Page 1

Installation manual

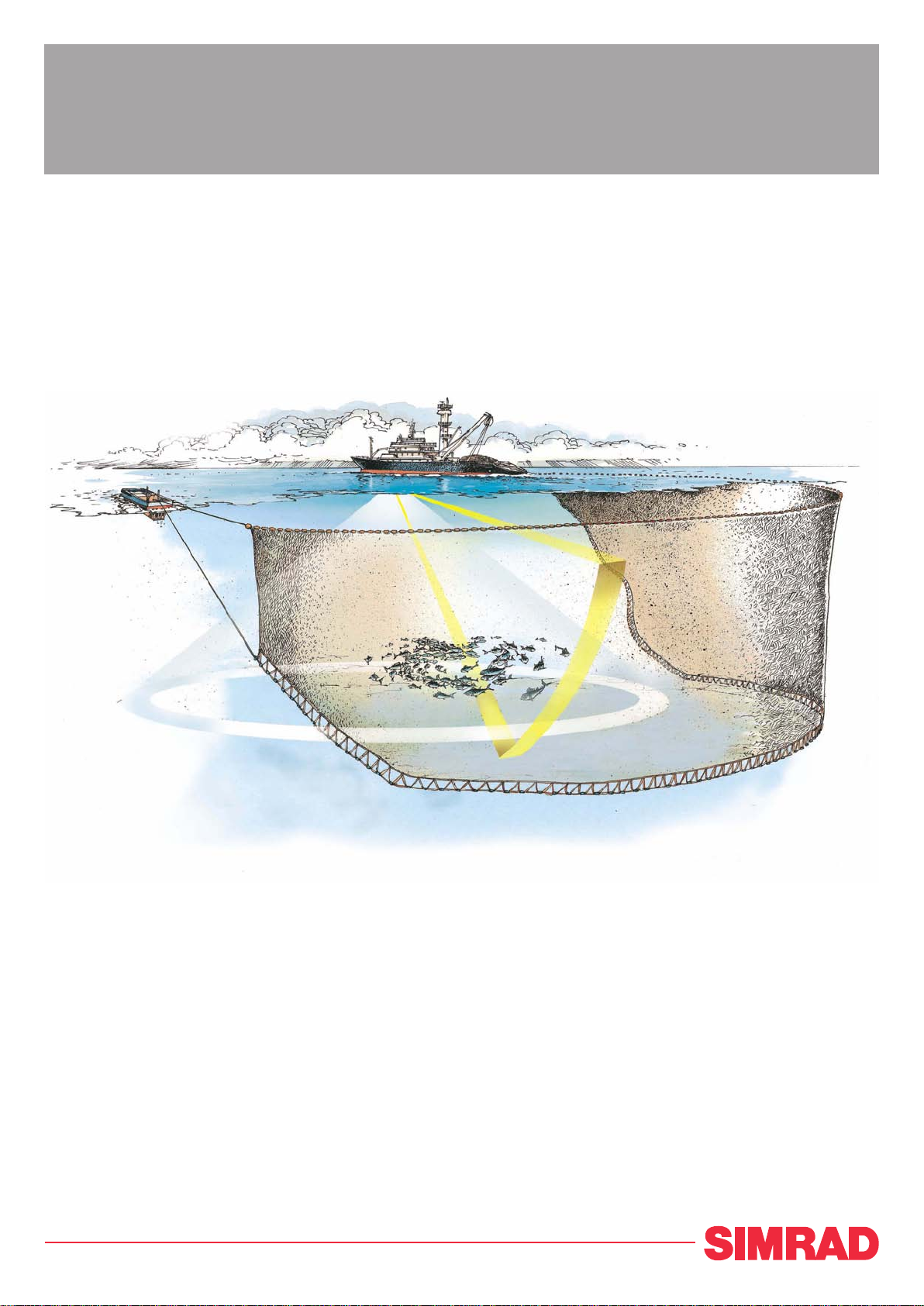

TECHNOLOGY FOR SUSTAINABLE FISHERIES

www.simrad.com

Simrad SX90

Fish nding sonar

Page 2

Page 3

SimradSX90

Installationmanual

Thisdocumentprovidesthenecessaryinformationof

howtoinstalltheSimradSX90Fishndingsonar.The

informationmustberegardedasgeneralguidelinesand

recommendationsonly.Theinstallationshipyardmust

designandmanufactureinstallationhardwaretottheSX90

Fishndingsonaroneachindividualvessel.

22January2009

307531/C

Page 4

History

Kongsbe r gM a rit imeA S

Stran d p r o m e n a de n5 0

P.O.Bo x1 11

N- 3 191H o rte n ,N orwa y

S im ra d

Tele p h o n e:+ 473 30 34 00 0

Tele fax:+ 473 30 42 98 7

contact@sim rad.com

w w w . s im r a d .c o m

Documentnumber:307531/ISBN-13:978-82-8066-092-3

Rev.A

Rev.B

Rev.C22January2009

01July2007Firstversion.

04July2008

Addedchapter“Technicalspecications”.Addedinformation

aboutmandatoryUPSsystems.Severalotherminorchanges.

Addedinformationrelatedtonewaudiooutput.Cabling

informationreorganized.

Copyright

©2009KongsbergMaritimeAS

TheinformationcontainedinthisdocumentremainsthesolepropertyofKongsbergMaritimeAS.Nopart

ofthisdocumentmaybecopiedorreproducedinanyformorbyanymeans,andtheinformationcontained

withinitisnottobecommunicatedtoathirdparty,withoutthepriorwrittenconsentofKongsberg

MaritimeAS.Thedocument,oranypartofit,maynotbetranslatedtoanyotherlanguagewithoutthe

writtenapprovalfromKongsbergMaritimeAS.

Disclaimer

KongsbergMaritimeASendeavourstoensurethatallinformationinthisdocumentiscorrectandfairly

stated,butdoesnotacceptliabilityforanyerrorsoromissions.

Warning

Theequipmenttowhichthismanualappliesmustonlybeusedforthepurposeforwhichit

wasdesigned.Improperuseormaintenancemaycausedamagetotheequipmentand/orinjury

topersonnel.Theusermustbefamiliarwiththecontentsoftheappropriatemanualsbefore

attemptingtoinstall,operateorworkontheequipment.

KongsbergMaritimeASdisclaimsanyresponsibilityfordamageorinjurycausedbyimproper

installation,useormaintenanceoftheequipment.

Support

IfyourequiremaintenanceonyourSimradproductcontactyourlocaldealer.Y oucanalsocontactususing

thefollowingaddress:s

w w . s i m r a d . c o m .Onourwebsiteyouwillalsondalistofourdealersanddistributors.

visitw

i m r a d . s u p p o r t @ s i m r a d . c o m .Ifyouneedinformationaboutourotherproducts,

Page 5

Installationmanual

Tableofcontents

ABOUTTHISMANUAL.....................................................11

SIMRADSX90FISHFINDINGSONAR..............................13

Basicinformation...................................................................................................13

Mainunits...............................................................................................................14

Wheelhouseunits........................................................................................14

Sonarroomunits.........................................................................................15

Installationprocedure.............................................................................................16

Systemdiagram......................................................................................................18

Scopeofsupply......................................................................................................19

Additionalrequireditems.......................................................................................19

Colourdisplay............................................................................................19

UninterruptedPowerSupply(UPS)..............................................................19

Installationtrunk.........................................................................................21

Speedlog...................................................................................................21

Coursegyro................................................................................................21

Additionaloptionalitems.......................................................................................21

Optionalhullunitsandinstallationtrunks.....................................................22

Optionalfunctionality.................................................................................23

Otherperipheralequipment.........................................................................23

Optionalaudiooutput..................................................................................25

Generalsupplyconditions......................................................................................27

Equipmentresponsibility.............................................................................27

Receipt,unpackingandstorage....................................................................27

Generalinstallationrequirements...........................................................................28

Approvalbyclassicationsociety................................................................28

Supplypower.............................................................................................28

Compassdeviation......................................................................................28

Noisesources.............................................................................................28

Drydocking...............................................................................................29

Wiring........................................................................................................29

INSTALLATIONPLANNING..............................................30

Aboutinstallationdrawings....................................................................................30

Locationofthehullunit.........................................................................................31

Sonarroomrequirements.......................................................................................32

Sonarroomarrangementexample..........................................................................34

SONARTRUNKINSTALLATION........................................36

Mountingthesonartrunk.......................................................................................37

Sonartrunkprotection............................................................................................38

307531/C

3

Page 6

SimradSX90

Sonartrunkinstallationprinciples..........................................................................38

Sonartrunkinstallationmeasurements...................................................................41

HULLUNITINSTALLATION.............................................42

Hullunitmodelsoverview.....................................................................................43

Howtounpackthehullunitfromitstransportbox...............................................44

Hullunitmounting.................................................................................................45

Bleedingaircock....................................................................................................47

Mechanicalsupport................................................................................................47

Transduceralignment.............................................................................................47

Hullunitinstallationchecklist...............................................................................48

TRANSCEIVERUNITINSTALLATION...............................49

TransceiverUnitpreparations................................................................................49

TransceiverUnitinstallationprocedure.................................................................49

WHEELHOUSEUNITSINSTALLATION..............................53

Physicallocationofwheelhouseunits....................................................................53

Maximumdistancesbetweentheunits...................................................................56

Installationofthedisplayunit................................................................................57

InstallationoftheOperatingPanel.........................................................................57

InstallationoftheProcessorUnit...........................................................................58

InstallationoftheBeamformerUnit......................................................................59

InstallationoftheInterfaceUnit............................................................................60

Installationoftheaudiosystem..............................................................................61

UPSINSTALLATION........................................................62

CABLELAYOUTANDINTERCONNECTIONS......................63

Cableplan...............................................................................................................64

Listofcables..........................................................................................................66

Cableprocedures....................................................................................................72

ConnectACmainstotheUninterruptedPowerSupply..................................73

ConnectthevideocablefromtheProcessorUnittothecolourdisplay...........74

ConnecttheUSBcablefromtheOperatingPaneltotheProcessorUnit...........75

ConnecttheOperatingPanel“Dualcable”....................................................76

ConnectthetwocablesfromtheInterfaceUnittotheProcessorUnit.............77

ConnecttheProcessorUnittotheBeamformerUnit......................................78

ConnectACmainsandgroundtotheProcessorUnit.....................................79

ConnectACmainsandgroundtotheBeamformerUnit................................80

ConnectACmainstothecolourdisplay.......................................................81

ConnectACmainstotheTransceiverUnit...................................................82

ConnectgroundtotheInterfaceUnit............................................................83

ConnectgroundtotheOperatingPanel........................................................84

ConnecttheBeamformerUnittotheTransceiverUnit...................................85

4

307531/C

Page 7

Installationmanual

ConnectACmainstotheMotorControlUnit...............................................86

ConnecttheTransceiverUnittotheMotorControlUnit................................87

ConnectACmainstotheHeatExchanger....................................................88

ConnecttheEthernetcableforscienticoutput.............................................89

Connectcabletoexternalaudiosystem........................................................89

Transducercable.........................................................................................90

Installationofinterfacecablestoperipheralequipment..................................90

Referencestocabledetailsanddrawings...............................................................90

START-UPPROCEDURES.................................................92

StartinguptheHullUnit........................................................................................92

Hullunitfamiliarization..............................................................................93

MotorControlUnitfamiliarization...............................................................94

Functionalcheck.........................................................................................95

Apply3-phaseACpower............................................................................96

Checkthehoistmotor’s3–phaseACconnections.........................................97

Checkthe3–phaseconnectionforcorrectrotationdirection...........................98

Checkthecontactoroperation......................................................................99

Functionalchecktoverifycorrecthoistandlowerfunctionality...................100

Startingupthewheelhouseunits..........................................................................102

CheckingtheOperatingPanel..............................................................................104

Functionaltest..........................................................................................104

StartinguptheTransceiverUnit...........................................................................112

Checkingthehoist/lowersystem..........................................................................113

Preparations..............................................................................................114

Selectthehullunittobeused.....................................................................114

Checkingthebridgefunctions....................................................................115

Checkingthesonarroomfunctions.............................................................118

Performself-noisetest..........................................................................................118

Startingupthesonarsystem.................................................................................119

Preparations.............................................................................................120

Actionsonthebridge................................................................................121

Actionsinthesonarroom..........................................................................122

Alignmentofthesonarpicture.............................................................................122

Adjustingthestabilisationsensoroffset...............................................................124

Deningownshipparameters..............................................................................125

Specifyshipdimensions............................................................................125

Specifyinstrumentpositionoffsets.............................................................126

INTERFACINGPERIPHERALEQUIPMENT......................128

Interfacesettings...................................................................................................128

Defaultinterfacesettings...........................................................................128

Howtochangetheinterfacesettings..........................................................129

Howtomonitorthetrafconaserialline...................................................130

307531/C

5

Page 8

SimradSX90

Installationprocedures.........................................................................................131

Connectingthespeedlog...........................................................................131

Connectingthecoursegyro.......................................................................133

Testprocedures.....................................................................................................134

Speedloginterfacetest.............................................................................134

Coursegyrointerfacesetupandtest...........................................................136

Positioningsysteminterfacesetupandtest.................................................137

Echosoundersysteminterfacesetupandtest..............................................137

Trawlsysteminterfacesetupandtest.........................................................138

Catchmonitoringinterfacesetupandtest...................................................139

Radiobuoysysteminterfacesetupandtest.................................................139

Currentmeterinterfacesetupandtest.........................................................140

FINALTESTSANDMEASUREMENTS..............................141

Sourcelevel(SL)measurements..........................................................................141

Preparations.............................................................................................142

Operationalmode.....................................................................................142

Testprocedure..........................................................................................143

Finalizingtheprocedure............................................................................143

Sourceleveltestresults.............................................................................144

Receivingvoltageresponse(VR)measurements.................................................145

Preparations.............................................................................................145

Testprocedure..........................................................................................145

Finalizingtheprocedure............................................................................146

Testresults...............................................................................................146

Noise/speedcurvemeasurements.........................................................................147

TECHNICALSPECIFICATIONS.......................................151

Powerspecications.............................................................................................151

Weightsandoutlinedimensions...........................................................................152

Environmentalspecications...............................................................................153

DRAWINGFILE.............................................................155

TransceiverUnitdimensions................................................................................156

InterfaceUnitdimensions....................................................................................157

MC80ProcessorUnitdimensions........................................................................158

MC81BeamformerUnitdimensions...................................................................159

OperatingPaneldimensions.................................................................................160

SX90Hullunitdimensions..................................................................................161

SX91Hullunitdimensions..................................................................................162

SX92Hullunitdimensions..................................................................................163

SX93Hullunitdimensions..................................................................................164

SX90/SX91Mountingtrunkdimensions.............................................................165

Page1......................................................................................................165

6

307531/C

Page 9

Installationmanual

Page2......................................................................................................166

SX92Mountingtrunkdimensions.......................................................................167

Page1......................................................................................................167

Page2......................................................................................................168

SX93Mountingtrunkdimensions.......................................................................169

Page1......................................................................................................169

Page2......................................................................................................170

SX90/SX91Optionaltrunkdimensions...............................................................171

SX92Optionaltrunkdimensions.........................................................................172

SX93Optionaltrunkdimensions.........................................................................173

SX90/SX91Blindcoverdimensions....................................................................174

SX92Blindcoverdimensions..............................................................................175

SX93Blindcoverdimensions..............................................................................176

AGENERALSAFETYRULES...............................................177

BEQUIPMENTHANDLING................................................178

Transportation.......................................................................................................178

Lifting...................................................................................................................178

Storagepriortoinstallationoruse.......................................................................179

Inspection.............................................................................................................180

Unpacking............................................................................................................181

Generalunpackingprocedure....................................................................181

Unpackingelectronicandelectromechanicalunits......................................182

Unpackingmechanicalunits......................................................................182

Unpackingtransducers..............................................................................182

Storageafterunpacking........................................................................................183

Storageafteruse...................................................................................................183

Cleaningcabinets......................................................................................183

Mechanicalunits.......................................................................................184

Cables......................................................................................................184

Internalbatteries.......................................................................................184

Dehumidier............................................................................................185

Coatings...................................................................................................185

Re-packaging........................................................................................................185

Temperatureprotection.........................................................................................185

Circuitboardhandlingandpackaging..................................................................186

Returningacircuitboard...........................................................................187

WhatisESD?.......................................................................................................187

CSX90CABLEDETAILS....................................................189

Cablingprinciples.................................................................................................189

Cablestoperipheraldevices.................................................................................190

Positioningsysteminterface......................................................................190

307531/C

7

Page 10

SimradSX90

Echosoundersysteminterface...................................................................191

Trawlsysteminterface..............................................................................191

Catchmonitoringsysteminterface.............................................................192

Currentmeterinterface..............................................................................193

Radiobuoysconnectioninterface...............................................................193

Cabledrawings.....................................................................................................194

InterfaceUnittoProcessorUnit................................................................195

Commercialcablewithmini-jack..............................................................196

InterfaceUnitseriallines..........................................................................197

Pulsespeedloginterface..........................................................................198

Externalsynchronisationinterface.............................................................199

RS-232totheInterfaceUnit.....................................................................200

SonarandITIcommunication....................................................................201

SonarandFS20/25communication............................................................202

SonarandPI44/PI54communication..........................................................203

SonarandPI30/PI32communication..........................................................204

Vesselground..........................................................................................205

ACmainswithIEC320/C21......................................................................206

ACmainstoMotorControlUnit...............................................................207

RJ45Ethernet,straight.............................................................................208

VGA/SVGADisplay.................................................................................209

USB.........................................................................................................210

DVI–IDisplay...........................................................................................211

Sonarserialline.......................................................................................212

OperatingPanel“Dual”............................................................................213

DBASICCABLEREQUIREMENTS......................................214

Cabletrays............................................................................................................214

RadioFrequencyinterference..............................................................................215

Physicalprotection...............................................................................................215

Grounding.............................................................................................................216

Cableconnections.................................................................................................216

Cableterminations................................................................................................216

Cableidentication...............................................................................................217

ETELEGRAMFORMATS....................................................218

TelegramsreceivedandsentbytheSX90............................................................219

Requiredsensors.......................................................................................219

Auxiliarysensors......................................................................................219

SpecicationofNMEAtelegrams.......................................................................221

DBSDepthbelowsurface.........................................................................221

DBTDepthbelowtransducer.....................................................................221

DPTDepth...............................................................................................222

GGAGlobalpositioningsystemxdata.....................................................222

8

307531/C

Page 11

Installationmanual

GLLGeographicalpositionlatitude/longitude............................................223

HDMHeading,magnetic...........................................................................223

HDTHeading,true...................................................................................223

MWDWinddirectionandspeed................................................................223

MWVWindspeedandangle.....................................................................224

TTMTrackedtargetmessage.....................................................................224

VBWDualgroundandwaterspeed...........................................................225

VTGCourseoverground&groundspeed..................................................226

VWRRelative(apparent)windspeedandangle..........................................226

YWPW aterpropagationspeed..................................................................226

ZDATimeanddate..................................................................................227

Specicationofproprietarytelegrams.................................................................227

DBSDepthoftrawlbelowsurface.............................................................227

GLLTrawlposition..................................................................................227

HFBTrawlheadropetofootropeandbottom..............................................228

MTWW atertemperatureatthetrawl.........................................................228

TDSTrawldoorspread.............................................................................228

TFITrawllling.......................................................................................229

TPCTrawlpositionincartesiancoordinates...............................................229

TPPTrackedtargetpositionormarker.......................................................230

TPTTrawlpositiontruevessel..................................................................230

TS2Trawlspread2...................................................................................230

TTSTrawltoshoaldistance......................................................................231

307531/C

9

Page 12

SimradSX90

10

307531/C

Page 13

ABOUTTHISMANUAL

Aboutthismanual

Purpose

Thepurposeofthismanualistoprovidetheinformationand

basicdrawingsrequiredforinstallationoftheSimradSX90Fish

ndingsonarsystem.

Abouttheseinstructions

Themanualisintendedfortechnicalpersonnel,engineersand

navalarchitects.Itisassumedthatthepersonnelisconversant

withthegeneralprinciplesofsonarinstallationandoperation.

Theseinstructionsmustbefollowedcarefullytoensureoptimal

sonarperformance.Asaguide,installationproceduresare

presentedintheordertheyaretobeperformed.Successful

completionofeachprocedureistobeconrmedbychecking

offthecorrespondingbox.Afterinstallation,thisdocument

shouldbestoredonboardthevesselforlaterreferencewhen

updatingorservicingtheequipment.Themanualalsodenesthe

equipmentresponsibility,andprovidesinstructionsforunpacking

andstorage.

Installationdrawings

Detailedvesselspecicmechanicaldrawingsfortheinstallation

mustbeprovidedbythecustomer,oranyshipyardcontractedto

performtheinstallation.Simradmay,onspecialorder,provide

assistancetothesedrawings.Drawingsmustbeapprovedby

theappropriatevesselcerticationauthoritypriortoinstallation

ofthesystem.

Note

Theinstallationinstructionsgiveninthisdocumentmustbe

adheredto.Failuretodosomayrendertheguaranteevoid.

KongsbergMaritimeASwillacceptnoresponsibilityforany

damageorinjurytothesystem,vesselorpersonnelcausedby

equipmentthathasbeenincorrectlyinstalledormaintained,

orbydrawings,instructionsorproceduresthathavenotbeen

preparedbyus.

307531/C

11

Page 14

SimradSX90

References

Refertothefollowingmanualsforadditionalinformation

abouttheSimradSX90sonarsystem.Ordernumbersin

brackets.Alldocumentscanbedownloadedfromourwebsite

t t p : / / w w w . s i m r a d . c o m .

h

•SimradSX90InstallationManual,English[307531]

•SimradSX90OperatorManual,English[307672]

•SimradSX90OperatorManual,Norwegian[315143]

•SimradSX90ReferenceManual,English[307670]

12

307531/C

Page 15

SIMRADSX90FISHFINDINGSONAR

StudythischaptertofamiliarizeyourselfwiththeSimradSX90

Fishndingsonarsystem.

Topics

•Basicinformationonpage13

•Mainunitsonpage14

•Installationprocedureonpage16

•Systemdiagramonpage18

•Scopeofsupplyonpage19

•Additionalrequireditemsonpage19

•Additionaloptionalitemsonpage21

•Generalsupplyconditionsonpage27

•Generalinstallationrequirementsonpage28

SimradSX90Fishndingsonar

Relatedtopics

•Generalsafetyrulesonpage177

•Equipmenthandlingonpage178

•Basiccablerequirementsonpage214

Basicinformation

TheSimradSX90Fishndingsonarisalongrange

omnidirectionallowfrequencysonar.Itisdesignedformedium

andlargesizedshingvessels,preferablyforpurseseiners,butit

isalsowellsuitablefortrawlers.Thesonarallowsyoutochoose

anoperationalfrequencybetween20to30kHz(in1kHzsteps),

andthebeamcanbeelectronicallytiltedfrom+10to–60degrees.

Greatemphasishasbeenplacedongivingthebestpossible

presentationsonahighresolutioncolourdisplay.TheProcessor

UnitiscontrolledbyMicrosoft’sWindowsXP®operating

system,whichresultinaexiblechoiceofdisplaymodesfora

largerangeofuserapplications.

Thesignalprocessingandbeamformingisperformedinafast

digitalsignalprocessingsystemusingthefulldynamicrange

ofthesignals.Inadditiontothetraditionalsinglefrequency

transceiversystem,theSimradSX90Fishndingsonarcontains

anadvancedfrequencymodulatedltersystem(FM).

Thecylindricalmulti-elementtransducerallowsthe

omnidirectionalsonarbeamtobetiltedelectronicallydownto

-60degrees.Thisallowsyoutoautomaticallytrackschoolsof

sh,andtoobservethewholewatervolumearoundthevessel.

Astabilisingsystemisincludedforelectronicpitchandroll

compensation.

307531/C

13

Page 16

SimradSX90

Mainunits

TheSimradSX90Fishndingsonarconsistsofthefollowing

units:

•Normallyinstalledinthewheelhouse:

–Displaymonitor

–OperatingPanel

–ProcessorUnit

–BeamformerUnit

–InterfaceUnit

–Amplierandloudspeakers(option)

•Normallyinstalledinthesonarroom:

–TransceiverUnit

–HullUnit

Wheelhouseunits

DisplayMonitor

TheDisplayMonitorisahigh-resolutioncolourLCD(Liquid

CrystalDisplay).Inadditiontothesonarpicture,themonitorcan

alsodisplaytheusermenufortheinteractiveoperation.Inorder

toeasethesituationcomprehension,certaincolourshavebeen

chosentobetterthedistinctionbetweenthevariouselementsin

thescene.

OperatingPanel

TheOperatingPanelcontainsallnecessarycontrolfunctions

foroperatingthesonar.Thecontrolsarearrangedinfunction

groups,whichgivesaclearandeasyoperation.Notethatall

sonaroperationalsomaybemadefromthetrackball,orfroman

optionalstandardmouse.

ProcessorUnit

TheProcessorUnitisamarinecomputer,whichrunsthe

MicrosoftWindowsXP®operatingsystem.Thesoftwareand

hardwarehasbeenmodiedbySimradtosuittheSX90sonar

requirements.Thepurposeofthiscomputeristoallowyou

tocontrolthesonar.Itprovidesthegraphicpresentationof

thesonarmodesandtheimagescreated,itholdsthemenu

system,itcommunicateswiththeOperatingPanel,andreads

14

307531/C

Page 17

SimradSX90Fishndingsonar

informationfromperipheralunitsbymeansoftheInterfaceUnit.

Thecomputerholdsaread/writeCDunittobeusedforfuture

softwareupgrades.

BeamformerUnit

TheBeamformerUnitisamarinecomputer,whichrunsthe

MicrosoftWindowsXP®operatingsystem.Thesoftwareand

hardwarehasbeenmodiedbySimradtosuittheSX90sonar

requirements.Thepurposeofthiscomputeristoperformthe

advancedsignalprocessingrequiredtopresenttheinformation

ontheProcessorUnit.Thecomputerholdsaread/writeCDunit

tobeusedforfuturesoftwareupgrades.TheBeamformerUnit

communicateswiththeTransceiverUnitinthesonarroomusing

asingleethernetcable.

InterfaceUnit

TheInterfaceUnitprovidesinterfaceforallauxiliaryequipment;

log,gyro,GPS,echosounder,trawlsystems,purseseinesystems

etc.

Amplierandloudspeakers

Anamplierwithoneortwoloudspeakersmaybeconnectedto

theBeamformerUnittoprovidetheaudiooutput.Theseoptional

itemsaren

o t providedwiththesonardelivery.

Sonarroomunits

TransceiverUnit

TheTransceiverUnitislocatedinthesonarroom,closeto

theHullUnit.OneEthernetcableisusedforcommunication

withtheBeamformerUnitinthewheelhouse.Thetransceiver

performsthetransmissionandreceptioncontrolofthe256

transmittersand256receiverchannels,whicharelocatedonthe

eightidenticaltransceiverboards.

HullUnit

ThestandardSX92HullUnitisdesignedtobelowered1.2meters

belowtheship’shull,whileanoptionalhullunitwilllowerthe

transducerto1,6metersbelowthehull.Thetransducercanalso

beloweredtoanyselectedmiddleposition.Notethatincaseof

voltagefailure,theHullUnitcanbemanuallyraisedorlowered

bymeansofahandcrank.

307531/C

15

Page 18

SimradSX90

Transducerarray

ThecylindricalTransducerarrayallowsthesonarbeamtogive

full360degreescoverageofthewatervolumedownto-60

degrees.Thesensorfortheelectronicstabilizationofthesonar

beamsishousedintheMotorControlUnit,whichismounted

ontheHullUnit.

WARNING

Ifthetransducerhitslargerobjectsorbottom,

thetransducershaftmaybebent,orinworstcase

itcanbebrokenoff.Abrokentransducershaft

willcausewaterleakageinthetopoftheshaft.

Topreventlargerleakagesinsuchacase,donot

raisethetransducershafttotheupperposition.

Topreventseriousdamagesitisthereforeofgreat

importancetohaveagoodpumpandwarning

systeminthesonarroom.

Installationprocedure

TheSimradSX90Fishndingsonarsystemisacomplexand

advancedproductforprofessionaluse.

Note

Inordertoobtainmaximumsafetyandperformance,itisvery

importantthattheinstallationproceduresinthismanualare

compliedto,andthatthetasksarecarriedoutinthesuccession

theyaredescribed.Thevesselownermustmakesurethatthe

installationshipyardholdstheapplicablecompetencetoperform

theinstallation,andthattheapplicablemaritimeauthoritiesare

availabletoverifyandcertifytheinstallation.

ObservethebasicrequirementsinGeneralsafetyruleson

page177!

Anoverallinstallationprocedureisprovidedbelow.The

proceduredoesnotdescribeanydetailedtasks,butreferstothe

relevantproceduresinthismanual.

1Basedonthevesseldrawingsandbestpractice,

determinewherethehullunitshallbelocated.Necessary

considerationsmustbetakentoavoidacousticandelectric

disturbances.Makesurethatthesonarroommeetsthe

specicationsprovided.RefertoInstallationplanningon

page30.

2Performthephysicalinstallationofthesonartrunk.The

installationshipyardmustprovideallnecessaryinstallation

drawingsinordertocarryoutthisoperation,andifrequired,

thesedrawingsmustbeapprovedbytheapplicablemaritime

16

307531/C

Page 19

SimradSX90Fishndingsonar

authorities.Thetrunkpenetratesthehull,anditistherefore

acrucialpartofthehullunitassembly.RefertoSonartrunk

installationonpage36.

3Installthehullunit.Duetoitsphysicalsizeandweight,and

thefactthatthetrunkpenetratesthevesselhull,itisvery

importantthatthehullunitisinstalledandsecuredproperly.

RefertoHullunitinstallationonpage42.

4InstalltheTransceiverUnit.RefertoTransceiverunit

installationonpage49.

5Installthewheelhouseunits.RefertoWheelhouseunits

installationonpage53.

6Performthesystemcabling.Observetheprocedureand

cableplaninsectionCablelayoutandinterconnectionson

page63.Foradditionalinformation,refertoSX90cable

detailsonpage189.Generalrequirementsforthecabling

areprovidedinBasiccablerequirementsonpage214.

7Performthestart-upproceduresasdetailedinsection

Start-upproceduresonpage92.

Note

Inordertosetupthesonarsysteminasafeandcorrect

manner,thesestart-upproceduresmustbecompliedto!

8Connecttheperipheralunits.Observethesetupandtest

proceduresinsectionInterfacingperipheralequipmenton

page128.Foradditionalinformation,refertoSX90cable

detailsonpage189.Generalrequirementsforthecabling

areprovidedinBasiccablerequirementsonpage214.

9Finally,checkthesourcelevelandreceivingvoltage

response,andmakethenoise/speedmeasurements.Observe

theproceduresinsectionFinaltestsandmeasurementson

page141.

307531/C

17

Page 20

SimradSX90

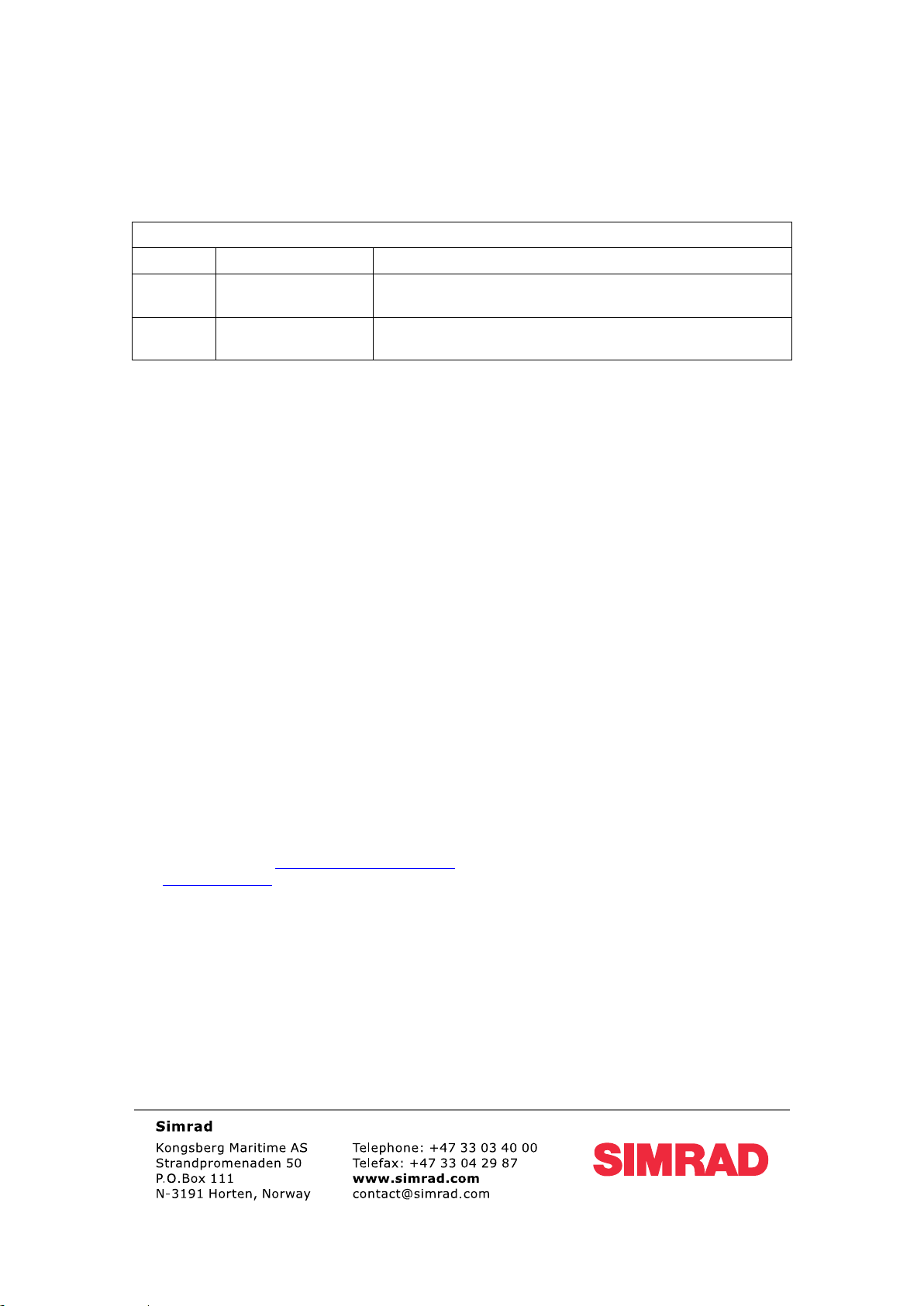

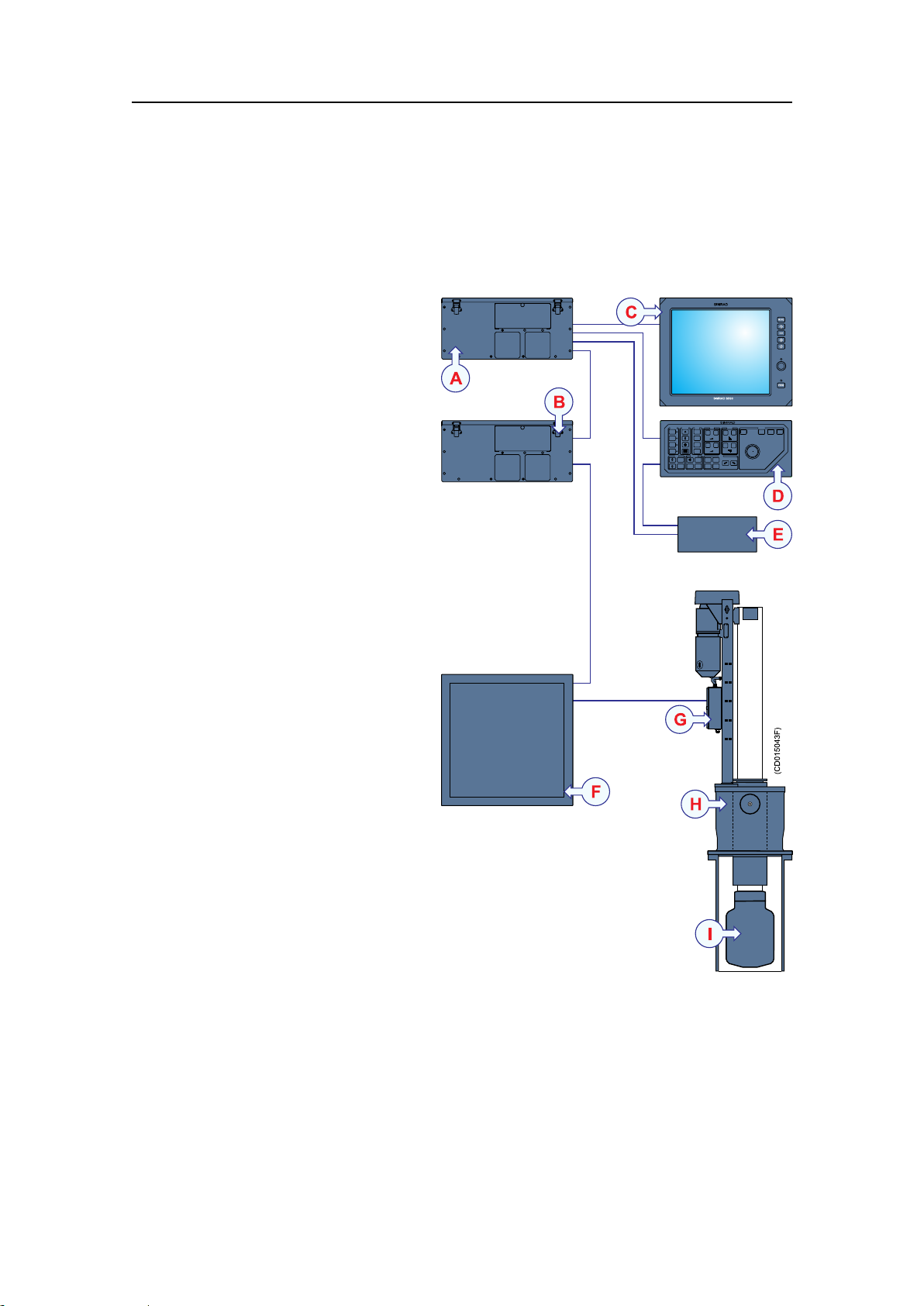

Systemdiagram

Figure1SX90Systemdiagram

SX90Items

AProcessorUnit

BBeamformerUnit

CColourdisplay

DOperatingPanel

EInterfaceUnit

FTransceiverUnit

GMotorControlUnit

HHullUnit

ITransducer

18

307531/C

Page 21

Scopeofsupply

ThestandardSimradSX90Fishndingsonarsystemis

comprisedofthefollowingmainunits.Allareincludedwiththe

standarddelivery.

•OperatingPanel[SH8-203593]

•ProcessorUnit[307664]

•BeamformerUnit[307666]

•InterfaceUnit[SP7-207891]

•TransceiverUnit(230V ac)[307668]

•SX92HullUnit[307476]

Additionalrequireditems

SimradSX90Fishndingsonar

Thefollowingadditionalitemsarerequiredforafullyoperational

sonar,buttheyaren

•Colourdisplay

•UninterruptedPowerSupply(UPS)

•Installationtrunk

•Speedlog

•Coursegyro

o t i n c l u d e d inthestandarddelivery:

Colourdisplay

TheSimradSX90FishndingsonarrequiresaVGAorDVI

colourdisplaywitharesolutionofatleast1280x1024pixels.

UninterruptedPowerSupply(UPS)

InordertoensurecontinuousoperationoftheSimradSX90

independentofvaryingqualityofthevessel’smainssupply,the

useofuninterruptedpowersupplies(UPS)isrequired.TwoUPS

unitsareused.Oneisusedtopowerthewheelhouseunits,while

theotherisusedtopowertheTransceiverUnit.

307531/C

19

Page 22

SimradSX90

Figure2NetProUPSunits

TheUPSunitsaren o t includedintheSX90standarddelivery.

WerecommendthatthefollowingUPSunitsareused:

WheelhouseUPSunit

•Manufacturer:GEDigitalEnergy

•Model:NetProNP1000

•Outputpower:1000V A/600W

•Physicaldimensions:

–Height:225mm

–Width:185mm

–Depth:430mm

–Weight:15kg

SonarroomUPSunit

•Manufacturer:GEDigitalEnergy

•Model:NetProNP2000

•Outputpower:2000V A/1200W

•Physicaldimensions:

–Height:293mm

–Width:220mm

–Depth:557mm

–Weight:27kg

Manufacturer

•GEDigitalEnergy

GeneralElectricCompany

CH–6595Riazzino(Locarno)Switzerland

w

w w . g e d i g i t a l e n e r g y . c o m

20

307531/C

Page 23

Installationtrunk

SimradSX90Fishndingsonar

Theinstallationtrunkrequiredforthehullunitinstallationisn

includedintheSX90standarddelivery.Theinstallationtrunk

maybefabricatedbytheshipyard,orsuppliedbySimradasan

option.Themechanicaldrawingsofthetrunkandblindcover

areincludedinthismanual.TheSimradSX90sonarisdelivered

withoutadomesystem.

TheoptionaltrunkofferedbySimradisapprovedbyDetNorske

Veritas(DNV),andincludesablindcoverandagasket.

Speedlog

Inordertooperatecorrectly,theSimradSX90Fishndingsonar

systemrequiresinputfromaspeedlog.Inmostcasesasuitable

sensorisalreadyinstalledonthevessel.Thespeedloginterface

parametersare:

•Pulselog:200pulsespernauticalmile

•Serialline:RS-232,StandardNMEA0183telegramformat

Adifferentialglobalpositioningsystem((D)GPS)canalsobe

used.

Relatedtopics

•Otherperipheralequipmentonpage23

o t

Additionaloptionalitems

Coursegyro

Inordertooperatecorrectly,theSimradSX90Fishnding

sonarsystemrequiresinputfromacoursegyro.Inmostcases

asuitablesensorisalreadyinstalledonthevessel.Thecourse

gyrointerfaceparametersare:

•Serialline:RS-232,StandardNMEA0183

IfthecoursegyroinstalleddoesnotoutputRS-232,anoptional

gyrointerfaceboxisavailable.Itwillconvertthefollowing

synchroandsteppinggyrosignals:

•3-phasesynchrosignal,20to150VL-L,50/60/400Hz,gear

ration1:360or1:180

•3-phasesteppersignal,20to150VL-L,gearration1:360or

1:180

GyrointerfaceOrderno.

LR40298-078535

Thefollowingoptionalequipmentandfunctionalitymaybe

orderedatanadditionalchargetoaugmentthestandardSimrad

SX90Fishndingsonarsystemdelivery.

307531/C

21

Page 24

SimradSX90

•Hullunitsandinstallationtrunks

•Additionalfunctionality:

–Scienticinterface

–Extendedrange

•Amplierwithoneortwospeakersforaudiooutput

•Otherperipheralequipmentandsensors

Optionalhullunitsandinstallationtrunks

Hullunits

ThestandardSX92HullUnitcanbelowered1.2metersataspeed

of24knots.Themountingangehas24boltswithpitchcentre

diameter(PCD)680mm.Otherhullunitsareavailableaslisted

below.

Table1HullunitsavailablefromSimrad

HullUnit

SX901.2m,24knots,20bolts,PCD620mm

SX911.6m,20knots,20bolts,PCD620mm

SX92*1.2m,24knots,24bolts,PCD680mm

SX931.6m,20knots,24bolts,PCD680mm

SX951,0m,12knots,16bolts,PCD540mm

(*=SX92isthestandardhullunit)

Note

SpecicationsOrderno.

307472

307474

307476

307478

310279

TheSimradSX90andSimradSX91hullunitsandtrunksare

discontinued.Theyareonlydeliveredonspecialorder .

Installationtrunks

Theinstallationtrunkmaybefabricatedbytheinstallation

shipyard,orsuppliedbySimrad.Severaltypesareavailablewith

variouspitchcentrediameters(PCD).

Table2OptionalinstallationtrunksavailablefromSimrad

Trunktype

SX90/SX9120bolts,PCD620mmSP9-205825

SX92/SX9324bolts,PCD680mmSP9-207516

SX9516bolts,PCD540mmSQ4–042508

22

SpecicationsOrderno.

307531/C

Page 25

SimradSX90Fishndingsonar

Note

TheSimradSX90andSimradSX91hullunitsandtrunksare

discontinued.Theyareonlydeliveredonspecialorder .

Optionalfunctionality

Extendedrange

Duetointernationalregulations,sonarswithoperationalrange

exceeding5000meterscanonlybeexportedonlicense.Forthis

reasonthestandardrangeontheSX90hasbeenlimitedto4500

meters.However,ifanexportlicenceisobtained,themaximum

rangecanbeextendedto8000meters.

OptionOrderno.

Extended8000mrange314506

Scienticinterface

Aspecialsoftwarekeycanbepurchasedtoenableanethernet

interfaceprovidingsonarbeamdata,sonarsettingsandprocessed

targetdata.Thisfeatureisveryusefulifthesonarisintended

forscienticpurposes.

OptionOrderno.

Scienticinterface

KIT-203477

Otherperipheralequipment

Inadditiontothepulseloginputdescribedabove,theSimrad

SX90FishndingsonarprovidesatotalofsevenRS-232

seriallines.Sinceoneisusedtointerfacethecoursegyro,the

remainingsixseriallinesmaybeusedfor:

•DifferentialGlobalPositioningSystem((D)GPS)

•Echosounder

•Catchmonitoringsystem

•Trawlsonar

•Currentmetersystem

•Radiobuoysystem

AlltheseperipheralsmaybeconnectedusingRS-232seriallines.

MostofthemwillcommunicatebymeansofthestandardNMEA

0183format.

307531/C

23

Page 26

SimradSX90

DifferentialGlobalPositioningSystem((D)GPS)

A(D)GPSmaybeinterfacedwiththeSimradSX90sonarto

establishthevessel’spositionandprovidecursorandmarker

latitudeandlongitude.Inadditiontonavigationaldata,the

(D)GPSmayalsobeusedfortheinputofspeedloginformation.

Most(D)GPSareequippedtopresentcourseinformation,but

thisdataisgenerallytooinconsistenttoprovideastablesonar

presentation.

Echosounder

Anexternalechosoundermaybeconnectedtothesonarto

providedepthinformationonthecatchcontrolpageofthe

sonar’sdisplay.

Catchmonitoringsystem

Toprovidetrawlandpurseseinedepthinformationonthesonar’s

display,thefollowingSimradcatchmonitoringsystemsmay

beconnected:

•SimradPI30Catchmonitoringsystem

•SimradPI32Catchmonitoringsystem

•SimradPI44Catchmonitoringsystem

•SimradPI54Catchmonitoringsystem

•SimradITIIntegratedTrawlInstrumentationsystem

Trawlsonar

Toprovidetrawlinformationonthesonar’sdisplay,oneofthe

followingSimradtrawlsystemsmaybeconnected:

•SimradFS903Trawlsonar

•SimradFS3300Trawlsonar

•SimradFS20/25Trawlsonar

•SimradFS70Trawlsonar

Currentmetersystem

Acurrentmetersystemmaybeconnectedtothesonartodisplay

thedirectionandspeedoftheseacurrentsonvariousdepths.The

followingcurrentsystemcanbeconnected:

•KaijoDCG-200

24

307531/C

Page 27

SimradSX90Fishndingsonar

Radiobuoysystem

AGPSbasedradiobuoysystemmaybeconnectedtothesonar

toshowthepositionandbuoydataonthedisplay.Thefollowing

buoysystemscanbeconnected:

•SERPE

•Ariane

•Ryokusei

Optionalaudiooutput

TheSimradSX90Fishndingsonarsystemprovidesanaudio

output.Inordertousethisfunction,youmustconnectan

amplierwithspeakerstotheaudiooutputontheBeamformer

Unit.

Abouttheaudiooutput

TheaudiooutputontheSimradSX90Fishndingsonarisaline

output,andnopoweramplierisprovidedtocreatesound.The

audiooutputmustthereforebeconnectedtoapoweredaudio

system.Thesystemmustincludeavolumecontrol,astheaudio

outputlevelfromthesonarisxed.Theaudiooutputlevelcan

notbecontrolledbytheAudiooffbuttonontheOperatingPanel,

asthisbuttonwillsilencetheaudiooutputcompletely.

Note

Donotconnectaloudspeakerdirectlytotheaudiooutput.This

maydamagetheaudiooutputcircuitry.

Werecommendthatoneofthefollowingaudiosystemsisused:

•PoweredspeakersystemforPCuse

•Stereosystemwithamplierandtwoormoreloudspeakers

307531/C

25

Page 28

SimradSX90

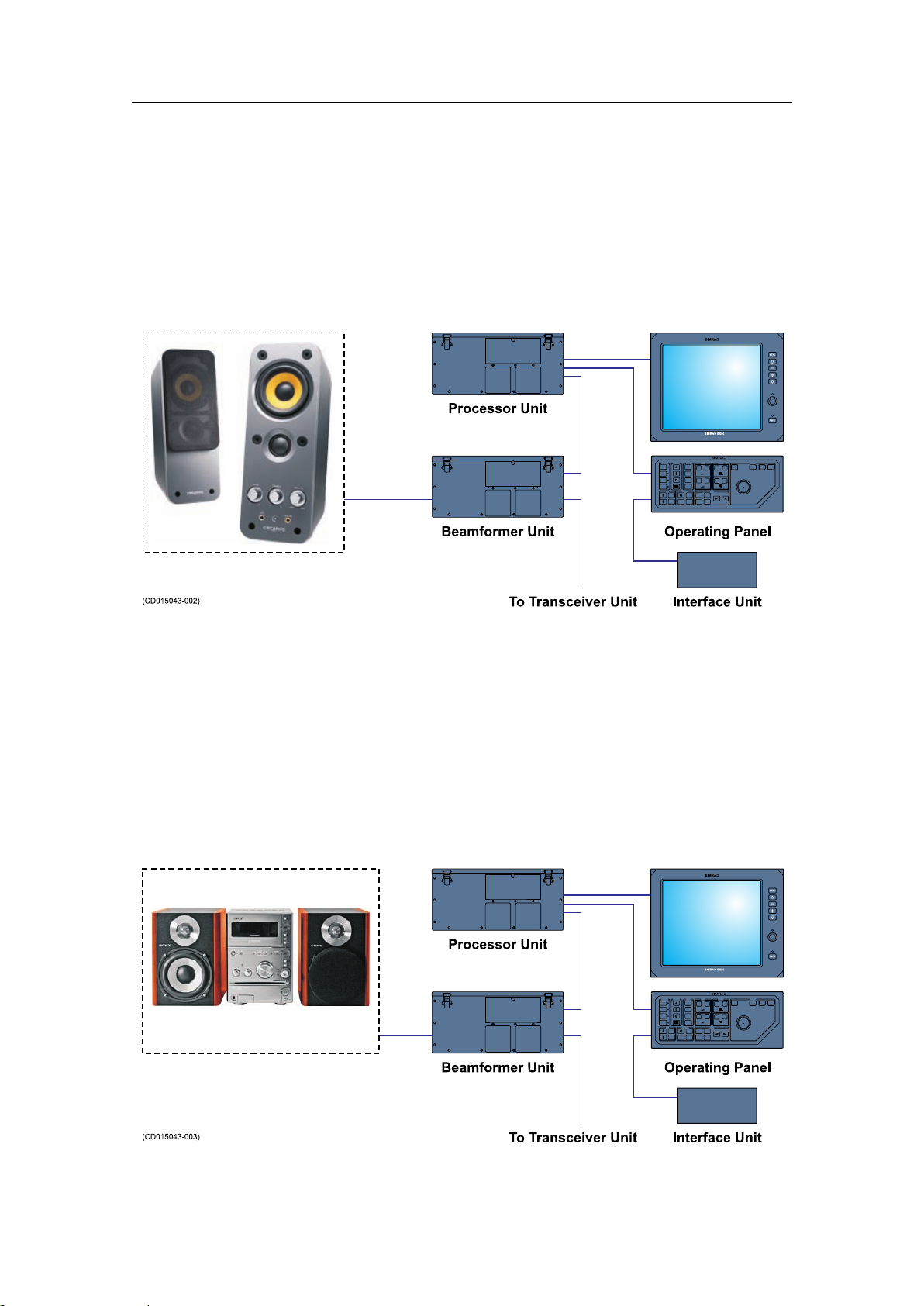

PoweredspeakersystemforPCuse

AcommercialpoweredspeakersystemforPCusecanbe

obtainedfromalmostanykindofshopforelectricappliances,

homestereoorcomputers.

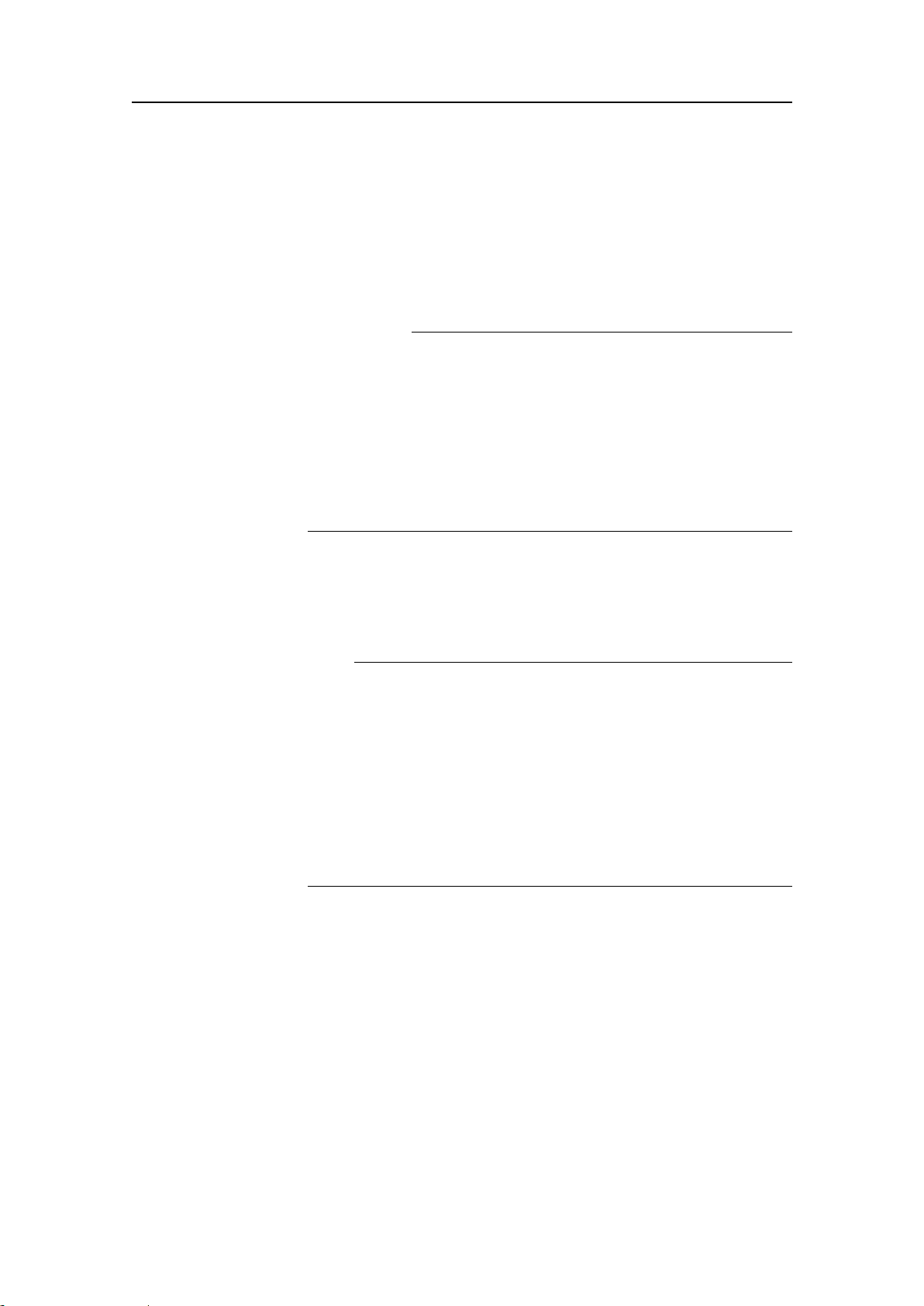

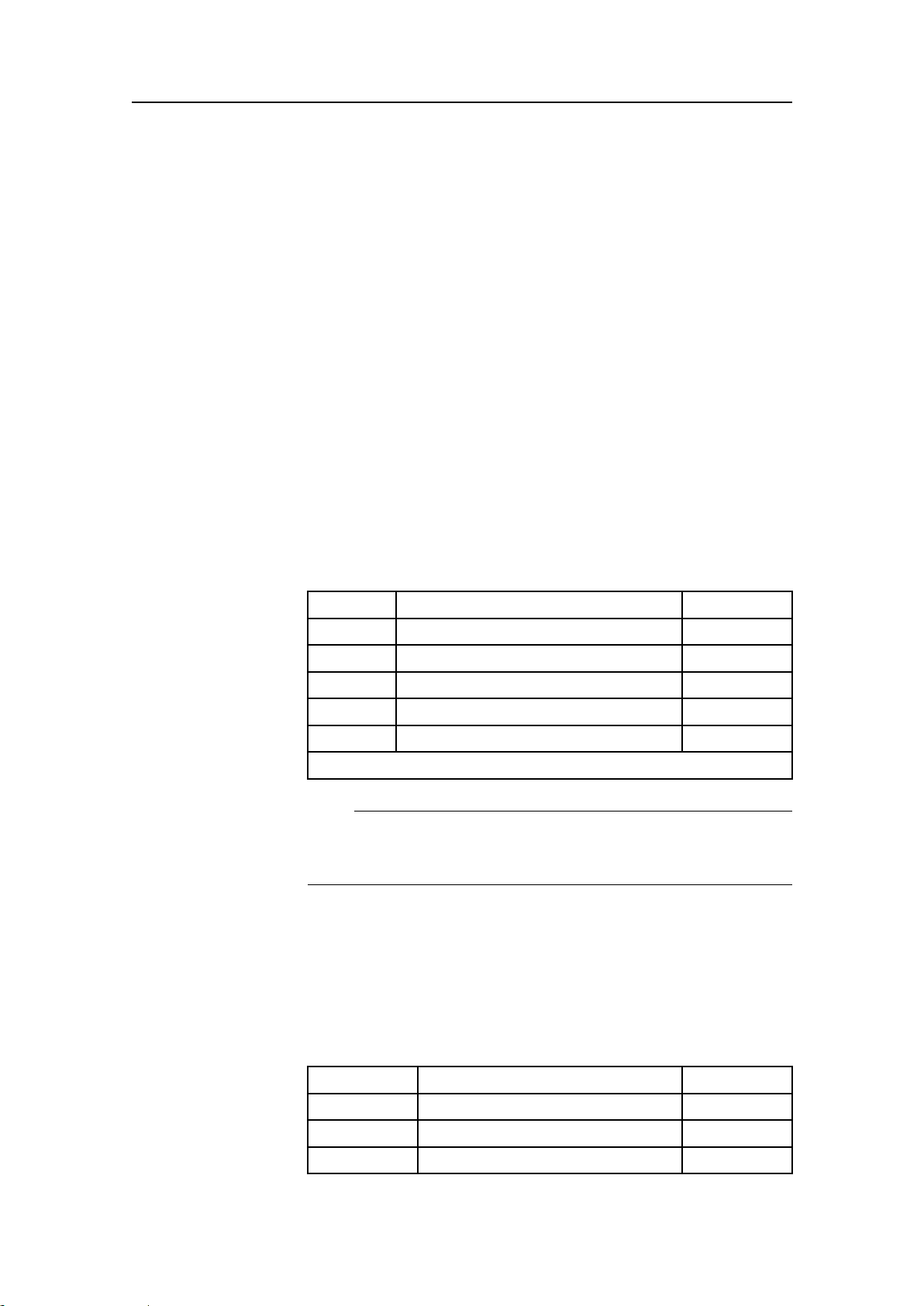

Figure3SonaraudiousingpoweredspeakersystemforPC

Thenumberofspeakers,sizeandpoweroutputcanbeselected

tosuitthecrewpreferences.Thelocationofthespeakersmustbe

decidedtoallowforeasyadjustmentoftheaudiolevel.

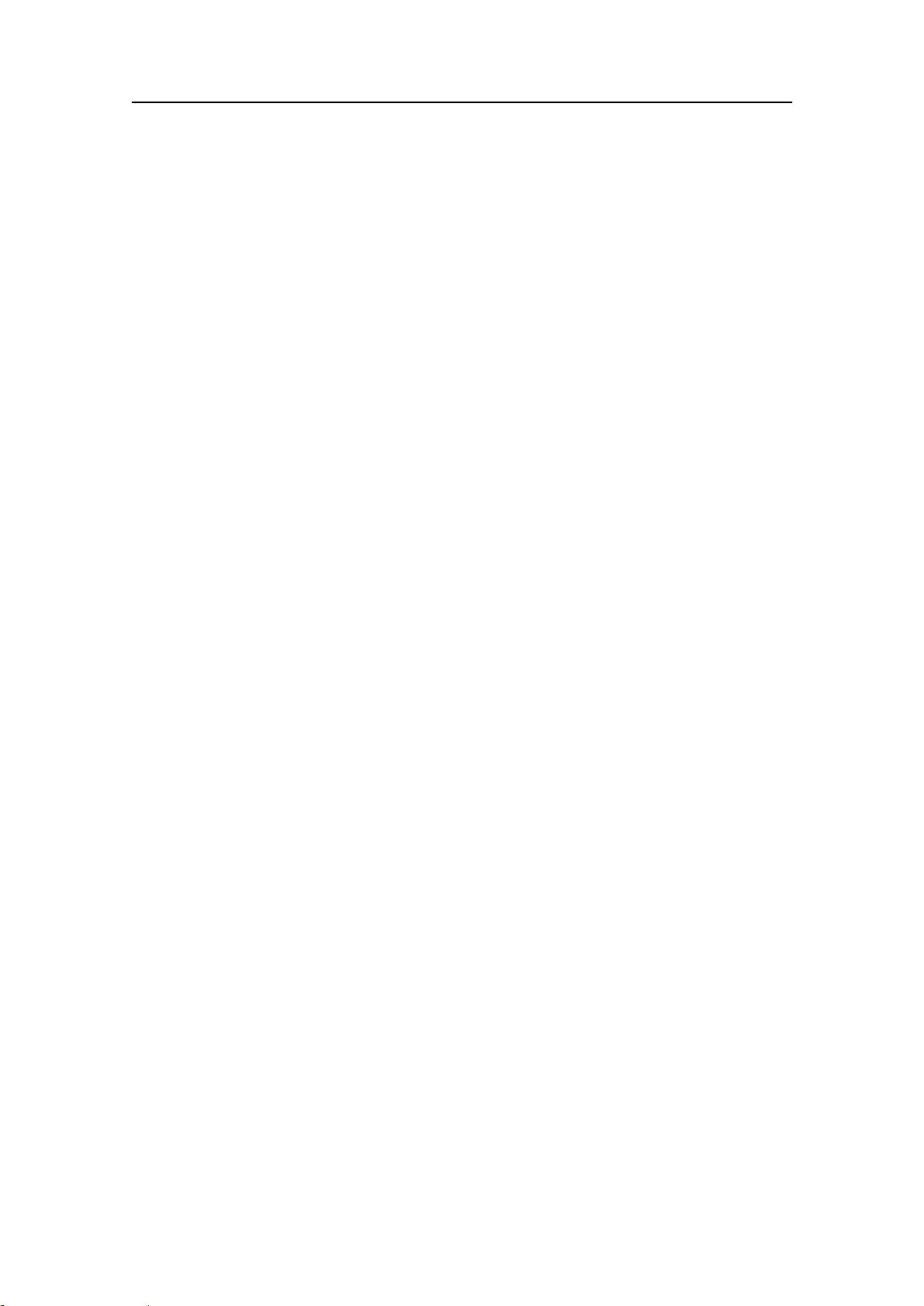

Stereosystemwithamplierandtwoormore

loudspeakers

Ifastereosystemisalreadyinstalledonthebridge,theaudio

outputfromthesonarcanbeconnectedtoanauxiliaryinput.

Figure4Sonaraudiousingexistingstereosystem

26

307531/C

Page 29

Generalsupplyconditions

SimradSX90Fishndingsonar

Theadvantageofthissetupisthatmoststereosystemsare

providedwitharemotecontrol,andthisallowsforeasy

adjustmentoftheaudiolevel.

ThefollowingsupplyconditionsareapplicabletothisSimrad

SX90Fishndingsonardelivery.

Equipmentresponsibility

Theshipyardperformingtheinstallationand/orequipmentdealer

becomesfullyresponsiblefortheequipmentuponreceiptunless

otherwisestatedinthecontract.Thedurationofresponsibility

includes:

•Theperiodoftimetheequipmentisstoredlocallybefore

installation.

•Duringtheentireinstallationprocess.

•Whilecommissioningtheequipment.

•Theperiodoftimebetweencommissioningandthenal

acceptanceoftheequipmentbytheenduser(normallythe

ownerofthevesselwhichtheequipmenthasbeeninstalled).

Unlessotherarrangementshavebeenmadeinthecontract,the

SX90Fishndingsonarsystemguaranteeperiod(asspeciedin

thecontract)beginswhentheacceptancedocumentshavebeen

signed

Receipt,unpackingandstorage

Uponacceptingshipmentoftheequipment,theshipyardand/or

thedealershouldensurethatthedeliveryiscompleteandinspect

eachshippingcontainerforevidenceofphysicaldamage.If

thisinspectionrevealsanyindicationofcrushing,dropping,

immersioninwateroranyotherformofdamage,therecipient

shouldrequestthatarepresentativefromthecompanyusedto

transporttheequipmentbepresentduringunpacking.

Allequipmentshouldbeinspectedforphysicaldamage,i.e.

brokencontrolsandindicators,dents,scratchesetc.during

unpacking.Ifanydamagetotheequipmentisdiscovered,the

recipientshouldnotifyboththetransportationcompanyand

SimradsothatSimradcanarrangeforreplacementorrepairof

thedamagedequipment.

Onceunpacked,theequipmentmustbestoredinacontrolled

environmentwithanatmospherefreeofcorrosiveagents,

excessivehumidityortemperatureextremes.Theequipment

mustbecoveredtoprotectitfromdustandotherformsof

contaminationwhenstored.

307531/C

27

Page 30

SimradSX90

Generalinstallationrequirements

Relatedtopics

•Equipmenthandlingonpage178

Thefollowinginstallationrequirementsareapplicabletothis

SimradSX90Fishndingsonardelivery.

Approvalbyclassicationsociety

TheSX90Fishndingsonartransducerinstallationmustbe

approvedbyDetNorskeV eritas(DNV)oranotherclassication

society.Theshipownerandshipyardperformingtheinstallation

areresponsibleforobtaininginstallationapproval.

Supplypower

Thesupplyvoltagetotheequipmentistobekeptwithin±10%of

theinstallation’snominalvoltage.Maximumtransientvoltage

variationsonthemainswitchboard’sbus-barsarenottoexceed

-15%to+20%ofthenominalvoltage(exceptunderfault

conditions).

SimradrecommendsthattheSX90Fishndingsonarispowered

usinganUninterruptablePowerSupply(UPS)withsinewave

output.TheUPSmusthavethecapacitytoindependently

maintainpowertothesystemforaminimumof10minutes.

Thisensuresthatthesystemcanbeswitchedoffinacontrolled

mannerintheeventofapowerfailure.

Compassdeviation

Oncetheinstallationiscomplete,thevesselmustbeswungwith

thesysteminboththeoperativeandinoperativemodes.The

shipownerandcaptainareresponsibleforupdatingthedeviation

tableaccordinglywithregardtothevessel’snationalregistryand

correspondingmaritimeauthority.

Noisesources

Thevessel’shull,rudder(s)andpropeller(s)shouldbethoroughly

inspectedindrydockpriortoinstallation.Roughnessbelow

thewater-linedeformitiesintheshellplatingandprotruding

obstaclescancreateunderwaternoise.Thesesourcesof

turbulencemustbesmoothedorremovedasbestaspossible.Itis

especiallyimportantthatthepropeller(s)isnotpittedordamaged.

28

307531/C

Page 31

SimradSX90Fishndingsonar

Drydocking

Makesurethatampleclearanceunderthesonartrunkand/or

protectionblisterisprovidedwhendrydockingthevessel.Avoid

locatingsupportingblocksorstructuresinthevicinityofthis

equipment.

Note

Thelocationofthetransducerand/orprotectionblistermustbe

notedonthevessel’ sdockingplanforfuturereference.

Powerdownallhydroacousticsystems,andlabeleachsystem

accordinglytopreventaccidentalpoweron.Removecircuit

breakersifnecessary.

Wiring

Allcablesrunningbetweensystemcabinetslocatedindifferent

roomsand/orondifferentdecksmustbesupportedandprotected

alongtheirentirelengthsusingconduitsand/orcabletrays.Note

thatthecablesmustnotbeinstalledinthevicinityofhigh-power

suppliesandcables,antennacablesorotherpossiblesources

ofinterference.

Formoredetailedinformationaboutcablesandwiring,referto

Basiccablerequirementsonpage214

307531/C

29

Page 32

SimradSX90

INSTALLATIONPLANNING

Note

Forinstallationinapreviouslyinstalledtrunksystem,rstread

theinformationaboutsonarroomrequirements.Thenproceed

totheHullUnitinstallationdescription.

Thischapterprovidesthemarineengineersresponsiblethe

informationnecessarytoplanandinstallthesonar’shullunit

accordingtoSimrad’srequirements.Correctinstallationofthe

sonartransducerisvitaltothesystem’sperformance.Several

variablesmustbetakenintoconsideration,themostimportant

ofwhichisthevessel’sconstruction.Thisguideisforusein

selectingthebestlocationforthetransducerandincludesabrief

descriptionofareastobeavoided.

Topics

Aboutinstallationdrawings

•Aboutinstallationdrawingsonpage30

•Locationofthehullunitonpage31

•Sonarroomrequirementsonpage32

•Sonarroomarrangementexampleonpage34

Allinstallationdrawingsmustbesuppliedbytheshipyard

performingtheinstallation.

Note

Theinstallationmustbeapprovedbythevessel’ snationalregistry

andcorrespondingmaritimeauthorityand/orclassication

society.Theshipownerandshipyardperformingtheinstallation

areresponsibleforobtainingandpayingforinstallation

approval.

Simradoffersfreeadviceforinstallationplanning.Proposed

arrangementsmaybesentforcommentaryorsuggestions

suppliedbySimrad.Thefollowingdrawingsshouldbesubmitted

shouldassistanceberequested:

•Generalarrangement

•Bodyplananddrawingsofrelevantbottomtanksand

cofferdams

•Linesplan

30

307531/C

Page 33

Locationofthehullunit

Foreandaft

Thehullunitshouldpreferablybelocatedwithin1/3to1/10

ofthevessel’sLengthBetweenPerpendiculars(LBP)fromits

ForwardPerpendicular(FP).Deviationsshouldnotbemade

withoutconsultingSimrad.

Athwartships

ThehullunitmaybelocatedontheCentreLine(CL)ofthe

vessel,oralongsideitskeel.Iftheinstallationisoffsetfromthe

vessel’scentreline,makesurethattransducertransmissionand

receptionwillnotbeobstructedbythekeel.

Figure5Locationofthehullunit

Installationplanning

AWaterlevelatnormaltrim

BW eldingmarkstoindicatehullunitlocationwhendocking

CLengthBetweenPerpendiculars(LBP)

D1/3to1/10ofLBP

Importantconsiderationsrelatedtonoise

Theinstallationtrunkmustbeinstalledsothatitwillremain

verticalundernormaloperatingconditions.Theprimarysources

ofunderwaterdisturbance(otherthanavessel’smainpropeller

andbow/sternthruster)thataffecttransducerreceptionare:

307531/C

31

Page 34

SimradSX90

Sonarroomrequirements

•Mainorbilgekeels

•Zincanodes

•Coolingelementsprotrudingfromthehull

•Equipmentsuchassonartransducersandpilottubes

•Seachests

•Overboarddischarges

•Dentsinthehull

Allappendagestothehull,indentationsandpipein/outletsare

potentialsourcesofunderwaternoise.Theymayactasresonant

cavitiesamplifyingnoiseatcertainfrequencies,createcavitation

orturbulence.Transducersshouldnotbelocatedinthevicinity

ofsuchobjectsandespeciallynotimmediatelyaftofthem.

Itisstronglyrecommendedtouseadedicatedcompartmentto

housethehullunitandthetransceivercabinet.Thesetwounits

mustalsobeinstalledrelativelyclosetoeachotherduetothe

limitedlengthofthetransducercables.Observetheseminimum

sonarroomrequirementstoobtainsuitableworkingconditions

forsonarinstallation,useandmaintenance.

Sizeandaccess

Awelldesignedsonarroomreducestheriskofcorrosionand

simpliesmaintenanceincreasingsystemreliability.

•Thesonarroommustbedimensionedtohousealltherelevant

cabinetsthatcomprisetheSX90Fishndingsonar.

•ThephysicaldistancebetweentheTransceiverUnitandthe

hullunitislimitedduetothelengthofthetransducercables.

•Thesonarroommustnotbeunnecessarilyobstructedby

girders,pipesetc.whichmightcauseinstallationproblemsor

impedemaintenance.

•Thesonarroommustbeaccessibleunderallconditionsat

seaorataberth.

•Alldoorsorhatchesmustbedesignedsothattheequipment

canberemovedwithoutbeingdisassembled.

Heating

Thesonarroommustbeequippedwithheater,dimensionedto

maintaintheequipmentwithinitsenvironmentaltolerances(at

least1000W),installedclosetothedeck.Heatingisalsoan

effectivemethodforreducinghumidity.

32

307531/C

Page 35

Installationplanning

Insulation

Bulkheadsmustbeinsulatedandprovidedwithaninteriorwall

tothedeck.Theinsulationshouldbetheminimumequivalent

of50mmofrock-wool.Inaddition,pipingpassingthroughthe

spacepronetocondensationmustbeinsulated.

Ventilation

Thesonarroommustbeconnectedtothevessel’sventilation

system.Ifthisisnotpossible,two3”ventsmustbeprovided

fromthesonarroomtothemaindeck.Intheroom,theairinlet

mustwheneverpossiblebelocatedclosetothedeckandthe

outletashighaspossible.Afunnelshapeddrip-collectormustbe

mountedbelowtheventpipestodivertmoisturetothebilge.On

themaindeck,thebestventilationisprovidedwhentheoutlet

pipeisatleastfourmetershigherthantheinletpipe.Tokeep

outseawater,rainandspray,theventilationpipesshouldbe

ttedwithgoosenecksortheequivalent.Ifthevesselislikely

tooperateintropicalconditions,asuitableairconditioning

systemmustbeinstalled.Thissystemmustbeabletoprovide

anambienttemperaturenotexceedingthemaximumoperating

temperaturesforthecabinetsinstalledintheroom.

Cableprotection

Ifthecablesbetweenthesonarroomequipmentandothersystem

unitslocatedindifferentcompartmentsonthevesselpass

throughhatchesorareaswheretheymaybedamaged,theymust

berunthroughconduits(minimum2”conduitisrecommended).

Electricalinstallationsandlights

Thesonarroommustbeequippedwithsuitablelightingto

simplifytheinstallationandtoaidfuturemaintenance.A

minimumnumberofelectricaloutletsmustbeprovidedforthe

systemunitsandotherequipment.

Bilgepumpanddecking

Thesonarroommustbeconnectedtothevessel’sbilgepump

system.Ifthisisnotpossible,aseparatebilgepumpforthe

sonarroommustbeinstalled.Oncetheinstallationhasbeen

completed,thesonarroommustbesuitablydeckedwithout

restrictingaccesstotheequipment.

Liftingdevice

Anattachmentpoint,ratedataminimumoftwo-2-tons,for

supportingaliftingdeviceshouldbelocatedabovethehullunit.

Thispermanentlyinstalledxturewillfacilitateinstallation

trunkandhullunitmounting,andalsomaybeusedforfuture

equipmentmaintenanceorreplacement.

307531/C

33

Page 36

SimradSX90

Removable

support

brackets

Transducercable

(Totallength4m)

Hatch

(min.680x1000)

TransceiverUnit

Ladder

500(*)

1600(*)

Allmeasurementsinmm

(*)=recommendedminimum

1600(*)

650(*)

150(*)

(CD015408A)

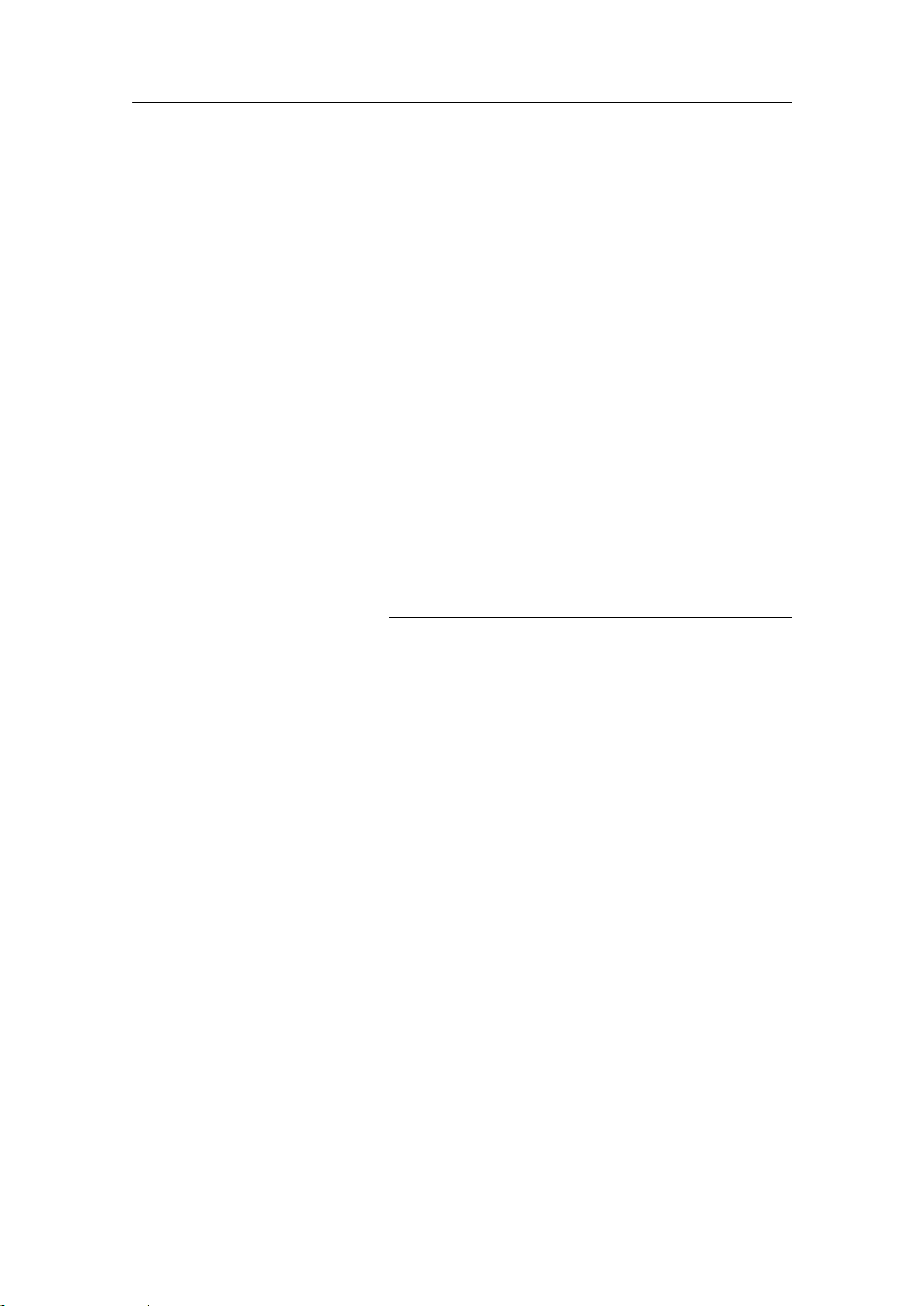

Sonarroomarrangementexample

Thesedrawingsillustrateatypicalsonarroomwithamplespace

forhullunit,transceiverunitandpersonnel.

Figure6Sonarroomarrangementexample,topview

34

307531/C

Page 37

Figure7Sonarroomarrangementexample,sideview

Airventpipes

(Min.diameter50mm)

Minimum4000mm

25

3000mm

(recommended+liftingdevice)

Loadcapacity

minimum2tonnes

Heater

TransceiverUnit

Pipes(10mm)

Airbleedingpipe

(Min.diameter10mm)

Lighting

1200mm(Recommended)

2115mm

(+400mmforSX91

andSX93)

250mm(minimum)

870mm

1600mm(SX91andSX93)

1200mm(SX90andSX92)

Max.1010mm

Min.910mm

(CD015408B)

Installationplanning

307531/C

35

Page 38

SimradSX90

SONARTRUNKINSTALLATION

Thesonartrunkprovidesthephysicalfoundationfortheentire

hullunitgantry .Thetrunkfurtherpenetratesthehull,anditis

thereforeacrucialpartofthehullunitassembly.Inorderto

ensurepropersonaroperation,thelocationofthesonartrunk

mustbecarefullyselected.

Note

Thisinstallationmanualdoesnotdescribetheinstallationofthe

SX95HullUnit.Forinformationaboutthatparticularhullunit,

refertothededicatedSimradSX95HullUnitinstallationmanual.

Atrunkwithablindcover–approvedbyDetnorskeV eritas

(DnV)–canbeorderedfromSimradasanoptionaldelivery,orit

maybemanufacturedbytheinstallationshipyardbasedonthe

drawingsinthismanualandthepropertiesofthehull.

Note

Theinstallationshipyardmustprovideallnecessaryinstallation

drawings,andifrequired,thesemustbeapprovedbythe

applicableauthorities.SeeAboutinstallationdrawingson

page30.

Topics

•Mountingthesonartrunkonpage37

•Sonartrunkprotectiononpage38

•Sonartrunkinstallationprinciplesonpage38

•Sonartrunkinstallationmeasurementsonpage41

Hullunitoutlinedimensiondrawings

•SX90Hullunitdimensionsonpage161

•SX91Hullunitdimensionsonpage162

•SX92Hullunitdimensionsonpage163

•SX93Hullunitdimensionsonpage164

•SX90/SX91Mountingtrunkdimensionsonpage165

•SX92Mountingtrunkdimensionsonpage167

•SX93Mountingtrunkdimensionsonpage169

•SX90/SX91Optionaltrunkdimensionsonpage171

•SX92Optionaltrunkdimensionsonpage172

•SX93Optionaltrunkdimensionsonpage173

•SX90/SX91Blindcoverdimensionsonpage174

•SX92Blindcoverdimensionsonpage175

36

307531/C

Page 39

•SX93Blindcoverdimensionsonpage176

Paralleltothe

centreline

(CD015404D)

Mountingthesonartrunk

Thelocationofthesonartrunkmustbecarefullyselected.

Note

Notetheorientationofthecentrelineofthetrunkwithregardto

themountingbolts.

Removethegasketonthetopangeduringwelding.

Figure8Orientationofthesonartrunk

Sonartrunkinstallation

Theheightfromthetopofthetrunkangetotheundersideof

theprotectionblistermustbeselectedasshownintheguresin

sectionSonartrunkinstallationprinciplesonpage38.

307531/C

37

Page 40

SimradSX90

Sonartrunkprotection

Note

Inordertoobtainoptimalsonarperformance,thetotalheight

ofthetrunkmustbeascloseaspossibletoitsstatedminimum

height.

Thetopangemustbeparalleltotheconstructionwaterlinein

boththefore-and-aftandathwartshipdirections.

Theinstallationtrunkmustbeweldedtoadoublingplatewhich

mustbeatleast1.5timesasthickasthesurroundingshellplating.

Thedoublingplate’snaldimensionsaretobegovernedbythe

approvedinstallationdrawingssuppliedbytheshipyard.The

trunkmustalsobestiffenedbyweldingknee-platestoitandthe

doublingplateinboththefore-and-aftandathwartshipdirections.

Protectingtheblister

Asteelblistermustbettedforprotection.Theblistershown

isweldedtotheshellplatingandthenlledwithoiltoprevent

corrosion.Thismethodprovidesexcellentprotectionand

simpliesmaintenance.

Corrosionprotection

Assoonasallinstallation,weldingandgrindinghasbeen

performed,thetrunkandthesurroundingareashouldbeprimed

andpaintedusingaqualityprotectivecoating.

Sonartrunkinstallationprinciples

Observethenexttwodrawings,theseillustratetheinstallation

ofthesonartrunk.

38

307531/C

Page 41

B

D

A

Fore-and-aftview

3-4knee-plates,mustbe

weldedtoframesorfloors

A:Asshortaspossible

B:Max.471/4"(1200mm)

C:Min.19/16"(40mm)

D:Min.357/8"(910mm)

E:Min.24"(610mm)

C

2.5-3xE

Thicknessofplates:

Knee-plates3/8"(10mm)

Blisteranddeflection

bracket1/4"(6mm)

Thecircularopeningofthe

blistershouldhavea

diameterequaltotheinside

diameterofthetrunk.

Deflection-bracketsshould

beweldedonlytothe

shell-plating.

Bottomview

Sideview

(CD015404N)

E

CD015404NPage1of2

Note:

Allmeasurementsareininchesandmm.

Thedrawingisnotinscale.

Sonartrunkinstallation

Figure9Installationofatrunkwithopenblister

307531/C

39

Page 42

2.5-3xE

B

D

A

Fore-and-aftview

Thicknessofplates:

Knee-plates3/8"(10mm)

Blisteranddeflection

bracket1/4"(6mm)

Thecircularopeningofthe

blistershouldhavea

diameterequaltotheinside

diameterofthetrunk.

Deflection-bracketsshould

beweldedonlytothe

shell-plating.

3-4knee-plates,mustbe

weldedtoframesorfloors

Plugforfillingofoil

Bottomview

A:Asshortaspossible

B:Max.471/4"(1200mm)

C:Min.19/16"(40mm)

D:Min.357/8"(910mm)

E:Min.24"(610mm)

Sideview

C

E

CD015404NPage2of2

Note:

Allmeasurementsareininchesandmm.

Thedrawingisnotinscale.

SimradSX90

Figure10Installationofatrunkwithoillledblister

40

307531/C

Page 43

Sonartrunkinstallationmeasurements

Sonartrunkinstallation

Forfuturereference,themeasurements“A”,“B”,“C”and“D”

fromthedrawingmustbemadeandnotedinthetablebelow.

Table3Trunkinstallationmeasurements

MillimetersInches

“A”

“B”

“C”

“D”

307531/C

41

Page 44

SimradSX90

HULLUNITINSTALLATION

ThischapterdescribesthephysicalinstallationoftheSimrad

SX90HullUnit.

Note

Thisinstallationmanualdoesnotdescribetheinstallationofthe

SX95HullUnit.Forinformationaboutthatparticularhullunit,

refertothededicatedSimradSX95HullUnitinstallationmanual.

Thehullunitisacrucialpartofthesonarsystem.Duetoits

physicalsizeandweight,andthefactthatthetrunkpenetrates

thevesselhull,itisveryimportantthatthehullunitisinstalled

andsecuredproperly.

Note

Theinstallationshipyardmustprovideallnecessaryinstallation

drawings,andifrequired,thesemustbeapprovedbythe

applicableauthorities.SeeAboutinstallationdrawingson

page30.

Topics

•Hullunitmodelsoverviewonpage43

•Howtounpackthehullunitfromitstransportboxonpage44

•Hullunitmountingonpage45

•Bleedingaircockonpage47

•Mechanicalsupportonpage47

•Transduceralignmentonpage47

•Hullunitinstallationchecklistonpage48

Relatedtopics

•Hullunitfamiliarizationonpage93

Hullunitoutlinedimensiondrawings

•SX90Hullunitdimensionsonpage161

•SX91Hullunitdimensionsonpage162

•SX92Hullunitdimensionsonpage163

•SX93Hullunitdimensionsonpage164

•SX90/SX91Mountingtrunkdimensionsonpage165

•SX92Mountingtrunkdimensionsonpage167

•SX93Mountingtrunkdimensionsonpage169

•SX90/SX91Optionaltrunkdimensionsonpage171

•SX92Optionaltrunkdimensionsonpage172

42

307531/C

Page 45

Hullunitmodelsoverview

SX90

SX92SX95

SX91

SX93

(CD015401-001)

Hullunitinstallation

•SX93Optionaltrunkdimensionsonpage173

•SX90/SX91Blindcoverdimensionsonpage174

•SX92Blindcoverdimensionsonpage175

•SX93Blindcoverdimensionsonpage176

TheSimradSX90sonarmaybedeliveredwithanyoneof

severaldifferenthullunitmodels.

Figure11SX90Hullunitmodels

•SX90:Thishullunithas1.2mstrokelength,anditis

designedformaximumspeed24knots.Itwilltontheold

Simradtrunkwith620mmpitchcentrediameter(PCD).

•SX91:Thishullunithas1.6mstrokelength,anditis

designedformaximumspeed20knots.Itwilltontheold

Simradtrunkwith620mmpitchcentrediameter(PCD).

•SX92:Thisisthe"standard"hullunitfortheSX90sonar.It

has1.2mstrokelength,anditisdesignedformaximumspeed

24knots.ItwilltonastandardSimradtrunkwith680mm

pitchcentrediameter.

307531/C

43

Page 46

SimradSX90

(CD015412B)

BB

C

A

•SX93:Thishullunithas1.6mstrokelength,anditis

designedformaximumspeed20knots.Itwilltonastandard

Simradtrunkwith680mmpitchcentrediameter.

•SX95:Thishullunithas1.0mstrokelength,anditis

designedformaximumspeed12knots.Itwilltonastandard

Simradtrunkwith540mmpitchcentrediameter.

Howtounpackthehullunitfromitstransportbox

Note

Thetransducerisprotectedtopreventdamageduringtransport

andhullunitinstallation.Thisprotectionmustremainattached

whilethehullunitisbeingmanoeuvredintothesonarroom.

Figure12Removingthehullunitfromitstransportbox

ALiftingeyeonthehoistingunit

BMountinghardware(woodencradleandsupport

construction)

CTransducerprotection

Procedure

1Removethetopcoverofthewoodenbox.

2Toremovethefasteninghardware(B),pulloutthenails

markedwithIndianink.

3Ifyouwishtoreusetheboxtoholdtheoldhullunit,make

surethatyoukeepallthefasteninghardwareusedtosecure

thehullunitinthewoodenbox.

4Fastentheliftingtackletothetwoliftingeyebolts(A)

onthetopofthehoistingunitandliftthehullunit(with

thetransducerprotectioninplace)carefullyoutofthe

transportationbox.

44

307531/C

Page 47

Hullunitinstallation

(CD015412C)

A

Note

Donotremovethetransducerprotection(C)fromthe

transduceruntiljustbeforethehullunitisloweredontothe

mountingtrunk.

Figure13Usethecorrectliftingeye!

Therearetwolifting

eyesoneachsideof

thehullunit:one

onthehoistingunit

andoneonthetopof

thetransducershaft.

Makesurethatyouuse

theliftingeyeonthe

hoistingunit(A)when

youliftthehullunitout

ofthetransportation

box!

5Ensurethatyoukeepthetransducercableandconnectordry.

Watchthesecarefullytopreventthemfrombeingdamaged,

stuckorhookedontoprotrudingobjectswhilemanoeuvring

thehullunitintothesonarroom.

Hullunitmounting

Thehullunitshouldnormallybeorientedwiththe

hoisting/loweringmotorpointingaft.Ifthisorientationmakes

theMotorControlUnitattachedtothehullunitdifcultto

access,thehullunitmaybeorientedinthemostsuitableposition.

307531/C

45

Page 48

SimradSX90

(CD015401B)

Bow

Figure14Orientationofthehullunit

Note

TheMotorControlUnitmustneverbephysicallydismounted

fromtheHullUnit.

Hullunitmountingprocedure

Tomakesurethattheprocedureisfollowed,tickoffeachtask

afterithasbeendone.

1

Useatackletolowerthehullunit(withthetransducer

protectioninplace)intothesonarroom

2Removetheblindcoverfromthetrunkandcheckthat

thegasketisnotdamaged.

3

Storetheblindcoverinthesonarroomforpossible

futureuse.

4Removethetransducerprotectionandlowerthehull

unitcarefullyontothetrunk.

5

Tightentheangenutswithatorqueofapproximately

470Nm.(OntheSX95hullunit,use140Nm.)

6Keepthetransducercableandconnectordry,and

handlethemwithgreatcaretopreventmechanicaldamage.

46

307531/C

Page 49

Bleedingaircock

(CD015401C)

A

B

C

Figure15Bleeding

aircock

Hullunitinstallation

Toavoiddamagetothetransducerby

thetransmissioninairinsidethetrunk,

apipewithaminimuminsidediameter

of10mmmustbeattachedtotheair

bleedingcock.Thisventshouldberun

withcontinuousrisetothemaindeck

orthroughthevessel’sside.Make

suretheairbleedingcockisopened.

AMinimum10mminternal

diameter

B3/8”pipethread

CV alveshowninopenedposition

Mechanicalsupport

Transduceralignment

Note

Toensurethesafetyofthesonarsystemandthevessel,itisvery

importantthatthemechanicalsupportofthehullunitgantry

issatisfactory.

Topreventunwantedvortexinducedvibration,thehullunit

mustbesecuredtothebulkhead.Usethetwopre-drilledholes

onthegantrytomountsupportbracketsinthefore-and-aftand

sidewaysdirection.Itmustbepossibletoremovethesupport

bracketsifmaintenanceisrequired.

Note

Ifyoudonotinstallapropermechanicalsupportforthehullunit

gantry,theguaranteewillbevoid!

Eventhoughyoumayhaveinstalledthehullunitoriented

differentlythanshowninthischapter,thetransducershalln o t

bemechanicallyaligned.

307531/C

47

Page 50

SimradSX90

TransduceralignmentisperformedintheSX90ProcessorUnit

byrotatingtheechopresentationonthedisplay.Thisisdescribed

insectionAlignmentofthesonarpictureonpage122.

Hullunitinstallationchecklist

Performaclosevisualinspectionofthesonarroomandthe

physicalinstallationofthehullunit.Refertothesonarroom

requirements,andllinthetablebelow.

Table4Hullunitinstallationchecklist

Item

Aretheaccesshatchessatisfactory?

Istheheatingsatisfactory?

Istheinsulationsatisfactory?

Istheventilationsatisfactory?

Istheairventpipesatisfactory?

Isabilgepumpinstalled?

Istheroomlightingsatisfactory?

Isthesonarroomsuitablydecked?

Isthemechanicalsupportofthehullunit

satisfactory?

DoyouhavesatisfactoryaccesstotheMotor

ControlUnit?

IftheanswertoanyofthesequestionsisNO,notethedeciencies

intheInstallationremarksandsignature.

Relatedtopics

•Sonarroomrequirementsonpage32

YESNO

48

307531/C

Page 51

TRANSCEIVERUNITINSTALLATION

TransceiverUnitpreparations

Transceiverunitinstallation

ThischapterexplainshowtoinstalltheSimradSX90Transceiver

Unit.Itisnormallypositionedinasonarroomclosetothehull

unit.

Topics

•TransceiverUnitpreparationsonpage49

•TransceiverUnitinstallationprocedureonpage49

Relatedtopics

•Sonarroomrequirementsonpage32