Page 1

OPERATOR

INSTRUCTIONS

SINGER

MODEL

1501

INTELLIGENT TERMINAL

SINGER

BUSINESS

MACHINES

Page 2

OPERATOR

INSTRUCTIONS

SINGER

INTELLIGENT

MODEL

TERMINAL

1501

22-6504-01

AUGUST

1975

SINGE;R

BUSINESS

.

PRIN~£D

MACHINES

IN

;U.S.A.

Page 3

REVISION

RECORD

Edition

Letter Suffix

Description

None

"

00

Original

Printing

August

-

1975

"

,

"

"

Operator Instructions

, .

8/75

Page 4

CONTENTS

SECTION

1

2

3

INTRODUCTION

GENERAL

DESCRIPTION

OPERATOR

OPERATING

3-1.

3-2.

3-3.

3-4.

3-5.

. . . .

CONTROL

PROCEDURES

Scope

Inspection of the

Application of

Loading a Tape

Normal

3-6. Unloading a

3-7.

3-8.

Removal

Error or

pANELS

..

of

this

Operation

Tape

of

Power

Check

...•

Section

Terminal

Power

...

Cartridge .

•...

Cartridge

Conditions

PAGE

iv

1-1

2-1

3-1

3-1

3-1

3-1

3-1

3-3

3~3

3-4

3-4

4

Tape

3-9.

OPERATOR

MAINTENANCE

Errors

4-1. General Information

4-2.

4-3.

4-4.

Tape

Leader

Freeing a

Drjve Cleaning

Replacement

Jammed

• . • . •

Loader

i

3-6

4-1

4-1

4-1

4-5

4-9

Page 5

CONTENTS

ILLUSTRATIONS

FIGURE

1-1

2-1

2-2

2-3

2-4

2-5

2-6

4-1

4-2

4-3

4-4

4-5

4-6

4-7

Singer

Location of the

Location of the

Keyboard

Controls

Tape

Tape

Releasing the

Seri

Removing

Cleaning the

Removing

Inserting the Leader Eyelet in the Clip

Connecting the

Model

Cartridge •

Cartridge with Cartridge

es

1500

1501

Layout

on

the

Tape

the

Leader

Capstan

the

Leader

Intelligent

Power

Switch

. . .

Tape

.

.

Loader

Dri

Leader

On/Uff

Well

. · .

Drive.

.

.

·

Retainer

ve

•

· · · ·

Eyelet •

After

Clip

From

Eyelet to the Post

Terminal. • • . • • . • • •

Switch

. .

Cap

Lock

Leader

the Clip

· · ·

.

· · ·

Removal

·

.

·

· ·

·

Channel

Channel

on

the

· · ·

· · · ·

· ·

.

· · ·

.

· · · ·

· · · ·

Clip.

..

·

· · ·

·

·

· · ·

· · ·

·

·

·

PAGE

1-1

2-2

2-2

2-2

2-3

2-4

2-4

4-2

4-3

~-~

4-4

4-5

4-6

4-7

4-8

4-9

4-10

Moving

Leader

Fre~ing

the Clip into the

Shown

a

Jammed

in

Tape

Loader

Path

Channel

·

ii

. .

·

·

· · · · ·

4-7

4-8

4-9

Page 6

CONTENTS

TABLES

TABLE

3-1

Error or

Check

Conditions

••••••••••••.•.••.

PAGE

3-5

iii

Page 7

This

manual

Intelligent

provides the operating instructions for the

Terminal.

It

includes the following information:

Model

INTRODUCTION

1501

SECTION 1 GENERAL

of

how

the

equipment

and

identifies

SECTION 2 OPERATOR

and

appearance of

what

each

control

SECTION 3 OPERATING

step-by-step procedures required to operate the

section

operating

conditions

SECTION 4 OPERATOR

be

provided in

does

programs.

performed

not include instructions

and

this

DESCRIPTION,

functions

all

major

CONTROL

all

does

PROCEDURES.

It

the

checks

MAINTENANCE.

by

the operator

section.

which

from

parts of the equipment.

PANELS.

operator controls.

when

it

is

does,

to

however,

be

and

provides a

the viewpoint of

This section

operated.

Included in

that

include a

made

to correct

Routine maintenance functions to

the procedures to

It

also

this

are provided with the

brief

machine.

them.

description

an

operator

shows

list

the location

briefly

section are the

perform

describes

This

of

error

them

are

iv

Page 8

SECTION

1

The

Singer

pact desk-top

houses a

efficient

can

serve

program

functions

program

Model

keyboard

1501

unit

that

slmi1ar to

Intelligent

provides

fi11-in-the-b1ank type

as

either

that

controls operation of the

can

be

tapes

and

input or output

obtained

by

following the

that

simply loading

Operator controls other than the

program

errors

in the keyboard

load,

is

and

both visual

program

on

section.

interrupt

the display screen

Terminal

all

the functions

shown

GENERAL

in figure

of

a mini-computer.

DESCRIPTION

1-1

is a com-

of a typewriter, a display screen

of

data

entry,

units,

1501.

instructions

keyboard

include power-on, system

two

tape drives

and a memory

that

Various, wide-ranging

different

given

pre-recorded

by

the

program.

that

stores the

switches. Notification of data entry

and

audible through a speaker

It

for

reset,

Figure 1-1. Singer

Model

1-1

1501

Intelligent

Terminal

Page 9

SECTION

2

The

Model

aside

the table

a.

b.

c.

d.

from

The

power

in figure 2-1.

A

well

INTERRUPT

figure 2-2.

The

keyboard,

supplemented

in figure 2-3.

On

each

the supply

which

these controls

1501

Intelligent

the keyboard.

below,

beneath the display screen houses the

;s

and

their

on/off switch

and

the

which

by

the addition of

tape drive, there

and

take-up

used

to lock the tape cartridge in place.

is

Terminal

The

function of these controls

location

is

SYSTEM

shown

RESET

is

similar in layout to

is a manual

reels.

in figure 2-4.

has

is

located

switches,

some

There

relatively

as

follows:

on

the

which

special purpose keys,

rewind

is

also a cartridge lock

OPERATOR

few

operator controls

right

side panel, as

PROGRAM

are

shown

that

of a typewriter

switch located

The

CONTROL

is

described in

LOAD/PROGRAM

in

location of

PANELS

shown

is

shown

between

lever,

Control

Keyboard

PROGRAM

PROGRAM

and

Rewind

Power

LOAD

INTERRUPT

SYSTEM

Button

on/off

Switch

RESET

Switch

Switch

Function

Data

entry

mined

Enables operator to load a

the tape in drive 2 (Switch forward for

program

Used

when

programs

Rewinds

Controls

up

for

and

various functions

by

program

load)

called for

tape into cartridge

AC

power

power

on)

by

to the

program

specific

1501

(Switch·

deter-

from

2-1

Page 10

OPERATOR

CONTROL

PANELS

Figure 2-1. Location of the

On/Off

Switch

Power

Figure 2-2. Location of the

Switch

Well

Figure 2-3.

Keyboard

2-2

Layout

Page 11

OPERATOR

CONTROL

PANELS

Figure 2-4. Controls

Operation of the

tape

cartridges.

100

contains

feet

a storage device

clear

outer case

CARTRIDGE

LOCK'LEVER

Model

1501

This snap-in

of

computer

used

with

fully

encloses the inner tape

REWIND

BUTTON

Intelligent

cartridge,

grade tape

all

Series

on

the

Tape

Drive

Terminal requires handling of the

which

on

1500

is

shown

in figure 2-5,

a floating inner

Intelligent

Terminals. A

reel,

reel.

and

is

located

the write pin

tape cannot

on

the IIwrite-enable

It

the tape

leader eyelet

is

Cartridge caps are supplied with

on

the

bottom

is

important

loaded.

the outer case

is

inserted into the position

be

written on.

of the

li

position.

that

is

loaded or the

must

be

is

a two-position hole for the write pin.

If

the write pin

cartridge,

the tape

the tape

be

fully

cartridge

in the position

each

rewound

removed

shown

cartridge

vibrating out of position during shipping.

it

off

with

bottom

rewind

fingertips.

side of the tape

loose tapes.

To

cartridge.

(See

figure 2-6.)

install

2-3

a cap,

Turn

on

is

may

be

from

in figure

To

push

the

cap

If

top of the

cartridge,

the

inserted into the position

written on;

this

is

called

within the cartridge before

the tape drive.

2-5

before the tape

to prevent the

remove

cap

the cap, simply

into place

in direction

The

eyelet

on

the

of

arrow to

tape

from

pry

Page 12

OPERATOR

CONTROL

PANELS

Figure 2-5.

Tape

Cartridge

Figure 2-6.

Tape

Cartridge with Cartridge

2-4

Cap

Page 13

SECTION

3

3-1.

3-2.

OPERATING

SCOPE

This section contains the procedures for operating the

Intelligent

further operating instructions.

by

this

you;

to explain the procedure to you.

INSPECTION

Inspect the terminal before using,

a.

b.

OF

THIS

SECTION.

Terminal

an

operator

section.

ask

your supervisor, sales engineer, or

Make

sure

place correctly.

Check

cables

when

Do

OF

THE

that

to see

and

plugs are properly connected.

up

to the point

errors or malfunctions occur are also included in

not attempt to perform

TERMINAL.

I/O

if

cabling

the

power

is

cord

at

which

Steps to

as

follows:

connected

is

properly

be

any

the

taken

step

field

and

terminator

plugged

program

and

that

service representative

Model

checks

is

in

1501

provides

to

not clear to

(if

and

any

PROCEDURES

be

made

any)

is

in

other

3-3.

3-4.

c.

Make

sure

that

the cooling airways are not blocked.

APPLICATION

a.

Turn

located

b.

Listen for indication

LOADING A TAPE

Always

tape, observe the following instructions

a. After

cover,

lever to the unlock

position.

OF

the

power

on

load the

opening

move

POWER.

on/off switch to the

the

right

CARTRIDGE.

first

the access

the locking

side of the unit near the back.

that

program

tape cartridge

the

fan

on

(up)

position.

is

operating properly.

on

tape drive

and

photographs:

The

2.

switch

To

load a

is

3-1

Page 14

b.

Lift

the loader.

called the cartridge

tion position.

c.

Insert

into tape drive

that

pin

the tape cartridge

the position of write

is

correct.

OPERATING

Thi

sis

inser-

2.

Check

PROCEDURES

Push

down

on

d.

with the tape cartridge

inserted.

Move

e.

the locking lever to

the lock position,

close the access cover.

the loader

and

3-2

Page 15

f.

g.

Locate

cover.

Move

tape,

OPERATING

PROCEDURES

the well beneath the visual display,

the

PROGRAM

and

close the access cover.

LOAD

switch

forward

to load the

and

lift

the

program

well

from

access

the

3-5.

NORMAL

After the

. tions appear

task

described in the following paragraphs.

3-6.

UNLOADING A TAPE

Unload

a.

b.

OPERATION.

program

is

completed; then

has

on

the display screen.

CARTRIDGE.

a tape cartridge

Open

the access cover and,

if

tape

is

not already

rewound

cartridge~

into the tape

push

button.

Move

th~

locking lever to

the

unlock

position.

been

the

loaded

unload

as

follows:

rewind

as a result

Follow

the tapes

of step (g) above, instruc-

these instructions until the

and

turn

off

the

machine

as

c.

Lift

the loader

3-3

Page 16

d.

Remove

Push

e.

tape cartridge

OPERATING

the tape cartridge.

down

the loader with

removed.

PROCEDURES

3-7.

3-8.

f.

Keep

the locking lever in

unlock

the

leader in place,

the access cover.

REMOVAL

a.

b.

ERROR

There

lems

Terminal.

be

OF

Turn

maintenance procedures.

taken.

the

is

located

Refer to Section 4 of

OR

CHECK

are several steps

that

position to

POWER.

power

on

CONDITIONS

occur during

Table

3-1

keep

and

close

on/off switch to the

the

right

lists

side

this

that

normal

some

panel

manual

an

operator

operation of the

of these

off

(down)

near the back.

and

perform

can

take to correct

Model

problems

position.

all

necessary operator

1501

and

the action

The

minor

Intelligent

switch

prob-

that

can

3-4

Page 17

OPERATING

PROCEDURES

Symptom

Cooling

rotating

lights

dri

Line

ves

on

fuse

fan

and

tape

blows

not

continually

Program

does

load

Burning

odor

Failure during

program

no

not

Table 3-1. Error or

Possible

1.

AC

line fuse

2.

AC

line

3.

AC

power

switch not

1.

Wrong

2.

Internal defect

1.

Tape

cartridge

Cause

cord loose

on/off

on

size fuse

installed

improperly

2.

PROGRAM

LOAD

defective

Burned

Component

Undetermined

Check

blown

switch

Conditions

Action to

Replace

Check

Turn

switch

Check

fuse.

line

fuse rating

be

cord.

on.

Taken

Call service representative.

Check

Tape

Loading

procedure.

Retry

Turn

PROGRAM

power

off

LOAD

switch

and

call

service representative

Retry

program

Display

Read

is

and/or write

errors

Leader

has

returning to

"home"

Tape

position

runaway

blank

trouble

Program

did not

load

Dirty read

1 •

2.

Dirty write

Dirty capstan

1 •

2. Faulty leader

Broken

1 •

2.

Broken

head

head

leader

tape

Retry

Follow

under

Clean

Replace

Follow

tape

runaway

program

load

directions

read/write errors.

capstan.

leader.

directions

under

3-5

Page 18

OPERATING

PROCEDURES

3-9.

TAPE

Tape

error

depending

ERRORS.

errors

may

occur

if

preventive maintenance

occurs, the tape read or write operation

on

the type of

error.

following:

Tape

Runaway.

If

both tape

off

immediately. There are

recommended

a.

If

the leader breaks, a tape

reels

that

ever spin uncontrollably

two

the

entire

program

using the procedure in Section 4 of

b.

If

the tape breaks, a tape

and

refer

this

to the procedure for freeing a

manual.

Read/Write Errors.

This type of

while loading a

of the tape drive.

be

reloaded

For

read/write

completed

be

determined. Depressing the

after

and

error

is

accompanied

program

The

the cause of the

errors

later

with data tapes, the current

reattempted.

tape, depress the

program

The

two

major

at

possible causes.

be

reattempted.

runaway

occurs.

this

runaway

by

occurs.

an

error

red

tape, or the

error

The

ERROR

is

determined

cause of the read/write

key

will quiet the

is

inadequate.

may

have

to

error

classes are the

high speeds, turn

In

all

cases

Replace

the leader,

manual.

Replace

jammed

tone.

rewind

copy

of the

the tape

loader in Section 4 of

If

read

button in the middle

program

and

program

error

If

a tape

be

aborted,

power

it

is

cartridge,

error

occurs

tape,

corrected.

should

be

error

must

tone.

may

Possible causes of read/write

a.

On

a tape write operation, the write pin

cartridge position.

b.

Dirt

on

the read/write heads, caused

maintenance.

c.

d.

Wrinkled

The

tape.

leader threading

was

tape guides.

errors

include the following:

was

not in the

by

inadequate preventive

bottom

not aligned in the proper grooves of the

3-6

Page 19

The

corrective action to

If

a.

b.

c.

unable to write

It

must

operation.

Check

leader

Section 4 of

Follow

if

be

the leader threading path

if

necessary

the tape drive cleaning procedure in Section 4 of

solutions (a)

in the

this

OPERATING

be

taken for read/write

on

a tape,

bottom

manual.

and

position

by

following the leader replacement procedure in

(b)

above

PROCEDURES

check

the position of the write pin.

on

the

cartridge.

and

inspect the leader. Replace the

do

not apply.

errors

is

as follows:

Retry

this

this

manual

3-7

Page 20

SECTION

4

4-1.

4-2.

OPERATOR

GENERAL

The

any

keyboard,

Foreign material

dampened

metallic objects

can

through into the electronic

Other than the overall cleaning outlined above, the only preventive

maintenance required of the user

once

leader

The

TAPE

INFORMATION.

Model

high-quality piece of

easily

inspection

1501

Intelligent

and

display screen regularly with a clean,

such

with a mild detergent or Freon.

such

each

week,

each

DRIVE

cause

CLEANING.

jamming

using the procedure in

time the tape drive

and

replacement procedures are included in

Terminal should

electronic

as

coffee or

as

paper

of the

circuits.

candy

clips

keys

is

is

cleaned,

be

given the care worthy

equipment.

should

Keep

and

hairpins, since these items

or

electrical

to clean

this

Dust

the cabinet,

soft

be

removed

the

keyboard

shorts

all

tape drives

section. Inspect the tape

and

replace

it

MAINTENANCE

cloth.

with a cloth

free of

if

they

drop

at

least

as necessary.

this

section.

of

Perform

a.

b.

c.

the following steps to clean each tape drive:

The

first

follows:

Move

(1)

(2) Firmly pull the loader

(3)

as

Lift

the leader eyelet

indicated in figure 4-3.

channel because the locking lever

Remove

twisted, replace

in

this

step

is

to

move

the locking lever to the unlock position

loader to the

cannot

performing the following step.

shown

Now

become

be

in figure 4-1,

that

familiar with the various

shown

the leader

section.

cartridge

raised, perform the steps in paragraph 4-4 before

the loader

in figure 4-2.

upward

from

its

it

as

described in the leader replacement procedure

the loader to the upright position, as

and

lift

the

insertion position.

retainer

and

lift

is

in the upright positio'n, take time to

Note

off

The

leader

path.

lock with a forefinger,

the loader.

components

the threading path of the leader.

the pin

is

If

on

the take-up

clip

will

in the unlock position.

the leader

If

the loader

on

the tape drive,

remain

has

in the

worn

reel,

spots or

as

as

clip

is

4-1

Page 21

OPERATOR

MAINTENANCE

Figure 4-1. Releasing the

d.

Obtain the tape cleaning

Freon

Wet

e.

tape guides,

scrubbed,

liquid,

a cotton

as

cotton

swab

and

shown

with

the capstan.

in figure 4-4.

kit.

swabs,

Freon

the side in order to clean the area

cotton

f

.'

C1

Do

g.

Place the leader eyelet

the leader along

swab

ean

the

wet,

exposed

and

replace

part of the 1 eader

not stretch the leader.

its

path,

back

of the tape guides.

h.

Return

the loader to the cartridge insertion position.

In

and

cloths.

liquid.

The

it

if

on

the pin

making

Loader

the

kit,

Scrub

capstan

The

scrubbing

where

it

becomes

us i ng

sure

Retainer

you

the

must

the tape

the cloths

on

the take-up

it

is

in the proper grooves

Lock

will find a

two

tape heads,

be

held while

motion

moves.

dirty.

wet

reel.

bottle

must

Keep

wi

of

being

be

from

the

th Freon.

Thread

4-2

Page 22

OPERATOR

MAINTENANCE

CAPSTAN

TAPE

GUIDES

LOADER

RETAINER

LOCK

LEADER

TAKE

UP

REEL

REWIND

BUTTON

CARTRIDGE

LOCK

LEVER

LEADER

CLIP

Figure

4-2. Series

4-3

1500

Tape

Drive

Page 23

OPERATOR

MAINTENANCE

J""A230,

.if'

..

Figure

4-3.

Removing

the

Leader

Eyelet

·CAPSTAN

Figure

4-4.

Cleaning

the

Capstan

4-4

After

Leader

Removal

Page 24

OPERATOR

MAINTENANCE

4-3.

LEADER

The

each

has

jammed

REPLACEMENT.

leader should

time

that

worn

spots or

it

be

could

is

in lock position perform the steps in paragraph 4-4 before

proceeding.

Perform

if

a.

b.

the following steps to gain access to the leader, inspect

necessary replace

Move

the locking lever to the

Lift

the loader to the cartridge insertion position.

c. Pull the loader

d.

Remove

the leader eyelet

figure 4-3.)

Move

e.

locking lever to the lock position.

in the lock position, the

may

be

removed.

step. )

inspected every

be

the cause of a tape

wrinkled,

it

it:

retainer

lock

from

clip

(See

figure

time

must

unlock

and

the pin

channel

4-5

for

the tape drive

problem.

be

replaced.

position.

lift

the loader.

on

the take-up

When

is

open

this

step

is

cleaned

If

the leader

If

the loader

is

it,

(See

figure 4-1.)

reel.

(See

the locking lever

and

the leader

and

the following

clip

and

and

is

LEADER

CLIP

Figure 4-5.

Removing

the

Leader

4-5

Clip

From

the Clip

Channel

Page 25

f.

g.

h.

Remove

take-up

replace

errors

If

guides

earlier

With

in the

the leader

reel.

it.

and

necessary, the leader, capstan,

may

in

the locking lever in the lock position,

clip

eyelet through the

OPERATOR

clip

from

If

it

is

If

a defective leader

MAINTENANCE

the

wrinkled, twisted, or

read/write errors are

be

cleaned

this

section.

channel,

at

as

clip

this

time.

pictured in figure 4-6.

channel.

clip

is

likely

two

channel

by

pulling

has

worn

not replaced, tape

to occur.

tape heads,

Tape

drive cleaning

insert

and

the leader eyelet

Push

it

toward

spots

on

runaway

three tape

is

described

the leader

the

it,

Connect

i .

pictured in figure 4-7.

MOve

j.

the leader eyelet to the post

Make

sure there are

on

the

clip,

no

the leader in a counterclockwise direction

making

twists in

as

shown

4-8 but with the locking lever in the lock position. Continue to

clip

gently pull the leader until the leader

and

will

k.

Move

now

Lift

1.

the pin

m.

Place the leader along the tape path,

go

no

further,

as

shown

the locking lever to the

securely in the

clip

channel.

the leader eyelet off the post

on

the take-up

reel.

proper grooves of the tape guides.

(See

insertion position.

figure 4-9.)

in

figure 4-8.

unlock

position.

on

Make

sure there are

making

Return

the leader

enters the

The

leader

clip

and

no

twists in leader.

sure the leader

the loader to the cartridge

CLIP CHANNEL

LEADER EYELET

a loop,

this

loop.

in figure

clip

channel

clip

place

is

as

is

it

on

in the

Figure 4-6. Inserting the

Leader

4-6

Eyelet in the Clip

Channel

Page 26

POST

ON

THE

CLIP

LEADER

EYELET

Figure 4-7. Connecting the

Leader

Eyelet to the Post

on

the Clip

Figure 4-8.

Moving

the Clip into the Clip

4-7

Channel

Page 27

OPERATOR

MAINTENANCE

LEADER

Figure 4-9.

Leader

Shown

4-8

in

Tape

Path

Page 28

OPERATOR

MAINTENANCE

4-4.

FREEING A JAMMED

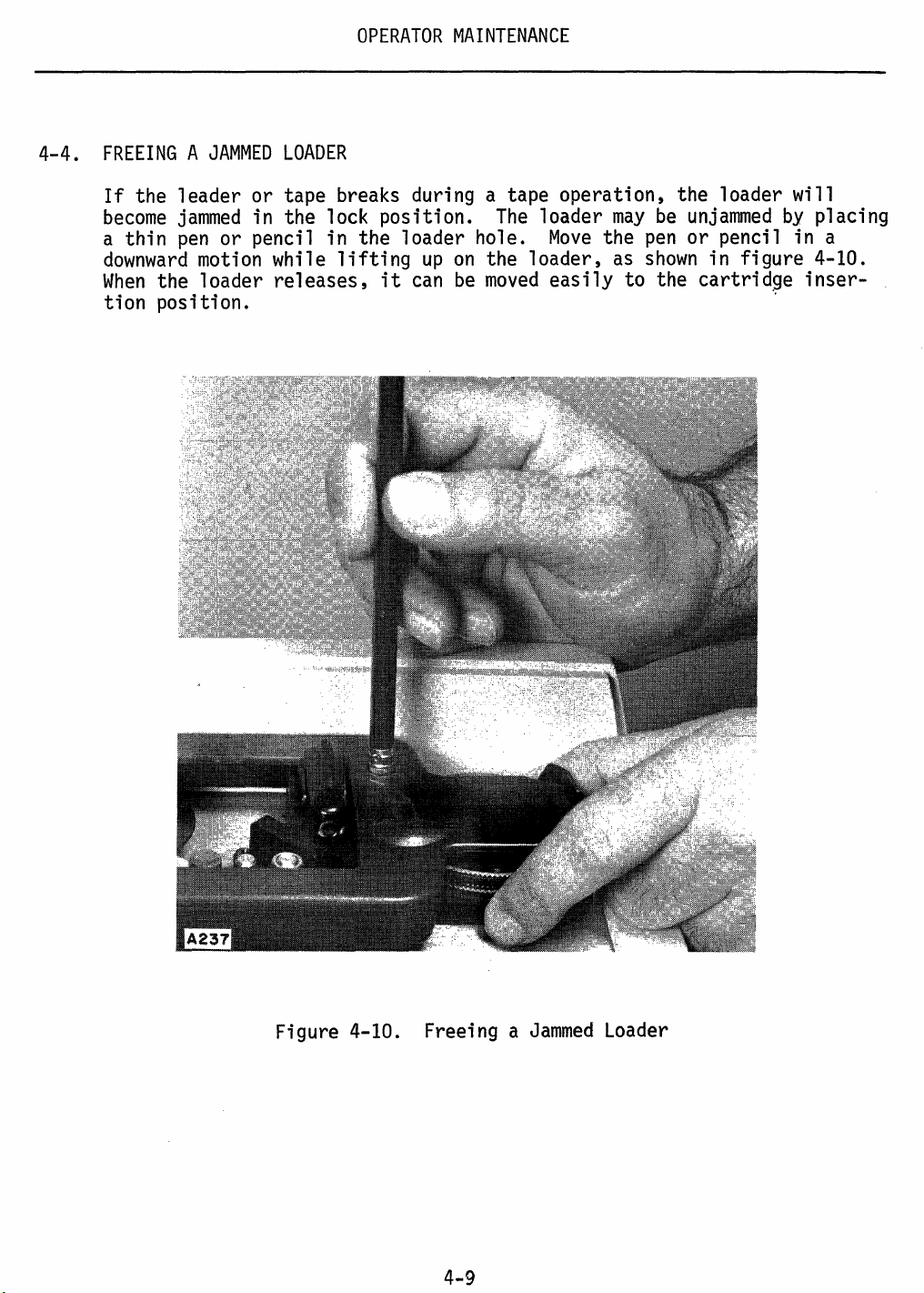

If

the leader or tape breaks during a tape operation, the loader will

become

a thin

downward

When

jammed

pen

or pencil in the loader hole.

motion

the loader

LOADER

in the lock position.

while

releases,

lifting

it

up

can

on

be

The

loader

Move

the loader,

moved

easily

may

be

unjammed

the

pen

or pencil in a

as

shown

in figure 4-10.

to the cartridge

tion position.

by

~

placing

inser-

Figure 4-10. Freeing a

4-9

Jammed

Loader

Page 29

OPERATOR

INSTRUCTIONS

FOR

THE

MODEL

Publication

We

produce

informative. That's our job.

So

welre asking

publications.

Add

any

comments

to include your

Does

If

this

not,

•

Please take a

manual

what

manuals

you

you

wish.

name

and

address.

meet

your needs?

additional information

1501

for you,

to help

few

minutes to

If

you

INTELLIGENT

No.

and

we

us

furnish

desire a reply to

Thank

would

TERMINAL

22-6504-01

want

you

you

answer

you.

be

of help to

to find

with the best possible

the following questions.

any

them

question,

you?

useful

be

sure

Yes

and

No

•

Can

you

find

what

you

Ire looking for,quickly

How

can

the organization

• Is the material easy to read

Are

Comments

•

Did

If

there

you

yes, please

enough

illustrations

------------------------------------------------------------

find

any

errors

cite

be

or ambiguities in the

page,

line,

improved:

and

to understand?

to support the text?

and/or figure

and

easily?

manual?

number

with your

Yes

Yes

Yes

comments.

No

No

No

Page 30

Staple

Fold

Staple

Back

Stamp

SINGER

BUSINESS

Publications

70

New

Dutch

Fairfield,

MACHINES

and

Lane

New

Jersey

Services

07006

Fold

Back

Page 31

,SINGER

BUSINESS

22-6504-01

MACHINES

Loading...

Loading...