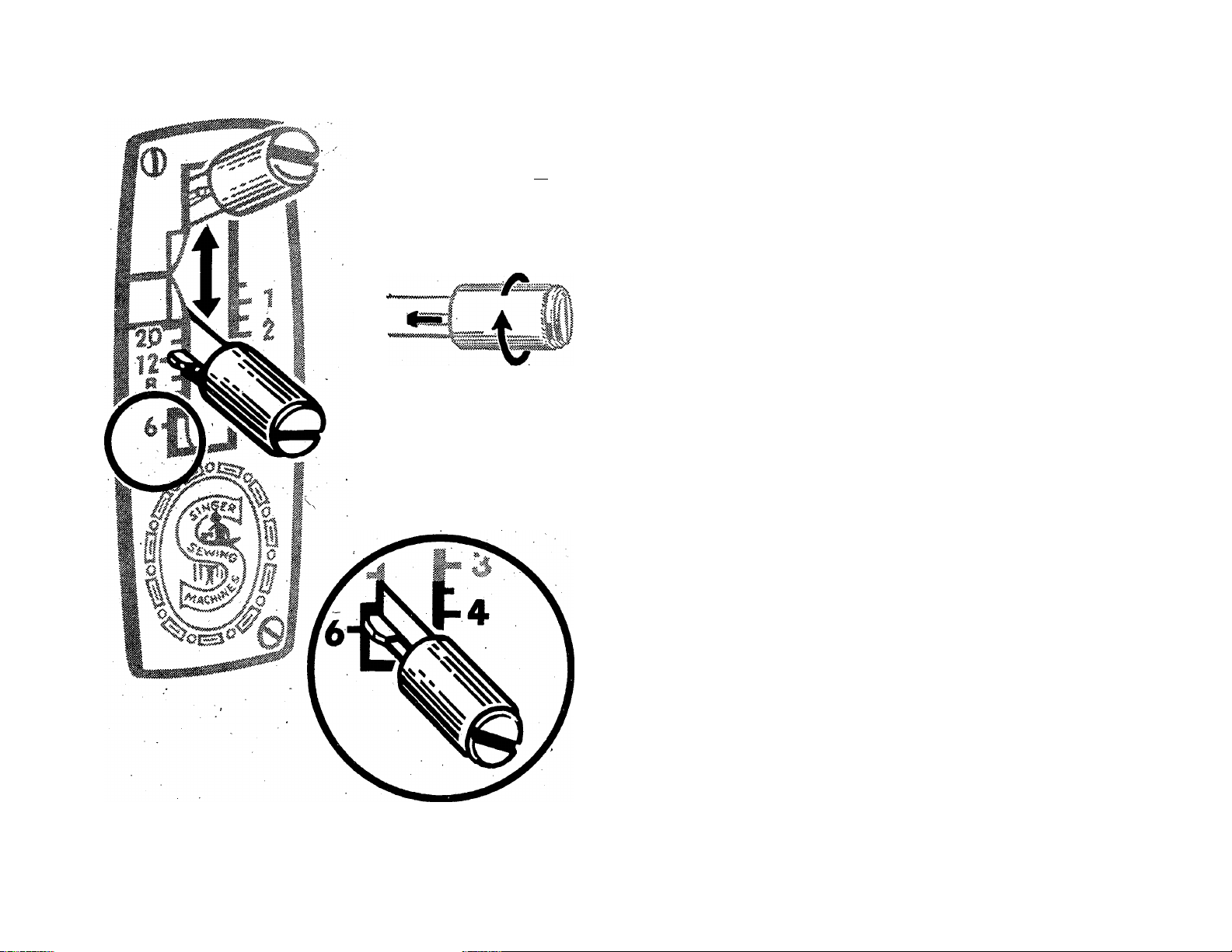

STITCH LENGTH REGULATOR

To release

^■V-WWAWW. v-y ♦ • • •• y%.

'v? m I ••.i/l’}

Numerals on the indicator represent

the number of stitches per inch.

"□CKl

s

To tighten

Locked

setting

The upper indented area of the indi

cator represents stitch lengths above 20.

The lower indented area of the regu

lator allows the No. 6 stitch length setting

to be "locked" in place when stitching

folds, pleats or multiple layers of heavy

fabric.

To set stitch length —

• Release pointer by turning thumb nut

to the left.

• Position lever for desired stitch length.

• Tighten pointer against plate by turn

ing thumb nut to right.

16

Once the pointer has been positioned,

reverse stitching is accomplished by raising

the lever to its highest point. The No. 6

"locked" position cannot be reversed.

Page 19

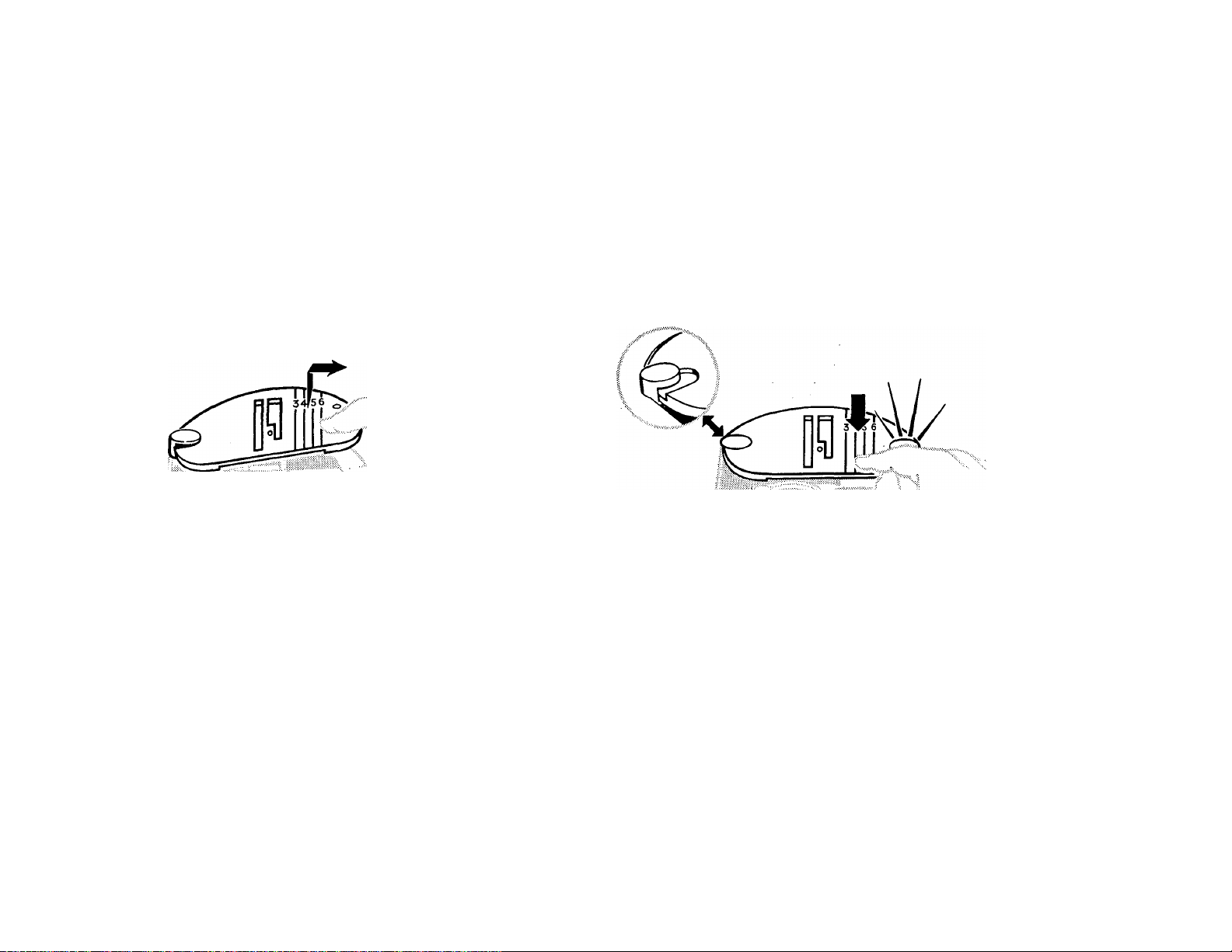

REMOVAL AND REPLACEMENT OF THROAT PLATE

Removal of throat plate

Replacement of throat plate

Raise presser bar. Turn hand-wheel until

needle bar has reached its highest position.

Open slide plate and grasp with thumb

under throat plate. Raise throat plate.

Place left side of throat plate on holding

pins, as shown above. Push downward to

engage plate in position. Close slide plata

17

Page 20

Hold needle

thread lightly

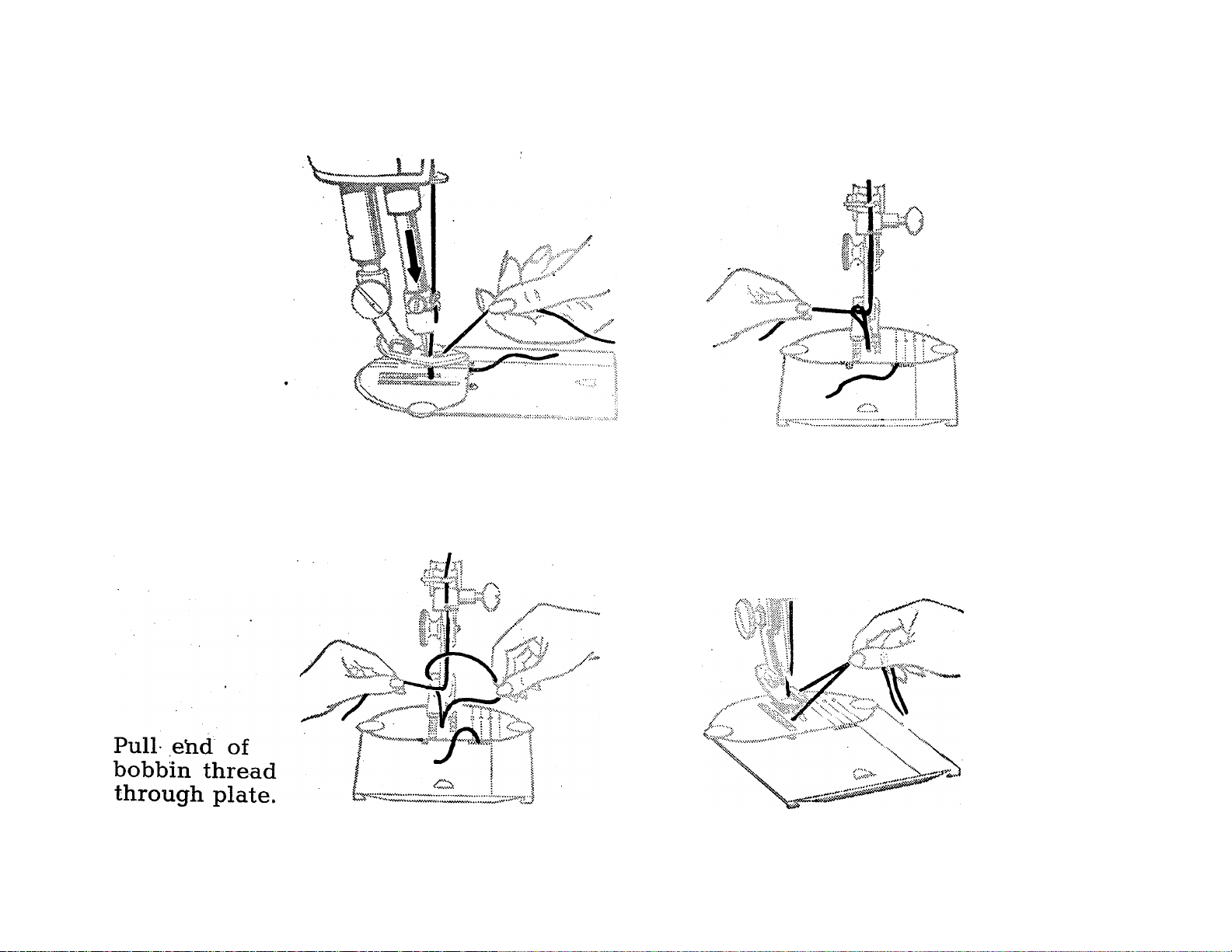

PREPARE TO SEW

!►

Turn hand wheel

so that needle

enters plate and

brings up bob

bin thread.

i U

18

)

Place both

needle and

bobbin threads

diagonally

under presser

foot.

Page 21

SEWING A SEAM

Set stitch regulator for desired stitch

length.

Position needle into fabric about V2

inch from edge.

li'

Î

I

Lower presser foot.

Raise stitch regulator to reverse,

â

i

"/ '' I

f '

'' vJ.'fi'J!'

füiVi5Si\i

psisssisaipte

19

Page 22

SEWING A SEAM (Cont'd)

Back stitch to edge of fabric for rein

forcement.

Lower stitch regulator.

/

Stitch to end of seam.

Raise stitch regulator.

20

Page 23

"l

t

Back stitch to reinforce end of seam.

Lower regulator to forward stitching position.

With take-up lever at highes.t point, raise presser foot and remove fabric.

21

Page 24

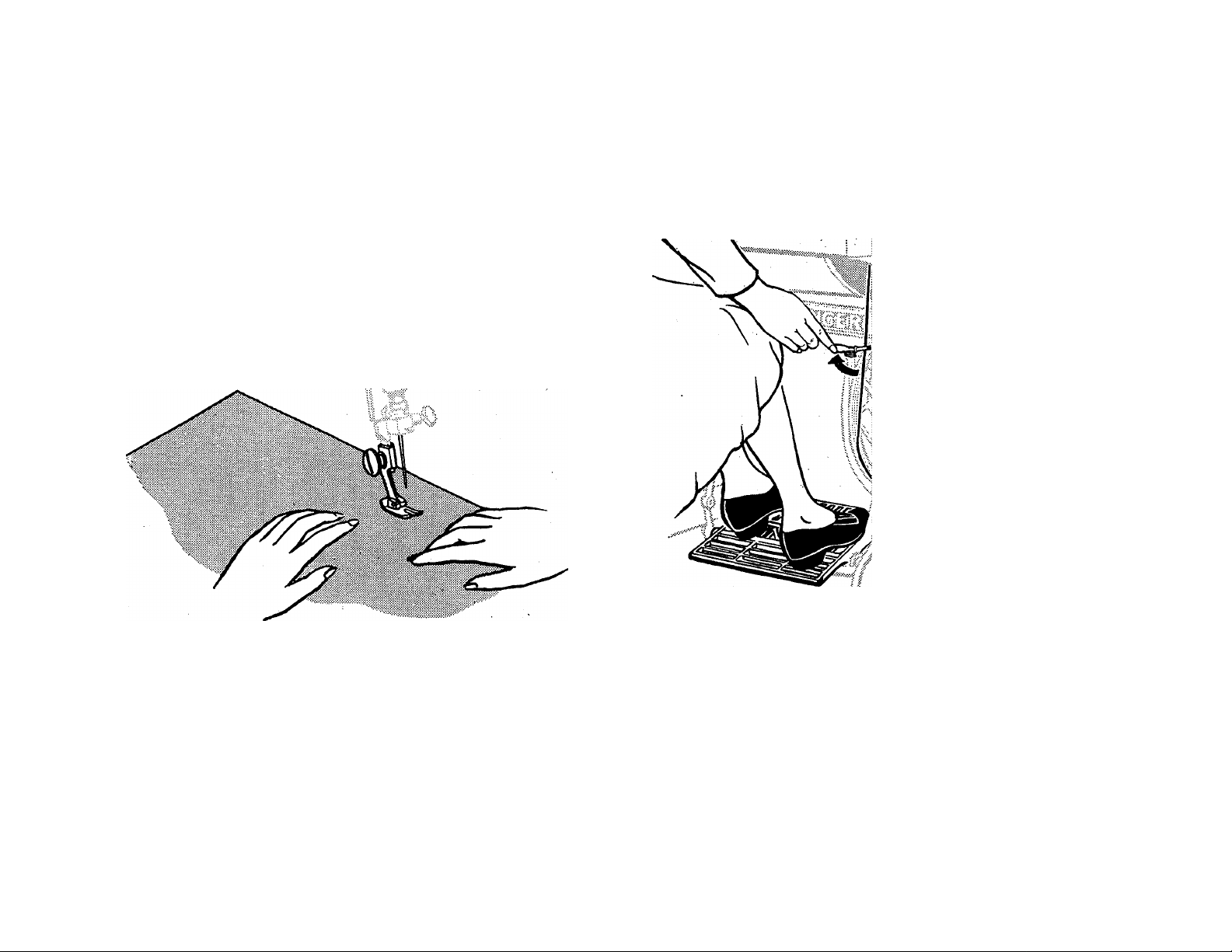

GUIDING AND SUPPORTING FABRIC

L

Most fabrics need, only to be guided in front of the presser foot.

Fabrics of unusual texture and weave, filmy sheers, crepes, knits, tricots, etc., require

support while being stitched.

For such fabrics, use a gentle tension on the seam by holding both in front and back

of the presser foot as illustrated.

22

\

Page 25

PRESSURE ADJUSTMENTS

vS.^

.<[• '.•}/,. d.-r/nrj’i^.fstj. /tr \ '•:

To decrease pressure, turn

m f''/,';

llj I '/¡V

C$i I s..

thumb screw upward.

To increase pressure, turn

Decrease Increase

Adjustment of the thumb screw regulates the amount of

pressure exerted on the material while it is being stitdied.

Smooth, even handling of several thicknesses of fabric

results when pressure is correctly regulated.

Too light a pressure will result in irregular feeding which

affects both quality of stitch and evenness of seams.

screw downward.

Too heavy a pressure not only affects stitch and seam

quality but will mar smooth surfaces and pile fabrics.

Surface finish, as well as the weight and texture of the

fabri or -st be considered in determining the amount of

pres sera needed.

23

Page 26

If| ft XVi f| \Vi^ f| w. fl f|

■■■'■■■■■-.

NEEDLE THREAD TENSION

Needle thread tension too

tight — correct by setting

dial to lower number.

Needle thread tension too

loose — correct by setting

dial to higher number.

A perfectly locked stitch results with upper and lower tensions balanced so that needle

and bobbin threads are drawn equally into fabric.

24

Page 27

BOBBIN THREAD TENSION

I vW fl fl f| V<t.^ f| (| fl

Bobbin thread tension too tight—correct

by turning screw in direction indicated.

WMSi WMSg WMMa W/MH 7IMAa WIMa ¥//ISa WMMg WflAt ¥S

Bobbin thread tension too loose—correct

by turning screw in direction indicated.

A perfectly locked stitch results with the upper and lower tensions balanced so that

needle and bobbin threads are drawn equally into fabrit.

25

Page 28

DARTS

Darts provide fit and contour in a gar

ment and should be accurately stitched.

A dart is usually stitched from the seam

edge, tapering, gradually to the point

where the last three or four stitches

parallel the fold. Stitch beyond the fabric

to form a thread cha'in V2 to Va inch in

length. Tie the thread ends into a single

knot close to the stitching.

Single Threads Darts —

Darts^ add styling and interest when

stitched with fold to outside of garment.

Thread ends at point of dart are elimina

ted wheiv single thread , principle is em

ployed.

Unthread needle. Use thread leading

off bobbin and rethread needle from back

to front. Tie bobbin and upper threads

together. Draw

bobbin thread up

through threading^

points, winding

enough on the

spool to complete

a single dart.

Lower needle into

edge of fold at

point of dart.

26

Lower foot and

stitch toward seam

edge.

Page 29

FREE MOTION WORK

Attaching Embroidery Hoop Guide —

Procedure —

• Remove presser foot.

• Remove throat plate.

Darning —

Procedure —

• Insert feed cover plate instead of regu

lar throat plate in the same manner as

described on page 17.

Household linens, children's clothes and

knit wear of all kinds can be repaired

with the darning stitch.

• Trim away any ragged edges from the

area to be darned. Centre the worn

section in embroidery hoops' to hold

it taut.

• Set stitch length regulator in neutral

position (no feeding motion).

27

Page 30

FREE MOTION WORK

Darning (Cont'd) —

• Position the work under the needle and

lower the presser bar lifter to activate

the tension. Hold the needle thread

loosely with the left hand, turn the

hand wheel over and draw the bobbin

thread up through the fabric with the

loop of the needle thread. Hold both

thread ends and lower the needle into

the fabric.

• Outline the area to be darned, with

running stitches for reinforcement.

Place the stitches V4" from the edge of

the open area.

•

• Run machine at a moderate speed and

control the hoops with a steady conti

nuous movement. Slow movement of

hoops will produce a short stitch, while

more rapid movement lengthens the

stitch.

Fairly long stitches are best for knit

and tricot fabrics as they are softer and

more flexible when the garment is worn.

Short stitches are best for cottons and

household linens as they approximate

the weave of the fabric and are strong

enough to withstand many launderings.

• Stitch across the opening, moving the

hoops under the needle at a slight

angle from lower left to upper right.

Keep lines of stitching closely spaced

and even in length.

28

The darning and embroidery foot (avai

lable separately) will also contribute to

the smooth handling of difficult materials

as it provides a close control of both

stitch and fabric.

Page 31

Decorative Designs —

FREE MOTION WORK

The darning technique is very effective

when used for monogramming and in the

creation of decorative designs.

Trace or transfer the design to be wor

• Preparé the machine as for darning

(see pages 27 and 28).

Designs may be "etched" by outlining

with short running stitches or filled by

placing the stitches close together, using

the, back and forth hoop motion. For a

crisp clean edge,, filled portions should

be outlined with a running stitch.

Move hoops slowly, following the out

line of the design. Maintain an even rate

of speed so that the stitches are evenly

spaced.

A test sample should be made before

ked to the right side of the fabric. Place

the work in embroiderY hoops large

enough to encompass the entire design.

Be ^ure the fabric is held taut.

proceeding with the actual work to de

termine stitch setting and: spacing. Some

fabrics may require addition of an under

lay of crisp lawn or organdie.

29

Page 32

the ATTACHMENTS

Foot Hemmer

Page 38

Seam Guide

Page 31

Zipper Foot

Page 33

Multi-slotted

Binder

Page 41

Gathering Foot

Page 49

Ruffler

Page 43

NOTE; The attachments which are not regularly furnished with your machine are available

for separate purchase at your local SINGER SEWING CENTRE.

30

Page 33

THE SEAM GUIDE

SEAMS

To guide seam stitching straight and

parallel to the edge of the fabric, adjust

the guide for proper seam width. Align

the guide with presser foot.

Pin seam edges and baste if necessary.

Hand basting can be eliminated on easy

The seam guide

aids in attaining

uniformity of seam width. It provides for

stitching to be spaced at any distance

between Vs" to IV4" from the edge of the

fabric.

APPLICATIONS

Seams

Top Stitching

The seam guide is used in connection

with the presser foot.

It is secured to the bed of the machine

in either of the threaded holes to the

to handle fabrics. Place pins with the

points toward the seam edge so they nip

into the fabric at the stitching line. The

hinged presser foot will ride freely over

the points. Guide the fabric edges lightly

against the guide while stitching.

right of the needle.

31

Page 34

Curved seams require additional treat

Top Stitching is a simple and practical

ment in handling. A shorter stitch will

provide greater elasticity and strength.

Set the seam guide at an angle so that the

end closest to the needle acts as a guide.

way to accent the lines of a garment and

at the same time give additional firmness.

Either single or multiple rows of stitch

ing can be expertly placed along lapels

and facing edges, around collars and

pockets and as a hem finish.

32

Page 35

THE ZIPPER FOOT

This foot is designed to facilitate the placement of stitching

close to a raised edge. The hinged feature of this foot insures

even feeding over pins, heavy layers of fabric or cross seams.

It is attached to the machine in place of the regular presser foot,

and may be adjusted to either the right or left side of the needle.

APPLICATIONS

Zipper Insertions

Tubular Cording

Preparation —

• Secure zipper foot to presser bar as

you would the regular presser foot.

Corded Seams

Slip Cover Welting

Adjustment to right or left of needle

is made by loosening thumb screw at back

of foot.

With foot down, check position of foot

by lowering needle into side notch,

making sure it clears foot.

Lock into position by tightening thumb

screw.

33

Page 36

ZIPPER INSERTION

Skirt Zipper —

• Machine baste the placket opening of

the skirt and press this seam open.

• Attach the zipper foot to the machine

and position it to the right of the

needle.

• Open the zipper.

• Place the zipper face down on the

seam allowance with the edge of the

teeth at the seam line.

• Turn the back seam allowance away

from the body of the skirt.

• Stitch the zipper tape to the seam

allowance.

34

Page 37

ZIPPER INSERTION (Cont'd)

Move the foot to the left. Close the

zipper and turn it face up.

Smooth back the seam allowance at the

edge of the zipper.

Top stitch it to the tape close to the

folded edge.

\

V.

\ n

\

\

1‘ill'll

] !'

a 1 11 .r'l l"'li u

laifei 1#

/

■

/

1« ‘i iV

Turn skirt to the right side and fold

zipper to the front of the garment.

Pin in place from the right side.

Baste.

Move the foot to the right.

V,

stitch across the lower end of the

zipper and up to the waistline.

Remove basting.

35

Page 38

CORDED WELTING

Cable cord comes in a variety of sizes.

When covered with a firmly woven fabric,

it makes a corded welting. that is an

excellent seam finish.

This welting is prepared in advance

and then stitched into the seam.

• Cut a true bias strip IV4 inches wide,

plus three times the width of the cord

of either self or contrasting fabric.

# Sew strips together on the lengthwise

grain to obtain desired length.

• Adjust zipper foot to the left side of

the needle.

36

• Encase the cord in the bias strip, raw

edges even.

• Lower presser bar.

• Stitch close to th« cord, using a stitch

length slightly longer than for seam

ing the weight of fabric being used.

Do not crowd the stitching against the

cord.

Page 39

CORDED SEAMS

The corded seam is a typical treatment

for slip covers, children's clothes, blouses

and lingerie.

When cording a seam the zipper foot is

usually adjusted to the right of the needle

so that the bulk of the work will fall to

the left.

Attach the corded welting to the right

side of a single seam edge, with the same

stitch length used to make the welting

(page 36). Guide the edge of the foot next

to cord but do not crowd.

Place the attached corded welting over

the second seam edge, and pin or baste

together.

Keep the first stitching uppermost as a

guide and position the seam under the

needle. Stitch, this time crowding the foot

against the cord.

This method produces evenly joined

seam edges and tightly set welting.

Curved seams are corded as easily as

straight seams, except that a shorter stitch

length is used. Since the seam allowance

of the welting is bias, it is not difficult

to shape it to the seam.

37

Page 40

THE FOOT HEMMER

The narrow hemmer

forms and stitches a per

fectly turned hem without

basting or pressing. It is

attached to the machine

in place of the regular

presser foot.

APPLICATIONS

Fine hems Hemming with lace

Edging ruffles Lace insertion

Sheer seams Lingerie finishes

Procedure —

• Hold thread ends in left hand and guide

raw edge in front of hemmer evenly

into scroll.

• Sew slowly, still holding thread ends

until hem is well started.

Soft fabrics will enter the scroll best

with the foot down; firm, crisp materials

with the foot raised.

Even feeding is essential to good hem

ming. The same width of fabric must be

kept in the scroll of the hemmer at all

times. A little practice will result in per

fectly formed hems.

• Attach foot hemmer to presser bar in

place of regular presser foot.

• At very edge of fabric form a double

Vs" fold. Crease this fold for about 2".

• Draw bobbin and needle threads under

hemmer.

• Place fabric under foot and stitch

through creased fold for several stit-

ches.

38

Page 41

HEMMED SEAMS

A hemmed seam is applied where a fine

narrow seam is appropriate. The proce

dure is the same as when making a plain

hem except that the upper layer of fabric

is held about Vs" to the left of the lower

layer to avoid bulk.

The hemmed seam may be started in

the same manner as when starting a hem.

The seam may be stitched flatly to the garment, if a flat seam is desired. Open the work

out flat, then insert the hem into the scroll. The hemmer will regulate the stitching

uniformly from the edge of the hemmed seam.

HEMMING WITH LACE

Most of the popular kinds of lace edging and insertion can be applied with the foot

hemmer. It is an excellent way to trim children's clothes and to finish lingerie hems.

Page 42

Lace Applied Over Hem —

• Fold and start hem the usual way.

• Starting about 1" down from end of

lace, place selvage under needle to

hold lace firmly.

• Raise foot slightly and slip lace under

back portion of foot, without disturbing

position of fabric.

• Stitch slowly, guiding fabric with left

hand, the lace with right.

Take care not to stretch the lace.

Lace Applied Under Hem —

Proceed the same way as when making

a hemmed seam.

• Slip lace in from the left as you would

the second piece of fabric.

This method is used where a neat finish

is desired on both sides of the material.

40

Page 43

MULTI-SLOTTED BINDER

Scroll for

Adjusting

lug \

unfolded

binding

Guide pins

Slots for

folded

bias tape

Centre slot

of scroll

The multi-slotted binder is used to apply

commercial binding as well as self fabric

Cut binding diagonally to form a long

point. Commercial binding in sizes 1 to 5

is inserted from the right into the appro

priate slot in the scroll. Unfolded bias

^Vi6 of an inch wide is inserted into the

opening at the end of the scroll.

Procedure —

• Attach binder to presser bar in place

of regular presser foot.

• Pull binding through scroll until the

evenly folded edges are under the

needle. The free length of the binding

is held between the guide pins.

bias to an unfinished edge.

This colourful trim is attractive when

applied to children's wear, aprons and

fabric furnishings. It is a practical finish

foi seam edges that ravel and for making

bound seams.

• Insert edge to be bound into centre of

scroll.

• Position stitching close to edge of

binding by moving scroll portion of

attachment to right or left by means

of adjusting lug.

41

Page 44

MULTi-SLOTTED BINDER

Lower the presser bar. Allow the attachment to do the work, merely guiding the fabric

into the centre of the scroll as you stitch.

Curved edges require slightly different fabric handling than straight edges.

Inside curves are straightened as they are fed into the binder. If the fabric is soft and

has a tendency to stretch, reinforce the edge with a single row of stitching before binding.

Outside curves tend to lead away from the centre slot of the scroll and should be

guided so that a full seam width is taken at the needle point. Do not attempt to pull or

straighten fabric into the full length of the scroll.

42

Page 45

THE RÜFFLER

Fork

arm

Adjusting

lever

Adjusting Points—

1. The adjusting lever sets the ruffler

for gathers or pleats. The Number 1 space

setting is for gathers and places fullness

at every stitch. Numbers 6 and 12 are

space settings for pleats, spacing them

either 6 or 12 stitches apart. The star is

for straight stitching and is used when

grouping gathers or pleats.

2. The adjusting finger is used only

for pleating and affects the width of the

pleat. It is thrown out of action by bring

ing it out of contact with the adjusting

screw, located directly to the right of it.

3. The adjusting screw regulates the

This attachment offers a simple and

effective way to make gathered and

pleated ruffles. Ruffles may be made sepa

rately or made and applied at the same

time. The ruffler is attached to the presser

bar in place of the regular presser foot.

fullness of gathers or pleats. When tur

ned in to its limit with the adjusting

finger in place, the attachment is set for

its deepest pleat. When turned' outward

to its limit with the adjusting finger out

of action, the ruffler gives only a hint of

fullness.

43

Page 46

THE RÜFFLER

Activating Parts. The ruffling blade and

the separator blade are of blue steel and

hold the material to be gathered between

them. The ruffling blade forms the gathers

or pleats by carrying the fabric to the

needle according to the spacing and full

ness to which the ruffler is adjusted. The

separator guide is slotted to guide seam

edges evenly and to separate the ruffle

strip from the material to which the ruffle

is attached.

Gathering —

• Set adjusting lever on Number 1 set

ting and throw adjusting finger out of

action.

• Turn adjusting screw for amount of

fullness desired and set stitch length

to space fullness. For maximum full

ness, turn adjusting screw in to its

limit; turn outward for less fullness.

Preparation —

• Raise needle to its highest point.

• Locate attachment on machine in place

of regular presser foot, at same time

fit fork arm over needle clamp screw.

Make sure both presser bar screw and

needle clamp screw are tightened secu

rely.

44

Page 47

The length of the sewing

machine stitch also affects

ruffle fullness. Since a given

THE RÜFFLER

attachment setting puts an

equal amount of fullness into

each stitch regardless of its

length, shortening the stitch

(more stitches to the inch)

makes the ruffle fuller; lengthening the

stitch (fewer stitches to the inch) makes it

less full. For fine, closely spaced gather

ing use a short stitch and an outward

adjustment of the adjusting screw. For

deeper, less closely spaced gathering,

turn the adjusting screw inward and use

a medium length‘stitch.

• Insert material to be gathered between

Ruffling

materiali

• Draw to back of needle.

• Lower presser bar and stitch.

The texture of the fabric influences the

performance the ruffler as well as the

results. Soft fabrics, cut on the crosswise

grain, are best adapted for gathering

ruffles. Always test stitdi length and

blue blades and through first separator

guide.

ruffler setting on a scrap of self fabric

before proceeding with the actual work.

45

Page 48

Attaching ruffle

• Place ruffle strip between

two blue blades and through

first separator guide.

• Place material to which ruffle

is to be attached between

THE RÜFFLER

separator blade and feed of

machine.

• Proceed as for plain gather

ing.

Right sides of fabrics are

placed together when the seam

is to fall to the inside.

46

Page 49

Pleating —

THE RÜFFLER

• Move adjusting lever of ruffler to desired space setting for pleats either 6 or 12 stitches

apart.

• Set stitch length.

For deepest pleat, activate adjusting finger and turn adjusting screw inward to its

maximum setting. For smaller pleats turn adjusting screw outward.

A short stitch places pleats more closely together; a long stitch separates the pleats for

a greater distance.

• Insert fabric to be. pleated between blue blades and into first separator guide.

• Lower presser bar and stitch.

47

Page 50

THE RÜFFLER

Crisp fabrics cut on the crosswise grain form the sharpest pleats. Glazed fabrics handle

best if the glazed side is downward and the soft backing is next to the ruffler blade.

Group Pleating —

By using the star setting

(straight stitching) alternately

with the 6 or 12 stitch setting,

pleats are formed in groups.

Even spacing between groups

is accomplished by counting the

number of stitches.

48

Page 51

THE GATHERING FOOT

Single or multiple rows of shirring can be quickly and

expertly placed with the gathering foot. Evenly spaced

shirring is ensured as this foot is designed to lock full

ness into every stitch.

Procedure —

• Attach gathering foot to presser bar in place of

regular presser foot.

• Place material under gathering foot and stitch in

usual way.

Shirring is usually done on the crosswise grain of

the fabric. Soft fabrics lend themselves to shirring

better than firm fabrics.

The amount of fullness is very simply controlled

by stitch length and degree of tension.

Longer stitch lengths and heavier needle and

bobbin thread tensions produce more fullness lhan

shorter stitch lengths and lighter tensions. Both upper

and lower tensions should always be balanced.

49

Page 52

TREADLE INFORMATION

To Replace Belt —

• Remove arm top cover as instructed

on page 53.

• Remove belt guard by removing screw

located at top of guard.

\

Lead belt through guide C, around

band wheel, and into eye of belt

Insert end of belt into cutout A so that

it enters groove in hand wheel.

Lead belt down through hole provided

in machine casting.

Insert opposite end of belt into cutout

B in bed of machine.

shifter D.

Join both ends of belt.

Replace arm top cover.

Replace belt guard.

Operate treadle as instructed on

pages 7 to 9.

NOTE: Tension on belt should be only heavy enough to keep belt from slipping.

50

Page 53

TO CLEAN THE MACHINE

When in regular use —

The machine should be cleaned perio

dically to remove the lint and fluff which

may have accumulated around the work

ing parts. To clean the bobbin case area,

see instructions for removing and re

placing bobbin case on page 52. Oil the

machine after each cleaning as instructed

on pages 53, 54 and 55.

When stored —

Clean

and

Oil

Clean

between

tension

discs

If the machine is to be stored away for

an indefinite period of time, a thorough

brush-cleaning to remove all traces of lint

and fluff, followed by swabbing of all

exposed parts with the lint-free brush

saturated with SINGER* Oil, is necessary

to protect the machine against rust da

mage. The areas that should be cleaned

and covered with a protective coat of oil

are shown in the illustration at the left.

51

Page 54

TO REMOVE AND REPLACE BOBBIN CASE

V' - 4?^

’■ V;.

••V '^.•5'/.%

' ' ''

\\ ' '■>'

\

t r

^1 / r

r . v'?

/v<

V^X ’x

V.

'X V

l; (fyj^

$1

III''" i

"

-----------------------------------

i. ^/' wV

S^s..

^ <•

Positioning

To clean hook raceway,

case as follows —

• Remove throat plate (see page 17) and

open slide plate (see page 14).

• Unlock bobbin case by lifting and pull

ing holder to right as shown.

• Remove bobbin case from machine.

• Remove all lint, fluff, loose thread ends

or any other foreign matter which

might clog the machine. v

• Replace bobbin case so that groove

under, tension spring fits on hook race

way and fork of case straddles positioning stud.

• Push bobbin case holder to left until it snaps down into lock position

• Close bed slide and replace throat plate.

remove bobbin

stud

.r

„,4‘/

52

Page 55

TO OIL THE MACHINE

To keep your machine in top condition, use SINGER Oil and SINGER* Lubricant.

Both are quality products especially prepared for sewing machines, and should always

be used in the care of your 414.

.....

..................

Clean the machine periodically as in

structed on page 51. "

.......

Apply a drop of oil to each place

indicated.

Remove screws A and lift off arm top

cover.

Apply a small amount qf lubricant to the gears as

shown. A tube of this lubricant can be purdiased

at your SINGER SEWING CENTRE.

Never apply oil to the gears.

53

Page 56

54

Open slide plate and apply a drop of

oil to the hook raceway as indicated.

Close slide plate, replace arm top

cover and close face plate.

Page 57

Tilt machine back and remove thumb nut from screw B, being careful, not to lose felt

washer, and remove cover from underside of machine.

Oil each of places indicated by arrows and occassionally apply a small quantity of

lubricant to teeth of gears as shown.

Replace bottom cover.

THE MOTOR REQUIRES NO LUBRICATION.

55

Page 58

ELECTRICAL INFORMATION

THE SINGER* Electric Motor in the electric

machine is furnished for operation on an alter

nating or direct current. Orders must state the

catalogue number of the motor, or the voltage,

and in the case of alternating current, the

number of cycles. '

Before Inserting Electric Plug A, be sure that

voltage and cycles stamped on electrical name

plate B are within range marked on your elec

tric meter installed by your power company.

56

Electrical Connections for Machine. Push 3-pin

terminal plug C on 3-pin terminal block at right

Of machine and connect plug A at other end of

cord to electric outlet.

Speed Controller. The speed of machine is

regulated by amount of pressure on the pedal

of the foot controller D or the knee lever.

Page 59

LIGHT

H

IB!

rr-

V

The light is turned "on" or "off" by the switch F.

I

To Remove Bulb. Remove screw H and lamp cover

E. Do not attempt to unscrew bulb. Press it into socket

and at same time turn bulb over in direction shown to

unlock bulb pin G, then withdraw bulb.

To Replace Bulb. Press new bulb into socket with

bulb pin G entering slot of socket and turn it over in

direction shown to lock bulb pin G in position. Replace

lamp cover E and securely fasten it in position with

screw H.

57

Page 60

Page 61

INDEX

Page

Attachments................................................30—49

Foot Hemmer

Gathering Foot.................................................. 49

Multi-slotted Binder .... 41—42

Ruffler

.........................................................

Seam Guide

Zipper Foot

Binding..................................

Bobbin

Removing

Winding

....................................................

Bobbin Case

Removal and Replacement . . 52

Threading........................................................... 15

Bobbin Thread Tension .... 25

Cleaning the Machine.......................................... 51

Seams.................................................................. 37

Welting

...............................................................

Darts ...................................................................... 26

Darning

...

...................................................27—28

Decorative Designs................................................ 29

Electrical Information .... 56—57

Motor

........

Light . 57

Embroidery ........ 29

.........................................

38—40

43—48

............................................

...

........................................33—37

.....

41—42

31—32

..........................................................

11—13

......................................................... 56

14

36

Fabrics, Guiding and Supporting

Features

Foot Hemmer

................................................

........................................

Hemmed Seams................................

Hemming with Lace . . .

Free Motion Work . . . . .

Darning..............................................

Decorative Designs ....

Gathering...............................................

Gathering Foot

.....................................

Guiding and Supporting Fabric

Hemming ........

Hemmed Seams . . . . .

Hemming with Lace . . .

Lace Hemming

....................................

Length of Stitch, Regulating

Light Bulb, Replacement of . .

Lubricating .

.

............................

Machine, Principal Parts . . .

Monograms, Free Motion Work

Motor......................................................

Multi-slotted Binder ....

Needle

Insertion

............................................

Thread Tension................................

Threading..........................................

Page

22

2

38— 40

39

39— 40

27—29

27—28

29

44—45

49

22

38— 40

39

39— 40

39—40

16

57

53—55

4

29

56

41—42

6

24

10

59

Page 62

INDEX

Needle and Thread Selection

Needle Thread Tension

Needle Threading . .

Needles and Thread .

Oiling ......

Prepare to Sew . . .

Pressure Adjustments

Principal Parts of Machine . .

Regulating Pressure on Material

Regulating Stitch Length . I .

Removal and Replacement of

Bobbin . . • • • • •

Bobbin Case ......

Throat Plate......................................

Reverse Stitching

Application ... . ...

Regulation . .... . .

Ruffler . . . ......

Attaching Ruffle . . . . .

Gathering ,

.

............................

Pleating . ... . . . .

Principal Parts

.................................

Seam Guide . . . . . . .

Seams ... . . . ' .

Page

5

" Top Stitching .......

24 Corded . . . . . ...

10

6

53—55

18

23

4

23

16

Curved . . . . . . . .

Hemmed

Straight . . . . . . . .

Supporting and Guiding . .

SINGER Service...................................

Single Thread Darts . . . .

Stitch Length Regulation . .

Tension Adjustments

Bobbin Thread .....

14

52

17

Needle Thread

Threading

Bobbin Case......................................

..................................

Needle

19—21

16

43__48

40

44—45

47—48

43—44

31—32

Throat Plate

Removal and Replacement .

To Operate the Machine . . .

Electric Drive

Treadle Drive

...................................

...................................

Treadle Information . . .

Winding a Bobbin . ....

Zipper Foot . . . . . . .

Welting and Corded Seams .

31—32 Zipper Insertion . . . . .

Page

32

37

32

39

31

22

3

26

16

25

24

15

10

17

7—9

7

7—9

50

. 11—13

. 33—37

. 36—37

. 34—35

60

Page 63

To all whom it may concern:

The improper placing or renewal of the trademark SINGER or

any other of the trademarks of The Singer Company (all of which are

duly Registered Trademarks) on any machine that has been repaired,

rebuilt, reconditioned, or altered in any way whatsoever outside a

SINGER factory or an authorized SINGER agency is forbidden.

Page 64

For your protection

SINGER Sewing Machines are sold and serviced wherever you

see the famous SINGER and Red “S“ Trademarks. When your

machine needs servicing call your SINGER SEWING CENTRE

to be sure of warranted SINGER parts and service. See address

in the classified telephone directory.

Loading...

Loading...