Page 1

Installation manual

Simrad transducers

Installation principles and guidelines

M A X I M I Z I N G Y O U R P E R F O R M A N C E A T S E A

www.SIMRAD.com

Page 2

Page 3

Echo sounder transducers

Installation manual

This document provides a generic description of echo

sounder transducer installation. The information must be

regarded as general guidelines and recommendations on

The installation shipyard must design and manufacture

installation hardware to fit each individual transducer and

vessel.

ly.

851-160164/H

September 2006

Page 4

Document history

Document number: 851-160164 / ISBN-10: 82-8066-036-4 / ISBN-13: 978-82-8066-036-7

Converted to XML format. Chapters listing all Simrad

transducers and their termination to the General Purpose

Rev.H

September 2006

Transceiver (GPT) are added. Several m inor changes to

other descriptions and illustrations. Interactive version on the

document (CHM format) introduced.

Copyright

©2006SimradHortenAS

The information contained in this document remains the sole property of Simrad Horten AS. No part of this

document may be copied or reproduced in any form or by an y means, and the information containe

dwithin

it is not to be communicated to a third party, without the prior written consent of Simrad Horten AS.

Disclaimer

Simrad Horten AS end eavours to ensure that all information in this document is correct and fairly stated,

but does not accept liability for any errors or omissions. The document can be changed without prior

notice.

Warning

The equipment to which this manual applies must only be used for the purpose for w

designed. Improp e r use or maintenance may cause dam age to the equipment and/or injury to personnel.

The user must be familiar with th e contents of the appropriate manuals before attempting to operate

or work on the equipment.

Simrad disclaims any responsibility for damage or injury caused by improper installation, use or

maintenance of the equipment.

hich it was

Support

If you require maintenance on your Simrad equipment, contact your local dealer. You can also contact

Simrad using the following e-mail address:

e-mail: contact@simrad.com

Simrad Horten AS

Strandpromenaden 50

P. O. Bo x 1 11

N-3191 Horten,

Norway

Telephone:+4733034000

Telefax:+4733042987

www.simrad.com

simrad.sales@simrad.com

Page 5

Installation manual

Table of contents

INTRODUCTION ................................................................ 5

TRANSDUCER LOCATION ...... ............................................ 6

Go deep .....................................................................................................................6

Vessel heave .............................................................................................................6

Noise from protruding objects on the hull................................................................6

Boundary water layer ...............................................................................................7

Propeller noise..........................................................................................................7

Inclination of the transducer face .............................................................................8

Summary and general recommendation...................................................................8

WAYS OF MOUNTING THE TRANSDUCER......................... 10

External mounting ..................................................................................................11

Transducer blister...................................................................................................16

Box keel..................................................................................................................22

Flush mounting in a steel tank................................................................................24

Acoustic window....................................................................................................26

Inside the hull.........................................................................................................28

Drop keel ................................................................................................................30

Retractable transducer ............................................................................................31

CABLE GLANDS ............................................................... 32

Order numbers........................................................................................................32

Cable gland for steel hulls ......................................................................................33

Cable gland for wood or GRP hulls .......................................................................34

Cable glands for small hulls...................................................................................35

Cable splicing.........................................................................................................36

STEEL CONDUIT.............................................................. 37

HANDLING AND MAINTENANCE ...................................... 38

Approved anti-fouling paints..................................................................................39

SIMRAD TRANSDUCERS .................................................. 40

All 12 kHz transducers...........................................................................................41

All 18 kHz transducers...........................................................................................41

All 27 kHz transducers...........................................................................................41

All 38 kHz transducers...........................................................................................42

All 50 kHz transducers...........................................................................................44

All 70 khz transducers............................................................................................45

All 120 khz transducers..........................................................................................46

All 200 kHz transducers.........................................................................................47

851-160164/H 3

Page 6

Simrad Echo sounder transducers

All 710 kHz transducers.........................................................................................49

GPT TRANSDUCER TERMINATIONS ................................. 51

Single beam, normal power transducer ..................................................................52

Single beam, high power transducer ......................................................................53

Dual beam (wide or narrow) transducer.................................................................54

Split beam transducer.............................................................................................55

Split beam transducer to single beam transceiver ..................................................56

Single beam transducer to split beam transceiver ..................................................57

Dual frequency, single beam transducer.................................................................58

Sidescan transducer ................................................................................................59

Deep water, split beam transducer..........................................................................60

ES38–10 transducer................................................................................................61

12-16/60 transducer................................................................................................62

50/200 Combi C transducer....................................................................................63

38/200 Combi C transducer....................................................................................64

4

851-160164/H

Page 7

INTRODUCTION

The purpose of this installation manual is to provide generic

descriptions and illustrations allowing the reader to understand

the basic principles for echo sounder transducer installation.

Note

The information in this document must be regarded as general

guidelines and recommendations only. The installation shipyard

must design and manufacture installation hardware to fiteach

individual transducer and vessel.

Whenever required, the installation shipyard must also have the

installation approved by the applicable maritime authorities.

For detailed information about the transducer to be installed, refer

to the documentation provided with the transducer. Drawings and

descriptions can also be obtained from h

Introduction

ttp://www.simrad.com.

851-160164/H 5

Page 8

Simrad Echo sounder transducers

TRANSDUCER LOCATION

A single answer to the question where to locate the transducer

cannot be given. It depends very much on the vessel’s

construction. However, there are some important guide lines.

Go deep

The upper water layers of the sea contain a myriad of small

air bubbles created by the breaking waves. In h eavy seas the

uppermost 5 to 10 metres may be air-filled, with the highest

concentrations near the surface. Air bubbles absorb and reflect

the sound energy, and may in worst cases block the sound

transmission totally. Therefore, mount the transducer at a deep

position on the hull.

Consider the situation when the vessel is unloaded, and when it

is pitching in heavy seas.

WARNING

The transducer must never be lifted free of the

water surface.

Not only will the sound transmission be blocked, but the

transducer may be damaged by slamming against the sea surface.

Another reason to go deep is cavitation in front of high power

transducers. Cavitation is the formation of small bubbles in the

water due to the resulting local pressure becoming negative

during parts of the acoustic pressure cycles. The cavitation

threshold increases with the hydrostatic pressure.

Vessel heave

Heave is the up and down movement of the vessel. It disturbs the

echo traces in the echogram, so that a flat bottom is displayed

as a wave. A transducer location in the middle of the vessel

minimises the influence of vessel roll a nd pitch.

Noise from protruding objects on the hull

Objects protruding from the hull, such as zinc anodes, sonar

transducers or even the vessel’s keel, generate turbulence and

flow noise. Also holes and pipe outlets are noise sources. They

may act as resonant cavities amplifying the flow noise at certain

frequencies. Do not place an echo sounder transducer in the

vicinity of such objects, and especially not close behind them.

For the same reason, it is very important that the hull area around

the transducer face is as smooth and level as possible. Even

traces of sealing compound, sharp edges, protruding bolts or bolt

holes without filling compound will create noise.

6

851-160164/H

Page 9

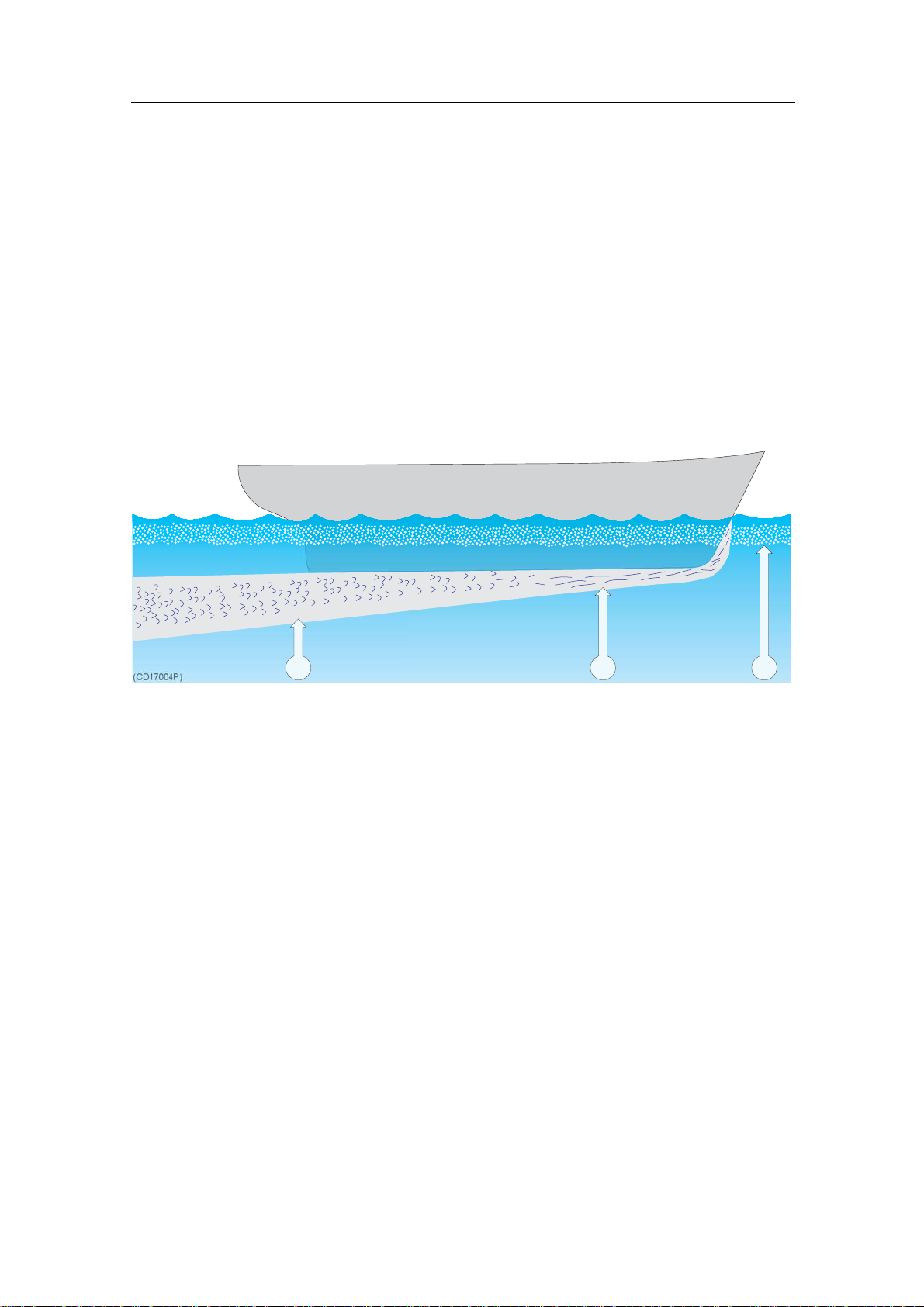

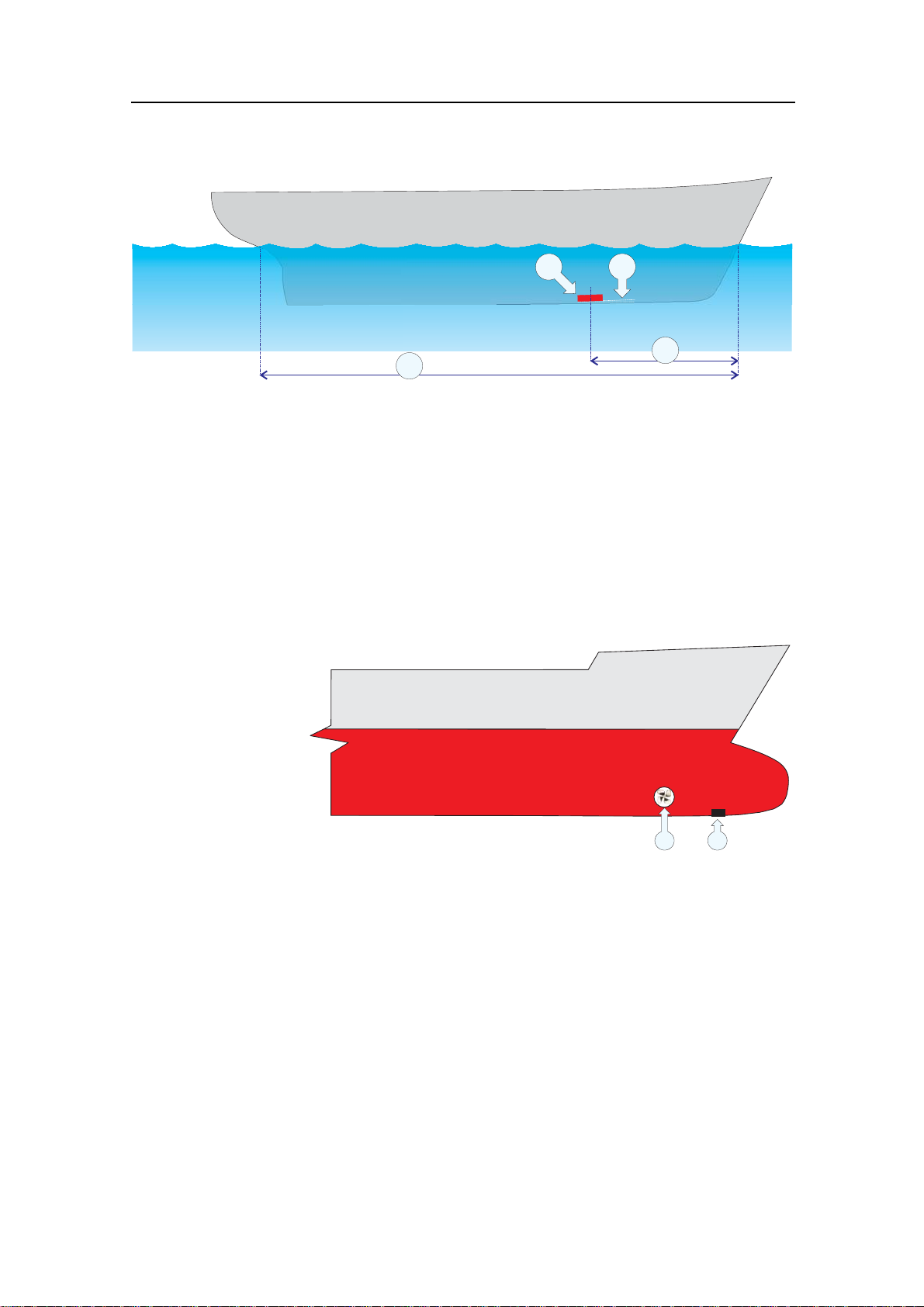

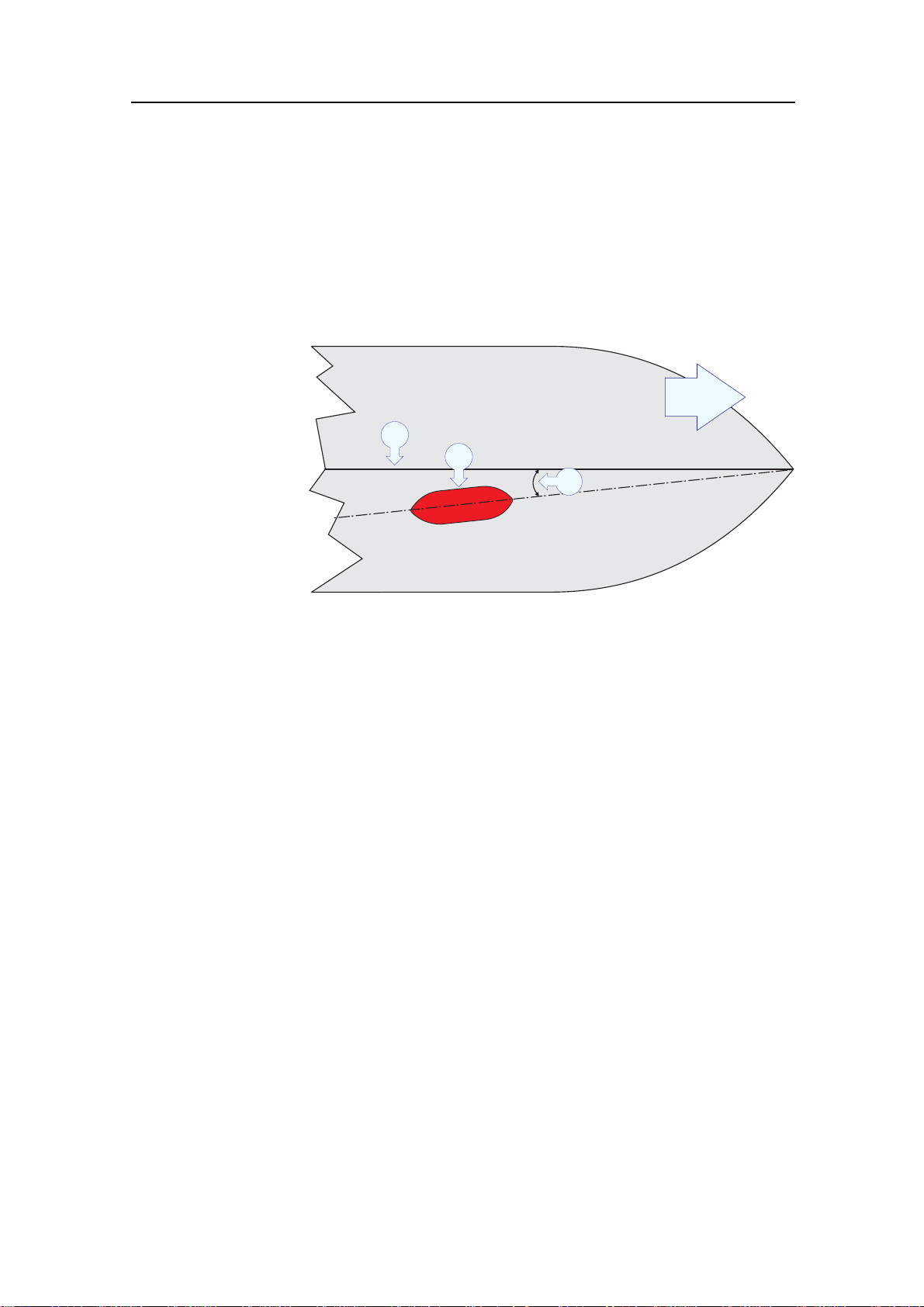

Boundary water layer

When the vessel forces its way through the sea, the friction

between the hull and the water creates a boundary layer. The

thickness of the boundary layer depends upon vessel speed and

the roughness of the hull. Objects protruding from the hull, and

dents in the hull, disturb the flow and increase the thickness of

the boundary layer. The flow in this boundary layer may be

laminar or turbulent. A laminar flow is a nicely ordered, parallel

movement of the water. A turbulent flow has a disorderly pattern,

full of eddies. The boundary layer increases in thickness when the

flow goes from laminar to turbulent. The figure below illustrates

the boundary layer of a vessel moving through the water.

Transducer location

(CD17004P)

Boundary water layers:

(A) = Turbulent flow

(B) = Laminar flow

(C) = Air bubbles in the water

Furthermore, air bubbles in the sea water are pressed down below

the hull and mixed into the boundary layer. The boundary layer

is thin underneath the forward part of the vessel, and increases in

thickness as it moves towards aft. If the sides of the hull are steep,

some of the air bubbles in the boundary layer may escape to the

sea surface along the vessel sides. It is our experience that a wide

and flat bottom, with a rising angle less than around 13 degrees,

is prone to giving air problems for the transducer. In any case a

transducer location in the forward part of the hull is preferred in

order to minimise the influence of the boundary layer.

Propeller noise

The propulsion propeller is the dominant noise source on most

fishing vessels, research vessels, merchant vessels and pleasure

crafts. The noise is transmitted through the sea water. For

this reason, the transducer should be placed far away from the

propeller, which means on the fore part of the hull. Positions

BAC

851-160164/H 7

Page 10

Simrad Echo sounder transducers

outside the direct line of sight from the propeller are favourable.

On small vessels with short distances it is advised to mount the

transducer on that side of the keel where the propeller blades

move upwards, because the propeller cavitation is strongest on

the other side. The cavitation starts most easily when the water

flows in the same direction as the propeller blade, and that is to

some degree the case at that side of the keel where the propeller

blades move downwards.

Bow thruster propellers are extremely noisy. When in operation,

the noise and cavitation bubbles make the echo sounder useless,

almost no matter where the transducer is installed. And when not

in operation, the tunnel creates turbulence, and if the vessel is

pitching, the tunnel may be filled with air or aerated water in the

upper position and release this in the lower position. Therefore,

an echo sounder transducer should be placed well away from

the bow thruster.

Inclination of the transducer face

Ideally, the transducer face should be mounted in parallel with the

sea surface when the vessel is in normal trim, as this will provide

the most accurate echo information. However, it is also very

important that the w

In order to ensure laminar flow, the transducer face may be tilted

slightly upwards in relation to the water flow. This allows the

flowing water to meet the face directly, and assures laminar flow.

The inclination angle must however be determined carefully. The

angle must be small on transducers with narrow beam angles. As

a rule of thumb, mount transducers with beam angles smaller

than seven degrees with minimum inclination angle. The smaller

beam angle your transducer has, the smaller the inclination angle

can be.

Ensure that you do not mount the transducer with a negative

inclination angle. This may cause turbulence under the transducer

face, and reduced echo sounder performance.

ater flow over the transducer face is laminar.

Summary and general recommendation

Some of the above guide lines are conflicting, and each case has

to be treated individually in order to find the best compromise.

Generally the propeller noise is the dominant factor, and a

recommended transducer location is in the fore part of the hull,

with maximum distance from the bow equal to one third of the

total length of the hull at the water line.

8

851-160164/H

Page 11

Transducer location

BA

(CD017004Q)

M

L

General recommendation for transducer location:

(A) = Transducer

(B) = Inclination angle

(L) = Hull length at water line

(M) = Maximum 1/3 of the hull length at water line (L)

If the vessel hull has a bulbous bow, this may well be a good

transducer location, but also here must be taken into consideration

the flow pattern of the aerated water. Often the foremost part

of the bulb is preferable.

(CD17004C)

A

B

Recommended location of the transducer on a bulbous hull:

(A) = Thruster

(B) = Transducer location

851-160164/H 9

Page 12

Simrad Echo sounder transducers

WAYS OF MOUNTING THE TRANSDUCER

There are many different ways to mount the transducer.

Topics

External mounting on page 11

Transducer blister on page 16

Box keel on page 22

Flush mounting in a steel tank on page 24

Acoustic window on page 26

Inside the hull on page 28

Drop keel on page 30

Retractable t ransducer on page 31

10

851-160164/H

Page 13

External mounting

Certain transducers have a streamlined housing, and these are

designed for installation outside the hull.

These transducers are mainly used on smaller vessels. A location

approximately 0.5 m aside from the keel may be adequate for

the passage of water between the keel and the transducer. The

figures illustrate external mounting of transducers on steel hulls

and on wood or polyester hulls respectively.

Smooth surface

Ensure that the surface of the transducer face, the hull plating

and putty around the transducer is as even and smooth as

possible. Obstructions on these surfaces will create problems

with turbulant flow.

Mounting screws must not be extruding from the transducer, and

the space around the screws must be filled with a compound (C)

and/or a locking ring.

Ways of mounting the transducer

851-160164/H

11

Page 14

Simrad Echo sounder transducers

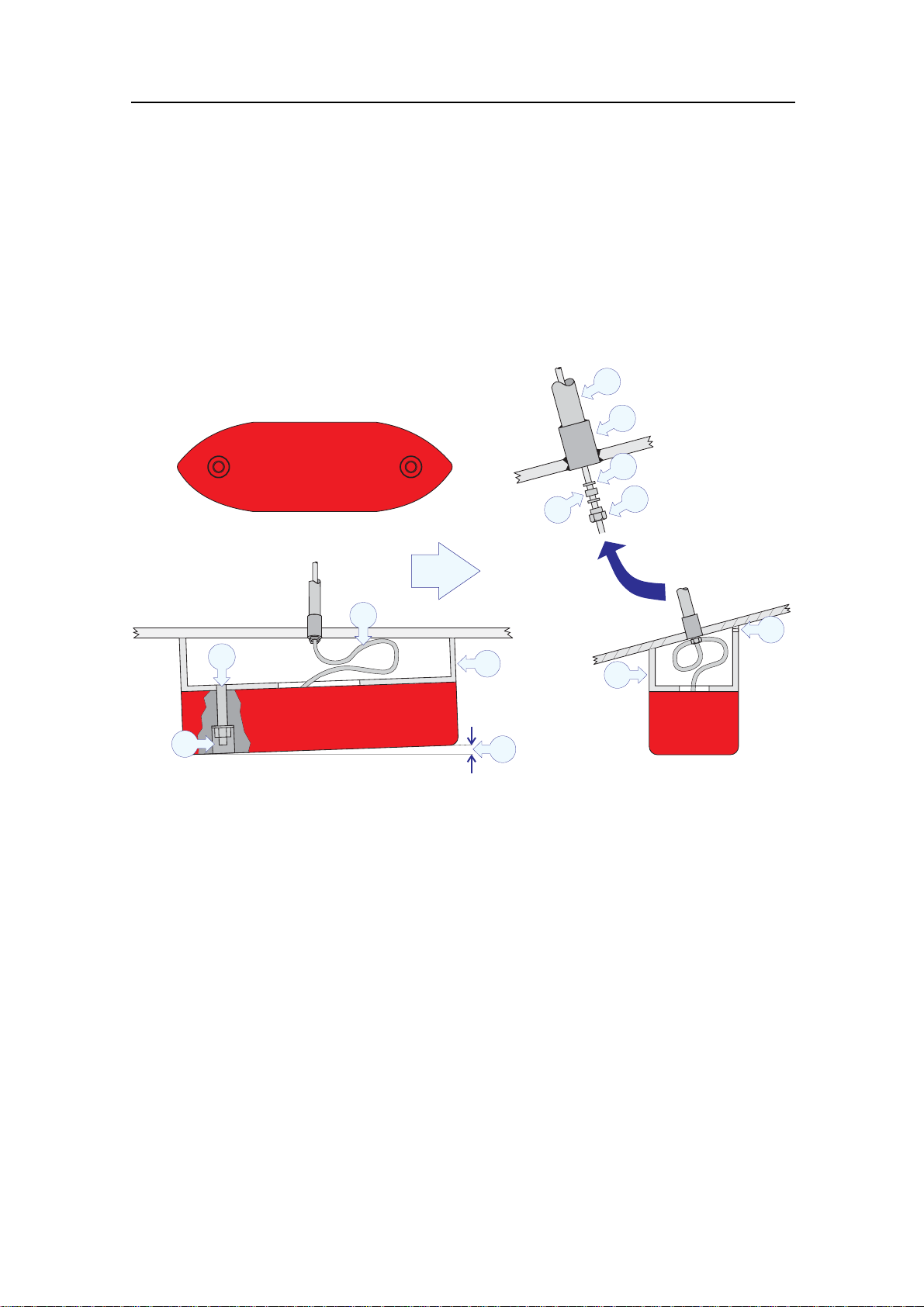

Steel hull

A fairing (A), made by the shipyard, is placed between the

transducer and the hull. It is required in order to adapt for the

deadrise angle of the hull, and it will also house a cable service

loop (B). The fairing can be made of wood or steel, and should

have the same outline dimensions as the transducer. Remember

to create an air outlet (E) on the fairing, and to fill the bolt holes

with a filling compound to ensure a smooth transducer surface.

1

2

3

(CD017007A)

C

4

5

F

B

E

I

A

A

D

(A) = Fairing

(B) = Cable service loop

(C) = Filling compound

(D) = Inclination angle

(E) = Air outlet

(F) = Forward

12

(I) = Threaded rod with nuts and washers, or bolt

(1) = Steel conduit

(2) = Stuffing tube

(3) = Washer

(4) = Rubber gasket

(5) = Packing nipple

851-160164/H

Page 15

Ways of mounting the transducer

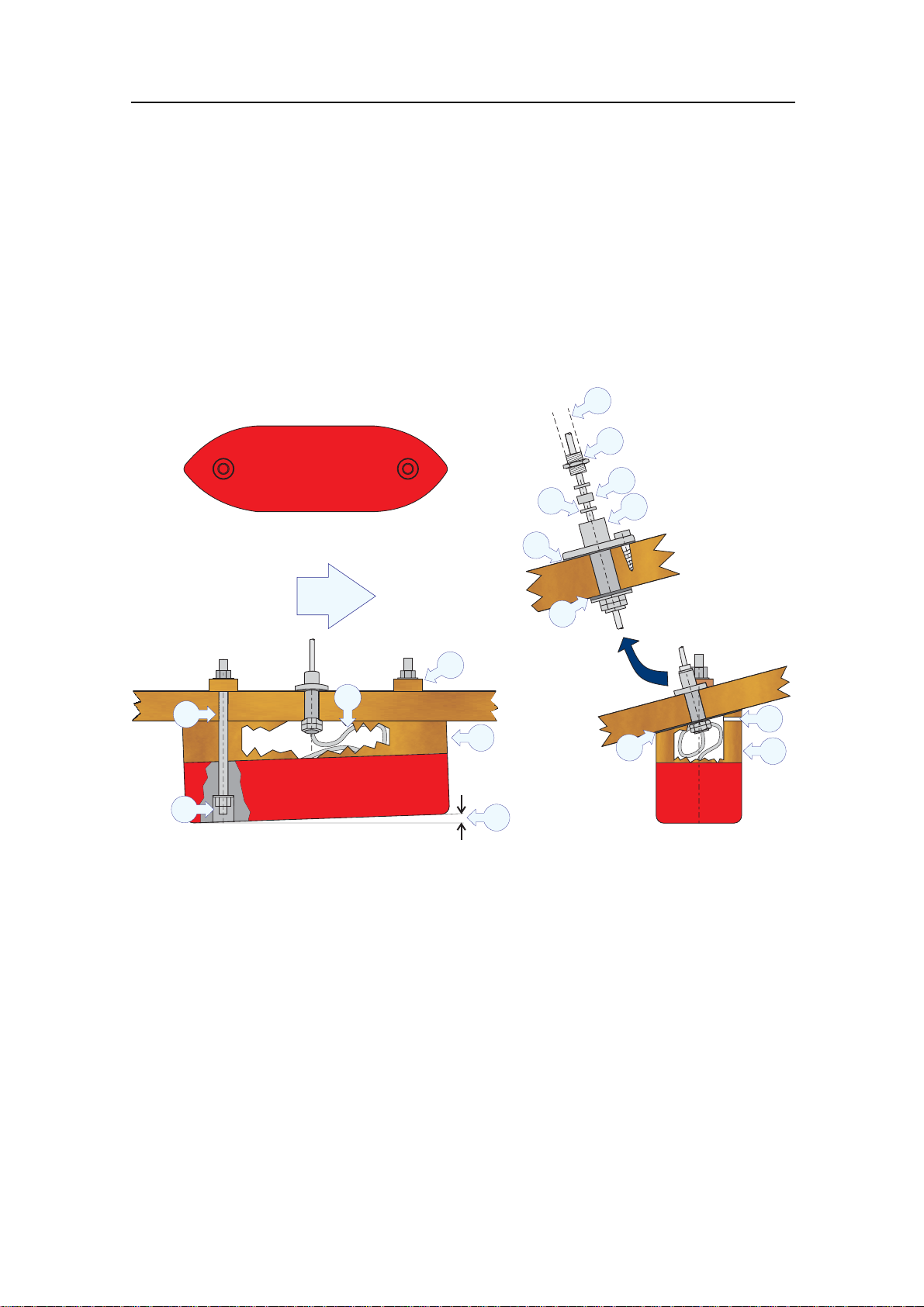

Wood or polyester hull

A fairing (A), made by the shipyard, is placed between the

transducer and the hull. It is required in order to adapt for the

deadrise angle of the hull, and will also house a cable service

loop (B). The fairing is made from wood, polyester or steel, and

should have the same outline dimensions as the transducer. Use

tarred f elt (H) between the fairing and the hull. Remember to

create an air outlet (E) on the fairing, and to fill the bolt holes

with a filling compound to ensure a smooth transducer surface.

1

5

4

3

2

I

(CD17007B)

C

F

G

B

A

(A) = Fairing

(B) = Cable service loop

(C) = Filling compound

(D) = Inclination angle

(E) = Air outlet

D

4

4

H

(1) = Steel conduit

(2) = Stuffing tube

(3) = Washer

(4) = Rubber gasket

(5) = Packing nipple

E

A

(F) = Forward

(G) = Shim (wood)

(H) = Tarred felt

(I) = Threaded rod with nuts

and washers, or bolt

851-160164/H 13

Page 16

Simrad Echo sounder transducers

Hull with flat bottom

If the vessel’s hull is flat you do not need a fairing. The

transducer is then be bolted directly to the hull using two bronze

or stainless steel bolts (I) and a cable bushing. Note that the

cable bushing must be mounted with proper gaskets (4) under

and over the hull, as well as sealing c ompound (J) around its

body. Also, fill the bolt holes with a filling compound to ensure

a smooth transducer surface.

F

(CD017007C)

4

J

(C) = Filling compound

(F) = Forward

(I) = Threaded rod with nuts and washers, or bolt

(3) = Washer

(4) = Rubber gasket

3

I

C

14

851-160164/H

Page 17

Ways of mounting the transducer

Toe-in

The primary consideration must be to allow laminar water flow.

In most cases t his is achieved by placing the transducer (A)

parallel with the keel (C). However, if the transducer is located

close to t he bow, the front of the transducer may have a few

degrees (5 to 8°) toe-in towards the bow. If you have a planing

hull, the toe-in must be 0°.

F

C

A

B

(CD017007D)

(A) = Transducer

(B) = 5 to 8° on deplacement hulls, 0° on planing hulls

(C) = Keel

(F) = Forward

851-160164/H 15

Page 18

Simrad Echo sounder transducers

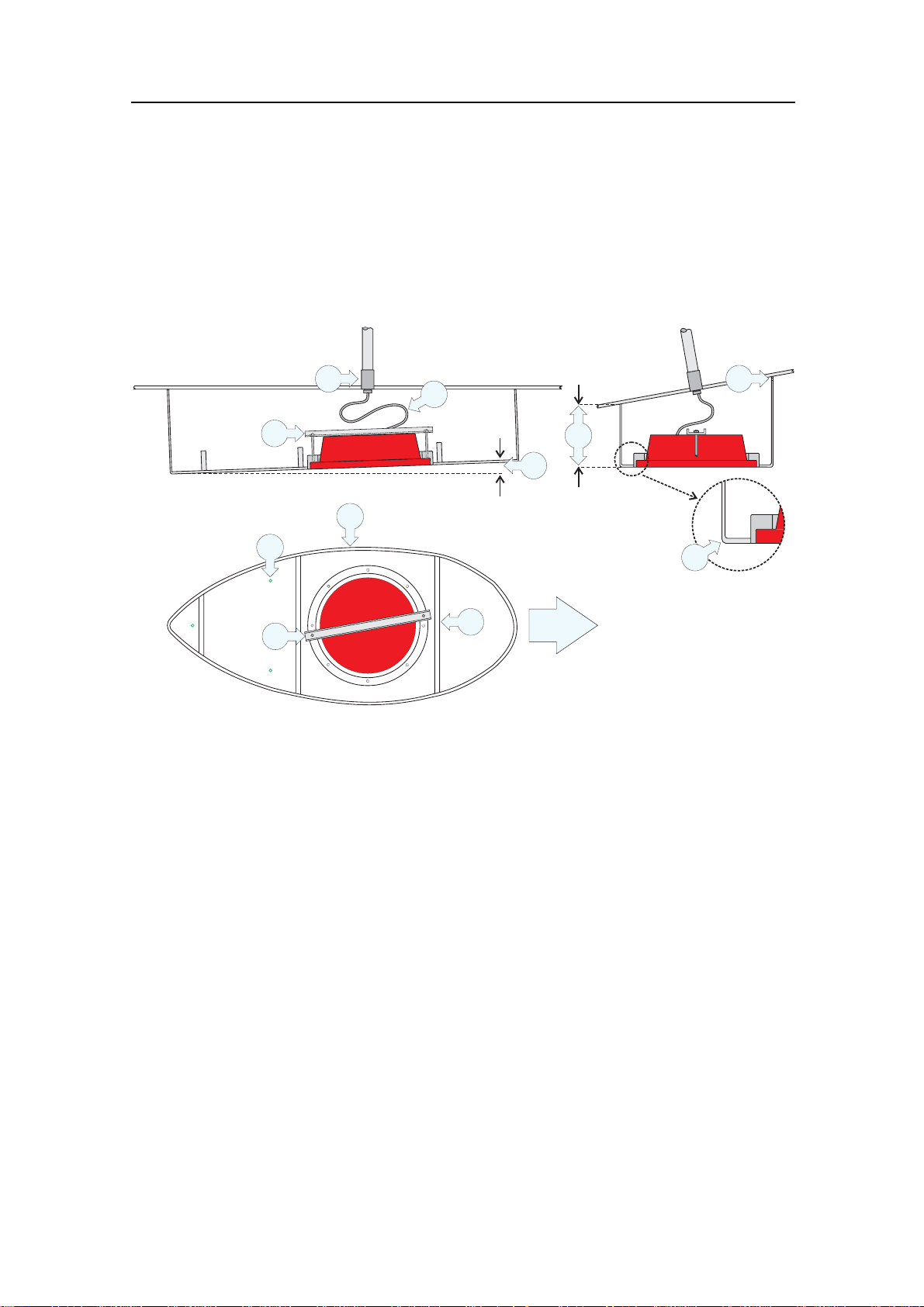

Transducer blister

With a transducer with circular housing, one recommended

installation method is by using a blister. The transducer blister

must be designed and manufactured by the installation shipyard

to fit the vessel’s size and hull shape.

Mounting and clamping rings

Circular transducers may be provided with mounting and

clamping rings, or with drawings to allow for local production

of these. The m ounting ring is welded to the hole in the

transducer blister, while the clamping ring fits around the edge

of the transducer body. Bolts through the clamping ring into the

mounting ring w ill then secure the transducer between them.

Note that several transducers use direction guides to allow correct

mounting.

Smooth surface

Mounting screws or bolts must not be extruding from the

transducer blister. Ensure that the surface of the transducer face,

the blister, the hull plating and putty around the transducer is as

even and smooth as possible. Obstructions on these surfaces will

create problems with turbulant flow.

Horizontal support bar

Large diameter transducers must be fitted with a horizontal

support bar. This bar can be secured to the mounting ring using

threaded rods.

16

851-160164/H

Page 19

Ways of mounting the transducer

Example: Large transducer

The illustration below shows a typical transducer blister designed

for a large t ransducer. Note that due to the physical size of

the t ransducer, a U-shaped support bar (E) is used to support

the transducer. The purpose of this support is to prevent the

transducer from being pushed up into the blister in heavy seas.

(CD017010A)

H

E

A

C

E

(A) = Streamlined blister

(B) = Stiffening rib

(C) = Drainage holes

(D) = Inclination angle

G

B

K

I

D

J

F

(G) = Cable service loop

(H) = Stuffing tube

(I) = Minimum 400 mm

(J) = Rounded corners

(E) = U-shaped support bar

(K) = Air outlet

(F) = Forward

851-160164/H 17

Page 20

Simrad Echo sounder transducers

Example: Small transducer

The illustration below shows a typical transducer blister designed

for a small transducer. The same blister design principles as for a

large transducer apply.

(CD017010B)

E

E

A

B

F

G

C

D

(A) = Streamlined blister

(B) = Mounting ring

(C) = Clamping ring

(E) = Air outlet

(F) = Forward

(G) = Transducer cable

(D) = Guide

Note that the transducer cable must be provided with a cable loop

inside the blister. Observe the vertical forward edge of the blister.

This will guide the water to each side of the blister.

18

851-160164/H

Page 21

Ways of mounting the transducer

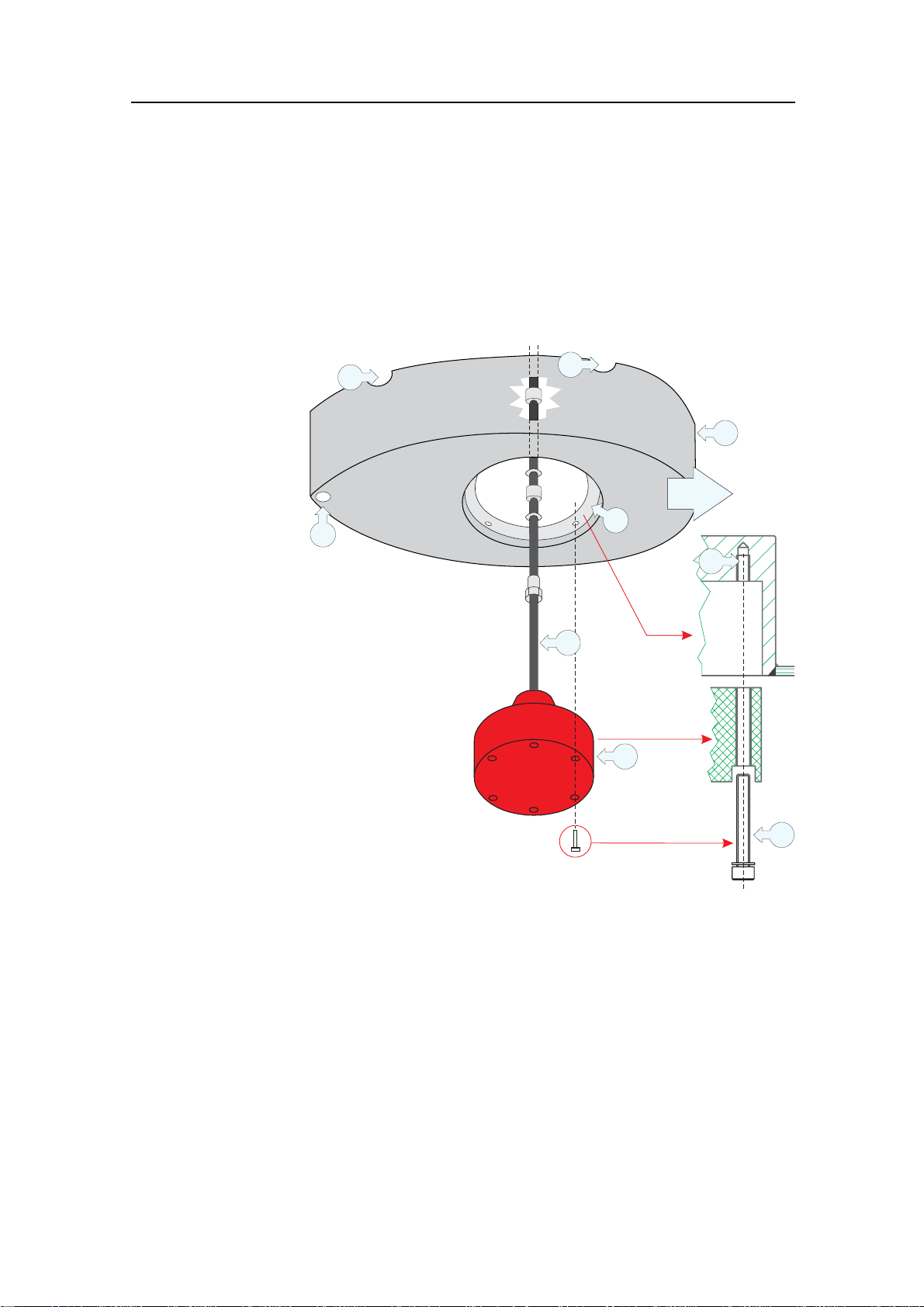

Example: Medium sized transducer without

clamping ring

The illustration below shows a transducer blister designed for a

medium sized transducers. The same blister design principles

apply. Note that the transducer is mounted without a clamping

ring, which makes it necessary to use a different mounting ring

design.

E

E

A

F

B

I

D

G

H

C

(CD017010E)

(A) = Streamlined blister

(B) = Mounting ring

(C) = Bolt

(D) = Self-locking threads

(E) = Air outlet

(F) = Forward

(G) = Transducer cable

(H) = Transducer

Note that the transducer cable must be provided with a cable loop

inside the blister. Observe the vertical forward edge of the blister.

This will guide the water to each side of the blister.

851-160164/H 19

Page 22

Simrad Echo sounder transducers

Common guidelines

The best performance is obtained with a blister height of 40 cm

or more. A streamlined shape and rounded edges reduce the flow

noise. A vertical leading edge or front will guide the aerated

water t o the sides of the blister. The orientation of the blister

should follow the water flow.

The interior of the blister must be filled with sea water. Use

drainage holes in the bottom and an air outlet on the top. The

water pressure behind the transducer will then compensate for

the outside pressure during vessel movements in rough sea.

Large diameter transducers must be fitted with a horizontal

U-shaped support bar. This bar can then be secured to the

mounting ring using threaded rods.

The transducer cable penetrates the hull in a stuffing tube. Leave

an adequate loop of the cable behind the transducer for easy

mounting or removal of the transducer.

Toe-in

The primary consideration must be to allow laminar water flow.

In most cases this is achieved by designing the blister in parallel

with the keel. However, if the blister is located close to the bow,

the front of the blister may have a few degrees toe-in towards

the bow.

A

C

B

(CD17010C)

(A) = Keel

(B) = Blister

(C) = Toe-in angle

20

Physical location

The blister is placed on one of the sides of the hull, and the

distance from the keel is a trade off between a close distance

giving a turbulent flow of water in a narrow passage, and a large

distance bringing the transducer higher up a nd also more affected

by vessel roll. Normally a distance of approximately 1 m is a

good compromise.

851-160164/H

Page 23

Ways of mounting the transducer

Observe the horizontal and vertical distances (X and Y) between

the keel and the transducer blister. On a medium sized vessel, the

horizontal distance (X) should be approximately 1 meter. The

vertical distance (Y) must in general be as small as possible. This

is important to prevent the keel from shadowing the transducer

beam in shallow waters.

(CD17010D)

B

A

Y

X

(A) = Keel

(B) = Transducer blister

(X) = Horizontal distance between keel and blister

(Y) = Vertical distance between the blister surface and the keel

851-160164/H

21

Page 24

Simrad Echo sounder transducers

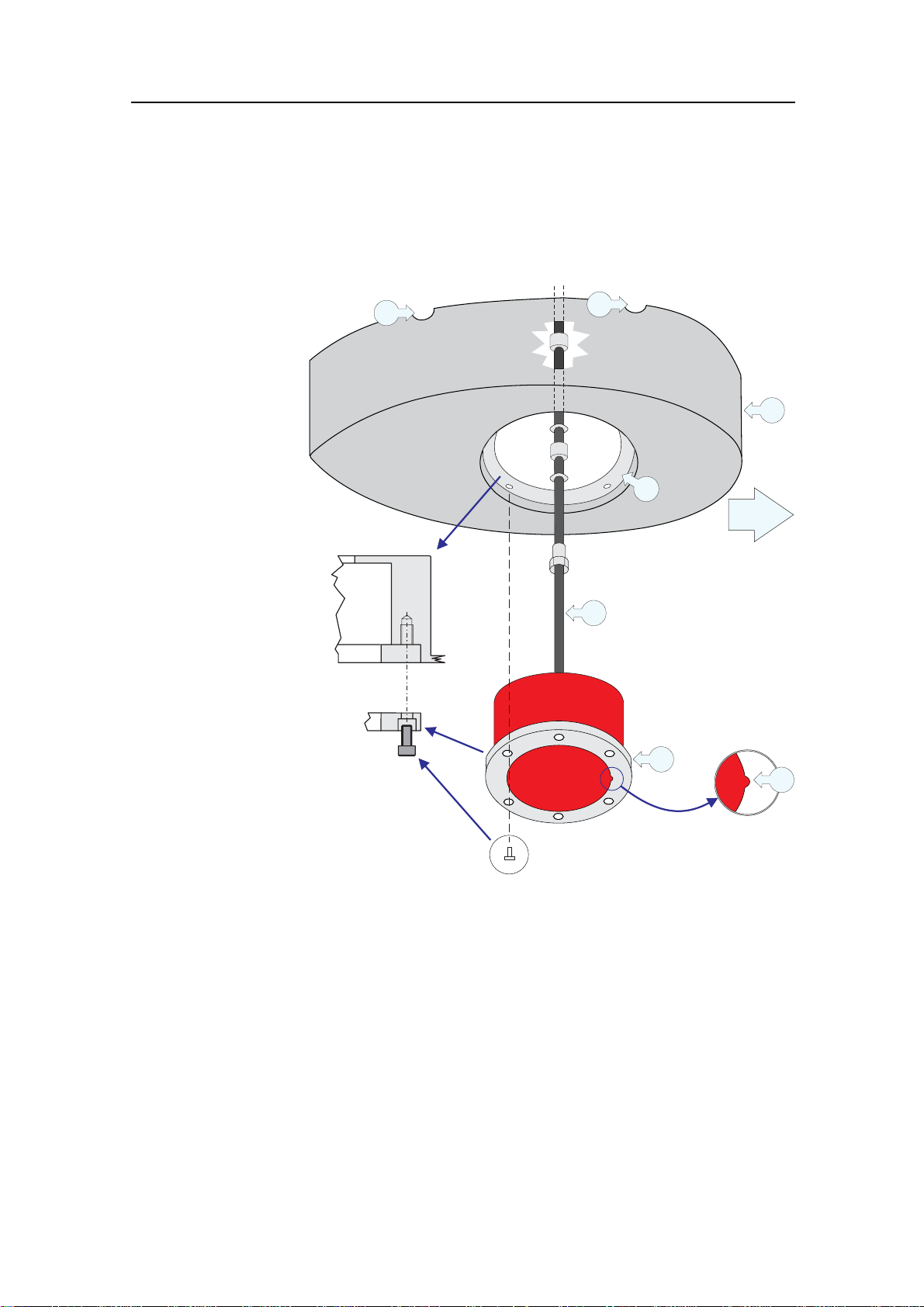

Box keel

Vessels with a box keel may use this for transducer installation.

The box keel is already the deepest part of the vessel. If the

box keel is too narrow to accommodate the transducer, it can be

widened, either symmetrically or to one side only. In the last

case the installation could also be described as a blister merged

into the keel.

Mounting and clamping rings

Circular transducers may be provided with mounting and

clamping rings, or with drawings to allow for local production of

these. The mounting ring is welded to the hole in the box keel,

while the clamping ring fits around the edge of the transducer

body. Bolts through the clamping ring into the mounting r ing

will then secure the transducer between them. Note that several

transducers use direction guides to allow correct mounting.

Smooth surface

Mounting screws or bolts must not be extruding from the box

keel. Ensure that the surface of the transducer face, the box,

the hull plating and putty around the transducer is as even and

smooth as possible. Obstructions on these surfaces will create

problems with turbulant flow.

Horizontal support bar

Large diameter transducers must be fitted with a horizontal

support bar. This bar can be secured to the mounting ring using

threaded rods.

22

851-160164/H

Page 25

Ways of mounting the transducer

Example

The figure below illustrates a symmetrical box keel installation.

(CD17011A)

D

C

B

E

A

(A) = Box keel

(B) = U-shaped support bar (only required on large transducers)

(C) = Stuffing tube

(D) = Cable in steel conduit

(E) = Cable service loop

851-160164/H 23

Page 26

Simrad Echo sounder transducers

Flush mounting in a steel tank

Flush mounting is used on very large vessels with a hull so deep

that no air bubbles are found below the hull, and on vessels

operating in shallow harbours or waters, where a protruding

blister can not be accepted.

The standard procedure for flushmountingonasteelvesselis

to weld a steel tank inside the hull, and mount the transducer

into this tank.

Mounting and clamping rings

Circular transducers may be provided with mounting and

clamping rings, or with drawings to allow for local production of

these. The m ounting ring is welded to the hole in the hull plating,

while the clamping ring fits around the edge of the transducer

body. Bolts through the clamping ring into the mounting r ing

will then secure the transducer between them. Note that several

transducers use direction guides to allow correct mounting.

Smooth surface

Mounting screws or bolts must not be extruding from the hull

plating. Ensure that the surface of the transducer face, the hull

plating and putty around the transducer is as even and smooth as

possible. Obstructions on these surfaces will create problems

with turbulant flow.

Horizontal support bar

Large diameter transducers must be fitted with a horizontal

support bar. This bar can be secured to the mounting ring using

threaded rods.

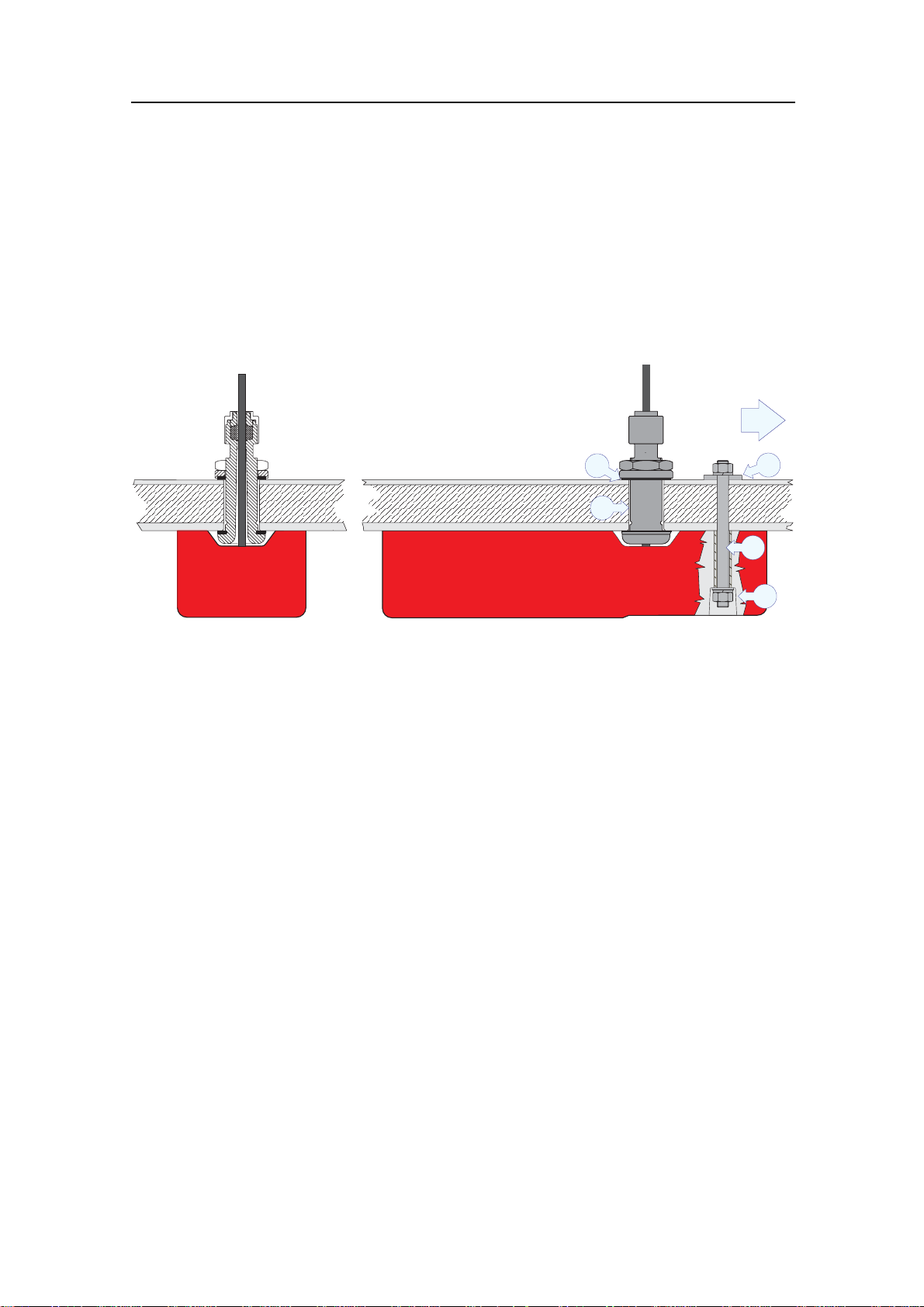

Water filled

As for a blister, the interior of the tank must be filled with water.

This can be accomplished by air release through a steel tube,

which is extended either to open air 1.5 m above the water line

or to the water outside the hull at a point higher than the tank

interior. If the tube is extended to open air, drainage must be

provided with leakage at the transducer flange or a separate hole

in the tank bottom.

24

851-160164/H

Page 27

Ways of mounting the transducer

Example

Transducer mounting in a steel tank is shown in the figure below.

G

F

A

B

C

(A) = Steel tank

(B) = Water

(C) = Drainage hole

(D) = Cable service loop

(E) = Steel tube for air outlet

(F) = Stuffing tube

E

D

(CD17012A)

(G) = Cable in steel conduit

851-160164/H 25

Page 28

Simrad Echo sounder transducers

Acoustic window

Vessels operating in arctic waters need special attention on

transducer installation. Floating blocks of ice may damage even

a flush mounted transducer face. For this situation Simrad offers

arctic tanks in different sizes.

Mounting and clamping rings

Circular transducers may be provided with mounting and

clamping rings, or with drawings to allow for local production

of these. The mounting ring is welded to the hole inside the

steel tank, while the clamping ring fits around the edge of the

transducer body. Bolts through the clamping ring into the

mounting ring w ill then secure the transducer between them.

Note that several transducers use direction guides to allow correct

mounting.

Smooth surface

Mounting screws or bolts must not be extruding from the

acoustic window. Ensure that the surface of the window, the hull

plating and putty around the transducer is as even and smooth as

possible. Obstructions on these surfaces will create problems

with turbulant flow.

Horizontal support bar

Large diameter transducers must be fitted with a horizontal

support bar. This bar can be secured to the mounting ring using

threaded rods.

26

851-160164/H

Page 29

Ways of mounting the transducer

Example

The transducer shown in the figure below is mounted inside the

tank behind a strong acoustic window which could be made of

polycarbonate. The tank is filled with oil.

A

B

(CD017012B)

(A) = Steel tank

(B) = Oil

(C) = Acoustic window

(D) = Cable service loop

(E) = Stuffing tube

F

G

E

D

C

(F) = Cable in steel conduit

(G) = Oil inlet

851-160164/H 27

Page 30

Simrad Echo sounder transducers

Inside the hull

The transducer can also be mounted inside the hull.

An installation of the transducer inside the hull, and sounding

through the hull, requires a good acoustic contact between the

transducer face and the hull. Build a tank around the transducer

and fill it with a liquid. Oil used in hydraulic systems is a well

suited liquid for this purpose. It contains no gas bubbles and

is non-corrosive.

Typical values of the two way loss are 3 dB for polyester, 6 dB

for a luminium and 10 dB for steel. Hulls made of wood or a

sandwich type with foam in the middle, attenuate the sound so

much that through hull sounding must be regarded as impossible.

The loss varies with the distance between transducer face and

the hull. The best result is obtained when the distance is half a

wavelength. Consult Simrad for advice. In addition to the loss,

the beam pattern is degraded, because a larger area of the hull is

set into vibrations.

Mounting and clamping rings

Circular transducers may be provided with mounting and

clamping rings, or with drawings to allow for local production

of these. The mounting ring is welded to the hole inside the

steel tank, while the clamping ring fits around the edge of the

transducer body. Bolts through the clamping ring into the

mounting ring w ill then secure the transducer between them.

Note that several transducers use direction guides to allow correct

mounting.

Smooth surface

Mounting screws or bolts must not be extruding from the

acoustic window. Ensure that the surface of the window, the hull

plating and putty around the transducer is as even and smooth as

possible. Obstructions on these surfaces will create problems

with turbulant flow.

Horizontal support bar

Large diameter transducers must be fitted with a horizontal

support bar. This bar can be secured to the mounting ring using

threaded rods.

28

851-160164/H

Page 31

Ways of mounting the transducer

Example

The transducer shown in the figure below is mounted inside the

hull. The tank is filled with oil.

G

D

A

B

(CD017012C)

(A) = Steel tank

(B) = Oil

(C) = Hull plating

(D) = Cable service loop

(E) = Stuffing tube

(F) = Cable in steel conduit

H

F

E

C

(G) = Hole for oil filling

(H) = Air outlet

851-160164/H 29

Page 32

Simrad Echo sounder transducers

Drop keel

The use of a drop keel with the purpose of stabilising the vessel

is well known.

A drop keel is also a superior platform for echo sounder

transducers. Such instrument keels have been built, mainly on

research vessels, often protruding as far as three meters below

the hull. At that depth, the water is free of air bubbles up to

very high sea states. The vessel is then able to perform reliable

acoustic measurements in open sea a larger part of the year.

(CD017012D)

A

B

C

(A) = Instrument keel shaft

(B) = Lowered position

(C) = Bottom view

30

851-160164/H

Page 33

Retractable transducer

Hull units allowing the transducer to be lowered and hoisted are

commonly used for horizontal looking sonars. When not in use,

the transducer is retracted i nto a trunk.

The retractable hull unit is more expensive than a blister, but on

vessels with a hull where it is difficult or impossible to install a

blister, it may still be worth while. The principles of a hull unit

with a retractable transducer is shown below.

Vessels without a keel and with a wide, flat bottom is an example

where a retractable hull unit can be the only acceptable method

for bringing the echo sounder transducer below the boundary

layer.

Ways of mounting the transducer

D

(CD017012E)

C

(A) = Transducer

B

E

A

(B) = Trunk

(C) = Transducer shaft

(D) = Transducer shaft sleeve

(E) = Keel

851-160164/H 31

Page 34

Simrad Echo sounder transducers

CABLE GLANDS

The transducer cable must pass through the hull using approved

cable glands for the type of vessel in question.

A steel cable gland is normally used on professional vessels

with steel hulls. A bronze cable gland can be delivered as an

option for vessels with wood or fibreglass hulls. Vessel not to be

classified can as an option use a cable gland made of plastic.

Note

Simrad strongly recommends that a length of conduit is fitted

around transducer cable glands made of steel or bronze and

extended over the water-line inside the vessel. This precaution

reduces the danger of flooding in the event of gland failure and

transducers installed in this manner are also easier to replace.

Some vessels may experience difficulties finding suitable areas

of the hull for mounting transducer cable glands due to existing

water tanks, concrete ballast or other obstacles. A possible

solution in such cases is to run the transducer cables in a steel

conduit aft along the hull until a suitable cable gland location is

available. The respective cable gland can then be installed as

described in the following instructions.

Note

Simrad takes no responsibility for the correct installation of

cable glands, associated hull modifications and/or structural

support of transducer cable penetration. These activities are

subject to individual approval by the respective classification

society for the vessel in question.

Order numbers

The cable glands described in this chapter are available as kits

from Simrad. Observe the following order numbers.

Steel hull cable gland kit (steel, 8 to 15 mm cables): 599-202216

Steel hull cable gland kit (steel, 17 to 18,5 mm cables): 305609

Wood/GRP hull cable gland kit (bronze): 119-038200

Small hull cable gland kit (plastic): 599-202182

32

851-160164/H

Page 35

Cable gland for steel hulls

This cable gland kit is designed for steel vessels. It must be

welded to the hull plates.

ø35

A

ø65

Cable glands

F

A

B

C

D

C

E

(CD17008A)

(A) = Steel conduit

(B) = Stuffing tube, DNV approved carbon steel st52.3

(C) = Washers

(D) = Rubber gasket

(E) = Packing nipple. Make sure that you do not damage the

transducer cable by tightening the packing nipple too hard!

(F) = Cable to the echo sounder (or a junction box)

The cable gland kit includes all of the necessary parts needed to

install the unit except screws.

Simrad recommends that a one inch steel conduit (that the

transducer cable will be run through) with an inside threaded

diameter of three-quarter inches is welded to the gland’s stuffing

tube. The conduit must extend to above the vessel’s water line.

851-160164/H 33

Page 36

Simrad Echo sounder transducers

Cable gland for wood or GRP hulls

A bronze cable gland kit is available for wood and GRP vessels.

F

A

B

C

B

C

C

B

(A) = Packing nipple. Make sure that y

transducer cable by tightening

the packing nipple too hard!

E

D

(CD17008B)

ou do not damage the

34

(B) = Washers

(C) = Rubber gaskets

(D) = Hole diameter 28 mm

(E) = Steel conduit

(F) = Cable to the echo sounder

The cable gland kit includes a

install the unit except scr

Simrad recommends that a

transducer cable will b

diameter of three-qua

nipple. This connect

extend to above the v

e run through) with an inside threaded

rter inches is attached to the gland’s packing

ion must be watertight, and the conduit must

essel’s water line.

ll of the necessary parts needed to

ews.

one inch steel conduit (that the

(or a junction box)

851-160164/H

Page 37

Cable glands for small hulls

This cable glands made of plastic is designed for those smaller

vessels that do not need to be classified.

Cable glands

A

J

B

A

C

D

E

(CD17008C)

F

G

H

I

(A) = Packing nut (bronze). Ensure that you do not to damage

the transducer cable by tightening the packing nut too hard!

(B) = Rubber gasket

(C) = Plastic disk

(D) = Rubber gasket

(E) = Stuffing tube

(F) = Backing nut (bronze)

(G) = Backing washer (plastic)

(H) = O-ring 42.5 x 3.0 N

(I) = O-ring 39.5 x 3.0 N

(J) = Cable to the echo sounder (or a junction box)

Stuffing tube hole diameter: 36 mm ±1.5 mm.

Apply ample amount of sealant between the backing washer (H)

and the hull plate.

The cable gland kit contains all the listed parts, except the sealant.

Note

The two O-rings must be clean, in

or other defects which could af

good condition and free of cuts

fect their watertight integrity.

851-160164/H 35

Page 38

Simrad Echo sounder transducers

Cable splicing

If you need to cut or lengthen the transducer cable, you must

splice it correctly. The cable between the junction box and the

transceiver must then be supplied by Simrad, and this must be

the same type as used on the transducer(s).

Note

Do not solder the wires together with only electrical tape for

insulation, as this will result in electrical noise and reduced

operational performance.

To splice the cable, use a metal junction box with EMC cable

glands and a terminal block. The terminal block must provide

solid fastening of the cable ends as well as sufficient insulation

between the wires.

Note

We recommend that the cable screen is connected to the junction

box chassis using the EMC cable glands, but if you do this, the

junction box chassis m

Thecablescreenm

through the junction box.

ust not be connected to ship’s ground.

ust not be connected to the ship’s ground

36 851-160164/H

Page 39

STEEL CONDUIT

It is strongly recommended to lay a steel conduit from t he

transducer’s cable gland to the echo sounder transceiver, and to

pull the transducer cable through this conduit. There are two

reasons for this.

• First, it will make it easier at a later stage to replace the

transducer.

• Second, noise and interference from other electrical equipment

is greatly reduced.

With a steel conduit the installation will satisfy the EU

regulations for EMC interference. Without a steel conduit, there

is a risk of reduced echo sounder performance.

The steel conduit must be unbroken and watertight from the

transducer to above the water line. From there, the cable can

be pulled further, or a junction box can be installed to facilitate

further connections. Note that the steel conduit must act as

a continuous electrical screen all the way. To ensure proper

shielding, the conduit must be electrically connected to the echo

sounder transceiver chassis.

Steel conduit

Steel conduit dimensions:

• minimum 35 mm inner diameter

• minimum 6 mm wall thickness (4.5 mm if galvanised)

If two or more transducers are installed close to each other it is

possible to pull their cables in the same steel conduit, provided

the conduit diameter is increased accordingly. However, for easy

replacement it is recommended that each transducer has its own

steel conduit.

851-160164/H 37

Page 40

Simrad Echo sounder transducers

HANDLING AND MAINTENANCE

Note

Do not lift the transducer by the cable.

Do not expose the transducer to direct sunlight.

Do not expose the transducer to excessive heat.

Some transducers are delivered with a cover plate on the face

for protection during transport. Let this plate stay on as long as

possible, but do not forget to remove it before the vessel goes

into the sea.

An anti-fouling paint may be applied to the transducer face.

Because some paint types may be aggressive to the polyurethane

in the transducer face, please consult Simrad’s l ist of approved

paints.

Note

Arctic tanks have acoustic windows made of polycarbonate.

These must neither be painted nor cleaned with chemicals.

During dry docking of the vessel, the transducer face may be

cleaned for shells and other marine fouling. Be careful not to

make cuts in the transducer face. Use a piece of wood or a very

fine grade emery paper.

38

851-160164/H

Page 41

Approved anti-fouling paints

This is Simrad’s list of approved antifouling paints on

polyurethane transducer housing.

Jotun

Head office address: P.O.Box 2021, N-3248 Sandefjord, Norway

Handling and maintenance

Website: w

ww.jotun.com.

1 Racing

2 Non-stop

3 Safeguard Universal primer (125 micron) with Antifouling

SeaQuantum Ultra (125 micron)

4 Antifouling Seaguardian

International Marine Coatings

Address: World-wide offices

Wesite: w

ww.international-marine.com.

1 Intersleek tie coat + 425 FCS

• BXA386/BXA390/BXA391 Grey

• HKA563/HKA570/HKA571 Yellow

• Mix BXA386, BXA390 and BXA391 first, then apply.

When dry, mix HKA563, HKA570 and HKA571, apply.

2 Intersmooth 360 Ecoloflex SPC

3 Micron Ekstra

Hempel IFA Coatings

Head office address: Hempel A/S, Lundtoftevej 150, Kgs.

Lyngby, DK-2800 Copenhagen, Denmark

Website: w

ww.hempel.com.

1 Hempel A/F Classic 76550

Note

Refer to the manufacturer’s documentation and dat

a sheets for

a complete procedure.

851-160164/H 39

Page 42

Simrad Echo sounder transducers

SIMRAD TRANSDUCERS

This chapter presents a list of all the current Simrad transducers.

For each transducer, information is provided to establish:

• the transducer type and frequency

• the opening angle(s)

• the order number for the transducer

• the order number for the transducer cable

• how it is connected to the General Purpose Transceiver (GPT)

unit

This list was correct at the time of writing. However, new

transducers a re frequently added to the product range. For an

updated list of all the currently available transducers, refer

to w

ww.simrad.com. Product specifications and installation

documents can be downloaded from the web site.

By means of various hardware and software configurations and

adjustments, the General Purpose Transceiver (GPT) unit is used

with the following echo sounder systems:

•SimradES60fish finding echo sounder

• SimradEK60scientific echo sounder

• Kongsberg Maritime’s EA 400 hydrographic echo sounder

• Kongsberg Maritime’s EA 600 hydrographic echo sounder

Topics

All 12 kHz transducers on page 41

All 18 kHz transducers on page 41

All 27 kHz transducers on page 41

All 38 kHz transducers on page 42

All 50 kHz transducers on page 44

All 70 khz transducers on page 45

All 120 khz transducers on page 46

All 200 kHz transducers on page 47

40

All 710 kHz transducers on page 49

Related topics

Cable splicing on page 36

851-160164/H

Page 43

All 12 kHz transducers

The following 12 kHz transducers are available.

Simrad 12-16/60

• Type and frequency: Single or dual beam, 12 kHz

•

Opening angle: 16° or 60° (Passive)

•

Typical applications: Fish finding, hydrographic and scientific

echo sounders

•

Order number, transducer: KSV-089510

•

Order number, transducer cable: 642-022491

GPT connection: 12-16/60 transducer on page 62

•

All 18 kHz transducers

The following 18 kHz transducers are available.

Simrad transducers

Simrad 18–11

• Type and frequency: Single beam, 18 kHz

Opening angle: 11°

•

•

Typical applications: Fish finding and hydrographic echo

sounders

•

Order number, transducer: KSV-088693

•

Order number, transducer cable: 642-016604

•

GPT connection: Single beam, normal power transducer on

page 52

Simrad ES18

• Type and frequency: Split beam, 18 kHz

•

Opening angle: 11°

•

Typical applications: Fish finding and scientific echo sounders

•

Order number, transducer: KSV-088694

•

Order number, transducer cable: 642–075072

•

GPT connection: Split beam transducer on page 55

All 27 kHz transducers

The following 27 kHz transducers are available.

Simrad 27-26/21

• Type and frequency: Dual beam, 27 kHz

•

Opening angle: 10 x 11° or 10 x 20°

•

Typical applications: Fish finding and hydrographic echo

sounders

851-160164/H

41

Page 44

Simrad Echo sounder transducers

• Order number, transducer: KSV-067159

Order number, transducer cable: 642-022491

•

GPT connection: Dual beam (wide or narrow) transducer on

•

page 54

All 38 kHz transducers

The following 38 kHz transducers are available.

Simrad 38-7

• Type and frequency: Single beam, 38 kHz

Opening angle: 7°

•

Typical applications: Fish finding and hydrographic echo

•

sounders

Order number, transducer: KSV-082776

•

Order number, transducer cable: 642-016604

•

GPT connection: Single beam, normal power transducer on

•

page 52

Simrad 38-9

• Type and frequency: Single beam, 38 kHz

Opening angle: 9°

•

Typical applications: Fish finding and hydrographic echo

•

sounders

Order number, transducer: KSV-203635

•

Order number, transducer cable: 642-016604

•

GPT connection: Single beam, normal power transducer on

•

page 52

Simrad ES38-10

• Type and frequency: Split beam, 38 kHz

Opening angle: 10°

•

Typical applications: Fish finding echo sounders

•

Order number, transducer: KSV-202714

•

Order number, transducer cable: 642-078215

•

42

GPT connection: ES38–10 transducer on page 61

•

Simrad ES38-12

• Type and frequency: Split beam, 38 kHz

Opening angle: 12°

•

Typical applications: Fish finding and scientific echo sounders

•

Order number, transducer: KSV-111497

•

851-160164/H

Page 45

Simrad transducers

• Order number, transducer cable: 642-078215

GPT connection: Split beam transducer on page 55

•

Simrad ES38B

• Type and frequency: Split beam, 38 kHz

Opening angle: 7°

•

•

Typical applications: Fish finding and scientific echo sounders

Order number, transducer: KSV-074531

•

Order number, transducer cable: 642-075072

•

•

GPT connection: Split beam transducer on page 55

Simrad ES38DD

• Type and frequency: Split beam, 38 kHz

Opening angle: 7°

•

Typical applications: Scientific echo sounders, towed array

•

•

Order number, transducer: KSV-113392

Order number, transducer cable: Shipyard supply

•

GPT connection: Deep

•

Simrad 38/200 Combi C

water, split beam transducer on page 60

• Type and frequency: Dual frequency single beam, 38 and 200

kHz

•

Opening angle: 13 x 21° and 7 x 7°

Typical applications: Fish finding echo sounders, Catch

•

monitoring systems

•

Order number, transducer: KSV-202192

Order number, transducer cable: 642-078215

•

GPT connection: 38/200 Combi C transducer on page 64

•

Simrad 38/200 Combi D

• Type and frequency: Dual frequency single beam, 38 and 200

kHz

•

Opening angle: 13 x 21° and 7 x 7°

Typical applications: Fish finding and hydrographic echo

•

sounders, Catch monitoring systems

Order number, transducer: KSV-203004

•

•

Order number, transducer cable: 642-078215

GPT connection: Dual frequency, single beam transducer on

•

page 58

851-160164/H 43

Page 46

Simrad Echo sounder transducers

Simrad 38/200 Combi W

• Type and frequency: Dual frequency single beam, 38 and 200

kHz

•

Opening angle: 31 x 31° and 31 x 31°

Typical applications: Fish finding echo sounders

•

Order number, transducer: KSV-208845

•

Order number, transducer cable: 642-078215

•

•

GPT connection: Dual frequency, single beam transducer on

page 58

All 50 kHz transducers

The following 50 kHz transducers are available.

Simrad 50-7

• Type and frequency: Single beam, 50 kHz

Opening angle: 7°

•

Typical applications: Fish finding and hydrographic echo

•

sounders

•

Order number, transducer: KSV-203665

Order number, transducer cable: 642-016604

•

•

GPT connection: Single beam, normal power transducer on

page 52

Simrad 50-18

• Type and frequency: Single beam, 50 kHz

Opening angle: 18°

•

Typical applications: Hydrographic echo sounders

•

Order number, transducer: KSV-082606

•

Order number, transducer cable: 642-016604

•

GPT connection: Single beam, normal power transducer on

•

page 52

Simrad 50-18POR

44

• Type and frequency: Single beam, 50 kHz, Portable

Opening angle: 18°

•

Typical applications: Hydrographic echo sounders, portable

•

Order number, transducer: KSV-088073

•

Order number, transducer cable:

•

• GPT connection: Single beam, normal power transducer on

page 52

851-160164/H

Page 47

Simrad transducers

Simrad 50/200 Combi C

• Type and frequency: Dual frequency single beam, 50 and 200

kHz

•

Opening angles: 10x16°and7x7°

•

Typical applications: Fish finding echo sounders, Catch

monitoring systems

Order number, transducer: KSV-202193

•

•

Order number, transducer cable: 642–078215

•

GPT connection: 50/200 Combi C transducer on page 63

Simrad 50/200 Combi D

• Type and frequency: Dual frequency single beam, 50 and 200

kHz

Opening angles: 10x16°and7x7°

•

•

Typical applications: Fish finding and hydrographic echo

sounders, Catch monitoring systems

•

Order number, transducer: KSV-203005

•

Order number, transducer cable: 642–078215

•

GPT connection: Dual frequency, single beam transducer on

page 58

All 70 khz transducers

The following 70 khz transducers are available.

Simrad ES70-11

• Type and frequency: Split beam, 70 kHz

•

Opening angle: 11°

•

Typical applications: Fish finding and scientific echo sounders

•

Order number, transducer: KSV-110280

•

Order number, transducer cable: 642–075072

•

GPT connection: Split beam transducer on page 55

Simrad ES70-7C

• Type and frequency: Split beam, 70 kHz

•

Opening angle: 7°

•

Typical applications: Fish finding and scientific echo sounders

•

Order number, transducer: KSV-203678

•

Order number, transducer cable: 642–078215

•

GPT connection: Split beam transducer on page 55

851-160164/H 45

Page 48

Simrad Echo sounder transducers

All 120 khz transducers

The following 120 khz transducers are available.

Simrad 120-25

• Type and frequency: Single beam, 120 khz

•

Opening angle: 10°

Typical applications: Fish finding and hydrographic echo

•

sounders

•

Order number, transducer: KSV-062615

•

Order number, transducer cable: 642-016604

GPT connection: Single beam, normal power transducer on

•

page 52

Simrad ES120-7

• Type and frequency: Split beam, 120 khz

•

Opening angle: 7°

•

Typical applications: Fish finding and scientific echo sounders

Order number, transducer: KSV-088277

•

•

Order number, transducer cable: 642-075072

•

GPT connection: Split beam transducer on page 55

Simrad ES120-7C

• Type and frequency: Split beam, 120 khz

•

Opening angle: 7°

•

Typical applications: Fish finding and scientific echo sounders

•

Order number, transducer: KSV-204580

Order number, transducer cable: 642-078215

•

•

GPT connection: Split beam transducer on page 55

Simrad ES120-7DD

• Type and frequency: Split beam, 120 khz

Opening angle: 7°

•

•

Typical applications: Scientific echo sounders, towed array

46

•

Order number, transducer: KSV-112417

•

Order number, transducer cable: Shipyard supply

GPT connection: Deep water, split beam transducer on page 60

•

Simrad ES120-7F

• Type and frequency: Split beam, 120 khz

•

Opening angle: 7°

•

Typical applications: Fish finding and scientific echo sounders

851-160164/H

Page 49

Simrad transducers

• Order number, transducer: KSV-110553

Order number, transducer cable: 642-078215

•

GPT connection: Split beam transducer on page 55

•

Simrad ES120-7G

• Type and frequency: Split beam, 120 khz

Opening angle: 7°

•

Typical applications: Scientific echo sounders

•

Order number, transducer: KSV-112101

•

Order number, transducer cable: 642-078215

•

GPT connection: Split beam transducer on page 55

•

Simrad ES120-2,5x10

• Type and frequency: Split beam, 120 kHz

Opening angle: 2,5 x 9,5°

•

Typical applications: Scientific echo sounders

•

Order number, transducer: KSV-111154

•

Order number, transducer cable: 642-078215

•

GPT connection: Split beam transducer on page 55

•

Simrad ES120-4x10

• Type and frequency: Split beam, 120 kHz

Opening angle: 4,4 x 9°

•

Typical applications: Scientific echo sounders

•

Order number, transducer: KSV-203004

•

Order number, transducer cable: 642-078215

•

GPT connection: Split beam transducer on page 55

•

Simrad 120-2x50

• Type and frequency: Sidescan, 120 kHz

Opening angle: 1,9 x 55°

•

Typical applications: Hydrographic sidescan echo sounders

•

Order number, transducer: KSV-088606

•

Order number, transducer cable:

•

• GPT connection: Sidescan transducer on page 59

All 200 kHz transducers

The following 200 kHz transducers are available.

Simrad 200-7C

• Type and frequency: Single beam, 200 kHz

851-160164/H 47

Page 50

Simrad Echo sounder transducers

• Opening angle: 7°

Typical applications: Fish finding and hydrographic echo

•

sounders

•

Order number, transducer: KSV-203378

Order number, transducer cable: 642-016604

•

•

GPT connection: Single beam, normal power transducer on

page 52

Simrad 200-7F

• Type and frequency: Single beam, 200 kHz

•

Opening angle: 7°

Typical applications:Hydrographic echo sounders

•

•

Order number, transducer: KSV-065414

Order number, transducer cable: 642-016604

•

•

GPT connection: Single beam, normal power transducer on

page 52

Simrad 200-7G

• Type and frequency: Single beam, 200 kHz

Opening angle: 7°

•

•

Typical applications: Hydrographic and scientificecho

sounders, Portable

•

Order number, transducer: KSV-210895

Order number, transducer cable: 642–076492

•

•

GPT connection: Single beam, normal power transducer on

page 52

Simrad 200-28E

• Type and frequency: Single beam, 200 kHz

Opening angle: 7°

•

•

Typical applications: Fish finding and hydrographic echo

sounders

•

Order number, transducer: KSV-109178

Order number, transducer cable: 642-016604

•

•

GPT connection: Single beam, normal power transducer on

page 52

Simrad 200-35

• Type and frequency: Single beam, 200 kHz

Opening angle: 3°

•

•

Typical applications: Hydrographic echo sounders

Order number, transducer: KSV-068181

•

48 851-160164/H

Page 51

Simrad transducers

• Order number, transducer cable: 642-016604

•

GPT connection: Single beam, normal power transducer on

page 52

Simrad ES200-7

• Type and frequency: Split beam, 200 kHz

•

Opening angle: 7°

•

Typical applications: Fish finding and scientific echo sounders

•

Order number, transducer: KSV-202718

•

Order number, transducer cable: 642-075072

•

GPT connection: Split beam transducer on page 55

Simrad ES200-7C

• Type and frequency: Split beam, 200 kHz

•

Opening angle: 7°

•

Typical applications: Fish finding and scientific echo sounders

•

Order number, transducer: KSV-203003

•

Order number, transducer cable: 642-078215

•

GPT connection: Split beam transducer on page 55

Simrad 38/200 Combi C

For information about this transducer, see All 38 kHz transducers

on page 42

Simrad 38/200 Combi D

For information about this transducer, see All 38 kHz transducers

on page 42

Simrad 38/200 Combi W

For information about this transducer, see All 38 kHz transducers

on page 42

Simrad 50/200 Combi C

For information about this transducer, see All 50 kHz transducers

on page 44

Simrad 50/200 Combi D

For information about this transducer, see All 50 kHz transducers

on page 44

All 710 kHz transducers

The following 710 kHz transducers are available.

851-160164/H 49

Page 52

Simrad Echo sounder transducers

Simrad 710-36E

• Type and frequency: Single beam, 710 kHz

•

Opening angle: 2,8°

•

Typical applications: Hydrographic and scientificecho

sounders

•

Order number, transducer: KSV-089292

•

Order number, transducer cable: 642-016604

•

GPT connection: Single beam, normal power transducer on

page 52

50

851-160164/H

Page 53

GPT transducer terminations

GPT TRANSDUCER TERMINATIONS

This chapter provides details cable drawings describing how the

various Simrad transducers are connected to the General Purpose

Transceiver (GPT) unit.

Cables

Single beam, normal power transducer on page 52

Single beam, high power transducer on page 53

Dual beam (wide or narrow) transducer on page 54

Split beam transducer on page 55

Split beam transducer to single beam transceiver on page 56

Single beam transducer to split beam transceiver on page 57

Dual frequency, single beam transducer on page 58

Sidescan transducer on page 59

Deep water, split beam transducer on page 60

ES38–10 transducer on page 61

12-16/60 transducer on page 62

50/200 Combi C transducer on page 63

38/200 Combi C transducer on page 64

851-160164/H 51

Page 54

Simrad Echo sounder transducers

Single beam, normal power transducer

This is the termination of the transducer cable from a single

frequency, single beam transducer to the transducer socket on the

General Purpose Transceiver Unit (GPT). The other end of the

cable is permanently fixed to the transducer.

Normal power output is achieved when the GPT is equipped with

a single transmitter board.

Transducer

cable

W802-1

Rev.E

A

N

Drain wire

Screen

B

C

D

E

Junction Box (1:1)

(Optional)

Connect to plug housing

M

J

F

H

Single frequency, single beam, normal power termination

If you need to splice the transducer cable, it is very important to

use the correct cable, and to avoid ground loops. We strongly

recommend the use of a junction box. We also recommend that

you install the transducer cable in a steel conduit.

GPT Transducer

socket

L

K

D

C

52

Related topics

Cable splicing on page 36

Steel conduit on page 37

851-160164/H

Page 55

GPT transducer terminations

Single beam, high power transducer

This is the termination of the transducer cable from a single

frequency, single beam transducer to the transducer socket on the

General Purpose Transceiver Unit (GPT). The other end of the

cable is permanently fixed to the transducer.

High power output is achieved when the GPT is equipped with

four transmitter boards.

Transducer

cable

W802-2

Rev.E

A

N

B

C

D

E

Junction Box (1:1)

(Optional)

Drain wire

Screen Connect to plug housing

M

F

H

Single frequency, single beam, high power termination

If you need to splice the transducer cable, it is very important to

use the correct cable, and to avoid ground loops. We strongly

recommend the use of a junction box. We also recommend that

you install the transducer cable in a steel conduit.

GPT Transducer

socket

L

K

J

A

B

C

D

E

F

H

J

Related topics

Cable splicing on page 36

Steel conduit on page 37

851-160164/H 53

Page 56

Simrad Echo sounder transducers

Dual beam (wide or narrow) transducer

This is the termination of the transducer cable from a single

frequency, dual beam transducer to the transducer socket on the

General Purpose Transceiver Unit (GPT). The other end of the

cable is permanently fixed to the transducer.

Note

Always check the transmit power if wide beam is selected in

order not to exceed the power capacity on the transducer.

Transducer cable

Narrow

Yellow/Green

Transducer cable

Wide

W802-3

Rev.E

A

N

B

C

D

E

F

Junction Box (1:1)

(Optional)

Blue

Brown

Screen

Junction Box (1:1)

(Optional)

Blue

Black

Screen Connect to plug housing

H

Connect to plug housing

GPT Transducer

M

L

K

J

Single frequency, dual beam (wide or narrow) termination

socket

C

D

C

D

54

If you need to splice the transducer cable, it is very important to

use the correct cable, and to avoid ground loops. We strongly

recommend the use of a junction box. We also recommend that

you install the transducer cable in a steel conduit.

Related topics

Cable splicing on page 36

Steel conduit on page 37

851-160164/H

Page 57

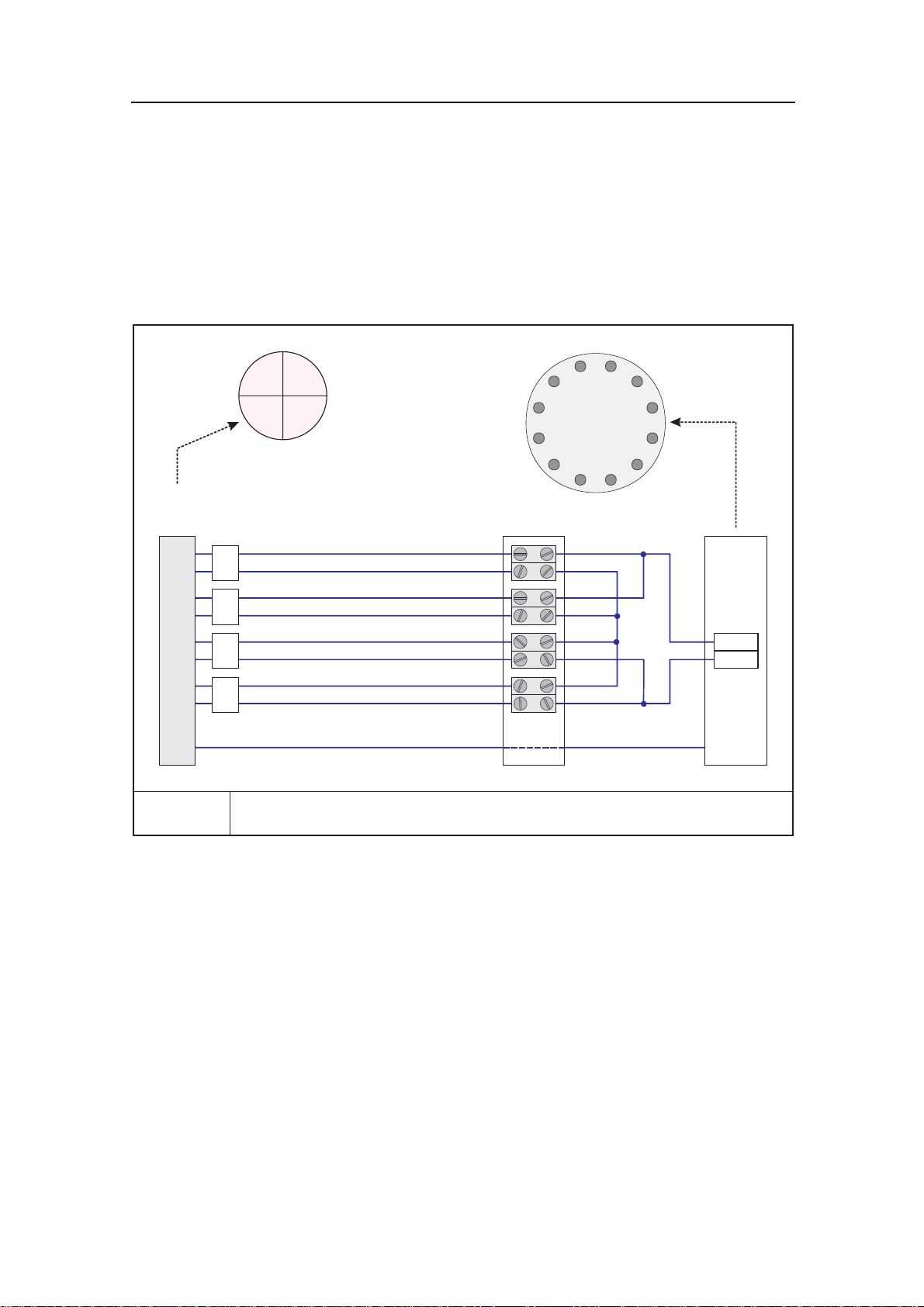

Split beam transducer

This is the termination of the transducer cable from a single

frequency, split beam transducer to the transducer socket on the

General Purpose Transceiver Unit (GPT). The other end of the

cable is permanently fixed to the transducer.

Forward

GPT transducer terminations

Port

Sections seen from top

Transducer

cable

W802-4

Rev.E

3

21

of the transducer

White

Black

1

White

Black

2

White

Black

3

White

Black

4

Screen

4

A

Starboard

B

C

D

E

F

Junction Box (1:1)

(Optional)

Blue

Black

Blue

Black

Blue

Black

Blue

Black

Alternative cable

colours

Blue

White

Orange

White

Green

White

Brown

White

Connect to plug housing

Single frequency, split beam termination

N

H

GPT Transducer

M

L

K

J

Channel 1

Channel 2

Channel 3

Channel 4

socket

H

J

E

F

C

D

A

B

If you need to splice the transducer cable, it is very important to

use the correct cable, and to avoid ground loops. We strongly

recommend the use of a junction box. We also recommend that

you install the transducer cable in a steel conduit.

Related topics

Cable splicing on page 36

Steel conduit on page 37

851-160164/H 55

Page 58

Simrad Echo sounder transducers

Split beam transducer to single beam transceiver

This is the termination of the transducer cable from a single

frequency, split beam transducer - wired as a single beam

transducer - to the socket on the General Purpose Transceiver

Unit (GPT). The other end of the cable is permanently fixed to

the transducer.

Forward

Port

Sections seen from top

Transducer

cable

W802-5

Rev.E

3

21

of the transducer

White

Black

1

White

Black

2

White

Black

3

White

Black

4

Screen

4

Starboard

A

N

B

C

D

E

F

H

GPT Transducer

M

L

K

J

Junction Box (1:1)

(Optional)

Blue

Black

Blue

Black

Blue

Black

Blue

Black

Alternative cable

colours

Blue

White

Orange

White

Green

White

Brown

White

Connect to plug housing

Single frequency, split beam connected as single beam

socket

D

C

56

If you need to splice the transducer cable, it is very important to

use the correct cable, and to avoid ground loops. We strongly

recommend the use of a junction box. We also recommend that

you install the transducer cable in a steel conduit.

Related topics

Cable splicing on page 36

Steel conduit on page 37

851-160164/H

Page 59

GPT transducer terminations

Single beam transducer to split beam transceiver

This is the termination of the transducer cable from a single

frequency, single beam transducer to the socket on a split beam

General Purpose Transceiver Unit (GPT). The other end of the

cable is permanently fixed to the transducer.

Transducer

cable

W802-9

Rev.A

GPT Transducer

M

L

K

J

socket

A

B

Junction Box (1:1)

(Optional)

A

N

B

C

D

E

F

H

C

D

E

F

H

Screen Connect to plug housing

J

Single frequency, single beam, to split beam transceiver, termination

If you need to splice the transducer cable, it is very important to

use the correct cable, and to avoid ground loops. We strongly

recommend the use of a junction box. We also recommend that

you install the transducer cable in a steel conduit.

Related topics

Cable splicing on page 36

Steel conduit on page 37

851-160164/H 57

Page 60

Simrad Echo sounder transducers

Dual frequency, single beam transducer

This is the termination of the transducer cable f rom a dual

frequency, single beam transducer to the socket on the General

Purpose Transceiver Unit (GPT). The other end of the cable is

permanently fixed to the transducer.

A

N

Transducer

cable

Pair 1

Pair 2

Screen

Black

White

Black

White

B

C

D

E

Junction Box (1:1)

(Optional)

Low frequency

High frequency

Connect to plug housing

M

L

K

J

F

H

Low frequency

High frequency

GPT Transducer

socket

C

D

H

J

W802-6

Rev.E

Pair 3

Pair 4

Black

White

Black

White

Thermistor

Not used

Thermistor

"Auxiliary" 25-pin

D-connector on GPT

Dual frequency, single beam termination

If you need to splice the transducer cable, it is very important to

use the correct cable, and to avoid ground loops. We strongly

recommend the use of a junction box. We also recommend that

you install the transducer cable in a steel conduit.

Related topics

Cable splicing on page 36

Steel conduit on page 37

4

17

58

851-160164/H

Page 61

Sidescan transducer

This is the termination of the transducer cable from two sidescan

transducers (port and starboard) to the socket on the General

Purpose Transceiver Unit (GPT). The other end of each cable

is permanently fixed to the transducers. If only one sidescan

transducer is used, connect is as a p

and D on the GPT socket.

GPT transducer terminations

ort side unit to terminals C

Transducer cable

Port side

Transducer cable

Starboard side

W802-7

Rev.D

A

N

B

C

D

E

F

Junction Box (1:1)

(Optional)

Screen Connect to plug housing

Junction Box (1:1)

(Optional)

Screen Connect to plug housing

H

GPT Transducer

M

L

K

J

Dual frequency sidescan termination

socket

C

D

H

J

If you need to splice the transducer cable, it is very important to

use the correct cable, and to avoid ground loops. We strongly

recommend the use of a junction box. We also recommend that