Page 1

TILLERPILOT

TP10, TP20 & TP30

SERVICE MANUAL

Page 2

Issue 4.0 17/09/03 SIMRAD

2

Simrad Margate Ltd

Star Lane, Margate, Kent CT9 4NP,UK

Telephone +44 (0) 1843 290290

Facsimile +44 (0) 1843 290471

E-Mail : productsupportmargate@simrad.com

CONTENTS

1 INTRODUCTION

1.1 Electronic PCBs

1.2 Mechanical Components

2 OPERATION

3 ASSEMBLY INSTRUCTIONS

4 MECHANICAL ASSEMBLY DRAWINGS

5 CIRCUIT DESCRIPTIONS

6 CIRCUIT DIAGRAMS

6.1 Circuit Schematics

6.2 Component Lists and Layouts

7 PROGRAMMING AND CONFIGURATION

8 FAULT FINDING

8.1 Common User Faults

8.2 Common Technical Faults

9 SPARE PARTS DETAIL

9.1 Spares

9.2 Service Aids

9.3 Accessories

10 TECHNICAL NOTES

© 2003 Simrad Margate Ltd

The technical data, information and illustrations contained in this publication were to the best of our knowledge correct at the time of going to print. We

reserve the right to change specifications, equipment, installation and maintenance instructions without notice as part of our policy of continuous

development and improvement. No part of this publication may be reproduced, stored in a retrieval system or transmitted in any form, electronic or

otherwise without prior permission from Simrad Margate Ltd. No liability can be accepted for any inaccuracies or omissions in the publication, although

every care has been taken to make it as complete and accurate as possible.

Page 3

3

Tiller Pilot TP10, TP20 & TP30

Section 1

Introduction

Page 4

Issue 4.0 17/09/03 SIMRAD

4

1 INTRODUCTION TO THE TP10, TP20 AND TP30 TILLERPILOT

The TP10, TP20 and TP30 Tillerpilots combine highly sophisticated electronics with advanced

software and powerful mechanical drive to provide accurate and reliable steering performance

under a variety of different conditions with minimal current consumption.

TP10 – is suitable for tiller steered sailing yachts up to 10M (34 Ft) in length.

TP20 – offers the same facilities as the TP10 and is fully compatible with the Navico Corus

instrument system to provide a complete navigation system. Options offered include connection to

an external compass, wind sensor or navigational receiver together with additional remote control

facilities.

TP30 – offers the same facilities as the TP20 with an improved re-circulating ball screw drive and

is suitable for tiller steered sailing yachts up to 12.8M (42 Ft) in length.

The main components of the Tiller Pilot are listed below:

Electronics PCBs

Early versions

TP10 PCB (TP10 only)

TP30 PCB (TP 20 & TP30)

Current Versions. The same PCB is used for all products. The wiring

loom carrying the NMEA data is left disconnected in the TP10.

TP10 / 20 / 30 Re-engineered PCB (Common to all)

Mechanical Components

General Assy : TP10

General Assy : TP20

General Assy : TP30

Page 5

5

Tiller Pilot TP10, TP20 & TP30

Section 2

Operation

Page 6

Issue 4.0 17/09/03 SIMRAD

6

2 OPERATING SIMRAD

This Service Manual only contains operating instructions for those features of the Simrad Tiller

Pilot range that are not normally available to the end user. For details of normal operation please

refer to the appropriate Simrad Instruction Manual.

Page 7

7

Tiller Pilot TP10, TP20 & TP30

Section 3

Assembly Instructions

Page 8

Issue 4.0 24/09/03 SIMRAD

8

3 ASSEMBLY INSTRUCTIONS

General Assembly : TP10

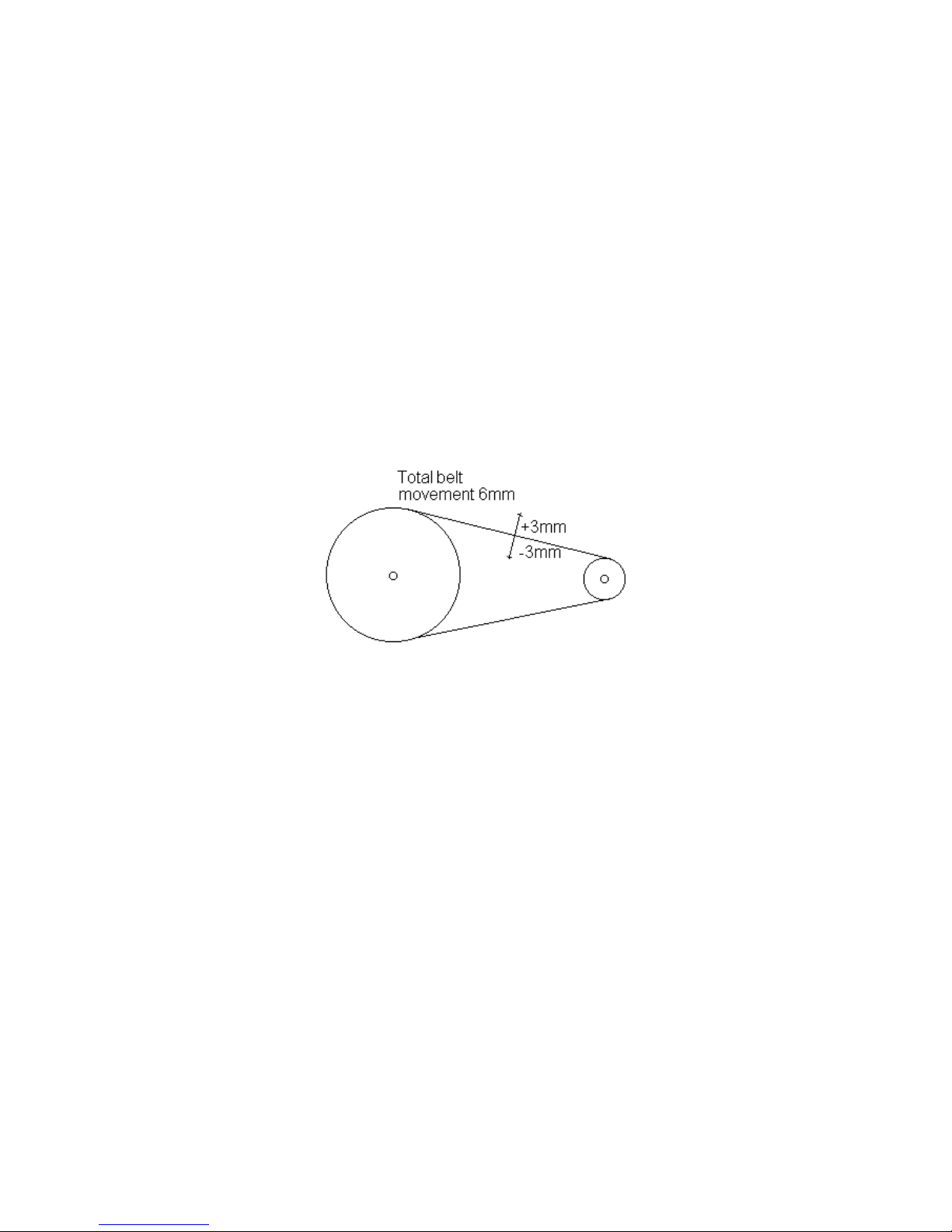

Motor and Drive Assembly. The Bottom Case Assembly is supplied fitted with appropriate

cables. Refer to detail in Drawing Number E03504 and insert the Push Rod Seal E00747, which

has a taper inner bore, into the case with the larger bore of the seal facing outwards. Fit “O” Ring

190026, spacer E02870 and End Cap E02495 and push home. Fit Retainer E03084 and secure

with 2 screws 200002 to hold the end cap, ensuring it is pushed fully in when the two screws are

tightened. Using a small brush, grease the ‘trough’ area and the bore which houses the seal, “O”

ring and spacer. Insert the Drive Assembly E03264 ensuring that the bearing slots into the bearing

housing and the drive belt 280027 is fitted around the pulley. Insert the Motor Assembly E02788

fitted with front and rear Motor Mounts E02502 and E02503 ensuring that the blue wire is

uppermost, the motor sits snugly into the bottom of the retaining slot and the drive belt is engaged

over the motor drive pulley. Check that the motor, belt and drive screw assembly move freely. Fit

Bearing Clamp E02497 on two Nylon Spacers 200115, one on each screw 200137, into the case

bottom and secure the bearing with the two screws. Refer to the sketch below and check that the

belt tension is within +/- 3mm.

Fit the Tiller Connector E02607 into the end of the Push Rod E02522 and screw in, finger tight.

Hall Effect PCB. Fit the Hall effect PCB onto the 2 pillars using 2 nylon washers 200037 as

spacers between the pillars and the PCB, and 2 screws 200139. Ensure that the separation

distance between the Magnets (E03208), seated in the 71 Tooth Pulley (E02505), and the Hall

Effect Devices (140010) does not exceed 1mm.

Main PCB. Feed the power, motor and feedback leads through the 2 grommets 190036 and the

appropriate grommet in the PCB Assembly cover and solder the connections to the PCB. Refer to

drawing and push PCB Assembly firmly onto the four bosses in the PCB Cover E02680. Clip the

compass Assembly E02637 into the Drilled PCB Cover E02680, it can only be fitted one way

round, ensuring that the lugs on the compass assembly line up with the 2 holes in the PCB cover

and push in. Refer to drawing E03504 and ensuring that the wires from the compass to the

connector lay over the PCB, insert plug into the socket on the PCB. Ensure all wires are clear of,

and not fouling the PCB cover seal, and position the PCB Cover complete with the PCB and

compass into the Case Top Assembly E02612. Screw down the PCB cover with 6 screws 200139

and fully tighten. Position the two grommets into case top, and push home into the two slots.

Wrap the ‘Wits” fixing 200196 around the cable loom, and using a screw 200139 fix into the top

cover.

Page 9

Issue 4.0 24/09/03 SIMRAD

9

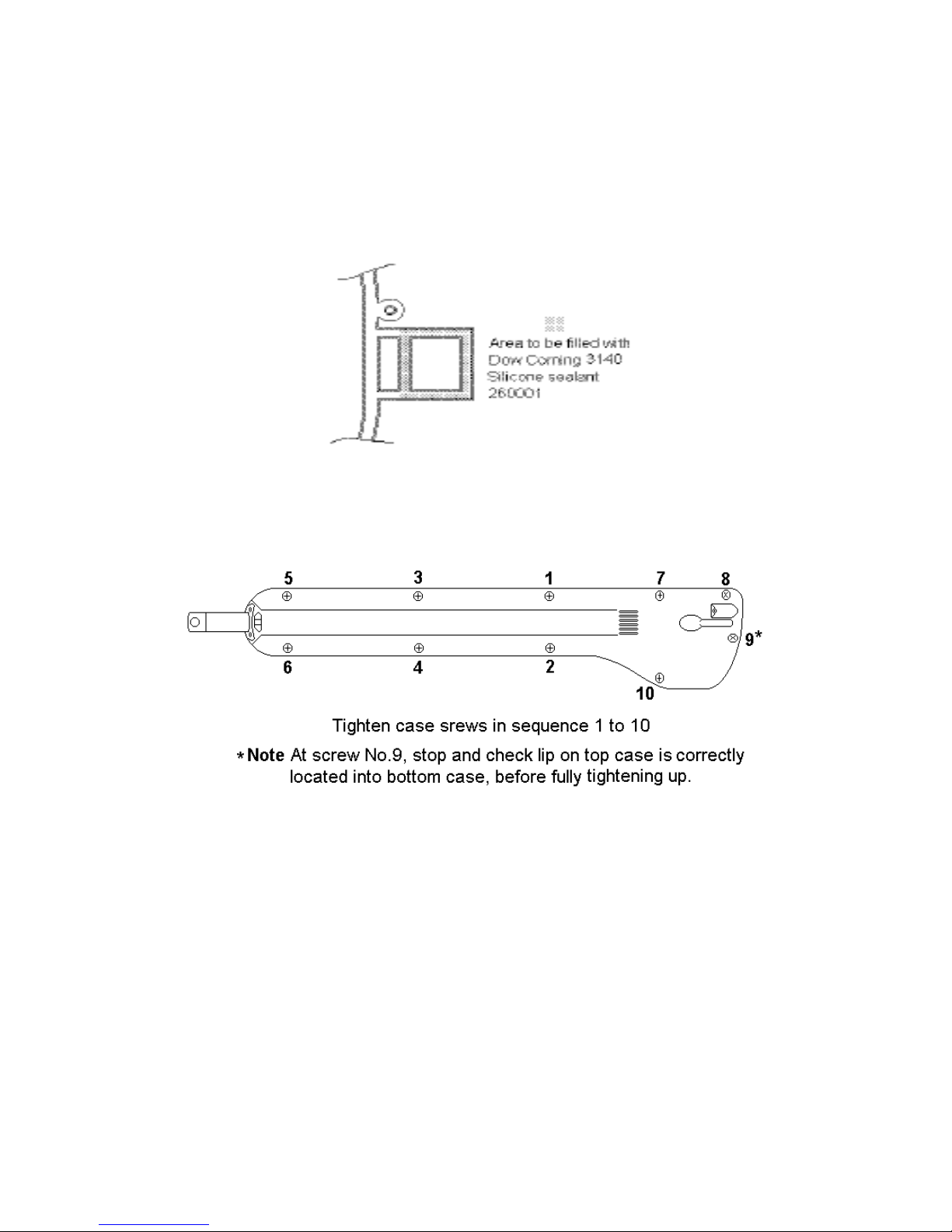

Main Seal. Fit the pivot pin into the square section at the rear of the prepared bottom case

ensuring that the pin hangs out of the case with the notch on the pivot facing towards the operating

rod of the tillerpilot. Fold the metal pin into its recess in the lower case. Position the Case Seal

E02498 onto the case bottom ensuring it is pushed fully into the grooved housing. Carefully lift the

case seal from around the area of the pivot pin and using a cotton bud apply Dow Corning 1205

Primer 260029 to the case. Fill a small hypodermic syringe with Dow Corning 3140 Silicone

sealant 260001 and run a small bead of sealant completely around the case seal in the area of the

square as shown below.

Refit the seal onto the case.

Final Assembly. Carefully position the case top onto the bottom ensuring that the case seal is

correctly located all round, squeeze the top and bottom halves of the case together, and fit the 10

screws 200088. Tighten down evenly all round in the sequence shown below:

Post Assembly Test. Remove the Tiller Connector E02607 and push the Tillerpilot Test Syringe

Part No. TP-SRY over the end of the Push Rod E02522. Depress the syringe piston and release,

the piston should return to its original position indicating that the integrity of the case seal has not

been compromised during fitting. Remove the Test Syringe and refit the Tiller Connector.

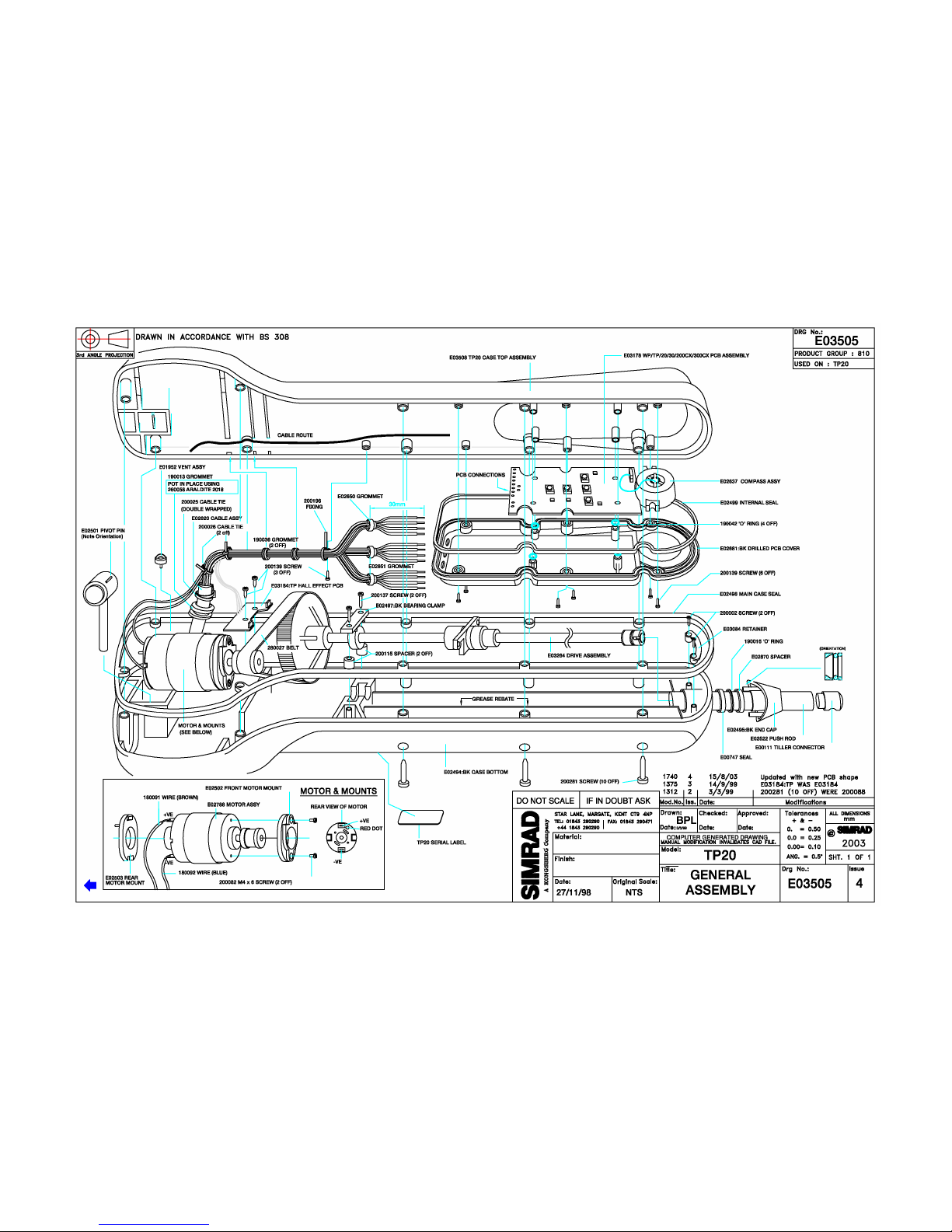

General Assembly : TP20

Refer to Drawing No. E03505. Assembly is identical to the TP10 with the following exceptions:

Case Bottom. The case bottom includes a third wiring (communications) loom to carry NMEA and

CANBUS data.

PCB Cover E02681. The PCB Cover is drilled with a third access point and grommet to accept

the NMEA and CANBUS data leads.

Page 10

Issue 4.0 17/09/03 SIMRAD

10

General Assembly : TP30

Refer to Drawing No. E03506. Assembly is identical to the TP20 with the following exception:

Drive Assembly E02618. The Drive Assembly employs a re-circulating ball screw. The assembly

is held in place by the metal mounting plate sitting in the mounting slots in both top and bottom

cases and drive belt tension is adjusted by the inclusion of spacing shims E02754 as required.

Page 11

11

Tiller Pilot TP10, TP20 & TP30

Section 4

Mechanical Assembly Drawings

Page 12

Issue 4.0 17/09/03 SIMRAD

12

4 MECHANICAL ASSEMBLY DRAWINGS

General Assembly : TP10 E03504

General Assembly : TP20 E03505

General Assembly : TP30 E03506

Page 13

13

Page 14

14

Page 15

15

Page 16

16

Tiller Pilot TP10, TP20 & TP30

Section 5

Circuit Descriptions

Page 17

Issue 4.0 17/09/03 SIMRAD

17

5 CIRCUIT DESCRIPTIONS

Tillerpilot Common PCB Assembly

Introduction. The PCB Assembly is a common item to all Wheelpilots and Tillerpilots. However,

when the PCB is used in the TP10 or WP10 those components concerned with NMEA and

CANBUS data are present but not in use, these components are highlighted in Red on the Circuit

Diagram Drawing No. E03372.

Supply and Regulation. The Tiller Pilots are designed to work from a 12 V source. Protection

against incorrect polarity is provided by D1 and D4. Capacitors C1and C3 are used as reservoirs

to hold up the supply voltage and reduce any supply dips. Protection against over-voltage spikes

is provided by Resistor R2 and Zener Diode ZD1 and Regulator REG1 provides a 5V regulated

supply. Transient Voltage Suppresser TVS1 protects the MOSFET drive transistors, TR10 to

TR13, from voltage spikes greater than +16V.

Microprocessor. Light Emitting Diodes LED1 to LED4 are driven from the microprocessor IC2

Ports P0.0 and P0.2 to P0.4 and turn OFF when the line goes HIGH via the transistor switches

TR2 to TR5. When the transistors are off, resistors R32, R34, R36 and R38 provide a low current

path for the LEDs to provide low level night illumination. The Audio Resonator AR1 is self

resonating and switches ON when Port P0.5 goes HIGH via the transistor switch TR1 and resistors

R59 and R60. The control key lines on Ports P4.0 to P4.4, normally pulled to +5V via resistors R7

to R11, are “scanned” by the microprocessor to detect if any of the switches have been operated

and pulled the line LOW.

NMEA Data In. NMEA data is optically isolated by IC5 and then fed into Port P2.4 of the

microprocessor. Transistors TR6, TR7 and TR8 and components D6, D7, D8, R17, R18 and R19

form a switch, protected from high voltages, driven from Port P0.1 of the microprocessor. The

switch is used to apply the synchronisation pulse (HR200_SYNC) to the NMEA line for products

employing a Hand (Remote) Controller.

CANBUS Data. CANBUS data in and out is driven by IC3 directly to and from Ports P2.1 and P2.0

respectively.

NB. Components shown in RED on the circuit diagram, Drawing No. E03372, are not in circuit

when the PCB is used with WP10 or TP10. The cable loom to connect them is absent from these

products.

Configuration Links. The Links, L1, L2 and L3, are used to configure the Microprocessor

to either Wheelpilot or Tillerpilot operation and to model versions 10, 20 or 30 in

accordance with the table below:

1 Model Link 1 Link 2 Link 3

TP 10 N / C N / C N / C

WP 10 N / O N /C N / C

TP 20 N / C N / C N / O

TP 30 N / C N / O N / O

WP 30 N / O N / O N / O

LEGEND N / C Normally Closed (soldered)

N / O Normally Open (unsoldered)

Page 18

Issue 4.0 17/09/03 SIMRAD

18

Microprocessor Reset. Integrated Circuit IC6 is an integrated reset generator for the

microprocessor which produces a reset LOW pulse of approximately 50mS duration at switch on

and whenever a 5v supply failure occurs. In addition to the reset provided by IC6, the

microprocessor has a built in watchdog timer which will create a reset if a software crash occurs for

any reason.

Non-Volatile Memory (NVM). Integrated Circuit IC3 provides 1Kbit of E

2

memory for the retention

of important data after power down.

Fluxgate (Compass). Two anti-phase signals are provided from microprocessor Ports P1.7 and

P1.6. These signals are buffered by TR15 and TR16 to provide a higher current drive to the

excitation coil of the fluxgate. A reference voltage level of +2 volts is provided by R46 and R53

decoupled by C53. The 2 coils, mounted at right angles, provide output signals proportional to the

sine and cosine of the Earth’s magnetic field. These signals are fed via the electronic switch IC9,

to 2 dual slope integrating analogue to digital converters IC7 and IC 8 plus associated

components. The outputs of the comparator IC7 are fed to the microprocessor Ports P1.4 and

P1.5 which provide input capture facilities. Accurate timing of the conversion is kept by the

microprocessor to provide simultaneous precision analogue to digital conversion of both sine and

cosine signals to avoid errors created by multiplexing the inputs.

Motor Drive. The motor drive signals (MDRIVE_A and MDRIVE_B) are generated from the

microprocessor at Ports P0.7 and P0.6, these lines being LOW when there is no drive and HIGH to

drive. The drive outputs control IC10 and IC11 which are comparators set at threshold levels of

+4V and +1V produced by the resistor network R71, R72 and R73. The comparators invert the

signals and provide the current to switch the MOSFETs in stages which prevents both P and N

channel MOSFETs on the same side of the “H-bridge” configuration, (i.e. TR10 and TR11 or TR12

and TR13), being partially switched on at the same time. When there is no drive, both N-channel

MOSFETs TR11 and TR13 are switched on giving a direct short across the motor to the 0V line

thus providing active braking

EMC. Capacitors with values of 100pF, 100nF and 1nF are extensively used to decouple noise

from switched data lines. Two A.C. coupled connections labelled “CHASSIS” , routed via

capacitors C63 and C64, were provided for interconnection to the internal metalwork for EMC

purposes. Tests have confirmed that connection is not required.

Hall Effect PCB.

Introduction. The Hall Effect PCB is a generic item which can be used for both Tillerpilots TP10,

TP20 and TP30 and Wheelpilots WP10 and WP30. For Tillerpilots, the Hall Effect devices are

mounted vertically into the PCB and horizontally for Wheelpilots. The circuit diagram for the Hall

Effect PCB is given in Drawing No. E03182.

Feedback. Two Hall Effect sensors HE1 and HE2 are mounted on the Hall Effect PCB and sense

the rotation of 2 small bar magnets mounted 180

0

apart in the pulley wheel. This produces a

quadrature feedback output, at logic levels, FB1 and FB2. The PCB is powered from the host unit

+5V regulated supply, the line being filtered by C1, and signals FB1 and FB2 are fed back to the

microprocessor via pull-up resistors on the host unit PCB.

Page 19

19

Tiller Pilot TP10, TP20 & TP30

Section 6

Circuit Diagrams

Page 20

Issue 4.0 17/09/03 SIMRAD

20

6 CIRCUIT DIAGRAMS

Circuit Schematics

Common PCB Circuit Diagram E03372

Hall Effect PCB Circuit Diagram E03182

Component Lists and Layouts

Common PCB Assembly Detail E03178

Hall Effect PCB Assembly Detail E03184

Early Version WP10 / TP10 Assembly Detail E03181

Early Version WP30 / TP20/30 Assembly Detail E03178 (Pre Iss. 6)

Page 21

21

Page 22

22

Page 23

23

Page 24

24

Page 25

25

Page 26

26

Page 27

27

Tiller Pilot TP10, TP20 & TP30

Section 7

Programming and Configuration

Page 28

Issue 4.0 19/09/03 SIMRAD

28

7 PROGRAMMING AND CONFIGURATION

This Service Manual only contains programming and configuration information for

those features of the autopilot which are not normally available to the end user. For

details of normal programming and configuration please refer to the appropriate user

manual.

Page 29

29

Tiller Pilot TP10, TP20 & TP30

Section 8

Fault Finding

Page 30

Issue 4.0 19/09/03 SIMRAD

30

8 FAULT FINDING

Common User Faults. Common user faults are included in the Diagnostics

Guide included in the user manual.

Common Technical Faults. None yet identified.

Page 31

31

Tiller Pilot TP10, TP20 & TP30

Section 9

Spare Parts Detail

Page 32

32

9 SPARE PARTS DETAIL

Spares Packs

TPPK1 TP10 / 20 MECHANICAL ASSEMBLY

TPPK2 TP10 TOP CASE

TPPK3 TP20/30 BOTTOM CASE

TPPK4 TP10 PCB CASE

TPPK5 WITHDRAWN

TPPK6 FLUXGATE ASSEMBLY

TPPK7 MOUNTING PIN, CUP AND CONNECTOR

TPPK8 MOTOR ASSEMBLY

TPPK9 FEEDBACK KIT

TPPK10 DRIVE BELT

TPPK11 CASE SCREW PACK

TPPK12 PUSH ROD SEAL PACK

TPPK13 CASE SEAL PACK

TPPK14 TP100 TOP CASE

TPPK15 GREY BOTTOM CASE

TPPK16 TP20 TOP CASE

TPPK1 7 TP20/30 PCB CASE

TPPK18 WITHDRAWN

TPPK19 WITHDRAWN

TPPK20 TP30 TOP CASE

TPPK21 COMMON PCB ASSEMBLY

TPPK22 TP30 MECHANICAL ASSEMBLY

TPPK23 TP300CX TOP CASE

TPPK24 TP200CX TOP CASE

TPPK25 TP10 BOTTOM CASE

9.2 Accessories

TB30 TILLER BRACKET 30mm

TB60 TILLER BRACKET 60mm

TB90 TILLER BRACKET 90mm

TB120 TILLER BRACKET 120mm

PB30 PEDESTAL BRACKET 30mm

PB60 PEDESTAL BRACKET 60mm

PB90 PEDESTAL BRACKET 90mm

CB1 CANTILEVER BRACKET

PRE30 PUSH ROD EXTENSION 30mm

PRE60 PUSH ROD EXTENSION 60mm

PRE90 PUSH ROD EXTENSION 90mm

PRE120 PUSH ROD EXTENSION 120mm

PRE150 PUSH ROD EXTENSION 150mm

PRE300 PUSH ROD EXTENSION 300mm

9.3 Service Aids

TP-SRY TILLERPILOT TEST SYRINGE

Page 33

33

Tiller Pilot TP10, TP20 & TP30

Section 10

Technical Notes

Page 34

Issue 4.0 19/09/03 SIMRAD

34

10 TECHNICAL NOTES

PS 139 Identification of Tillerpilot variants

PS 140 Improved bonding of drive pulley to motor drive shaft

PS 173 Positioning of Feedback PCB

PS 174 Re-engineered Main PCB

Page 35

Issue 4.0 19/09/03 SIMRAD

35

Technical Note

FOR THE ATTENTION OF THE SERVICE MANAGER

NUMBER : PS 139

PRODUCT : Tillerpilot – TP100 / TP200CX /

TP300C / TP300CX / TP10 / TP20 /

TP30

SUBJECT : Identification of Variants

DATE : 1 October 1999

There are a number of variants of Tillerpilots currently in use which, though

similar in appearance, are built and operate differently. Positive identification is

therefore essential when ordering spare parts to ensure that the correct item is

dispatched.

The main aids to identification are:

1. Lack of a Hall Effect PCB indicates Back emf, earliest, version.

2. Hall Effect PCB with microprocessor mounted in socket indicates

intermediate version.

3. Hall Effect PCB with surface mount microprocessor indicates

latest version.

A table of variants identified by serial number and drawings, General Assembly,

PCB Assembly and Circuit Diagram, to aid identification of the different PCBs, is

given below:

Page 36

Issue 4.0 19/09/03 SIMRAD

36

TILLERPILOT VARIANTS. The Tillerpilot variants can be conveniently divided into 3 groups:

1. Feedback produced from the motor back emf.

2. Feedback produced from a Hall Effect PCB.

3. Introduction of Surface Mount microprocessor (SMu)

TP100

Back emf

TP200CX

Back emf

TP300C

Back emf

TP300CX

Back emf

TP100

Hall Effect

TP200CX

Hall Effect

TP300CX

Hall Effect

TP200CX

SM u

TP300CX

SM u

u No. E02517 E02520 E02520 E02520 E03190 E03189 E03189 E03398 E03398

Man from Start Start Start MK3143 PE8818 PB1484 OD6415 Not Yet In Production

Ser

No. to PE8818 PB1483 MI2954 OD6414 Continue Continue Continue

Gen Assy E02587 Not Issued E02616 E02616 E03299 E03262 E03300

PCB Assy E02515 E02518 E02518 E02518 E03181 E03178 E03178

Cct Diag E02549 E02550 E02550 E02550 E03179 E03176 E03176

TP10

SM u

TP20

SM u

TP30

SM u

u No. E03398 E03398 E03398

Man from OL7635 OL1384 OL7190

Ser

No. to Continue Continue Continue

Gen Assy E03504 E03505 E03506

PCB Assy E03181 E03178 E03178

Cct Diag E03371 E03372 E03372

Page 37

Issue 4.0 19/09/03 SIMRAD

37

Technical Note

FOR THE ATTENTION OF THE SERVICE MANAGER

NUMBER : PS 140

PRODUCT : Tillerpilot – TP100 / TP200CX /

TP300C / TP300CX / TP10 / TP20 /

TP30

SUBJECT : Improved bonding of drive pulley

to motor drive shaft.

DATE : 1 October 1999

The 20 Toothed Pulley Part No. E02839 is a push fit onto the motor drive shaft,

see sketch below, and the bonding is enhanced with Loctite 270 Part No.

260025. Instances have occurred where the bonding has weakened resulting in

reduced drive efficiency or operational failure. An improved bonding adhesive

Loctite 638 Part No. 260063 has been identified and approved for use. All

Tillerpilot repairs should be carried out using the new adhesive.

The new bonding agent has been used in the manufacture of all Tillerpilots with

the alphabetic prefix PC, 1 March 1999, and subsequent serial numbers. The

Product Support Department should be informed of any units found to be

slipping post production date 1 March 1999.

Page 38

Issue 4.0 19/09/03 SIMRAD

38

Page 39

Issue 4.0 19/09/03 SIMRAD

39

Page 40

Issue 4.0 19/09/03 SIMRAD

40

Page 41

Issue 4.0 19/09/03 SIMRAD

41

Page 42

Issue 4.0 19/09/03 SIMRAD

42

Page 43

Issue 4.0 19/09/03 SIMRAD

43

Page 44

Issue 4.0 22/09/03 SIMRAD

44

Loading...

Loading...