Page 1

Instru-Ctions for -asing

SINGER

Sewing faciline 31Q

THE SINGER COMPANY

Page 2

Page 3

SINGER 3i9

SWING-NEEDLE MACHINE

*A Trademark of THE SINGER COMPANY

Outstanding for its simplicity, the 319W2 is a

straight stitching machine of highest quality

plus an automatic zigzag machine with the

convenience of built-in stitch designs affording

unlimited versatility.

Page 4

AS THE OWNER OF THIS NEW SINGER «'AUTOMATIC”

You should take pride in having the finest zigzag sewing machine ever made for home use. You can

be confident that this extraordinarily versatile machine is built with the expert care and knowledge

that have made SINGER the best-known and respected name in sewing machines the world over

for more than a century. With it you can do beautiful and ornamental stitches automatically!

No more skill is required than it takes to sew an ordinary seam. This amazing machine will speed

through your straight sewing and then, by simply raising one or more levers you can do decorative

stitching in no more time or with no more effort than it takes to do straight stitching.

The 319W2 has all of the convenience of built-in stitches, yet all of the versatility of interchange

able FASHION* Discs. Change the FASHION Disc on the front of the machine and you have added

not one but many new stitches. Designs result from single lever operation or from the use of a

combination of levers. Truly the 319W2 is the simplest, most versatile automatic zigzag machine

on the market today.

TO GET THE MOST ENJOYMENT FROM YOUR SINGER

Take advantage of the free sewing lessons to which you are entitled! Skilled, SINGER-trained

teachers will give you personal guidance and assist you in learning the fundamentals of home

sewing.

Copyright © 1956 by The Singer Company

Page 5

SINGER SERVICE

Wherever you go you will find expert, dependable SINGER* Service close at hand. SINGER is

interested in helping you keep your SINGER Sewing Machine in top running condition. That is

why you should always call your SINGER CENTER if your machine ever requires adjustment or

repair. When you call your SINGER CENTER you can be sure of obtaining the services of a trained

SINGER repair man and can be assured of warranted SINGER* parts when needed! Look for

the famous red "S” Trade Mark on your SINGER CENTER and the ever ready SINGER Service Car.

EVERYTHING FOR THE WOMAN WHO SEWS

The answer to your sewing needs is at your SINGER CENTER. There you will find a wide choice

of sewing necessities and notions, sewing instructions and guidance and services for covering

buttons, hemstitching, making belts and buckles, to mention a few. Look in your telephone direc

tory under THE SINGER COMPANY.

Page 6

4

ADVANCED FEATURES OF THE SINGER 319

1. SIMPLICITY^—Truly the easiest to oper

ate zigzag machine made.

2. VERSATILITY—A straight stitching ma

chine of highest calibre capable of full

zigzag and automatic decorative stitching.

3. AUTOMATIC STITCHES—By means of

levers—scallops, blind stitched hems,

decorative designs, simple mending are

automatically accomplished. An amazing

number of lovely designs result from using

a combination of levers. For a greater

variety of stitch designs—more than

you’ve ever thought possible—merely

change the FASHION Disc.

4. TWIN-NEEDLE STITCHING can be done

by inserting the SINGER Twin-Needle,

especially sturdy and accurate because

the two blades are bonded in metal.

5. ROTARY MOVEMENT for smooth, quiet

performance . . . full rotary sewing hook.

6. FULL VISION BOBBIN CASE facilitates

removal and replacement. Time-saving,

extra capacity, round bobbin.

7. CALIBRATED TENSION within a single

turn, tensions are regulated for any type

of fabric and for any type of stitching.

8. REVERSIBLE FEED for sewing either

forward or backward—easy to back stitch

and fasten ends of seams.

9. CALIBRATED STITCH REGULATOR

with fingertip control.

10. SMOOTH, SEAMLESS THROAT PLATES

clip on to ensure snag-free performance.

11. POSITIVE FEED for handling all types of

fabrics.

12. FEED THROW-OUT permits darning and

embroidering.

13. PERFECT CONTROL whether sewing at

high or low speeds, the pick up and stop

are quick and effortless.

14. SINGER* Light illuminates working area—

prevents eye strain, lamp easily renewed.

15. ONE-WAY NEEDLE CLAMP makes it

almost impossible to place needle in

clamp incorrectly.

16. ALUMINUM CONSTRUCTION means

durability and light weight.

Page 7

ELECTRICAL INFORMATION

The SINGER* Electric Motor

is located at the back of the machine, and is

regularly furnished for operation on an

alternating current of 110-120 volts, 25-75

cycles, or on 110-120 volts direct current.

Special motors can be furnished for direct, or

alternating current for any voltage between 50

and 250, and for 32 volts direct current.

Before Inserting Electric Plug—

be sure that voltage and number of cycles

stamped on motor nameplate are within range

marked on electric meter installed by electric

power company.

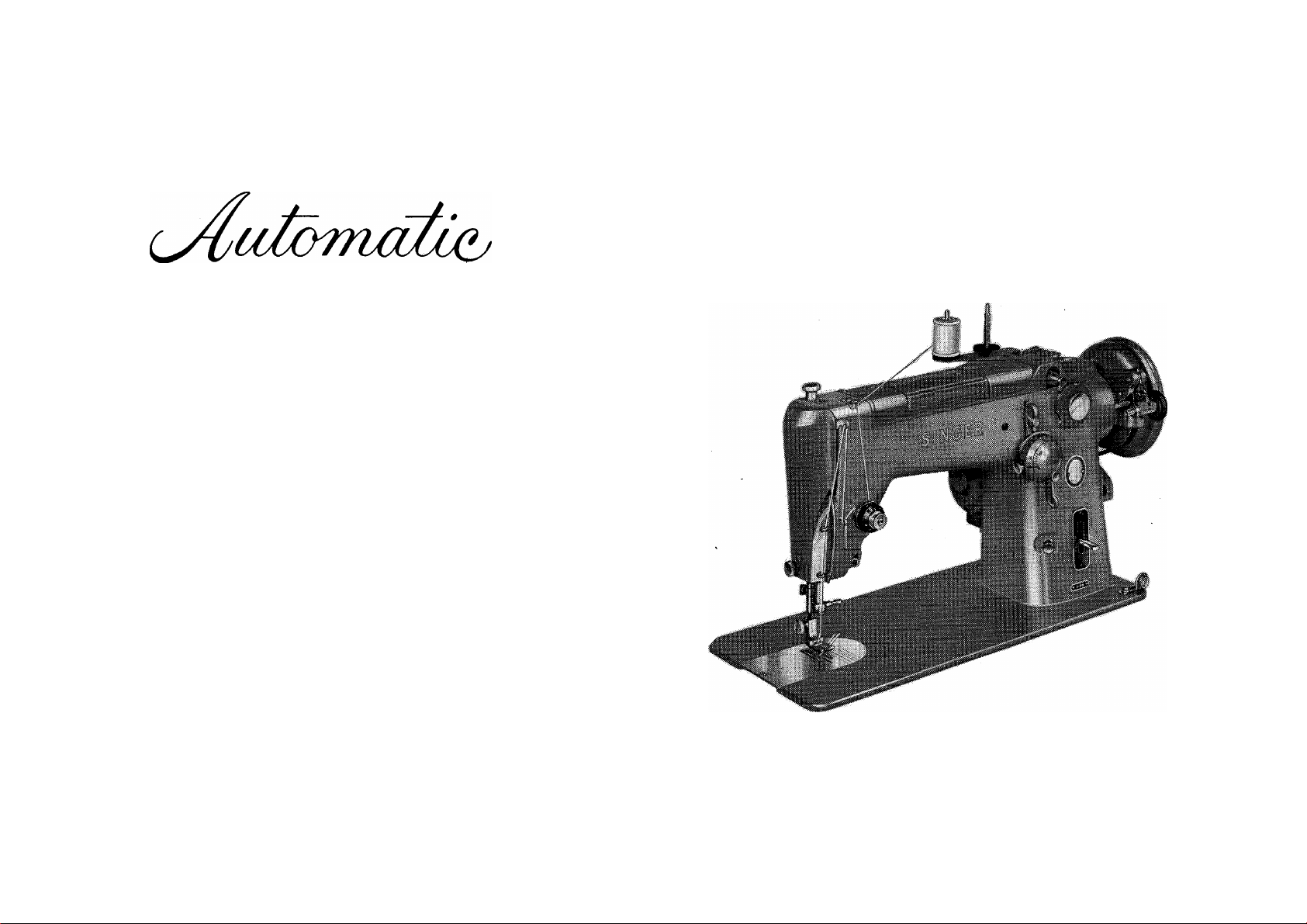

Electrical Connections for Machine

Push 3-pin safety plug A, Fig. 1, into 3-pin

terminal block at right of machine and connect

plug at other end of oord to electric outlet.

Speed Controller

The speed of machine is regulated by amount

of pressure on foot controller or knee con

troller.

Fig. 1. Electrical

Connection for Machine

Page 8

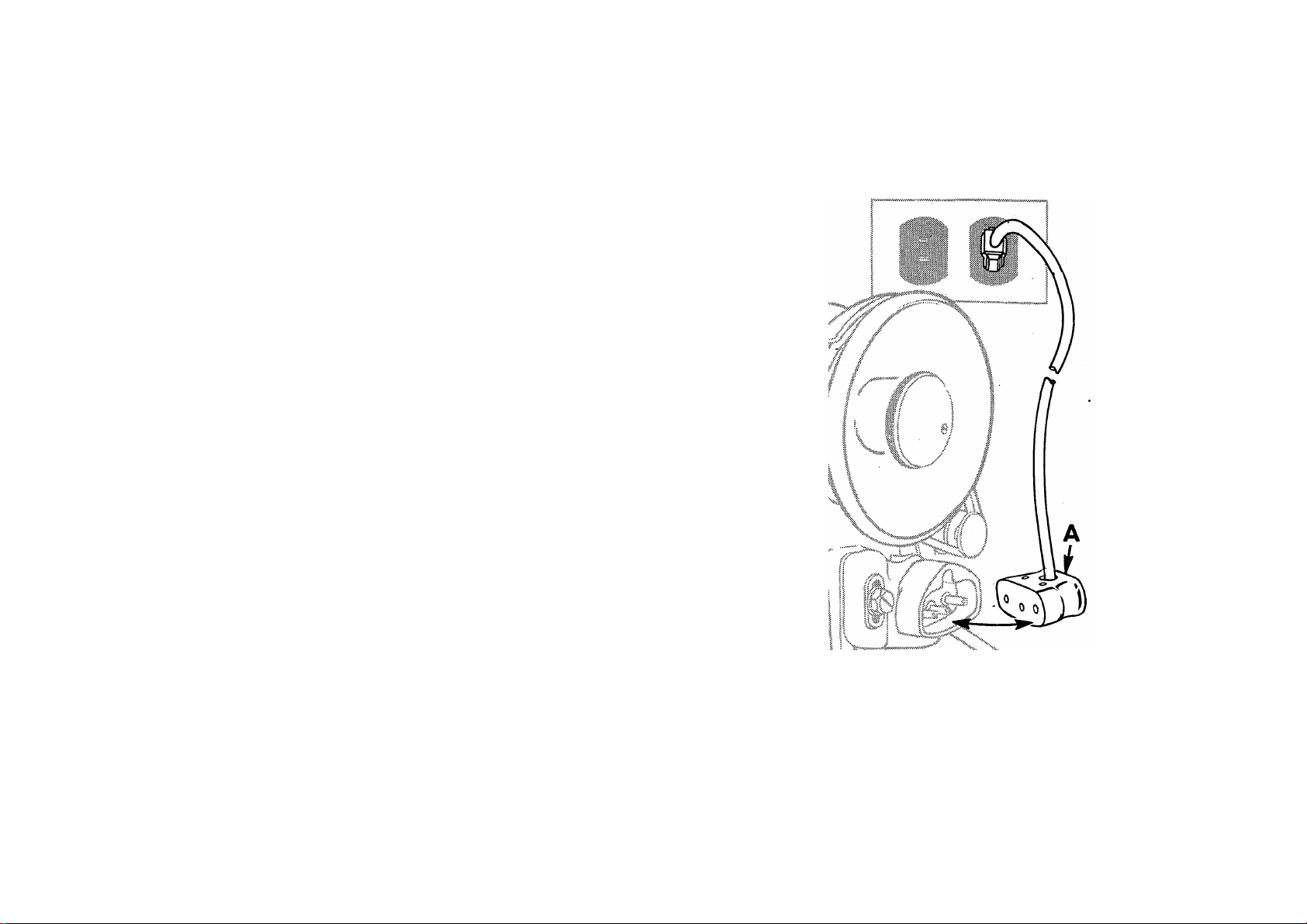

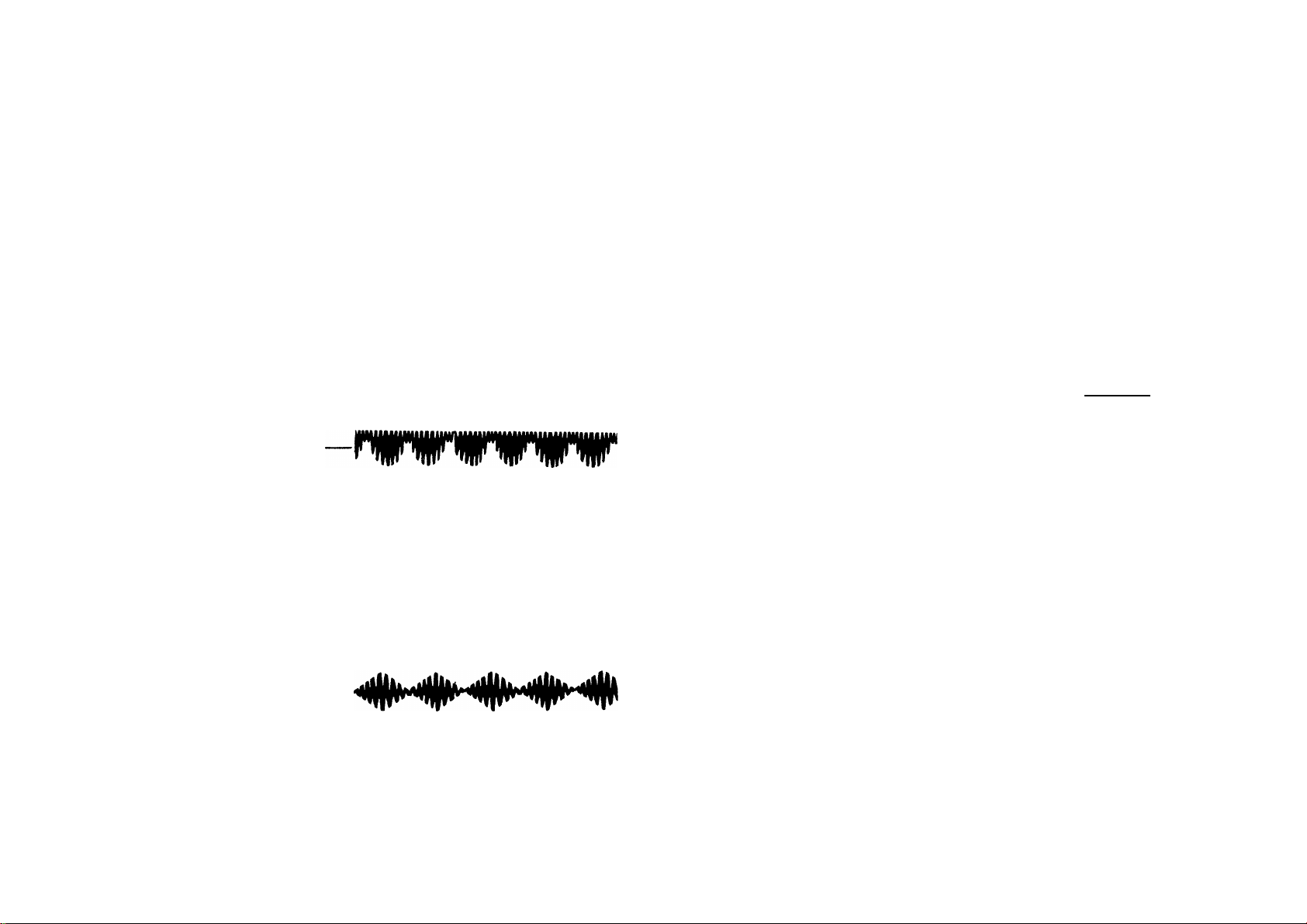

AUTOMATIC STITCHING

When all stitch levers, shown in Fig. 2, are

at their lowest position and the bight control

lever T, Fig. 26, in '"0” position, highest

quality straight stitching is done.

An amazing number of lovely useful stitches

aro produced automatically when you raise

one or more of the stitch levers.

For the most attractive of these combination

designs not more than three levers should be

Twenty-four additional FASHION Discs are

furnished with the machine. Each of these

FASHION Discs is interchangeable with the

one on the front of the machine. With each

disc, a new variety of combinations can be pro

duced, through the use of one or more levers.

Attached to the outside of the machine is the

Blind Stitch disc, which is engaged by the first

lever.

Fig. 2. Stitch Levers

\ \

\ \

Fig. 3. Stitch Lever E

in Position

Page 9

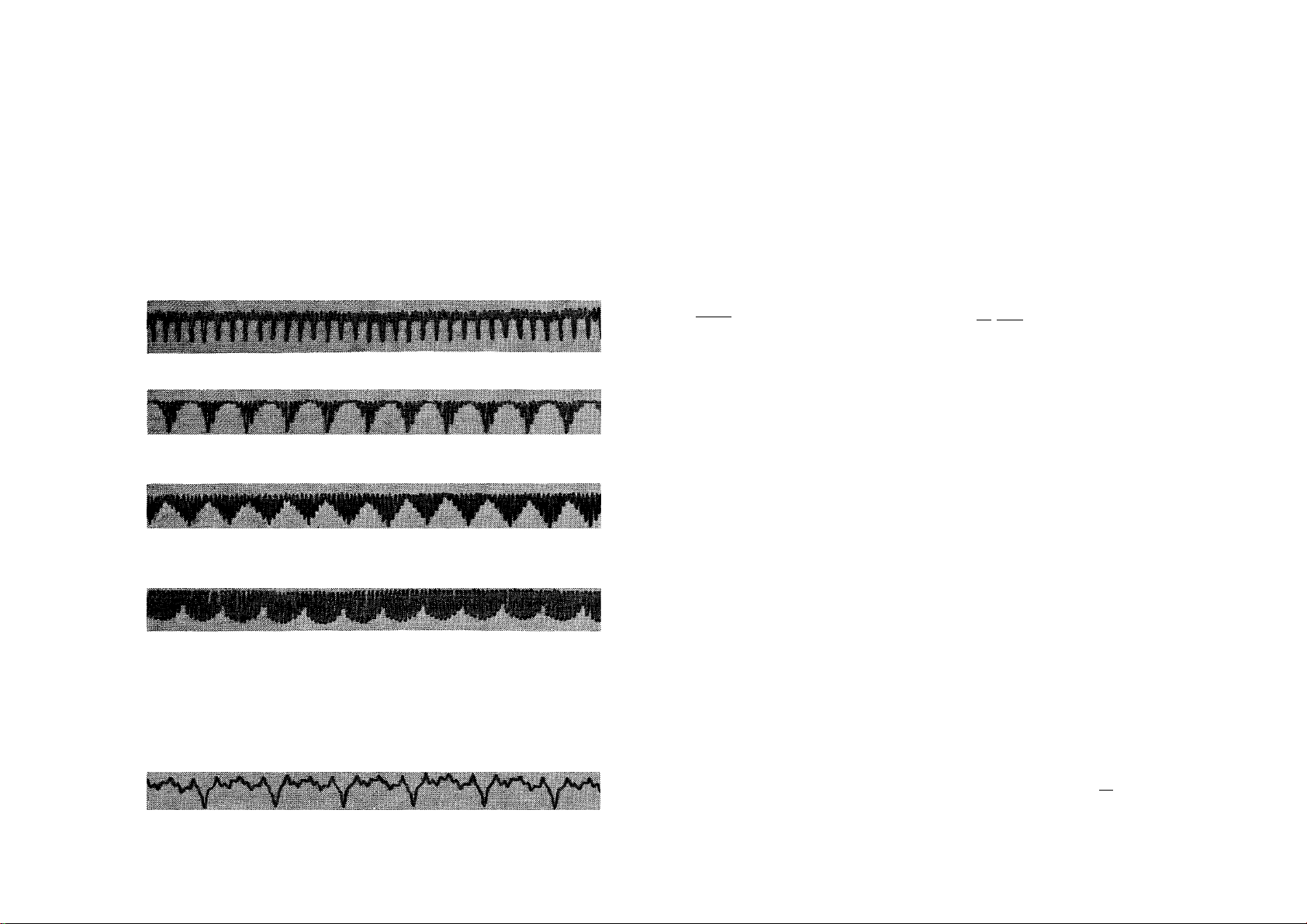

AUTOMATIC STITCHING

Five automatic stitch designs are built into the machine. Merely lift the designated lever to

produce the stitch indicated on the lever. The maximum width of the stitch is achieved when

bight is set at 5. Narrower designs result from setting the bight at less than 5. An almost zero

stitch length gives a solid design, while a longer stitch length gives an open pattern. Twin needle

stitching is done at 3 bight or less.

Zigzag—Lever A

For; Buttonholes

Sewing buttons

Reinforcing seams

Hairline seams

Cording seams

Invisible seams on lace

Multiple Stitch ZigzagFor: Reinforcing

Patching

Mending

Decorative stitching

Scallop—Lever C

For; Faced scallops

Decorative stitching

Abutted seams

Elastic seams

Binding blankets

illlllil|l||llll|l|ll Zigzag Point—Lever D vvvvvv^

Applique

Satin stitch

Script stitch

Shadow applique

Satin stitch scallop

"Lever B / ^ ^ ^ ^ \

Overlapped seams

A A

For; Decorative edging

Decorative border

Ball—Lever E

For; Motif designs

Border designs

Decorative applications

Monograms

Blind Stitch

For; Hems

Facings

Zippers

Overedging seams and facings

Decorative stitching

Applying bands and lace

Di„ i\rY~T'TT1

Applique of bands

or lace

Decorative applique

NOTE: To change the direction of pattern produced by FASHION Discs 5, 10, 15, 16, 17 and 18,

reverse the disc on the shaft.

Page 10

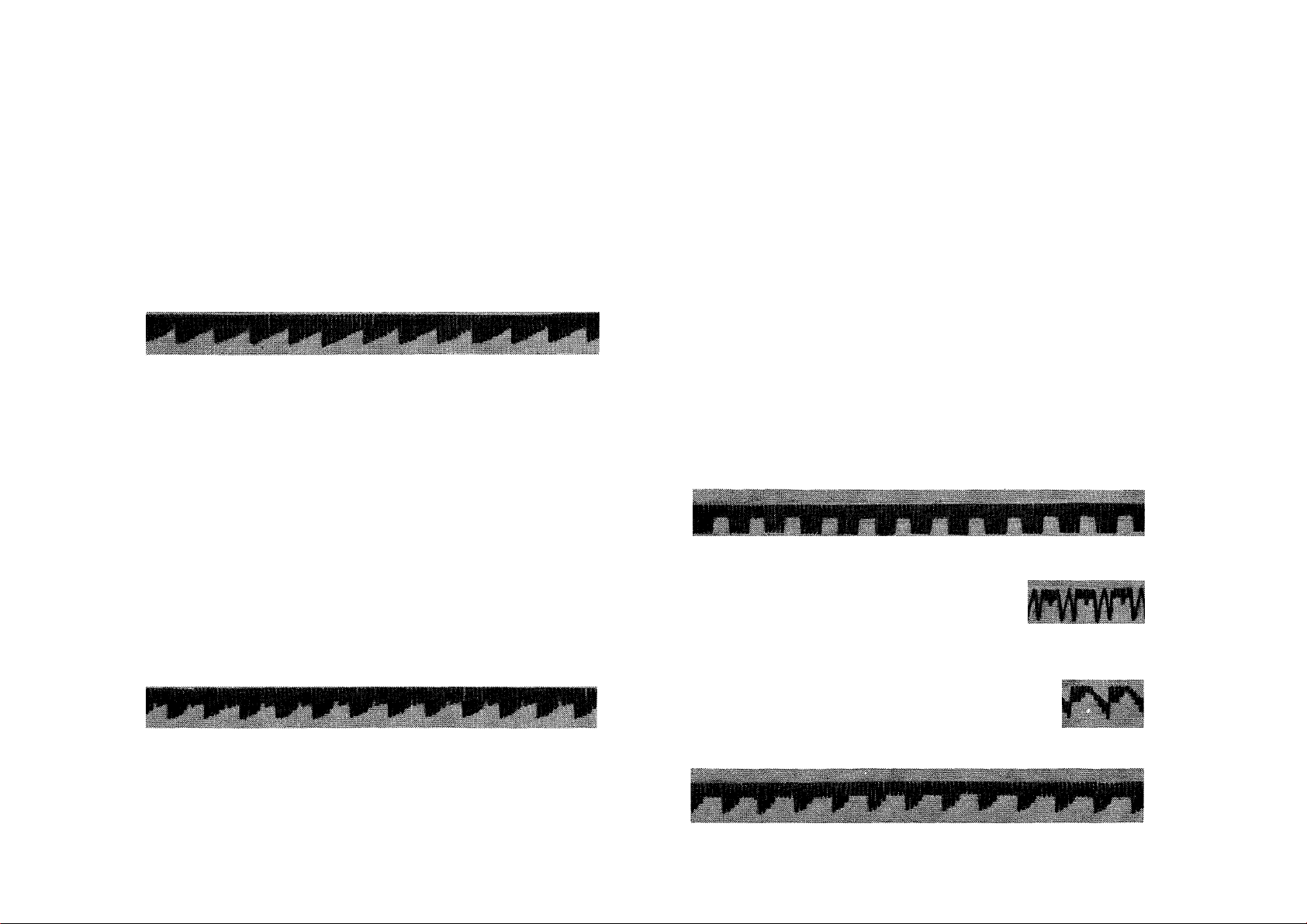

8

AUTOMATIC STITCHING

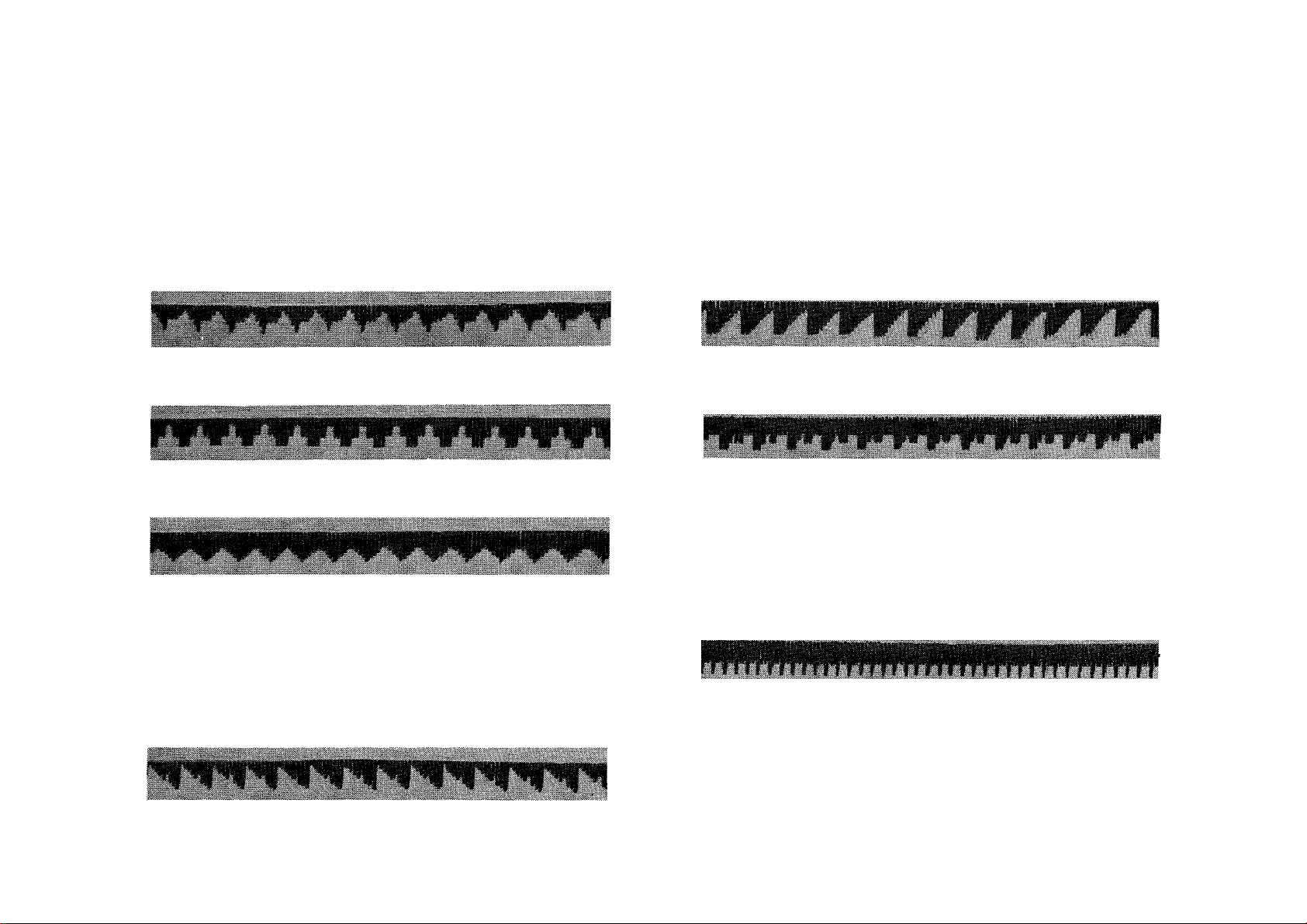

Twenty-four additional FASHION Discs are included with this machine. (Discs 14 and 19 are

built into the machine as Levers D and E, respectively, and produce designs as shown on page 7.)

The 24 additional discs produce the following designs:

Arrowhead (5)- Three Step (18) —iXVVVV'

Domino (6) —

Shell Edge (7)—

Solid Scallop (8)

Icicle (9)

-------

Banner (10)

Key (11) —

-----

iilwWl^ Curved Mending (20) \ / \ y

A A A A /

■/ V y ^ / N /

Thunderbird (21)

Semaphore {¡22) —

Solid Pyramid (23)

Open Pyramid (24)—/\/\/ \/\/\/\/

Spiny (25)—

Walls of Troy (12) Block (26) —

Solid Diamond (13)

Long Oblique (15) \ \

Shingle (16)-

---

Pennant (17) —

Fagoting (27)’

Comb (28)—

Pavilion (29) •

Platform (30)

---------

■liXA.i..Li. J..AJ. LX J..U.1.IJ.

nTrTrTnTlT

Ml Mi M Ml m M

in nl M In m Mi

^^Vl^^^VlVA^Vl^V

AAAA/VVWWW

MMAA MMi ^MAA MMM MM

./ \ /1 / \ I \ I \ I \ j

|A|M 1^^

^^^A

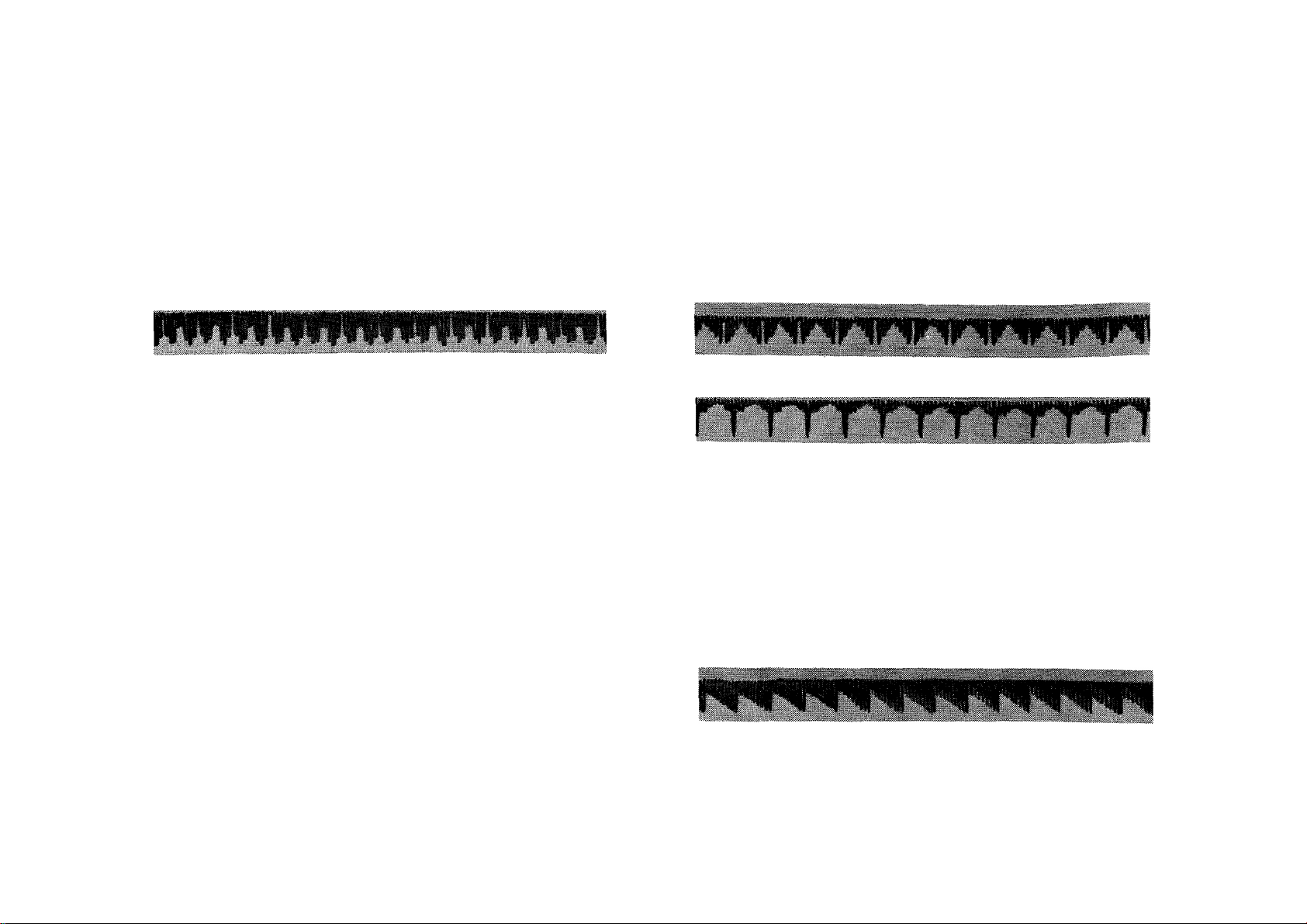

Page 11

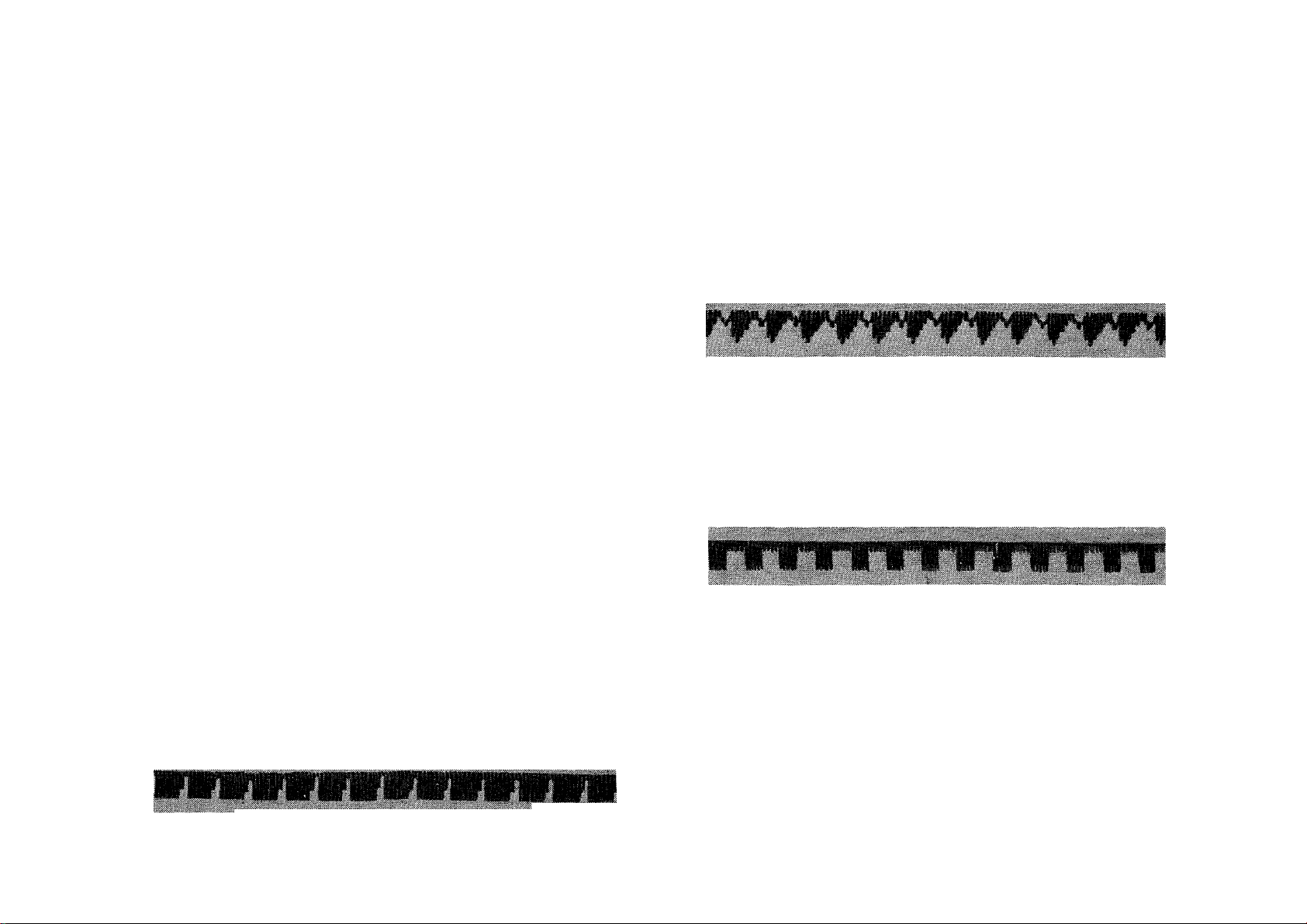

COMBINATION STITCHES

(With Levers)

The following stitches result from using at one time two or more of the levers which engage the

built-in FASHION Discs:

i^Himii jiÉiiA iriiitiM jütttiB BiiftiiE ifÉâfcËi mutiii ÊÊMaSk

Levers A and B

Levers A and C

Levers A and D

Levers A and E

Levers B and C

Levers B and E

Levers C and E

Levers D and E

Levers A, C and E

Levers B, C and D

iiWWlir ^**^**-*- iMÉM tMÊMt ÉMIto JÉfljiMi MéÊtM iâKto«* —>

Levers B and D

Levers B, D and E

Page 12

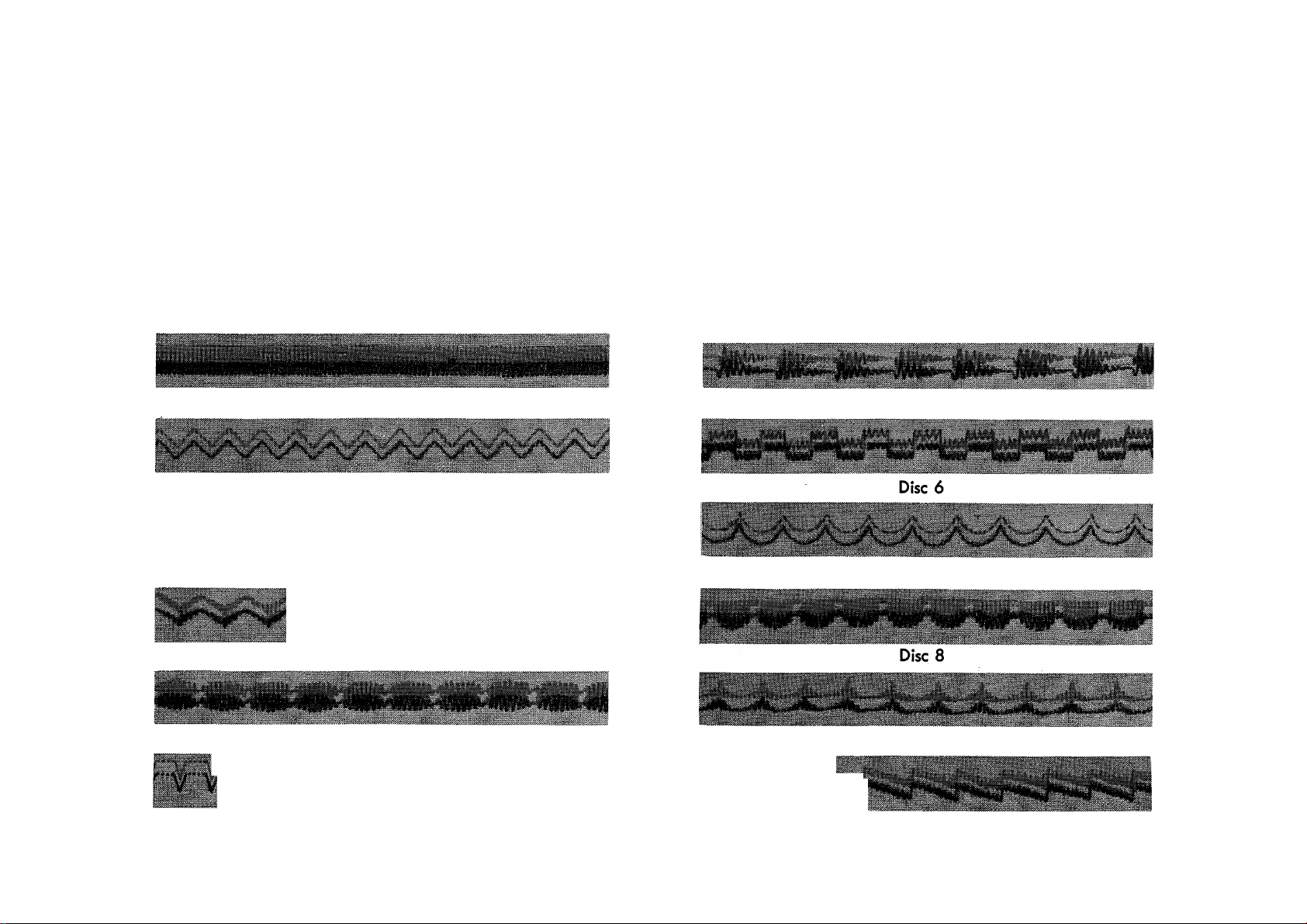

10

COMBINATION STITCHES

(With Levers and Disc)

The following Stitches are produced by using at the same time one or more of the levers which

engage the built-in FASHION Discs and Discs 5 or 6:

Lever A, Disc 5

Lever B, Disc 5

Lever E, Disc 5

Levers A and B, Disc 5

Levers A and E, Disc 5

Levers B and E, Disc 5

Levers A, B and E, Disc 5

Lever A, Disc 6

wvfvwwwvn

Lever B, Disc 6

Lever D, Disc 6

Levers B and D, Disc 5

Levers A and E, Disc 6

Page 13

11

COMBINATION STITCHES

(With Levers and Disc)

The following stitches are produced by using at the same time one or more of the levers which

engage the built-in FASHION Discs and Discs 7, 8, 9 or 10: -

Lever A, Disc 7

Lever B, Disc 7

Lever C, Disc 7

Lever D, Disc 7

Lever E, Disc 7

Levers A and D, Disc 7

Levers B and C, Disc 8

Levers B and D, Disc 8

Levers B and D, Disc 9

Lever A, Disc 10

MVVVWVVVVVVVV»

Levers A and B, Disc 7

Levers D and E, Disc 10

Page 14

12

COMBINATION STITCHES

(With Levers and Disc)

The following stitches are produced by using at the same time one or more of the levers which

engage the built-in FASHION Discs and one of the discs numbered from 11 to 21:

»'VWWWWWW

Lever D, Disc 11

Lever A, Disc 12

Lever A, Disc 13

Lever E, Disc 15

Lever A, Disc 17

Levers A and E, Disc 1 8

^TVrrrrfWnrVTI

Lever A, Disc 20

Lever A, Disc 21

Lever E, Disc 16

Lever B, Disc 21

Page 15

13

COMBINATION STITCHES

(With Levers and Disc)

The following stitches are produced by using at the same time one or more of the levers which

engage the built-in FASHION Discs and one of the discs numbered from 21 through 30:

Lever D, Disc 21

Lever E, Disc 21

Lever E, Disc 22

Lever B, Disc 25

«sгsw5»^x•>:1ws«;»№'*Kí»»«w^aг»■wí»x<<<•»^»!Wi»íWïW»íWíss<>^^т•;«•.•»:

Lever D, Disc 26

Lever A, Disc 29

Lever A, Disc 30

Lever B, Disc 30

yVVVVVVVV'VVV*^

Lever A, Disc 26

Lever D, Disc 30

Page 16

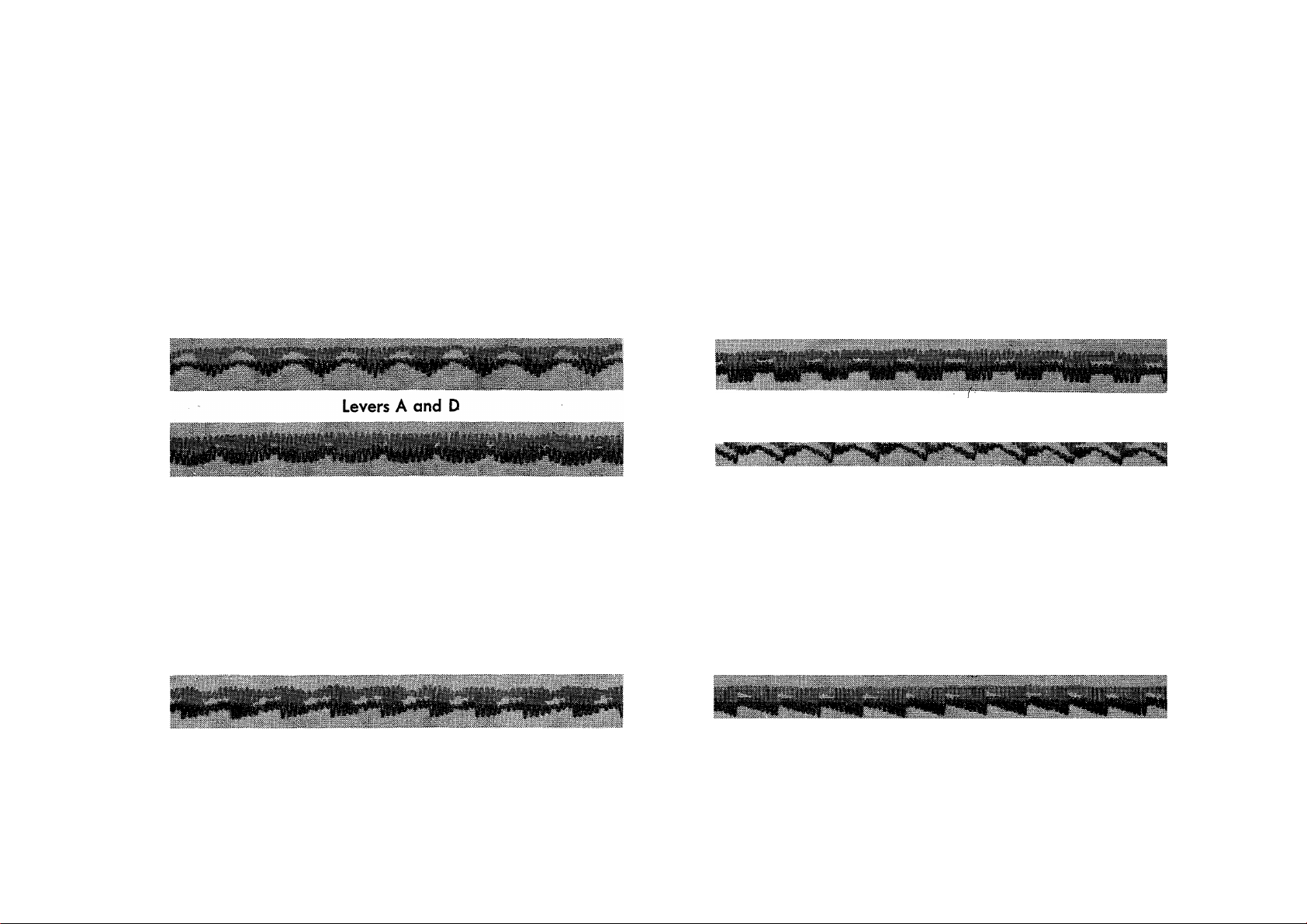

14

TWIN NEEDLE DECORATIVE STITCHING

The following stitches are produced by using one lever at a time or one of the FASHION Discs as

listed. The bight is limited to 3 and the stitch length is set between 25 and 0. The satin stitch foot

is used for closed designs. Scalloping and running-stitches are done with the all-purpose presser

foot:

Lever A

Lever B

Lever C

Lever D

Lever E

Disc 3

Disc 5

Disc 7

Disc 9

Disc 10

Page 17

15

TWIN NEEDLE DECORATIVE STITCHING

The following stitches are produced hy using one or more levers and one FASHION Disc at the

same time as listed. The bight is limited to 3 and the stitch length is set between 25 and 0. The

satin stitch foot is used for closed designs and the scalloping and running stitches are done with

the all-purpose presser foot.

Lever A, Disc 6

Wi1^«* - ito Î *

Levers A and E

Levers B and C

Levers A, C and E

Lever E, Disc 5

Levers A and B, Disc 5

Lever D, Disc 6

Lever B, Disc 7

Lever D, Disc 7

Lever A, Disc 10

Levers D and E, Disc 10

Page 18

FABRIC, THREAD, NEEDLE AND STITCH LENGTH CHART

TYPES OF FABRICS

Filmy materials comparable to Net, Marquisette, Chiffon,

Silk and Chiffon Velvets, Voiles, Ninon

16

THREAD

SIZES

50 Embroidery

100 Cotton

00 and 000 Silk

Nylon Thread

NEEDLE

SIZES

9

MACHINE STITCH SEHINGS

FOR STRAIGHT SEWING

INSIDE

SEAMS

15 to 20

TOP

STITCHING

15 to 20

Sheer materials comparable to Lawn, Dimity, Synthetic

Sheers, Paper Taffetas, Pure Silks, Gossamer Silks, Silk or

Synthetic Tricots, Synthetic Velvets, Satins

Lightweight materials comparable to Gingham, Cham-

bray. Pique, Poplin, Percale, Cretonne, Chintz, Faille, Bengaline. Wool Flannel, Wool Jersey, Wool Crepe, Cotton Velvets

and Velveteens, Lightweight Suitings

Medium heavy materials comparable to Corduroy, Crash,

Gabardine, Rep, Heavy Suitings and Coatings

Heavy materials comparable to Sailcloth, Denim, Ticking,

Overcoatings

Plastic materials

When ordering needles, always specify "Class and Variety 206 x 13” and state the size and quantity required.

See page 43 for ordering TWIN NEEDLES.

50 Embroidery

80 to 100 Cotton

A Silk

Nylon Thread

50 Mercerized

60 to 80 Cotton

A Silk

Heavy Duty Mer.

40 to 60 Cotton

Nylon Thread

30 to 40 Cotton

Thread

50 Embroidery

Nylon Thread

50 Mercerized

n

14

or

16

16

18

11 or 14

12 to 15

12

10 12

8 10

10 12

15 to 20

15 to 18

Page 19

17

NEEDLES AND THREAD

This machine uses a 206x13 Needle—

available in Sizes 9, 11, 14, 16 and 18.

For best stitching results, thread should he

selected according to fabric to be stitched. Needle

must be of correct size for thread to pass freely

through eye of needle. Select correct needle

according to table on page 16. Be sure that

needle is not blunt or bent.

NOTE: Thread breakage is sometimes caused by

variations in the diameter of thread. Such break

age is overcome by using the next size larger

needle.

Use like threads for needle and bobbin. Do not

use silk on bobbin and mercerized thread in

needle, or vice versa.

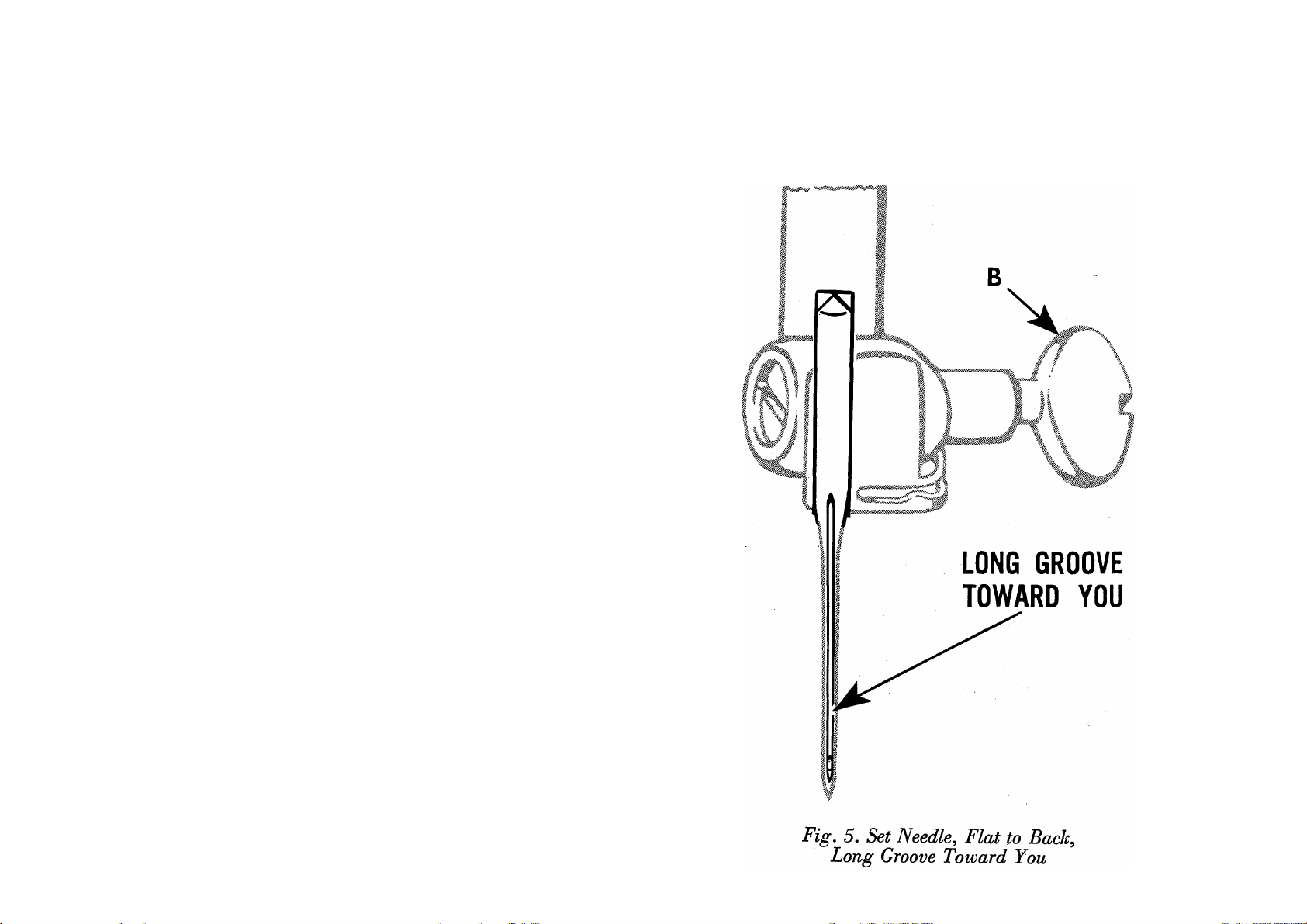

TO SET THE NEEDLE

Raise the needle bar to its highest position and

loosen needle clamp thumb screw B, Fig, 5.

Insert needle into clamp as far as it will go with

flat side to the back and long groove

toward you. Then tighten thumb screw B.

Page 20

18

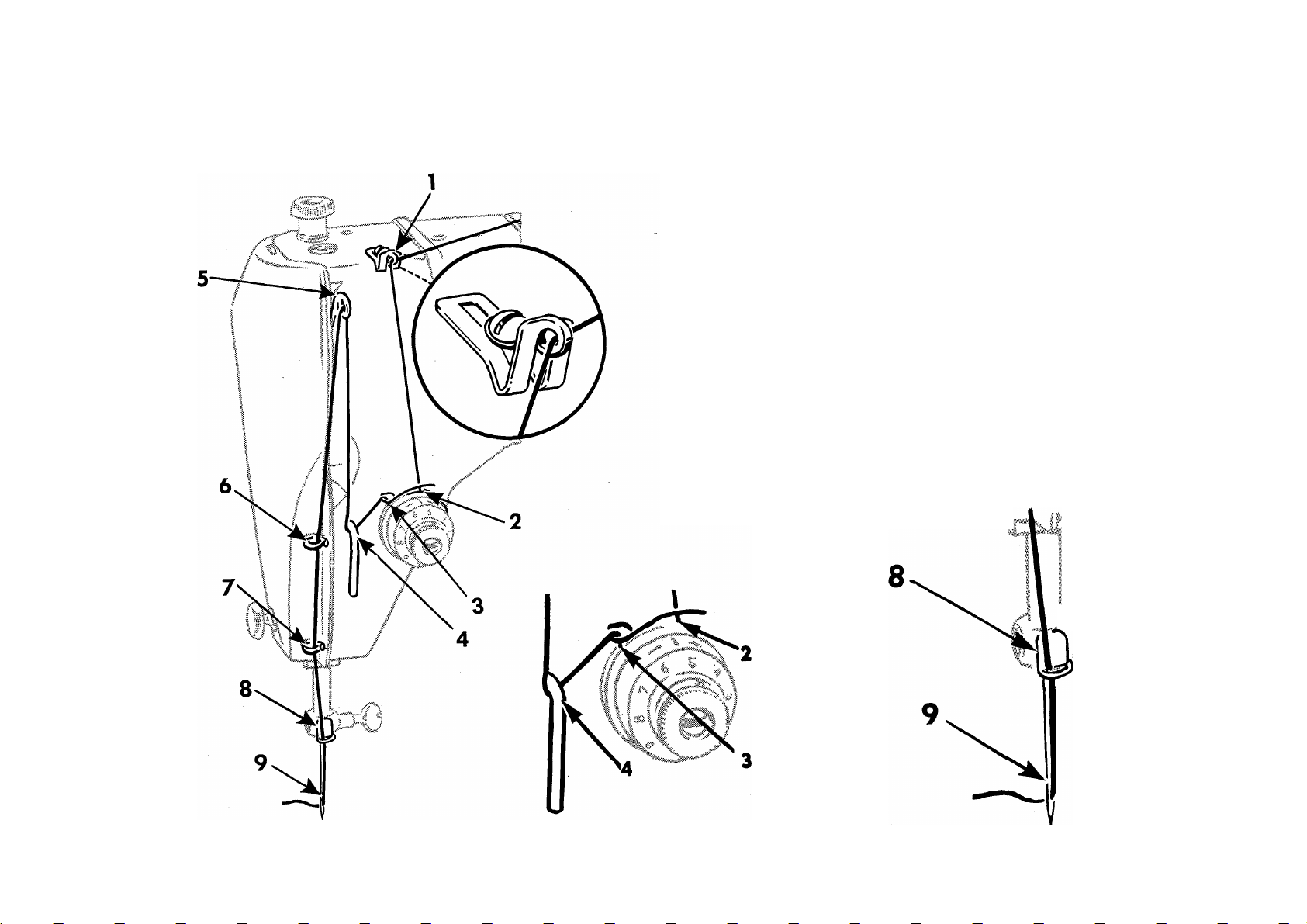

UPPER THREADING—SINGLE NEEDLE

Raise take-up lever 5 to its highest point.

Place thread on spool pin and hold with right hand.

Lead thread into self-threading guide 1 from under side,

Down and from right to left behind or in front of center

tension disc 2 (Center disc separates threads for twin

needle sewing.)

Into the loop of the take-up spring 3,

Under the slack thread regulator 4,

Up and from right to left through hole in take-up lever 5,

Down through guides 6 and 7 on face plate,

Into guide 8 on needle clamp,

From front to back through eye of needle 9.

Draw about two inches of thread through eye of needle

with which to start sewing.

Fig, 6. Upper Threading

Fig. 7. Threading Tension

Fig. 8. Threading Needle from

Front to Back

Page 21

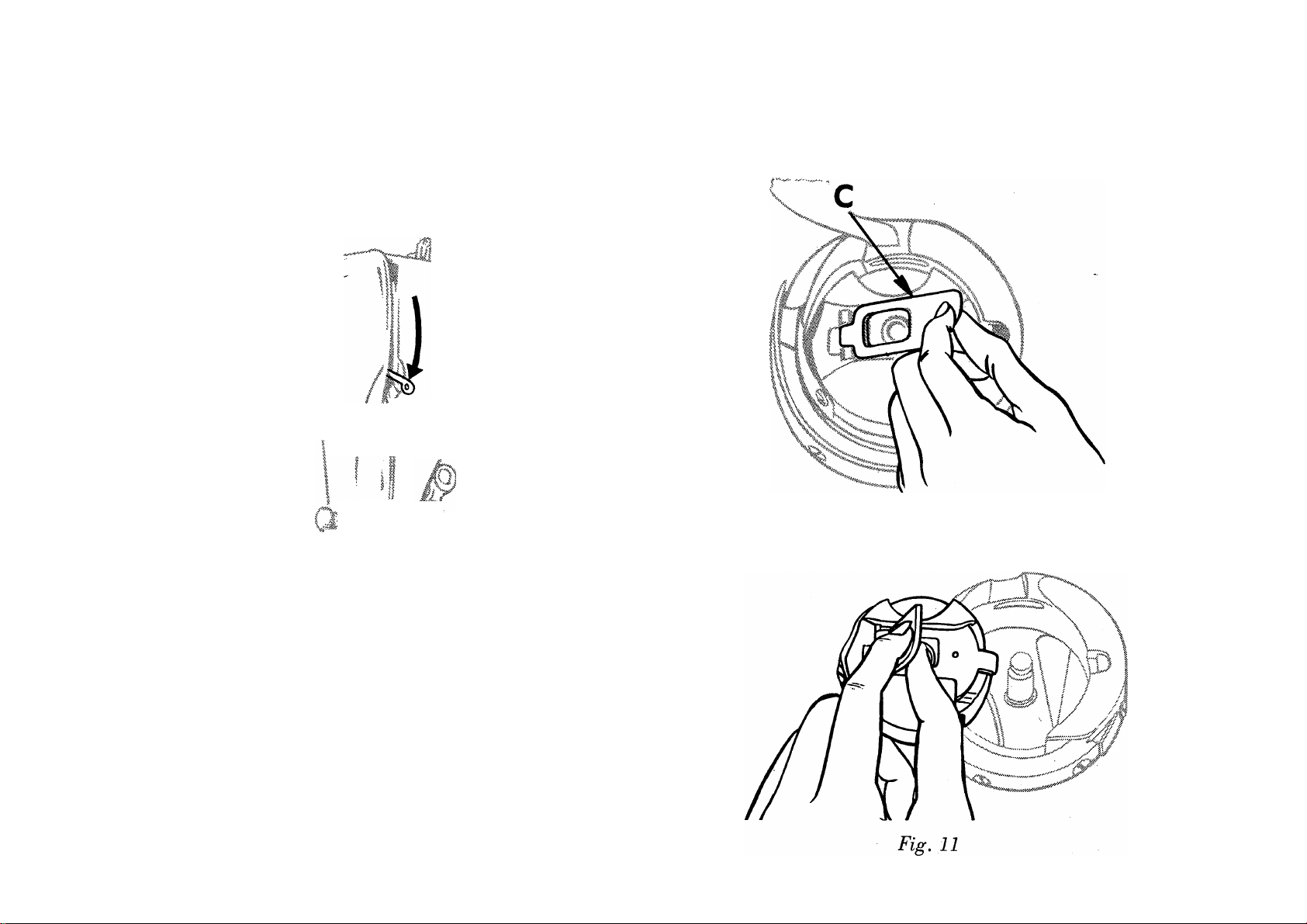

TO REMOVE THE BOBBIN

1. Bring take-up lever to its lowest point.

19

11

li,

. . ...

i i

I -"'n i

§ \ I

I

I ■ ¥ i ^

'a . &

^•> .V^Vi>«S

' "'. ■■ *’n

\ 1

.j

\$

Fig. 10

3. Open bobbin case latch C.

? W if

K.

:<i«.;....5

Fig. 9

2. Tilt machine back on its hinges.

4. Lift case and release latch to remove bobbin.

Page 22

// \

|: / ? ,v

i'i I SI

iia i ^||

|s ”-™-‘

y

: \ i %ii1i- )

Q '

♦

I

I ' 5

20

\ / \ /

\\ /

Fig. i2

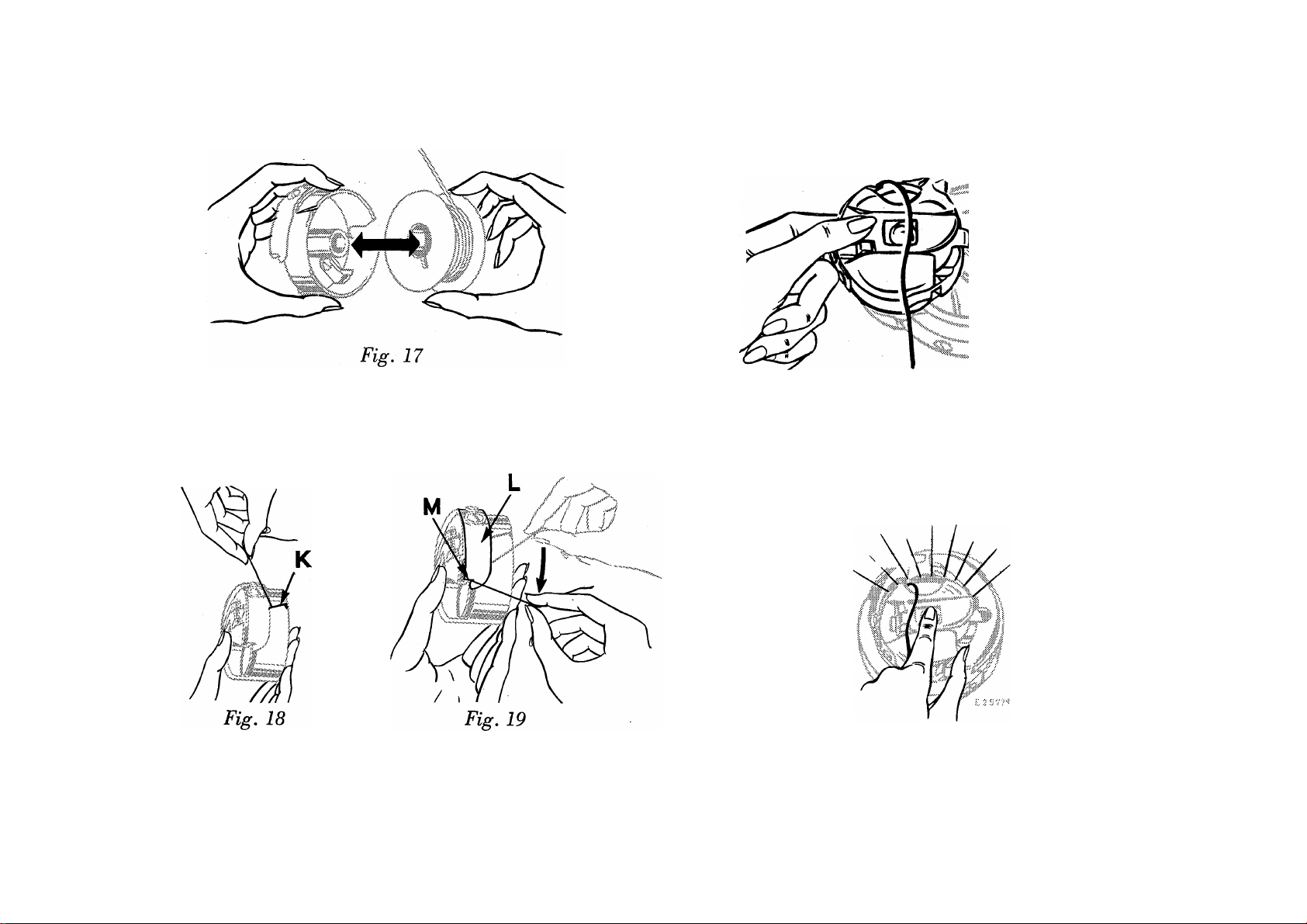

1. Place bobbin on bobbin

winder spindle and turn until

pin enters slot in right side of

bol)bin.

Fig. 13

2. Lock bobbin in place by

pressing bobbin winder down

ward until latch D engages.

Fig. 14

3. Place spool of thread on either spool pin.

Draw thread through self-threading guide E on arm of

machine and pass thread down and from left to right

under tension F on bed. Lead thread up to bobbin and

thread from inside, through slot in left side of bobbin G.

Page 23

21

Allow tension discs F, Fig. 14, to control

flow of thread so that it winds on bobbin in

uniform, level rows. Do not guide or hold

thread when winding bobbin

Fig. 15

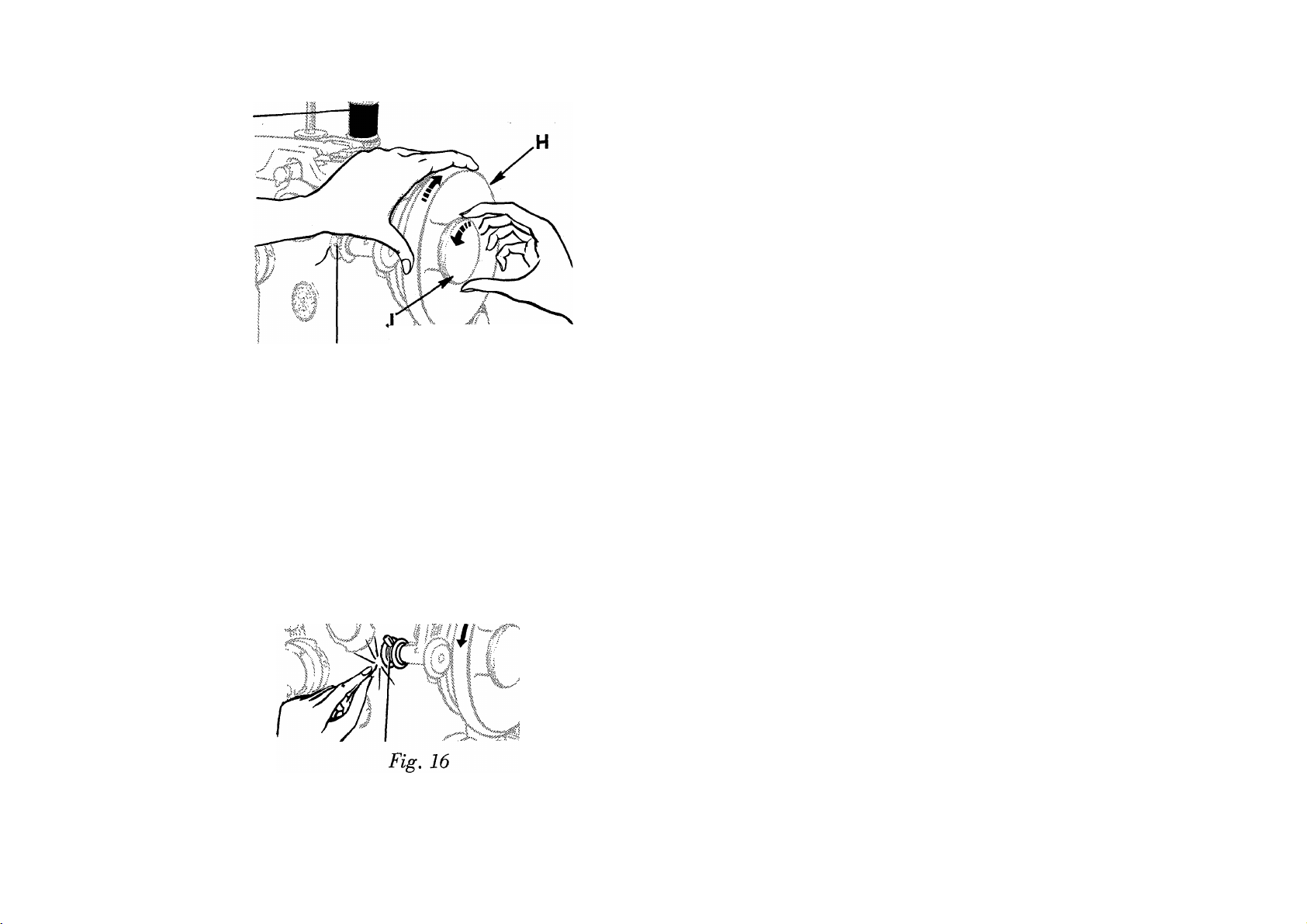

4. Hold hand wheel H with left hand, and

with right hand, loosen stop motion screw J

to release hand wheel from stitching mecha

nism as shown above.

5. Hold end of thread and press controller

pedal as for sewing. End of thread must be

held until it breaks off.

Thé bobbin winder will stop automatically

when the bobbin is filled. When less than a full

bobbin is desired, lift latch D. Remove bobbin

from spindle and retighten screw J, Fig. 15.

NOTE: If bobbin does not wind evenly, loosen

screw

which holds tension bracket F

in

position and move bracket to the left if bobbin

winds high on the right; move bracket to the

right if bobbin winds high on the left. When

bracket is properly centered, thread will wind

evenly across bobbin. Retighten tension

bracket screw.

Bobbin can be wound while machine is sewing.

Page 24

22

TO THREAD BOBBIN CASE TO REPLACE BOBBIN CASE

ci:::::®

1. Hold bobbin so that thread will unwind in

direction shown.

Hold bobbin case as shown above and place

bobbin into it.

2. Pull thread into slot K, under tension

spring L and into slot M at end of spring.

Allow about three inches of thread to hang

free from bobbin case.

Fig. 20

3. Grasp bobbin case between left thumb and

forefinger at latch hinge point as shown.

Tilt right edge of bobbin case slightly to en

gage post.

Fig. 21

4. Release bobbin case and press forefinger

against bobbin case until it snaps in place as

shown.

Page 25

23

FOR ALL-PURPOSE STITCHING

This SINGER Class 319 machine €omes

equipped with five built-in stitch designs, one

removable FASHION Disc, an All-purpose

Throat Plate 105266, and an All-purpose

Hinged Presser Foot. This throat plate and

presser foot have the same wide opening to

accommodate the swing of the needle. With

the equipment listed below, the machine can

perform straight, zigzag or ornamental

stitching.

Fig. 24. All-purpose

Hinged Presser Foot

Fig. 22. Bight Control Set

for Straight Stitching

Fig. 23.

All-purpose Throat Plate with guide lines

for seam width gauged from center of

needle hole and cross lines for gauging

square corners.

Fig. 25. Stitch Levers

A, B, C, A E

Page 26

24

TO PREPARE FOR SEWING

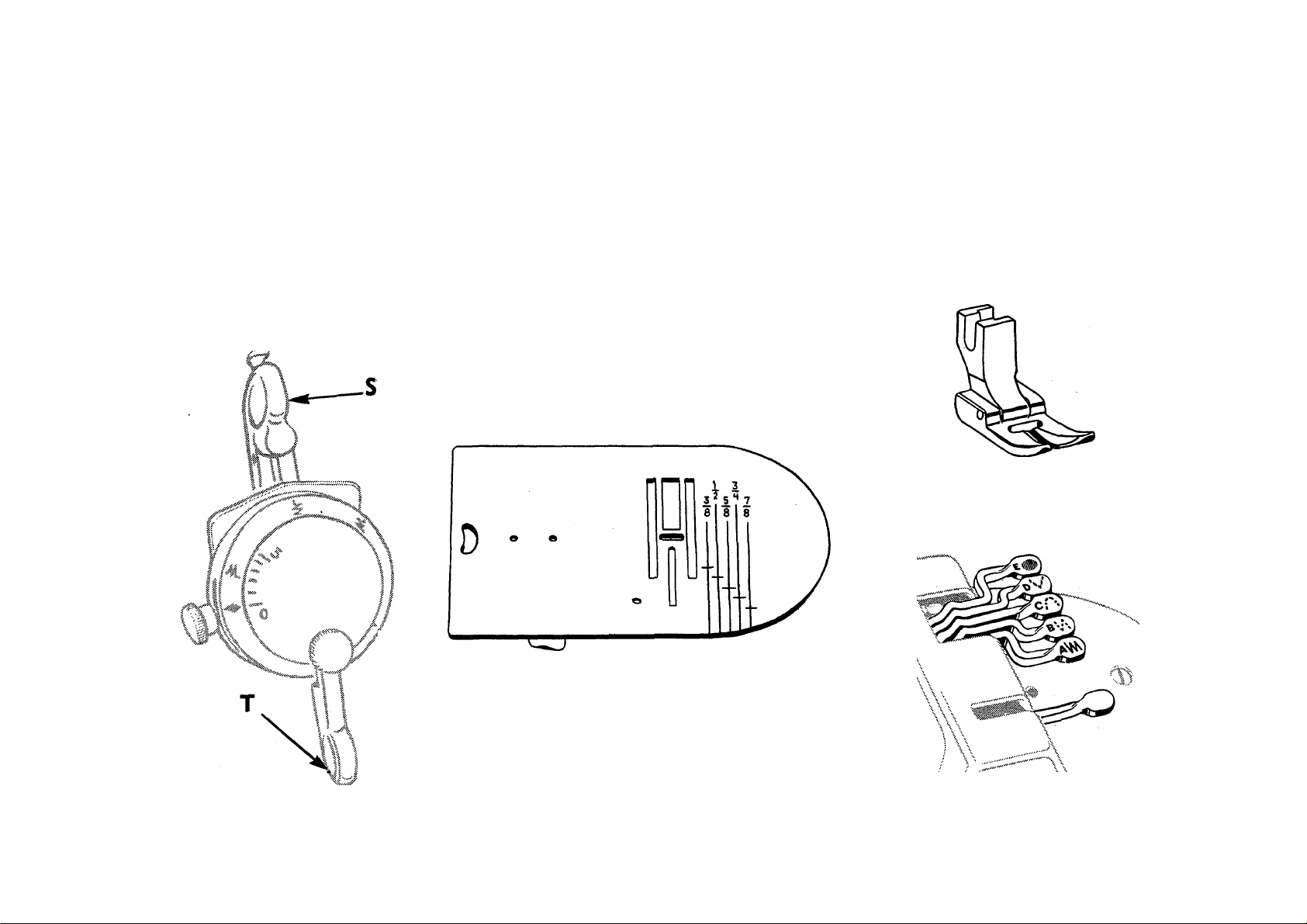

STRAIGHT STITCHING—Set needle posi

tion lever S and bight lever T as shown in

Fig. 26. Set stitch levers in downward posi

tion, as shown in Fig. 27.

Fig. 26

ZIGZAG STITCHING—Set bight lever as

desired between I and 5 as shown in Fig. 28,

and lift Zigzag Lever A, as shown in Fig. 29.

Fig. 28

Fig. 27

Page 27

25

TO PREPARE FOR SEWING (continued)

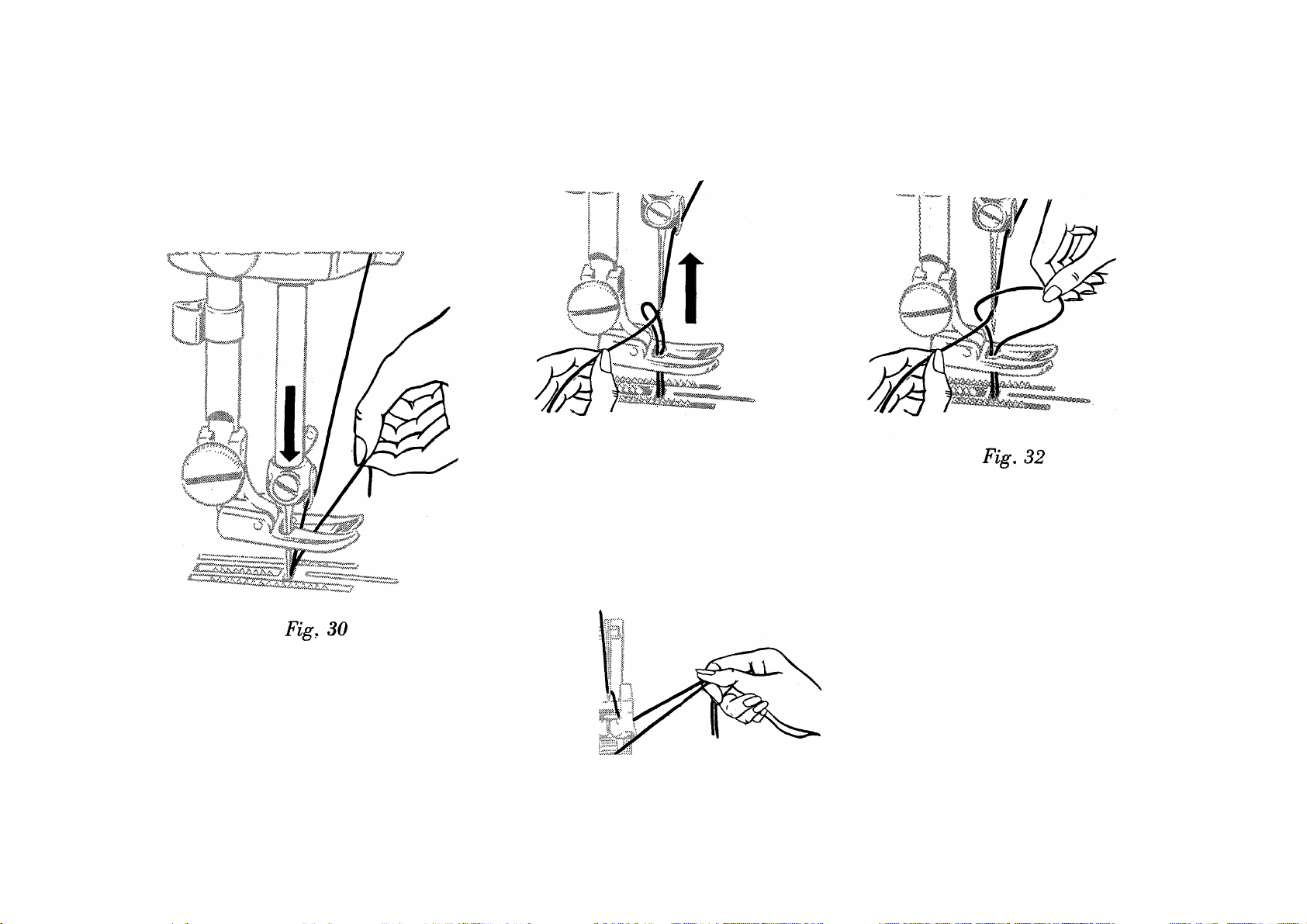

Fig. 31

2. Pull up needle thread and bobbin thread

will come with it, as shown in Figs. 30, 31

and 32.

1. Hold end of needle thread

with left hand and turn hand

wheel toward you until needle

goes down and up again, and

take-up lever returns to its

highest point.

Fig. 33

3. Lay both threads back

under presser foot diagonally

across feed to the right or left

depending upon which side of

the needle the material is to be

located. See Fig. 33. When

the presser foot is lowered the

threads will be firmly held be

tween the feed and the presser

foot.

Page 28

26

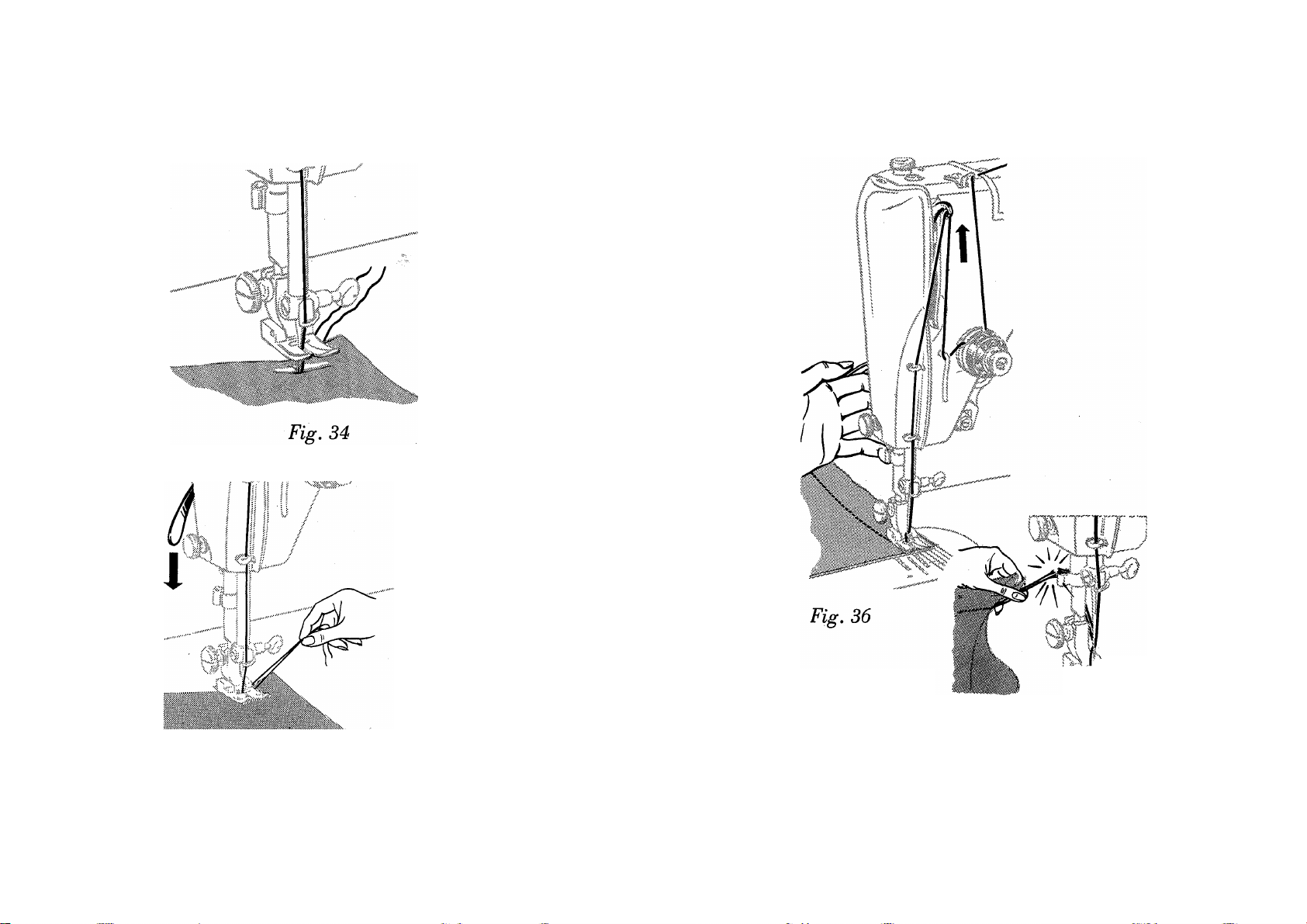

TO START SEWING

1. Bring take-up lever to

its highest point. Place ma

terial under presser foot.

2. Position needle in the

fabric.

3. Lower foot. Hold threads

which have been drawn to

the back toward the right

under the foot. Press con

troller pedal to start ma

chine. The speed depends

upon the amount of pressure

on the controller pedal.

TO REMOVE THE WORK

Fig. 37

4. Stop machine with take-up

lever at its highest point.

Fig. 35

5. Raise foot, draw fabric toward

the back and left and sever

threads on thread cutter.

Page 29

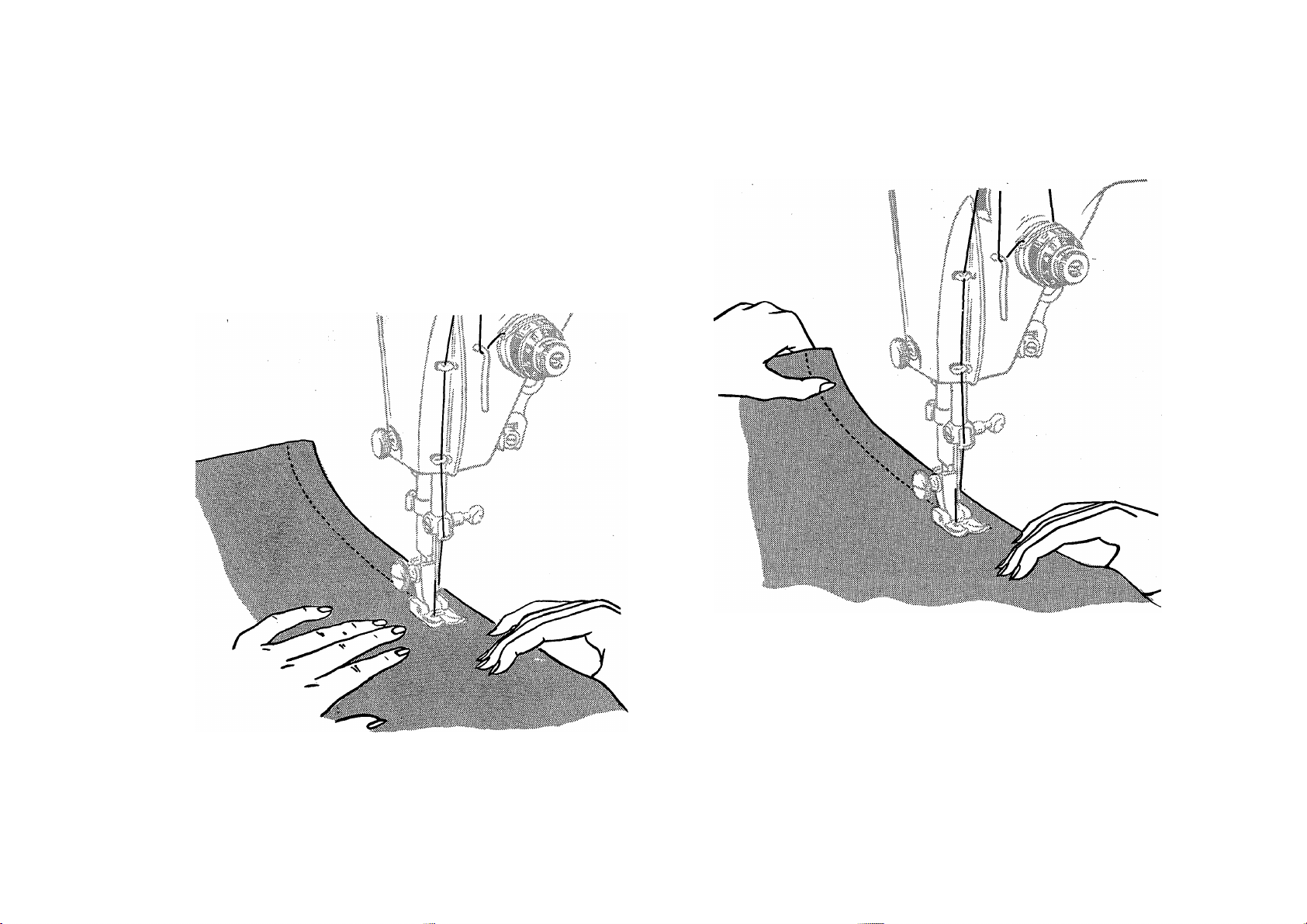

TO GUIDE AND SUPPORT MATERIAL

To avoid uneven tension, length of stitching

and distorted seams, never pull the ma

terial when sewing. Never operate the

machine without material under the presser

foot.

27

Fig, 38. Guiding Material While Sewing

Most materials require only guiding for best

sewing results, as shown above.

Fig. 39. Supporting Miracle Fabrics

Nylon, Dacron, Orion, and blends with rayon,

puffed weaves, sheers, jersey and tricot which

by their nature require light pressure, require

support while stitching. This support is given

by holding the material taut in back and in

front of the foot as the machine stitches and

assures a smooth even seam, as shown above.

Page 30

28

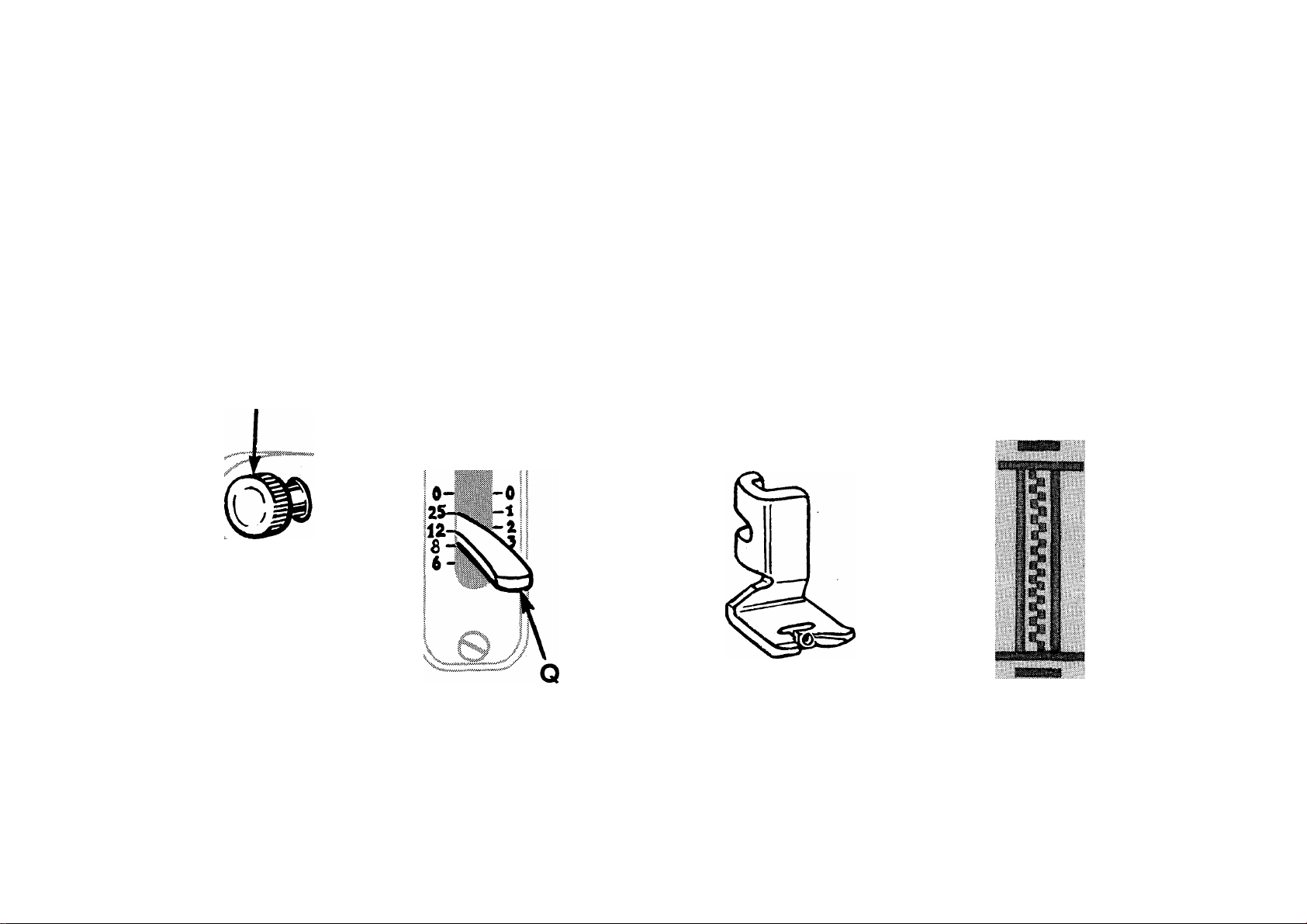

TO REGULATE LENGTH OF STITCH

Straight Stitching—The numerals on the

left of the stitch indicator scale denote the

approximate number of stitches per inch.

Zigzag Stitching—The lengthwise distance

between needle penetrations is controlled by

the stitch regulator.

To Reverse the Direction of Feed—To

feed the material toward you, raise the lever

Q, Fig. 40 as far as it will go. The machine

will then stitch in a reverse direction, thus

making it easy to ''back stitch” and to fasten

ends of seams.

STITCH LENGTH FOR SATIN STITCHING

Fig. 40.

Stitch Length Regulator

To lengthen stitch, loosen limit screw R

enough to allow top of stitch regulator lever

Q to be lowered just below number desired.

Turn limit screw R until top of stitch lever Q

rises to setting desired.

Fig. 41. Satin

Stitch Foot

Satin stitching. Fig. 42, is done with stitch

regulator lever Q set between 25 and 0

position and with the Satin Stitch Foot

Fig. 42. Satin Stitching

Fig. 41.

Page 31

29

SATIN STITCHING—(Continued)

While stitching on a scrap of material, set

stitch regulator lever at 25, then carefully and

slowly turn limit screw R until stitches are

placed closely together, allowing material to

feed smoothly and evenly without irregularity.

The exact setting of the stitch length for

closed satin stitching will vary with the tex

ture of the fabric, the amount of needle and

bobbin thread tension, and with the operator

depending upon whether she holds the fabric

firmly or lightly. A light tension and light even

handling are recommended for satin stitching.

Foot 105251 provides a channel for satin

stitching and gives smooth uniform results.

TO START AT GIVEN PLACE IN A DESIGN

Stitch on a scrap of material until that point

in the design is reached which is to be repro

duced. Remove scrap from under the foot.

e2S7BS

Loosely woven or soft fabrics give best results

when backed with crisp lawn. This backing is

cut away close to the stitching when work is

completed.

Where satin or design stitching is to be done

on a single thickness of the garment, a backing

is essential on most fabrics.

Fig. 43

Fig. 44

Place work under needle. Position needle,

hold thread ends, drop presser foot and stitch.

This procedure is recommended for scalloping

and precise design stitching with all FASHION

Discs.

Page 32

30

BIGHT CONTROL

STRAIGHT STITCHING with straight stitch

ing presser foot, Fig. 46, and straight stitching

throat plate. Fig, 45. The small openings in these

fittings limit straight stitching to central needle posi

tion only. Set bight control at ''0” and stitch levers in

"down” position.

D

Fig, 45

Fig, 46

ZIGZAG STITCHING must be done with the all

purpose throat plate, Fig. 48, and the all-purpose

presser foot, Fig. 49, or any of the special feet which

nave a wide opening to accommodate the sideward

movement of the needle. Lever A is lifted for zigzag

stitching and the bight lever is set at 1, 2, 3, 4 or 5

depending upon the width of stitch desired. Needle

position of right, left or central may be used.

Straight stitching can also be done with this all

purpose equipment.

Fig, 47

To lock bight lever T for straight

stitching bring "0” mark W

opposite indicator V, loosen

MAXIMUM BIGHT STOP

SCREW X, then retighten. Loosen

and move intermediate bight

regulator screw U until it en

gages the notch, then retighten.

AUTOMATIC STITCHING requires the same

throat plate and presser feet as for zigzag stitching.

Levers B, C, D, E or any of the added FASHION Discs

may be used. In addition combinations of levers may

be used to produce an unlimited variety of com

bination stitches.

Page 33

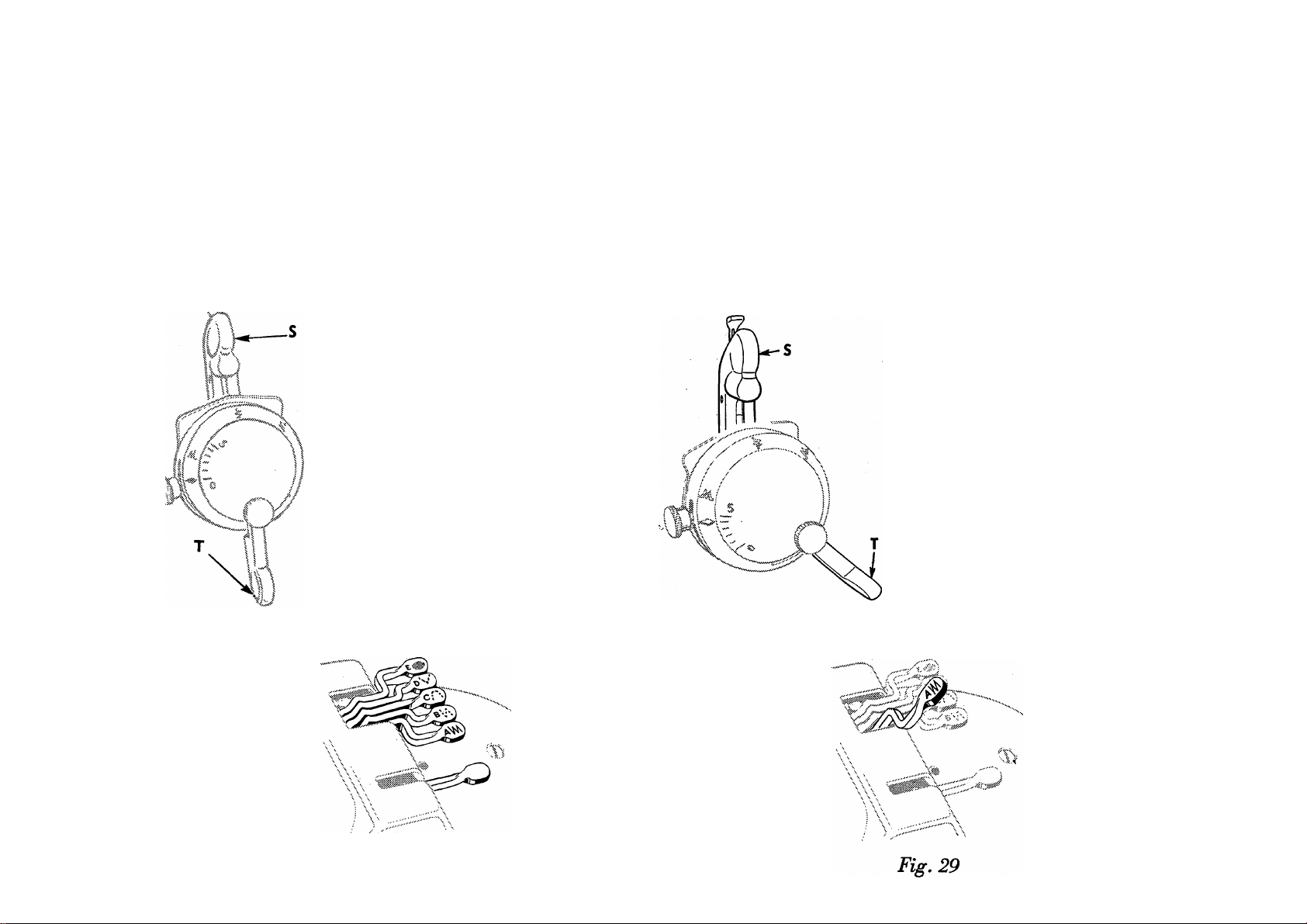

BIGHT LEVER T, Fig. 50, regulates the width of

zigzag stitch or stitch pattern.

BIGHT SCALE is marked "0” to "5”. Each line

between '"0” and "5” denotes the width of stitch pat

tern obtainable up to a maximum of approximately

he inch.

BIGHT INDICATOR. Arrow V is the mark to

which the desired point on the bight scale is set.

31

INTERMEDIATE BIGHT REGULATOR

SCREW U, Fig. 51, acts as an intermediate springstop for a desired minimum bight. This spring-stop

can be passed over to zero bight if desired.

These stops allow you to operate the bight lever

manually between set positions without continual

reference to the dial while sewing. For example: To

limit zigzag stitching between 'T” and "4”, set bight

lever at ''4”, loosen MAXIMUM BIGHT LEVER

STOP SCREW X, then tighten. To set minimum

position 'T”, set bight lever so that arrow V is at *T”,

loosen INTERMEDIATE BIGHT REGULATOR

SCREW U and move it up or down until you feel the

notch engaged, then tighten screw U. The bight lever

is now set to limit the maximum bight at "4” and the

minimum at "1”. Other limits such as *T” and **3”

or and "3” can be obtained in the same manner,

see Fig. 51.

When free movement of the bight lever is desired

between zero and a given bight, screw U should be

moved down as far as it will go and then securely

tightened. Screw X is used to limit the maximum

bight.

ZERO BIGHT is synonymous with straight stitching.

MAXIMUM BIGHT. The machine will sew the

maximum width of stitch or stitch pattern when bight

lever is set at "5”, approximately he inch.

MAXIMUM BIGHT STOP SCREW X restricts

the movement of the bight lever to a maximum width

of stitch less than 5 when set at a given position.

CAUTION: When Straight Stitching Throat Plate

105268 is used, bight lever T must be set at 0,

needle must be set at central position, and all

stitch levers must be down.

Do not make any zigzag stitch, needle position

or stitch lever adjustments while needle is in

material.

Page 34

32

NEEDLE POSITION CONTROL

RIGHT

Fig. 52

When needle position lever S is

set to the left on the dial, as

shown in Fig. 52, the machine

sews at the extreme left for

straight stitching and, as the

bight is changed from ”0” to

*'5”, the needle swings from

the extreme left, as shown

in Fig. 52A for zigzagging.

Fig. 52A

Fig. 53

When needle position lever S

is set at the central position,

as shown in Fig. 53, the

needle swings equally to

the left and right of cen

ter, as shown in Fig. 53A.

Fig 53A

Fig. 54

When needle position lever S

is set to the right, as shown

in Fig. 54, the needle swings

from the extreme right,

as shown in Fig. 54A.

Fig. 54A

CAUTION: Left needle position, right needle position and stitch levers in '"up”

position are used only with the general-purpose throat plate, for straight stitching as well as zigzag

stitching.

Raise needle out of fabric before changing positions of bight control, needle position

and stitch levers.

Page 35

33

TO CHANGE FASHION DISCS

Raise needle out of material.

Set stitch levers in "down” position.

Remove knurled nut Y.

Grasp edges of FASHION Disc Z and draw it

off shaft.

Place new FASHION Disc on shaft so that

pin A2 engages at slot B2.

Replace nut Y and tighten securely. To avoid

variation in stitching, FASHION Disc must

be held in position firmly.

Set bight and needle position levers to de

sired settings and proceed as for regular

Fig. 55. Step 1. Removing Knurled Nut

Page 36

34

TO REGULATE PRESSURE ON PRESSER FOOT

The amount of pressure influences the ease

with which you achieve a straight seam and

uniform stitching. The pressure should be

heavy enough to prevent side creepage of

material and light enough to carry the material

without marking.

■A2

"V., }.-i \

The surface finish on fabrics, as well as their

weight, determine amount of pressure to be

applied. The glazed surface of chintz and pol

ished cotton, the loose nap surface of satin,

the deep piled surface of velvet, the delicate

and broken surface of lace and brocade, all

require a lighter pressui e.

To set a light pressure, turn thumb screw

A2, Fig. 57 upward until fabric moves easily

under presser foot without slipping and with

out showing feed marks.

To set a heavy pressure, turn thumb screw A2

downward until the fabric moves easily and

the seam edges are carried evenly by the foot

and the feed. Heavy, spongy fabrics like towel

ing, chenille, coating, etc., require heavier

pressure.

\ i I

1 k"

IM icSp m ^

i'^i i iji pi'

/A

U \

f !

■ H

ÍÍ

■ f

Fig. 57

Thumb Screw

Adjusted for

Light Pressure

L ^

N-? ^ \ i

k t f n

!«■ \ • / /:

, i

KJJ

Fig. 58

Thumb Screw

Adjusted for

Heavy Pressure

Page 37

35

TO REGULATE PRESSURE ON PRESSER FOOT

Light

»7/

'■SSW№Î«ÿÿÎT«»'№ÎîSÎ%ÎïWS5ÿÿSSÿWWRWK ^

Medium

x-K-»»»»»;«-

'<ww:«oc»x*xx«««««»««’ wsss5Kix«»x«»r

^ I >-

' r"N ■ " /""'"É. y'-'""\

Heavy

Page 38

NEEDLE THREAD TENSION

Thread Tensions for Straight Stitching

For perfect stitching, the tension on needle

and bobbin threads must be heavy enough to

pull threads to center of material and make a

firm stitch.

To Regulate Needle Thread Tension

The tension on needle thread can be tested

only when presser foot is down.

The numerals "0” to "9” on dial B2 indi

cate different degrees of tension that can be

obtained. The higher the number the greater

the tension. The numbers do not denote size

of thread or ounces of tension.

36

Fig. 59. Needle Thread

Tension Too Tight

When tension has been correctly set for aver

age sewing, note number at indicator line C2.

This setting may be quickly regained should

the tension be altered for special work or

change in size of thread.

Tensions Balanced

Page 39

needle thread tension (continued)

In the unbalanced tensions of Fig. 59, the

needle thread lies straight along top side of

material, caused by too heavy tension on

needle thread.

37

In the unbalanced tensions of Fig. 60, the

bobbin thread lies straight along under side of

material, caused by too light tension on needle

thread.

Fig. 60. Needle Thread

Tension Too Loose

Tensions Balanced

Page 40

38

TO REGULATE BOBBIN THREAD TENSION

The tension on bobbin thread is regulated by

the larger screw nearest the center of the ten

sion spring, as shown in Fig. 61.

When adjusting bobbin thread tension, a slight

turn of the screw is all that is needed to make

a fine adjustment, because the full range of

tension from zero to a maximum is made

within IM turns of tension regulating screw.

To increase tension, turn this screw gradually

over to the right.

To decrease tension, turn this screw gradually

over to the left.

Balanced Tensions

Page 41

39

BOBBIN THREAD TENSION (continued)

TO SET BOBBIN THREAD TENSION

Wind bobbin with a 50 yard spool of size "A”

silk thread.

Fig. 62 . Bobbin Thread

Tension Too Tight

x\

\

Thread bobbin case

and adjust tension so

that weight of bobbin

case with a bobbin of

50 yards of "A” silk

will cause the case to

slide slowly5 when held

suspended by the

thread. See Fig. 63.

Balanced Tensions

For correct tension,

its downward move

ment should be very

slow.

Fig. 63

Page 42

40

Satin Stitching

NEEDLE THREAD TENSION

Satin stitching and solid, closed design stitch

ing require a lighter needle thread tension

than for straight stitching or open design

stitching.

Wide satin stitching re

quires the lightest sew

ing tension. Set the ten

sion dial so the indica

Fig. 64

tor line is between 0 and

2, as shown in Fig. 64.

At ''0” there should be a very slight pull on

the thread to indicate there is a minimum

tension.

Soft fabrics should be

backed with crisp lawn

or organdy to prevent

cording and the dial

should be set at 2 or less,

as shown in Fig. 66.

Fig. 66

Fig. 65

For narrower satin

stitching, slightly more

tension may be used. Set

the dial between 2 and 4,

as shown in Fig. 65.

Fig. 67.

Corded Satin

Stitching resulting

from excessive

tension

Fig. 68.

Smooth Satin

Stitching Produced

with correct

tension

Page 43

41

SHOULD IT BECOME NECESSARY TO REMOVE

AND DISASSEMBLE NEEDLE THREAD TENSION

Turn thumb nut E2 to the left (counter-clockwise)

until "0” on dial G2 stops at center line on indicator

L2. To separate pin F2 in thumb nut E2 from dial

TO REASSEMBLE AND REPLACE NEEDLE THREAD TENSION

Make sure that tension releasing pin R2 is in place in

stud N2. Replace the tension parts on the stud N2 as

follows: Replace the three tension discs M2 with the

thick flat disc separating the convex surfaced discs.

Then replace the indicator L2, open side out, on stud

with plus and minus signs at top, then insert tension

spring K2 in indicator with the first (half) coil of this

spring straddling the lower half of the stud. Place stop

G2, press in dial, unscrew thumb nut and remove it.

Then remove tension parts from stud N2, as shown in

Fig. 69. Do not remove stud N2.

washer on stud with extension J2 above stud, so that

it clears the first (half) coil of tension spring. Next,

place dial G2 on stud with No. 2 opposite stop washer

extension J2, then push dial to compress tension

spring and at the same time screw thumb nut E2 on

stud, inserting pin F2 on nut in one of the holes in

dial G2. Then lower presser bar and turn thumb nut

E2 to left until "0” on dial G2 stops at center line on

indicator L2. Thread the tension and

02 P2 Q2

pull thread through tension discs to

test amount of tension on thread at

"0” position.

At this point there should be a slight

pull on the thread to indicate that

there is a minimum tension which

gradually increases with the turning

of thumb nut E2 to the right, pro

viding a full range of tensions with

one revolution of the thumb nut. If

the pull is too strong for a minimum

tension, press in dial G2 to disen

gage pin F2 on nut from dial, and

Fig. 69. Needle Thread Tension Assembly

Page 44

42

reset pin in one of holes at left of previous setting.

This resetting will produce less tension at "0”. Repeat

this process until minimum desired tension

obtained.

If there is no tension at press in dial G2 and

reset pin F2 on nut in one of holes at right of previous

setting, repeating this process until a slight minimum

tension is obtained. The tension on thread take-up

spring 02 and stroke of this spring should be just

sufficient to take im slack of needle thread until point

of needle reaches fabric in its descent.

To adjust tension on thread take-up spring 02, remove

tension disc assembly, disengage end of spring from

groove in tension stud, revolve spring and place its

end in the groove which produces correct tension.

To regulate stroke of thread take-up spring 02 loosen

screw Q2, Fig. 69, and turn the thread take-up

spring regulator P2, Fig. 69 until correct stroke

is obtained, then tighten screw Q2.

is

TO CHANGE THE THROAT PLATE

When changing from All-purpose Throat Plate to

Straight Stitching Throat Plate or Embroidery Plate,

FIRST raise needle to its highest point, set the needle

position lever at its central position and set bight lever

at "0”. Remove presser foot. Tilt the machine head

slightly with right hand.

With the left hand tilt the rounded end of throat plate

by pressing it up from the underside enough to clear

the pin and feed dog as shown in Fig. 70. Then draw

the plate to the left.

Fig. 70. Changing the Throat Plate

To insert the Throat Plate, slip both ends of its

^ring beneath the edges of the opening, as shown in

Fig. 70, and, while it is slightly tilted, slide it over the

feed dog, into position.

Lower the machine head into place.

Page 45

43

TO SET TWIN NEEDLES

This machin« uses a 306x1 Twin Needle in

size 3/14. The markings on the needle indicate

the spacing (3) and size of the needle (14).

Follow procedure described for setting single

needle (see page 17).

CAUTION—Before stitching with Twin Nee

dles be sure the needle position lever is set at

central as shown in Fig. 22, page 23 and

that the machine is operated at a bight not

exceeding 3. Set bight limit screw X, Fig. 50,

page 31 to lock the bight lever at the point

desired but not to exceed 3.

For Twin Needle work the wide slotted throat

plate 105266, and the wide slotted all-purpose

presser foot 105250 or the satin stitch foot

105251 must he used. Heavy, closely stitched,

solid patterns require the satin stitch foot

while straight stitching, scalloping or running

stitch designs are more effectively done with

the all-purpose presser foot. Failure to use the

proper throat plate or presser feet with the

wide openings will blunt or break needles.

Fig, 71. Inserting Twin Needles Into

Needle Clamp

Page 46

44

UPPER THREADING—TWIN NEEDLES

Place a spool on each of the two spool pins.

Thread each point with one thread at a time in the same

manner as for single needle threading with exception of the

tension. Pass one thread between the rear and center

tension discs and the second thread between the

center and front tension discs.

Thread the eye of each needle from

front to back. Threads must not cross

or bind each other. <

Start to sew with threads positioned in

the same way as when stitching with

single needle. , '

Fig. 72

I ^

i I

i I

I I I

Fig. 73

Fig, 74

Page 47

45

TWIN NEEDLE AIR TUCKING

Use: All-purpose throat plate

All-purpose presser foot

Twin Needles

Central needle position

0 bight

12 to 25 stitch

Simple air tucking is effective as an accent

when used to carry out a design or for straight

or diagonal lines of stitching. The two threads

carried by the twin needles interlock with a

single bobbin thread to form air tucking. When

the needle thread tension is increased, the

fabric between the lines of stitching is raised,

creating air tucking.

Select thread of a size appropriate for the

needle being used as well as a thread appro

priate for the fabric. The Fabric, Thread,

Needle and Stitch Length Chart on page 16

is a helpful guide.

Square corners are made by turning twice

while the needles are out of the fabric.

Stitch until the inside needle has reached the

corner. Raise presser foot when needles are

out of the fabric. Make a one-eighth turn of

the fabric, allowing the inside needle to enter

Fig. 75. Twin Needle Air Tucking

for the second time into the corner stitch

penetration. Turn hand wheel until the

needles go down and up again and rise out of

the fabric.

Make the second eighth turn of the fabric.

Allow the inside needle to enter for the third

time into the corner stitch penetration. Con

tinue to stitch in a straight line. When design

is completed draw threads to the underside

and tie.

When using parallel lines of air tucking,

spacing should be such that foot does not ride

over a previously stitched row.

Page 48

46

SEWING SUGGESTIONS

Breaking of needles might he caused by:

1. Wrong size of needle for thread and material—,

see page 16.

2. Wrong throat plate or presser foot for the type of

work being done—see pages 52 and 53.

3. Wrong setting of needle position lever and/or

bight lever—see pages 24, 30, 31 and 32.

4. Pulling of material when stitching—see page 27.

5. Loosely fastened presser foot or special fittings.

6. Wrong class of needle—see page 16.

Breaking of needle thread might he

caused hy:

1. A knot in thread.

2. Thread too coarse for needle—see page 16.

3. Wrong threading—see pages 18 and 44.

4. Upper tension too tight—see pages 36 to 42.

5. Needle blunt or bent.

6. Needle set incorrectly—see pages 17 and 43.

7. Roughened hole in throat plate.

8. Wrong arrangement of threads when starting to

sew—see page 25.

9. Needle thread tension too light.

10. Damaged sewing hook.

2. Bobbin thread tension too tight

42.

3. Bent Bobbin.

4. Damaged Bobbin Case.

see pages 36 to

Skipping of stitches might he caused by:

1. Wrong setting of needle—see pages 17 and 43.

2. Needle blunt or bent.

3. Needle too small for thread—see page 16.

4. Damaged presser foot.

5. Damaged throat plate.

Looped stitching might be caused hy:

1. Wrong threading—see pages 18 and 44.

2. Tensions set incorrectly—see pages 36 to 42.

3. Needle too fine for thread used.

4. Improper presser foot.

Gathering or Puckering of material

might he caused by:

1. Failure to use crisp lawn or organdy backing when

zigzag stitching with a very wide bight and/or on

sheer materials.

2. Excessive needle and bobbin thread tensions.

3. Improper presser foot.

Breaking of bobbin thread might be

caused hy:

1. Wrong threading of bobbin case—see page 22.

If the suggestions offered here do not correct your sewing problems, call your local SINGER CENTER.

If machine runs heavily after standing idle for a

long period, apply a few drops of kerosene at all oiling

points, run the machine for a few minutes, then wipe

clean and apply SINGER* Oil as described on pages

47, 48, 49 and 50.

Page 49

47

PROTECTION AGAINST RUST DAMAGE

Your sewing machine was built to exacting standards of precision and workmanship. Its perform

ance depends on the care and treatment it receives when in use and especially before storing away.

Lint and fluff, if not removed prior to storage will, during humid

periods, absorb and hold moisture, and thus accelerate rust damage

to highly polished thread handling and other exposed parts. The

extent of rust damage would depend upon the length of time the

X ..s-.-N

ii /’X V

CLEAN

AND^

machine remained in idle storage in an unventilated closet, attic or

basement room.

1 ■' tT

- Í

Fig. 75A

■ i< OfL

;> ^

i/CLEAN

CLEAN

Sudden drops in temperature will cause moisture to form on parts,

which if not protected by a film of oil, would rust and damage while

in storage.

Proper storage care suggests thorough brush-cleaning to remove all

traces of lint and fluff, followed by swabbing of all the exposed parts

with a lint-free brush, Fig. 75B, saturated with SINGER oil. See

Fig. 75A for the areas that should be cleaned and coated with a

protective coat of oil.

Fig. 75B. SINGER Lint Brush

Oil-fired ovens; fumes from open flame gas heaters will

cause corrosion, especially if the parts are covered with lint.

Lint brush may be purchased at your local SINGER CENTER.

Page 50

TO OIL THE MACHINE

Preparation

Remove face plate and throat plate and swing back

cover plate toward hand wheel.

Remove dust and lint with brush.

CAUTION: Do not brush sewing hook with fine

bristle brush. (Fine bristles break off and clog the

hook.) Use only brush with stiff bristles such as shown

in Fig. 75B, page 47.

48

Fig. 76. Front View, Showing Oiling Points

Oiling

Apply a drop of oil to all points indicated in Figs. 76,

77, 78, 79 and 80.

Page 51

49

Remove face plate S2, Fig. 76 by taking out thumb

screw T2 and slipping plate up and off screw at U2. Oil the

points indicated in Fig. 78 and then replace plate S2.

U2

Apply a drop of oil to race of bobbin case holder as shown

in Fig. 79.

4

4

4

Fig. 78. Face Plate Removed^

Showing Oiling Points

Fig. 79. Oiling Point in

Bobbin Case Holder

Page 52

50

Turn the machine back on its hinges and oil the places shown in Fig. 80.

The motor requires no lubrication.

Page 53

51

Grasp light socket so that thumb extends over switch X2. Then press

shade with thumb at Y2 to release shade from two catches and slide it

halfway out of shade holder A3. Then press bulb into socket and at

same time turn bulb over from machine as far as it will go to unlock

pin Z2 (see Fig. 83). Withdraw the bulb.

To Insert a New Bulb

Press bulb into socket and turn it over toward machine until pin Z2

enters notch in socket (see Fig. 83). Return shade to its normal

position as shown in Fig. 81.

UNLOCKS

Fig. 83. Locking or

Unlocking Bulb Pin

Fig. 84. Inserting

Bulb in Socket

Page 54

52

ALL-PURPOSE STITCHING EQUIPMENT

189632 Embroidery Plate

105266 All-purpose Throat Plate

105250 All-purpose Hinged Presser Foot

The wide openings in the equip

ment on this page will accommo

date the full range of settings at

tained by moving the needle posi

tion and bight position levers to

any point required.

\ iU

86616 Buttonholer Foot

160847 Multi-slotted Binder

105251 Satin Stitch Foot

189648 Button-Sewing Foot

189653 Shell Hemmer

Page 55

't—;

r

S'' »

105268 Straight Stitching

Throat Plate

53

STRAIGHT STITCHING EOUIPMENT

105248 Straight Stitching

Presser Foot

ir<

ÜI

160845 Cording

or Zipper Foot

{Left Toe)

160846 Cording

or Zipper Foot

{Right Toe)

120598 Ruffler

Fig, 85. Machine Set for

Straight Stitching

CAUTION: All of the parts shown on this page are designed for straight stitching only. They

must not be used for zigzag stitching. Use only AFTER needle position lever S is set at central

position, and bight lever T is set at "0”, as shown in Fig. 85.

Page 56

NEEDLE POSITION LEVER

PRESSURE REGULATING

THUMB SCREW

THREAD TAKE-UP LEVER

FACE PLATE

TAKE-UP SPRING

NEEDLE THREAD TENSION

TENSION REGULATING

THUMB NUT

FACE PLATE

THUMB SCREW

THREAD CUTTER

PRESSER BAR

NEEDLE

PRESSER FOOT

THUMB SCREW

54

SPOOL PINS

DISC FOLLOWER

FASHION DISC

KNURLED THUMB NUT

HANDLE

LATCH

BOBBIN WINDER

HAND WHEEL

BIGHT INDICATOR SCALE

3-PIN TERMINAL

MAXIMUM BIGHT STOP SCREW

BIGHT CONTROL LEVER

STITCH REGULATOR AND

FEED REVERSING LEVER

STITCH INDICATOR

BOBBIN WINDER

THREAD TENSION

STITCH REGULATOR LIMIT SCREW

PRESSER FOOT

FEED DOG

THROAT PLATE

'NEEDLE BAR

'NEEDLE CLAMP THUMB SCREW

'NEEDLE CLAMP

Fig, 86. Names of Principal Parts of 319 Machine

Page 57

55

APPLICATION OF SINGER AUTOMATIC

TO CONSTRUCTION OF GARMENTS AND FURNISHINGS

STRAIGHT STITCHING

finish causes the fabric to cling to the needle,

either on its upward or downward stroke.

r\

\\ry//‘

fFi"

\ / w

Fig. 87

I

W>x

Fig. 88

Straight stitching is accomplished with all

stitch levers in a downward position and with

the bight set at zero as shown in Figs. 87 and

88.

Central needle position is used for straight

stitching except in the unusual situation when

it is desirable to alter the location of the

needle in relationship to the center of the

presser foot.

The Straight Stitching Throat Plate

and Straight Stitching Presser Foot are

designed to accommodate all fabrics, but

especially delicate, soft fabrics, sheers, crepe

weaves and all fabrics where the weave or

convenient for stitching curved seams, follow

ing the edge of a lapped seam, the fold of a

pleat or when placing an edge-stitching on a

yoke or collar. The narrow right toe affords

an excellent view at the right of the needle

for such work.

To Lock Bight Control for Straight

Stitching. When straight stitching, set nee

dle position lever at central, bight lever T at

zero and set maximum bight stop screw X as

shown in Fig. 87. Then bring the inter

mediate bight regulator screw U upward or

downward until you feel the notch engaged.

Test Stitch. It is a good practice to test

stitch on a scrap of fabric before stitching a

garment to determine the correctness of ten

sions, length of stitch and pressure. The

Fabric, Thread, Needle and Stitch Length

Chart on page 16, is a useful guide to the

correct needle, thread and stitch length for a

wide variety of fabrics.

The Straight Stitching Presser Foot is

Page 58

£2(>0&B

56

PLAIN SEAMS—BACK STITCHING

Plain Seams comprise a large part of general sewing.

Seam ends are stayed with back stitching to prevent

their opening during fitting and assembling the gar

ment. Position needle a few stitches from the edge

of the garment. Hold threads which have been drawn

to the back and right under presser foot. Stitch in

reverse to the edge and then forward until end of

seam is reached. Back stitch again to stay end of

seam.

Fig. 89. Seaming Dress Sections

Fig. 90. All-purpose Scored Throat Plate

The All-purpose Presser Foot and All-purpose

Throat Plate are frequently used for both zigzag

stitching and straight stitching and must be used

when straight stitching in other than central needle

position.

The scoring on the throat plate of your SINGER

Swing-Needle makes it easy to guide your stitching

an exact distance from an edge. The cross line

markings indicate the point at which to pivot in

seaming a square corner for each seam width.

Page 59

57

FITTED DARTS

Darts are conveniently stayed at the points by stitch

ing beyond the fabric about one-half inch to foto a

thread chain. Tie these chained threads into a pllin

knot. The last three or four stitches of a dart must be

very close and parallel to the fold, resulting in a

smooth shaping of the garment.

TORSO OR SHAPED DARTS

Torso and shaped darts are stronger and more flexible

when stitched with a shallow zigzag. Stitch the points

for a distance of one inch with straight stitching.

Zigzag center portion.

Use: All-purpose Throat Plate and Presser Foot

Central Needle Position

H to 1 Bight

25 Stitch for Zigzag and 12 Stitch for Straight

Stitching

Lever A

Torso or Shaped Darts

ilSIilim

ml0lk

’ijlmMléf' "

Fig. 92

li

Fig. 93. Contour Dart

Along Raw Edges

CONTOUR DARTS IN INTERFACINGS

Contour darts in interfacings provide perma

nent shaping without bulk when cut, lapped

and zigzag stitched along raw edges as in

Fig. 93. The dart is often cut away, edges

abutted and stayed with straight grain strip

of muslin as in Fig. 94.

Use: All-purpose Throat Plate and Presser Foot

Central Needle Position

5 Bight

25 Stitch

Lever B

Fig

94. Contour Dart

with Abutted Edges

Page 60

m

m

i

|i ;

:E

■

1 1

58

ACCENTED DARTS

Darts add styling and interest when stitched with the fold

to outside of garment. Thread ends at the point of the

dart are eliminated when the single thread principle for

stitching is employed. With thread leading through the

throat plate from bobbin, thread needle from back to

front. Tie bobbin and upper threads together and draw

knot through threading points toward spool until a suffi

cient length of the thread leading from the bobbin has

passed the thread guide nearest the spool to complete

stitching the full length of the dart. Stitch from point of

dart toward edge of garment section. Back stitch to rein

force at outer edge.

Further accent is given to such a dart when an arrowhead

is placed at the point.

Fig. 95. Single Thread Darts

For Arrowhead, use:

All-purpose Throat Plate and Presser Foot

Central Needle Position

5 Bight

Almost 0 Stitch length

Arrowhead Disc No. 5

Page 61

59

CONTROL OF FULLNESS

Contour and shaping are accomplished in garments of soft

and sheer fabrics by contour shirring. Equip machine for

straight stitching, and with a stitch length of 12 or less,

according to the fabric, place five rows of parallel stitching

3^8 inch apart, with the first row Y2 inch from the outside

edge. Draw threads to inside of garment at one end only and

tie. Form a pin tuck across the ends of stitching. Form

shirring by pulling the threads on inside of garment at

second end until shirring has been drawn together suffi

ciently so that garment sections match. Knot thread ends

and finish with a pin tuck. Join sections of garment together.

Three rows of stitching are visible when finished.

Fig. 96. Contour Shirring in Process

When controlling eased fullness in a sleeve cap, at

the elbow of a long fitted sleeve, in the shaping of a

circular hem or in joining yoke or fitting seams,

two lines of control stitching are used and pin

tucks are omitted.

Fig. 97. Contour Shirring Completed

Page 62

£23?3-#

Fig. 98. Couched Elastic Shirring in Process

60

COUCHED ELASTIC SHIRRING

Elastic thread is often used to control fullness at the

waistline or cuff. Zigzag stitch over one or two strands

of elastic thread, drawing the elastic thread to give the

tautness desired. Knot ends securely. This treatment

provides a snug fit with elasticity. Either side may be

used as right side, depending upon the effect desired.

Use: All-purpose Throat Plate and Presser Foot

Central Needle Position

1 Bight

12 Stitch

Lever A

ELASTIC SHIRRING

Elastic thread is wound on the bobbin without stretch

ing, while regular sewing thread is used in the needle.

The machine is regulated for straight stitching. Stitch

parallel rows with a 10 stitch. The bobbin tension is

regulated so that it is heavy enough to stretch the

elastic thread when stitching, but light enough to

avoid breaking or fraying. Thread ends are fastened

securely by tying.

Fig. 99. Elastic Shirring Completed

Page 63

61

ZIGZAG SEAMING

After seams have been basted and fitted, mark

outline of seam on both sections of garment

with hand basting. Remove basting that joined

seams and lay one section over other with seam

lines matching and hand baste. Remove mark

ing stitches. Satin Stitch Foot 105251 (see

page 52) is used to follow outline of lace

motif that runs through seam lap.

Cut away excess seam up to stitching on both

right and wrong sides, using curved em

broidery scissors.

Fig. 100. Invisible Seam for All-Over Lace

Use: All-purpose Throat Plate and

Satin Stitch Foot 105251

Central Needle Position

IH Bight

Above 25 Stitch

Lever A

.•’if ^

■;.f ■ .s-- •■ „/

V: -?• r-

■ i“'' '..v'

i-' ' Ì*

-V" .’*k* '

- ■ >5i’ ■ ,

-» * *;»

' -* «™= '.',

^ ».ft ^ ^ *

» y %; 4k' -,

* ^.0 . , /^-4

. *V- <'

Fig. 101. Invisible Seam for All-Over Lace Embroidery

•xir '-'tif-™®,.:'.

> A, kt \

Page 64

62

CORDING

SEAM WITH SATIN STITCH FOOT 105251

Place a thread through the eye at the front of the foot and

lead it underneath the foot. Cover thread with closely

spaced zigzag stitches.

Use: All-purpose Throat Plate and

Satin Stitch Foot 105251

Central Needle Position

Fig. 102. Cording a Seam with

Satin Stitch Foot 105251

2 Bight

Above 25 Stitch

Lever A

HAIRLINE SEAM IN SHEERS

For a dainty hairline seam in sheers that is also frayproof, follow shaped seam line with a fine cording stitch,

then cut surplus seam away close to line of stitching. This

type of seam may be used either inside or outside.

RIP-PROOF SEAM FOR LINGERIE

For rip-proot seams in lingerie, first straight stitch fitted

seam on wrong side and press both edges to one side.

Fig. 103. Hairline Seam in Sheers

Fig. 104. Rip-proof Seam for Lingerie

Use: 0 Bight

15 Stitch for Straight Stitching

On right side of garment, top stitch with a fine zigzag

stitch allowing needle to enter alternately channel of

seam and seam thickness.

Use: All-purpose Throat Plate and All-purpose Presser Foot

Central Needle Position

2 Bight

25 Stitch

Lever A for Zigzag Stitching.

Page 65

63

INVISIBLE SEAM FOR HORSEHAIR OR

NET BANDINGS

Use: All-purpose Throat Plate and

All-purpose Presser Foot

Central Needle Position

13^ Bight

25 Stitch

Lever A

Guide braid or banding so that edges are abutted as they meet

when passing under slot of foot.

HEAVY DUTY REVERSIBLE SEAM

Fig. 105. Invisible Seam in Horsehair

Fig. 106. Heavy Duty Reversible Seam

Use: All-purpose Throat Plate and Presser Foot

Central Needle Position

2 Bight

Above 12 Stitch

Lever A

For heavy duty, strain-proof seams, use double interlocked

seam, zigzagged on both sides. Turn under raw edge of one

section, and turn up raw edge of joining section. Interlock two

raw edges and zigzag across one seam on right side and across

other seam on wrong side, producing a double fell, doubly

reinforced, with elasticity against strain when wearing.

Page 66

STAYED SEAM FOR JERSEY OR CREPE

Fig. 107. Stayed Seam in Jersey

OVERLAPPED SEAM FOR INTERLINING

64

Seams in fabrics that stretch or bias seams in firm fabrics

are often stayed with seam tape for durability. Position

seam tape with edge exactly on seam line. If seam is

curved, shape seam tape by steaming at the ironing board.

Hand baste if necessary. Stitch with fine zigzag stitching.

Press seam open, after clipping on curve.

Use: All-purpose Throat Plate and Presser Foot

Central Needle Position

K to 1 Bight

12 to 25 Stitch

Lever A

The seams of an interlining are always overlapped to

avoid excessive bulk in a garment. Care must be taken to

use the full seam allowance. Stitch in the center of the

overlap with multiple stitch zigzag. Trim excessive width

from seam edges. This seaming is durable, flexible and

free of bulk.

Use: All-purpose Throat Plate and Presser Foot

Central Needle Position

5 Bight

12 Stitch

Lever B

Fig. 108. Overlapped Seam

for Interlining

Page 67

65

SEAIW FINISHES

TO OVERCAST OPEN SEAMS

Turn raw edge toward wrong side and, while stitching, let it pass

over flanged toe of All-purpose Presser Foot and through slot.

Guide material so that needle, when swinging to the right,

pierces material exactly at edge.

Use: All-purpose Throat Plate and Presser Foot

Central Needle Position

2 Bight

15 Stitch

Lever A

TO FINISH SEAMS IN TRICOT OR SHEERS

Step 1. Stitch seam with short straight stitching

using Straight Stitching Throat Plate and Straight

Stitching Presser Foot. Support material when

stitching as described on page 27.

Step 2. Finish seam edges together with stitching

controlled with the Blind Stitch Disc No. 3. Trim

seam allowance close to stitching. This finish pre

vents fraying and provides a fine smooth edge.

Use: (for seam finish) All-purpose Throat Plate

and Presser Foot

Central Needle Position

1 or 2 Bight

25 Stitch

Blind Stitch Disc No. 3

Fig. 109. Overcasting

Open Seams

Fig. 110. Finishing Seam in Tricot

Page 68

66

TO OVERCDGE SEAMS

Seam edges support the garment and should always carry a durable finish if fit is to be maintained

after long wearing. The stitch made with the Blind Stitch Disc is especially durable and free of

bulk when used as a seam finish.

When seam edges are pressed in the same direction, they are overedged together, and when

pressed open, they are overedged separately.

Use: All-purpose Throat Plate and Presser Foot

Central Needle Position

4 or 5 Bight

25 Stitch

__________

,

Blind Stitch Disc No. 3

Fig. 11.1. Overedging Seam Edges Together

Fig. 112. Overedging Open

Seams in Process

V V;V ¥ 'V ViV V V ¥V'i v ¥ V ¥ V

Fig. 113. Overedged Open

Seams—Completed

Page 69

67

TO MAKE BUTTONHOLES

Step 1. Marking the Material

Mark position and length of buttonholes with basting stitches (see Fig. 114) or marking

chalk.

Step 2. Setting the Machine

Use: All-purpose Throat Plate and Buttonhole Foot 86616 (see page 52)

Left Needle Position (see page 32)

Above 25 Stitch (Stitch on a scrap to attain close setting of stitches.)

2 Bight for Side Stitches of Buttonhole (Use intermediate bight regulator screw.)

4 Bight for Barring Stitches (Use maximum bight stop screw X)

0 Bight for Fastening Stitches

Lever A

NOTE: Bight settings of 2/^ for Side Stitches and 5 for Barring Stitches make slightly

heavier buttonholes.

Step 3. Guiding

With bight lever at 2, position the needle just left of central marking and stitch using

point of buttonhole foot as a guide to keep stitches just left of central marking. (Note

slot in buttonhole foot for drawing needle and bobbin threads through.)

CENTER LINE

OF BUTTONHOLE

r.

t

Fig. 114. Step 1.

Marking Location of

Buttonholes with

Basting Stitches

When needle has reached end of marking, leave needle in fabric at the point nearest

center as shown by A in the illustrations.

Lift foot and using needle as a pivot, turn work around clockwise, as indicated by

arrow B.

Page 70

68

C A

Fig. 116

Step 4

Fig. 117

Step 5

Step 4. Pivoting

Lower foot and take one stitch, leaving needle in material at point C.

Step 5. Barring

With bight lever at 4 take six stitches, leaving needle in fabric at point D at left.

Step 6. Finishing Buttonhole Edge

Fig. 118

Step 6

Return bight lever to 2 and stitch second side of buttonhole,

keeping point of buttonhole foot just left of central marking to

provide sufficient cutting space.

Stop within six stitches of end, leaving needle in fabric at point E

at outside marking. This point may be easily determined, while

stitching, by observing last stitch in first row at lower edge of

opening in buttonhole foot.

''TSKtr"'' '

Fig. 119

Fig. 120

Step 7

Step 7. Finishing Final Bar and

Fastening Stitch

With bight lever at 4 take six stitches

to complete final bar. Set bight lever at

0 and take three fastening stitches at F.

Gut buttonhole along line of center

marking.

Fig. 121

Page 71

Raised or Gimp Buttonholes

Fig. 122. Making

Gimp Buttonholes

69

Insert No. 8 pearl cotton or buttonhole twist

thread through eyelet in front of buttonhole

foot, as shown in Fig. 122 and proceed as for

regular buttonholes as instructed on pages 67

and 68.

£¿1776

Fig. 123. Gimp Buttonholes

Page 72

Fig. 124. To Lower

the Feed

70

TO SEW ON BUTTONS

Lower the feed by turning machine back on its hinges and loosening screw L3,

Fig. 124, turning it over to left (using a screwdriver, if necessary) as far as it

will go. Bring machine forward into place and move stitch regulator lever Q,

Fig, 40, page 28, to 0 position.

When regular sewing is resumed,

tighten feed throw-out screw L3,

turning it to right as far as it will go.

Use: All-purpose Throat Plate

Button Sewing Foot 189648

Left Needle Position

Approximately 3 Bight

0 Stitch

Lever A

Fig. 125. Sewing on Buttons

With bight at 0, position button, drop needle through center of left hole.

Then lower button sewing foot. Turn hand wheel over toward you until

needle rises. Set bight at approximately 3 or so that needle, on its right

swing, enters center of right hole. Then stitch. Needle should enter each

hole six times. To fasten stitch, set bight at 0 and take 3 stitches in left

hole of button.

TO SEW ON BUTTONS WITH THREAD SHANK

Follow steps outlined above and in addition, hold pin or needle between

holes in button to deepen stitches and provide thread shank. A long thread

shank results when the heavy end of sewing machine needle is used in

dace of a pin. Tighten needle thread tension if stitches appear to be

f

oosely set.

Will

Fig. 126. Sewing Buttons with

Thread Shank

Page 73

71

TO SEW ON SNAPS AND HOOKS AND EYES

No Presser Foot is used for sewing on snaps. Instead,

hold snap in place with tweezers, stiletto, or the point of

embroidery scissors.

Lower the feed as instructed on page 70.

Use: All-purpose Throat Plate

Left Needle Position.

0 Stitch setting

2 Bight

Lever A

£ZU39

Turn hand wheel over by hand to bring needle in position

Sewing on Snaps and Hooks and Eyes

Fig. 127

ready for its left swing. Center needle in first hole and

take 6 overedging stitches, leaving needle in hole at left

position on last stitch. Change bight to 0 and take 3 fasten

ing stitches. Carrying thread across snap, center needle in

next hole and change bight to 2. Take 6 over edging stitches, then returning bight to 0, take 3

fastening stitches. Continue this process with each hole.

The same procedure and settings are followed

when sewing on hooks and eyes except that

after taking 6 overedging stitches in first hole

of hook, leave needle in center of hole and

turn work so that next 6 overedging stitches

changing bight to 0, finish with 3 fastening

stitches.

Follow same procedure for sewing on eye,

taking 6 overedging stitches in first hole,

6 overedging stitches across to second hole,

6 overedging stitches to side of hole, and,

will carry across bar of hook, then proceeding

to second hole, take 6 overedging stitches and

changing bight to 0, finish with 3 fastening

stitches.

Page 74

BLIND STITCHED AND DECORATIVE HEMS

Fig. 128.

Blind Stitched Hem in Process

72

BLIND STITCHED HEMS WITH FOLDED EDGE

Blind Stitched hems are appropriate for curtains, draperies,

table linens and fabric furnishings. Fold, press and baste

hem, keeping basting stitches at least M" from upper fold

of hem.

Place hem against feed, turning the bulk of the work back

in a soft fold. Position needle into folded edge of the hem

near this soft fold. The Blind Stitch Disc produces four

straight stitches separated by a single sideward stitch to the

left. The sideward stitch should pierce the soft fold, result

ing in a Blind Stitched hem. The bight is regulated at 2 or 3,

depending on the weight and texture of the fabric.

The length of stitch regulates the distance between the

Blind Stitches.

Use: All-purpose Throat Plate and

Cording Foot (right toe) 160846

Central to Left Needle Position

2 or 3 Bight

12 to 25 Stitch

Blind Stitch Disc No. 3

CAUTION: Left needle position must be used when bight

3 or 4 is used with Cording Foot (right toe).

Fig. 129. Blind Stitched Hem Completed

Page 75

73

SHADOW HEMS FOR TRICOT

Baste hem one-half inch from top edge. Posi

tion under All-purpose Presser Foot and stitch

with 13^ to 2 Bight, 25 Stitch and Blind Stitch

Disc No. 3.

Trim raw edge near solid line of stitching. A

small stitch will he visible at regularly spaced

intervals on the right side of garment. To make

this stitch less apparent, reduce width of bight.

Fig. 130. Shadow Hem for Tricot in Process

Fig. 131. Shadow Hem in Tricot Completed

Use: All-purpose Throat Plate and Presser Foot

Central Needle Position

13^ to 2 Bight

25 Stitch

Blind Stitch Disc No. 3

Page 76

74

BLIND STITCHED HEM FINISHED WITH SEAM TAPE

Hems in skirts, dresses or coats have extra width at the top

of the hem which must be considered. When the garment is

flared or circular, there is more fullness in the hem than in

straight cut styles. This fullness must be controlled before

the hem is finished, if a smooth hem is to result.

After the length of the garment is marked, pin and baste

with silk thread one-quarter inch from crease of hem. Press,

to shape hem allowance, then measure and cut hem to

desired width.

Fig. 132. Seam Tape Basted to Hem

Edge Before Blind Stitching

Control fullness by placing a line of straight stitching onequarter inch from top edge of hem and draw bobbin thread,

easing fullness and shaping top of hem to garment. Steam

to shrink excess fullness.

Baste and stitch seam tape along this quarter inch control

thread. Hand baste through center of seam tape in prepara

tion for Blind Stitching.

Position hem against feed with inside of garment rolled to

the left to form a soft fold at basting line. Blind Stitch hem

with the machine equipped as follows:

Use: All-purpose Throat Plate and Presser Foot

Central to Left Needle Position

1 to 3 Bight

12 to 25 Stitch

Blind Stitch Disc No. 3

Fi^ 133. Blind Stitching Hem

Finished with Seam Tape

Page 77

75

BLENDED CIRCULAR HEM

Circular hems in heavy coatings are smoothly

finished, when the fullness is removed, by cut

ting away narrow wedges at regular intervals to

allow the hem to conform exactly to the shape

of the garment. The cut should not extend

beyond one inch from the lower fold of the

hem. Garments where this treatment is used

are usually lined and the lining is carried to

one inch from the edge.

Bring cut edges together and stitch with

Multiple Stitch Zigzag Disc. Should the fabric

be loosely woven, an underlay of thin lawn

may be used as a stay on the underside.

Use: All-purpose Throat Plate and Presser Foot

Central Needle Position

5 Bight

25 Stitch

Lever B

The edge of the hem is finished by over edging

with Blind Stitch Disc No. 3, 5 bight, and

25 stitch, as described on page 66.

Hand baste hem to garment three-eighths inch

Fig. 134. Blended Circular Hem

from top edge of hem. Place hem against feed

and turn garment to form a soft roll at basting

line as in Fig. 133, page 74.

Use: All-purpose Throat Plate

Cording Foot (right toe) 160846

Needle Position, slightly left of Center

2 to 3 Bight

Blind Stitch Disc No. 3

Page 78

Fig, 135, Applique Shadow Hem in Process

76

APPLiaUE SHADOW HEMS

Shadow hems are lovely for table linens of crisp

organdy or fine linen, as well as for dresses or aprons of

sheer, crisp fabrics. Baste hem to full depth of design,