Page 1

USER'S MANUAL

EN

WIRED CONTOLLER

SWC-02

Page 2

“Originalinstructions”

IMPO

RTANT N

Read this manual ca

or operating your new air conditioning

unit. Make sure to save this manual for

futu

re r

efe

ence.

r

OTE:

r

efully befo

r

e installing

Page 3

User Notices

For correct installation and operation, please read all instructions carefully. Before

reading the instructions, please be aware of the following items:

(1) Prohibit installing the wired controller at wet or sunshine places.

(2) Do not knock, throw or frequently disassemble the wired controller.

(3) Do not operate the wired controller with wet hands.

(4) Do not remove or install the wired controller by yourself. If there is any

please contact our after-sales service center.

(5) The wired controller is a general model, applicable for several kinds of units.

Some functions of the wired controller are not available for certain kinds of units, more

details please refer to the owner’s manual of unit. The setting of such unavailable

function will not affect unit’s operation.

(6) The wired controller is universal. The remote receiver is either in the indoor unit

or in the wired controller. Please refer to the specific models.

question,

Page 4

Contents

1 Display ..................................................................................... 1

1.1 Appearance ................................................................................ 1

1.2 Instructions for Related Displayed Symbols ............................... 2

2 Buttons .................................................................................... 3

2.1 Button Graphics ......................................................................... 3

2.2 Function Instructions of Buttons ................................................. 3

3 Operation Instructions .............................................................. 3

3.1 Menu Structure........................................................................... 3

3.2 On/Off ........................................................................................ 5

3.3 Mode Setting .............................................................................. 5

3.4 Temperature Setting ................................................................... 5

3.5 Fan Setting ................................................................................ 5

3.6 Swing Setting ............................................................................. 6

3.7 Functions Setting ....................................................................... 8

3.8 Unit Status

3.9 Current Error View ..................................................................

3.10 Timer Setting .......................................................................... 15

3.11 Clock Setting .......................................................................... 20

3.12 Lock Setting ........................................................................... 21

View ....................................................................... 12

. 13

4 Installation Instructions .......................................................... 22

4.1 Parts and Dimension of Wired Controller ................................. 22

4.2 Installation Requirements ......................................................... 23

4.3 Installation Methods ................................................................. 23

4.4 Disassembly ............................................................................ 26

Page 5

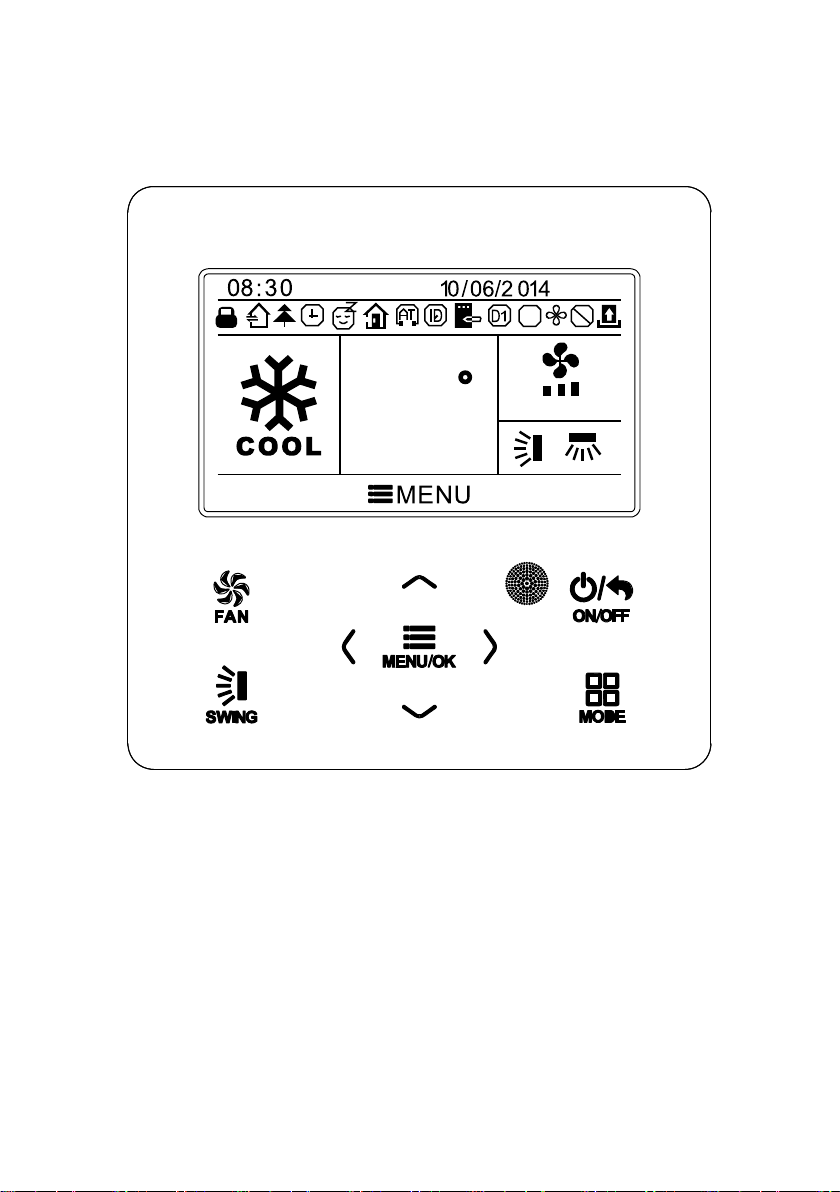

1 Display

1.1 Appearance

MON

$

SET

C

AUTO

26

Fig.1 Appearance of wired controller

1

Page 6

1.2 Instructions for Related Displayed Symbols

No. Symbols Instructions

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Shielding status (Buttons, temperature, ON/OFF, mode or energy saving is

Up and down swing function

Left and right swing function

Fresh air function

Sleep function

Auto mode

Cooling mode

Dry mode

Fan mode

Heating mode

Health function

I-Demand function

Absence function

shielded by remote monitor)

Current set fan speed

Memory function (Memory in power failure)

DRED function

17

18

19

20

21

22

$

Gate card pulled-off status or nobody presented status

Save function

X-fan function

Timer on status

Quiet function

Function lock

2

Page 7

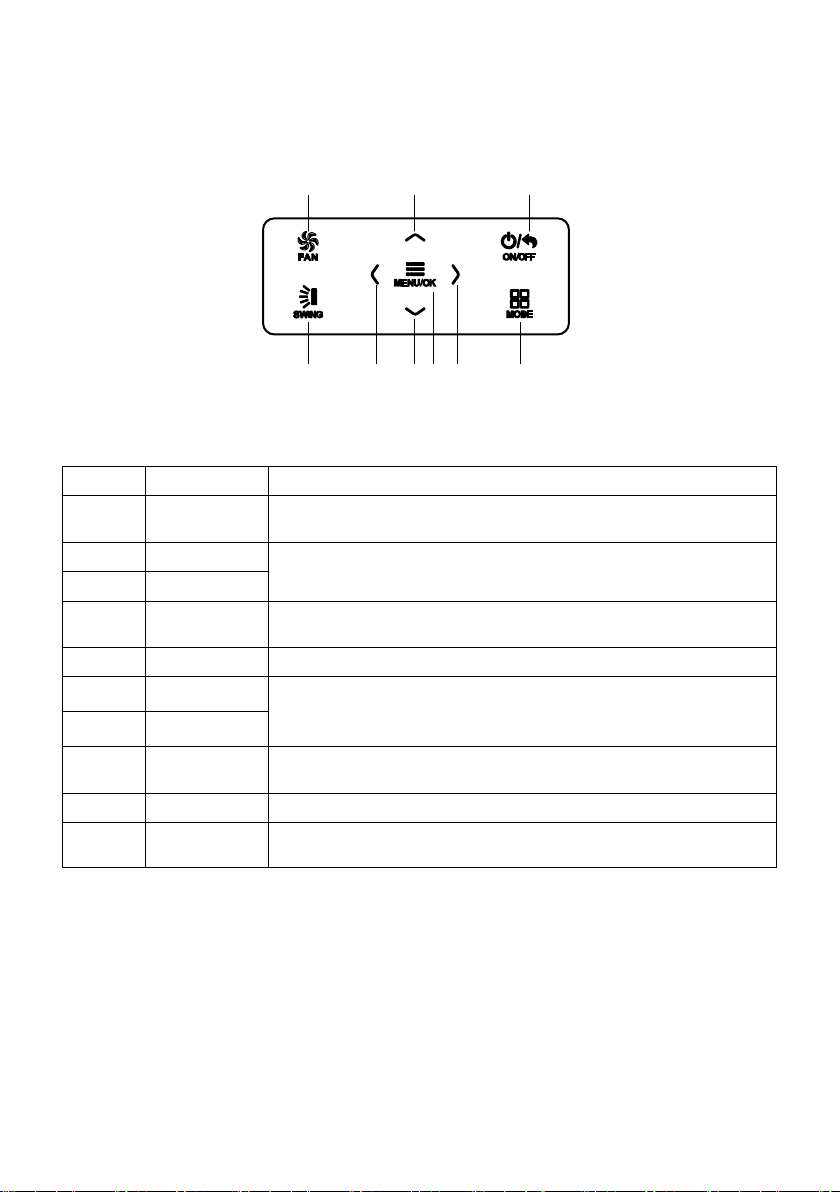

Buttons

2

2.

1 Button Graphics

1 2 3

4

2 Function Instructions of Buttons

2.

o. Button name Button Function

N

1 F

2

6

3

4

5

8

7

9 M

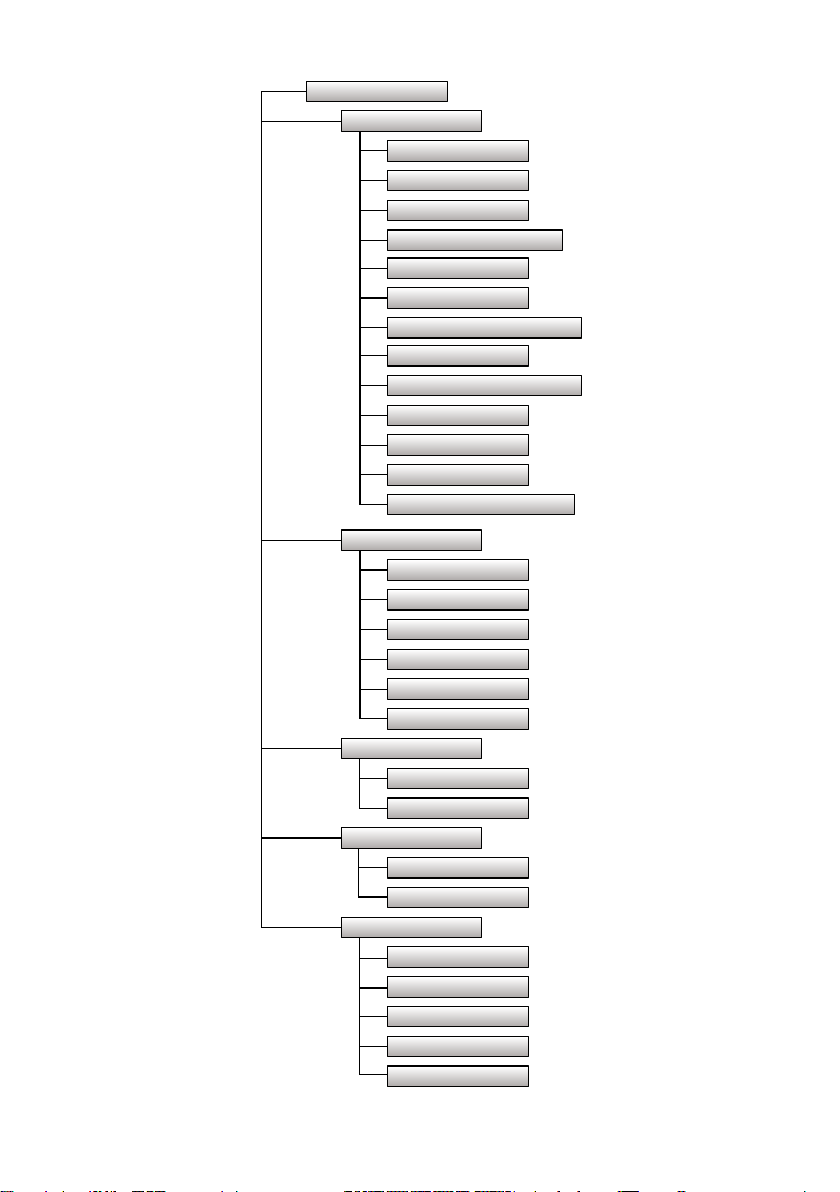

3 Ope

3.

1 Menu Structure

Norm

AN

∧

∨

ON/OFF/BACK

SWING Set up&down swing and set left&right swing

<

>

MENU/OK

ODE Set auto, cooling, dry, fan and heating modes for indoor unit.

Set low speed, medium speed,high speed, turbo and auto speed.

(1)

Set temperature

(2)

Set parameter

(3)

Move option cursor

(1) Turn on or turn off unit

Return to last page

(2)

Set related function on or off

(1)

Move option cursor

(2)

(3) Set parameter

Enter menu page

(1)

Confirm setting

(2)

ration Instructions

al setting of wired controller can be set directly on the main page, including

5 6 97 8

Fi

g. 2 Button graphics

fan speed, swing, set temperature, mode, ON/OFF. The setting and status view of

other functions can be set in corresponding submenu. Detailed menu structure is as

shown in Fig. 3.

3

Page 8

Main menu

User function menu

Fresh air function setting

Sleep function setting

Health function setting

I-DEMAND function setting

Absence function setting

Memory function setting

Fixed-angle swing function setting

Save function setting

Auxiliary heat function setting

Dry function setting

Quiet function setting

Air function setting

Fahrenheit Temperature Setting

Timer setting menu

Once

Daily

Weekly timer

Two week timer

Countdown timer on

Countdown timer off

Clock setting menu

Time format setting

Clock setting

View function menu

Unit status view

Current error view

Function lock menu

Unit ON/OFF lock

Mode setting lock

Temperature setting lock

Fan speed setting lock

Key lock

Fig. 3 Menu structure

4

Page 9

3.2 On/Off

When the wired control is on main page, press ON/OFF button to turn on the unit.

Press ON/OFF button again to turn off the unit. The interfaces of On/Off status are

shown in Fig. 4 and Fig. 5.

SET

26

MON

SET

C

26

MON

C

AUTO

Fig. 4 Off interface Fig. 5 On interface

3.3 Mode Setting

Under On status, pressing MODE button can set mode circularly as:

(COOLING) (DRY) (FAN) (HEATING)

(AUTO)

If save function is on, auto mode is not available.

Note:

3.4 Temperature Setting

Under unit on status, pressing “∧” or “∨” button on the main page increases or

decreases set temperature by 1℃(1℉); holding “∧” or “∨” button increases or

decreases set temperature by 1℃(1℉) every 0.3s.

In cooling,dry,fan and heating mode,temperature setting range is 16℃~30℃

(61℉~86℉). Under auto mode, set temperature cannot be adjusted.

3.5 Fan Setting

Under On status, pressing FAN button can set fan speed circularly as:

Low→Medium→High→Turbo→Auto→Low

Symbols displayed are as shown in Fig. 6.

TURBO AUTO

Fig. 6 Fan

setting

5

Page 10

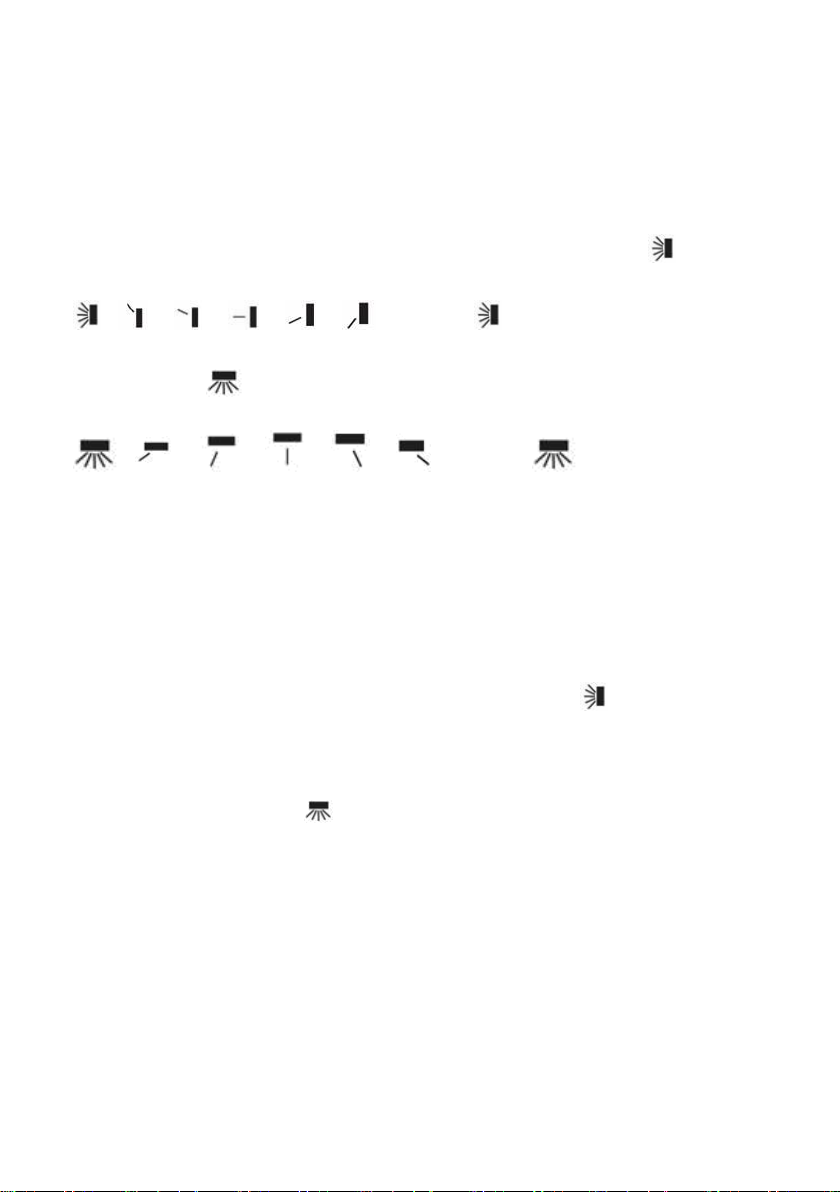

3.6 Swing Setting

In unit on status, press SWING button for swing setting. Two swing modes are

available: fixed-angle swing and simple swing.

When fixed-angle swing mode is set, swing operation is as follows:

In unit on status, press SWING button to select up&down swing

swing angle will be adjusted circularly as below:

→ → → → → → closed →

Select up&down swing and left&right swing through “<” or “>” button. When

left&right swing

below:

→ → → → → → closed→

Note:

①.

Turn on fixed-angle swing mode in function setting page;

②.

If fixed-angle swing is not available for the model, fixed-angle swing will be

invalid when the wired controller turns on fixed-angle swing mode.

Simple swing mode: when fixed-angle swing mode is turned off, swing operation is

as below:

Pressing SWING button under unit on status, up&down swing frame occurs. Then

press SWING button to turn on or turn off up&down swing.

up&down swing is on and is not displayed when up&down swing is off. When up&down

swing frame have not disappeared, press “<” or “>” button to switch to left&right swing

setting. Then left&right swing frame occurs. In this case, press SWING button to turn on

or turn off left&right swing.

displayed when left&right swing is off. For detailed operation, please refer to Fig. 7.

is selected. Left&right swing angle will be adjusted circularly as

is displayed when

is displayed when left&right swing is on and is not

. Up&down

6

Page 11

SET

26

MON

C

AUTO

SET

26

MON

C

AUTO

Press SWING button to enter swing

setting status.

MON

SET

C

26

AUTO

Press SWING button to turn on or

turn off simple left&right swing

and fixed-angle left&right swing.

MON

SET

C

26

AUTO

Press SWING button to turn on or

turn off simple up&down swing

and fixed-angle up&down swing.

MON

SET

C

26

AUTO

Press “<”or “>” button to switch

between up&down swing and

left&right swing setting.

After finishing setting, setting status

will be exited automatically after 5s.

Fig. 7 Swing setting

7

Page 12

3.7 Functions Setting

Press MENU/OK button on main page to enter main menu page. Press “∧” or “∨”

or “<” or “>” button to select the function setting symbol. Then press MENU/OK button

to enter user function setting page. Press “∧” or “∨” button to select specific function

item. Press “<” or “>” button to turn on or turn off this function. If the function item

cann’t be set, it will displays with gray color. Please refer to Fig.8.

MON

SET

26

C

AUTO

SEARCH

LOCK

TIMER

FUNCTION

CLOCK

IN main page.

FUNCTION

FRESH AIR

Press MENU/OK button to enter function setting page;

press “∧” or “∨” to select function item, and press “< ” or

“>” button to set the function.

ON

ON

ON

ON

ON

ON

OFF

OFF

OFF

OFF

OFF

OFF

Fig. 8 Function setting

Press MENU/OK button to enter main menu page.

TIMER

SEARCH

LOCK

Press “>” button to select function setting item.

FUNCTION

8

CLOCK

Page 13

3.7.1 Fresh Air Function Setting

After entering user function page, press “ ” or “ ” button to select fresh air

function and press “ ” or “ ” button to turn on or turn off air function. Press MENU

button to adjust the mode of fresh air.

After entering fresh air mode setting, press “ ” or “ ” button to adjust the mode in

the range of 1~10. After setting, press MENU button to save the setting.

3.7.2 Sleep Function Setting

After entering user function page, press “∧” or “∨” button to select sleep function

and press “<” or “>” button to turn on or turn off sleep function with auto saving.

If this function is turned on, the unit will operate according to the preset sleep curve

to provide comfortable sleep environment.

Note:

●In fan or auto mode, sleep function is not available.

●Sleep function will be cancelled when turning off the unit or switching modes.

9

Page 14

3.7.3 Health Function Setting

After entering user function page, press “∧” or “∨” button to select health function

and press “<” or “>” button to turn on or turn off health function with auto saving.

3.7.4 I-DEMAND Function Setting

After entering user function page, press “∧” or “∨” button to select IDEMAND

function option and press “<” or “>” button to turn on or turn off this function with auto

saving.

Note:

This function is only available in cooling mode.

●

When this function has been set, set temperature is displayed in SE.

●

In this case, temperature setting and fan speed setting are shielded.

This function will be cancelled when switching modes.

●

●

This function and sleep function cannot be on simultaneously. If I-demand

function is set firstly and then sleep function is set, I-demand function will be

cancelled while sleep function will be valid, and vice versa.

3.7.5 Absence Function Setting

After entering user function page, press “∧” or “∨” button to select holiday function

option and press “<” or “>” button to turn on or turn off this function with auto saving.

This function is used to maintain indoor temperature so that unit can realize fast

heating.

Note:

●This function is only available in heating mode.

●When this function has been set, set temperature is displayed in 8℃(46℉). In this

case, temperature setting and fan speed setting are shielded.

●This function will be cancelled when switching modes.

●

This function and sleep function cannot be on simultaneously. If absence function

is set firstly and then sleep function is set, absence function will be cancelled while

sleep function will be valid, and vice versa.

3.7.6 Memory Function Setting

After entering user function page, press “∧” or “∨” button to select memory

function and press “<” or “>” button to turn on or turn off memory function with auto

saving.

3.7.7 Fixed-angle Swing Mode Setting

After entering user function page, press “∧” or “∨” button to select lock swing

function option and press “<” or “>” button to turn on or turn off this function with auto

saving.

If fixed-angle swing function is not available for the connected unit, this

Note:

function will be cancelled automatically after setting.

10

Page 15

3.7.8 Save Function Setting

After entering user function page, press “∧” or “∨” button to select save function

and press “<” or “>” button to turn on or turn off save function. Press MENU button to

enter save function setting page.

After entering save function setting page, press “<” or “>” button to select cooling

or heating limitation temperature. After selecting cooling or heating limitation

temperature, press “∧” or “∨” button to adjust limitation temperature value. After

setting, press MENU button to save the setting.

Note:

When save function has been set, auto mode cannot be set.

3.7.9 Auxiliary Heating Function Setting

After entering user function page, press “∧” or “∨” button to select auxiliary

heating function and press “<” or “>” button to turn on or turn off this function with auto

saving.

3.7.10 X-fan Function Setting

After entering user function page, press “∧” or “∨” button to select dry function

option and press “<” or “>” button to turn on or turn off this function with auto saving.

Note:

●

This function is only available in cooling mode and dry mode.

3.7.11 Quiet Function Setting

After entering user function page, press “∧” or “∨” button to select quiet function

and press “<” or “>” button to turn on or turn off this function with auto saving.

Note: This function is only available in cooling mode, heating mode and auto

mode.

3.7.12 Fahrenheit Temperature Setting

After entering user function page, press “∧” or “∨” button to select Fahrenheit

temperature function and press “<” or “>” button to turn on or turn off this function

with auto saving. After closing this function, Celsius temperature will be displayed.

11

Page 16

3.7.13 Air Function Setting

After entering user function page, press “∧” or “∨” button to select Air Function

and press “<” or “>” button to turn on or turn off air function. Press MENU button to

adjust the mode of Air Function .

After entering Air Function mode setting, press “∧” or “∨” button to adjust the

mode in the range of 1~2. After setting, press MENU button to save the setting.

The each mode means as follows:1- suction 2-discharge

3.8 Unit Status View

Press MENU button to enter the menu and select the function symbol to be viewed.

Then press MENU button to enter view function page. Press “∧” or “∨” button to select

status view function. Press MENU button to enter unit status view page. Press BACK

button to return to the last page. Please refer to Fig. 9.

The following statuses can be viewed: if auxiliary heating is operating;indoor ambient

temperature; outdoor ambient temperature.

SEARCH

UNIT STATUS

SEARCH

TIMER

FUNCTION

CLOCK

ERROR INFORMATION

LOCK

Fig. 9 Status View

12

UNIT STATUS

INDOOR TEMPERATURE

OUTDOOR TEMPERATURE

19℃

19℃

RETURN

Page 17

3.9 Current Error View

When error occurs in the unit, error symbol will be displayed on the main page of

wired controller to indicate that the unit is with error. In this case, you can enter error

view page to view the current error.

Press MENU button to enter the menu and select the function symbol to be viewed.

Then press MENU button to enter view function page. Press “∧” or “∨” button to select

error information. Press MENU button to enter err

errors, press “∧” or “∨” to turn pages. Press BACK button to return to the last page.

Please refer to Fig. 10.

or view page. If there are too many

AM

SET

ERROR INFORMATION

E6

MON

AUTO

RETURN

TIMER

SEARCH

LOCK

FUNCTION

CLOCK

SEARCH

UNIT STATUS

ERROR INFORMATION

Fig. 10 Current Error View

13

Page 18

Error

Return air temperature sensor open/

short circuited

evaporator temperature sensor open/

short circuited

Indoor unit liquid valve temperature

sensor open/short circuited

Indoor gas valve temperature sensor

open/ short circuited

IPM temperature sensor open/short

circuited

Outdoor ambient temperature sensor

open/ short circuited

Outdoor unit condenser mid-tube

temperature sensor open/short circuited

Discharge temperature sensor open/

short circuited

Indoor and outdoor communication error E6 Compressor startup failure Lc

DC bus under-voltage protection PL High discharge temperature protection E4

DC bus over-voltage protection PH Overload protection E8

Compressor phase current sensing

circuit error

Compressor demagnetization protection HE Over phase current protection P5

PFC protection Hc Compressor desynchronizing H7

IPM Temperature Protection P8 IPM Current protection H5

Over-power protection L9

System charge shortage or blockage

protection

Capacitor charging error PU

High pressure protection E1

Low pressure protection E3

Compressor stalling LE

Over-speeding LF

Drive board temperature sensor error PF Indoor unit full water error E9

AC contactor protection P9 Anti-freezing protection E2

Temperature drift protection PE AC input voltage abnormal PP

Sensor connection protection Pd Whole unit current sensing circuit error U5

DC bus voltage drop error U3 4-way valve reversing error U7

Outdoor fan 1 error protection L3 Motor stalling H6

Outdoor fan 2 error protection LA PG motor zero-crossing protection U8

compressor inhalation temperature

sensor error

Error

Code

F1 Drive board communication error P6

F2 Compressor overheating protection H3

b5 Indoor and outdoor units unmatched LP

Communication line misconnected or

b7

expansion valve error

P7 E7

F3 Pump-down Fo

F4 Jumper error C5

F5 Forced defrosting H1

U1 Whole unit over-current protection E5

Compressor phase loss/reversal

protection

Frequency restricted/reduced with whole

F0

unit current protection

Frequency restricted/reduced with IPM

current protection

Frequency restricted/reduced with high

discharge temperature

Frequency restricted/reduced with anti-

freezing protection

Frequency restricted/reduced with

overload protection

Frequency restricted/reduced with IPM

temperature protection

dc

Error

Error

Code

dn

Ld

F8

En

F9

FH

F6

EU

U0Indoor fan tripping error

14

Page 19

Error

Communication error between IDU and

grid conne ct ion

Communication error between ODU and

grid conne ct ion

Main error a t grid connec tion side

Error

Code

IDU network address error

Ln

Ip address alloca tion over flow

LM

y2

Error

Error

Code

y3

yb

3.10 Timer Setting

The wired controller can set 6 kinds of timer: one time clock timer, everyday timer,

one week timer, two week timer, countdown timer on and countdown timer off. Select

timer symbol after entering menu page. Press MENU button to enter timer setting page.

Press “∧” or “∨” button to select one kind of timer. Press “<” or “>” button to turn on

or turn off this timer. Please refer to Fig. 11.

TIMER

SEARCH

LOCK

TIMER

FUNCTION

CLOCK

ONCE

DAILY

WEEKLY

TWO WEEK

TIMER ON

TIMER OFF

ON

ON

ON

ON

ON

ON

OFF

OFF

OFF

OFF

OFF

OFF

Fig. 11 Turn on or turn off timer

3.10.1 One Time Clock Timer

The wired controller can set one time clock timer. If the unit is off, timer on can be

set. If the unit is on, timer off can be set. This timer will be carried out for only once

when timer time is reached and then the timer will be off automatically.

In timer function setting page, when one time timer is selected, press “<” or “>”

button to turn on or turn off this timer function.

setting page,

as shown in Fig. 12.

Press “<” or “>” button to select timer hour or minute and press “∧” or “∨” button

to adjust time. Holding “∧” or “∨” button increases or decreases time rapidly. After

finishing setting, press MENU button to save timer time.

Press MENU button to enter timer time

15

Page 20

ONCE

12:46 ON

Fig. 12 Setting page of one time clock timer

Note: If this timer function is turned on, when the unit is turned on or turned off, this

timer function will be cancelled automatically.

3.10.2 Daily Timer

In daily timer, user can set eight segments of timer individually. The individual

segment will be valid only when it is turned on. In each segment, you can set time, unit

ON/OFF, set temperature in cooling (it is valid only when the current mode is cooling),

set temperature in heating (it is valid only when the current mode is heating). Please

refer to Fig. 13.

After entering daily timer setting page, press “<” or “>” button

item. Press “∧” or “∨” button to adjust the value. Press MENU button to save setting.

to select setting

DAILY

SCH TIME OnOFF COOL HEAT

1

ON

2

ON

3

ON

4

ON

5

OFF

ON

OFF

ON

ON

OFF

26℃

26℃

26℃

26℃

26℃

26℃

26℃

26℃

26℃

26℃

Fig. 13 Daily timer setting

3.10.3 Weekly Timer

The user can set the everyday timer content for a week. In each day, the user can

set eight segments of timer content. The unit will execute corresponding timer setting in

a w

eek.

16

Page 21

After entering weekly timer setting page, press “<” or “>” button to select the day

to be set. Then press MENU button to enter timer programming of that day. Press “<”

or “>” button to select the item to be set. Press “∧” or “∨” button to adjust the content.

Press MENU button to save setting. Please refer to Fig. 14.

WEEKLY SCHEDULE

WEEK SUN MON TUE WED THU FRI SAT

1

2

3

4

5

OFF

ON

ON

ON

OFF

09:00

OFF

ON

ON

ON

ON

26℃

26℃

26℃

26℃

26℃

26℃

26℃

26℃

26℃

26℃

Enter weekly timer schedule

setting page.

WEEKLY SCHEDULE

WEEK SUN MON TUE WED THU FRI SAT

1

2

3

4

5

ON

ON

ON

ON

OFF

09:00

OFF

ON

ON

ON

ON

26℃

26℃

26℃

26℃

26℃

26℃

26℃

26℃

26℃

26℃

Press “∧” or “∨” button to

adjust the content.

WEEKLY SCHEDULE

WEEK SUN MON TUE WED THU FRI SAT

1

2

3

4

5

OFF

ON

ON

ON

OFF

09:00

OFF

ON

ON

ON

ON

Press “<” or “>” button to

select the day to beset.

WEEKLY SCHEDULE

WEEK SUN MON TUE WED THU FRI SAT

1

2

3

4

5

OFF

ON

ON

ON

OFF

09:00

OFF

ON

ON

ON

ON

Press MENU/OK button to

enter timer programming of

that day.

26℃

26℃

26℃

26℃

26℃

26℃

26℃

26℃

26℃

26℃

26℃

26℃

26℃

26℃

26℃

26℃

26℃

26℃

26℃

26℃

WEEKLY SCHEDULE

WEEK SUN MON TUE WED THU FRI SAT

1

2

3

4

5

ON

ON

ON

ON

OFF

09:00

OFF

ON

ON

ON

ON

26℃

26℃

26℃

26℃

26℃

26℃

26℃

26℃

26℃

26℃

Press “<” or “>” button to

select the item to be set.

Fig. 14 Weekly timer setting

WEEKLY SCHEDULE

WEEK SUN MON TUE WED THU FRI SAT

1

2

3

4

5

OFF

ON

ON

ON

OFF

09:00

OFF

ON

ON

ON

ON

26℃

26℃

26℃

26℃

26℃

26℃

26℃

26℃

26℃

26℃

After finshing setting, press

MENU/OK button to save

timer setting. Then the cursor

will turn back to day selection.

17

Page 22

3.10.4 Two Week Timer

The user can set the everyday timer content for two weeks. In each day, the user

can set eight segments of timer content. The unit will execute corresponding timer

setting in two weeks.

In timer function setting page, press “∧” or “∨” button to select two week timer

setting and then press MENU button to enter two week timer menu page. Press “∧” or

“∨” button to select current week option and then press “<” or “>” button to set current

week as first week or second week. Press MENU button to save current week setting.

Please refer to Fig. 15.

TIMER

ONCE

DAILY

WEEKLY

TWO WEEK

TIMER ON

TIMER OFF

ON

ON

ON

ON

ON

ON

OFF

OFF

OFF

OFF

OFF

OFF

TWO WEEK TIMER MENU

CURRENT WEEK

TWO WEEK SCHEDULE

FIRST WEEK

Fig. 15 Setting of current week

After entering two week timer menu page, press “∧” or “∨” button to select the two

week schedule option and then press MENU button to enter two week timer

programming. After entering two week timer setting page, press “<” or “>” button to

select the day to be set. Then press MENU button to enter timer programming of that

day. Press “<” or “>” button to select the item to be set. Press “∧” or “∨” button to

adjust the content. Press MENU button

to save setting. Press BACK button to exit this

page. The setting symbols please refer to weekly timer setting.

3.10.5 Countdown Timer

Countdown timer includes timer on and timer off. Unit On/Off after a desired hour

can be set. In unit on status, timer off can be set, or timer off and timer on can be set

simultaneously. In unit off status, timer on can be set, or timer off and timer on can be

set simultaneously. If timer off in x hours and timer on in y hours are set simultaneously

n unit on status, the unit will be off in x hours and then the unit will be on in y hours after

i

timer off.

18

Page 23

After entering timer on setting page, press “∧” or “∨” button to increases or

decreases timer time by 0.5h. Press MENU button to save setting. Press BACK

button to return to the last page. Please refer to Fig. 16.

TIMER ON

0.5

Fig. 16 Countdown timer on

After entering timer off setting page, press “∧” or “∨” button to increases or

decreases timer time by 0.5h. Press MENU button to save setting. Press BACK

button to return to the last page. Please refer to Fig. 17.

TIMER OFF

0.5

HOURS ON

HOURS OFF

Fig. 17 Countdown timer off

If timer function is on, the set hours will decrease as the unit operation time

reases. In this case, residual hours can be viewed after entering timer setting page.

inc

19

Page 24

This timer function will be carried out for only once and then it will be cancelled

automatically.

Note: If this timer function is turned on, when the unit is turned on or turned off, this

timer function will be cancelled automatically.

3.11 Clock Setting

3.11.1 Time Format Setting

The user can set the time format in 12-hour system or 24-hour system. Select

clock symbol in menu page and then press MENU button to enter clock setting page.

Press “∧” or “∨” button to select time format and then press “<” or “>” button to

select 1 2-hour system or 24-hour system. Please refer to Fig. 18.

CLOCK

SEARCH

TIMER

FUNCTION

CLOCK

CLOCK FORMAT

CLOCK

24

12

LOCK

Fig. 18 Time format selection

3.11.2 Clock Setting

Select clock symbol in menu page and then press MENU button to enter clock

setting page. Press “∧” or “∨” button to select time set and then press MENU button to

enter time setting.

Press “<” or “>” button to select setting items: hour, minute, year, month, day;

press “∧” or “∨” button to set the value and then press MENU button to save setting.

Please refer to Fig. 19.

Note: If you need to use both the wired controller and remote controller,

please set the time of them identically.

20

Page 25

SEARCH

TIMER

FUNCTION

CLOCK

CLOCK

CLOCK FORMAT

CLOCK

24

12

LOCK

CLOCK

TIME : 12 :05

DATE : 2014/10/08

Fig. 19 Clock setting

3.12 Lock Setting

Select lock symbol in menu page and then press MENU button to enter lock setting

page. Press “∧” or “∨” button to select the item to be locked and then press “<” or “>”

button to lock or unlock. Please refer to Fig. 20.

Items can be locked: ON/OFF, mode setting, temperature setting, fan speed

setting, key lock. After locking, the corresponding item cannot be set through buttons.

If the keys are locked, all keys cannot be operated after returning to the main page.

ase unlock according to the instructions on main page. During unlocking, press

Ple

MENU button, press “<” button and then press “>” button to unlock keys.

21

Page 26

Fig. 20 Lock setting

4 Installation Instructions

4.1 Parts and Dimension of Wired Controller

Fig. 21 Dimension of wired controller

unit:mm

31 2

Fig. 22 Parts of wired controller

No. 1 2

Name

Quantity 1 3 1

Panel of wired

controller

Sponge 20

Screw M4×25

20 3

× ×

Soleplate of wired

controller

22

3

Page 27

4.2 Installation Requirements

(1) Prohibit installing the wired controller at wet places.

(2) Prohibit installing the wired controller at the places with direct sunshine.

(3) Prohibit installing the wired controller at the place near high temperature

objects or water-splashing places.

4.3 Installation Methods

CN2 terminal is used for connecting

indoor unit and it must be connected.

CN3 terminal and CN4 terminal are

CN3CN4

CN3CN4

CN2

used for connecting the centralized

CN2

controller, and these two terminals

have the same function. Customers

can select one or two terminal(s) for

connection according to the needs.

Fig. 23 Installation diagram for wired controller

Fig. 23 is the simple installation process of wired controller; please pay attention to

the following items:

(1) Before installation, please cut off the power for indoor unit;

(2) Pull out the four-core twisted pair line from the installation holes and then let it go

through the rectangular hole behind the soleplate of the wired controller.

23

Page 28

(3) Stick the soleplate of wired controller on the wall and then use screw M4×25 to fix

soleplate and installation hole on wall together, attach the sponge 20×20×3 at the

screw hole and then press it with fingers to make sure it’s attached firmly.

(4) Insert the four-core twisted pair line into the slot of the wired controller and then

buckle the front panel and the soleplate of the wired controller together.

(5) Block the four-core wire into the groove at the left side of wiring column; bundle

the front panel of wired controller to its soleplate.

Note:

Separate the signal and communication lines of the wired controller from

the power cord and connection lines between the indoor and outdoor unit, with a

minimum interval of 20cm, otherwise the communication of the unit will probably

work abnormally.

If the air conditioning unit is installed where is vulnerable to electromagnetic

interference,then the signal and communication lines of the wired controller must

be the shielding twisted pair lines.

The 4-core terminal connects the air conditioner, while the 2-core terminal

connects the centralized controller

wire is same as that of 4-core connection wire.

No need

to set the wire of wired controller into the clasp.

. The connecting method for the 2-core connection

For matching with different models, the patch cord and the connectionwire

are necessary. As shown in fig. A.

Fig. A: Schematic diagram of patch cord and connection wire

If the air conditioner has been installed with the patch cord used for

connecting the wired controller.

24

(fig. C)

Page 29

Only use the connection wire (fig. B).

Connect the terminal ② to the terminal ④ of patch cord which has been installed

on the air conditioner; insert terminal ① to needle stand CN2 of wired controller.

If there’s protection terminal ③, pull out the protection terminal at first and then

install it.

Fig. B: Schematic diagram of connection wire: Connect terminal ① with wired

controller CN2; connect terminal ② with the terminal ④ of patch cord

Fig. C: Schematic diagram of patch cord: Terminal ③ is the protection terminal;

connect terminal ④ to the terminal ② of connection wire ;connect

terminal ⑤ to the terminal of wired controller of air conditioner

If the air conditioner hasn’t been installed with the patch cord used for

connecting the wired controller.

Use the connection wire and patch cord. Pull out the protection terminal of

patch cord at first, connect the connection wirewith the patch cord according to fig.

D, and then insert the terminal ① of connection wire into the needle stand CN2 of

wired controller and insert the terminal ⑤ of patch cord into the terminal of wired

controller of air conditioner as well.

Fig. D: Schematic diagram after the connection wire and the patch cord have

been connected: connect the terminal ② of connection wire and the

terminal ④ of patch cord

25

Page 30

4.4 Disassembly

Fig. 24 Disassembly diagram for wired controller

CN3CN4

CN2

CN3CN4

CN2

26

Page 31

ADDRESS SETTINGS

1. Press + at the same time and hold for 5 s, wired controller will enter function

interface.

2. Press or button, choose „Address Set“, press enter setting interface.

3. Press or button, choose corresponding address mode (0 use to central controller,

1 use to long distance control, this function is reserved), and then press or button to

adjust the address value (1–16), press confirm setting.

In the DEBUG SET There are 4 choices for ambient temp sensor :

temp sensor is located at return inlet in all mode.

temp sensor is located at wired controller in all mode.

auto A(temp sensor is located at return inlet in cooling, dry and fan mode, temp sensor is located at wired

controller in heating and auto mode).

auto B(temp sensor is located at return inlet in heating and auto mode, temp sensor is located at wired

controller in cooling, dry and fan mode).

Page 32

NOTE CONCERNING PROTECTION OF

ENVIRONMENT

This product must not be disposed of via normal household waste after its service life, but must be

taken to a collection station for the recycling of electrical and electronic devices. The symbol on the

product, the operating instructions or the packaging indicate such disposal procedures. The materials

are recyclable in accordance with their respective symbols. By means of re-use, material recycling or

any other form of recycling old appliances you are making an important contribution to the protection

of our environment. Please ask your local council where your nearest disposal station is located.

In case of quality problem or other please contact your local supplier or authorized service center.

Emergency number: 112

PRODUCER

SINCLAIR CORPORATION Ltd.

1-4 Argyll St.

London W1F 7LD

Great Britain

www.sinclair-world.com

This product was manufactured in China (Made in China).

REPRESENTATIVE

SINCLAIR Global Group s.r.o.

Purkynova 45

612 00 Brno

Czech Republic

TECHNICAL SUPPORT

SINCLAIR Global Group s.r.o.

Purkynova 45

612 00 Brno

Czech Republic

Tel.: +420 800 100 285

Fax: +420 541 590 124

www.sinclair-solutions.com

info@sinclair-solutions.com

Loading...

Loading...