Page 1

com

TECHNOLOG

SUS

S

Installation Manual

Simrad ST90

Fish nding sonar

Y FOR

TAINABLE FISHERIE

www.simrad.

Page 2

Page 3

SimradST90

Fishndingsonar

InstallationManual

Thepurposeofthismanualistoprovidetheinformation,procedures

andbasicdrawingsrequiredforthephysicalinstallationoftheSimrad

ST90.Themanualisintendedfortechnicalpersonnel;suchasskilled

shipyardworkers,electricians,qualiedengineersandnavalarchitects.

ForinformationaboutthepracticaluseoftheST90,refertotheST90

ReferenceManualand/ortheST90OperatorManual.Youcanalso

ndinformationintheST90ContextSensitiveOn-lineHelp.

Caution

Asasafetyprecaution,youmustneverturnontheST90whenthe

shipisindrydock.Thetransducermaybedamagedifittransmits

inopenair.

442703/B

July2019©KongsbergMaritimeAS

Page 4

Documentinformation

•Product:SimradST90

•Document:InstallationManual

•Documentpartnumber:442703

•DocumentISBNnumber:N/A

•Revision:B

•Dateofissue:5July2019

Copyright

TheinformationcontainedinthisdocumentremainsthesolepropertyofKongsberg

MaritimeAS.Nopartofthisdocumentmaybecopiedorreproducedinanyformorby

anymeans,andtheinformationcontainedwithinitisnottobecommunicatedtoathird

party,withoutthepriorwrittenconsentofKongsbergMaritimeAS.

Warning

Theequipmenttowhichthismanualappliesmustonlybeusedforthepurposefor

whichitwasdesigned.Improperuseormaintenancemaycausedamagetothe

equipmentand/orinjurytopersonnel.Y oumustbefamiliarwiththecontentsofthe

appropriatemanualsbeforeattemptingtooperateorworkontheequipment.

KongsbergMaritimedisclaimsanyresponsibilityfordamageorinjurycausedby

improperinstallation,useormaintenanceoftheequipment.

Disclaimer

KongsbergMaritimeASendeavourstoensurethatallinformationinthisdocumentis

correctandfairlystated,butdoesnotacceptliabilityforanyerrorsoromissions.

Supportinformation

Ifyourequiremaintenanceorrepair,contactyourlocaldealer.Y oucanalsocontactus

usingthefollowingaddress:simrad.support@simrad.com.Ifyouneedinformation

aboutourotherproducts,visithttps://www .simrad.com.Onthiswebsiteyouwillalso

ndalistofourdealersanddistributors.

KongsbergMaritimeAS

www.kongsberg.com

Page 5

InstallationManual

Tableofcontents

ABOUTTHISMANUAL............................................................15

SIMRADST90........................................................................17

Important..........................................................................................................................17

Systemdescription...........................................................................................................19

Keyfeatures.....................................................................................................................21

Systemdiagram................................................................................................................22

Systemunits.....................................................................................................................23

Displaydescription.................................................................................................23

ProcessorUnitdescription......................................................................................23

TransceiverUnitdescription..................................................................................24

OperatingPaneldescription...................................................................................26

Hullunitdescription...............................................................................................27

Transducerdescription...........................................................................................29

Installationtrunkdescription..................................................................................30

Scopeofsupply................................................................................................................32

Basicitemsprovidedwithastandarddelivery.......................................................32

Additionalrequireditems.......................................................................................35

Additionaloptionalitems.......................................................................................39

Generalsafetyrules..........................................................................................................46

Installationrequirements..................................................................................................47

Supplypowerrequirements....................................................................................47

UninterruptiblePowerSupply(UPS)requirements...............................................47

Cablesandwiringrequirements.............................................................................48

Compassdeviationrequirements............................................................................48

Noisesources..........................................................................................................49

Drydockingrequirements......................................................................................49

Requirementforclassicationapproval.................................................................49

Networksecurity..............................................................................................................50

Supportinformation.........................................................................................................51

PREPARATIONS.....................................................................53

Installationsummary........................................................................................................54

Aboutinstallationdrawings.............................................................................................57

Tools,equipmentandconsumablesrequiredforST90installation.................................57

Personnelqualications...................................................................................................58

Choosingthebestlocationforthehullunit.....................................................................59

Aboutthehullunitlocation....................................................................................59

Deningtheforeandaftlocationofthehullunit..................................................60

442703/B

3

Page 6

SimradST90

Deningtheathwartshipslocationofthehullunit................................................61

Importantconsiderationsrelatedtonoise...............................................................61

Locationofhardwareunitsonthebridge........................................................................62

Basicrequirementsforthelocationofbridgeunits...............................................62

Maximumdistancebetweeneachbridgeunit........................................................63

Choosingthebestlocationforthedisplay.............................................................64

ChoosingthebestlocationfortheProcessorUnit.................................................65

ChoosingthebestlocationfortheOperatingPanel...............................................65

Sonarroomrequirements.................................................................................................66

Aboutthesonarroom.............................................................................................66

Environmentalrequirements..................................................................................66

Requirementsforwatertightintegrity....................................................................67

Sizeandaccessrequirements.................................................................................68

Requirementsforinsulation,heatingandventilation.............................................68

Requirementsforelectricalinstallations,cablesandcommunication...................69

Requirementsforbilgepumpanddecking.............................................................70

Liftingrequirements...............................................................................................71

Orientationofthehullunit.....................................................................................72

Sonarroomarrangement:Topview.......................................................................73

Sonarroomarrangement:Sideview......................................................................74

Sonarroomarrangement:Sideview......................................................................75

Acousticnoise..................................................................................................................76

Introductiontotheacousticnoisechallenge..........................................................76

Contributingfactors................................................................................................76

Selfnoise................................................................................................................78

Ambientnoise.........................................................................................................80

Electricalselfnoise................................................................................................81

Reverberation.........................................................................................................81

Somemeanstoreduceacousticnoise....................................................................82

INSTALLINGTHEOPTIONALGATEVALVEDN500..................85

Gatevalveinstallationoverview......................................................................................86

Abouttheoptionalgatevalve..........................................................................................88

Gatevalvesystemdescription.........................................................................................89

Gatevalveinstallationprinciples.....................................................................................91

Mechanicalsupportbrackets............................................................................................93

Installingthemountingange.........................................................................................94

Mountingangeandmanualgatevalveinstallation..............................................97

Mountingangeandhydraulicgatevalveinstallation..........................................99

Installationexample.............................................................................................101

Installingthegatevalve.................................................................................................102

4

442703/B

Page 7

InstallationManual

Installingthetransducerdock........................................................................................103

Installingthehydraulicunits..........................................................................................105

Verifyingthequalityofthegatevalveinstallation........................................................106

MOUNTINGTHEINSTALLATIONTRUNK...............................109

Installationtrunkmountingoverview............................................................................110

Abouttheinstallationtrunk...........................................................................................112

O-ring...................................................................................................................113

Mechanicalsupportbrackets................................................................................114

Designandinstallationdrawings.........................................................................115

Mountingtheinstallationtrunk......................................................................................115

Mountingthetrunkextender..........................................................................................118

Verifyingthequalityoftheinstallation.........................................................................119

Installationexample:Standardtype..............................................................................122

Installationexample:Oillledtype..............................................................................123

INSTALLINGTHEHULLUNIT...............................................124

Hullunitinstallationoverview......................................................................................125

Aboutthehullunitinstallation......................................................................................127

Mechanicalsupportbrackets................................................................................127

O-ring...................................................................................................................128

Designandinstallationdrawings.........................................................................129

Hullunitinstallationexample:Topview.............................................................130

Hullunitinstallationexample:Sideview............................................................131

Hullunitinstallationexample:Sideview............................................................132

Hullunitfamiliarization.................................................................................................133

Unpackingthehullunitfromitstransportbox..............................................................134

Mountingthehullunitontopoftheinstallationtrunk..................................................136

Connectingaventilationpipetotheairbleedingcock..................................................139

Designingandmountingmechanicalsupportbracketstosecurethehullunit..............139

Hullunitandtransduceralignment................................................................................141

Inspectingthetransducer...............................................................................................142

Verifyingthequalityofthehullunitinstallation...........................................................143

INSTALLINGTHEST90HARDWAREUNITS..........................146

Installingthedisplay......................................................................................................147

InstallingtheEnixProcessorUnit.................................................................................148

InstallingtheOperatingPanel(Mk1)............................................................................150

InstallingtheOperatingPanel(Mk2)............................................................................151

InstallingtheTransceiverUnit.......................................................................................153

TransceiverUnitinstallationprocedure...............................................................153

Locationofthemountingbrackets.......................................................................156

Installationofthemountingbrackets...................................................................157

442703/B

5

Page 8

SimradST90

ConnectingtheTransceiverUnittovesselground...............................................158

CABLELAYOUTANDINTERCONNECTIONS...........................159

Readthisrst.................................................................................................................160

Topsidecableplan..........................................................................................................161

TopsidecableplanwithoptionalOperatingPanelMk1................................................163

Sonarroomcableplan...................................................................................................164

ListofST90cables........................................................................................................166

Topsidecables......................................................................................................166

TopsidecableswithoptionalOperatingPanelMk1.............................................167

Sonarroomcables................................................................................................168

Comments.............................................................................................................169

InstallingtheST90cables..............................................................................................171

Prerequisitesforcableinstallation.......................................................................171

InstallingtheST90topsidecables........................................................................172

InstallingtheST90sonarroomcables.................................................................175

ProcessorUnitrearconnectors.............................................................................177

OperatingPanelconnectors..................................................................................179

TransceiverUnitconnectors.................................................................................180

ACmainspowercable(3-phase)totheMotorControlUnit...............................181

ProcessorUnitgraphicadapter......................................................................................182

ProcessorUnitserialadapter.........................................................................................184

ProcessorUnitserialadapter................................................................................184

RS-485seriallineconnectionusingtwoorfourwires........................................186

MoxaCP114EL-ISeriallineadapter...................................................................187

SettinguptheMoxaCP114EL-Iserialports.......................................................188

Seriallinesplitters.........................................................................................................190

Aboutseriallinesplitters......................................................................................190

ØverlandUPC-3005Seriallinesplitterdescription.............................................191

ØverlandUPC-3005Technicalspecications......................................................192

ØverlandUPC-3005Connections........................................................................193

ØverlandUPC-3005Dimensions.........................................................................194

ØverlandUPC-5000PSeriallinesplitterdescription...........................................195

ØverlandUPC-5000PTechnicalspecications....................................................196

ØverlandUPC-5000PConnections......................................................................197

ØverlandUPC-5000PDimensions.......................................................................198

SettinguptheST90inasynchronizedsystem..............................................................199

Aboutsynchronization.........................................................................................199

Synchronizationmodes........................................................................................199

SynchronizationusingClearToSend(CTS)andRequestToSend(RTS)

signals..............................................................................................................200

6

442703/B

Page 9

InstallationManual

Synchronizationsequences...................................................................................201

SettinguptheST90inasynchronizedsystem.....................................................202

Cabledrawingsandspecications.................................................................................206

ACpowercableusingIECC13inlinesocket......................................................207

Groundcable........................................................................................................209

RS-232seriallineconnectionusingthreewires..................................................210

RS-232seriallineconnectionusingvewires....................................................211

RS-422seriallineconnectionusingvewires....................................................212

RS-232usedassynchronizationtrigger(inputoroutput)...................................213

RS-485seriallineconnectionusingtwoorfourwires........................................214

MoxaCP114EL-ISeriallineadapter...................................................................215

RJ45HighspeedEthernetcable(1000Base-t).....................................................217

RJ45HighspeedEthernetcable(FromProcessorUnittoTransceiver

Unit).................................................................................................................218

K-SyncinterfacetogenericRS-232synchronizationinput.................................219

SimradTU40interfacetogenericRS-232synchronizationinput.......................221

CommunicationandpowercablefortheOperatingPanel(Mk1).......................223

EthernetcablewithnoisesuppressorfromTransceiverUnittoMotorControl

Unit..................................................................................................................224

ACmainspowercable(3-phase)totheMotorControlUnit...............................225

Emergencyhoistconnections...............................................................................226

ConnectionbetweenthegatevalveandtheMotorControlUnit.........................228

Aboutseriallines..................................................................................................230

Basiccablerequirements...............................................................................................233

Cabletrays............................................................................................................233

Radiofrequencyinterference...............................................................................234

Physicalprotectionofcables................................................................................234

Groundingofsystemcables.................................................................................235

Cableconnectionsandterminations.....................................................................235

Cableidentication...............................................................................................235

Cableglandsandterminationprocedures............................................................236

SETTINGTOWORK..............................................................241

Settingtoworksummary...............................................................................................242

InspectingtheST90installation....................................................................................245

Visualinspectionofthedisplay............................................................................245

VisualinspectionoftheProcessorUnit...............................................................247

VisualinspectionoftheOperatingPanel.............................................................248

VisualinspectionoftheTransceiverUnit............................................................250

Visualinspectionofthehullunit..........................................................................251

EnvironmentalinspectionoftheTransceiverUnit...............................................253

442703/B

7

Page 10

SimradST90

VerifyingthatallST90cablesareproperlyconnected.........................................255

Startingupthehullunit.................................................................................................257

Hullunitdescription.............................................................................................257

Hullunitfamiliarization.......................................................................................260

MotorControlUnitfamiliarization......................................................................261

InitialsafetycheckoftheMotorControlUnit.....................................................262

Checkingthehostingmotor’s3-phaseACconnections.......................................263

Connectingthe3-phaseACpowertotheMotorControlUnit............................265

Ventingthetransducershaftsleeve......................................................................266

Checkingthe3-phaseconnectionforcorrectrotation..........................................268

CheckingtheoperationoftheHoistingandLoweringcontactors.......................270

Checkingthetransducerloweringandhoistingfunctionality..............................273

TurningontheST90forthersttime...........................................................................276

Verifyingthatoperationalpoweriscorrect..........................................................276

TurningontheProcessorUnitforthersttime...................................................277

SettinguptheOperatingPanel(Mk2)..................................................................278

TurningontheTransceiverUnitforthersttime................................................281

TurningontheST90toPassivemode.................................................................282

MeasuringtheBITEnoisewiththetransducerdisconnectedfromthe

TransceiverUnit..............................................................................................283

MeasuringtheB-Scannoisewiththetransducerdisconnectedfromthe

TransceiverUnit..............................................................................................285

ConnectingthetransducercablestotheTransceiverUnit...................................287

TurningontheentireST90systemforthersttime............................................289

TurningontheST90.............................................................................................294

Insertingtheinstallationparameters..............................................................................296

Deningtheshiporiginanddimensions..............................................................296

Deningtheinstallationparametersforthetransducer........................................298

Adjustingthebuilt-inmotionsensoroffset..........................................................301

Deningtheinstallationparametersforthemotionreferenceunit

(MRU).............................................................................................................304

ConguringtheST90fornormaloperation...................................................................307

Selectingmeasurementunits................................................................................307

Settingupthealarmlimitsforsystemprotection.................................................308

Selectinghullunit.................................................................................................309

Deningthemiddlepositionofthetransducer....................................................310

ConguringtheST90fordatarecording.............................................................312

Conguringtheenvironmentalparameters..........................................................313

Selectingmenulanguage......................................................................................314

Savingthecurrentusersettings............................................................................315

Selectingwhichoperatingpaneltouse................................................................316

8

442703/B

Page 11

InstallationManual

AssigningcustomusersettingstotheOperatingPanel.......................................317

AssigningfunctionstotherotaryswitchesontheOperatingPanel.....................318

AssigningfunctionstoF1,F2andF3ontheOperatingPanel.............................319

UsingasingleOperatingPaneltocontrolmorethanonesonar(Mk2)...............320

UsingmorethanoneOperatingPaneltocontrolthesonar(Mk2)......................324

Settinguptheinterfacestoperipheraldevices..............................................................328

Installingnavigationsensorsandothersensors...................................................328

DeningtheserialandEthernet(LAN)portparameters.....................................329

Settinguptheinputfromanavigationsystem(GPS)..........................................331

Settinguptheinterfaceforspeedloginput..........................................................333

Settinguptheinterfaceforcoursegyroinput......................................................336

Conguringthesensorinterface...........................................................................338

Settinguptheinputfromamotionreferenceunit(MRU)...................................340

SettinguptheST90inasynchronizedsystem.....................................................342

TestingtheST90operationalfunctionality....................................................................345

Checkingthetransducerlowerandhoistfunctionality........................................345

MeasuringtheBITEnoiseinPassivemodewiththetransducerconnectedto

theTransceiverUnit.........................................................................................350

VerifyingST90operationbymeansoftheBITEfunctionality...........................352

VerifyingST90operationbymeansoftheElementBITEfunctionality.............356

Makinganoise/speedcurvetodeterminevesselnoise........................................360

Testingtheinterfaceswithperipheraldevices...............................................................365

Verifyingthecommunicationwithanavigationsystem(GPS)...........................365

Verifyingthecommunicationwithspeedlog.......................................................367

Verifyingthecommunicationwiththecoursegyro.............................................369

Verifyingthecommunicationwiththemotionreferenceunit(MRU).................371

Verifyingtheinstallationparameters.............................................................................374

Verifyingvesseloriginandshipdimensions........................................................374

Verifyingtheinstallationparametersforthetransducer......................................376

Verifyingtheinstallationparametersfortheglobalpositioningsystem(GPS)

antenna.............................................................................................................377

Verifyingtheinstallationparametersforthemotionreferenceunit

(MRU).............................................................................................................378

CreatingabackupwiththeST90congurationandsoftwareinstallation....................381

AboutST90softwarebackupandrestore............................................................381

CreatingaProcessorUnitimageonaUSBashdriveusingtheAcronisTrue

Imageprogram.................................................................................................382

RestoringaProcessorUnitimagefromaUSBashdriveusingtheAcronis

TrueImageprogram........................................................................................383

CreatingabootableUSBashdriveusingtheAcronisTrueImage

program............................................................................................................385

442703/B

9

Page 12

SimradST90

Installationremarks........................................................................................................387

TECHNICALSPECIFICATIONS..............................................388

Introductiontotechnicalspecications.........................................................................389

Performancespecications............................................................................................389

Powerrequirements.......................................................................................................393

Displaypowerrequirements.................................................................................393

ProcessorUnitpowerrequirements.....................................................................393

OperatingPanelpowerrequirements(Mk1)........................................................393

OperatingPanelpowerrequirements(Mk2)........................................................394

TransceiverUnitpowerspecications.................................................................394

HullUnitpowerrequirements..............................................................................394

Weightsandoutlinedimensions....................................................................................396

Displayweightandoutlinedimensions................................................................396

ProcessorUnitweightandoutlinedimensions....................................................396

OperatingPanelweightandoutlinedimensions(Mk1).......................................397

OperatingPanelweightandoutlinedimensions(Mk2).......................................397

TransceiverUnitweightandoutlinedimensions.................................................397

ST92HullUnitweightandoutlinedimensions...................................................398

ST93HullUnitweightandoutlinedimensions...................................................398

ST94HullUnitweightandoutlinedimensions...................................................399

Environmentalrequirements..........................................................................................400

Displayenvironmentalrequirements....................................................................400

ProcessorUnitenvironmentalrequirements........................................................400

OperatingPanelenvironmentalrequirements(Mk1)...........................................401

OperatingPanelenvironmentalrequirements(Mk2)...........................................401

TransceiverUnitenvironmentalrequirements.....................................................401

HullUnitenvironmentalrequirements.................................................................401

Compasssafedistance...................................................................................................403

Displaycompasssafedistance.............................................................................403

ProcessorUnitcompasssafedistance..................................................................403

OperatingPanelcompasssafedistance(Mk1).....................................................403

OperatingPanelcompasssafedistance(Mk2).....................................................404

TransceiverUnitcompasssafedistance...............................................................404

HullUnitcompasssafedistance..........................................................................404

Minimumdisplayrequirements.....................................................................................404

DRAWINGFILE....................................................................406

Aboutthedrawingsinthedrawingle..........................................................................407

Systemunits...................................................................................................................408

385609ProcessorUnitdimensions......................................................................409

204688OperatingPaneldimensions(Mk1).........................................................413

10

442703/B

Page 13

InstallationManual

440698OperatingPanelcut-outdrawing(Mk2).................................................415

443179OperatingPaneldimensions(Mk2).........................................................416

439594OperatingPaneladapterplate(Mk2)......................................................419

381457TransceiverUnitdimensions...................................................................421

Hullunitdrawings.........................................................................................................424

447567HullUnitdimensionsST92.....................................................................425

435546HullUnitdimensionsST93.....................................................................428

447545HullUnitdimensionsST94.....................................................................431

Installationtrunkdrawings............................................................................................434

436691Installationtrunkdimensions..................................................................435

207485Blindangedimensions(ø760mm).......................................................438

439413Trunkextender(350mm)........................................................................439

374676Trunkextender(180mm)........................................................................442

GatevalveDN500drawings..........................................................................................445

082973MountingangeDN500..........................................................................446

083045GatevalveinstallationDN500................................................................449

33498GatevalvedimensionsDN500..................................................................451

37357GatevalvedimensionsDN500..................................................................454

DATAGRAMFORMATS..........................................................457

AboutNMEAandstandarddatagramformats..............................................................458

NMEA..................................................................................................................458

AbouttheNMEAdatagramformats....................................................................458

NMEAsentencestructure....................................................................................459

StandardNMEA0183communicationparameters..............................................460

NMEAdatagramformats...............................................................................................461

NMEADBSdatagram..........................................................................................461

NMEADBTdatagram.........................................................................................462

NMEADPTdatagram..........................................................................................463

NMEAGGAdatagramformat.............................................................................463

NMEAGGKdatagramformat.............................................................................464

NMEAGLLdatagramformat..............................................................................465

NMEAHDGdatagramformat.............................................................................466

NMEAHDMdatagramformat............................................................................467

NMEAHDTdatagramformat.............................................................................467

NMEARMCdatagramformat.............................................................................468

NMEAVBWdatagramformat............................................................................469

NMEAVHWdatagramformat............................................................................470

NMEAVLWdatagramformat.............................................................................470

NMEAVTGdatagramformat.............................................................................471

NMEAZDAdatagramformat.............................................................................471

442703/B

11

Page 14

SimradST90

Proprietarydatagramformats........................................................................................473

KongsbergDFTWaterleveldatagramformat.....................................................473

KongsbergOFSDropkeeldatagramformat........................................................474

SimradA TSdatagramformat...............................................................................474

SimradDBSdatagramformat..............................................................................475

SimradHFBdatagramformat..............................................................................475

SimradPSIMDHBdatagramformat....................................................................476

SimradPSIMP-Ddatagramformat......................................................................476

SimradPSIMP-Fdatagramformat.......................................................................478

SimradTDSdatagramformat..............................................................................479

SimradTPRdatagramformat...............................................................................480

SimradTPTdatagramformat...............................................................................480

Teledyne/TSS1datagramformat..........................................................................481

KongsbergEMAttitude3000datagramformat...................................................483

Third-partydatagramformats........................................................................................485

AtlasDepthdatagram...........................................................................................485

FurunoGPhvedatagramformat...........................................................................485

HemisphereGNSSGPHEVdatagramformat......................................................486

EQUIPMENTHANDLING.......................................................487

TransportingKongsbergMaritimeequipment...............................................................488

Liftingunitsandtransportationboxes...........................................................................489

Inspectionofunitsandtransportationboxesafterarrival..............................................490

Specicationsforstoragepriortoinstallationoruse.....................................................491

Unpackinginstructions..................................................................................................492

Unpackingstandardpartsandunits......................................................................493

Unpackingmechanicalunits................................................................................494

Unpackingelectronicandelectromechanicalunits..............................................495

Specicationsforstorageafterunpacking.....................................................................496

Packinginstructionsforstorageorshipping..................................................................497

Storageafteruse.............................................................................................................498

Cleaninganelectroniccabinetorunit..................................................................499

Cleaningamechanicalorelectromechanicalunit................................................500

Cleaningthehullunit...........................................................................................501

Handlinginstructionsforprintedcircuitboardsandelectronicmodules......................502

Unpackingandhandlingprintedcircuitboardsandelectronicmodules.............503

ReturningaprintedcircuitboardoranelectronicmoduletoKongsberg

Maritime..........................................................................................................504

AboutElectrostaticDischarge(ESD)...................................................................506

Disposalofoldproducts................................................................................................507

GENERALSUPPLYCONDITIONS..........................................509

12

442703/B

Page 15

InstallationManual

Receipt,unpackingandstorage.....................................................................................509

Equipmentresponsibility...............................................................................................510

442703/B

13

Page 16

SimradST90

14

442703/B

Page 17

Aboutthismanual

Aboutthismanual

Thepurposeofthismanualistopresentthedescriptionsanddrawingsrequiredtoinstall

theSimradST90Fishndingsonar.

Targetaudience

Themanualisintendedfortechnicalpersonnel;suchasskilledshipyardworkers,

electricians,qualiedengineersandnavalarchitects.Itisassumedthatyouunderstand

thegeneralprinciplesofmaritimeelectronicequipment.Y oumustalsobefamiliarwith

computerhardware,interfacetechnologyandinstallationofelectronicandmechanical

products.

Installationinstructions

Theinstructionsprovidedinthismanualmustbefollowedcarefullytoensureoptimal

performance.Asaguide,installationproceduresarepresentedintheordertheymust

bedone.

Theequipmentdescribedinthismanualincludesthecompletesystemwithrelevant

cabinets.Unitsprovidedlocallybythecustomer,installationshipyardorlocal

representativearenotdescribed.

Informationaboutthirdpartyproductsand/orservicesmaynotbeincludedinthis

manual,eventhoughthesemaybeprovidedasapartoftheST90delivery.Refertothe

relevantend-userdocumentationprovidedbythemanufacturer.

Note

KongsbergMaritimeASwillacceptnoresponsibilityforanydamageorinjurytothe

system,vesselorpersonnelcausedbyequipmentthathasbeenincorrectlyinstalledor

maintained,orbydrawings,instructionsorproceduresthathavenotbeenprepared

byus.

Installationdrawings

Theinstallationshipyardmustprovideallnecessarydesignandinstallationdrawings,as

wellastherelevantworkstandardsandmountingprocedures.Theinstallationshipyard

mustdesignandmanufacturerelevantinstallationhardwaretoteachindividual

hardwareunit.

442703/B

15

Page 18

SimradST90InstallationManual

Note

Ifrequired,alldocumentsprovidedbytheshipyardforthephysicalinstallationofthe

ST90mustbeapprovedbythevessel’ snationalregistryandcorrespondingmaritime

authorityand/orclassicationsociety.Suchapprovalmustbeobtainedbeforethe

installationcanbegin.Theshipownerandshipyarddoingtheinstallationareresponsible

forobtainingandpayingforsuchapproval.

TheoutlinedimensionsoftheST90unitsarefoundintheDrawinglechapterinthis

manual.

Thesourcedrawings(normallyinAutoCadformat)canbedownloadedfromourwebsite.

•https://www.simrad.com/st90

Onlineinformation

Allend-usermanualsprovidedforoperationandinstallationofyourSimradST90canbe

downloadedfromourwebsite.

•https://www.simrad.com/st90

OurwebsitealsoprovidesinformationaboutotherSimradproducts.

Registeredtrademarks

Observetheregisteredtrademarksthatapply.

Windows

®

isaregisteredtrademarkofMicrosoftCorporationintheUnitedStatesand

othercountries.

Simrad

®

,SIMRAD

®

andtheSimrad

®

logoareeitherregisteredtrademarks,or

trademarksofKongsbergMaritimeASinNorwayandothercountries.

Wewantyourfeedback

WewanttoimproveST90continuously.Wealsowantourend-userdocumentationtobe

comprehensiveandrelevant.Y oucanhelp.Pleaseprovidecomments,suggestionsor

constructivecriticismtoanyofoursupportofces.

16

442703/B

Page 19

Topics

Important,page17

Systemdescription,page19

SimradST90

SimradST90

Keyfeatures,page21

Systemdiagram,page22

Systemunits,page23

Scopeofsupply,page32

Generalsafetyrules,page46

Installationrequirements,page47

Networksecurity,page50

Supportinformation,page51

Important

TheST90isanadvancedproduct.Aswithmostotheradvancedinstruments,thereis

importantinformationthatyouneedtoknow.

Watertightintegrity

Thesize,locationanddesignofthesonarroommustfullalltherequirementstothe

vessel’swatertightintegrity.

Intheeventofamajorleak,itmustbepossibletocloseallwatertighthatchesand/or

doorstotheroomtomaintainvesselstabilityandsafety .Thephysicalsizeofthesonar

roommustbelimited,sothatintheeventofamajorleak,theoodingoftheroomwill

notinduceinstability,orcausethevesseltocapsizeorsink.

Formoreinformation,see:Sonarroomrequirements,page66

442703/B

17

Page 20

SimradST90InstallationManual

BeforeyouturnontheST90

BeforeyouturnontheST90,makesurethatyouhavesufcientwaterdepthtolower

thetransducer!

Caution

YoumustneverturnontheST90whentheshipisindrydock.Thetransducermaybe

damagedifittransmitsinopenair.

WhentheST90isnotused

WhenyoudonotusetheST90,turnofftheentiresystem.

Note

YoumustNEVERturnofftheST90bymeansoftheon/offswitchontheProcessorUnit.

YoumustALW AYSusetheOperatingPanelorselectExitonthetopbar .

Whenyouaredockingyourvessel

YoumustneverturnontheST90whentheshipisindrydock.Thetransducermaybe

damagedifittransmitsinopenair.TopreventinadvertentuseoftheST90,pullout

themainsplugontheProcessorUnitwheneveryourvesselisindrydock.Additional

precautionarymeasurersshouldbeconsidered.

Ifsomethingbreaksdown

Ifyoubelievethatsomethinghasbrokendown,contactyourlocaldealer.Alistofall

ourdealersisprovidedonourwebsite.

•https://www.simrad.com

Ifyouareunabletocontactadealer,observethesupportinformationinthispublication.

WhenyouwanttoturnofftheST90

YoumustNEVERturnofftheST90bymeansoftheon/offswitchontheProcessorUnit.

WhenyoudonotusetheST90,turnitoffwiththePowerbuttonontheOperatingPanel.

IfthetransducerisloweredwhenyouturnofftheST90,itisautomaticallyretractedto

itsupperposition.

Note

IfyouturnofftheST90bymeansoftheon/offswitchontheProcessorUnityoumay

damagethesoftwareandtheinterfacesettingsusedtocommunicatewithexternal

devices.

18

442703/B

Page 21

SimradST90

Manualoperationofthehullunit

Intheeventofimproperoperation,thepowerfulelectricmotoronthehullunitmay

causeseriousdamagetotheequipmentand/orinjurytopersonnel.Therefore,beforeyou

startmanualoperation,readcarefullythroughtherelevantoperatingprocedures.

Note

Youmustfamiliarizeyourselfwiththecorrecthandlingmethodsandtherelevantsafety

requirements.

Rulesfortransducerhandling

Atransducermustalwaysbehandledasadelicateinstrument.Incorrectactionsmay

damagethetransducerbeyondrepair.Aphysicalblowtothetransducerfacemayeasily

damageoneormoreelements.Observethesetransducerhandlingrules:

•Donotactivatethetransducerwhenitisoutofthewater.

•Donothandlethetransducerroughlyandavoidimpacts.

•Donotexposethetransducertodirectsunlightorexcessiveheat.

•Donotdamagetheouterprotectiveskinofthetransducer.

•Donotusehigh-pressurewater,sandblasting,metaltoolsorstrongsolventstoclean

thetransducer.

•Donotsteponthetransducercables.

•Donotdamagethetransducercables,andavoidexposuretosharpobjects.

Relatedtopics

Generalsafetyrules,page46

Installationrequirements,page47

Networksecurity,page50

Supportinformation,page51

Systemdescription

TheSimradST90isalongrangeandlowfrequencyshndingsonarwitha360degrees

coverage.TheST90isdesignedformediumandlargesizedshingvessels.

Ifhighperformanceisyournumber1criteriawhenchoosingasonar;suchaslongrange,

highresolution,narrowbeamsandhighsourcelevels,thisisyournaturalchoice.We

madenocompromisesduringthedesignoftheST90.Ourgoalwassimplytomakethe

ultimatehighperformanceshndingsonar.WiththeSimradST90,weuselower

frequenciesthantheSX90andSU90sonars.Inordertoachievethis,acompletelynew

transducerhasbeendesigned.EachelementislargerthanthepreviousSX90andSU90

elements,butthenumberofelementsisthesameastheSU90.Thisallowsforthesame

narrowbeam,andultimatelyalongerrange.TheST90hasbeendesignedtosearchwith

442703/B

19

Page 22

SimradST90InstallationManual

verylongrangesinallweatherandseaconditions.Whetheritisheavyweather,hard

bottom,openwaters,weaktargets-allechoesarehandledbytheST90duetothefully

stabilizedandverynarrowbeamscombinedwiththecuttingedgesignalprocessing.

Thecentreoperationalfrequencyis19kHz,butyoucanselectanyoperationalfrequency

from14to24kHzinstepsof1kHz.Thecylindricalmulti-elementtransducerallows

theomnidirectionalsonarbeamstobetiltedelectronicallyfrom-10to+84degrees.

Thisallowsyoutoautomaticallytrackschoolsofsh,andtoobservethewholewater

volumearoundthevessel.

TheST90providesanumberofstandardinterfacelinesforcommunicationwith

peripheraldevicesandsensors.Typicalinputsaregeographicalinformationfroma

positioningsystem,vesselspeedandcurrentheading.Bydefault,theST90usesa

built-inmotionsensor.Forimprovedoperationalaccuracy,anexternalmotionreference

unit(MRU)canbeconnected.

Thenarrowbeamopeningangle(6.5°@17kHz)andthehighsourcelevelmakesthe

ST90averypowerfulandhighresolutionlowfrequencysonar.Thenarrowbeams

providedbytheST90giveyouseveraladvantages.

•Theyincreasetherangeandresolution,andofferaverticalviewwithadditional

detailsandaclearerpicture.

•TheymaketheST90evenmoreidealwhenyouneedtosearchforshclosetothesea

bottom,orclosetothesurface,atlongranges.

•Theyprovideafarbetterverticalviewwithless"bottomclimbing"thatwhatisseen

onsonarswithawiderbeam.

•Thenarrowbeamsalsodecreasethenoiselevel.

TheST90offersthesameuserinterfaceandoperatingsoftwareasourothersonars,

echosoundersandcatchmonitoringsystems.Thisenableseasierandfastertraining

ofnewusers.

TheST90echopresentationsareoptimizedformultipledisplays.Providedthatyouhave

connectedadditionaldisplaystoyourProcessorUnit,youcanusetheDockingViews

functiontotakeanysonarviewandplaceitonaseparatedisplay.Whenyoumovea

viewtoanotherdisplay,itwillautomaticallybescaledforthebestpossibleresult.

Itiscommonforsonarstorequiremanypingstobuildthevariousviewsintheecho

presentation.Thesesonarsmayforexampleneedonepingtobuildthe360degreesomni

view,andthenseveraladditionalpingstofetchtheechoesfortheverticalviews.On

theST90,allthesonarviewsinthepresentationarebuiltusingtheechoesfromone

singleping.Thisdramaticallyimprovestheupdaterateandprovidesbetterreal-time

information.

TheST90permitsyoutorecordreal-timesonarsituations.Thisallowsyoutoreplay

completesequences.Theplaybackcontainstheexactsameechoinformation,andcanbe

usedformissionhistory,trainingortroubleshootingpurposes.

Greatemphasishasbeenplacedonanintuitiveuserinterfaceandthebestpossiblesonar

presentationsonahighresolutioncolourdisplay.

20

442703/B

Page 23

SimradST90

TheST90isequippedwiththecelebratedsignalprocessingsoftwaredevelopedby

KongsbergMaritime.TheST90offersseveralpulsetypes.ThisincludesHyperbolic

FM(HFM)transmissions.Thispulsetypeisalsoknownas"chirp".Itensuresaclutter

freepicturewithveryhighresolutioninrange.Thesignalprocessingandbeamforming

isperformedinafastdigitalsignalprocessingsystemusingthefulldynamicrange

ofthesignals.

Relatedtopics

Systemdiagram,page22

Systemunits,page23

Keyfeatures

TheSimradST90isalongrangeandlowfrequencyshndingsonarwitha360degrees

coverage.WemadenocompromisesduringthedesignoftheST90.Ifhighperformance

isyournumber1criteriawhenchoosingasonar;suchaslongrange,highresolution,

narrowbeamsandhighsourcelevels,thisisyournaturalchoice.

•360degreesomnidirectional

•Operationalfrequencyadjustablefrom14to24kHzinstepsof1kHz

•Narrowbeams(6.5°@17kHz)

•HFM(HyperbolicFrequencyModulation)transmissions(Thispulsetypeisalso

knownas"chirp".)

•Largedynamicrange

•Highdenition

•Stabilizedbeams

•Easyoperation

•Storeandrecallsonardata

•Deneandsaveyourownusersettings

•Clearandeasilycomprehensivesonardata

•Supportsmultipledisplays.

•12transceiverboardsprovide384individualchannels

ThenarrowbeamsprovidedbytheST90giveyouseveraladvantages.Theyincrease

therangeandresolution,andofferaverticalviewwithadditionaldetailsandaclearer

picture.Thenarrowbeamsalsodecreasethenoiselevel.

442703/B

21

Page 24

SimradST90InstallationManual

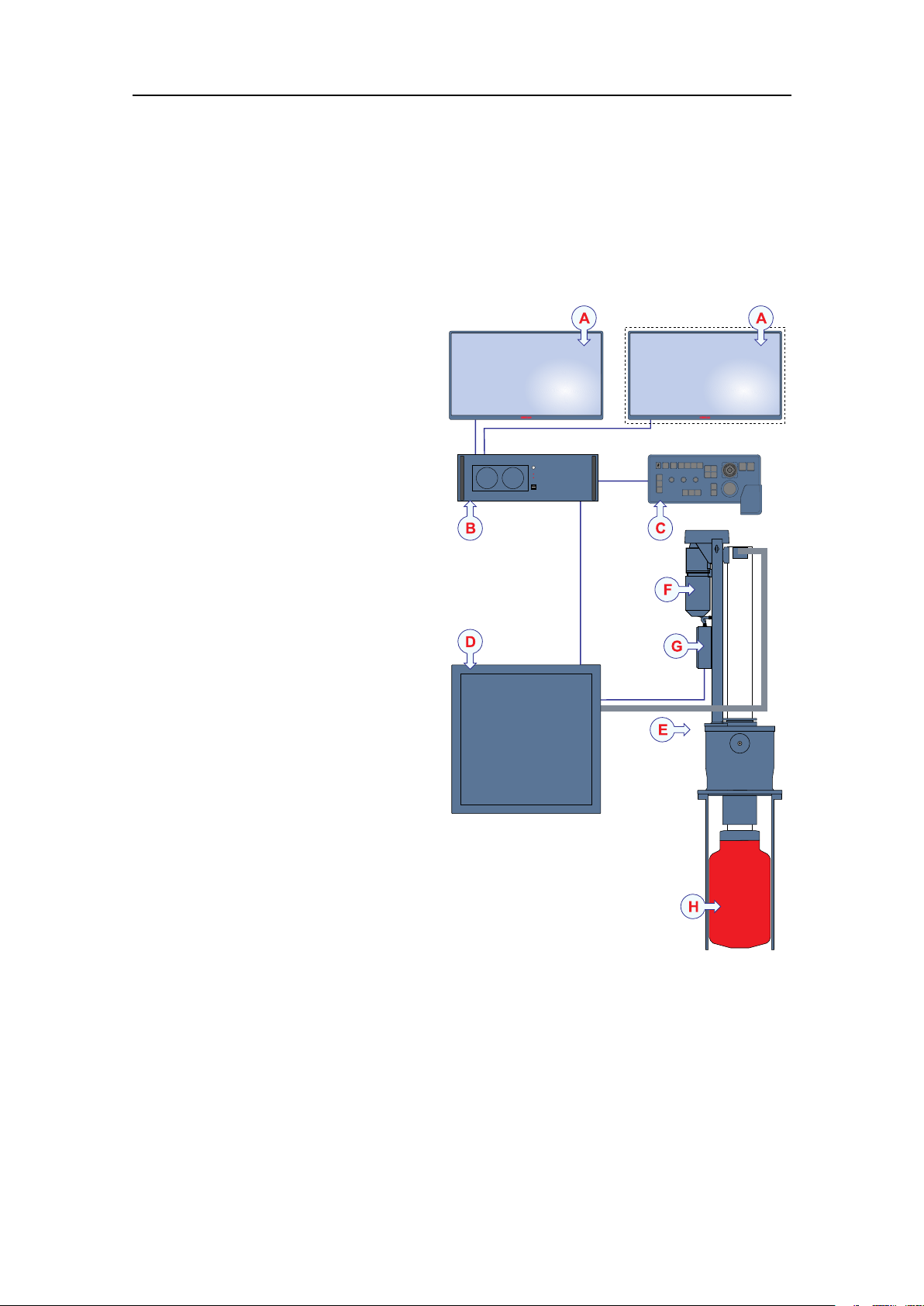

Systemdiagram

ThesystemdiagramidentiesthemaincomponentsofabasicST90system.Only

themainconnectionsbetweentheunitsareshown.Detailedinterfacecapabilitiesand

powercablesarenotshown.

ADisplay(Theseconddisplayis

optional.)

BProcessorUnit

COperatingPanel

DTransceiverUnit

EHullUnit

FHoistmotor

GMotorControlUnit

HTransducer

Inthispublication,thecomputeris

referredtoastheProcessorUnit.

Unlessotherwisespeciedina

contract,thedisplayisnotincluded

inthestandarddeliveryfromSimrad.

Thisisacommercialitemthatcan

bepurchasedlocally.

Achoiceofhullunitsisavailable

fortheST90Fishndingsonar.The

hullunitsofferdifferentlowering

depthsandcablelengths.Thesame

transducerisusedonallhullunit

types.Thesameinstallationtrunk

isusedonallhullunittypes.

Relatedtopics

Systemdescription,page19

Systemunits,page23

22

442703/B

Page 25

Systemunits

Topics

Displaydescription,page23

ProcessorUnitdescription,page23

TransceiverUnitdescription,page24

OperatingPaneldescription,page26

Hullunitdescription,page27

Transducerdescription,page29

Installationtrunkdescription,page30

SimradST90

Displaydescription

AdisplayisarequiredpartoftheST90Fishndingsonar.Forbestreadability,the

displaymustbeprotectedfromglareandhavethecorrectheightandangle.

AnycommercialdisplaycanbeusedwiththeST90Fishndingsonar,providedthatthe

displaymeetstheminimumrequirements.

ThedisplayisnotastandardpartoftheST90delivery.Thisisacommercialitemthat

canbepurchasedlocally.KongsbergMaritimemayprovideasuitabledisplay.

Thechosendisplaymustbedesignedformaritimeuse,anditmustmeettheminimum

performancespecications.Youmustalsomakesurethatthechosendisplaysupports

thevideoformatsprovidedbytheProcessorUnit.

Relatedtopics

Systemunits,page23

Scopeofsupply,page32

ProcessorUnitdescription

TheST90ProcessorUnitisaruggedandpowerfulcomputer.Itisdesignedforlonglife

inademandingmaritimeenvironment.TheProcessorUnitcontainstheoperational

software,andofferstheuserinterfacethatallowsyoutocontroltheST90.Furthermore,

itoffersanumberofserialandEthernetlinesforcommunicationwithexternaldevices.

Adedicatedmaritimecomputerisprovidedwith

theST90Fishndingsonar.Inthispublication,the

computerisreferredtoastheProcessorUnit.Itisset

upwithallnecessarysoftware.TheProcessorUnitis

normallymountedonthebridge.

442703/B

23

Page 26

SimradST90InstallationManual

TheProcessorUnitisdesignedforruggedmaritimeuse.Ithasbeencustomizedby

KongsbergMaritime.Exceptfromthefans,itcontainsnomovingparts.Thecomputer

isbasedonacommercialdesign,butthesoftwareandhardwarehavebeenspecied

byKongsbergMaritimetosuittheST90requirements.TheProcessorUnitcabinetis

placedonshockabsorbers.

TheProcessorUnitisbasedontheMicrosoft

®

Windows®10operatingsystem.

ThecomputeroffersmultipleUSBportsforusewithfuturesoftwareupgrades.These

USBportsalsoallowyoutoexportscreencapturesfromtheST90.

Note

TheoperatingsystemhasbeenmodiedtomakethecomputerworkwiththeST90.

ThesemodicationsincluderemovalofallsafetyfeaturesprovidedbyMicrosoft

®

built-inrewallandallvirusprotectionfeatureshavebeenremoved.Anyattemptto

usethecomputerforanyotherpurposesthanST90operation,suchasgames,desktop

applicationsandInternetconnection,mayresultinseriousdamagetotheprogram.Such

damagesarenotcoveredbythewarranty.

Relatedtopics

Systemunits,page23

Scopeofsupply,page32

InstallingtheEnixProcessorUnit,page148

Technicalspecications,page388

385609ProcessorUnitdimensions,page409

.The

TransceiverUnitdescription

TheST90TransceiverUnitisprovidedtotransmitacousticenergythroughwater.This

transmissionandreceptionarecommonlyreferredtoasaping.Aftereachtransmission,

thetransceiverreceivestheechoesfromthetargetsinthewaterand/ortheseabed.These

echoesarelteredandampliedandthenconvertedintodigitalformat.

TheST90TransceiverUnitisnormallylocatedin

thesonarroom.Itismountedonthebulkheadusing

powerfulshockabsorbers.Thephysicaldistanceto

thehullunitislimitedbythelengthofthetransducer

cables.

TheTransceiverUnitcontrolsthetransmissionand

receptionmadebythe384transmittersand384

receiverchannels.12identicaltransceiverboards

areused.TheTransceiverUnitalsoholdsanEthernet

switchandalargecapacitorbank.Aninternalpower

supplyisprovidedtosupplytherequiredDCvoltages

totheTransceiverUnit.

24

442703/B

Page 27

SimradST90

TwohighcapacityEthernetcablesconnecttheProcessorUnittotheTransceiverUnit.

AnotherhighqualityEthernetcableisusedtoconnecttheTransceiverUnittotheMotor

ControlUnitonthehullunit.Itisveryimportantthathigh-qualityEthernetcablesare

used.Y oumustuseCA T-5ESTP(ShieldedTwistedPair)qualityorbetter.Ifyouuse

cableswithlowerbandwidthcapacityyouwillreducetheST90performance.Donot

connecttheProcessorUnittotheTransceiverUnitusinganexistinglocalareanetwork

(LAN).

Tip

WestronglyrecommendthatminimumthreeEthernetcablesareinstalledbetweenthe

sonarroomandthebridge.Twocablesareforoperationaluse,whiletheothersare

spare.

Thetransducercablesarepluggedintothesidewallofthetransceivercabinetusinga

specialconnector.Theconnectorsforpowerandinterfacesarelocatedatthebottom

ofthecabinet.

Note

ToextendthelifetimeoftheST90TransceiverUnit,itmustbemountedatdryandclean

locationwithsufcientventilation.Observethesonarroomrequirements

TheTransceiverUnitisttedwithacommercialheatexchanger.Thepurposeoftheheat

exchangeristoprovideastable,cleanandtemperaturecontrolledenvironmentforthe

electroniccircuitryinsidetheTransceiverUnit.Theheatexchangeralsoinhibitsdust

anddirtparticlesfromenteringtheTransceiverUnit.Theheatexchangerispowered

from230VACusingaseparateoutlet.

Relatedtopics

Systemunits,page23

Scopeofsupply,page32

InstallingtheTransceiverUnit,page153

Technicalspecications,page388

381457T ransceiverUnitdimensions,page421

442703/B

25

Page 28

SimradST90InstallationManual

OperatingPaneldescription

TheOperatingPaneloffersallnecessarycontrolfunctionsfornormaloperationofthe

ST90.

ThecontrolsprovidedbytheOperatingPanelare

arrangedinlogicalfunctionalgroups.Thisoffers

youclearandeasyoperationwithfastaccesstokey

functionality.ThemajorityoftheST90functionscan

beaccessedusingthetrackballontheOperatingPanel

andthemenusystemshownintheST90presentation.

Tip

YoucanalsouseastandardcomputermousetocontroltheST90.Themousecanbe

connectedtoeithertheOperatingPanelordirectlytotheProcessorUnit.

AdedicatedEthernetcableisusedtoconnecttheOperatingPaneltotheProcessorUnit.

TheOperatingPanelisprovidedwithabuilt-inpowersupply .Themainsvoltageforthe

OperatingPanelis115or230V AC,anditwillautomaticallysensethesupplyvoltage.

Note

TheST90supportstwodifferentoperatingpanels.Thesearereferredtoas"Mk1"and

"Mk2".

AsecondaryOperatingPanelmaybeconnectedtotheST90ProcessorUnit.Thismay

beusefulinconjunctionwithaseconddisplayifyouwishtocontroltheST90fromtwo

differentlocationsonyourvessel.

Relatedtopics

Systemunits,page23

Scopeofsupply,page32

InstallingtheOperatingPanel(Mk2),page151

Technicalspecications,page388

SettinguptheOperatingPanel(Mk2),page278

UsingasingleOperatingPaneltocontrolmorethanonesonar(Mk2),page320

UsingmorethanoneOperatingPaneltocontrolthesonar(Mk2),page324

204688OperatingPaneldimensions(Mk1),page413

440698OperatingPanelcut-outdrawing(Mk2),page415

443179OperatingPaneldimensions(Mk2),page416

439594OperatingPaneladapterplate(Mk2),page419

26

442703/B

Page 29

SimradST90

Hullunitdescription

ThehullunitprovidedwiththeST90isdesignedtolowerthetransducerdownbelowthe

ship’shullwhentheST90shallbeused.WhentheST90isswitchedoff,thetransducer

ishoistedforprotection.

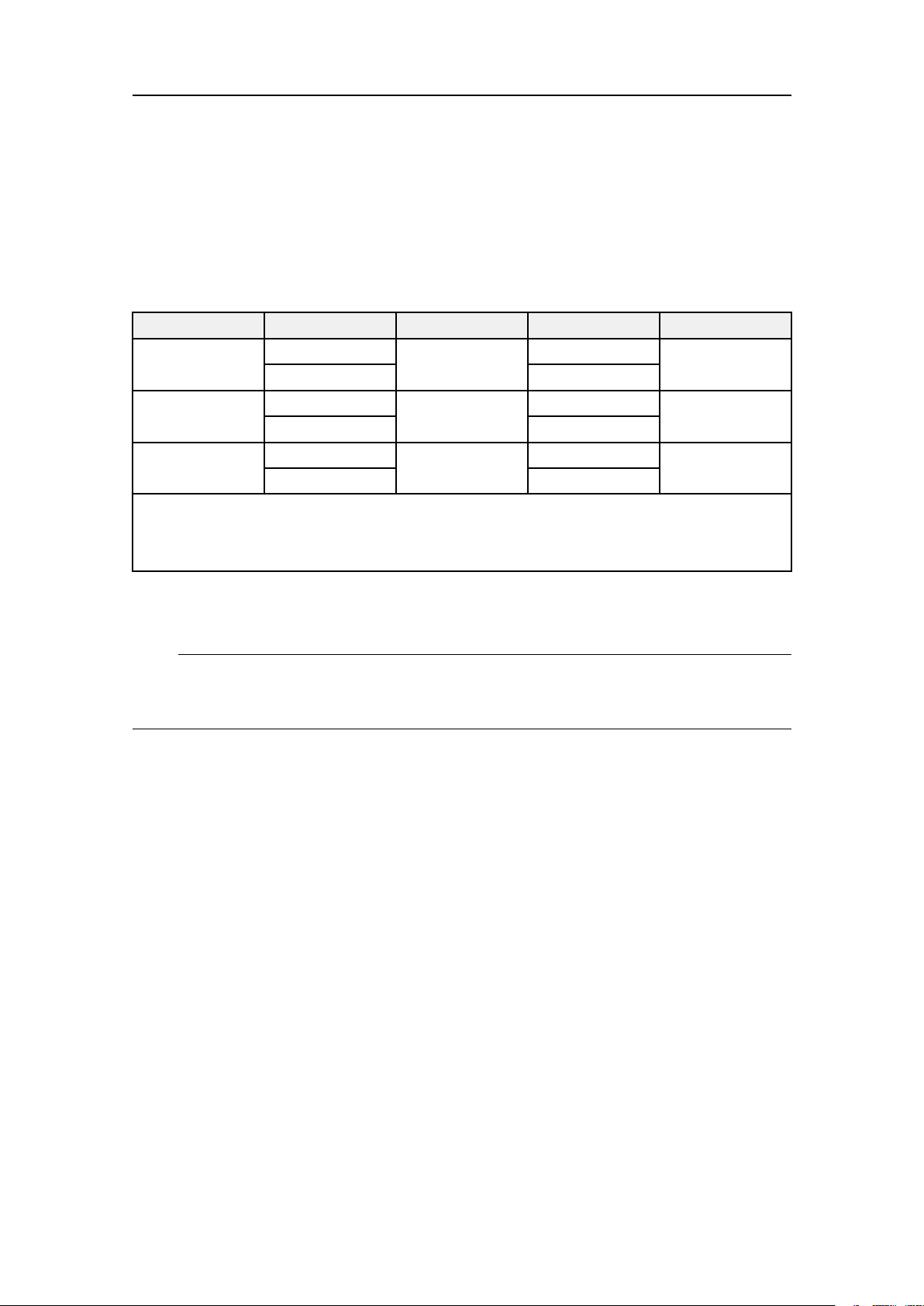

TheST90Fishndingsonarcanbeprovidedwithoneofthefollowinghullunits.

HullUnit

Outlinedimensionsdrawings:

-ST92:447567

-ST93:435546

-ST94:447545

Partnumber

4414864.6m ST92

441488

4385204.6m ST93

441490

4414924.6m ST94

441494

Loweringdepth

1.2m

1.6m

2.1m

Transducercable

7m

7m

7m

Maximumspeed

21knots

16knots

11knots

Thesametransducerisusedonallhullunittypes.Thesameinstallationtrunkisusedon

allhullunittypes.

Note

OntheST94HullUnit,thetransducerisautomaticallyhoistedto1.6metreswhenvessel

speedexceeds1 1knots.

Thehullunitisalargemechanicalconstruction.Itismountedonthetopofthe

installationtrunk.Theinstallationtrunkpenetratestheship’shull,andallowsthe

transducertobeloweredintothesea.Thehullunitisnormallylocatedintheforward

partofthevessel.Thislocationisrecommendedtoavoidthenoisefromthepropellers

andtheengine.

ThepurposeoftheMotorControlUnitistocontrolthehoistingmotoronthehullunit.

WhenyoumaketheappropriatecommandsontheST90sonar,theMotorControlUnit

willstartandstopthemotor.Itwillalsomakesurethatthemotorrotatesthecorrectway.

Themotionsensorforthebuilt-inelectronicstabilizationofthesonarbeamsisprovided.

•Tolowerthetransducer,pressDownontheOperatingPanel.Toindicatetransducer

movement,theDownindicatorlampashes,andanaudiblesignalissounded.When

thebottompositionhasbeenreached,theindicatorlampislit,andtheaudiblesignal

stops.

•Toretractthetransducer,pressUpontheOperatingPanel.

Thetransducercanalsobeloweredtoanyselectedmiddleposition.OntheOperating

Panel,pressMiddle.Incaseofpowerfailure,thetransducercanberaisedorlowered

manuallybymeansofahandcrank.

442703/B

27

Page 30

SimradST90InstallationManual

Note

IfyouforgettohoistthetransducerbeforetheST90isswitchedoff,thetransduceris

hoistedautomaticallybeforethepowerisdisconnected.Thetransducerisalsohoisted

automaticallyifaseriousmalfunctionoccurstothecommunicationbetweenthebridge

andthehullunit.

Caution

Ifthetransducerhitslargerobjectsorbottom,thetransducershaftmaybebent,or

-inworstcase-itcanbebrokenoff.Abrokentransducershaftwillcausewater

leakagethroughthetopoftheshaft.Ifyoususpectthatthetransducershaftisseriously

damagedwithholes,donot

Topreventseriousdamagetothevesselorthevesselstability,youmusthaveawater

pumpandawarningsysteminthesonarroom.

retractthetransducertoitsupperposition.

Relatedtopics

Systemunits,page23

Scopeofsupply,page32

Installingthehullunit,page124

HullUnitpowerrequirements,page394

ST92HullUnitweightandoutlinedimensions,page398

ST93HullUnitweightandoutlinedimensions,page398

ST94HullUnitweightandoutlinedimensions,page399

HullUnitenvironmentalrequirements,page401

HullUnitcompasssafedistance,page404

447567HullUnitdimensionsST92,page425

435546HullUnitdimensionsST93,page428

447545HullUnitdimensionsST94,page431

Settingtoworksummary,page242

Startingupthehullunit,page257

Hullunitdescription,page27

Hullunitfamiliarization,page133

MotorControlUnitfamiliarization,page261

InitialsafetycheckoftheMotorControlUnit,page262

Checkingthehostingmotor’s3-phaseACconnections,page263

Connectingthe3-phaseACpowertotheMotorControlUnit,page265

Ventingthetransducershaftsleeve,page266

Checkingthe3-phaseconnectionforcorrectrotation,page268

CheckingtheoperationoftheHoistingandLoweringcontactors,page270

Checkingthetransducerloweringandhoistingfunctionality,page273

28

442703/B

Page 31

SimradST90

Transducerdescription

ThecylindricalST90transducerallowsthesonarbeamtoprovideafull360degrees

coverageofthewatervolume.

ALowerpartofshaftsleeve

BLowerpartoftransducershaft

CTransducerwithitsredprotectivecoating

Thetransducerconvertstheelectricenergygeneratedbythe

TransceiverUnittophysicalvibrations.Thesevibrationsalter

thewaterpressure,andcreateanacousticpulsethatissentinto

thewater.Theacousticsignalistransmittedasabeam.The

durationoftheacousticpulse,aswellasitsfrequencyand

shape,arecontrolledbytheTransceiverUnit.Thedirection

andopeningangleofthebeamiscontrolledbytheTransceiver

Unitandthephysicalpropertiesofthetransducer.After

thetransmission,thetransducerworksasa"microphone".It

convertsthewaterpressurecreatedbytheacousticechoesto

electricenergy.TheseweakechosignalsaresenttotheampliersintheTransceiverUnit.

Thetransducerislargeandheavy.Itcontains384individualelements.

Thetransducerismountedatthebottomendofthehullunit’stransducershaft.This

allowsthetransducertobeloweredintothewaterforoperationaluse,andretractedfor

protectionwhentheST90isturnedoff.Byloweringthetransducerintothewater,you

mayalsobeabletoreducethenoisecreatedbythelaminarowofwateralongthehull.

Note

Theredprotectivecoatingisanvitalpartofthetransducer.Itisveryimportantthat

neitherthiscoatingnortheinternalpartsofthetransduceraredamagedduringthe

handling,installationorcleaning.Anyholesand/orscratchesinthetransducersurface

willallowwatertopenetratethetransducer.Ifaleakoccurs,thetransducermustbe

replaced.

Rulesfortransducerhandling

Atransducermustalwaysbehandledasadelicateinstrument.Incorrectactionsmay

damagethetransducerbeyondrepair.Aphysicalblowtothetransducerfacemayeasily

damageoneormoreelements.Observethesetransducerhandlingrules:

•Donotactivatethetransducerwhenitisoutofthewater.

•Donothandlethetransducerroughlyandavoidimpacts.

•Donotexposethetransducertodirectsunlightorexcessiveheat.

•Donotdamagetheouterprotectiveskinofthetransducer.

•Donotusehigh-pressurewater,sandblasting,metaltoolsorstrongsolventstoclean

thetransducer.

442703/B

29

Page 32

SimradST90InstallationManual

•Donotsteponthetransducercables.

•Donotdamagethetransducercables,andavoidexposuretosharpobjects.

Relatedtopics

Systemunits,page23

Scopeofsupply,page32

Installingthehullunit,page124

HullUnitpowerrequirements,page394

ST92HullUnitweightandoutlinedimensions,page398

ST93HullUnitweightandoutlinedimensions,page398

ST94HullUnitweightandoutlinedimensions,page399

HullUnitenvironmentalrequirements,page401

HullUnitcompasssafedistance,page404

447567HullUnitdimensionsST92,page425

435546HullUnitdimensionsST93,page428

447545HullUnitdimensionsST94,page431

Installationtrunkdescription

Theinstallationtrunkprovidesthephysicalfoundationfortheentirehullunit.The

installationtrunkpenetratesthehull.Itisthereforeacrucialpartofthehullunit

assembly.InordertoensureproperST90operation,thephysicallocationofthe

installationtrunkmustbecarefullyselected.

Note

Theinstallationtrunkisnotincludedinthestandarddelivery.

Theinstallationtrunkisnotusedwhenagatevalveismounted.Theinstallationtrunkis

replacedwithatransducerdock.

Theinstallationtrunkmaybefabricatedbytheshipyard,orsuppliedbyKongsberg

Maritimeasanoption.Thedrawingsoftheinstallationtrunkandtheblindangeare

includedinthismanual.

Theinstallationtrunk-withablindange-canbeorderedfromKongsbergMaritimeas

anoptionaldelivery.Asanalternative,theinstallationtrunkcanbemanufacturedbythe

shipyardbasedonthedrawingsinthismanual.Alocallymanufacturedinstallationtrunk

canbeadjustedtobettertthepropertiesofthevessel’shull.

Note

Iftheinstallationtrunkismanufacturedlocally,theinstallationshipyardisresponsible

forobtainingtheapprovalcerticatesfromtherelevantnationalregistry.

30

442703/B

Page 33

Relatedtopics

Systemunits,page23

Scopeofsupply,page32

Mountingtheinstallationtrunk,page109

436691Installationtrunkdimensions,page435

207485Blindangedimensions(ø760mm),page438

SimradST90

442703/B

31

Page 34

SimradST90InstallationManual

Scopeofsupply

Topics

Basicitemsprovidedwithastandarddelivery,page32

Additionalrequireditems,page35

Additionaloptionalitems,page39

Basicitemsprovidedwithastandarddelivery

ToassembleacompleteST90system,youwillneedasetofsystemunits.Themain

unitsrequiredareprovidedwiththestandarddelivery.Otherrequiredunitsmaybe

purchasedfromKongsbergMaritimeorobtainedlocally.Someunitsareoptional.

WhenyouunpackthepartsprovidedwiththeST90delivery,makesurethatthecorrect

itemsareincluded.

Basicitems

ItemPartnumberInthebox

TransceiverUnit

ProcessorUnit

OperatingPanel(Mk1)

OperatingPanel(Mk2)

Connectioncable

TheST90supportstwodifferentoperatingpanels.Thesearereferredtoas"Mk1"and"Mk2".

441481

441484Computer

SH8-203593

442453

329512

TransceiverUnit

Powercable

Ethernetcable(10m)

Powercable

Seriallineconnectorsandadapters

DVItoVGAadapter

Documentation

Software

PhoenixContact"VariosubRJ45

Quickcon"connectorx2

OperatingPanel

Interfacecables

Mountinghardware

OperatingPanel

Ethernetcable

Mountinghardware

Ethernetcable(100m)

HullUnit

TheST90Fishndingsonarcanbeprovidedwithoneofthefollowinghullunits.The

sametransducerisusedonallhullunittypes.Thesameinstallationtrunkisusedon

allhullunittypes.

32

442703/B

Page 35

SimradST90

ItemPartnumberInthebox

HullUnitST92

HullUnitST93

HullUnitST94

EachhullunitisprovidedwithanO-ringforusebetweenthehullunitangeandthetopofthe

installationtrunk(ortransducerdock).Relevantmountinghardware(bolts,nutsandwashers)are

alsoincluded.

441486

441488

438520

441490

441492

441494

HullUnit

Transducer

Transducercable4.6m

O-ring(540-078749)

HullUnit

Transducer

Transducercable7m

O-ring(540-078749)

HullUnit

Transducer

Transducercable4.6m

O-ring(540-078749)

HullUnit

Transducer

Transducercable7m

O-ring(540-078749)

HullUnit

Transducer

Transducercable4.6m

O-ring(540-078749)

HullUnit

Transducer

Transducercable7m

O-ring(540-078749)

Operationalsoftware

Operationalsoftwareisprovidedonasuitablemedia.Theoperationalsoftwareis

installedontheProcessorUnit,andreadyforuse.

End-userdocumentation

End-userdocumentationisprovidedonpaperand/ordigitalformats.Alldocumentation

relatedtooperationandinstallationcanbedownloadedfromourwebsite.

•https://www.simrad.com/st90

Relatedtopics

Scopeofsupply,page32

Installingthehullunit,page124

HullUnitpowerrequirements,page394

ST92HullUnitweightandoutlinedimensions,page398

ST93HullUnitweightandoutlinedimensions,page398

ST94HullUnitweightandoutlinedimensions,page399

HullUnitenvironmentalrequirements,page401

HullUnitcompasssafedistance,page404

447567HullUnitdimensionsST92,page425

442703/B

33

Page 36

SimradST90InstallationManual

435546HullUnitdimensionsST93,page428

447545HullUnitdimensionsST94,page431

34

442703/B

Page 37

SimradST90

Additionalrequireditems

AdditionalitemsareavailablefortheST90.SomearerequiredforST90operation.

TheseitemsmustbeaddedtotheST90forfulloperationalfunctionality.Theadditional

itemscanbeprovidedbyKongsbergMaritime.Youcanorderthemwiththeotherbasic

ST90items.Y oucanalsopurchasetheseitemsfromyourdealer,agentorlocalsupplier.

Topics

Installationtrunk,page35

Display,page36

UninterruptiblePowerSupply(UPS),page37

Speedlog,page37

Coursegyro,page38

Installationtrunk

Aninstallationtrunkisrequiredforhullunitinstallation.Theinstallationtrunkisnot

includedinthestandarddelivery.