Page 1

F*rM 2#31S

Rmr, (157)

SEWING MACHINES

INSTRUCTIONS

FOR USING

SINGER*

REVERSIBLE FEED

LOCK STITCH, FOR FAMILY USE

WEtUitiNG

Oil,

Farts, »n

F il AIRS f #R

Y#ui* MACHiNi

^SINGER '

THE SINGER MANÜFACTORING GO.

Lo*K F#ii iHK

; Ftr *5’'

' I'tiRRK A!*f-r '

ERY.' '

;n u. 3. A

Page 2

THE IMPORTANCE OF USING

SINGER*

LUBRICANTS FOR

YOUR ELECTRIC SEWING MACHINE

it

The Best is the Cheapest”

Use SINGER Sewing Machine

Oil on Machine

Knowing from many years* experience

the great importance of using good oil,

SINGER sells an extra quality sewing

machine oil, in cans, especially prepared

for sewing machines.

TO ALL WHOM IT MAY CONCERN:

The improper placing or renewal

of the Trade Mark SINGER’ ’ or any

other of the Trade Marks of The Singer

Manufacturing Company (all of which are

duly Registered Trade Marks) on any

machine that has been repaired» rebuilt,

reconditioned, or altered in any way

whatsoever outside of a SINGER factory or

an authorized SINGER agency is forbidden.

Page 3

20316

INSTRUCTIONS FOR USING

SINGER

15*

SEWING MACHINES

(WITH ATTACHMENTS)

REVERSIBLE FEED

OSCILLATING SHUTTLE

FOR FAMILY USE

THE SINGER MANUFACTURING COMPANY

*A Trade Mark of THE SINGER MANUFACTURING COMPANY

Copyright (c) 1951 by The Singer Manufacturing Company

Page 4

to

Page 5

8

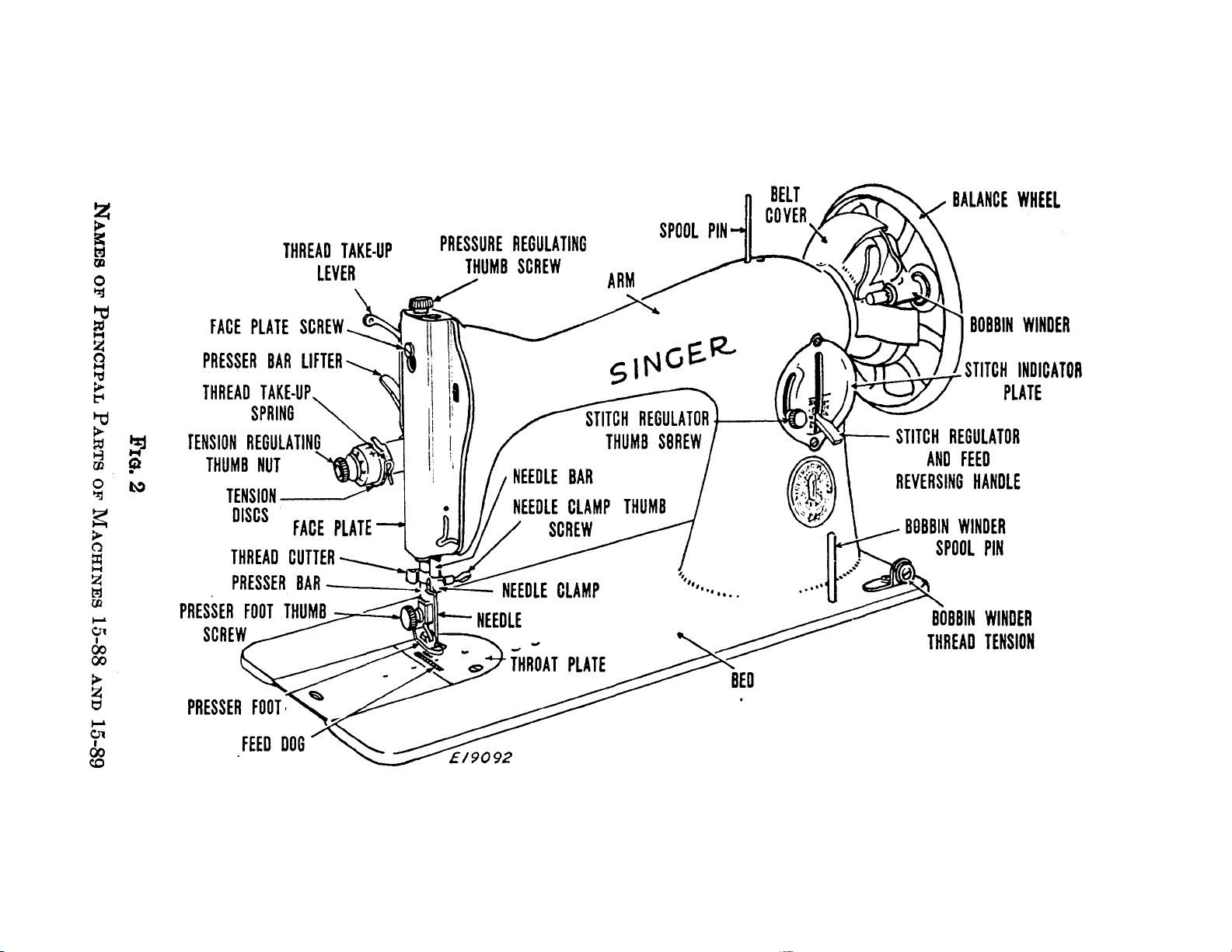

DESCRIPTION

These SINGER family sewing machines will give

you practically life-time service.

Machine 15-88 is intended for operation by foot

power and is regularly equipped with a treadle stand.

Machine 15-89 has a hand driving attachment

and is provided with a wooden base and cover. This

portable outfit can be conveniently carried from

place to place as desired.

Each machine has an oscillating shuttle on a hori

zontal axis and makes the lock stitch. Both machines

have reverse feeding mechanism which enables you

to sew either in a forward or backward direction,

making it easy to back tack and to fasten the ends

of seams.

In addition to plain sewing, a great variety of

pleasing effects such as hemming, binding, edge

stitching, shirring, ruffling, etc., can be produced

with the aid of the attachments furnished with each

machine. These attachments and other popular

SINGER Fashion Aids will enable you to obtain the

much desired tailored appearance of professionally-

made garments and to add new fashion touches or

finishes demanded by swiftly changing styles at a

fraction of the cost of ready-made garments.

READ THIS BOOK CAREFULLY TO GET

THE UTMOST SERVICE

FROM YOUR SEWING MACHINE

Page 6

SINGER SERVICE

Now that you have purchased your new SINGER,

we do not want you to feel that your relations

with us have come to an end. You are cordially

invited to visit your SINGER Shop at any time for

assistance in your sewing problems. You will be

most welcome.

We hope, too, that you will make the SINGER

Shop your headquarters for sewing supplies and

service. Only there or through authorized bonded

SINGER representatives can you secure warranted

SINGER Sewing Machine Oil, needles, belts, parts,

etc., so important in getting the best results from

your machine. And remember, only an authorized

SINGER representative should be allowed to touch

your machine when repairs or adjustments are required.

World-wide SINGER Service has no equal.

Use it!

Page 7

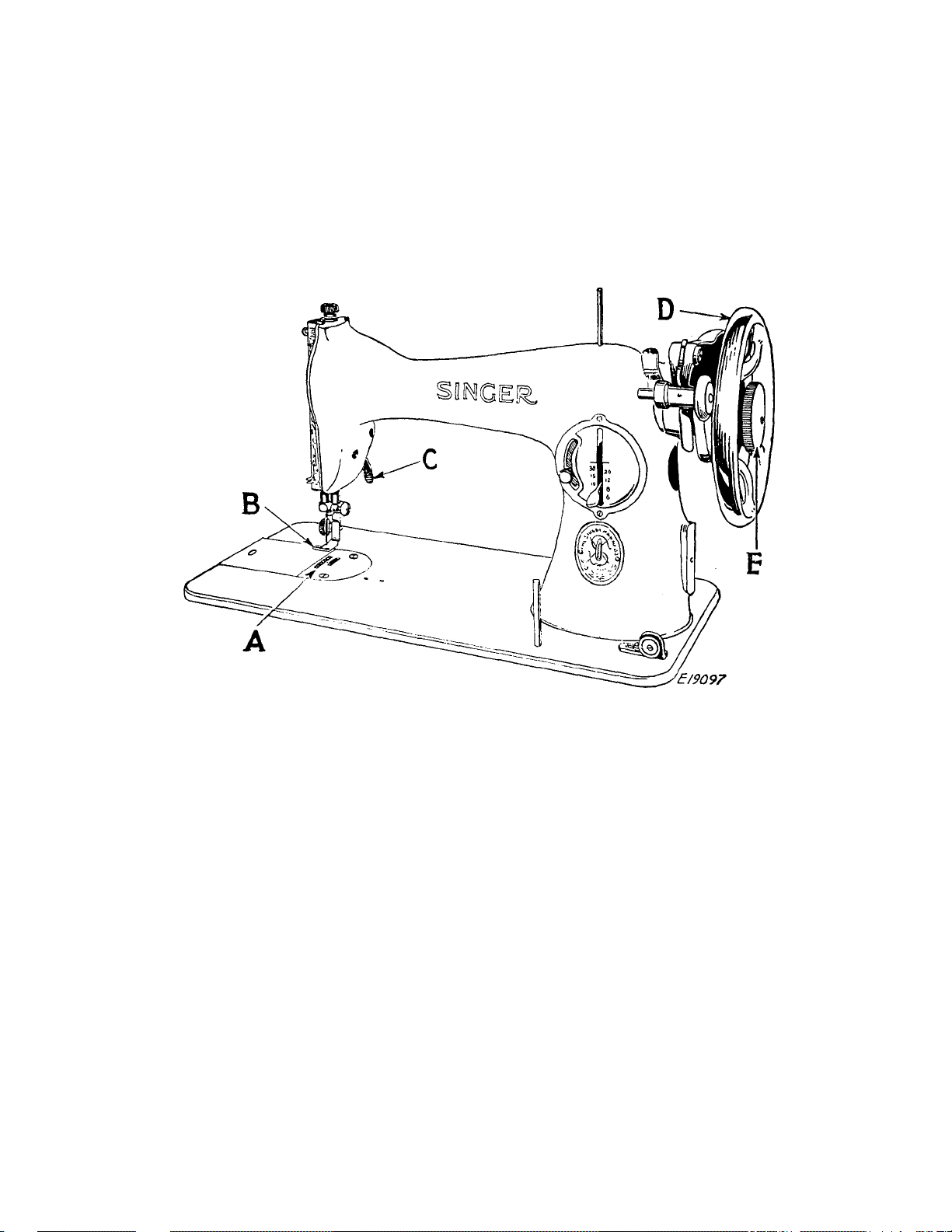

TO OPERATE THE TREADLE MACHINE

(See Fig. 3)

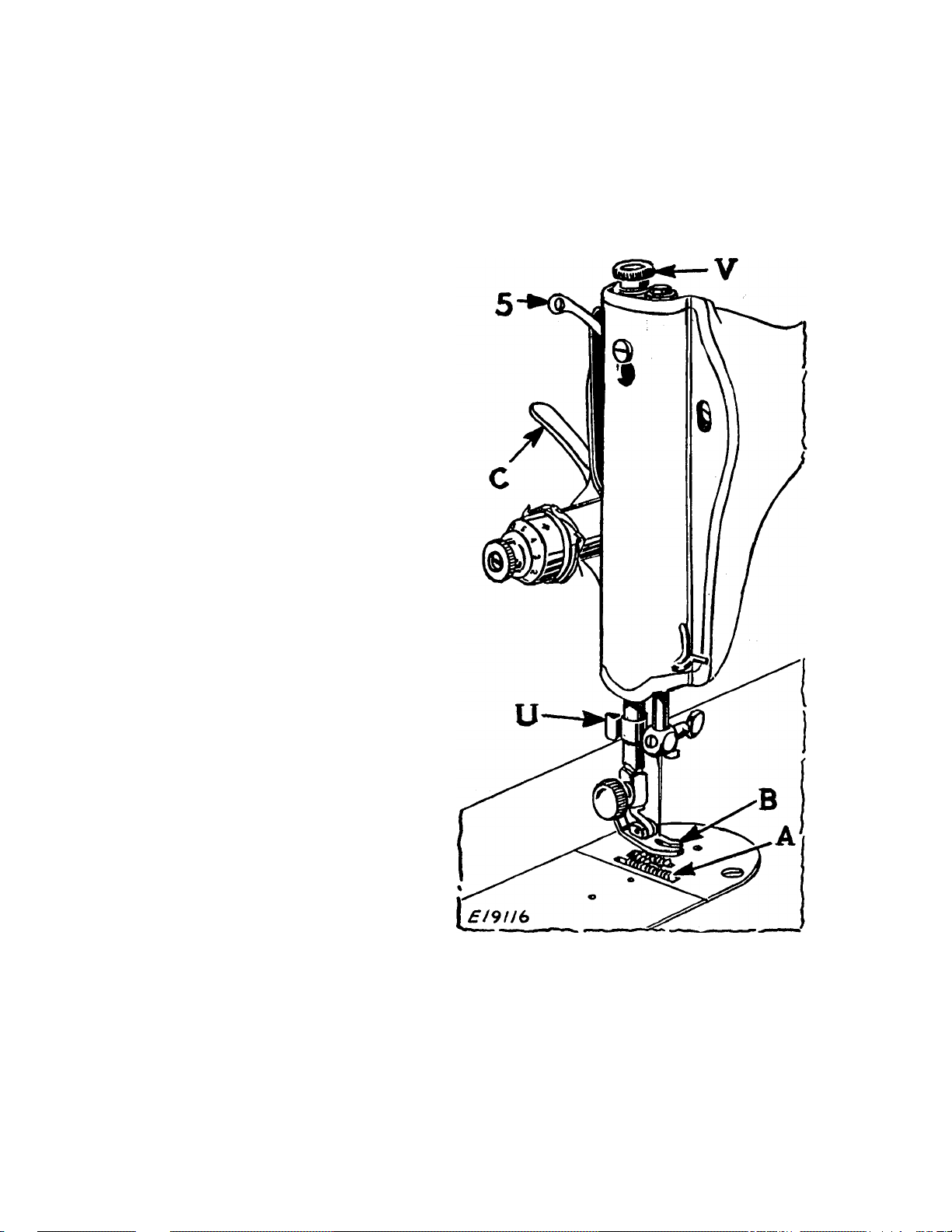

Raise the presser foot B by means of the presser

bar lifter C to prevent injury to the foot B and feed A.

Fig. 3. Front View of the Machine

Hold the balance wheel D with the left hand and,

with the right hand, loosen the stop motion screw E

to release the balance wheel from the stitching

mechanism.

Place your feet upon the treadle and, with the

right hand, turn the balance wheel over toward you.

Continue the balance wheel in motion by an alter

nate pressure of heel and toe on the treadle, until a

regular and easy movement is acquired. Then tighten

the stop motion screw E to connect the balance wheel

with the stitching mechanism.

Place a piece of cloth under the presser foot B and

lower the foot by means of the presser bar lifter C

and operate the machine, without thread, until you

have become accustomed to guiding the material.

Page 8

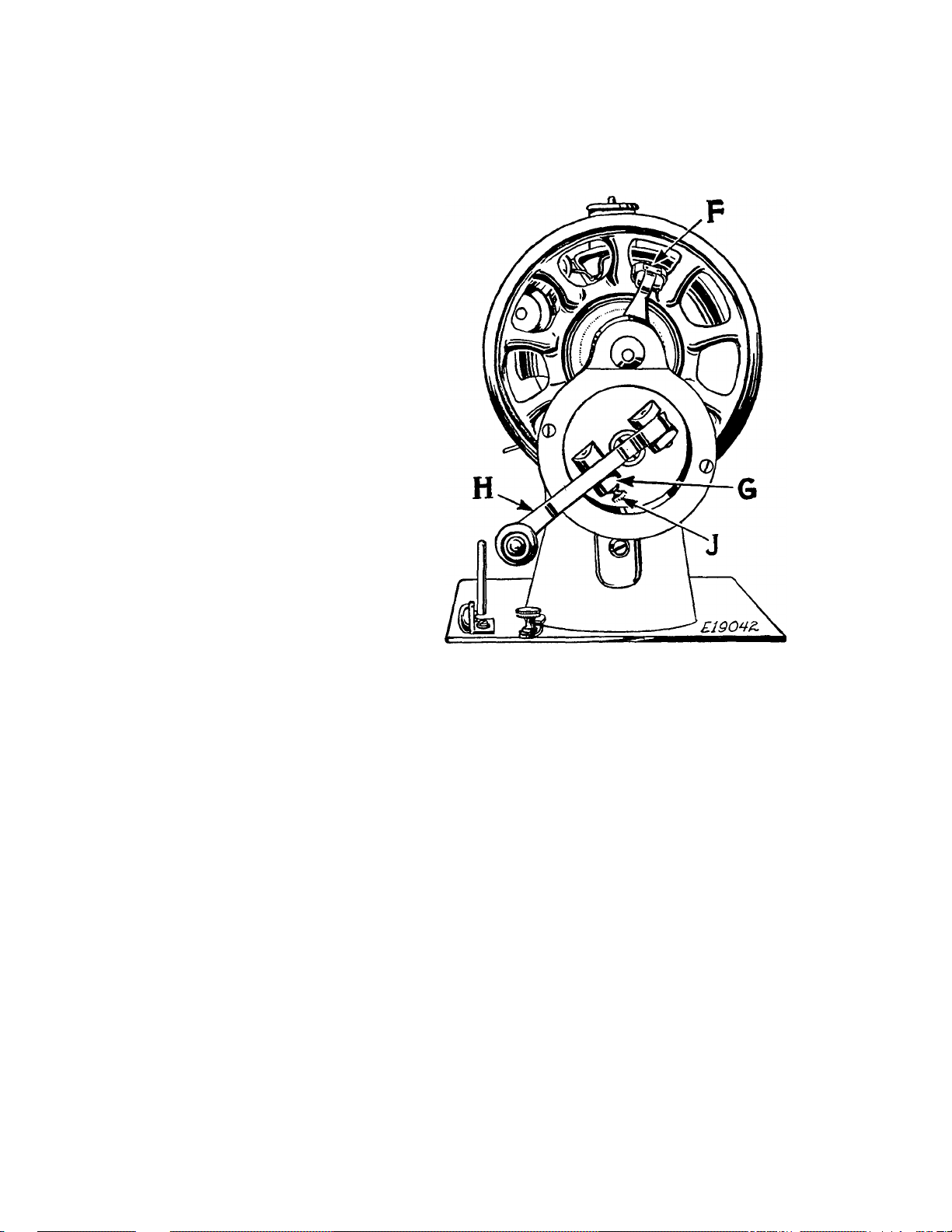

TO OPERATE THE HAND MACHINE

Place the lever H

of the hand driving

attachment in the

socket G and turn

the hinged finger F

back between the

spokes of the balance

wheel, as shown.

6

(See Fig. 4)

Fig. 4. End View of Machine 15-89

Showing Hand Driving Attachment

Raise the presser foot B, Fig. 3 by means of the

presser bar lifter C, Fig. 3 to prevent injury to the

foot B and feed A, Fig. 3.

Turn the lever H of the hand driving attachment

over from you, continuing the motion thus begun

until a regular and easy movement is acquired. Then

tighten the stop motion screw E, Fig. 3 to connect

the balance wheel with the stitching mechanism.

Place a piece of cloth under the presser foot

B, Fig. 3, lower the foot by means of the presser bar

lifter C, Fig. 3 and operate the machine, without

thread, until you have become accustomed to guid

ing the material with the left hand.

NOTE: To release the lever H from the socket G,

withdraw the plunger J and pull out the lever.

Page 9

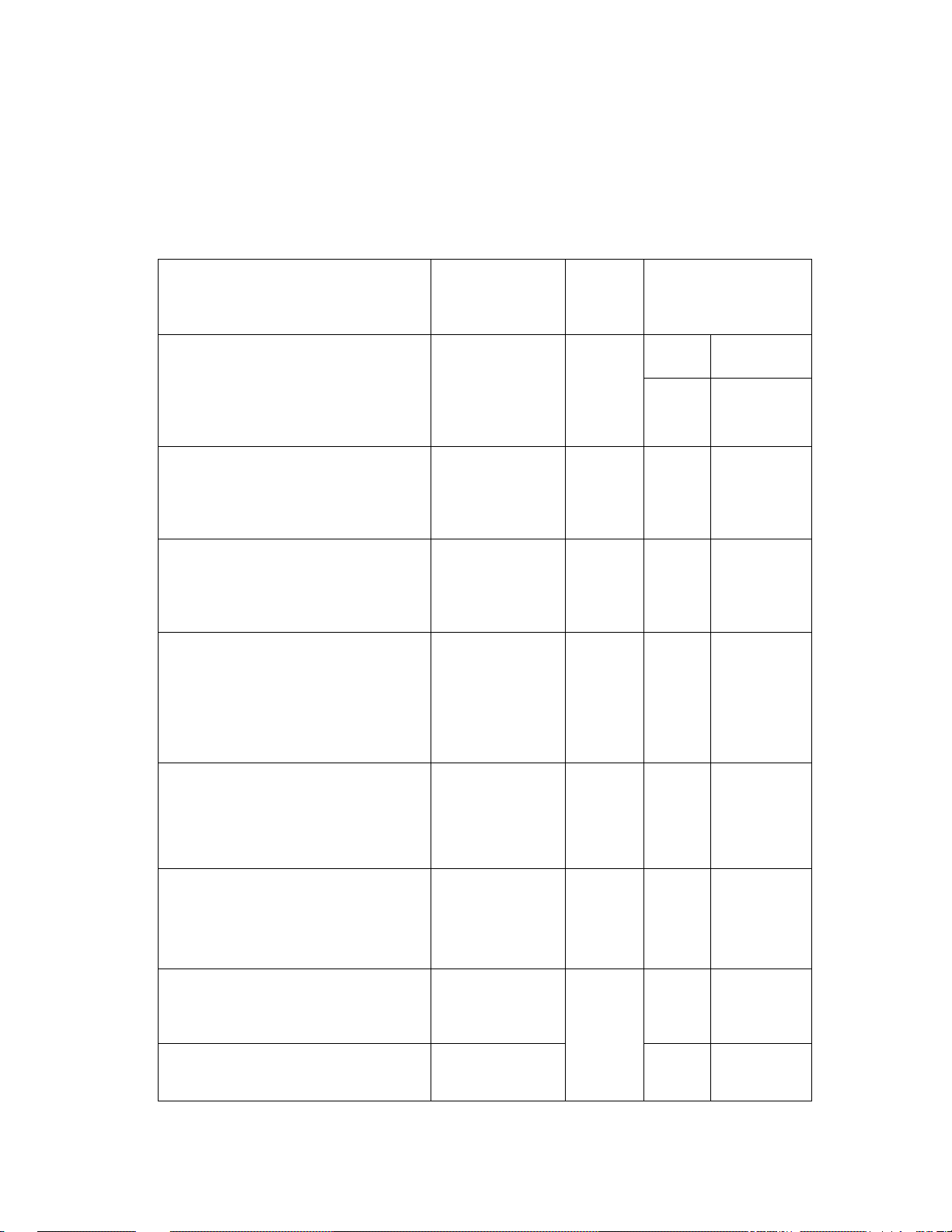

CHART SHOWING THE RELATIONSHIP OF

TYPES OF FABRICS,

THREAD AND NEEDLE SIZES AND

MACHINE STITCH SETTINGS

MACHINE

TYPES OF

FAB BIGS

THREAD

SIZES

NEEDLE

SIZES

STITCH

SETTINGS

Filmy materials comparable

to Net, Marquisette,

Chiffion, Silk, Organdie,

Ninon, Silk Velvet, Nylon

Sheers.

Sheer materials comparable

to Lawn, Dimity, Voile,

Batiste, Rayon Sheer,

Rayon Crepe, Silk Crepe.

Lightweight materials com

parable to Gingham, Chambray. Sheer Wool Crepe,

Taffeta.

Medium lightweight mater

ials comparable to Poplin,

Pique, Percale, Chintz.

Faille, Bengaline, Wool

Flannel, Wool Crepe, W'ool

Jersey.

Medium heavy materials

comparable to Crash, Gab

ardine, Rep, Corduroy,

Velveteen, Coatings, Suit

ings.

Heavy materials compar

able to Sailcloth, Sturdy

Denim, Ticking, Drill

Cloth, Heavy Coating.

100 Cotton

00 and 000

Silk

80 to 100

Cotton

0 Silk

50 Mercerized

60 to 80

Cotton

A Silk

50 Mercerized

50 to 70

Cotton

A or В Silk

50 Mercerized

40 to 50

Cotton

C Silk

Heavy Duty

Mercerized

30 to 40 Cotton

20to24 Cotton

D Silk

9

11 12-15

14

14

16

18

19

18 or 19

INSIDE

SEAMS

15-20

12

12

10

8

TOP

STITCHING

20-30

15-20

15-18

15-16

12

10

40 to 60 Linen

Very heavy materials com

parable to overcoating.

20 to 24 Cotton

E Silk

21

6

8

Mercerized

Plastic materials.

Cotton

11

10 12

When ordering needles, always specify “Class and

Variety 15x1 ’ ’and state the size and quan ti ty required.

Page 10

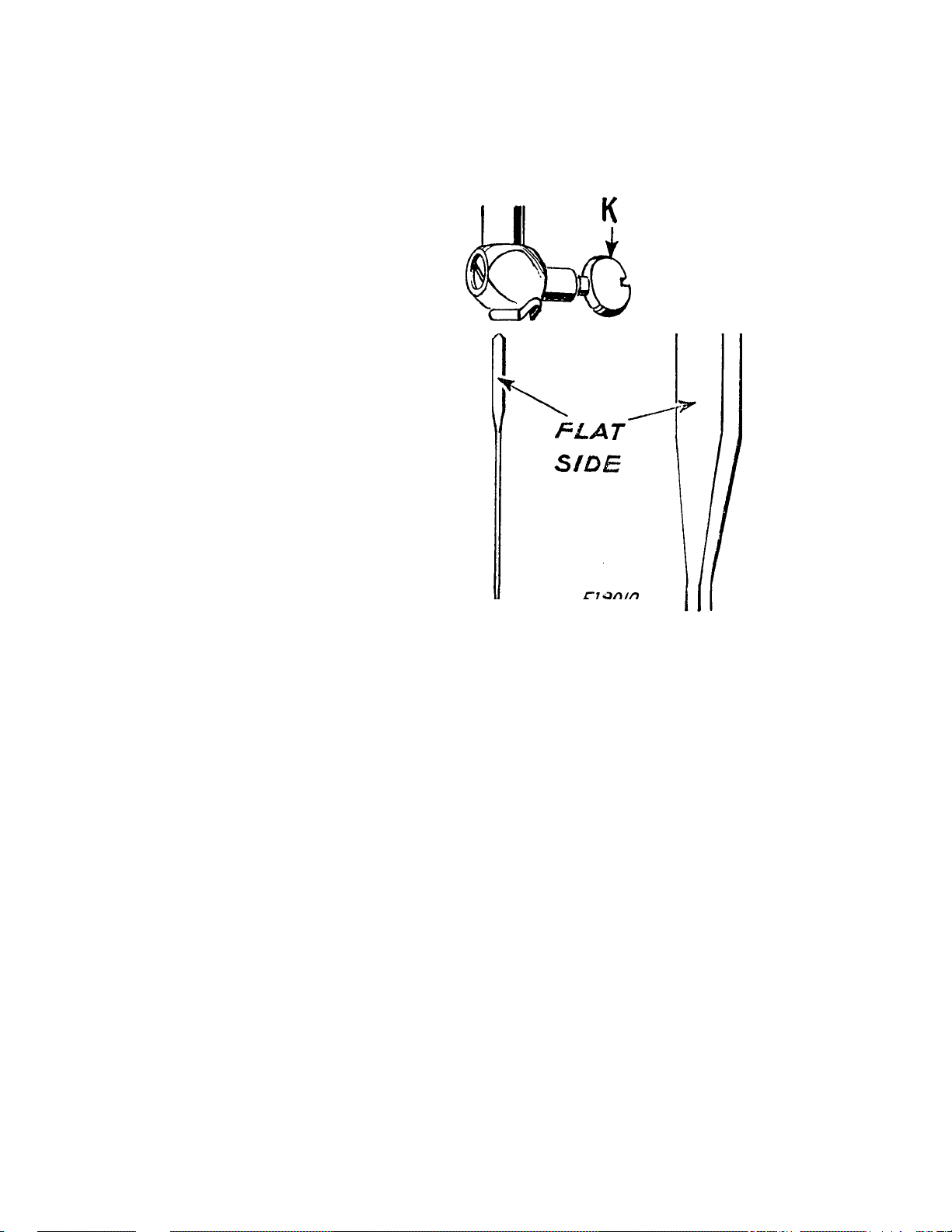

TO SET THE NEEDLE

Select the cor

rect needle ac

cording to the

table on page 7.

Be sure that the

needle is not

blunt or bent.

Raise the needle

bar to its highest

position and

loosen the thumb

screw K in the

needle clamp.

Push the needle

with its flat side

to the left up

into the needle

clamp as far as

it will go, then

tighten the

thumb screw.

8

Eieoio

Fig. 5. Setting the Needle

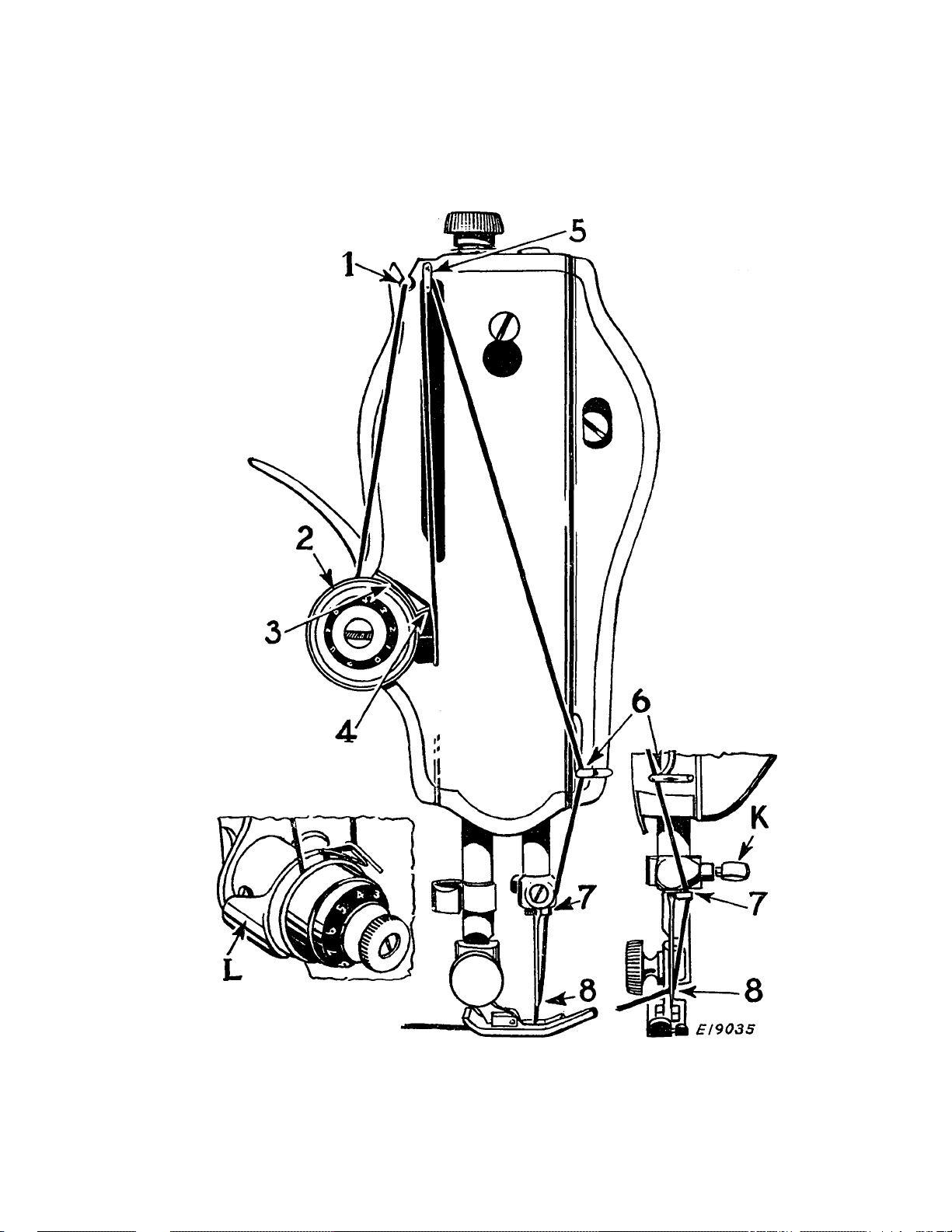

UPPER THREADING

(See Fig. 6 on the Following Page)

Raise the take-up lever 5 to its highest point.

Place the spool of thread on spool pin at top of

machine

Pass the thread through the thread guide 1

Down, under and from back to front between the

tension discs 2 (the thread guard L guiding the

thread between the discs)

Hold the spool tightly and pull the thread against

the take-up spring 4 until it enters the retain

ing fork 3

Pass the thread from back to front through the

hole 5 in the take-up lever

Down through the guide 6 on the face plate

Into the guide 7 on the needle clamp

From right to left through the eye 8 of the needle.

Draw about two inches of thread through the eye

of the needle with which to commence sewing.

Page 11

9

Fig. 6. Upper Threading

Page 12

10

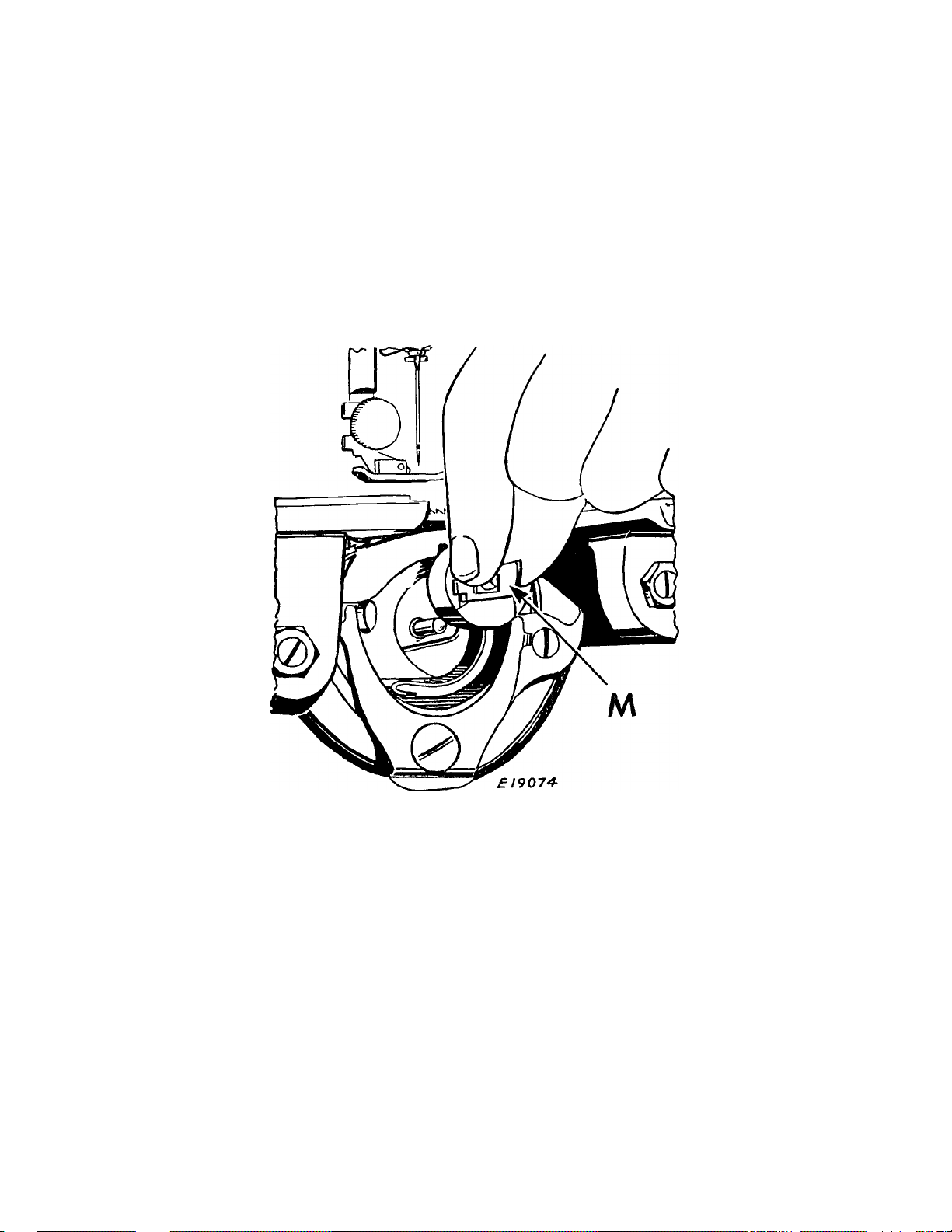

TO REMOVE THE BOBBIN

Raise the take-up lever 5, Fig. 6 to its highest point.

Withdraw the bed slide plate. Reach down with

the left hand and open the bobbin case latch M and

lift out the bobbin case. Release the latch and re

move the bobbin from the bobbin case.

Fig. 7. Removing the Bobbin Case

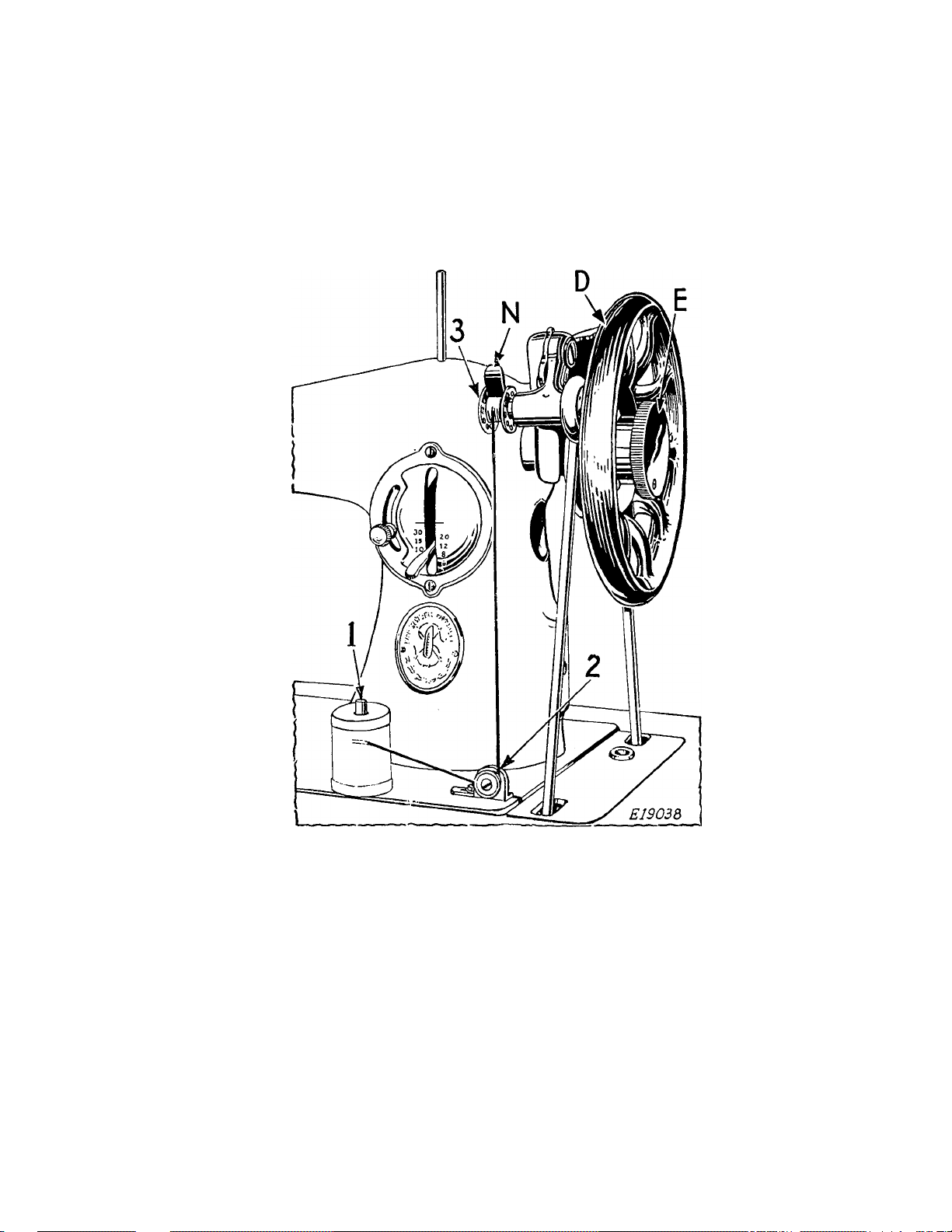

TO WIND THE BOBBIN

(See Fig. 8 on the Following Page)

Hold the balance wheel D with the left hand and,

with the right hand, loosen the stop motion screw E

to release the balance wheel from the stitching

mechanism.

Place the bobbin on the bobbin winder spindle as

far as it will go, having the small pin enter the

hole in the side of the bobbin.

Page 13

11

Place the spool of thread on the spool pin 1

Pass the thread to the right between the tension

discs 2

Up and to the left through one of the holes in the

left side of the bobbin 3, from the inside.

Fig. 8. Winding the Bobbin

The end of the thread must be held by the hand

until a few coils are wound and then should be

broken off.

Press down on the bobbin and the bobbin winder

latch will drop down and hold the bobbin winder

pulley against the hub of the balance wheel.

Then operate the machine the same as for sewing.

When sufficient thread has been wound upon the

bobbin, the bobbin winder is automatically released

from the balance wheel.

Then tighten the stop motion screw E.

Page 14

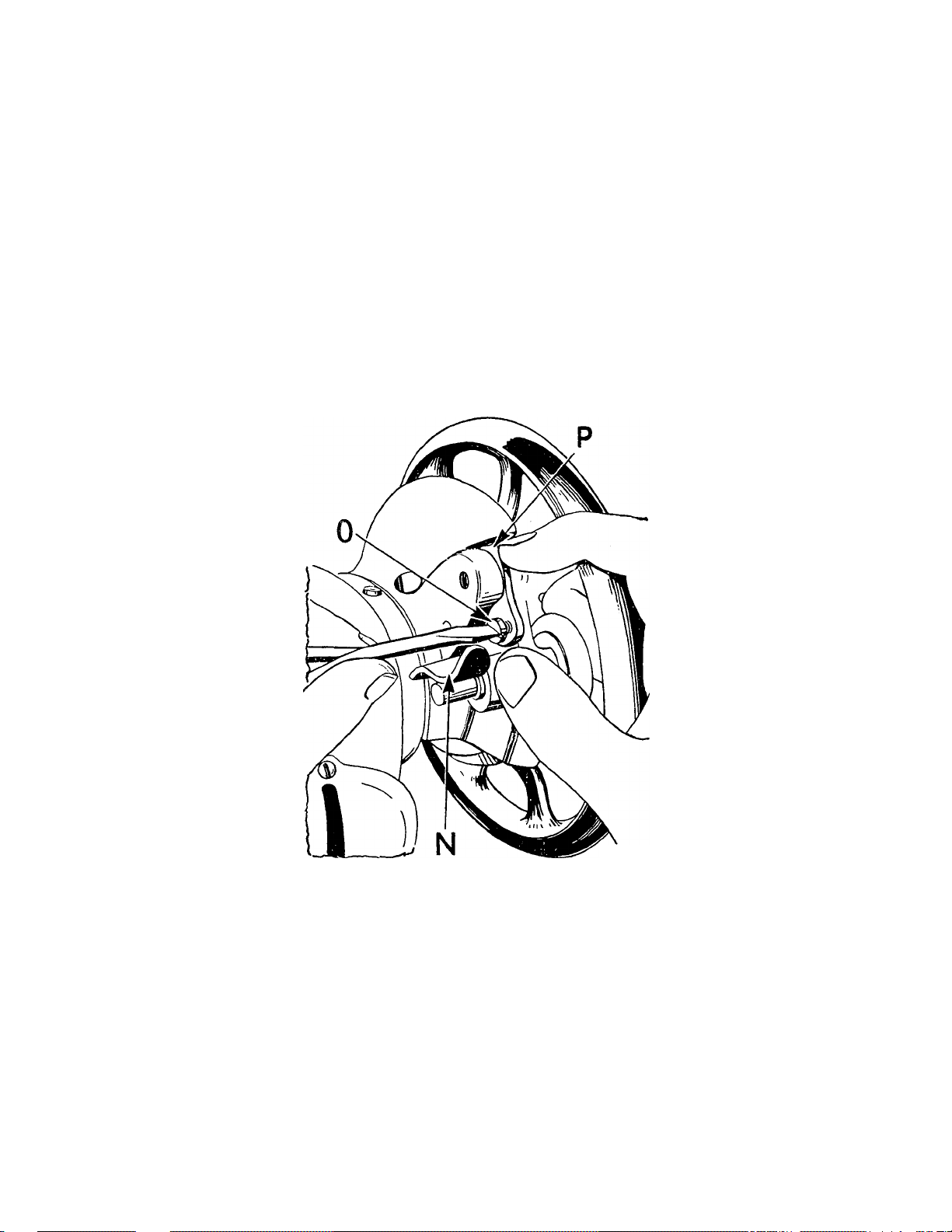

12

If the pressure of the bobbin winder pulley against

the hub of the balance wheel is insufficient for wind

ing the bobbin, press down the bobbin winder until

the latch N, Fig. 9 drops down and holds it, then

loosen the adjusting screw O, Fig. 9. With the fore

finger, push back the upper end of the slotted plate

P as far as it will go, as shown in Fig. 9, and at the

same time press the bobbin winder pulley against

the hub of the balance wheel, then tighten the

adjusting screw O.

£19072

Fig. 9. Adjustment of Bobbin Windek

If the thread does not wind evenly on the bobbin,

loosen the screw which holds the tension bracket

2, Fig. 8 in position on the bed of the machine and

slide the tension bracket to the right or left, as may

be required, then tighten the screw.

Bobbins can also be wound while the machine

is sewing.

Page 15

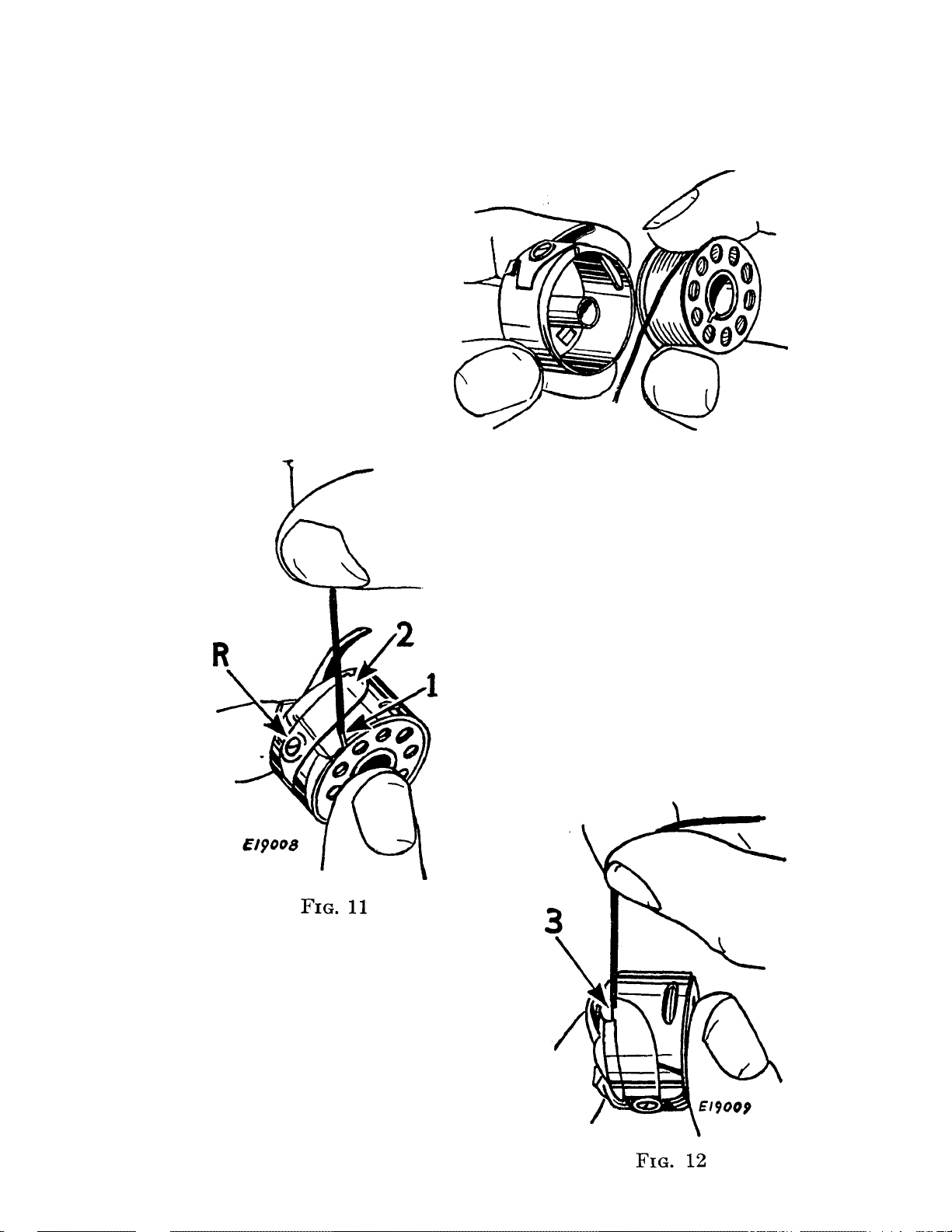

TO THREAD THE BOBBIN CASE

Hold the

bobbin so that

the thread will

unwind in the

direction

shown in

13

Fig. 10.

EI9007

Fig. 10

Hold the bobbin

case as shown in

Fig. 10, and place

the bobbin into it.

Pull the thread into

the slot 1, under the

tension spring 2 and

into the slot 3 at the

end of the spring.

Page 16

14

TO REPLACE THE BOBBIN CASE

Hold the bobbin case by the latch and place it

on the stud T of the shuttle body with the position

finger S opposite the notch at the top of the shuttle

race.

£19096

Fig. 13. Bobbin Case Threaded and Replaced

Release the latch and press the bobbin case back

until the latch enters the groove in the stud. Allow

about three inches of thread to hang free from the

bobbin case and close the bed slide plate.

Page 17

TO PREPARE FOR SEWING

Hold the end of the

needle thread with the

left hand and turn

the balance wheel

over toward you

until the needle goes

down and up again and

the thread take-up

lever 5, Fig. 16 is at its

highest point. Pull up

the needle thread and

15

bobbin thread will come

with it, as shown in

Fig. 14.

Fig. 15

Threads in Position to

Commence Sewing

Fig. 14

Drawing Up the Bobbin Threat

Lay both threads back

under the presser foot diag

onally across the feed, as

shown in Fig. 15, to the right

or left, depending upon

which side of the needle the

material is to be located, so

that when the presser foot

is lowered, the threads will

be firmly held between the

feed and the presser foot.

Page 18

TO COMMENCE SEWING

Be sure to have the

thread take-up lever

5 at its highest point.

Place the material

beneath the presser

foot B, lower the foot

by means of the presser

bar lifter C and com

mence to sew, turning

16

the balance wheel over

toward you.

Never pull the ma

terial along when

stitching. This is liable

to bend the needle.

Guide the material only.

Never operate the

machine without cloth

under presser foot.

Fig, 16

The slide over the bobbin case should be kept

closed when the machine is in operation.

The balance wheel must always turn over toward

the operator.

Page 19

17

TO TURN A CORNER

Stop the machine when the needle is commencing

its upward stroke. Raise the presser foot and turn

the work as desired, using the needle as a pivot,

then lower the presser foot.

BASTING

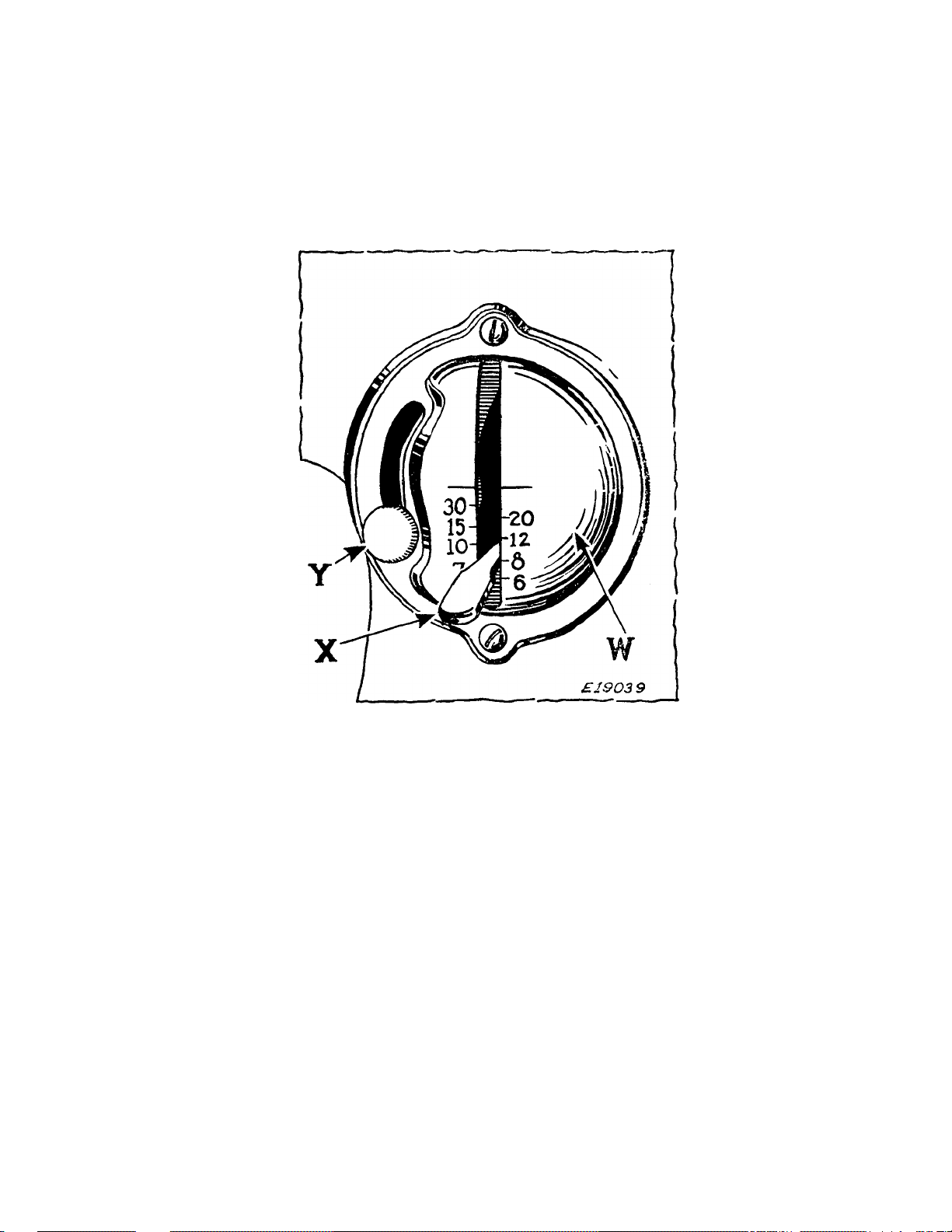

The longest stitch, No. 6 on the stitch indicator,

adjusted by lever X, Fig. 17, is satisfactory

for basting. These basting stitches can be easily

removed by clipping every sixth stitch and with

drawing the long continuous thread.

Machine basting is firmer, more even and much

quicker than hand basting.

TO SEW BIAS SEAMS

Use a shorter stitch when sewing bias or curved

seams to increase the elasticity of the seam and

to prevent seam failure under strain.

No change in tensions is required.

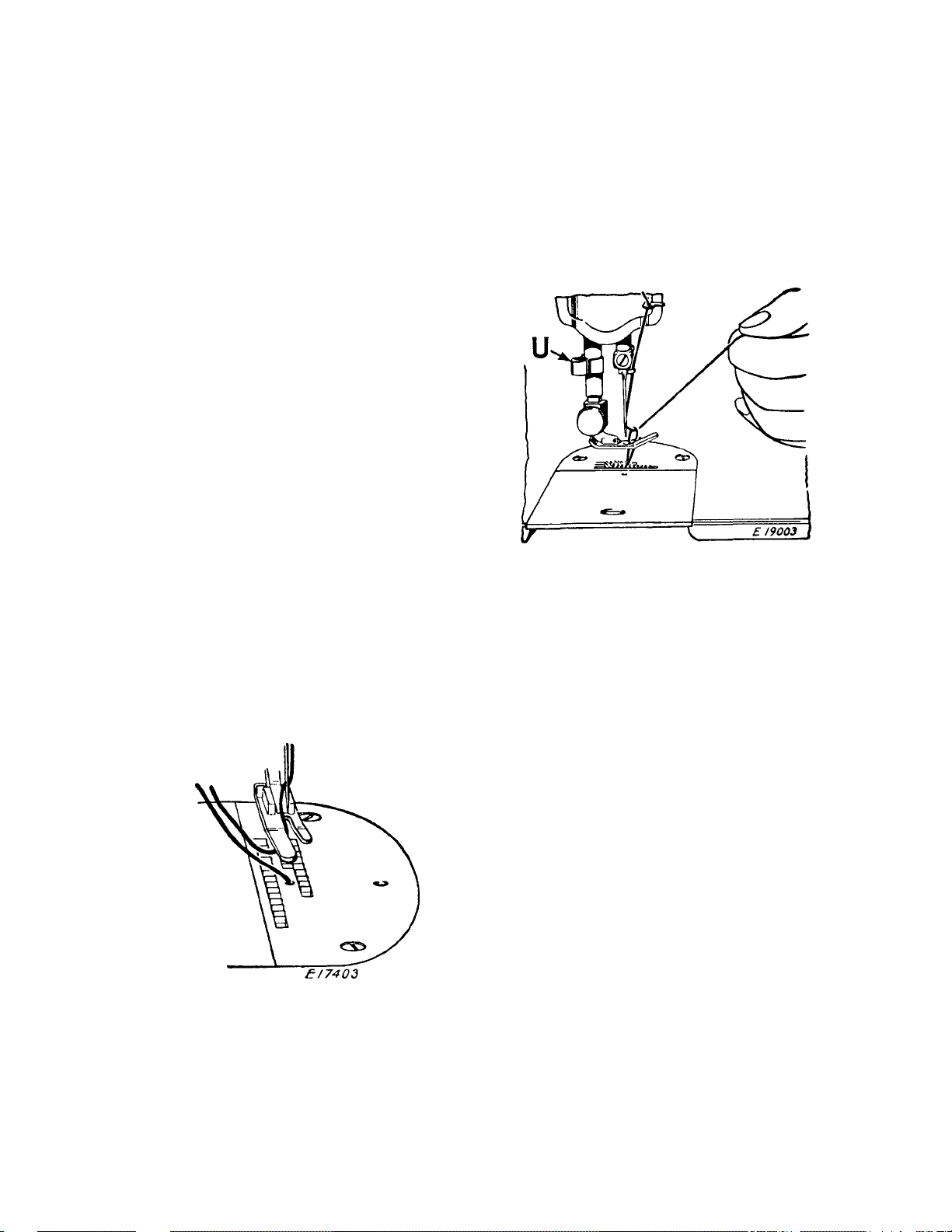

TO REMOVE THE WORK

Stop the machine with the thread take-up lever

5, Fig. 16 at its highest position. Raise the presser

foot, draw the fabric back and to the left, and sever

the threads on the thread cutter U, Fig. 16. Place

the ends of the threads under the presser foot, as

shown in Fig. 15.

Page 20

18

TO REGULATE THE LENGTH OF STITCH

The machine is adjustable to make from 6 to 30

stitches per inch, as indicated by the numerals on

the stitch indicator plate

W.

Fig. 17. Showing Lever for Reversing Direction

OF Feed and Regulating Length of Stitch

The number of stitches to the inch that the ma

chine is set to make is indicated by the number

which is in line with the upper side of the stitch

regulating lever X.

To change the length of stitch, loosen the thumb

screw Y and move it to the bottom of the slot. Then

move the stitch regulating lever X until its upper

side is in line with the number of the desired length

of stitch. Now move the thumb screw Y until the

stitch regulating plate touches the lever X, then

tighten the thumb screw

Y.

The machine will now make the indicated number

of stitches to the inch in either a forward or reverse

direction, depending on whether the lever X is at

its lowest or highest position.

Page 21

19

TO REGULATE THE DIRECTION OF FEED

To feed the material from you, push down the

stitch regulating lever X Fig. 17 as far as it will go.

To feed the material toward you, raise the stitch

regulating lever X as high as it will go.

The direction of feeding can be reversed at any

point of a seam without removing the work from

the machine.

The reverse feed makes it easy to do 'Tack tack

ing” and to fasten the ends of seams.

TO REGULATE PRESSURE ON

PRESSER FOOT

For ordinary sewing, the pressure of the presser

foot on the material seldom requires changing. Heavy

materials require more pressure than light weight

materials. The pressure should be only heavy enough

to prevent the material from rising with the needle

and to enable the feed to move the work along

evenly. To increase the pressure, turn the thumb

screw V, Fig. 16 clockwise or downward. To lighten

the pressure, turn the thumb screw so that it screws

upvrard.

SINGER Needles should be used

in SINGER Machines

These Needles and their Containers

are marked wi th the

Company’s Trade Mark "SIMANCO.*” i

Need I es in Containers marked

"FOR SINGER MACHINES”

are NOT SINGER made needles. 2

Page 22

20

THREAD TENSIONS

For ordinary stitching, the needle and bobbin

threads should be locked in the center of the thick

ness of the material, thus:

Fig. 18. Perfect Stitching

If the tension on the needle thread is too tight, or

if that on the bobbin thread is too loose, the needle

thread will lie straight along the upper surface of

the material, thus:

---

Enm

Fig. 19. Tight Needle Thread Tension

If the tension on the bobbin thread is too tight,

or if that on the needle thread is too loose, the bobbin

thread will lie straight along the under side of the

material, thus:

m.

E1I3I9

Fig. 20. Loose Needle Thread Tension

TO REGULATE THE

NEEDLE THREAD TENSION

The tension on the

needle thread can be

regulated only when

the presser foot is

down.

The numerals “0 to

9’’ on the dial C, Fig.

21 indicate the dif

ferent degrees of ten-

sion that can be

obtained. The num

bers do not denote the

size of thread or ounces

of tension.

Fig. 21. Needle Thread Tension

Page 23

21

When the tension has been correctly set for aver

age sewing, note the number at the indicator line Q,

so that the tension may be reset should it be altered

for special work or change in size of thread.

To increase the tension, turn the thumb screw A

gradually to the right (clockwise) until the required

tension is obtained. Each higher number denotes

increased tension.

To decrease the tension, turn the thumb screw

A gradually to the left (counter-clockwise) until the

required tension is obtained. Each lower number

denotes less tension.

TO REGULATE THE

BOBBIN THREAD TENSION

The tension on the bobbin thread is regulated by

the screw R, Fig. 11 in the tension spring on the

outside of the bobbin case. To increase the tension,

turn the screw R over to the right. To decrease

the tension, turn this screw over to the left.

When the tension on the bobbin thread has been

once properly adjusted, it is seldom necessary to

change it, as a correct stitch can usually be obtained

by varying the tension on the needle thread.

Page 24

22

TO DISASSEMBLE THE

NEEDLE THREAD TENSION

NOTE: The needle thread tension, Figs. 21

to 23 inclusive, is correctly adjusted at the fac

tory to produce the complete range of tensions

with one revolution of the thumb nut A,

There should be no necessity for removing or

taking this tension apart. However if, for any

reason, it becomes necessary to remove the

tension, proceed as follows:

Turn the thumb nut A, Fig. 22 away from you

(toward the left) until it stops at “0” on the num-

A B c s F

DF2

M P

Fig. 22, Needle Thread Tension Disassembled

bered dial C. Press in the dial to disengage the pin

B in the thumb nut and remove the thumb nut,

£190St

dial, stop washer D, tension spring F, indicator G,

the two tension discs H, thread guard plate L, and

the tension releasing pin J, as shown in Fig. 22. To

remove the pin J from the stud N, take off the face

plate and tilt it so that the pin will drop out.

Page 25

23

TO REASSEMBLE THE

NEEDLE THREAD TENSION

Replace the face plate, insert the tension releasing

pin in the stud, place the thread guard plate on the

Fig. 23. Reassembling and Replacing the Tension

stud, being sure that the lug M, Fig. 22 engages

the short recess P to prevent the plate from turn

ing on the stud. Next, place the two tension discs

H on the stud, having the flat thread-bearing sides

of the discs together. Replace the indicator G with

the large open side facing end of stud so that the

plus and minus signs will be readily seen from a

sewing position as shown in Fig. 23. Insert the ten

sion spring F in the indicator so that the first half

turn F2 of this spring will straddle the lower half of

the tension stud. Guide the stop washer D onto the

stud so that the extension S will be above the ten

sion stud as shown in Fig. 23.

NOTE; If the

spring and stop

washer are in cor

rect position, the

extension will clear

the first

halfcoil of the spring,

as shown in

Fig. 24.

Next place the

numbered dial on

the stud so that the

Fig. 24

£ /90*8

numeral 2 is oppo

Page 26

24

site the stop washer extension S, then push

the dial to compress the spring so that the

thumb nut can be turned onto the stud,

carefully guiding the pin in the thumb nut into

one of the holes in the numbered dial. Lower

the presser bar and turn the thumb nut

A to the

left until it stops at “0.” Thread the tension and

pull the thread through the tension discs to test the

amount of tension at the position. At this point

there should be a barely perceptible pull on the

thread to indicate that there is a minimum tension

which gradually increases with the turn of the thumb

nut to the right, providing a full range of tensions

from light to heavy within one revolution of the

thumb nut. If the pull is too strong for a minimum

tension, press in the numbered dial to disengage the

pin in the thumb nut from the dial and reset the pin

in one of the holes to the

left of the previous setting.

This resetting of the pin will produce less tension at

zero. On the other hand, should there be insufficient

tension at zero, press in the dial and reset the pin

in one of the holes to the right of the previous set

ting. Repeat this process until the desired minimum

tension is obtained.

If Correct Stitching is Not Obtained:

If the bobbin thread tension has been disturbed,

or a correct stitch cannot be obtained without a

very heavy or very light needle thread tension, then

the following procedure is recommended:

Using No. 50 thread in the needle and on the bob

bin, adjust the needle thread tension as instructed

above. Then turn the tension thumb nut to “4” and,

with two thicknesses of thin material in the machine,

adjust the bobbin thread tension, as instructed on

page 21, until the stitch is correctly locked in the

material as shown in Fig. 18.

A wide range of materials and threads can now

be accommodated without further adjustment of

the bobbin thread tension.

Page 27

25

TO OIL THE MACHINE

If the machine is used continuously, it should be

oiled daily. If moderately used, an occasional oiling

is sufficient.

Apply one drop of oil at each of the places indicated

by the unlettered arrows in Figs. 25 and 27 to 29.

Draw to the left the bed slide plate, and after

removing the lint and dust which may have accumu

lated (see instructions on pages 28, 29 and 30),

apply oil to the shuttle race A, Fig. 30. The slide

should then be closed.

Page 28

26

Loosen the thumb screw in the round cover plate

at the back of the machine, turn the plate upward

and fasten by tightening the screw. Turn the bal

ance wheel over toward you until the connecting

Fig. 26. Oiling Points at the Back of the Machine

rod Z, Fig. 26 is at its highest position. Then apply

a few drops of oil through the hole in the top of the

machine, to the wick which is retained in the cap

of the connecting rod, as shown in Fig. 26. Also

oil the other moving parts inside, turn the cover

nlate down and fasten it as before.

Page 29

27

Loosen the screw A2, Fig. 27

near the upper end of the face

plate, raise the plate and slip

it off over the head of the

screw. Apply one drop of oil

at each of the places indicated

by the unlettered arrows in

Fig. 27, then replace the face

plate and fasten it as before.

Fig. 27. End View

“Showing Oiling Points

Apply a drop of

oil at each of the

oil holes in the hand

driving attachment,

as shown by arrows

in Fig. 28.

Fig. 28. Oiling Points in

Hand Driving Attachment

Page 30

28

When the machine is used on a foot power stand,

to reach the parts underneath the bed of the ma

chine, press the belt shifter to the left and operate

£/9096

Fig. 29. Oiling Points in Base of Machine

the treadle meanwhile until the belt is released,

then turn the machine back on its hinges. Apply

one drop of oil at each of the places indicated by

arrows in Fig. 29.

Also lubricate each of the bearing points in the

stand.

Machine Working Heavily;

If the machine runs hard after standing idle for

some time, use a little kerosene in the oiling places,

run the machine rapidly, then wipe clean and oil.

To Clean the Stitch Forming Mechanism:

After considerable use, the stitch forming mechan

ism in the bed of the machine may become clogged

with lint and this may interfere with the perfect

operation of the machine.

Page 31

29

Occasionally remove the shuttle from the machine,

as instructed below and remove any lint, etc., which

has accumulated in the machine.

TO REMOVE THE SHUTTLE

Draw to the left the bed slide plate. Turn the

balance wheel over toward you until the needle is

Fig. 30. Showing Position of Shuttle for

Removal from Machine

at its highest point and the point of the shuttle is

at the position shown in Fig. 30.

Remove the bobbin case and bobbin. Take out

the thumb screw D, Fig. 30, also the spring

C, Fig. 30 and the shuttle race back B, Figs. 30

and 31. The shuttle A, Figs. 30 and 31 may now

be easily removed and the parts cleaned.

Page 32

30

TO REPLACE THE SHUTTLE

See that the needle is at its highest point. Replace

the shuttle with its point A in the position shown

£/9033

Fig. 31. Shuttle and Paets Removed from Machine

in Fig. 31, then replace the other parts in the order

illustrated in Fig. 31. Replace and tighten the

thumb screw D. Replace the bobbin and bobbin

case and close the bed slide plate.

Page 33

31

SEWING SUGGESTIONS

Breaking of Needles Might be Caused by;

(1) Improper Size of Needle for Thread and Material.

See page 7.

(2) Needle Bent.

(3) Pulling of Material when Stitching.

(4) Needle Striking Improperly Fastened Presser Foot

or Attachments.

(5) Crossing Too Thick Seams with Too Small a Needle.

Breaking of Needle Thread Might be Caused by:

(1) A Knot in the Thread.

(2) Improper Threading. See page 9.

(3) Upper Tension Too Tight. See page 20.

(4) Needle Set Incorrectly. See page 8.

(5) Needle Blunt or Bent.

(6) Thread Too Coarse for Needle. See page 7.

(7) Roughened Hole in Throat Plate.

(8) Improper Arrangement of Threads to Commence

Sewing. See page 15.

Breaking of Bobbin Thread Might be Caused by:

(1) Improper Threading of the Bobbin Case.

See page 13.

(2) Bobbin Thread Tension Too Tight. See page 21.

Skipping of Stitches Might be Caused by;

(1) Improper Setting of Needles. See page 8.

(2) Needle Blunt or Bent.

(3) Needle Too Small for Thread. See page 7.

Belt Tension:

The belt should be just tight enough to keep from

slipping. If too loose, remove the hook at one end,

shorten the belt and rejoin.

Free Instruction for using the machine is gladly

given at any SINGER Shop.

Page 34

32

DARNING OR EMBROIDERING

Turn the machine back on its hinges. Unscrew as

far as possible the thumb screw B, Fig. 32 which

is located in the lower end of the slot of the feed

A B

Fig. 32. Adjustment for Darning or Embroidering

lifting crank A, Fig. 32. The feed is thus rendered

inoperative and will not interfere with the free

movement of the work. Bring the machine forward

into place.

Move the stitch regulating lever X, Fig. 17 to

its neutral position in the center of the slot at the

front of the machine.

Remove the presser foot and let down the presser

bar lifter C, Fig. 16 to restore the tension on the

needle thread which is released when the lifter is raised.

Draw up the bobbin thread as instructed on

page 15.

Page 35

When darning

flat work, it is

advisable to use

embroidery

hoops to hold

the work.

Place the work

in the machine,

having the un

worn part near

the hole under

the needle. Com

mence the darn

ing by making a

line of stitches

across the hole a

little longer than

the width of the

hole. Continue ma

king parallel lines

33

K "'' I

-■'W:- i

Fig. 33. Darning in Process

of stitches across the

and forward and at

hole, moving the work backward

the same time gradually moving

the work side-

-r-.= -/-"v"i wise until the

hole is covered

Cf with lines of

; stitches running

".crj across the hole.

:g ? Then commence

; as before and

T ; move the work

, lengthwise of the

\ hole until the

stitches across

2 the hole are

V; completely cov-

ered and the

£!2M'-. darn is finished.

Fig. 34. Darning Finished

Page 36

34

When you have finished the darning or embroidery,

raise the presser bar lifter and replace the presser

foot. Turn the machine back on its hinges and move

the thumb screw B, Fig. 32 down to the bottom

of the slot of the feed lifting crank A, Fig. 32 and

make sure that the thumb screw is firmly tightened.

Bring the machine forward into place, return the

stitch regulating lever X, Fig. 17 to its original posi

tion and the machine is ready for regular stitching.

Stockings and socks, underwear, etc., can be

more conveniently darned on the machine with the

SINGER Darner which can be purchased at any

SINGER Shop or from any SINGER Salesman.

SINGER Needles should be used

in SINGER Machines

These Needles and their Containers

are marked with the

Company’s Trade Mark “SIMANCO.*” i

Needles in Containers marked

“FOR SINGER MACHINES”

are NOT SINGER made needles. 2

Page 37

35

INSTRUCTIONS

FOR USING

THE ATTACHMENTS

Page 38

36

THE FOOT HEMMER

The foot hemmer may be used for hemming the

edge of the material, making hemmed and felled

seams and for hemming and sewing on lace in one

operation.

e/bobff

Fig. 35. Foot Hemmer

To Attach the Foot Hemmer:

Raise the needle to its highest point, remove the

presser foot and attach the foot hemmer to the

presser bar in place of the presser foot.

Pull up the bobbin thread as instructed on page 15.

To Start the Hem at the Edge;

(1) Fold the edge of the material over about }/s inch

at the starting point for a distance of about

one inch.

(2) Place the material in the foot hemmer with the

folded edge at the back of the hemmer leading

at an angle to the right.

Page 39

37

(3) Draw the material toward you through the hem-

mer, at the same time folding the edge a second

time. Continue to draw the material through

the hemmer until the edge is just under the

needle.

Fig. 36. Hemming Edge of Material

(4) Place the needle and bobbin threads under the

foot hemmer, lower the hemmer and commence

to sew, assisting the starting of the hem by

slightly pulling the threads from the back while

sewing.

(5) Keep the mouth of the foot hemmer full to pro

duce a smooth, even hem.

Page 40

38

TO MAKE A HEMMED SEAM WITH THE

FOOT HEMMER

(1) When making this seam,

the garment must first be

fitted and the edge of the ma

terial trimmed, allowing for

about yg inch seam. Insert

the two edges of the material,

right sides together, in the

hemmer in the same manner

as a single hem as shown in

Fig. 37. If the material is

bulky, place the edge of the

Fig. 37

Making a Hemmed Seam

(First Operation)

upper piece of material about

ys inch to the left of the

edge of the under piece.

(2) The free edge of the hem

med seam may be stitched

flat to the garment, if

desired. To do this, open

the work out flat, wrong

side up, then insert the

hem in the scroll of the

hemmer, holding the edge

of the hem in position

while it is being stitched.

If the seam is stitched

flat to the garment, one

row of stitching is visible

on the right side.

Fig. 38

Making a Hemmed Seam

(Second Operation)

Page 41

39

TO MAKE A FELLED SEAM WITH THE

FOOT HEMMER

(1) Place the right

sides of the material to

gether, having the edge

of the upper piece about

3/8 iJich to the left of the

edge of the under piece»

Stitch the two pieces to

gether, using the hemmer

as a presser foot. Guide

both pieces by the pro

Fig. 39. Making a Felled Seam

(First Operation)

(2) Open the work

out flat, wrong side up,

and hem the free edge

of the seam, stitching it

flat to the garment as

jecting toe of the hem

mer, as shown in Fig. 39.

shown in Fig. 40.

F;g. 10. Making a Felled Seam

(Second Operation)

Page 42

40

TO НЕМ AND SEW ON LACE

IN ONE OPERATION

(1) Start the hem in the regular way.

(2) Hold the hem in position with the needle.

Fig. 41. Hemming and Sewing on Lace

(3) Raise the presser bar and insert the edge of the

lace in the slot of the hemmer and back under

the hemmer.

(4) Lower the presser bar and commence sewing,

catching the edge of the lace with the needle.

(5) Guide the hem with the right hand and the lace

with the left, being careful not to stretch the

lace as it enters the hemmer.

Page 43

41

ADJUSTABLE HEMMER

To Make Hems from 3/16 to 15/16 Inch Wide

(1) Attach the adjustable hemmer to the presser bar

in place of the presser foot.

(2) Pull up the bobbin thread, as instructed on page 15.

Fig. 42. Showing How Adjustable Hemmer is Used

FOR Making Hems up to 15/16 Inch Wide

(3) Loosen the thumb screw on the hemmer and move

the scale until the pointer registers with the

number of the desired width of hem, No. 1 indi

cating the narrowest hem and No. 8, the widest,

then tighten the thumb screw.

(4) Place the cloth in the hemmer and draw it back

and forth until the hem is formed, as shown

in Fig. 42.

(5) Draw the end of the hem back under the needle,

lower the presser bar and commence to sew.

(6) Guide sufficient cloth into the hemmer to turn the

hem properly.

Page 44

42

ADJUSTABLE HEMMER

To Make Hems Wider than 15/16 Inch

(1) Loosen the thumb screw on the hemmer, move the

scale to the right as far as it will go, then swing

it toward you, as shown in Fig. 43, and tighten

the thumb screw.

(2) Fold and crease the desired width of hem.

Fig. 43. Showing How Adjustable Hemmer is Used

FOR Making Hems Wider than 15/16 Inch

(3) Place the fold under the extension at the right

of the hemmer and the edge into the folder, as

shown in Fig. 43.

(4) Draw the end of the hem back under the needle,

lower the presser bar and commence to sew.

(5) Guide the cloth to keep the hem flat.

Page 45

43

MULTIPLE SLOTTED BINDER

This multiple slotted Binder will apply unfolded

bias binding ^inch in width and commercial folded

binding in sizes if 2y 3) 4 and 5 to the seams or to

the edges of garments. These sizes of folded binding

are 34, /4, A and inch in width, respectively,

and are fed through slots of corresponding sizes in

the binder scroll. See Fig. 44. Binding may be

purchased in a variety of materials and colors.

For convenience in determining the correct width

of unfolded binding inch), this measurement

is marked on the Binder, as shown in Fig. 44.

The two upright guide pins shown in Fig. 44 elim

inate manual guiding of the binding.

ADJUSTING

LUG

SCROLL FOR

UNFOLDED

OUTSIDE

SLOTS FOR

DIFFERENT

WIDTHS OF

FOLDED

BINDING

CENTER SLOT

OF SCROLL

Fig. 44. Multiple Slotted Binder 160359

EDGE GUIDE

FOR PIPING

ONLY

BINDING

B/BI6S

The wide range of bindings that can be applied

with this Binder makes it useful for a large variety

of work. It will be found particularly advantageous

for making children’s wear, lingerie, summer dresses,

and other dainty articles which call for the nar

rower bindings.

Page 46

44

As two different widths of binding of contrasting

color can be fed through the Binder at the same

time, attractive binding and piping effects can be

produced in one operation.

TO ATTACH THE BINDER

Raise the needle to its highest position, then at

tach the Binder to the presser bar in place of the

presser foot.

See that the needle enters the center of the

needle hole.

TO INSERT THE BINDING

IN THE BINDER

Cut all binding to a long point

to the left, as shown in Fig. 45.

Folded Bias Binding must be

inserted in the slot or slots of cor

responding sizes. See

Fig. 48.

Unfolded or Raw Edge Bias

Binding must be inserted in the

open end of the scroll. See

Fig. 46.

After inserting the pointed end of the binding in

the Binder, push it through until the full width of

the binding is under the needle.

Guide the binding by means of the two upright

pins, as shown in Figs. 46 and 48.

Page 47

45

TO INSERT THE GARMENT

IN THE BINDER

Place the edge to be bound as far to the right as

it will go in the center slot of the scroll, as shown in

Fig. 46, and draw it back under the binder foot.

Fig. 46. Binding with Unfolded Binding

Lower the Binder by means of the presser foot

lifter, and commence to sew. Keep the material

well within the center slot of the scroll so that the

edge will be caught in the binding.

TO ADJUST THE BINDER

To bring the inner edge of the binding closer to

the stitching, move the scroll C2, Fig. 46 to the

right by means of the lug B2, Fig. 46. This is

the usual adjustment when binding straight edges.

When binding curves, move the scroll to the left

to bring the inner edge of the binding farther from

the stitching and allow for the sweep of the curve.

Page 48

46

PIPED EDGE

To produce a piped edge on garments, move the

lug B2, Fig. 47 to the left to bring the stitching

about midway of the folded binding.

Fig. 47

Position of Garment and Binding when Piping Edges

Crease the raw edges of the garment toward the

wrong side about 3^ inch, and insert the folded

edge, raw edges uppermost, into the edge guide on

the Binder, and beneath the binding.

When stitched, both sides of the garment will be

finished, and the right side will show the piped edge.

Page 49

47

PIPING AND BINDING IN

ONE OPERATION

A garment can be piped and bound in one opera^

tion, as shown in Fig. 48.

Fig. 48. Piping and Binding in One Operation

IMPORTANT : When piping and binding at the

same time, as shown above, insert the narrow width

of binding first in its slot, then insert the wider

width in its slot. Two consecutive widths should

not be used at the same time. That is, if No. 1

is used, the wider binding should not be smaller than

No. 3 . If No. 2 is used, the wider binding should

be not less than No. 4. Never use Nos. 1 and 2,

or 2 and 3, etc., together.

Use the upright guide pins to guide the wider of

the two widths of binding, as shown in Fig. 48.

Page 50

48

TO BIND OUTSIDE CURVES

Allow the edge to be bound to pass freely through

the scroll without crowding against the scroll wall.

The material must be guided from the back of the

Binder and to the left, permitting unfinished edges

to swing naturally into the scroll of the Binder.

Fig. 49. Binding an Outside Curve

Never pull the binding while it is being fed through

the Binder, as this may stretch the binding, making

it too narrow to stitch or to turn in the edges.

When binding curves, turn the material only as

fast as the machine sews.

Do not push the material in too fast as this will

pucker the edge.

Do not stretch the material as this will distort

the edge so that the curve will not have the proper

shape when finished.

If the stitching does not catch the edge of the

binding, adjust the scroll slightly to the left.

TO BIND INSIDE CURVES

When binding an inside curve, straighten out the

edge of the material while feeding it into the Binder,

being careful not to stretch the material.

Soft materials like batiste or crepe de chine require

a row of stitching added close to the edge of the

curve before binding.

Page 51

49

TO APPLY FRENCH FOLDS

TO CURVES

Place the material under the Binder and stitch

the binding onto the face of the material, as shown

in Fig. 50.

Fig. 50. Applying a French Fold

For guidance in applying the rows of French folds,

mark the material with a line of basting stitches

or with chalk or pencil.

Page 52

50

THE EDGE-STITCHER

This attachment should be used when the stitch

ing must be kept accurately on the extreme edge of

the material. It is also useful for sewing together

laces, insertions and embroideries, sewing in position

hemmed or folded edges, piping or sewing flat braid

to a garment.

To Adjust the

Edge-Stitcher

Fasten this attachment to

the presser bar in place of

the presser foot.

See that the needle enters

the center of the'needle hole.

i

The distance from the line

of stitching to the edge of

the material in the slots is

regulated by moving the lug

D2, Fig. 51 to the right or

left.

The Edge-Stitcher

Fig. 51

To Sew Lace Together:

(1) Insert one of the laces in slot 1 of the edge stitcher

and the other in slot 4, Fig. 51.

(2) Adjust the lug D2 until the edges to be joined

are caught by the stitching.

(3) Slightly overlap the edges of the lace while stitch

ing to keep them against the ends of the slots.

^4) Loosen both thread tensions to avoid puckering

of fine lace.

Page 53

51

Fig. 52. Sewing Lace Together

To Insert Lace or Ribbon:

(1) Fold the edge of the material to which the lace

or ribbon is to be sewn and insert it in the slot 1

of the edge-stitcher.

(2) Insert the lace or ribbon in the slot 4 of the edge-

stitcher and proceed to sew.

(3) Cut away the surplus folded material close to

the stitching.

Fig. 53. Setting in Lace Insertion

Page 54

To Pipe with the

Edge-Stitcher

(1) Cut the piping bias and

twice the width of the

slot 3 so that it can be

folded once.

(2) Insert the piping with its

folded edge to the left

in slot 3 and the edge

52

to be piped in slot 4,

Fig. 51.

Piping with Edge-Stitcher

Fig. 54

To Apply Folded Bias Tape or Military Braid

(1) Place the garment under the edge-stitcher and the

tape in slot 1 or 4, Fig. 51.

Fig. 55. Applying Bias Folded Tape

(2) To make square corners, sew to the turning point,

remove the tape from the attachment, form the

corner by hand, replace the tape and continue

stitching.

(3) To space two or more parallel rows, mark the

material with a guide line, using a crease, chalk

or basting thread.

Page 55

To Stitch a Wide Hem

(1) A wide hem may be

stitched evenly on

sheets, pillow slips,

etc., with the edge-

Stitcher after the

hem has been

measured and the

edge turned.

(2) Insert the edge in slot

5, Fig. 51, and ad

just the lug D2 to

stitch as close to

the edge as desired.

53

Fig. 56.

Making a Wide Hem

To Make a French Seam

Fig. 57.

Making a French Seam

(Second Operation)

(1) To make a uniform

width French seam,

insert the two edges

to be joined, wrong

sides together, in

slot 1 or 2 Fig. 51

and stitch close

to the edge.

(2) Fold both right sides

together and insert

the back of the

seam in the slot 1

and stitch, allow

ing just enough

margin to conceal

the raw edges.

Page 56

54

To Tuck with the Edge-Stitcher

The maximum width of tuck that can be made

with the edge-stitcher is 3^ inch.

Fig. 58. Tucking with the Edge-Stitcher

(1) Fold and crease the material for the desired width

of tuck.

(2) For succeeding tucks, fold the material the de

sired distance from the previous tuck, running

the fold lengthwise over a straight edge, then

crease the folds.

(3) Insert the creased folds in the slot 1 and adjust

the edge-stitcher to the right or left for the de

sired width of tuck. Use a light tension, short

stitch and fine thread and needle.

Page 57

55

GATHERING FOOT

To Shirr with the Gathering Foot

(1) Fasten the Gathering Foot to the presser bar in

place of the presser foot.

Fig. 59. Shirring with the Gathering Foot

(2) Place the material under the Gathering Foot and

stitch in the usual way.

(3) The fullness of the shirring or amount of gather

ing is regulated by the length of stitch. A longer

stitch increases the fullness of the gathers.

Page 58

56

PRINCIPAL PARTS OF THE RÜFFLER

Fig. 6ü. Principal Parts of the Rüffler

A—Foot—attaches ruffler to the presser bar.

B—Fork Arm—straddles the needle clamp.

C—Adjusting Screw—regulates fullness of the gathers.

D—Projection—engages the slots in adjusting lever.

E—Adjusting Lever—sets the ruffler for gathering or

for making a plait once at every six stitches or once

every twelve stitches as desired; also for disengag

ing the ruffler, when either plaiting or gathering

is not desired.

F—Adjusting Finger—regulates the width or size

of the plaits.

G—Separator Guide—contains slots into which

the edge of the material is placed to keep the

heading of the ruffle even; also for separating

the material to be ruffled from the material to

which the ruffle is to be attached.

H—Ruffling Blade—pushes the material in plaits

up to the needle.

J—Separator Blade—prevents the teeth of the

ruffling blade coming into concact with the

feed of the machine or the material to which

ruffle or plaiting is to be applied.

Page 59

57

TO ATTACH THE RUFFLER

(1) Raise the needle to its highest point.

(2) Loosen the presser foot thumb screw and attach

the ruffler to the presser bar in place of the

presser foot, at the same time placing the fork

arm B astride the needle clamp.

(3) See that the needle enters the center of the needle

hole in the ruffler.

Fig. 61. Gathering with the Ruffler

TO ADJUST THE RUFFLER FOR GATHERING

(1) Swing the adjusting finger F away from the needle.

(2) Raise the adjusting lever E and move it until the

projection D can be entered in the slot

marked

O

O

£/00a9X

Fig. 62.

Correct Position for Material to be Ruffled

MATeR/AL

(3) Insert the material to be ruffled between the two

blue blades Line 2, Fig. 62.

(4) Draw the material slightly back of the needle,

lower the presser bar and commence to sew.

(5) For fine gathering, turn the adjusting screw C

upward and shorten the stitch.

(6) For full gathering, turn the adjusting screw C

downward and lengthen the stitch.

Page 60

58

To Make a RufHe and Sew it to a Garment

in One Operation

(1) Insert the material to be ruffled between the two

blue blades Line 2, Fig. 63.

Fig. 64

Making a Ruffle and Attaching it in One Operation

(2) Place the material to which the ruffle is to be

attached under the separator blade

Line 1, Fig. 63.

(3) Proceed the same as for plain gathering.

Page 61

59

To Make a RufHe and Attach it with a

Facing in One Operation

(1) Insert the material to be ruffled between the two

blue blades Line 2, Fig. 65.

^RUFFLING MA TERIA^^

GARMENT^*

EIB090A

Fig. 65. Correct Positions for the Materials

(2) Place the material to which the ruffle is to be at

tached under the separator blade Line 1, Fig. 65.

(3) Place the facing material over the upper blue

blade Line 4, Fig. 65.

Fig. 66. Making a Ruffle and Attaching

IT WITH A Facing in One Operation

(4) If the facing is to be on the right side of the gar

ment, place the wrong sides of the garment

and ruffle together.

(5) If the facing is to be on the wrong side, place the

right sides of the garment and ruffle together.

Page 62

60

To Pipe a Ruffle:

Cl) Insert the material to be ruffled between the two

blue blades Line 3, Fig. 67. This material must

not exceed inches in width.

Fig. 67. Correct Positions for the Materials

(2) The piping material is usually cut on the bias and

it should be about 34 inch wide when folded in

the center. Place the piping material in the

ruffler, following Line 5, Fig. 67 with the folded

edge of the piping to the right.

Fig. 68. Piping a Ruffle

(3) Fold the edge of the material to which the piping

and ruffling are to be attached and insert it in

the rufffer, following Line 6, Fig. 67.

Page 63

61

To Adjust the Ruffler for Plaiting:

(1) Raise the adjusting lever E and move it until the

projection D can be entered in the slot marked

“6.” The ruffler will then plait once every six

stitches. To plait once every 12 stitches, have

the projection D enter the slot “12’* in the

adjusting lever E.

Fig. 69. Plaiting with the Ruffler

(2) Insert the material to be plaited between the two

blue blades Line 2, Fig. 70.

MATERIAL

Fig. 70. Correct Position for the Material

(3) To increase the width of plait, move the adjust

ing finger F back toward the needle and turn

the adjusting screw C downward. To make a

smaller plait, turn the adjusting screw C up

ward. The distance between plaits is regulated

by the length of stitch.

Page 64

62

To Adjust the Ruffler for Group Plaiting;

(1) To make the space between the groups of plaits,

raise the adjusting lever E and move it until

the projection D can be entered in the small

slot indicated by the star on the adjusting lever

E. The ruffler will then stop plaiting and plain

stitching will be made.

Fig. 71. Group Plaiting with the Ruffler

(2) When the desired space is made, set the projec

tion D in either of the slots 6 or 12.

(3) Insert the material to be plaited between the two

blue blades Line 2, Fig. 72.

MATERIAL

Fig. 72. Correct Position for the Material

TO OIL THE RUFFLER

Occasionally apply a drop of oil to the working

parts of the ruffler at each of the places indicated

in Fig. 71.

Page 65

63

The SINGER Universal Threader and

Seam Ripper

Makes Threading Easy

£¡3004

This useful little accessory enables you to thread a

hand sewing needle or a machine needle without eyestrain. As shown on the following page, it also serves

Threading

Needle

WITH

SINGER

Needle

Threader

etSBJB

as a seam ripper with a blade set at just the right

angle for quickly picking out stitches. Both ends

fold into the handle like a jack-knife. It is sold by

all SINGER Shops at a reasonable price.

Page 66

64

The SINGER Material Gripper

Taking out stitches is no longer a tedious job when

you use the SINGER Seam Ripper and Material

Opening Seam with

SINGER Seam Ripper

Material Gripper Holds Cloth

Gripper, as shown above. The gripper acts as a

third hand, holding your material while you pin,

sew or rip. It is sold by all SINGER Shops at a

reasonable price.

Page 67

THE I MPO RTA NCE OF US ING

SINGER*

NEEDL ES FOR YO UR

SEWI NG MACH INE

You will obtain the best stitchm g

resu lts fro m your sewing machin e

if it is fitte d with

a SINGER

Need le.

SINGER

chase d from any

or

SINGER

SINGER

in the

Need les can be pur

SINGER

Sale sman .

Need les are containe d

SINGER

Gree n Needle

Shop

Pack et with the famo us red letter

"S" upon it .

Page 68

FOR YOUR PROTECTI

Singer sells its machines onl

SINGER Sewing Centers, identifi

\

i

i

CO

yj c

Red “S” on the window, and nevei

department stores or other outlets.

When your machine needs servi«

your Singer Sewing Center anc

of warranted SINGER parts and

Check local address in teiephon

tory under name of

SINGER SEWING MACHINE CO>

o S

c

O S

oo

Loading...

Loading...