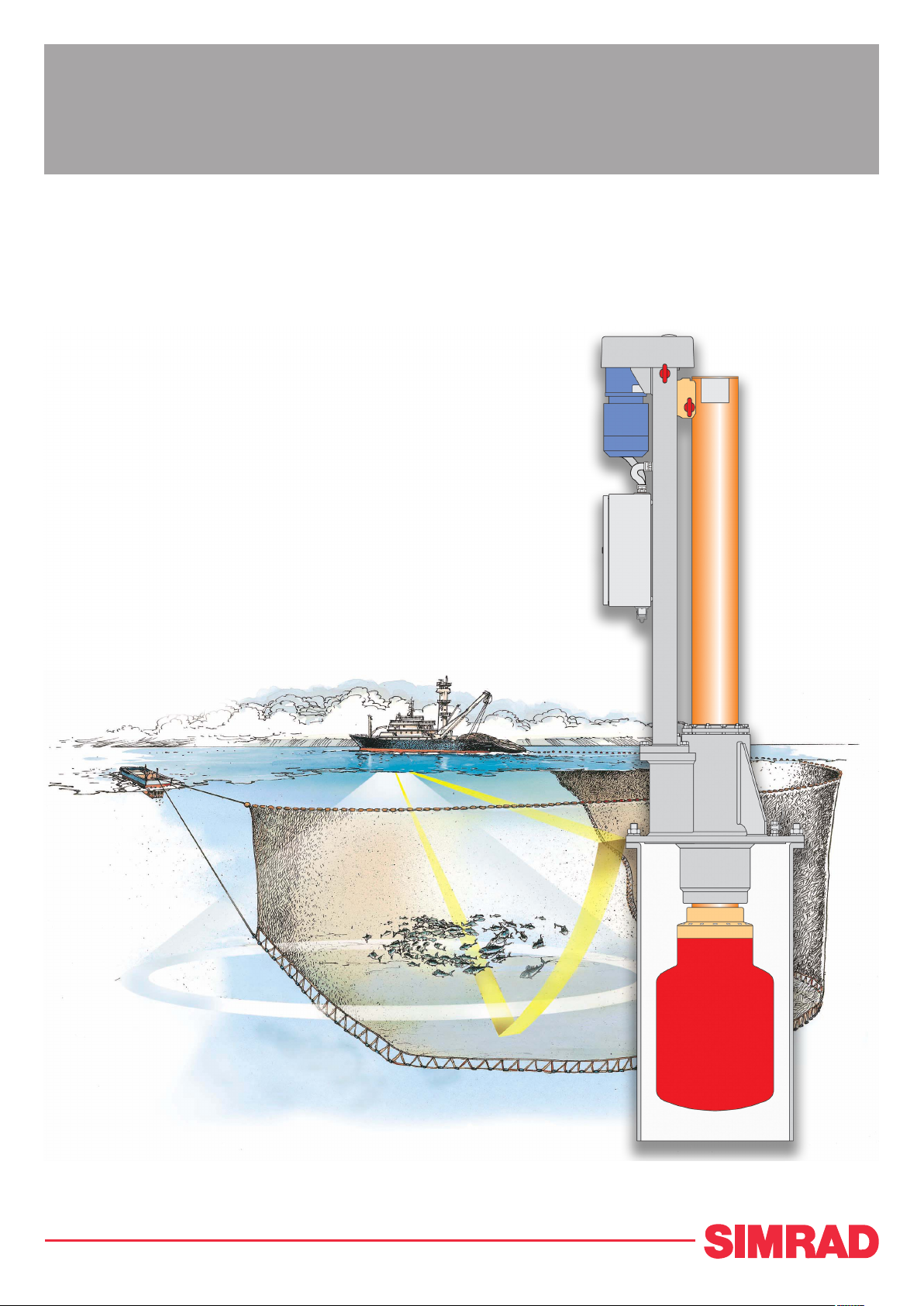

Page 1

Installation manual

TECHNOLOGY FOR SUSTAINABLE FISHERIES

www.simrad.com

Simrad SX95

Hull unit

Page 2

Page 3

Simrad SX95

Installation manual

This document provides the necessary information of how

to install the Simrad SX95 Hull Unit.

For the remaining sonar installation and setup procedures,

refer to the Simrad SX90 Installation manual.

The information provided in this manual must be regarded

as general guidelines and recommendations. The installation

shipyard must design and manufacture installat

to fit the Simrad SX95 Hull Unit on each individual vessel.

ion hardware

319568/B

14 May 2008

Page 4

Document history

Document number: 319568

Rev.A

Rev.B

18 April 2008 First version.

14 May 2008

Information added to drawing 322202. See SX95 Mounting trunk

outline dimensions on page 56.

Copyright

©2008 Kongsberg Maritim e AS

The information co ntained in this document remains the sole property of Kongsberg Maritime AS. No part

of this document may be copied or reproduced in any form or by any means, and the information contained

within it is not to be communicated to a third party, without the prio r written consent of Kongsberg

Maritime AS. The document, or any part of it, may not be translated to any other language without the

written approval from Kongsberg Maritime AS.

Disclaimer

Kongsberg Maritime AS endeavours to ensure tha t all information in this document is correct and fairly

stated, but does not accept liability for any errors or omissions.

Warning

The equipment to which this manual applies must only be used for the purpose for which it

designed. Improper use or maintenance may cause d am age tothe equipment and/or injury to personnel.

The user must be familiar with the contents of the appropriate manuals before attempting to install,

operate or work on the equipment.

Kongsberg Maritime AS disclaims any responsibility for damage or injury caused by improper

installation, use or maintenance of the equipment.

was

Support

If you require maintenance on your Sim rad SX95 Hull Unit, contact your local dealer. You can also contact

us using the following address: s

products, visit w

Simrad

Kongsberg Maritime AS

Strandpromenaden 50

P. O. Bo x 1 1 1

N-3191 Horten, Norway

ww.simrad.com.Onourwebsiteyouwillalsofind a list of our dealers and distributors.

imrad.support@simrad.com.I

Telephone:+4733034000

Telefax:+4733042987

www.simrad.com

simrad.sales@simrad.com

f you need information about our other

Page 5

Installation manual

Table of contents

ABOUT THIS MANUAL ....................................................... 7

SIMRAD SX95 HULL UNIT ................................................. 9

Hull unit familiarization .........................................................................................10

Hull unit main parts................................................................................................ 11

Hull unit models overview ..................................................................................... 12

Technical specifications.......................................................................................... 13

Power specifications.................................................................................... 13

Weights and dimensions, hull unit ................................................................ 13

Weights and dimensions, mounting trunk ..................................................... 13

Environmental specifications....................................................................... 14

INSTALLATION PLANNING.............................................. 15

Location of the hull unit ......................................................................................... 16

Sonar room requirements ....................................................................................... 17

Sonar room physical properties.................................................................... 17

Sonar room environmental requirements ...................................................... 18

Sonar room electrical requirements.............................................................. 19

Sonar room special requirements ................................................................. 19

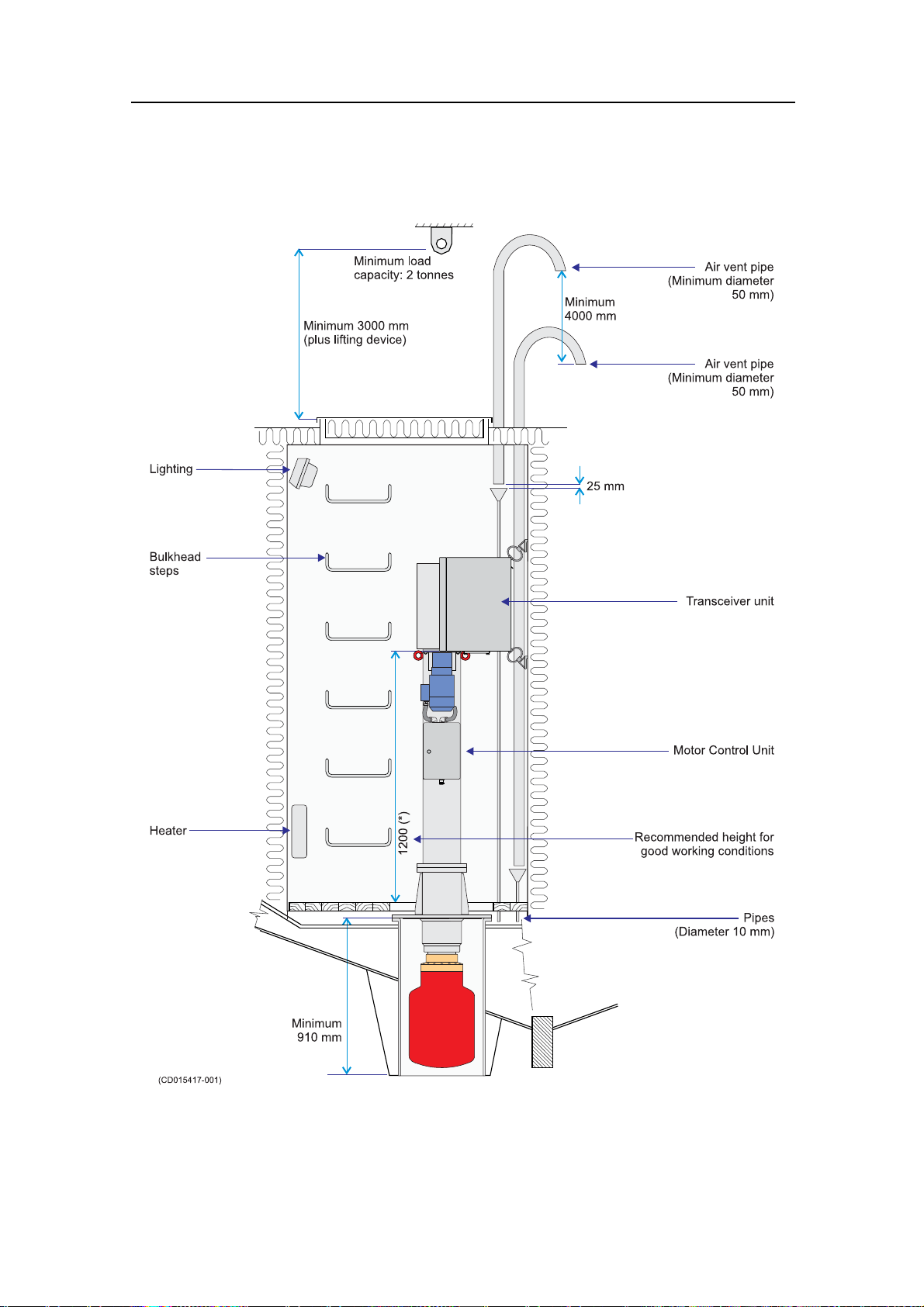

Sonar room arrangement example.......................................................................... 20

SONAR TRUNK INSTALLATION........................................ 22

Mounting the sonar trunk ....................................................................................... 23

Sonar trunk protection ............................................................................................ 24

Sonar trunk installation principles.......................................................................... 24

Sonar trunk installation measurements...................................................................27

HULL UNIT INSTALLATION ............................................. 28

How to unpack the hull unit from its transport box ............................................... 29

Hull unit mounting ................................................................................................. 30

Bleeding air cock.................................................................................................... 31

Mechanical support ................................................................................................ 32

Transducer alignment ............................................................................................. 32

Hull unit installation check list...............................................................................33

CABLE LAYOUT AND INSTALLATION ............................... 34

Cable plan............................................................................................................... 35

Cabling principles...................................................................................................36

Cable procedures ....................................................................................................37

AC mains to Motor Control Unit (C06) ........................................................ 38

Transceiver Unit to Motor Control Unit (C32) .............................................. 39

Transducer cable (C35) ............................................................................... 40

319568/B 3

Page 6

Simrad SX95

START-UP PROCEDURES ................................................. 41

Starting up the Hull Unit ........................................................................................41

Hull unit familiarization .............................................................................. 42

Motor Control Unit familiarization............................................................... 43

Functional check......................................................................................... 44

Apply 3-phase AC power ............................................................................ 45

Check hoist motor’s 3–phase AC connections............................................... 46

Check the 3–phase connection for correct rotation direction........................... 47

Check the contactor operation...................................................................... 48

Functional check with hoist and lower operations ......................................... 49

Alignment and offset adjustments.......................................................................... 51

Alignment of the sonar picture..................................................................... 51

Adjusting the stabilisation sensor offset........................................................ 52

DRAWING FILE ............................................................... 54

SX95 Hull unit outline dimensions ........................................................................ 55

SX95 Mounting trunk outline dimensions .............................................................56

SX95 Mounting trunk production ..........................................................................57

Blind cover for sonar trunk ....................................................................................58

A CABLE DETAILS............................................................... 59

Detailed list of cables ............................................................................................. 59

SX90/C06 AC mains to Motor Control Unit ................................................. 59

SX90/C32 Transceiver to Motor Control ethernet.......................................... 59

SX90/C35 Transducer cable ........................................................................ 59

Cable specifications................................................................................................60

AC mains cable to Motor Control Unit......................................................... 61

Ethernet cable with RJ45, “straight”............................................................. 62

Cable connections...................................................................................................63

Motor Control Unit connections................................................................... 64

Transceiver Unit connections....................................................................... 65

B BASIC CABLE REQUIREMENTS ........................................ 66

Cable trays..............................................................................................................66

Radio Frequency interference ................................................................................67

Physical protection ................................................................................................. 67

Grounding............................................................................................................... 67

Cable connections...................................................................................................68

Cable terminations.................................................................................................. 68

Cable identification.................................................................................................68

C E QUIPMENT HANDLING .................................................. 69

Transportation.........................................................................................................69

Lifting..................................................................................................................... 69

Storage prior to installation or use ......................................................................... 70

4

319568/B

Page 7

Installation manual

Inspection ............................................................................................................... 71

Unpacking ..............................................................................................................72

General unpacking procedure ...................................................................... 72

Unpacking electronic and electromechanical units ........................................ 72

Unpacking mechanical units ........................................................................ 73

Unpacking transducers ................................................................................ 73

Storage after unpacking.......................................................................................... 73

Storage after use ..................................................................................................... 74

Cleaning cabinets........................................................................................ 74

Mechanical units......................................................................................... 74

Cables........................................................................................................ 75

Internal batteries ......................................................................................... 75

Dehumidifier .............................................................................................. 76

Coatings..................................................................................................... 76

Re-packaging.......................................................................................................... 76

Temperature protection........................................................................................... 76

Circuit board handling and packaging....................................................................77

Beware of ESD!.......................................................................................... 77

Unpacking and handling circuit boards......................................................... 77

Unpacking on board .................................................................................... 77

Returning a circuit board............................................................................. 78

What is ESD? ......................................................................................................... 78

319568/B 5

Page 8

Simrad SX95

6 319568/B

Page 9

ABOUT THIS MANUAL

Purpose

The purpose of this manual i s to provide the information and

procedures required for installation of the Simrad SX95 Hull unit.

Note

This manual only describes the installation of the hull unit. For

the remaining sonar installation and setup procedures, refer to

the Simrad SX90 Installation manual.

About these instructions

The manual is intended for technical personnel, engineers and

naval architects. It is assumed that the personnel is conversant

with the general principles of sonar installation and operation.

These instructions must be followed carefully to ensure optimal

sonar performance. As a guide, installation procedures are

presented in the order they are to be performed. Successful

completion of each procedure is to be confirmed by checking

off the corresponding box. After installation, this document

should be stored on board the vessel for later reference when

updating or servicing the equipment. The manual also defines the

equipment responsibility, and provides instructions for unpacking

and storage.

About this manual

Installation drawings

Detailed vessel specific mechanical drawings for the installation

must be provided by the customer, or any shipyard contracted to

perform the installation. Simrad may, on special order, provide

assistance to these drawings. Drawings must be approved by

the appropriate vessel certification authority prior to installation

of the system.

Note

The installation instructions given in this document must be

adhered to. Failure to do so may render the guarantee void.

Kongsberg Maritime AS will accept no responsibility for any

damage or injury to the system, vessel or personnel caused by

equipment that has been incorrectly installed or maintained,

or by drawings, instructions or procedures that have not been

prepared by us.

319568/B 7

Page 10

Simrad SX95

References

Refer to the following manuals for additional information

about the Simrad SX90 sonar system. Order numbers in

brackets. All documents can be downloaded from our web site

h

ttp://www.simrad.com.

• SX90 Installation Manual [307531]

• SX90 Operator Manual [307672]

• SX90 Reference Manual [307670]

8

319568/B

Page 11

SIMRAD SX95 HULL UNIT

This chapter offers an introduction to the main parts and technical

specifications of the Simrad SX95 hull unit.

Topics

• Hull unit familiarization on page 10

• Hull unit main parts on page 11

• Hull unit models overview on page 12

• Technical specifications on page 13

Simrad SX95 Hull Unit

319568/B 9

Page 12

Simrad SX95

Hull unit familiarization

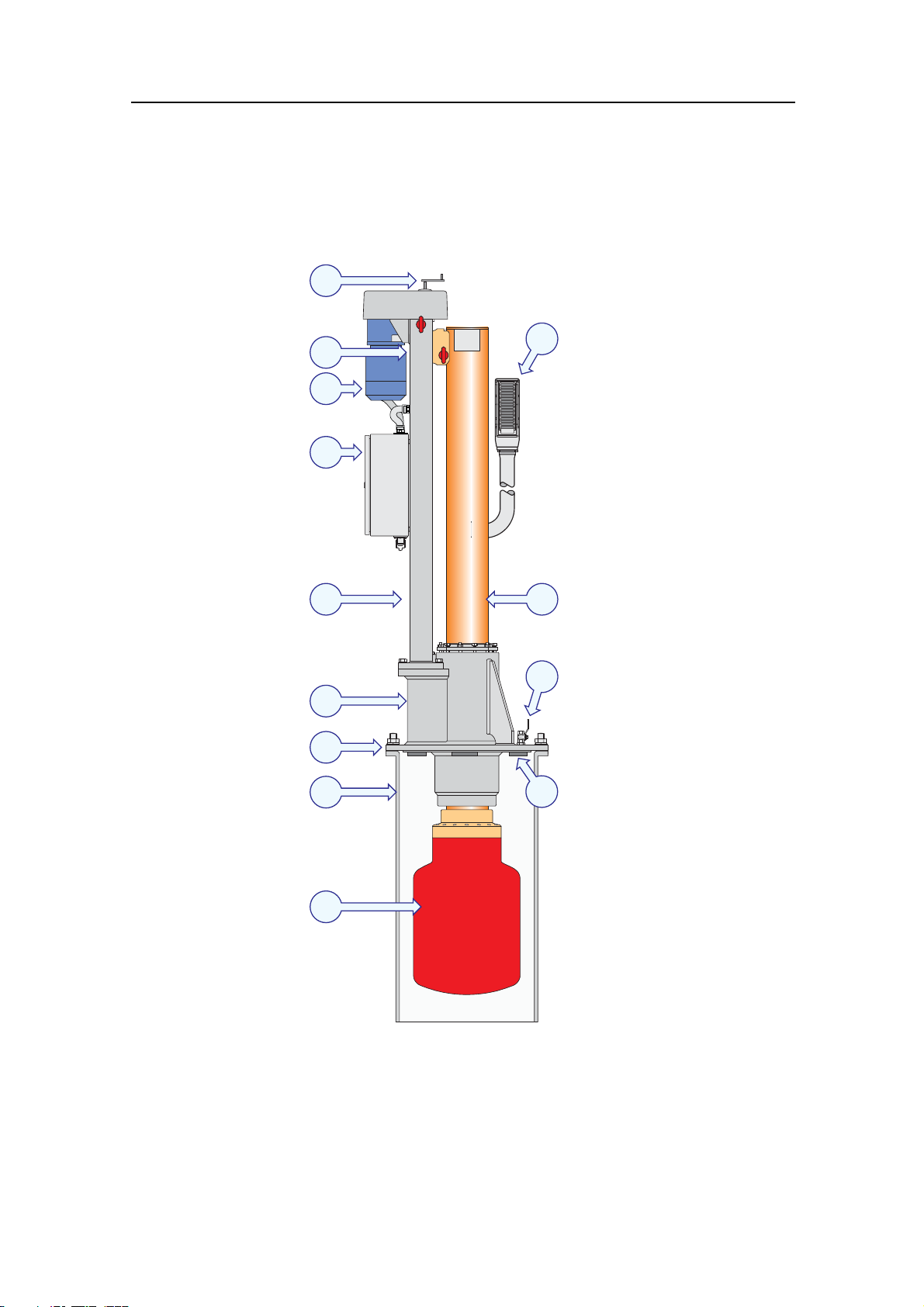

Figure 1 Hull unit familiarization

A

B

C

D

E

F

G

H

J

K

(A) Hand crank

L

(B) Identification label

(C) Hoisting motor

(D) Motor Control Unit

(E) Hoisting unit

M

(F) Transducer shaft sleeve

10

(G) Mounting flange

(H) Mounting trunk

(I) Transducer

I

(J) Transducer cable

(K) Transducer shaft

(L) Air bleeding cock

(CD015414-003)

(M) Zinc anodes

319568/B

Page 13

Hull unit main parts

The hull unit is l ocated in the sonar room, close to the transceiver.

It is mounted on a mounting trunk, which accommodates the

transducer when the sonar is switched off. As the transducer

shaft penetrates the ship’s hull, it is required that all personnel

handling installation and service are familiar with the hull unit’s

main parts and operational principles.

Simrad SX95 Hull Unit

A The

hand crank is used for manual hoisting and lowering

of the transducer shaft. When not in use, the hand crank is

stored inside the Motor Control Unit.

B The

identification label provides the hull unit’s name, as well

as its registration- and serial numbers.

C The

hoisting motor is used to lower and hoist the transducer

shaft. In order to rotate in both directions, the motor is

powered by a 3-phase voltage. The motor is controlled by

the Motor Control Unit.

D The

Motor Control Unit controls the hoisting motor. It also

contains the sensor required for sonar beam stabilization.

E The

hoisting unit performs the hoisting and lowering of the

transducer by converting the rotary motion from the motor

to a vertical linear motion for the transducer shaft.

F The

transducer shaft sleeve supports the transducer shaft

and ensures that the assembly is water tight. The area

between the upper and lower bearings is also used as a

grease reservoir for the lubrication of the bearings and for

additional water tightening.

G The

mounting flange provides mechanical fastening of the

hull unit to the mounting trunk. A gasket is used to make the

assembly watertight.

319568/B

H The

mounting trunk accommodates the transducer when the

transducer is retracted.

Note

The trunk is not included in the standard delivery of the

sonar, but can be ordered as an option.

I The transducer has a cylindrical shape. It contains 256

separate wide-band transducer elements.

J The

transducer cable contains two wires for each transducer

element. All are housed in a flexible hose which ends up in

a plug unit for connection to the Transceiver Unit.

K The

transducer shaft penetrates the shaft sleeve, and allows

the transducer to be lowered and hoisted. The transducer is

connected to the lower end of the transducer shaft using a

special plug.

11

Page 14

Simrad SX95

L The air bleeding cock is provided to avoid air inside the trunk.

We recommend that a pipe is connected to this cock with

continuous rise to the main deck or through the vessel side.

M A number of

zinc anodes are mounted below the mounting

flange to prevent corrosion on the transducer shaft.

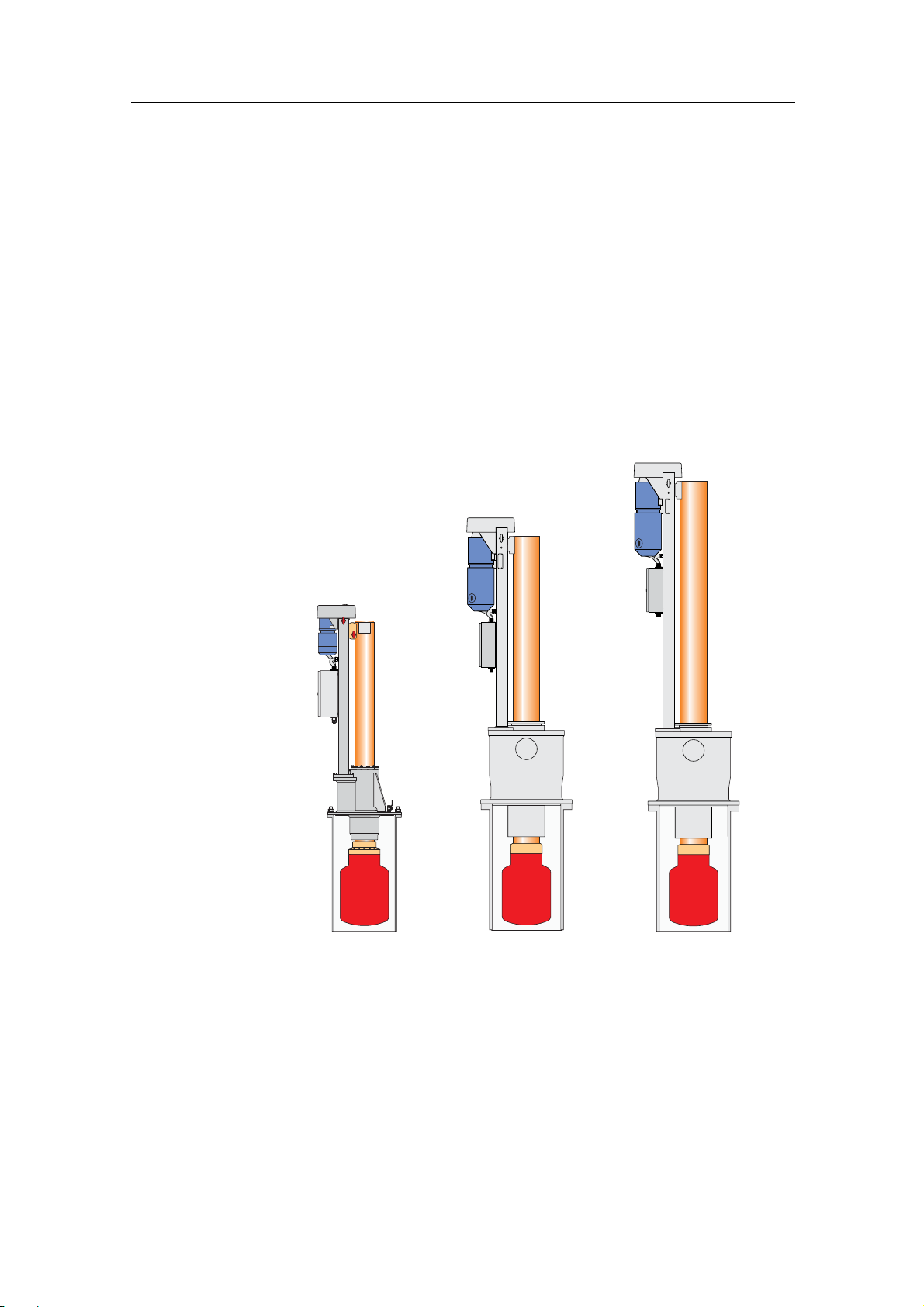

Hull unit models overview

The Simrad SX90 sonar may be delivered with any one of several

different hull unit models.

Figure 2 SX90 Hull unit models

(CD015401-001)

12

SX90

SX92SX95

SX91

SX93

• SX90: This hull unit has 1.2 m stroke length, and it is designed

for maximum speed 24 knots. It will fit on a standard Simrad

trunk with 620 mm pitch centre diameter (PCD).

• SX91: This hull unit has 1.6 m stroke length, and it is designed

for maximum speed 20 knots. It will fit on a standard Simrad

trunk with 620 mm pitch centre diameter (PCD).

• SX92: This is the "standard" hull unit for the SX90 sonar. It

has 1.2 m stroke length, and it is designed for maximum speed

24 knots. It will fit on a standard Simrad trunk with 680 mm

pitch centre diameter.

319568/B

Page 15

• SX93: This hull unit has 1.6 m stroke length, and it is designed

for maximum speed 20 knots. It will fit on a standard Simrad

trunk with 680 mm pitch centre diameter.

• SX95: This hull unit has 1.0 m stroke length, and it is designed

for maximum speed 12 knots. It will fit on a standard Simrad

trunk with 540 mm pitch centre diameter.

Technical specifications

This section provides the basic technical specifications for the

Simrad SX95 Hull Unit.

Note

We are engaged in continuous development of our products and

reserves the right to alter specifications without prior notice.

Simrad SX95 Hull Unit

Power specifications

• Voltage:

– Nominal: 230 / 380 / 440 Vac, 3-phase (selectable)

– Deviation, 230 Vac: 15 % of nominal voltage

– Deviation, 380/440 Vac: 340 to 485 Vac

– Tra n sient: 20 % of nominal voltage, recover time 3 s

• Power consumption: 1100 VA

• Frequency:47to63Hz

Weights and dimensions, hull unit

• Weight: Approximately 500 kg

• Dimensions:

– SX95 Hull unit outline dimensions on page 55

Weights and dimensions, mounting trunk

• Weight: Approximately 68 kg

• Height: 990 mm

• Flange diameter: 580 mm

• Trunk diameter: 508 mm

• Drawing:

– SX95 Mounting trunk outline dimensions on page 56

– SX95 Mounting trunk production on page 57

– Blind cover for sonar trunk on page 58

319568/B 13

Page 16

Simrad SX95

Environmental specifications

• Operational temperature: 0 to +40°C

• Storage temperature: -40 to +70°C

• Humidity: 5 to 95% non-condensing

14

319568/B

Page 17

INSTALLATION PLANNING

Note

For installation in a previously installed trunk system, first read

the information about sonar room requirements. Then proceed

to the Hull Unit installation description.

This chapter provides the marine engineers responsible the

information necessary to plan and install the sonar’s hull unit

according to Simrad’s requirements. Correct installation of the

sonar transducer is vital to the system’s performance. Several

variables must be taken into consideration, the most important

of which is the vessel’s construction. This guide is for use in

selecting the best location for the transducer and includes a brief

description of areas to be avoided.

Note

Installation planning

All installation drawings must be supplied by the shipyard. The

installation must beapproved by the vessel’s national registry and

corresponding maritime authority and/or classification society.

The shipowner and shipyard performing the installation are

responsible for obtaining and paying for installation approval.

Simrad offers free advice for installation planning. Proposed

arrangements may be sent for commentary or suggestions

supplied by Simrad. The following drawings should be submitted

should assistance be requested:

• General arrangement

• Body plan and drawings of relevant bottom tanks and

cofferdams

• Lines plan

Topics

• Location of the hull unit on page 16

• Sonar room requirements on page 17

• Sonar room arrangement example on page 20

319568/B 15

Page 18

Simrad SX95

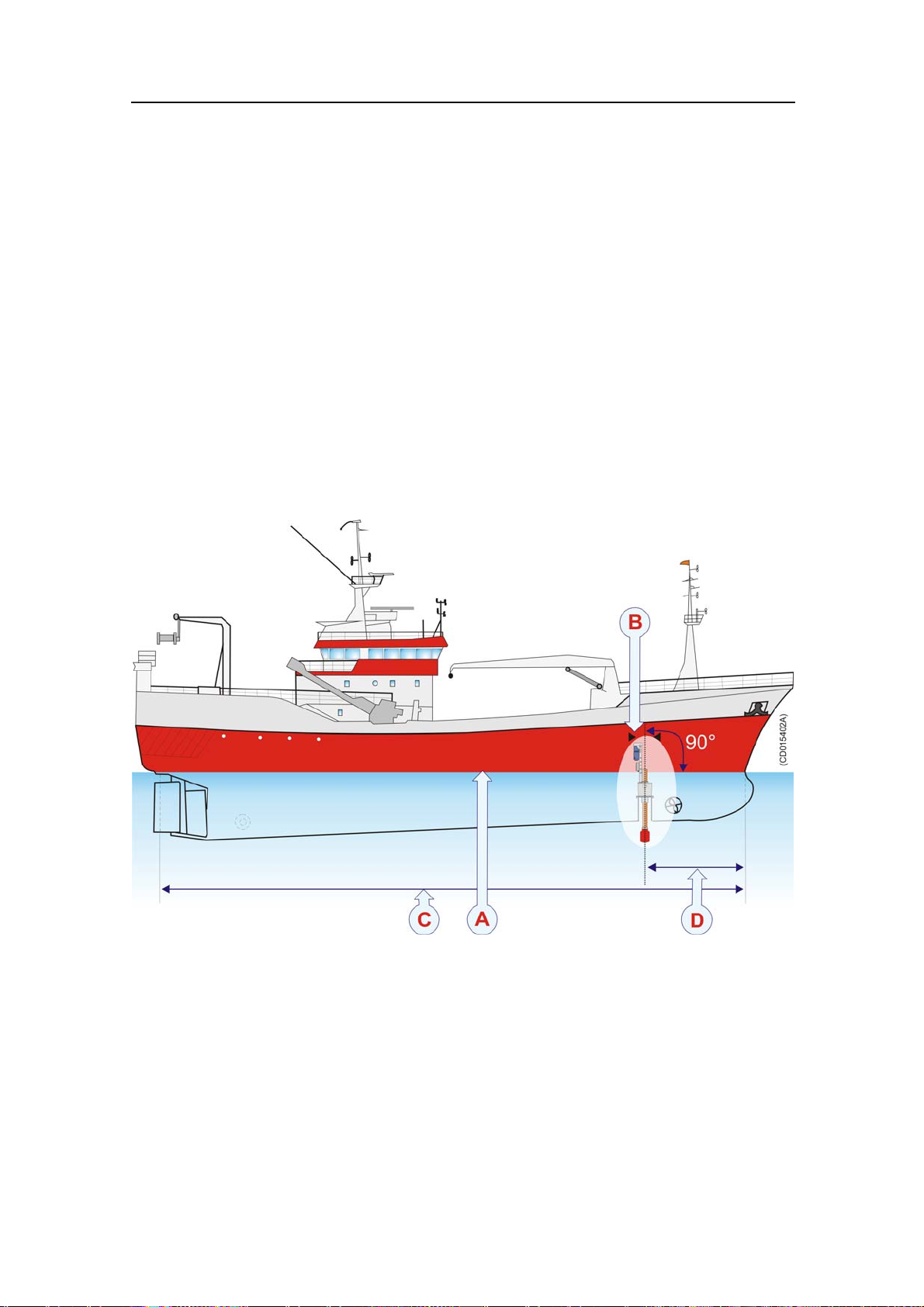

Location of the hull unit

Fore and aft

The hull unit should preferably be located within 1/3 to 1/10

of the vessel’s Length Between Perpendiculars (LBP) from its

Forward Perpendicular (FP). Deviations should not be made

without consulting Simrad.

Athwartships

The hull unit may be located on the Centre Line (CL) of the

vessel, or alongside its keel. If the installation is offset from the

vessel’s centre line, make sure that transducer transmission and

reception will not be obstructed by the keel.

Figure 3 Location of the hull unit

16

A Water level at normal trim

B Welding marks to indicate hull unit location when docking

C Length Between Perpendiculars (LBP)

D 1/3to1/10ofLBP

Important considerations related to noise

The installation trunk must be installed so that it will remain

vertical under normal operating c onditions. The primary sources

of underwater disturbance (other than a vessel’s main propeller

and bow/stern thruster) that affect transducer reception are:

319568/B

Page 19

• Main or bilge keels

• Zinc anodes

• Cooling elements protruding from the hull

• Equipment such as sonar transducers and pilot tubes

• Sea chests

• Overboard discharges

• Dents in the hull

All appendages to the hull, indentations and pipe in/outlets are

potential sources of underwater noise. They may act as resonant

cavities amplifying noise at certain frequencies, create cavitation

or turbulence. Transducers should not be located in the vicinity

of such objects and especially not immediately aft of them.

Sonar room requirements

Installation planning

It is strongly recommended to use a dedicated compartment to

house the hull unit and sonar transceiver unit. These two units

must also be installed relatively close to each other due to the

limited length of the transducer cables. Observe these minimum

sonar room requirements to obtain suitable working conditions

for sonar installation, use and maintenance.

Sonar room physical properties

The following physical properties must be taken into

consideration when the sonar room is planned:

•Size

• Access hatches

•Lifting

•Deck

Size

The sonar room must be dimensioned to house both the hull

unit and the transceiver unit. This is due to the limited length

of the flexible hose protected cabling (approximately 3.5 m)

connecting these two units. A well designed sonar room reduces

the risk of corrosion and simplifies maintenance increasing

system reliability. The sonar room should not be unnecessarily

obstructed by girders, pipes etc. which might cause installation

problems or impede maintenance.

Access hatches

The sonar room must be accessible under all conditions at sea or

at a berth. All doors or hatches should be designed so that the

equipment can be removed without being disassembled.

319568/B 17

Page 20

Simrad SX95

Lifting device

An attachment point, rated at a minimum of two -2- tons, for

supporting a lifting device should be located above the hull unit.

This permanently installed fixture will facilitate installation

trunk and hull unit mounting, and also may be used for future

equipment maintenance or replacement.

Deck

Once the installation has been completed, the sonar room should

be suitably decked without restricting access to the equipment.

Sonar room environmental requirements

The following environmental properties must be taken into

consideration when the sonar room is planned:

•Heating

• Insulation

• Ventilation

Heating

The sonar room should be equipped with heater, dimensioned to

maintain the equipment within its environmental tolerances (at

least 1000 W), installed close to the deck. Heating is also an

effective method for reducing humidity.

Insulation

Bulkheads must be insulated and provided with an interior wall

to the deck. The insulation should be the minimum equivalent

of 50 mm of rock-wool. In addition, piping passing through the

space prone to condensation must be insulated.

Ventilation

The sonar room should be connected to the vessel’s ventilation

system. If this is not possible, two 3-inch vents must be provided

from the sonar room to the main deck. In the sonar room, the air

inlet should be located in close to the deck and the outlet as high

as possible. A funnel shaped drip-collector should be mounted

below the vent pipes to divert moisture to the bilge.

18

On the main deck, the best ventilation is provided when the outlet

pipe is at least four meters higher than the inlet pipe. To keep out

sea water, rain and spray, the ventilation pipes should be fitted

with goosenecks of the equivalent.

319568/B

Page 21

Installation planning

Sonar room electrical requirements

The following electrical requirements must be taken into

consideration when the sonar room is planned:

• Conduit

• Bilge pump

• Lights

Conduit

If the cable between the wheelhouse and the sonar room passes

through hatches or areas where it may be damaged, it should be

run through a conduit (two inch conduit is recommended).

Bilge pump

The sonar room should be connected to the vessel’s bilge pump

system. If this is not possible, a separate bilge pump for the sonar

room must be installed.

Lights

The sonar room should be equipped with suitable lighting to

simplify the installation and aid future maintenance.

Sonar room special requirements

The following special requirements must be taken into

consideration when the sonar room is planned:

• Air vent pipe

• Precautions for dry docking

Air vent pipe

An air vent conduit with a minimum of 10 mm internal diameter

must be attached to the air bleeding cock on the hull unit. The

pipe should be laid with continuous rise to free air on deck or

through the ship’s side.

Note

Through-hull modifications are subject to approval by the vessel’s

national registry and corresponding maritime authority. The

shipowner and shipyard are responsible for obtaining installation

approval.

Precautions f or dry docking

Make sure that ample space is provided between the vessel and

dry dock for system installation.

To facilitate future dry docking, mark the position of the installed

trunk on the ship drawings as well as on the hull.

319568/B 19

Page 22

Simrad SX95

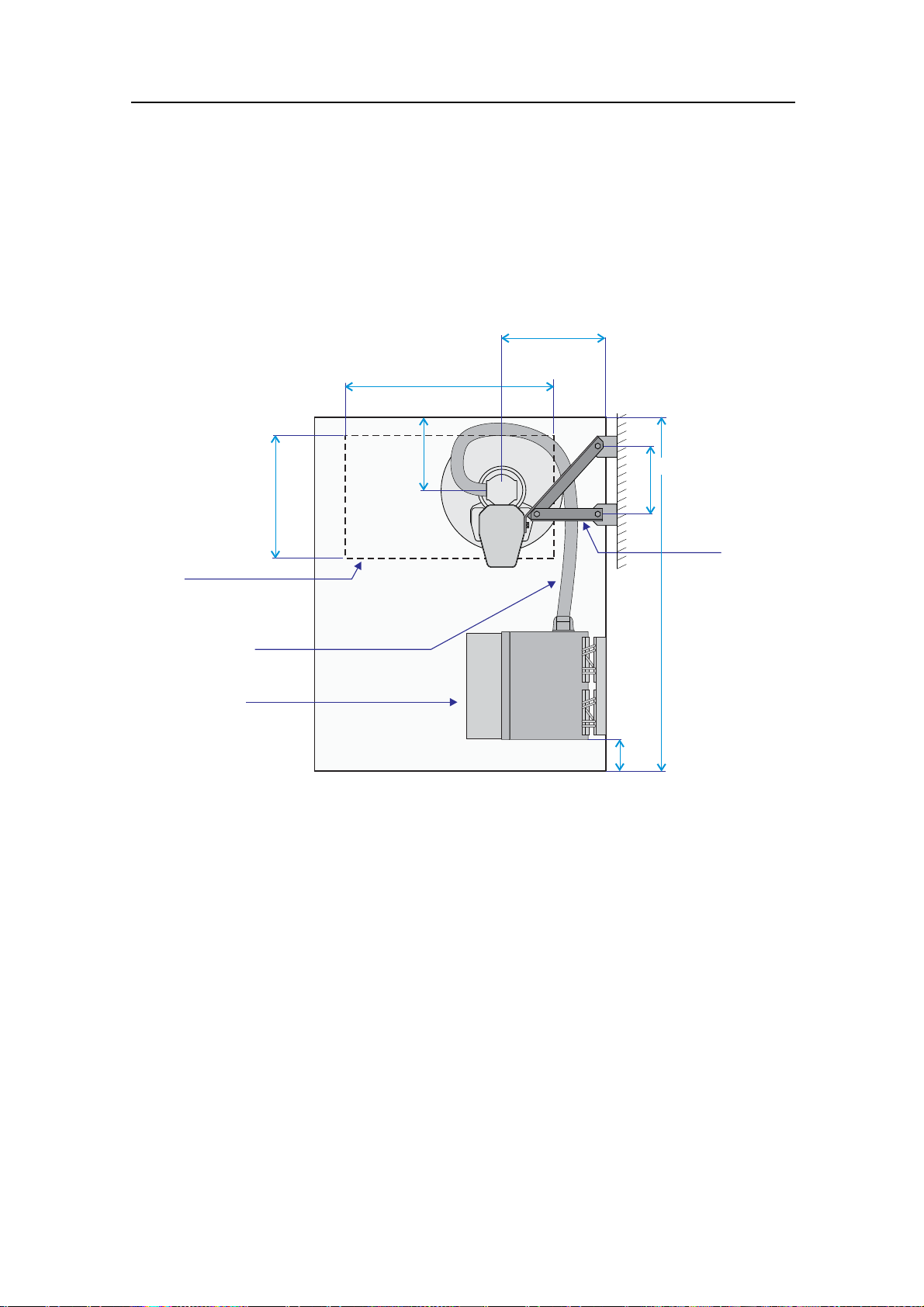

Sonar room arrangement example

These drawings illustrate a typical sonar room with ample space

for hull unit, transceiver unit and personnel.

Figure 4 Sonar room arrangement example, top view

500 mm (*)

1000 mm (*)

600 mm (*)

Hatch

(Minimum size

550 x 1000 mm)

Transducer cable

(Total length 3.5 m)

Transceiver Unit

(CD015417-002)

400 mm (*)

(*) = Recommended minimum

300 mm (*)

Removable

supports

brackets

Maximum

1000 mm

150 mm (*)

20 319568/B

Page 23

Figure 5 Sonar room arrangement example, side view

Installation planning

319568/B

21

Page 24

Simrad SX95

SONAR TRUNK INSTALLATION

The sonar trunk provides the physical foundation for the entire

hull unit g antry. The trunk further penetrates the hull, and it is

therefore a crucial part of the hull unit assembly. In order to

ensure proper sonar operation, the location of the sonar trunk

must be carefully selected.

A trunk with a blind cover – approved by Det norske Veritas

(DnV) – can be ordered from Simrad as an optional delivery, or it

may be manufactured by the installation shipyard based on the

drawings in this manual and the properties of the hull.

Note

The installation shipyard must provide all necessary installation

drawings, and if required, these must be approved by the

applicable authorities.

Topics

• Mounting the sonar trunk on page 23

• Sonar trunk protection on page 24

• Sonar trunk installation principles on page 24

• Sonar trunk installation measurements on page 27

Hull unit installation drawings

• SX95 Hull unit outline dimensions on page 55

• SX95 Mounting trunk outline dimensions on page 56

• Blind cover for sonar trunk on page 58

• SX95 Mounting t runk production on page 57

22

319568/B

Page 25

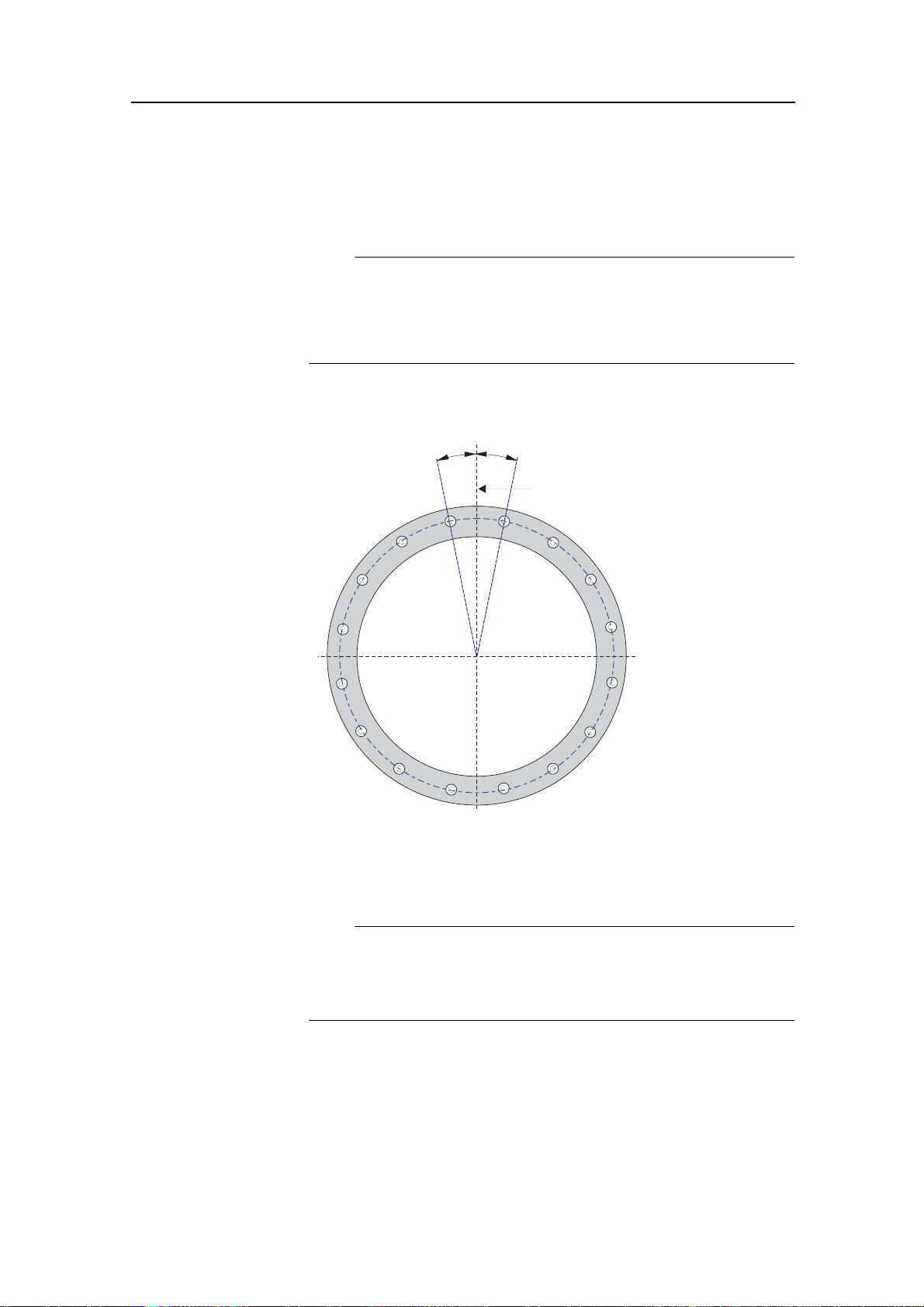

Mounting the sonar trunk

The location of the sonar trunk must be carefully selected.

Note

Note the orientation of the centre line of the trunk with regard to

the mounting bolts.

Remove the gasket on the top flange during welding.

Figure 6 Orientation of the sonar trunk

µ

Sonar trunk installation

µ± °1

Parallel to

centre line

(CD015415-003)

The height from the top of the trunk flange to the underside of

the protection blister must be selected as shown in the referenced

figures.

Note

In order to obtain optimal sonar performance, the total height

of the trunk must be as close as possible to its stated minimum

height.

The top flange must be parallel to the construction waterline in

both the fore-and-aft and athwartship directions.

The installation trunk must be welded to a doubling plate which

must be at least 1.5 times as thick as the surrounding shell plating.

The doubling plate’s final dimensions are to be governed by the

319568/B 23

Page 26

Simrad SX95

approved installation drawings supplied by the shipyard. The

trunk must also be stiffened by welding knee-plates to it and the

doubling plate in both the fore-and-aft and athwartship directions.

Sonar trunk protection

Protecting the blister

A steel blister must be fitted for protection. The blister shown

is welded to the shell plating and then filled with oil to prevent

corrosion. This method provides excellent protection and

simplifies maintenance.

Corrosion protection

As soon as all installation, welding and grinding has been

performed, the trunk and the surrounding area should be primed

and painted using a quality protective coating.

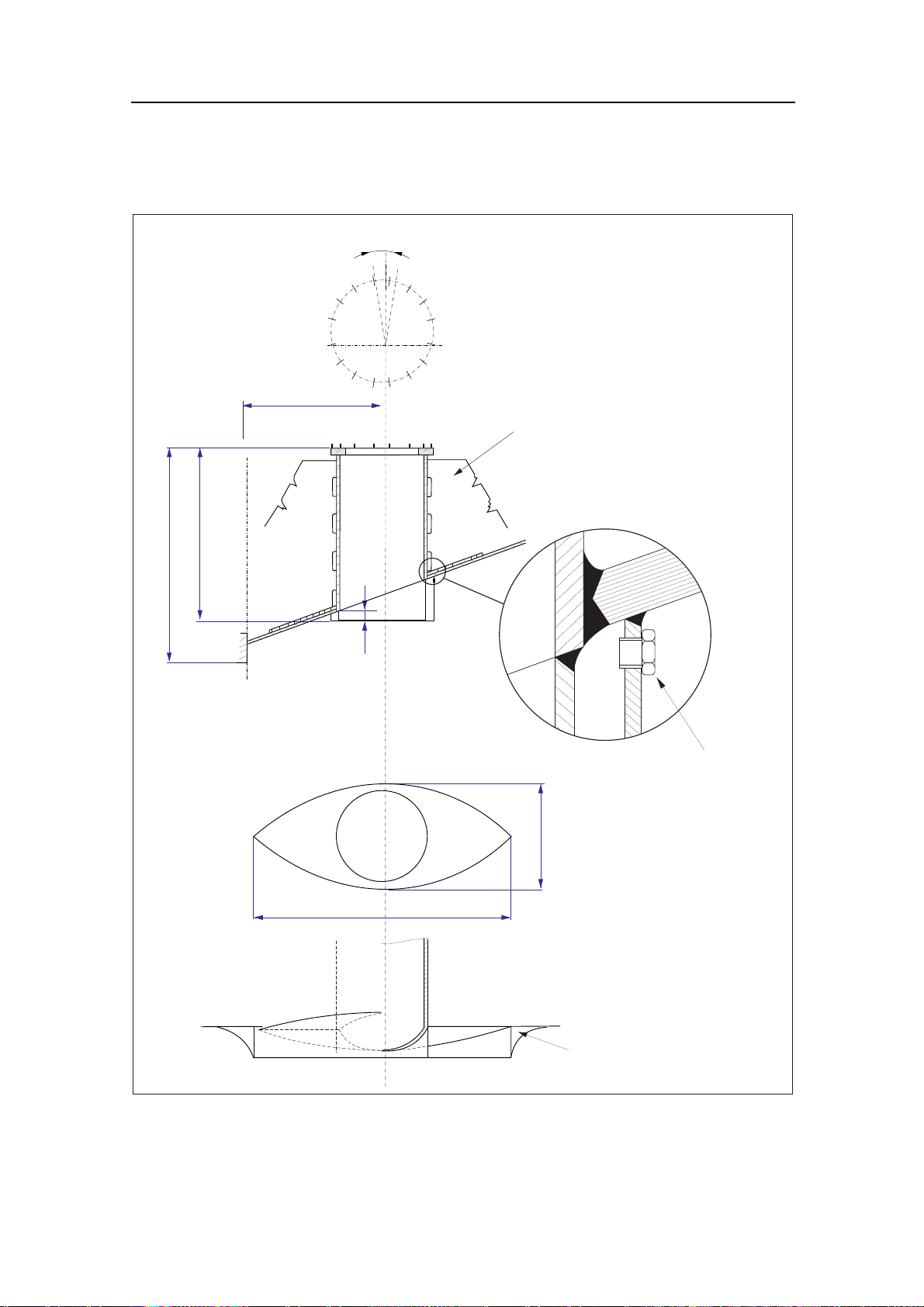

Sonar trunk installation principles

Observe the next two drawings, these illustrate the i nstallation

of the sonar trunk.

24

319568/B

Page 27

Figure 7 Installation of a trunk with open blister

Fore-and-aft view

A

Sonar trunk installation

A:

As short as possible

B:

Max. 35 7/8" (910 mm)

C:

Min. 1 9/16" (40 mm)

D:

Min. 35 7/8" (910 mm)

E:

Min. 22" (560 mm)

3-4 knee-plates, must be

welded to frames or floors

D

B

Bottom view

Side view

2.5-3xE

C

Plug for filling of oil

Thickness of plates

E

Knee-plates: 3/8" (10 mm)

Blister and deflection

bracket: 1/4" (6 mm)

The circular opening of the

blister should have a

diameter equal to the inside

diameter of the trunk.

Deflection-brackets should

be welded only to the

shell-plating.

(CD015415-004)

319568/B 25

Page 28

Simrad SX95

Figure 8 Installation of a trunk with oil filled blister

Fore-and-aft view

A

3-4 knee-plates, must be

A:

As short as possible

B:

Max. 35 7/8" (910 mm)

C:

Min. 1 9/16" (40 mm)

D:

Min. 35 7/8" (910 mm)

E:

Min. 22" (560 mm)

welded to frames or floors

D

B

Bottom view

Side view

2.5 - 3xE

C

Thickness of plates

E

Knee-plates: 3/8" (10 mm)

Blister and deflection

bracket: 1/4" (6 mm)

The circular opening of the

blister should have a

diameter equal to the inside

diameter of the trunk.

Deflection-brackets must

only be welded to the

(CD015415-005)

shell-plating.

26 319568/B

Page 29

Sonar trunk installation

Sonar trunk installation measurements

For future reference, the measurements “A”, “B”, “C” and “D”

from the drawing must be made and noted in the table below.

Table 1 Trunk installation measurements

Millimeters Inches

“A”

“B”

“C”

“D”

319568/B 27

Page 30

Simrad SX95

HULL UNIT INSTALLATION

This chapter describes the physical installation of the Simrad

SX95 Hull Unit.

The hull unit is a crucial part of the sonar system. Due to its

physical size and weight, and the fact that the trunk penetrates

the vessel hull, it is very important that the hull unit is installed

and secured properly.

Note

The installation shipyard must provide all necessary installation

drawings, and if required, these must be approved by the

applicable authorities.

Topics

• How to unpack the hull unit from its transport box on page 29

• Hull unit mounting on page 30

• Bleeding air cock on page 31

• Mechanical support on page 32

• Transducer alignment on page 32

• Hull unit installation check list on page 33

Related topics

• Hull unit familiarization on page 10

Hull unit installation drawings

• SX95 Hull unit outline dimensions on page 55

• SX95 Mounting trunk outline dimensions on page 56

• Blind cover for sonar trunk on page 58

• SX95 Mounting t runk production on page 57

28

319568/B

Page 31

Hull unit installation

How to unpack the hull unit from its transport box

Note

The transducer is protected to prevent damage during transport

and hull unit installation. This protection must remain attached

while the hull unit is being manoeuvred into the sonar room.

Figure 9 Removing the hull unit from its transport box

A

BB

C

A Lifting eye on the hoisting unit

B Mounting hardware (wooden cradle and support

construction)

C Transducer protection

1 Remove the top cover of the wooden box.

2 To remove the fastening hardware (G), pull out the

marked with Indian ink.

3 If you wish to re-use the box to hold the old h

sure that you keep all the fastening hardw

ull unit, make

are used to secure

the hull unit in the wooden box.

(CD015414-004)

nails

4 Fasten the lifting tackle to the two lift

on the top of the hoisting unit and lift

the transducer protection in place)

ing eye bolts (A)

the hull unit (with

carefully out of the

transportation box.

Note

Do not remove the transducer protection (H)fromthe

transducer until just before the hull unit is lowered onto the

mounting trunk.

319568/B 29

Page 32

Simrad SX95

Figure 10 Use the correct lifting eye!

There are two lifting

eyes on each side of

the hull unit: one

on the hoisting unit

and one on the top of

the transducer shaft.

Make sure that you use

the lifting eye on the

A

hoisting unit (A)when

you lift the hull unit out

of the transportation

box!

(CD015412C)

5 Ensure that you keep the transducer cable and connector dry.

Watch these carefully to prevent them from being damaged,

stuck or hooked on to protruding objects while manoeuvring

the hull unit into the sonar room.

Hull unit mounting

Figure 11 Orientation of the hull unit

Bow

The hull unit should normally be

oriented with the hoisting/lowering

motor pointing aft. If this orientation

makes the Motor Control Unit attached

to the hull unit difficult to access, the

hull unit may be oriented in the most

suitable position.

Note

The Motor Control Unit must never be

physically disconnected from the Hull

Unit.

(CD015400D)

30 319568/B

Page 33

Hull unit installation

Hull unit mounting procedure

Observe the following procedure. To ensure correct operation,

tick off every item when the action has been carried out.

1

protection in place) into the sonar room

2

the gasket is not damaged.

3

future use.

4

unit carefully onto the trunk.

5

140 Nm.

6

handle them with great care to prevent mechanical damage.

Bleeding air cock

Figure 12 Bleeding air cock

A

Use a tackle to lower the hull unit (with the transducer

Remove the blind cover from the trunk and check that

Store the blind cover in the sonar room for possible

Remove the transducer protection and lower the hull

Tighten the flange nuts with a torque of approximately

Keep the transducer cable and connector dry, and

To avoid damage to the transducer by the transmission

in air inside the trunk, a pipe with a minimum inside

diameter of 10 mm must be attached to the air bleeding

cock. This vent should be run with continuous rise to the

main deck or through the vessel’s side. Make sure the

air bleeding cock is opened.

(CD015401C)

B

C

(A) Minimum 10 mm internal diameter

(B) 3/8” pipe thread

(C) Valve shown in opened position

319568/B 31

Page 34

Simrad SX95

Mechanical support

Note

To ensure the safety of the sonar system and the vessel, it is very

important that the mechanical support of the hull unit gantry

is satisfactory.

To prevent unwanted vortex induced vibration, the hull unit

must be secured to the bulkhead. Use the two pre-drilled holes

on the gantry to mount support brackets in the fore-and-aft and

sideways direction. It must be possible to remove the support

brackets if maintenance is required.

Transducer alignment

Even though you may have installed the hull unit oriented

differently than shown in this chapter, the transducer shall n

be mechanically aligned.

ot

Transducer alignment is performed in the SX90 Processor Unit

by rotating the echo presentation on the display. This is described

in section Alignment and offset adjustments on page 51.

32

319568/B

Page 35

Hull unit installation check list

Perform a close visual inspection of the sonar room and the

physical installation of the hull unit. Refer to the sonar room

requirements, and fill in the table below.

Table 2 Hull unit installation check list

Hull unit installation

Item

Are the access hatches satisfact ory?

Is the heating satisfactory?

Is the insulation satisfactory?

Is the ventilation satisfactory?

Is the air vent pipe satisfactory?

Is a bilge pump installed?

Is the room lighting satisfactory?

Is the sonar room suitably decked?

Is the mechanical support of the hull unit

satisfactory?

Do you have satisfactory access to the Motor

Control Unit?

YES NO

If the answer to any of these questions is NO, note the deficiencies

in the Installation remarks and signature.

Related topics

• Sonar room requirements on page 17

319568/B 33

Page 36

Simrad SX95

CABLE LAYOUT AND INSTALLATION

This chapter describes the installation requirements for Simrad

SX95 hull unit cables. These instructions must be used together

with the applicable cable plan.

Note

All electronic installations and corresponding wiring must be in

accordance with the vessel’s national registry and corresponding

maritime authority and/or classification society.

If no such guidelines exist, we recommend that Det Norske

Veritas (DNV) Report No. 80-P008 «Guidelines for Installation

and Proposal for Test of Equipment» be used as a guide.

Topics

• Cable plan on page 35

• Cabling principles on page 36

• Cable procedures on page 37

Related topics

• Detailed list of cables on page 59

• Cable specifications on page 60

• Cable connections on page 63

• Basic cable requirements on page 66

34

319568/B

Page 37

Cable plan

The list below shows the cables used by the SX95 Hull Unit.

Figure 13 Simrad SX95 Hull Unit cable plan

(CD015503B)

Cable layout and installation

SX90/C31

K

SX90/C04*

SX90/C17

(Vac)

SX90/C06 (3-phase Vac)

SX90/C05*

List of units

(G) = Transceiver Unit

(H) = Hull Unit

(I) = Motor Control Unit

G

SX90/C32*

SX90/C35*

H

I

List of cables

SX90/C06: AC Mains to Hull Unit

SX90/C32: Ethernet control

SX90/C35: Transducer cable

319568/B 35

Page 38

Simrad SX95

Cabling principles

This chapter provides generic information about the cabling

principles.

Cable identifications

On the cable layout drawing and in the corresponding cable

list(s), all cables are identified with individual cable numbers.

Unless otherwise defined, each cable is identified with a Cxx

number, where xx is an integer. References are made to dedicated

cable drawings. If required, the shipyard or owner may also

identify the cables according to their own system. Unless

otherwise specified, this document will however only refer to the

identification numbers provided by Simrad.

Cable parameters

A drawing with additional parameter specifications for each c able

is provided. Each cable drawing may, when applicable, include:

• Required minimum specifications

• Connections at each end (including reference to the

corresponding: system unit, terminal board identification and

plug/socket to be used)

• Corresponding terminations

• Number of cores

System and shipyard cables

Cables fall into two categories.

• System cables: These cables are supplied by Simrad.

• Shipyard cables: These cables must be provided by the

shipyard performing the installation, or the shipowner.

Note

Simrad accepts no responsibility for damage to the system or

reduced operational performance caused by improper wiring.

36 319568/B

Page 39

Cable procedures

Observe the following procedure to perform the sonar cabling.

Note that detailed information about cable specifications,

termination and connectors are provided in the referenced

sections. To ensure correct operation, tick off every item when

the action has been carried out. All cables are provided by

Simrad unless otherwise specified.

Note

Before you perform the sonar cabling, ensure that the mains

circuit breaker for the sonar system is switched off.

In order to provide for maintenance and to allow for vibration,

make sure that some slack is inserted on all cables.

Note

Cable layout and installation

DO NOT mount the flexible transducer cable to the Transceiver

Unit. This will be described later.

Topics

• AC mains to Motor Control Unit (C06) on page 38

• Transceiver Unit to Motor Control Unit (C32) on page 39

• Transducer cable (C35) on page 40

Related topics

• Transceiver Unit connections on page 65

• Motor Control Unit connections on page 64

319568/B 37

Page 40

Simrad SX95

AC mains to Motor Control Unit (C06)

1 Connect the 3–phase AC mains cable C06 from the

Figure 14 C06 connections

Motor Control Unit to the vessel’s AC mains.

Note

This cable must be provided by the installation shipyard.

Use 4 x 2.5 mm² cable, ensure that the screen is properly

terminated in the cable gland.

DO NOT apply 3–phase power to the Motor Control Unit

until instructed by the applicable start-up procedure.

For additional details, see SX90/C06 AC mains to Motor

Control Unit on page 59 and AC mains cable to Motor

Control Unit on page 61.

38 319568/B

Page 41

Cable layout and installation

Transceiver Unit to Motor Control Unit (C32)

If the Transceiver Unit has been installed, make the following

connection:

1

2

Figure 15 C32 connections

Locate the 8 meters terminated C32 patch cable

provided with the transceiver.

Connect the ethernet cable C32 from the left ethernet

socket under the Transceiver Unit to the ethernet socket on

the Motor Control Unit.

319568/B 39

Page 42

Simrad SX95

Transducer cable (C35)

The transducer cable (C35) is provided by Simrad. It is physically

connected to the top of the transducer shaft, and terminated in the

other end with a large connector.

Note

Do not mount the flexible transducer cable to the Transceiver

Unit. This operation is described in the Simrad SX90 Installation

manual.

40 319568/B

Page 43

START-UP PROCEDURES

The procedures in this chapter shall be carried out once all the

hardware units have been installed, and the cabling is finished.

Note

When you carry out these procedures, make sure that you only

perform those tasks described, and in the given order.

Check off every item in the procedure as you carry on.

Topics

• Starting up the Hull Unit on page 41

• Alignment and offset adjustments on page 51

Starting up the Hull Unit

Start-up procedures

Observe the following procedure to start up the Hull Unit. To

ensure correct performance, tick off every item when the action

has been carried out.

WARNING

Beforeyoustartupthesonarequipmentona

recently launched vessel, make sure that the depth

under the keel is sufficient for the transducer to

be lowered safely.

When you start up the equipment on board a

vessel in dry dock, check first under the vessel

and inside the sonar room. Personnel, tools and

other potential obstructions must be kept clear of

thetransducerandrelatedloweringandhoisting

machinery to avoid personal injury or damage to

the equipment.

Topics

• Hull unit familiarization on page 42

• Motor Control Unit familiarization on page 43

• Functional check on page 44

319568/B

• Apply 3-phase AC power on page 45

• Check hoist motor’s 3–phase AC connections on page 46

• Check the 3–phase connection for correct rotation direction

on page 47

• Check the contactor operation on page 48

• Functional check with hoist and lower operations on page 49

41

Page 44

Simrad SX95

Hull unit familiarization

Figure 16 Hull unit familiarization

A

B

C

D

E

F

G

H

J

K

(A) Hand crank

L

(B) Identification label

(C) Hoisting motor

(D) Motor Control Unit

(E) Hoisting unit

M

(F) Transducer shaft sleeve

42

(G) Mounting flange

(H) Mounting trunk

(I) Transducer

I

(J) Transducer cable

(K) Transducer shaft

(L) Air bleeding cock

(CD015414-003)

(M) Zinc anodes

319568/B

Page 45

Motor Control Unit familiarization

Figure 17 Motor Control Unit familiarization

Start-up procedures

(A) Internal 24 Vdc power supply

HOIST STOP

REMOTE LOWER

S302 P302

S303

S301

E301

K303

L1

K302K301

L2

A

F301

(CD015409B)

B

(B) Ethernet connector

(F301) Fuse for internal power

supply

(E301) Terminal strip for AC

mains input

(K301) Hoisting contactor

(K302) Lowering contactor

(K303) Phase watch relay

(L1) Yellow indicator light

(L2) Green indicator light

(S301) Motor protecting switch

(S302) Hoist/lower selector

(S303) Hand crank with safety

switch

(P302) Connector for hull unit

limit switches and rotation sensor

During normal operational conditions, the two following

indicator lamps shall be lit:

• Indicator lamp

L1 indicates that the phase watch relay K303

is activated. This mean that the 3-phase voltage is applied

to the hoist/lower system, and that the three phases are

correctly connected with regard to the training direction of

the hoist/lower motor.

• Indicator lamp

L2 indicates that the internal +24 Vdc power

supply for the control electronic is operational.

319568/B 43

Page 46

Simrad SX95

Functional check

Before you commence with the start-up procedure, check the

following items. To ensure correct operation, tick off every item

when the task has been carried out.

1

Check that the 3-phase mains fuses are disconnected

in the ship’s fuse box.

2

Use a spanner to open the door on the Motor Control

Unit which is mounted on the Hull Unit gantry.

3

Locate the motor protecting switch S301,andcheck

that the operating handle is pressed down to OFF position.

4

Check that t he hoist/lower switch S302 in the Motor

Control Unit is set in the STOP position.

44

319568/B

Page 47

Start-up procedures

Apply 3-phase AC power

Observe the following procedure to apply 3-phase mains power

to the hull unit.

1

Locate the motor protecting switch S301 in the Motor

Control Unit, and check that the operating handle is pressed

down to OFF position.

2

Check that t he hoist/lower switch S302 in the Motor

Control Unit is set in the STOP position.

3

Re-insert the 3-phase mains fuses for the hull unit in

the ship’s fuse box.

4

Measure the three-phase voltage on the terminals E301

in the Motor Control Unit.

• Write down the measured voltage here:

Supply voltage:

5 Adjust the release current on the motor protecting

switch

S301 according to the three-phase voltage:

• 230 Vac: 5,5 A

• 380/440 Vac: 4 A (minimum)

Figure 18 Motor Control Unit with S301 and E301

S302

S301

E301

(CD015409K)

HOIST STOP

REMOTE LOWER

319568/B 45

Page 48

Simrad SX95

Check hoist motor’s 3–phase AC connections

In order to ensure that the hoisting motor operates properly, and

to avoid serious damage to the motor, you must check that the

motor connections are made in accordance with the supplied

3–phase voltage.

1

Remove the 3-phase mains fuses for the hull unit in

the vessel’s fuse box.

2

Remove the cover for the mains connection on the

motor.

3

Refer to the illustration, and check if the motor

connections are made in accordance with the supplied

3–phase voltage.

Figure 19 Mains connection to the motor

230 Vac

380/440 Vac

46

(CD015407A)

Note

The order of the connection wires must not be changed!

4 If the connections do not match the 3–phase voltage,

rewire to make them correspond to the m easured voltage.

5

Re-insert the 3-phase mains fuses for the hull unit in

the vessel’s fuse box.

319568/B

Page 49

Start-up procedures

Check the 3–phase connection f or correct rotation direction

The Motor Control Unit is equipped with a Phase Watch Relay

(

K303), which prevents operation of the hoist/lower motor if

the 3-phase connections are wrong with respect to the motor’s

rotation direction.

Figure 20 Motor Control Unit with S302, S301, E301, K303

and LED L1

HOIST STOP

S302

REMOTE LOWER

S301

E301

(CD015409L)

K303

L1

1 Check that t he hoist/lower switch S302 in the Motor

Control Unit is set in the STOP position.

S301 by

2

Switch on the motor protecting swi

pressing the operating handl

3

4

Check that the LED L1 on the front of the Phase

Watch Relay (

K303)islit.

If the LED is not lit, observe the following procedure:

e upwards to ON position.

tch

1 Disconnect the ship’s 3-phase fuses.

2 Change two of the 3-phase connections on the terminal

E301 in the Motor Control Unit.

3 Re-insert the 3-phase fuses in the ship’s fuse box.

4 Check again that the LED on the front of the Phase

Watch Relay (

5

Switch off the motor p

pressing the operat

319568/B 47

K303)islit.

rotecting switch

S301 by

ing handle downwards to OFF position.

Page 50

Simrad SX95

Check the contactor operation

Normally, in this part of the test procedure, the transducer shaft

will be in upper position with the upper limit switch activated.

This operational test of the hoist/lower contactors will not require

the 3-phase power to be applied to the motor.

Figure 21 Motor Control Unit with S301, S302, K301, K302 and L2

1 Locate the motor protecting switch S301,andcheck

that the operating handle is pressed down to OFF position.

2

Check that the LED indicator L2 on the front of the

24 Vdc power supply is lit.

3

Set the hoist/lower switch S302 to HOIST position,

and check that the hoisting contactor

K301 is not activated.

• If the contactor was activated, press the upper limit switch

S304 upwards, and check that the contactor is deactivated.

4

5

Set the hoist/lower switch S302 to the LOWER position

and check that the lowering contactor

K302 is activated.

Press the lower limit switch S305 downwards, and

check that the contactor is deactivated while activating the

switch.

6

7

Locate the hand crank inside the Motor Control Unit.

Remove the hand crank from its storage position, and

check that the contactor is deactivated. D

o not place the

hand crank back into its storage position.

8

Set the hoist/lower switch S302 to the STOP position.

48 319568/B

Page 51

Start-up procedures

Functional check with hoist and lower operations

The hull unit is now all powered up, and the final functional test

can take place.

1

Verify that the hand crank is removed from its storage

position in the Motor Control Unit.

2

Switch on the motor protecting switch S301 by

pressing the operating handle upwards to ON position.

3

Set the hoist/lower switch S302 to the LOWER

position.

Figure 22 Motor Control Unit with S301, S302 and S303

HOIST STOP

REMOTE LOWER

S302

S303

S301

(CD015409N)

4 Check the training direction of the hoist/lower motor

by very briefly pressing the hand crank safety switch

5

If the transducer shaft was hoisted, perform the

S303.

following procedure:

1 Disconnect the vessel’s 3-phase mains fuses.

2 Change two of the 3-phase connections in the mains

connection box on the motor.

3 Re-insert the 3-phase mains fuses in the vessel’s fuse

box.

4 Check that the transducer shaft is lowered when briefly

pressing the h and crank safety switch

319568/B 49

S303.

Page 52

Simrad SX95

6 Set the hoist/lower switch S302 to the STOP position.

7

Put the hand crank back to its storage position in the

Motor Control Unit.

8

Check if there is sufficient space under the keel to

lower the transducer.

9

Make sure that the flexible transducer cable is in

such a position that the transducer can be lowered without

stretching or hard-bending the cable.

Note

Watch the cable carefully during the next steps in this

procedure!

10 Set the hoist/lower switch S302 to LOWER position to

lower the transducer all the way down.

• Lowering will be stopped automatically when the top of

the transducer shaft makes contact with the lower limit

switch

S305.

• If necessary, the lowering operation can easily be stopped

in any position by setting the switch

S302 to STOP

position.

11

Set the hoist/lower switch S302 to HOIST position to

hoist the transducer back up.

• Hoisting will be stopped automatically when the top of

the transducer makes contact with the upper limit switch

S304.

• If necessary, the hoisting operation can easily be stopped

in any position by setting the switch

S302 to STOP

position.

12

Repeat the hoist/lower operation to find the best

position for a permanent fastening of the flexible transducer

cable.

13

14

Set the hoist/lower switch S302 to STOP.

Switch off the motor protecting switch S301 by

pressing the operating handle downwards to OFF position.

The hull unit is now ready for further cabling (Ethernet cable to

the transceiver unit for hoist/lower control) and system testing.

The system test is provided in the relevant sonar installation

manual.

50

319568/B

Page 53

Alignment and offset adjustments

When the system start-up procedure for the complete sonar

system has been performed, you must acquire the alignment

angle of the sonar picture and the stabilisation sensor offset.

These values must be entered into the sonar system.

Alignment of the sonar picture

Independent of the hull unit orientation, the alignment is always

defined as:

• the angle measured clockwise from the bow to the 0 degrees

transducer mark.

The 0 degrees transducer mark is located outermost on the

mounting flange, and it is marked as a red “0”. Depending on

the transducer mounting, it can be located at any angle on the

mounting flange, not necessarily as shown in the illustration

below.

Start-up procedures

Figure 23 Hull unit alignment

This is the alignment angle

o

0 transducer

mark

Bow

0

(CD015400F)

Observe the following procedure to align the sonar picture.

1 Locate the 0° transducer mark.

2 Estimate the approximate alignment angle ( 0 to 360°)

clockwise from the bow to the 0° transducer mark.

• The 22,5° angle between each mounting bolt can be used

as an aid.

3 Turn the echo picture on the display in the following way:

1 Open the

2 Click the

319568/B 51

Setup menu.

Test to open the System test menu.

Page 54

Simrad SX95

3 Click the Installation Menu button, and observe that the

menu appears on the top of the display.

4 Select

transceiver configuration

Installation →Alignment. Observe that the Sonar

parameter dialogue appears at

the bottom of the menu field.

5 Click the

Alignment button.

6 Enter the estimated alignment angle.

4 Check that the echo picture on the display is correct in

relation to the ambient situation.

• If not, make a fine adjustment of the alignment.

In order to make a correct alignment, a particular target such

as a buoy is required. When the alignment is correct, write the

angle here.

Alignment correction (degrees):

Adjusting the stabilisation sensor offset

Independent of the hull unit orientation, the offset of the

stabilization sensor is always defined as:

• the angle measured clockwise from the 0 degrees transducer

mark to the 0 degrees reference for the stabilization sensor.

The 0 degrees transducer mark is located outermost on the

mounting flange. The 0 degrees reference for the stabilization

sensor is always related to the gantry, as indicated in the figure

below.

Figure 24 Offset angle definition

This is the offset angle

o

0 transducer

mark

0

Bow

o

0 stabilisation

sensor

(CD015400G)

52 319568/B

Page 55

Start-up procedures

Estimating the offset angle

Observe the following procedure to estimate the offset of the

stabilization sensor.

1 Locate the 0 degrees transducer mark.

2 Estimate the approximate offset angle (0 to 360°) clockwise

from the 0° transducer mark to the 0° reference stabilization

mark.

• The 22,5° angle between each mounting bolt can be used

as an aid.

3 Record the estimated offset angle.

Offset angle(degrees):

Entering the stabilisation offset angle

Observe the following procedure to enter the offset stabilization

angle as a parameter into the sonar system.

1 Open the

2 Click the

3 Click the

Setup menu.

Tes t button to open the System test menu.

Installation Menu button, and observe the menu

that appears on the top of the display.

4 Select

5 Observe that t he

Installation →Installation →Alignment.

Sonar transceiver configuration parameter

dialogue appears at the bottom of the menu field.

6 Click the

Offset button.

7 Enter the estimated offset angle.

319568/B 53

Page 56

Simrad SX95

DRAWING FILE

This chapter contains relevant drawings related to the electrical

and physical installation of the S X95 Series hull unit.

Note

The mechanical drawings are for information and guidance only.

They are not in scale. All dimensions are in mm unless otherwise

is noted.

The original drawings are available on PDF and/or AutoCad’s

DWG format. See the product CD, or visit w

to download.

Hull unit drawings

• SX95 Hull unit outline dimensions on page 55

ww.simrad.com

• SX95 Mounting trunk outline dimensions on page 56

• Blind cover for sonar trunk on page 58

• SX95 Mounting t runk production on page 57

54

319568/B

Page 57

SX95 Hull unit outline dimensions

Drawing file

155

[6,102]

1645

[64,764]

874

[34,409]

Lifting

point

Lifting

point

220

[8,660]

990

[38,976]

ø150

[5,906]

382

[15,039]

Note:

All measurements are in mm and [inches].

The drawing is not in scale.

1000

[39,370]

ø483

[19,016]

ø508

[20,000]

ø580

[22,835]

Bow

ø662

[26,063]

CD015414-005 Page 1 of 1

318900 Rev.A

319568/B 55

Page 58

Simrad SX95

SX95 Mounting trunk outline dimensions

56 319568/B

Page 59

SX95 Mounting trunk production

Classification society marking

3

-

+

990

Drawing file

45°

10

18

-0

+1

(508)

22.5°

M16

0.5

16 HOLES,SPACING 22.5

+1

-0

ø460

ø540

ø580

2

+

-

(12.5)

O

Note:

All measurements are in mm.

The drawing is not in scale.

319568/B 57

CD15106-003 Page 1 of 1

830-113361 Rev.A

Page 60

Simrad SX95

Blind cover for sonar trunk

2

0

-

+

13

+

0.5

-

18

0.5

16 holes, spacing 22.5

o

Note:

All measurements are in mm

The drawing is not in scale

ø540

2

+

-

ø580

CD015106-001 Page 1 of 1

830-113362 Rev.A

58 319568/B

Page 61

APPENDIX A — CABLE DETAILS

This appendix contains specific cable details related to the

Simrad SX95 Hull Unit.

Topics

• Detailed list of cables on page 59

• Cable specifications on page 60

• Cable connections on page 63

Detailed list of cables

The list below specifies each cable used on the Simrad SX95

Hull Unit. References are made to detailed cable drawings and

specifications.

SX90/C06 AC mains to Motor Control Unit

Appendix A Cable details

The AC mains to the Hull Unit is connected to the Motor Control

Unit. This is a special mains cable, and it must be provided by

the installation shipyard.

Note

This cable can be prepared for installation, but it must NOT be

connected to the Motor Control Unit until specifically instructed

by the setup procedure.

Related topics

• Motor Control Unit connections on page 64

• AC mains cable to Motor Control Unit on page 61

SX90/C32 Transceiver to Motor Control ethernet

The Transceiver Unit is connected to the Motor Control Unit by

means of a single Ethernet cable. A suitable cable is provided

by Simrad.

Related topics

• Transceiver Unit connections on page 65

• Motor Control Unit connections on page 64

• Ethernet cable with RJ45, “straight” on page 62

SX90/C35 Transducer cable

The transducer cable is physically connected to the transducer. It

is connected to the side socket of the Transceiver Unit by means

of a special connector.

319568/B 59

Page 62

Simrad SX95

Cable specifications

The drawings provided specifies in detail each cable used by

the SX95 Hull Unit.

60

319568/B

Page 63

Appendix A Cable details

HOIST STOP

REMOTE LOWER

AC mains cable to Motor Control Unit

This cable is used to connect 3-phase mains supply and ship’s

ground to the hoist/lower motor on the hull unit. The connections

are made to the Motor Control Unit.

Ground

HOIST

Motor Control Unit

Main

screen

Cable

access

Observe proper

cable grounding!

3-phase

230/380/440 Vac mains

W323

Rev.B

Caution

Observe the difference between 230 Vac and 380/440

Vac wiring on the hoist motor!

• Conductors: 4 x 2.5 mm²

• Screen: Overall braided

• Voltage: 750 V

• Maximum diameter: 17 mm

AC Mains supply, Motor Control Unit

319568/B 61

Page 64

Simrad SX95

Ethernet cable with RJ45, “straight”

This cable is used to provide standard ethernet connections. Note

that various categories exists. Normally, Cat.5 and Cat.6 cables

are used in local area networks with bandwidth exceeding 100

Mbit

Ethernet cables are available commercially in different lengths,

colours and categories.

Pin 1

RJ45 plug

Tx Data+ Tx Data+

Tx Data- Tx Data-

Rx Data+ Rx Data+

Rx Data- Rx Data-

W403

Rev.B

Pin 8

Pin 1

View

Pin 8

RJ45 plug

11

22

33

44

55

66

77

88

Pairs

Ethernet 10Base-T “Straight Through”

(White/Orange)

(Orange)

(White/Green)

(Blue)

(White/Blue)

(Green)

(White/Brown)

(Brown)

62

In order to prevent noise and crosstalk, you are strongly advised

to use the cable pairs indicated in the drawing.

• Conductors: Defined by the manufacturer

• Screen: Overall screened

• Voltage: Defined by the manufacturer

• Maximum diameter: Defined by the manufacturer

• Termination: RJ45 in each end

319568/B

Page 65

Cable connections

Care must be taken to ensure that the correct terminations are

used for all cable conductors, especially those that are connected

to terminal blocks. In this case, crimped sleeve-terminations

must be fitted to prevent the conductor core from fraying and

making a bad connection with the terminal block.

Note

Wherever crimped terminals are used, the correct size of crimp

and crimping tool m

Appendix A Cable details

ust be used.

319568/B 63

Page 66

Simrad SX95

Motor Control Unit connections

The illustration below shows the cable connections used on the

Motor Control Unit.

Figure 25 Motor Control Unit connections

(CD015409C)

HOIST STOP

REMOTE LOWER

Ground

3-phase

230/380/440 Vac mains

A

(A) 3–phase AC Mains power input (SX90/06)

(B) Ethernet connector (SX90/33)

Note

Observe proper grounding of th

cable to Motor Control Unit on

e mains cable. See AC mains

page 61 for details.

B

64 319568/B

Page 67

Appendix A Cable details

Transceiver Unit connections

The illustration below shows the cable sockets used on the

Transceiver Unit.

Figure 26 Transceiver Unit connections

(A) Ethernet connector for Motor Control unit (SX90/C32)

(B) Ethernet connector for wheelhouse (SX90/C31)

(C) AC Mains power connector (SX90/C05)

319568/B 65

Page 68

Simrad SX95

APPENDIX B — BASIC CABLE REQUIREMENTS

This chapter provides general information related to the

installation of system cables.

Cable trays

All permanently installed cables associated with the system

must be supported and protected along their entire l engths using

conduits and/or cable trays. The only exception to this rule is

over the final short distance (maximum. 0,5 meters) as the cables

run into the cabinets/units to which they are connected. These

short service loops are to allow the cabinets to move on their

shock mounts, and to allow maintenance and repair.

• Wherever possible, cable trays must be straight, accessible and

placed so as to avoid possible contamination by condensation

and dripping liquids (oil, etc.). They must be installed away

from sources of heat, and must be protected against physical

damage. Suitable shields must be provided where cables are

installed in the vicinity of heat sources.

• Unless it is absolutely unavoidable, cables should not be

installed across the vessel’s expansion joints. If the situation

is unavoidable, a loop of cable having a length proportional

to the possible expansion of the joint must be provided. The

minimum internal radius of the loop must be at least twelve

times the external diameter of the cable.

• Where a service requires duplicate s upply lines, the cables

must follow separate paths through the vessel whenever

possible.

• Signal cables must not be installed in the same cable tray or

conduit as high-power cables.

• Cables containing insulation materials with different

maximum-rated conductor temperatures should not be

bunched together (that is, in a common clip, gland, conduit or

duct). When this is impractical, the cables must be carefully

arranged such that the maximum temperature expected in

any cable in the group is within the specifications of the

lowest-rated cable.

• Cables with protective coverings which may damage other

cables should not be grouped with other cables.

66

• Cables having a copper sheath or braiding must be installed

in such a way that galvanic corrosion by contact with other

metals is prevented.

• To allow for future expansion of the system, all cables should

be allocated spare conductor pairs. Also, space within the

vessel should be set aside for the installation of extra cables.

319568/B

Page 69

Appendix B Basic cable requirements

Radio Frequency interference

All cables that are to be permanently installed within 9 m (30

ft) of any source of Radio Frequency (RF) interference such as

a transmitter aerial system or radio transmitters, must, unless

shielded by a metal deck or bulkhead, be adequately screened by

sheathing, braiding or other suitable material. In such a situation

flexible cables should be screened wherever possible.

It is important that cables, other than those supplying services to

the equipment installed in a radio room, are not installed through

a radio room, high power switch gear or other potential sources

of interference. Cables which must pass through a radio room

must be screened by a continuous metal conduit or trunking

which must be bonded to the screening of the radio room at its

points of entry and exit.

Physical protection

Grounding