Page 1

Instruction Manual

and Parts List

High Speed Straight

Lockstitch Sewing Machine

20 / 20C

30 / 30C

70 / 70C

191D

® Singer is a registered trademark of The Singer Company Limited or its affiliated companies.

© 2009 Copyright The Singer Company Limited

Page 2

Contents

1 Safety Instructions 1

1.1 Important Safety Instructions 1

1.2 Safe Operation 2

2 Product Description and Machine Specification 3

2.1 Product Description 3

2.2 Machine Specification 4

2.3 Motor, Motor Pulley and V-Belt Specifications 4

3 Setup and Adjustment Instructions 5

3.1 Table Cut-Out Drawing 5

3.2 Oil Reservoir Installation 6

3.3 Belt Cover and Bobbin Winder Installation 7

3.4 Lubrication 8

3.5 Thread Take-up Lever Oil Supply Adjustment 8

3.6 Rotating Hook Oil Supply Adjustment 9

3.7 Needle Attachment 10

3.8 Bobbin Case Attachment 11

3.9 Machine Threading 11

3.10 Stitch Length Adjustment 12

3.11 Thread Tension Adjustment 12

3.12 Thread Take-Up Spring Adjustment 13

3.13 Knee Lifter Height Adjustment 14

3.14 Presser Foot Lifter Adjustment 14

3.15 Presser Foot Pressure Adjustment 15

3.16 Feed Timing Adjustment 16

3.17 Feed Dog Height Adjustment 17

3.18 Needle to Rotating Hook Relation Adjustment 18

3.19 Presser Bar Height Adjustment 19

3.20 Thread Take-Up Stroke Adjustment 20

4 Maintenance 21

4.1 Machine Head Cleaning 21

4.2 Lubrication 21

4.3 Safety Inspection 21

5 Troubleshooting 22

Page 3

Contents

6 Parts List 23

6.1 Frame and Cover Components 24

6.2 Arm Shaft and Thread Take-Up Lever Components 26

6.3 Needle Bar, Upright Shaft and Rotating Hook Driving Shaft

Components

6.4 Presser Foot Components 30

6.5 Feed Mechanism Components 32

6.6 Lubrication Components 34

6.7 Oil Reservoir Components 36

6.8 Belt Cover, Bobbin Winder and Thread Stand Components 38

6.9 Machine Accessories 40

28

Page 4

Safety Instructions

1.1

Important Safety

Instructions

Important

When using the

machine, basic safety

procedures must

be followed. Read

with attention all

instructions before

using the machine.

When using it,

understand that

all basic safety

instructions are

not limited to the

following items.

Read all instructions,

take care of this

manual, and use it

as reference when

necessary.

• Before running the machine, make

sure all relevant safety specifications are adequate to specifications and technical standards in

your country.

• The machine should not be run

without its safety devices.

• The machine should only be operated by properly trained personnel.

• For your safety, goggles must be

used while running the machine.

• Turn off or unplug the machine

when the following situations arise:

• Passing the thread by the needle or replacing the bobbin or

looper.

• Replacing the needle, presser

foot, throat plate, feed dog and

sliding plate.

• When the machine is in maintenance.

• When the operator is not running the machine.

• In case of lubricant oil contact

with the eyes or skin, washed the

surface with plenty of icy water

with a generous amount of cold

water. In case of ingestion, seek

medical help immediately.

• Maintenance and repair on electric equipment should only be

made by qualified personnel. If

any electric device is damaged,

the machine should be immediately stopped.

• Before starting the machine in full

running, a test must be conducted

to assure that machine and operator are able to perform the task.

• The machine should not be placed

next to a sound source as an ultrasonic welding machine and other

equipment.

• The machine should only be run

with the proper electric cable and

connectors, and also the adequate

grounding.

• The machine should only be used

to sew materials as indicated in

its instructions manual, and indications of use should be followed.

Singer will not be held responsible

for any damage caused by unauthorized changes in the product.

• Repair, fitting or maintenance

should only be performed by

properly trained personnel.

High Speed Straight Lockstitch Sewing Machine | Instruction Manual and Parts List

1

Page 5

1.2

Safe Operation

• To avoid the risk of electric shock,

do not open the motor wiring box

and do not touch the components

assembled inside the wiring box.

• To avoid injuries do not run the

machine without the belt cover or

in case any other safety device is

removed.

• To avoid possible injuries keep fin-

gers,

wheel, belt and motor when the machine is running. Nothing should be

placed near those parts.

• To avoid injuries never put your

fingers next to the rotating hook

and the thread take-up lever cover

when the machine is running.

• To avoid possible injuries be care-

ful when putting down or lifting

the machine head.

head and clothes far from

• If you machine is equipped with

a servomotor, it does not make

noises while being driven. To avoid

a possible accident caused by an

unexpected start, be sure the machine is turned off.

• To avoid electrical shock, do not

run the machine without proper

grounding.

• To minimize the risk of accidents

or damage in electric components

caused by electric discharge turn

the machine off before unplugging it.

• Clean the machine periodically.

• To avoid accident in case of a sudden start of the machine always

turn it off when laying it down, or

remove the belt cover and the belt.

High Speed Straight Lockstitch Sewing Machine | Instruction Manual and Parts List

2

Page 6

2.1

Product

Description

Product Description

and Machine Specification

High Speed Straight Lockstitch Sewing Machine

High Speed Straight Lockstitch Sewing Machine | Instruction Manual and Parts List

3

Page 7

2.2

Machine

Specification

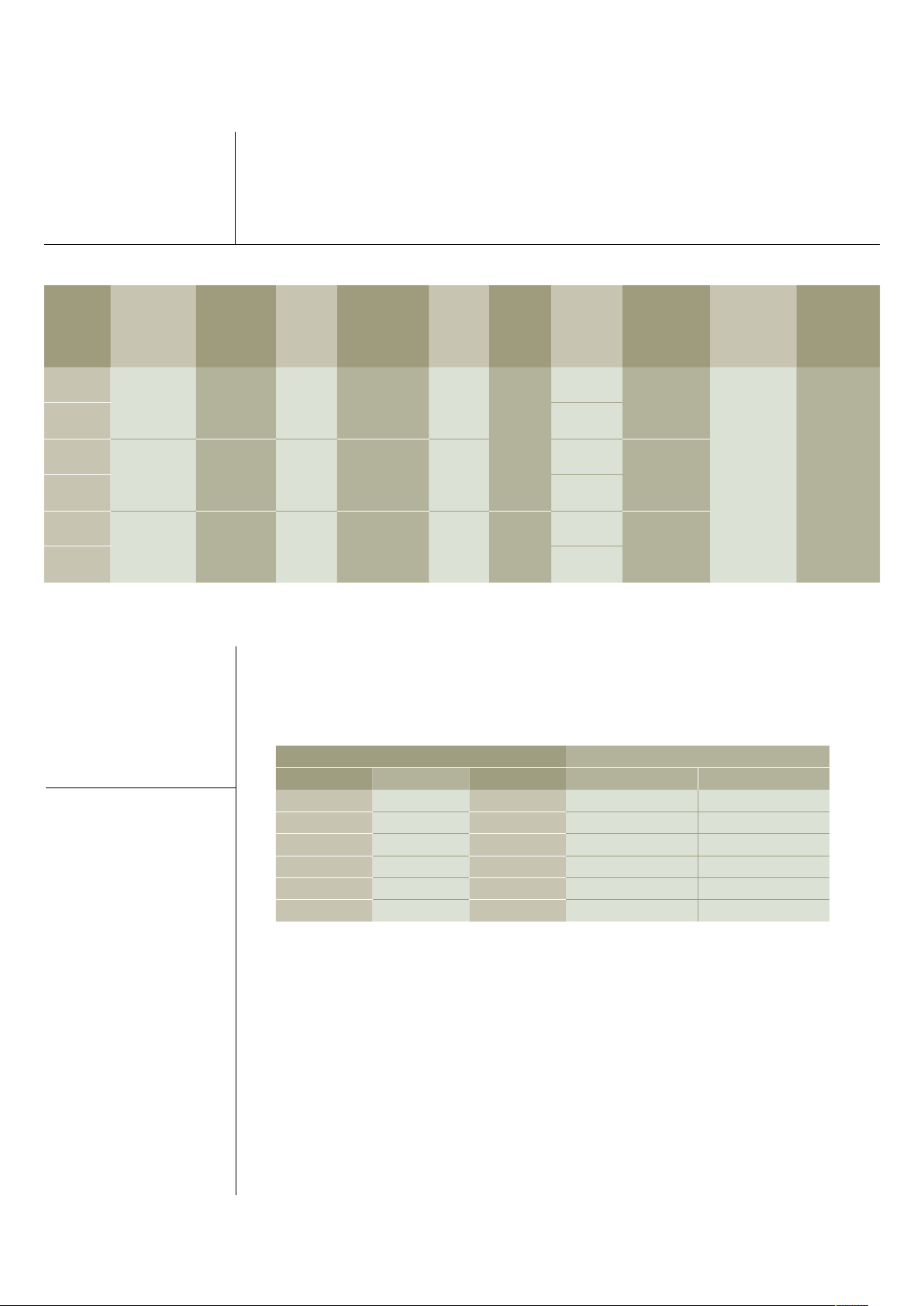

Table 1 – Machine Specification

Singer

Model

191D-20

191D-20C

191D-30

191D-30C

191D-70

191D-70C

Application Maximum

Light to

medium

Medium to

heavy

Heavy

2.3

Motor, Motor

Pulley and V-Belt

Specifications

Speed

[spm]

5,000 5.0 5.5/13.0 30.7

4,500 5.0 5.5/13.0 35.0

3,000 7.0 5.5/13.0 35.0 Large

Stitch

Length

[mm]

Height of

Presser Foot

by hand / by

knee [mm]

Needle

Bar

Stroke

[mm]

Hook

Type

Regular

• ½ HP (400W) 2-pole (high speed) clutch motor

• M type v-belt

Table 2 – Machine Speed vs. Motor Pulley Diameter

Machine Speed [spm] Motor Pulley Diameter [mm]

191C-20 / 20C 191C-30 / 30C 191C-70 / 70C 50 Hz 60 Hz

5,000 - - 125 105

4,500 4,500 - 115 95

- 4,000 - 100 85

- 3,500 - 90 75

- - 3,000 75 65

- - 2,500 65 55

Hook

Origin

Standard

Koban/

Hirose

Standard

Koban/

Hirose

Standard

Koban/

Hirose

Needle Cat. Lubrication Lubrication

1955-01 #14

Fully

1955-01 #18

1955-01 #21

Automatic

Lubrication

Oil

Singer “C”

type oil

High Speed Straight Lockstitch Sewing Machine | Instruction Manual and Parts List

4

Page 8

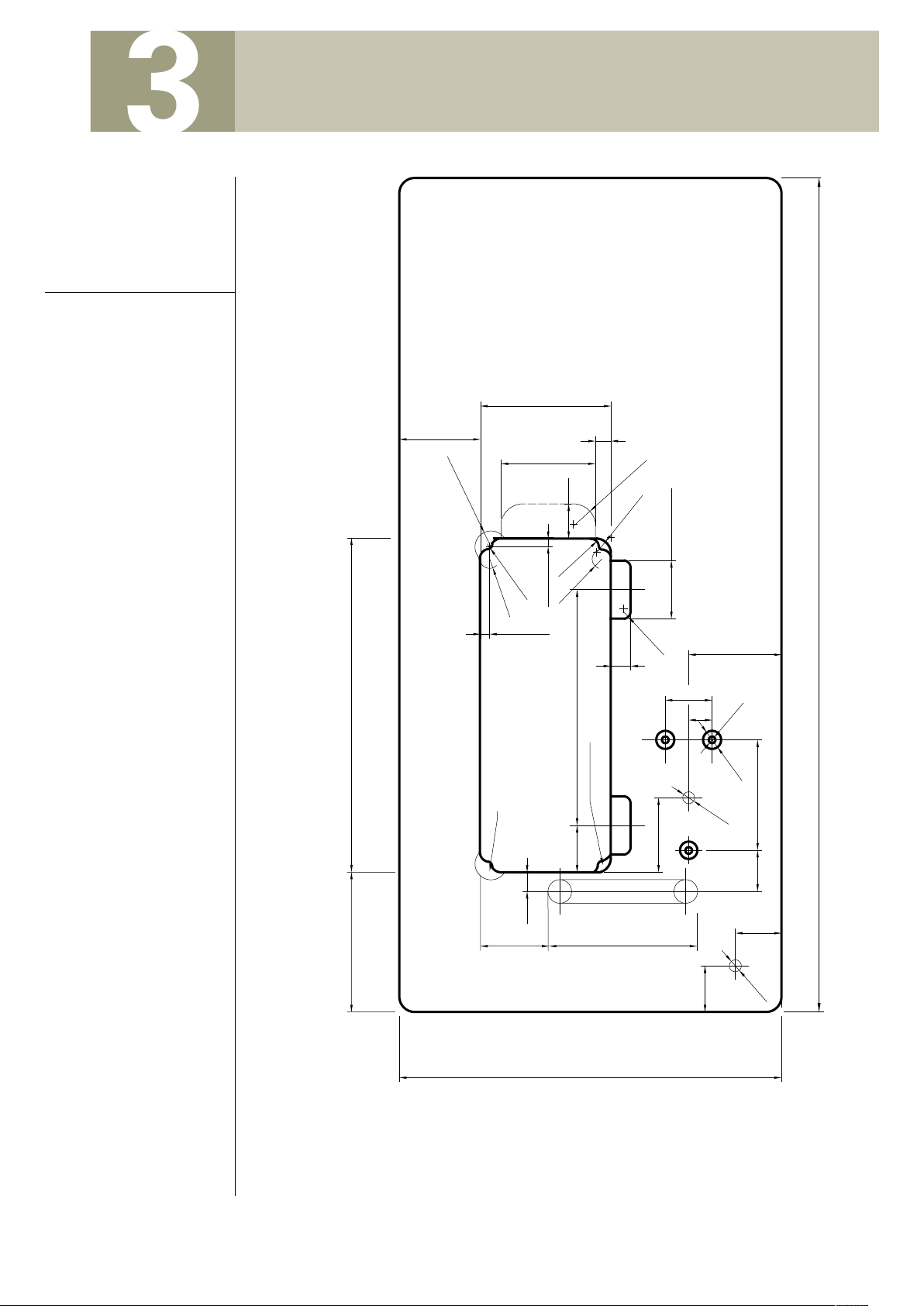

3.1

Table Cut-Out

Drawing

Setup and Adjustment Instructions

+ 1

- 0

181

115

2

-R

2

2

.

5

- 0

+ 1

130

2-R18

4

-R

1

2-12.75

0

2-12.75

2-DEEP 23

50

4-R10

2-R20

339.7

68.1

22

2-R30

2-R20

28

2-DEEP 18

4-R1

0

108

2-80

2-DEEP 17

66

33

DEEP 1

Ø

D

EE

P

1

28

130

Ø8.5

Ø

6

1200

2

4

159

59

28

200 480

95 206

65

535

65

Ø18

Figure 1

High Speed Straight Lockstitch Sewing Machine | Instruction Manual and Parts List

5

Page 9

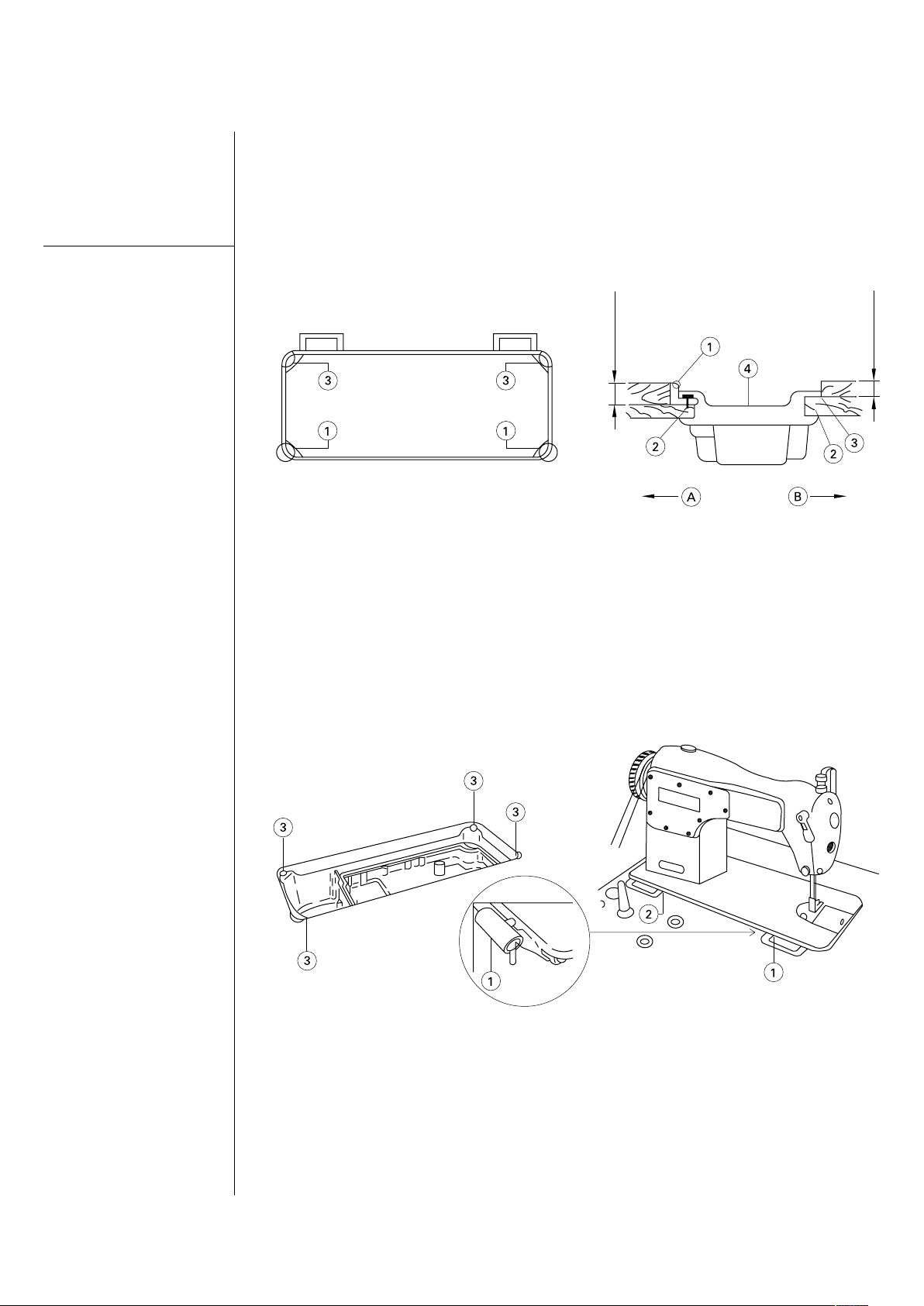

3.2

Oil Reservoir

Installation

The oil reservoir should rest on the

four corners of the machine table

groove.

Two rubber seats ‘1’ for supporting

the head portion on the operator

side ‘A’ are fixed on the extended

portion of the table by using nail ‘2’,

and the other two rubber cushion ‘3’

on the hinge side ‘B’ are attached by

nail too. Then, the oil reservoir ‘4’ is

placed (Figures 2 and 3).

Figure 2 Figure 3

Two hinges ‘1’ fit into the hole in the

machine bed, and the machine head

fitted the table hinge’s rubber ‘2’,

before the machine head is placed

23.5mm

to the cushions ‘3’ on the four corners of the table (Figures 4 and 5).

19.5mm

Figure 4 Figure 5

High Speed Straight Lockstitch Sewing Machine | Instruction Manual and Parts List

6

Page 10

3.3

Belt Cover and

Bobbin Winder

Installation

Caution

For safety, the

belt cover should

be installed.

The left and

right parts of the

bobbin winder

should be parallel

to the plate

belt slot on the

machine table.

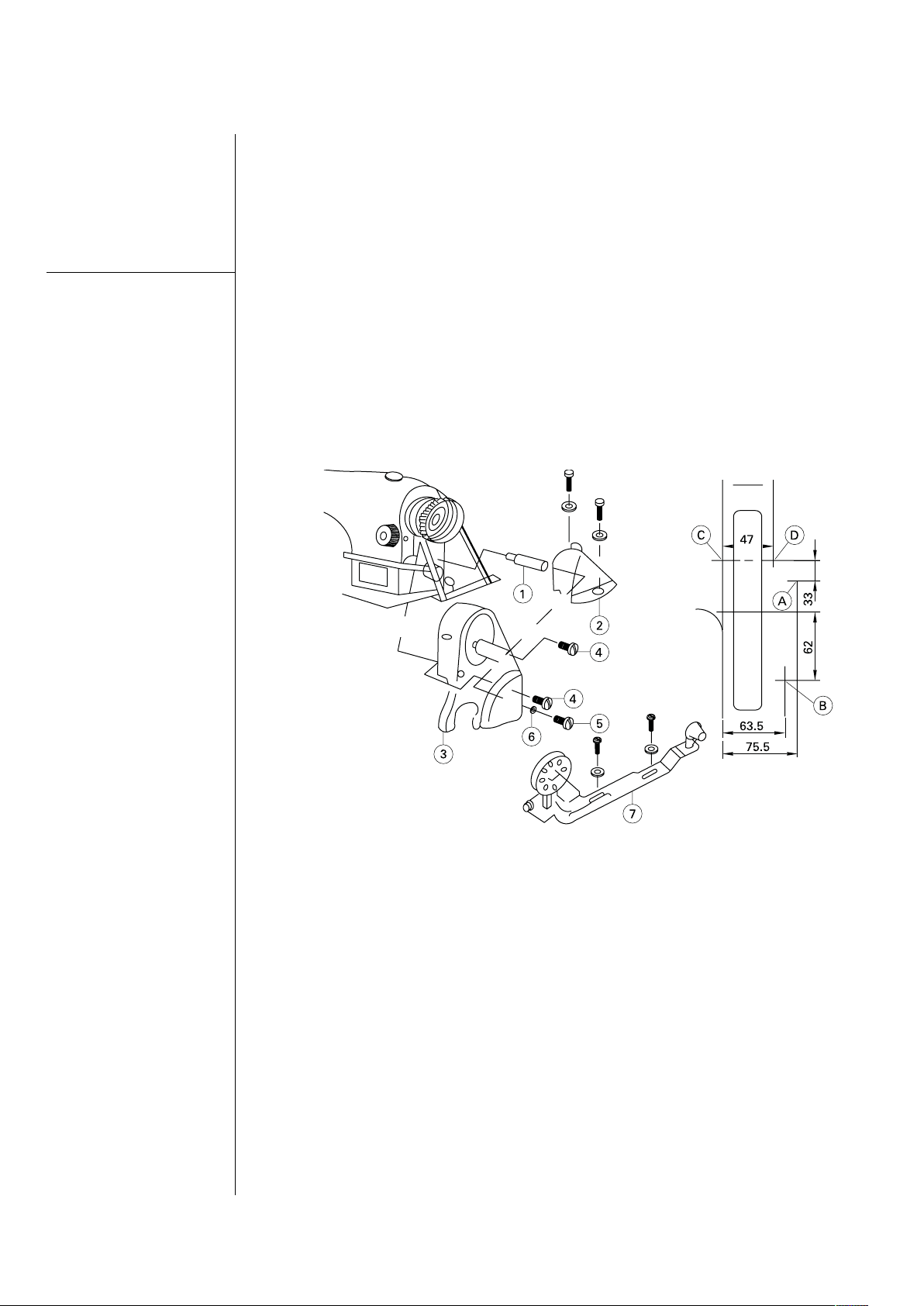

Drill four holes ‘A’, ‘B’, ‘C’ and ‘D’,

in the machine table for screws

(Figure 6).

Insert support ‘1’ in the threaded

hole in the housing.

Install the front belt cover ‘3’ and

get the hand wheel in the middle of

the cover hole.

Install the back belt cover ‘2’ at

holes ‘C’, ‘D’.

Fix the front belt cover ‘3’ on the

support with screws ‘4’, ‘5’ and

washers ‘6’. The tightening torque

for the screw ‘4’ is about 30 kgf×cm,

and for the screw ‘5’ is about 25

kgf×cm.

Move the back belt cover ‘2’ backward, until its rubber touches the

front belt cover ‘3’, move it again for

0.5~1.0 mm and fix it with screws

and washers.

Fix bobbin winder ‘7’ at hole A’, ‘B’

with screws and washers.

Figure 6

High Speed Straight Lockstitch Sewing Machine | Instruction Manual and Parts List

7

Page 11

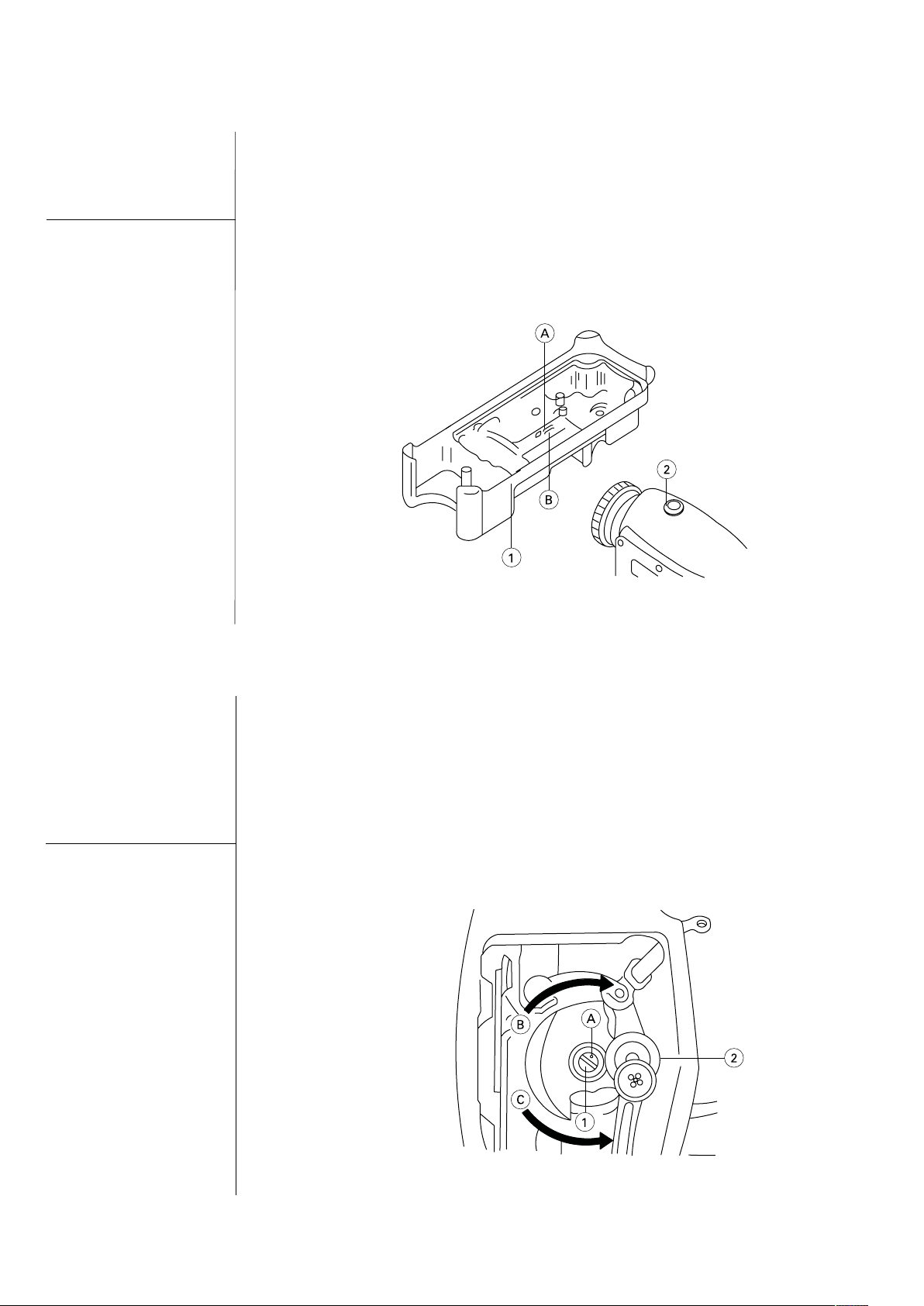

3.4

Lubrication

Before turning the machine on,

fill oil reservoir ‘1’ with sewing

machine oil up to ‘MAX’ mark ‘A’

(Figure 7).

When you operate the machine after lubrication, you will see splashing oil through oil sight window ‘2’

if the lubrication is adequate.

Precaution

When you first operate

your machine after set

up or after an extended

period of disuse, run

your machine at 2,000

to 2,500 spm for about

10 minutes for the

purpose of bread-in.

When the oil level lowers below

‘MIN’ mark ‘B’, refill the oil reservoir with the specified oil.

Figure 7

Note that the amount of the splashing oil is unrelated to the amount

of the lubricating oil.

3.5

Thread Take-up

Lever Oil Supply

Adjustment

Adjust the amount of oil supplied

to the thread take-up and needle

bar crank ‘2’ by turning adjusting

pin ’1’ (Figure 8).

The minimum amount of oil is

reached when marker dot ‘A’ is

brought close to needle bar crank

‘2’ by turning the adjusting pin ’1’

in direction ’B’.

The maximum amount of oil is

reached when marker dot ‘A’ is

brought to the position just opposite from the needle bar crank by

turning the adjusting pin ’1’ in direction ‘C’.

Figure 8

High Speed Straight Lockstitch Sewing Machine | Instruction Manual and Parts List

8

Page 12

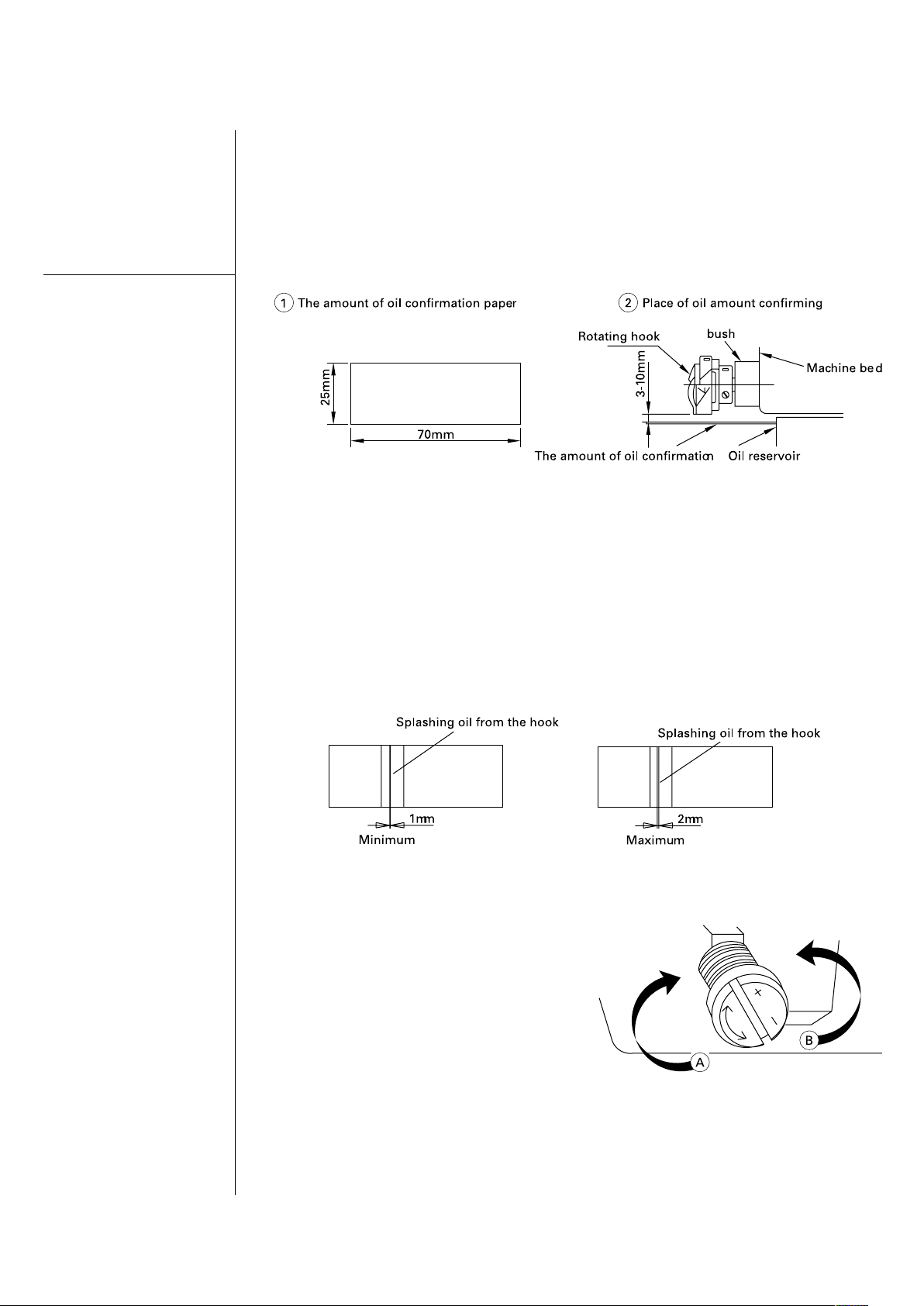

3.6

Rotating Hook

Oil Supply

Adjustment

Unused machine should run idle for

3 minutes (Moderate intermittent

operation).

The amount of oil confirmation paper

must be inserted in the state when

the machine is running (Figure 9).

Figure 9

Make sure the oil in the oil reservoir

is within ‘MAX’ and ‘MIN’.

The confirming time of the oil

amount is 5 seconds (check the period of time with a watch).

Sample showing the appropriate

amount of oil (Figure 10)

The amount of oil can be adjusted

according to the different sewing

process but it must be a suitable

amount. Otherwise the hook will

Figure 10

Adjusting the amount of oil supplied to the hook (Figure 11)

Turning the oil adjusting screw of the

hook shaft bushing on bed toward

‘+’ in direction ‘A’, the oil amount

will be increased, and toward ‘-‘ in

direction ‘B’, the oil amount will be

decreased.

After adjustment the machine must

be idling for thirty seconds. It can be

confirmed the state of oil supplied.

generate heat or the sewing material will be contaminated.

Use the amount of oil confirmation

paper for three times to observe the

amount of oil. Adjust the screw until

the mark on the paper unchanged.

Figure 11

High Speed Straight Lockstitch Sewing Machine | Instruction Manual and Parts List

9

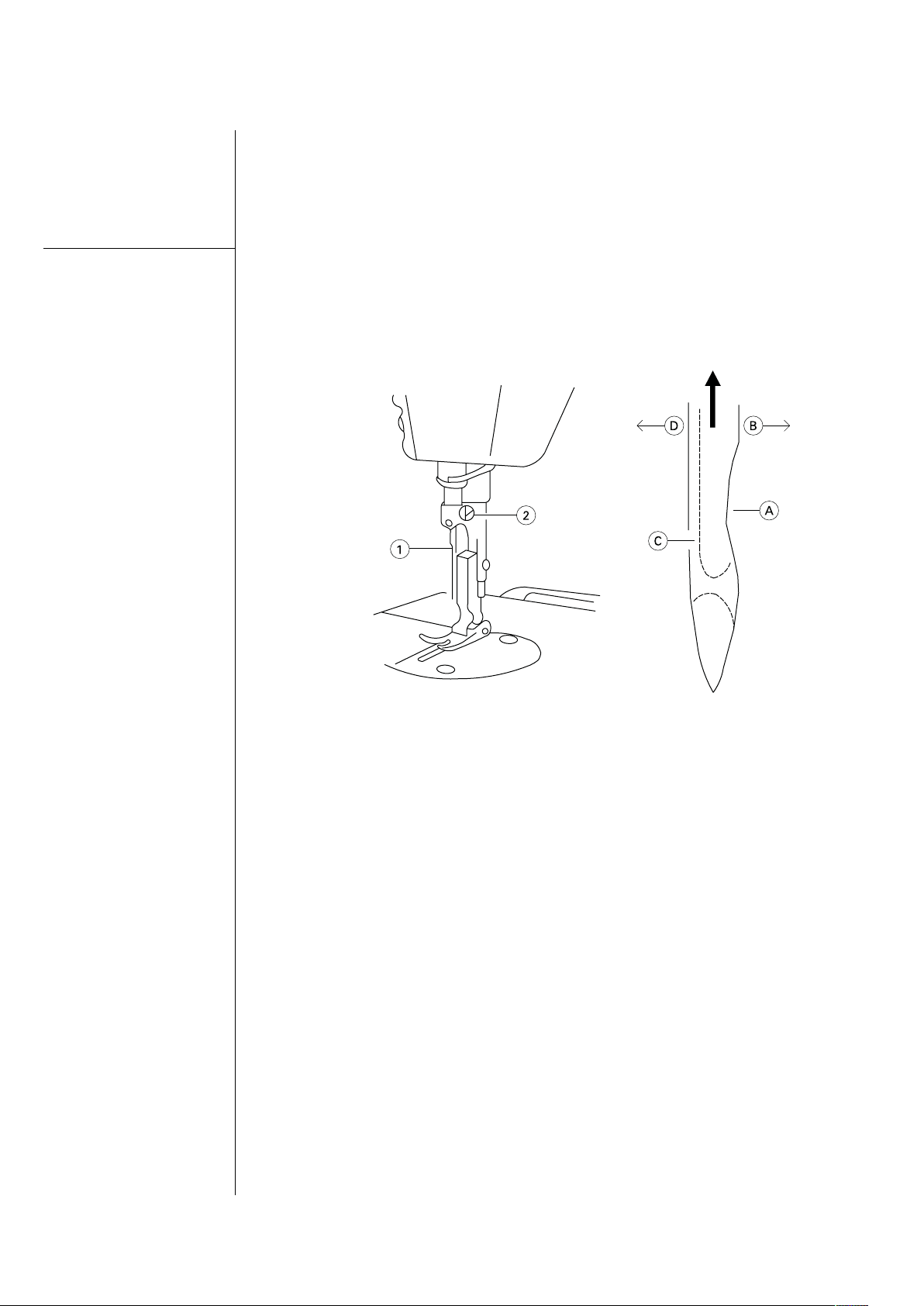

Page 13

3.7

Needle

Attachment

Caution

Choose a proper

needle size

according to the

count of thread and

the type of sewing

material used.

The power supply

should be cut off

before attaching

the needle.

Turn the hand wheel until the needle bar reaches the highest point

of its stroke (Figure 12).

Loosen screw ‘2’ and hold needle

‘1’ with its indented part ‘A’ facing

exactly to the right in direction ‘B’.

Insert the needle in the direction

of the arrow until it will go no further.

Tighten the screw ‘2’.

Make sure the long groove ‘C’ of

the needle is facing exactly to the

left in direction ‘D’.

Figure 12

High Speed Straight Lockstitch Sewing Machine | Instruction Manual and Parts List

10

Page 14

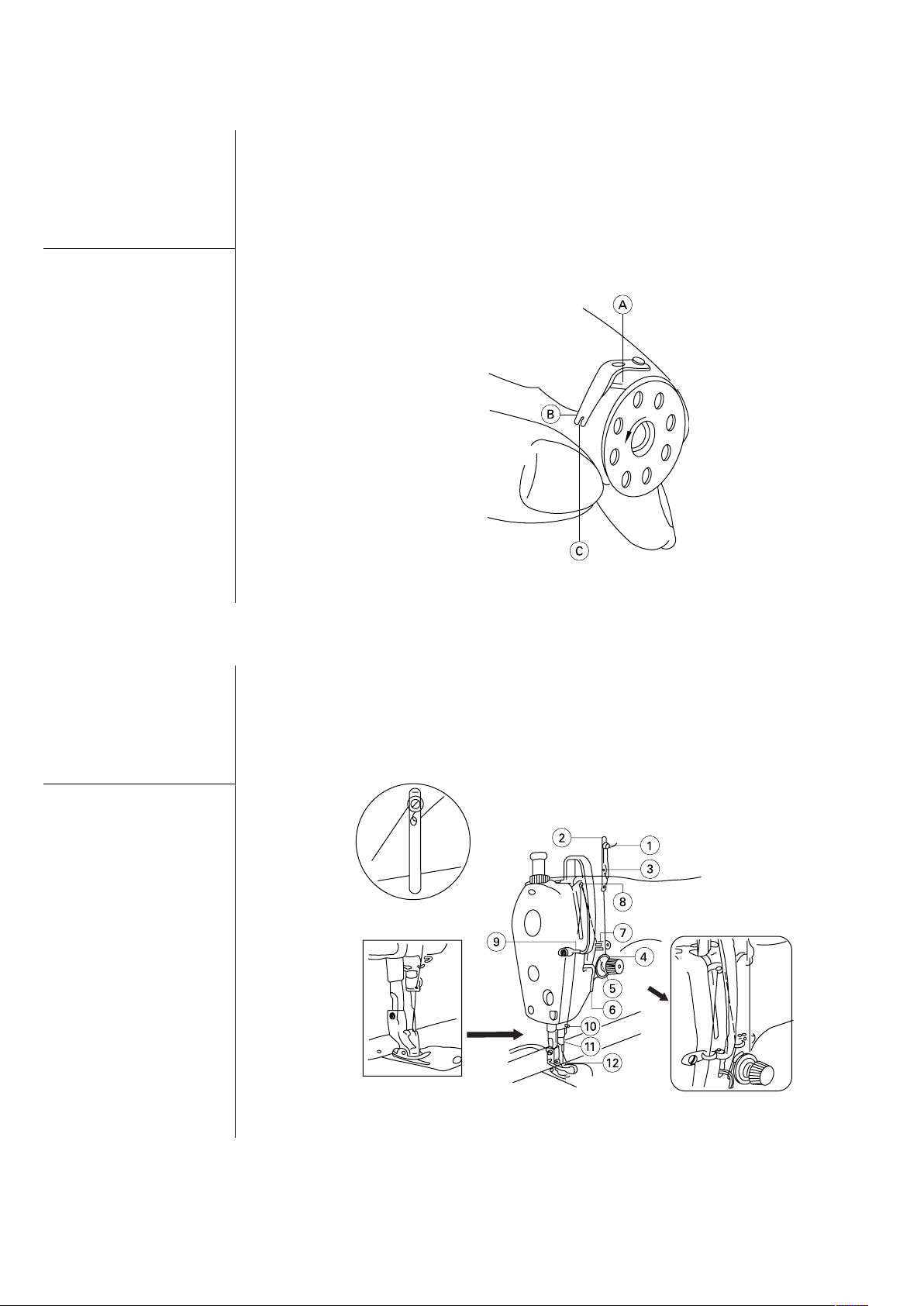

3.8

Bobbin Case

Attachment

Fix the bobbin into bobbin case with

that the thread open end is directed

to the left as observed from you.

Pass the thread through thread slit

‘A’, and pulls it in direction ‘C’. By

doing so, the thread will pass un-

der the tension spring and come

out from notch ‘B’ (Figure 13).

When pulling the thread ‘C’, the

bobbin should rotate in the direction of the arrow.

3.9

Machine

Threading

When threading the machine head,

the needle bar should be at the

highest point of its stroke.

Figure 13

Thread the machine in the order

shown below. Leave thread approximately 4 cm long in the needle

(Figure 14).

Figure 14

High Speed Straight Lockstitch Sewing Machine | Instruction Manual and Parts List

11

Page 15

3.10

Stitch Length

Adjustment

Turn stitch length dial ‘1’ in the direction of the arrow, and align the desired number to marker dot ‘A’ on the

machine arm (Figure 15).

The indication of the dial is in millimeters.

Figure 15

When you want to decrease the stitch

length, turn stitch length dial ‘1’ while

pressing feed reverse lever ‘2’ in the

direction of the arrow.

3.11

Thread Tension

Adjustment

Adjusting needle thread tension

(Figure 16)

Adjust the tension of needle thread

using tension adjusting nut ‘1’ according to different sewing conditions.

Turn the nut ‘1’ clockwise (in direction ‘A’), the tension will increase.

Turn the nut ‘1’ counterclockwise

(in direction ‘B’), the tension will

decrease.

Adjusting the bobbin thread tension (Figure 17)

Turn the tension adjusting screw ‘2’

clockwise (in direction ‘C’), the bob-

bin thread tension will increase.

Turn the screw ‘2’ counterclockwise

(in direction ‘D’), the bobbin thread

tension will decrease.

Figure 16 Figure 17

High Speed Straight Lockstitch Sewing Machine | Instruction Manual and Parts List

12

Page 16

3.12

Thread

Take-Up Spring

Adjustment

The adjustment of the stroke of the

thread take-up spring (Figure 18)

Loosen setting screw ‘2’.

Turn the thread tension post ‘3’

clockwise (in direction ‘A’), the

stroke of the thread take-up spring

will be increased.

Turn the thread tension post ‘3’

counter-clockwise (in direction ‘B’),

the stroke of the thread take-up

spring will be decreased.

Loosen setting screw ‘4’ and turn

the tension post ‘3’.

Turn the tension post ‘3’ clockwise

(in direction ‘A’), the pressure of the

spring will be increased.

Turn the tension post ‘3’ counter clockwise (in direction ‘B’), the

pressure will be decreased.

• Usually, the thread take-up spring

‘1’ has been properly adjusted before leaving the factory.

Adjusting the pressure of the

take-up spring ‘1’ (Figure 19)

Loosen setting screw ‘2’ and take

out thread tension assembly ‘5’.

Figure 18 Figure 19

thread

• Only when sewing special clothes

or using special thread is readjustment necessary.

High Speed Straight Lockstitch Sewing Machine | Instruction Manual and Parts List

13

Page 17

3.13

Knee Lifter Height

Adjustment

When using the knee lifter, the

standard height of presser foot is

10 mm.

You can adjust the presser foot lift

up to 13 mm by turning the knee

lifter adjusting screw ‘1’ (Figure 20).

Figure 20 Figure 21

When the presser foot lifts to over

10 mm, be sure that the bottom end

of the needle bar ‘2’ in its lowest

position does not hit the presser

foot ‘3’ (Figure 21).

3.14

Presser Foot Lifter

Adjustment

Turn the presser foot lifter ‘1’ in

direction ‘A’ to lift the presser foot

(Figure 22).

The presser foot will go up about

5.5 mm and stop.

The presser foot will go back to its

original position when the lifter is

turned down in direction ‘B’ (Figure 23).

Figure 22 Figure 23

High Speed Straight Lockstitch Sewing Machine | Instruction Manual and Parts List

14

Page 18

3.15

Presser Foot

Pressure

Adjustment

Loosen the nut ’2’, and turn the

presser spring regulator ‘1’ clockwise (in direction ‘A’), the pressure

of the presser foot will be increased

(Figure 24).

Turn the regulator ‘1’ counter clock-

wise (in direction ‘B’), the pressure of the presser foot will be decreased.

Tighten nut ‘2’.

For general sewing of the fabrics,

the standard height of the presser

spring regulator ‘1’ will be around

33~36 mm (5 kg).

33 36

˜

mm

Figure 24

High Speed Straight Lockstitch Sewing Machine | Instruction Manual and Parts List

15

Page 19

3.16

Feed Timing

Adjustment

Caution

If the feed

eccentric cam is

moved too far,

the needle will

be broken.

Loosen screws ‘2’ and ‘3’ in feed

eccentric cam ‘1’, move the feed

eccentric cam ‘1’ in the direction

of the arrow or opposite direction

of the arrow, and firmly tighten the

screws ‘2’ and ‘3’ (Figure 25).

For the standard adjustment, adjust

so that the top surface of feed dog

and the top end of needle eyelet

are flush with top surface of throat

plate when the feed dog descends

below the throat plate.

To advance the feed timing in order

to prevent uneven material feed,

move the feed eccentric cam in the

direction of the arrow.

To delay the feed timing in order to

increase stitch tightness, move the

feed eccentric cam in the direction

from the arrow.

Figure 25

High Speed Straight Lockstitch Sewing Machine | Instruction Manual and Parts List

16

Page 20

3.17

Feed Dog Height

Adjustment

Caution

If the screw ‘2’

is tightening

too much, the

crank ‘1’ will

be worn out.

When the feed dog ‘A’ is at its high-

est position, the teeth should be

above the top surface of the throat

plate ‘B’ as the below height for

each machine variety (Figure 26).

Loosen screw ‘2’ of crank ‘1’.

Move the feed bar up or down to

make a correct height.

Securely tighten screw ‘2’.

See description below for height

Figure 26

High Speed Straight Lockstitch Sewing Machine | Instruction Manual and Parts List

17

Page 21

3.18

Needle to

Rotating

Hook Relation

Adjustment

Precaution

If the clearance

is too small, the

rotating hook points

will wear out, and

too big, it will cause

the skip stitch.

When replacing the

rotating hook, it

should be using the

original one.

Adjusting the height of the needle

bar (Figure 27)

Turn the handwheel until the needle bar has been at the lowest

point, loosen the setscrew ‘1’.

The line ‘A’ on the needle bar ‘2’

align with the bottom end of needle

bar lower bushing ’3’, then securely

tighten the setscrew ‘1’.

Adjusting the position of the rotating hook

Loosen two rotating hook setscrews and turn the handwheel until the line ‘B’ on needle bar align

with the bottom end of needle bar

lower bushing ‘3’.

After the above adjustments steps,

the rotating hook point ‘5’ aligns

with the center of needle ‘4’, and

make sure the clearance between

the needle and the rotating hook

‘5’ is 0.04~0.1 mm.

Figure 27

High Speed Straight Lockstitch Sewing Machine | Instruction Manual and Parts List

18

Page 22

3.19

Presser

Bar Height

Adjustment

Loosen setscrew ‘1’ (Figure 28) and

adjust the height of the presser bar.

When the presser foot rises to the

highest, the distance between the

throat plate and the presser foot is

5.5 mm (Figure 29).

Tighten the setscrew ‘1’ after adjustment.

5,5mm

Figure 28 Figure 29

High Speed Straight Lockstitch Sewing Machine | Instruction Manual and Parts List

19

Page 23

3.20

Thread Take-

Up Stroke

Adjustment

When sewing for heavy weight material, the thread guides ‘1’ move to

the left (in direction ‘A’) to increase

the length of thread pulled out by

the thread take-up.

When sewing light weight material,

the thread guides ‘1’ move to the

right (in direction ‘B’) to decrease

the length of thread pulled out by

the thread take-up.

When marker line ‘C’ on the thread

guide ‘1’ is aligned with the center of

the screw that is standard (Figure 30).

Figure 30

High Speed Straight Lockstitch Sewing Machine | Instruction Manual and Parts List

20

Page 24

4

4.1

Machine Head

Cleaning

4.2

Lubrication

Maintenance

Clean the machine periodically with

a soft and dry cloth to remove the

excess of dust on the machine head.

Do not use any kind of lacquer thinner to wipe the surface.

If the machine was idle for a long

time, lubricate the machine according to the instructions of topics

3.4 to 3.6.

4.3

Safety

Inspection

Check periodically if all safety devices are properly installed and adjusted.

Check if all fixing and supporting

screws of the machine head are

adequately tighten.

Check if the v-belt is not excessively

worn and if it has the right tension.

Check if there is no overheating in

the electrical motor and check if the

power cord and plug are not damaged.

High Speed Straight Lockstitch Sewing Machine | Instruction Manual and Parts List

21

Page 25

Troubleshooting

Problems Possible Causes Possible Solutions

1.

Needle break

Thread break

Skip stitches

Loosen stitches

Wrinkled stitches

Needle is installed wrong

2.

Wrong needle type or size

3.

Needle is bended

4.

Wrong relation with rotary hook

5.

Needle doesn’t center the needle hole of throat plate

or presser foot

1.

Low quality thread

2.

Thread is thicker than needle hole

3.

Wrong threading

4.

Thread tension is too strong

5.

Needle is installed wrong

6.

Thread stand installed wrong

7.

Thread tension disc, thread guide, needle, hook point

and needle plate are burred

8.

Wrong relation with rotary hook

1.

Wrong relation of needle and hook point

2.

Wrong threading

3.

Needle is installed wrong

4.

Inadequate thread tension

5.

Hook point is damaged

6.

Needle is bended

1.

Wrong threading

2.

Thread is thicker than needle hole

3.

Inadequate thread tension

4.

Wrong setting of needle and hook point

1.

Thread tension is too strong

2.

Take-up spring is too strong

3.

Inadequate pressure of presser foot

4.

Inadequate height of feed dog

5.

Needle is too thick

1.

Install needle correctly

2.

Use proper needle for fabric and thread

3.

Replace needle

4.

Readjust the rotary hook

5.

Readjust the needle plate and presser foot

1.

Change the thread

2.

Use proper needle for fabric and thread

3.

Rethreaded the machine correctly

4.

Readjust the thread tension nut

5.

Install needle correctly

6.

Install thread stand correctly

7.

Grind off, polish or replace by a new parts

8.

Readjust needle and hook point relation

1.

Readjust needle and hook point

2.

Rethread the machine correctly

3.

Installed needle correctly

4.

Readjust the thread tension nut

5.

Replace by a new part

6.

Replace needle

1.

Rethread the machine correctly

2.

Use proper needle for fabric and thread

3.

Readjust the thread tension nut

4.

Readjust needle and hook point

1.

Readjust the thread tension nut

2.

Readjust the take-up spring

3.

Readjust the presser foot pressure

4.

Readjust the feed dog

5.

Use proper needle for fabric and thread

High Speed Straight Lockstitch Sewing Machine | Instruction Manual and Parts List

22

Page 26

Parts List

High Speed Straight Lockstitch Sewing Machine | Instruction Manual and Parts List

23

Page 27

6.1

Frame and Cover

Components

No. Part No. Description

1 10101034 Face plate 1 1 1 1 1 1

2 10122096 Face plate gasket 1 1 1 1 1 1

3 101S11010 Screw SM1/8x44 L=4 1 1 1 1 1 1

4 10112024 Arm oil shield assembly 1 1 1 1 1 1

5 10122005 Rubber plug 2 2 2 2 2 2

High Speed Straight Lockstitch Sewing Machine | Instruction Manual and Parts List

20 20C 30 30C 70 70C

Qty.

24

Page 28

6.1

Frame and Cover

Components

No. Part No. Description

6 10122003 Rubber plug 1 1 1 1 1 1

7 101S11001 Screw SM3/16x28 L=9 8 8 8 8 8 8

8 10112063 Side plate 1 1 1 1 1 1

9 10122097 Side plate gasket 1 1 1 1 1 1

10 10122006 Rubber plug 1 1 1 1 1 1

11 10122007 Rubber plug 1 1 1 1 1 1

12 100017 Frame 1 1 1 1 1 1

13 10113003 Two-hole thread eyelet guide 1 1 1 1 1 1

14 J900112-001 Singer "S" cameo 1 1 1 1 1 1

15 101S11004 Screw SM3/16 x 28 L=6 2 2 2 2 2 2

17 10113004 Right arm thread guide 1 1 1 1 1 1

18 101S11007 Screw SM11/64 x 40 L=6 1 1 1 1 1 1

1011301500 Thread tension regulator assembly 1 1 1 1 0 0

19

400597 Thread tension regulator assembly 0 0 0 0 1 1

20 101S16001 Tension adjusting nut 1 1 1 1 1 1

21 10112007 Tension disk stopper 1 1 1 1 1 1

10127002 Tension spring 1 1 0 0 0 0

22

10127017 Tension spring 0 0 1 1 1 1

23 10112006 Tension disk holder 1 1 1 1 1 1

24 10112005 Thread tension disk 2 2 2 2 2 2

25 101S30002 Tension post 1 1 1 1 1 1

26 10127001 Thread take-up spring 1 1 1 1 1 1

27 10103011 Tension post socket 1 1 1 1 1 1

28 101S15005 Screw SM9/64x40 L=5.5 1 1 1 1 1 1

29 101S15006 Screw SM15/64x28 L=7 1 1 1 1 1 1

30 10126002 Tension releasing pin 1 1 1 1 1 1

10115001 Throat plate 1 1 0 0 0 0

31

10115005 Throat plate 0 0 1 1 0 0

10115014 Throat plate 0 0 0 0 1 1

32 101S17002 Screw SM11/64 x 40 L=8.5 2 2 2 2 2 2

33 10113005 Left arm thread guide 1 1 1 1 1 1

34 101S11007 Screw SM11/64x40 L=6 1 1 1 1 1 1

35 10122003 Rubber plug 2 2 2 2 2 2

36 101S11001 Screw SM3/16x28 L=9 3 3 3 3 3 3

37 1011500200 Slide plate assembly 1 1 1 1 1 1

38 10115002 Slide plate 1 1 1 1 1 1

39 10127009 Slide plate spring 1 1 1 1 1 1

40 101S11019 Screw SM3/32x56 L=1.9 2 2 2 2 2 2

41 101S12001 Screw stud 4 4 4 4 4 4

42 10112002 Scale base plate 1 1 1 1 1 1

43 101S11002 Screw SM11/64 x 40 L=5 2 2 2 2 2 2

44 J900191-xxx Model plate 1 1 1 1 1 1

45 R03001 Model plate rivet 2 2 2 2 2 2

10112062 Thread take-up lever cover 1 1 1 1 0 0

46

10112064 Thread take-up lever cover 0 0

47 11237003 Safety label 1 1 1 1 1 1

48 1011300700 Thread guide rod assembly 1 1 1 1 1 1

49 10112008 Thread guide rod 1 1 1 1 1 1

50 10112009 Tension disk 2 2 2 2 2 2

51 10127004 Tension spring 1 1 1 1 1 1

52 101S30003 Hinge screw 1 1 1 1 1 1

53 J900112-002 Singer logo resin plate (front) 1 1 1 1 1 1

54 J900112-004 Singer logo resin plate (back) 1 1 1 1 1 1

20 20C 30 30C 70 70C

Qty.

0 0 1 1

High Speed Straight Lockstitch Sewing Machine | Instruction Manual and Parts List

25

Page 29

6.2

Arm Shaft

and Thread

Take-Up Lever

Components

High Speed Straight Lockstitch Sewing Machine | Instruction Manual and Parts List

26

Page 30

6.2

Arm Shaft

and Thread

Take-Up Lever

Components

No. Part No. Description

1 10126001 Thread take-up crank shaft 1 1 1 1 1 1

2 101S15001 Screw SM15/64 x 28 L=10.5 1 1 1 1 1 1

3 101S3001 Screw 1 1 1 1 1 1

10105001 Thread take-up lever link 1 1 0 0 0 0

4

10105006 Thread take-up lever link 0 0 1 1 0 0

1223800300 Thread take-up lever link assembly 0 0 0 0 1 1

6 10124001 Needle bearing 2 2 2 2 2 2

1011000100 Needle bar crank 1 1 0 0 0 0

7

1011000400 Needle bar crank 0 0 1 1 0 0

1221000100 Needle bar crank 0 0 0 0 1 1

8 10105002 Needle bar crank rod 1 1 1 1 1 1

9 101S15007 Screw SM9/64 x 40 L=4.8 1 1 1 1 1 1

10 101S15004 Screw SM9/32 x 28 L=16 1 1 1 1 1 1

11 10104001 Counter weight 1 1 1 1 1 1

101S15002 Screw SM1/4 x40 L=6 2 2 2 2 2 2

12

13

10122010 Rubber ring 1 1 1 1 1 1

14 101S11003 Screw SM9/32 x 28 L=6 1 1 1 1 1 1

10110003 Feed drive eccentric cam 1 1 1 1 0 0

15

400058 Feed drive eccentric cam 0 0 0 0 1 1

16 101S11013 Screw SMI/4 x 40 L=11 2 2 2 2 2 2

17 10103001 Arm shaft bushing (rear) 1 1 1 1 1 1

18 10122008 Oil seal 2 2 2 2 2 2

19 H03002 Snap ring 1 1 1 1 1 1

20 10108001 Thrust collar 1 1 1 1 1 1

21 101S15007 Screw SM1/4 x 40 L=6 2 2 2 2 2 2

22 10103004 Arm shaft bushing (front) 1 1 1 1 1 1

23 10112003 Oil adjusting collar 1 1 1 1 1 1

24 10103003 Arm shaft bushing (middle) 1 1 1 1 1 1

25 101S15006 Screw 1 1 1 1 1 1

26 10112017 Thrust collar 1 1 1 1 1 1

27 10135007 Hand wheel 1 1 1 1 1 1

28 101S15008 Screw SM15/64 x 28 L=15 2 2 2 2 2 2

29 10102001 Arm shaft 1 1 1 1 1 1

30 10122012 Roller felt 1 1 1 1 1 1

31 101S11005 Oil amount adjusting pin 1 1 1 1 1 1

20 20C 30 30C 70 70C

Qty.

High Speed Straight Lockstitch Sewing Machine | Instruction Manual and Parts List

27

Page 31

6.3

Needle Bar,

Upright Shaft and

Rotating Hook

Driving Shaft

Components

No. Part No. Description

1 10122013 Cap 1 1 1 1 1 1

2 10103009 Needle bar bushing (upper) 1 1 1 1 1 1

10102002 Needle bar 1 1 0 0 0 0

3

10102012 Needle bar 0 0 1 1 0 0

10102021 Needle bar 0 0 0 0 1 1

4 10138002 Needle bar connection 1 1 1 1 1 1

5 101S11005 Screw SM9/64 x 40 L=6 1 1 1 1 1 1

6 10109001 Slide block 1 1 1 1 1 1

10113001 Needle bar thread guide 1 1 0 0 0 0

7

10113009 Needle bar thread guide 0 0 1 1 1 1

10103010 Needle bar bushing (lower) 1 1 0 0 0 0

8

10103023 Needle bar bushing (lower) 0 0 1 1 1 1

High Speed Straight Lockstitch Sewing Machine | Instruction Manual and Parts List

20 20C 30 30C 70 70C

Qty.

28

Page 32

6.3

Needle Bar,

Upright Shaft and

Rotating Hook

Driving Shaft

Components

No. Part No. Description

9 101S11006 Screw SM 1/8 x 44 L=4.5 1 1 1 1 1 1

10 10113002 Needle bar thread guide 1 1 1 1 1 1

1955-01 Needle #14 1 1 0 0 0 0

11

1955-01 Needle #18 0 0 1 1 0 0

1955-01 Needle #21 0 0 0 0 1 1

12 10125004 Gear 1 1 1 1 1 1

13 101S15009 Screw SMI/4 x 40 L=8 8 8 8 8 8 8

14 10125003 Pinion (upper) 1 1 1 1 1 1

15 10125002 Gear large 1 1 1 1 1 1

16 10125001 Pinion (lower) 1 1 1 1 1 1

17 10102007 Upright shaft 1 1 1 1 1 1

10118003 Bobbin 1 1 1 1 0 0

18

10818501 Bobbin 0 0 0 0 1 1

19 10103017 Upright shaft bushing (upper) 1 1 1 1 1 1

20 101S15006 Screw SM3/16 x28 L=9 1 1 1 1 1 1

21 10103016 Upright shaft bushing (lower) 1 1 1 1 1 1

22 10103015 Hook shaft bushing (rear) 1 1 1 1 1 1

10118504 Rotating hook 1 0 0 0 0 0

23

10118001 Rotating hook 0 1 0 0 0 0

10118505 Rotating hook 0 0 1 0 0 0

10118509 Rotating hook 0 0 0 1 0 0

11018001 Rotating hook 0 0 0 0 1 0

10818001 Rotating hook 0 0 0 0 0 1

24 10108002 Thrust collar 1 1 1 1 1 1

25 101S11012 Screw SM I 1/64x 40 L=4 .8 2 2 2 2 2 1

10112016 Position finger 1 1 0 0 0 2

26

10112032 Position finger 0 0 1 1 0 0

27 101S11011 Screw SM11/64 x 40 L=9.5 1 1 1 1 1 1

28 1010000000 Hook shaft bushing (front) 1 1 1 1 1 1

29 101S15008 Screw 1 1 1 1 1 1

30 10122015 Thrust collar 1 1 1 1 1 1

31 10123002 Screw SM 11/64 x40 L=3.5 2 2 2 2 2 2

10102006 Hook shaft 1 1 1 1 0 0

32

12202003 Hook shaft 0 0 0 0 1 1

10118501 Bobbin case 1 1 1 1 0 0

33

10118517 Bobbin case 0 0 0 0 1 0

10818502 Bobbin case 0 0 0 0 0 1

34 10123003 Oil wick 1 1 1 1 1 1

35 101S30005 Oil seal screw 1 1 1 1 1 1

36 101S15006 Screw SM3/16 x 28 L=12 1 1 1 1 1 1

37 10109002 Needle bar slid block guide 1 1 1 1 1 1

38 101S11008 Screw SM11/64x40 L=8 2 2 2 2 2 2

20 20C 30 30C 70 70C

Qty.

High Speed Straight Lockstitch Sewing Machine | Instruction Manual and Parts List

29

Page 33

6.4

Presser Foot

Components

High Speed Straight Lockstitch Sewing Machine | Instruction Manual and Parts List

30

Page 34

6.4

Presser Foot

Components

No. Part No. Description

1 10111001 Hand lifter 1 1 1 1 1 1

2 101S11010 Screw SM9/64 x 40 L=9.5 1 1 1 1 1 1

3 O01004 Rubber ring 1 1 1 1 1 1

4 1011000200 Hand lifter cam assembly 1 1 1 1 1 1

5 1011201100 Hand lifter link assembly 1 1 1 1 1 1

6 H05009 Snap ring 1 1 1 1 1 1

7 101S20001 Link screw stud 2 2 2 2 2 2

1011600100 Presser foot assembly 1 1 0 0 0 0

8

1011600400 Presser foot assembly 0 0 1 1 0 0

1011600800 Presser foot assembly 0 0 0 0 1 1

9 H05009 Snap ring 3 3 3 3 3 3

10 10112010 Lifting lever 1 1 1 1 1 1

11 H05009 Snap ring 1 1 1 1 1 1

12 101S20004 Screw 1 1 1 1 1 1

13 101S20003 Screw 1 1 1 1 1 1

14 10112014 Lifting lever link 1 1 1 1 1 1

15 10126003 Connecting rod vertical 1 1 1 1 1 1

16 10112013 Lifting lever connection rod 1 1 1 1 1 1

17 H05009 Snap ring 2 2 2 2 2 2

18 10127008 Tension release return spring 1 1 1 1 1 1

19 10127003 Tension release pin spring 1 1 1 1 1 1

20 10126003 Tension release supporting pin 1 1 1 1 1 1

21 10112012 Tension release plate 1 1 1 1 1 1

22 101S20002 Tension release screw stud 1 1 1 1 1 1

23 101S30004 Presser spring regulator 1 1 1 1 1 1

24 101S16002 Presser spring regulator nut 1 1 1 1 1 1

25 10102003 Presser guide bar 1 1 1 1 1 1

10127005 Presser spring 1 1 0 0 0 0

26

10127018 Presser spring 0 0 1 1 1 1

27 10109003 Presser bar guide bracket 1 1 1 1 1 1

28 10102004 Presser bar 1 1 1 1 1 1

29 10113008 Presser bar thread guide 1 1 1 1 1 1

30 101S15007 Screw SM 1/4 x 40 L=8 1 1 1 1 1 1

31 101S11005 Screw SM 9/64 x 40 L=8.5 2 2 2 2 2 2

32 10103012 Presser bar bushing (lower) 1 1 1 1 1 1

33 101S11009 Screw SM9/64 x 40 L=I0.5 1 1 1 1 1 1

34 10128002 Washer 1 1 1 1 1 1

35 10122034 Presser bar oil protection bushing 1 1 1 1 1 1

20 20C 30 30C 70 70C

Qty.

High Speed Straight Lockstitch Sewing Machine | Instruction Manual and Parts List

31

Page 35

6.5

Feed Mechanism

Components

No. Part No. Description

10105005 Feed regulator connecting rod 1 1 1 1 0 0

1

12212003 Feed regulator connecting rod 0 0 0 0 1 1

2 10126016 Feed regulator pin 1 1 1 1 1 1

3 10101004 Feed regulator 1 1 1 1 1 1

4 10103020 Feed regulator bushing 1 1 1 1 1 1

5 10126014 Feed regulator screw 1 1 1 1 1 1

6 10127010 Spring 1 1 1 1 1 1

7 10126015 Pin 1 1 1 1 1 1

10111052 Feed dial 1 1 1 1 0 0

8

12211001 Feed dial 0 0 0 0 1 1

9 101S11022 Screw SM3/16X28 L=18 1 1 1 1 1 1

10105003 Feed rock shaft crank connecting rod 1 1 1 1 0 0

10

400083 Feed rock shaft crank connecting rod 0 0 0 0 1 1

11 10126006 Pin 1 1 1 1 1 0

High Speed Straight Lockstitch Sewing Machine | Instruction Manual and Parts List

20 20C 30 30C 70 70C

Qty.

32

Page 36

6.5

Feed Mechanism

Components

No. Part No. Description

12 101S11005 Screw SM9/64x 40 L=6 1 1 1 1 1 1

13 10105004 Feed lifting rock shaft crank connecting rod 1 1 1 1 1 1

14 10122016 Rubber ring 1 1 1 1 1 1

10127012 Spring 1 1 1 1 0 0

15

12227001 Spring 0 0 0 0 1 1

16 H05009 Snap ring 1 1 1 1 1 1

17 1010400500 Feed reverse arm assembly 1 1 1 1 1 1

18 101S17003 Screw 1 1 1 1 1 1

19 H05009 Snap ring 1 1 1 1 1 1

20 101S11005 Screw SM9/64x 40 L=6 2 2 2 2 2 2

21 1012007 Pin 2 2 2 2 2 2

22 10109005 Link 2 2 2 2 2 2

23 10109004 Link 2 2 2 2 2 2

24 1010100200 Feed adjust link assembly 1 1 1 1 1 1

25 10126009 Feed adjust link shaft 2 2 2 2 2 2

26 101S15010 Screw SM15/64x28 L=7 2 2 2 2 2 2

27 101S11005 Screw SM9/64x40 L=6 2 2 2 2 2 2

28 10126013 Feed bar shaft 1 1 1 1 1 1

29 H03001 Retaining ring 1 1 1 1 1 1

10114001 Feed dog 1 1 0 0 0 0

30

10114004 Feed dog 0 0 1 1 0 0

10114012 Feed dog 0 0 0 0 1 1

31 101S11018 Screw SM1/8X44 L=6 2 2 2 2 2 2

32 1010700100 Feed bar assembly 1 1 1 1 1 1

33 10112018 Feed spring hook plate 1 1 1 1 1 1

34 10102008 Feed rock shaft 1 1 1 1 1 1

35 10126011 Pin 1 1 1 1 1 1

36 101S11005 Screw SM9/64x 40 L=6 1 1 1 1 1 1

37 101S16003 Nut SM9/32X 28 1 1 1 1 1 1

10104002 Feed rock shaft crank 1 1 1 1 0 0

38

12204003 Feed rock shaft crank 0 0 0 0 1 1

39 101S11016 Screw SM3/16 X 28 L=15.5 1 1 1 1 1 1

40 10104004 Feed lifting rock shaft crank (back) 1 1 1 1 1 1

41 101S11021 Screw SM3/16 x 28 L=15.5 1 1 1 1 1 1

42 101S20005 Screw 1 1 1 1 1 1

43 10102009 Feed driving shaft 1 1 1 1 1 1

44 10108003 Thrust collar 1 1 1 1 1 1

45 101S15002 Screw SM1/4 x 40 L=6 2 2 2 2 2 2

46 10103018 Feed rock shaft bushing 1 1 1 1 1 1

47 101S11023 Screw SM3/16 x 28 L=7 1 1 1 1 1 1

48 101S11025 Screw SM11/64 x 40 L=7 1 1 1 1 1 1

49 H03001 Retaining ring 1 1 1 1 1 1

50 10101003 Feed bar driving crank 1 1 1 1 1 1

51 101S11016 Screw SM3/16 x 28 L=14 1 1 1 1 1 1

52 10128003 Washer 1

53 10104003 Lifting fork 1 1 1 1 1 1

54 101S11020 Screw SM11/64 x 40 L=10.5 1 1 1 1 1 1

55 10103018 Feed driving shaft bushing 1 1 1 1 1 1

56 10108003 Thrust collar 1 1 1 1 1 1

57 101S15002 Screw SM1/4 x 40 L=6 2 2 2 2 2 2

58 10122017 Rubber ring 1 1 1 1 1 1

59 10102010 Feed reverse shaft 1 1 1 1 1 1

60 10103021 Feed reverse shaft bushing 1 1 1 1 1 1

61 10101005 Reverse feed control lever 1 1 1 1 1 1

62 101S15007 Screw SM1/4 x 40 L=8 1 1 1 1 1 1

63 101S15011 Screw SM1/4 x 40 L=10 1 1 1 1 1 1

64 10112019 Adjusting link spring guide 1 1 1 1 1 1

10127011 Reverse feed spring 1 1 1 1 0 0

65

12227002 Reverse feed spring 0 0 0 0 1 1

66 101S11025 Screw SMI 1/64 X 40 L=5 2 2 2 2 2 2

67 10126010 Screw 0 0 0 0 1 1

68 GT0569 Washer 0 0 0 0 1 1

69 GT0570 Feed adjusting shaft 0 0 0 0 1 1

20 20C 30 30C 70 70C

Qty.

1 1 1 1 1

High Speed Straight Lockstitch Sewing Machine | Instruction Manual and Parts List

33

Page 37

6.6

Lubrication

Components

High Speed Straight Lockstitch Sewing Machine | Instruction Manual and Parts List

34

Page 38

6.6

Lubrication

Components

No. Part No. Description

1 10111004 Oil sight window 1 1 1 1 1 1

2 10122019 Rubber ring 1 1 1 1 1 1

3 10121002 Arm shaft oil tube 1 1 1 1 1 1

4 101S30008 Oil pump support 1 1 1 1 1 1

5 101S11026 Screw SM15/64 x 28 L=9 1 1 1 1 1 1

6 101S11004 Screw SM3/16 x 28 L=6 1 1 1 1 1 1

7 10127015 Oil felt clip 1 1 1 1 1 1

8 1012701500 Oil return tube assembly 1 1 1 1 1 1

9 10112023 Oil return tube holder 1 1 1 1 1 1

10 10123001 Oil wick 1 1 1 1 1 1

11 10121003 Oil tube 1 1 1 1 1 1

12 10112022 Oil tube holder (lower) 1 1 1 1 1 1

13 101S11026 Screw SM15/64 x 28 L=9 1 1 1 1 1 1

14 10127014 Spring 1 1 1 1 1 1

15 101S30009 Oil adjusting screw 1 1 1 1 1 1

16 1012000100 Oil pump assembly 1 1 1 1 1 1

17 10112020 Oil pump installing base 1 1 1 1 1 1

18 101S11011 Screw x 8 3 3 3 3 3 3

19 10120001 Oil pump 1 1 1 1 1 1

20 10111003 Oil pump impeller 1 1 1 1 1 1

21 101S30006 Screw 3 3 3 3 3 3

22 10111007 Oil pump cover 1 1 1 1 1 1

23 10112021 Oil pump impeller cover 1 1 1 1 1 1

24 10122018 Plunger 1 1 1 1 1 1

25 10127013 Plunger spring 1 1 1 1 1 1

26 101S30007 Plunger screw 1 1 1 1 1 1

27 10121001 Hook driving shaft oil tube 1 1 1 1 1 1

28 101S11011 Screw SM11/64 x 40 L=9.5 1 1 1 1 1 1

29 10136001 Oil tube joint 1 1 1 1 1 1

30 101S11010 Oil wick set plate screw 2 2 2 2 2 2

31 10112025 Oil wick set plate assembly 1 1 1 1 1 1

32 10112026 Presser plate 1 1 1 1 1 1

33 101S11033 Screw 1 1 1 1 1 1

20 20C 30 30C 70 70C

Qty.

High Speed Straight Lockstitch Sewing Machine | Instruction Manual and Parts List

35

Page 39

6.7

Oil Reservoir Components

High Speed Straight Lockstitch Sewing Machine | Instruction Manual and Parts List

36

Page 40

6.7

Oil Reservoir

Components

No. Part No. Description

1 10111005 Knee presser lift rod 1 1 1 1 1 1

2 1010100600 Oil reservoir assembly 1 1 1 1 1 1

3 10101006 Oil reservoir 1 1 1 1 1 1

4 10122020 Gasket 1 1 1 1 1 1

5 10122031 Rubber cushion 1 1 1 1 1 1

6 101S11028 Screw 4 4 4 4 4 4

7 10122021 Rubber ring 1 1 1 1 1 1

8 101112027 Knee lifter connecting rod 1 1 1 1 1 1

9 10127016 Spring 1 1 1 1 1 1

10 H05010 Snap ring 1 1 1 1 1 1

11 10101008 Bracket 1 1 1 1 1 1

12 101S12003 Screw SM9/32x 20 L=20 1 1 1 1 1 1

13 101S16004 Nut SM15/64 x 28 2 2 2 2 2 2

14 101S15012 Screw SM15/64 x 20 L=30 2 2 2 2 2 2

15 101S12002 Screw 2 2 2 2 2 2

16 10102011 Knee lifter shaft 1 1 1 1 1 1

17 1011202800 Knee lifter plate assembly 1 1 1 1 1 1

18 10122024 Knee lifter plate cover 1 1 1 1 1 1

19 10112028 Knee lifter plate rod 1 1 1 1 1 1

20 10122025 Knee lifter plate rubber 1 1 1 1 1 1

21 10112029 Knee lifter plate 1 1 1 1 1 1

22 10112030 Knee lifter plate holder 1 1 1 1 1 1

23 101S12004 Screw SM15/64 x 28 L=15 1 1 1 1 1 1

24 10122022 Oil reservoir felt cushion 2 2 2 2 2 2

25 10122023 Oil reservoir rubber cushion 2 2 2 2 2 2

26 101S30010 Nail 4 4 4 4 4 4

20 20C 30 30C 70 70C

Qty.

High Speed Straight Lockstitch Sewing Machine | Instruction Manual and Parts List

37

Page 41

6.8

Belt Cover,

Bobbin Winder

and Thread Stand

Components

High Speed Straight Lockstitch Sewing Machine | Instruction Manual and Parts List

38

Page 42

6.8

Belt Cover,

Bobbin Winder

and Thread Stand

Components

No. Part No. Description

1 1011100600 Belt cover assembly 1 1 1 1 1 1

2 10111006 Belt cover 1 1 1 1 1 1

4 1011100900 Belt cover back assembly 1 1 1 1 1 1

5 10111009 Belt cover back 1 1 1 1 1 1

6 1011101000 Belt cover back latch 1 1 1 1 1 1

7 101S30012 Belt cover support 1 1 1 1 1 1

8 101S11029 Belt cover screw 2 2 2 2 2 2

9 101S11030 Screw 1 1 1 1 1 1

10 10128007 Washer 1 1 1 1 1 1

11 101S30011 Screw 2 2 2 2 2 2

12 10128006 Washer 2 2 2 2 2 2

13 1011203200 Bobbin winder assembly 1 1 1 1 1 1

14 10112037 Thread tension bracket 1 1 1 1 1 1

15 S04006 Screw SMI 1/64 x 40 L=7 1 1 1 1 1 1

16 10112038 Tension disk 2 2 2 2 2 2

17 10127018 Tension spring 1 1 1 1 1 1

18 101S16005 Tension nut 1 1 1 1 1 1

19 S04006 Screw SMI 1/64' x 40 L=5 1 1 1 1 1 1

20 10112035 Rubber brake bracket 1 1 1 1 1 1

21 10122027 Rubber brake 1 1 1 1 1 1

22 10112036 Bobbin winder spring 1 1 1 1 1 1

23 10120006 Hinge screw SMI/Sx44 L=12.5 1 1 1 1 1 1

24 S04017 Screw 1 1 1 1 1 1

25 S04006 Screw 1 1 1 1 1 1

26 10128001 Washer 1 1 1 1 1 1

27 10112032 Bobbin winder base 1 1 1 1 1 1

28 10101010 Bobbin winder pulley 1 1 1 1 1 1

29 10102012 Bobbin winder post 1 1 1 1 1 1

30 101S30014 Screw 2 2 2 2 2 2

31 10128008 Washer 2 2 2 2 2 2

32 1013100900 Thread stand assembly 1 1 1 1 1 1

33 10122028 Rubber cap 1 1 1 1 1 1

34 10131008 Spool post (lower) 1 1 1 1 1 1

35 10131009 Spool post (upper) 1 1 1 1 1 1

36 10112039 Spool post joint 1 1 1 1 1 1

37 10112040 Spool arm (upper) 1 1 1 1 1 1

38 10112041 Spool arm (lower) 1 1 1 1 1 1

39 S04013 Screw 2 2 2 2 2 2

40 10113010 Thread guide 2 2 2 2 2 2

41 10131010 Spool pin 2 2 2 2 2 2

42 10128009 Spring washer 2 2 2 2 2 2

43 10128002 Washer 2 2 2 2 2 2

44 101S16006 Nut 2 2 2 2 2 2

45 10111013 Spool rest 2 2 2 2 2 2

46 10111014 Spool retainer 2

47 10128010 Washer 2 2 2 2 2 2

48 10128006 Spring washer 1 1 1 1 1 1

49 N02003 Nut 1 1 1 1 1 1

50 10104003 Screw 2 2 2 2 2 2

51 101S11020 Nut 2 2 2 2 2 2

52 10102009 Spool rest cushion 2 2 2 2 2 2

20 20C 30 30C 70 70C

Qty.

2 2 2 2 2

High Speed Straight Lockstitch Sewing Machine | Instruction Manual and Parts List

39

Page 43

6.9

Machine

Accessories

High Speed Straight Lockstitch Sewing Machine | Instruction Manual and Parts List

40

Page 44

6.9

Machine

Accessories

No. Part No. Description

1 1011203100 Machine hinge plate 2 2 2 2 2 2

2 10122026 Machine hinge rubber cushion 2 2 2 2 2 2

3 101S30010 Nail Set 4 4 4 4 4 4

1955-01 Needle #14 3 3 0 0 0 0

4

1955-01 Needle #18 0 0 3 3 0 0

1955-01 Needle #21 0 0 0 0 3 3

5 10131002 Screw driver (large) 1 1 1 1 1 1

6 10131003 Screw driver (medium) 1 1 1 1 1 1

7 10131004 Screw driver (small) 1 1 1 1 1 1

10118003 Bobbin 3 3 3 3 0 0

8

10818501 Bobbin 0 0 0 0 3 3

9 IP07042-001 Dust cover 1 1 1 1 1 1

10 10111011 Machine rest pin 1 1 1 1 1 1

11 1011105500 Oil container 1 1 1 1 1 1

12 10131001 Oil reservoir magnet 1 1 1 1 1 1

20 20C 30 30C 70 70C

Qty.

High Speed Straight Lockstitch Sewing Machine | Instruction Manual and Parts List

41

Page 45

P/N 364331-001

® Singer is a registered trademark of The Singer Company Limited or its affiliated companies.

© 2008 Copyright The Singer Company Limited

Rev 0 - Jan.2010

Loading...

Loading...