Page 1

Installation manual

TECHNOLOGY FOR SUSTAINABLE FISHERIES

www.simrad.com

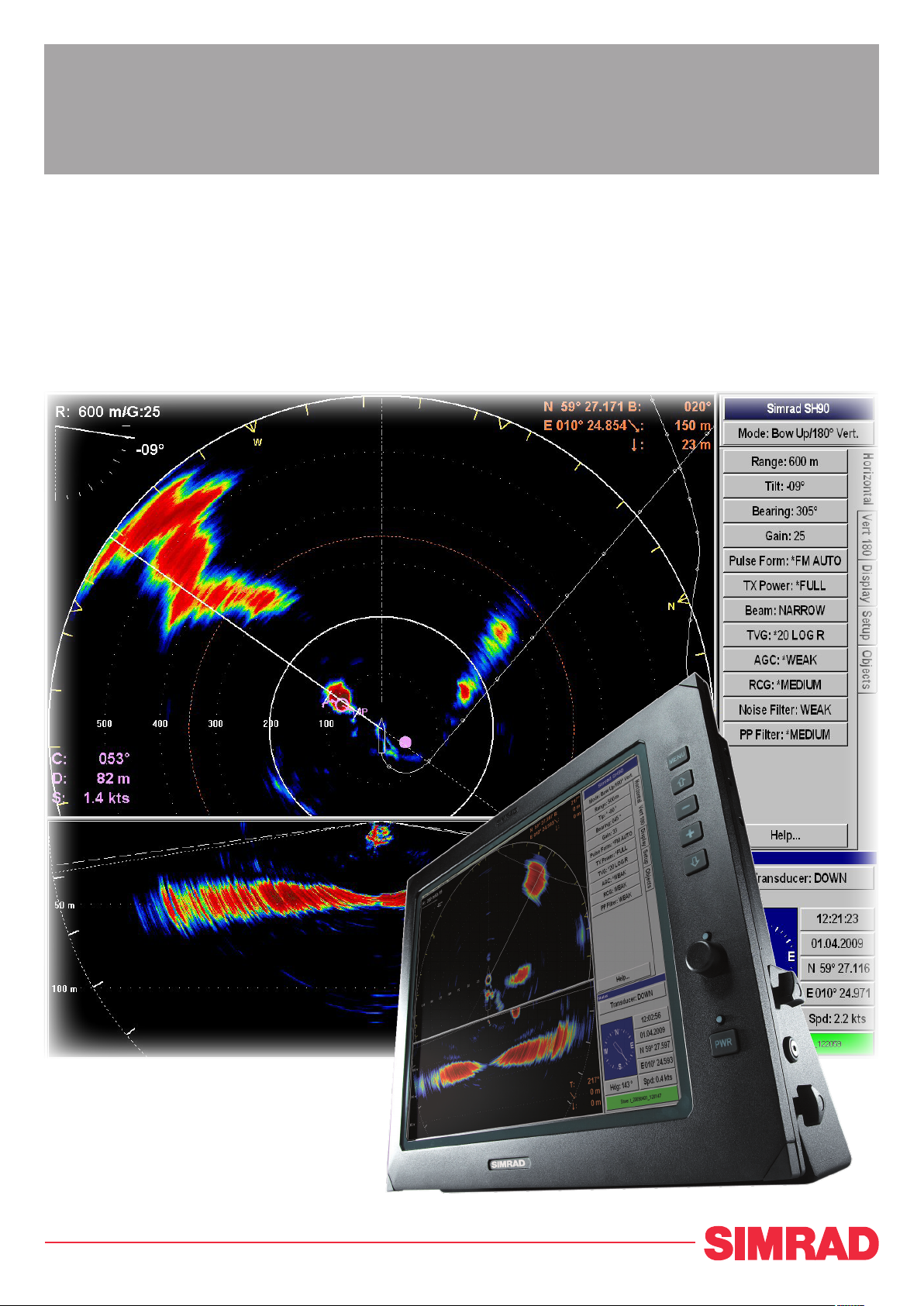

Simrad SH90

Fish nding sonar

Page 2

Page 3

SimradSH90

Installationmanual

Thismanualprovidesyouwiththebasicinformation

requiredtoinstalltheSimradSH90.Formoredetailed

informationaboutthepracticaluseoftheproduct,referto

theSimradSH90OperatormanualortheSimradSH90

Referencemanual.

323776/A

09.06.2010

Page 4

History

KongsbergM a r it imeA S

Strandprom e n a de n5 0

P.O.Bo x1 11

N- 3 1 91H o rten ,N o rway

S im ra d

Teleph on e :+ 473 30 34 00 0

Telefa x:+ 473 30 42 98 7

contact@ s im ra d . com

w w w .s im r a d . c o m

Documentno:323776/V ersion:A/ISBN-13:978-82-8066-125-1

Rev.A09.06.2010

Firstissue.

Copyright

©2010KongsbergMaritimeAS

TheinformationcontainedinthisdocumentremainsthesolepropertyofKongsbergMaritimeAS.Nopart

ofthisdocumentmaybecopiedorreproducedinanyformorbyanymeans,andtheinformationcontained

withinitisnottobecommunicatedtoathirdparty ,withoutthepriorwrittenconsentofKongsberg

MaritimeAS.Thedocument,oranypartofit,maynotbetranslatedtoanyotherlanguagewithoutthe

writtenapprovalfromKongsbergMaritimeAS.

Disclaimer

KongsbergMaritimeASendeavourstoensurethatallinformationinthisdocumentiscorrectandfairly

stated,butdoesnotacceptliabilityforanyerrorsoromissions.

Warning

Theequipmenttowhichthismanualappliesmustonlybeusedforthepurposeforwhichit

wasdesigned.Improperuseormaintenancemaycausedamagetotheequipmentand/orinjury

topersonnel.Theusermustbefamiliarwiththecontentsoftheappropriatemanualsbefore

attemptingtoinstall,operateorworkontheequipment.

KongsbergMaritimeASdisclaimsanyresponsibilityfordamageorinjurycausedbyimproper

installation,useormaintenanceoftheequipment.

Supportinformation

Ifyourequiremaintenanceorrepair,contactyourlocaldealer.Youcanalsocontactususingthefollowing

address:contact@simrad.com.Ifyouneedinformationaboutourotherproducts,visitourwebsite.On

thewebsiteyouwillalsondalistofourdealersanddistributors.

Page 5

Installationmanual

Tableofcontents

ABOUTTHISMANUAL.....................................................11

SIMRADSH90.................................................................13

Basicinformation...................................................................................................13

Mainunits...............................................................................................................14

Wheelhouseunits........................................................................................14

Sonarroomunits.........................................................................................15

Systemdiagram......................................................................................................17

Installationprocedure.............................................................................................18

Scopeofsupply......................................................................................................20

Additionalrequireditems.......................................................................................20

DisplayUnit.............................................................................................20

UninterruptedPowerSupply(UPS)..............................................................20

Installationtrunk.......................................................................................21

Speedlog...................................................................................................21

Coursegyro................................................................................................21

Additionaloptionalitems.......................................................................................22

Installationtrunk.........................................................................................22

Scienticinterface......................................................................................22

Otherperipheralequipment.........................................................................23

Generalsupplyconditions......................................................................................24

Equipmentresponsibility.............................................................................24

Receipt,unpackingandstorage....................................................................25

Generalinstallationrequirements...........................................................................25

Approvalbyclassicationsociety................................................................25

Supplypower.............................................................................................26

Compassdeviation......................................................................................26

Noisesources.............................................................................................26

Drydocking...............................................................................................26

Wiring........................................................................................................26

Supportinformation...............................................................................................27

INSTALLATIONPLANNING..............................................28

Aboutinstallationdrawings....................................................................................28

Locationofthehullunit.........................................................................................29

Sonarroomrequirements.......................................................................................31

Sonarroomarrangementexample..........................................................................33

Sonarroomarrangementexample................................................................33

Sonarroomarrangementexample................................................................34

Hullunitorientationexample.......................................................................35

323776/A

3

Page 6

SimradSH90

SONARTRUNKINSTALLATION........................................36

Mountingthesonartrunk.......................................................................................37

Sonartrunkprotection............................................................................................38

Sonartrunkinstallationprinciples..........................................................................38

Sonartrunkinstallationmeasurements...................................................................41

HULLUNITINSTALLATION.............................................42

Howtounpackthehullunitfromitstransportbox...............................................43

Hullunitmounting.................................................................................................45

Mechanicalsupport................................................................................................47

Transduceralignment.............................................................................................47

Hullunitinstallationchecklist...............................................................................48

TRANSCEIVERUNITANDPOWERSUPPLYUNIT

INSTALLATION...............................................................49

TransceiverUnitpreparations................................................................................49

PowerSupplyUnitpreparations.............................................................................50

TransceiverUnitinstallationprocedure.................................................................50

PowerSupplyUnitinstallationprocedure..............................................................54

WHEELHOUSEUNITSINSTALLATION..............................55

Physicallocationofwheelhouseunits....................................................................55

Installationrequirements.............................................................................56

Locationofthecolourdisplay......................................................................56

LocationoftheOperatingPanel...................................................................57

LocationoftheOperatingPanelPowerSupply.............................................57

LocationoftheProcessorUnit.....................................................................57

Maximumdistancesbetweentheunits...................................................................58

Installationofthecolourdisplay............................................................................59

InstallationoftheOperatingPanel.........................................................................59

InstallationoftheOperatingPanelPowerSupply.................................................60

InstallationoftheProcessorUnit...........................................................................60

UPSINSTALLATION........................................................62

CABLELAYOUTANDINTERCONNECTIONS......................63

Cableplan...............................................................................................................64

Listofcables..........................................................................................................66

Cableprocedures....................................................................................................72

ConnectACmainstotheUninterruptedPowerSupply..................................72

ConnectthevideocablefromtheProcessorUnittothecolourdisplay...........73

ConnecttheUSBcablefromtheOperatingPaneltotheProcessorUnit...........74

ConnecttheOperatingPanel“Dualcable”....................................................75

ConnecttheOperatingPanelpowersupplytotheProcessorUnit...................76

ConnectACmainsandgroundtotheProcessorUnit.....................................77

4

323776/A

Page 7

Installationmanual

ConnectACmainstothecolourdisplay.......................................................78

ConnectgroundtotheOperatingPanel........................................................79

ConnecttheProcessorUnittotheTransceiverUnit.......................................80

ConnectACmainstotheTransceiverUnit...................................................81

ConnectthepowercablefromthePowerSupplyUnittotheTransceiver

Unit...........................................................................................................82

ConnecttheEthernetcablefromthePowerSupplyUnittotheTransceiver

Unit...........................................................................................................83

ConnectACmainsandgroundtothePowerSupplyUnit..............................84

ConnectACmainstotheMotorControlUnit...............................................85

ConnecttheTransceiverUnittotheMotorControlUnit................................86

ConnecttheEthernetcableforscienticoutput.............................................87

Transducercable.........................................................................................88

Installationofinterfacecablestoperipheralequipment..................................88

ProcessorUnitseriallines......................................................................................88

Seriallinesupport.......................................................................................88

JumperandDIPswitchsettings...................................................................89

Adaptercable.............................................................................................91

Referencestodetailedcabledrawingsandspecications......................................92

START-UPPROCEDURES.................................................93

StartinguptheHullUnit........................................................................................93

Hullunitfamiliarization..............................................................................94

MotorControlUnitfamiliarization...............................................................95

Functionalcheck.........................................................................................96

Apply3-phaseACpower............................................................................97

Checkthehoistingmotor’s3–phaseACconnections.....................................98

Checkthe3–phaseconnectionforcorrectrotationdirection...........................99

Checkthecontactoroperation....................................................................100

Functionalchecktoverifycorrecthoistandlowerfunctionality...................101

Startingthewheelhouseunits...............................................................................103

CheckingtheOperatingPanel..............................................................................104

Functionaltest..........................................................................................104

Startingupthesonarroomunits..........................................................................112

Checkingthehoist/lowersystem..........................................................................113

Checkingthebridgefunctions....................................................................114

Checkingthesonarroomfunctions.............................................................116

Performself-noisetest..........................................................................................117

Startingupthesonarsystem.................................................................................118

Preparations..............................................................................................118

Actionsonthebridge.................................................................................119

Actionsinthesonarroom..........................................................................120

Alignmentofthesonarpicture.............................................................................121

323776/A

5

Page 8

SimradSH90

Deningownshipparameters..............................................................................122

Specifyshipdimensions............................................................................122

Specifyinstrumentpositionoffsets.............................................................122

INTERFACINGPERIPHERALEQUIPMENT......................124

Interfaceandtelegramsoverview.........................................................................124

Interfacesettings...................................................................................................127

Defaultinterfacesettings...........................................................................127

Howtochangetheinterfacesettings..........................................................127

Howtomonitorthetrafconaserialline...................................................132

Synchronisationwithotheracousticsystems.......................................................133

Aboutsynchronisation..............................................................................133

SH90setupasSlave.................................................................................134

SH90setupasMaster...............................................................................134

Synchronisationsequences........................................................................135

Installationprocedures.........................................................................................136

Connectingthespeedlog...........................................................................136

Connectingthecoursegyro.......................................................................137

Testprocedures.....................................................................................................138

Speedloginterfacetest.............................................................................138

Coursegyrointerfacesetupandtest...........................................................139

Positioningsysteminterfacesetupandtest.................................................140

Echosoundersysteminterfacesetupandtest..............................................141

Trawlsysteminterfacesetupandtest.........................................................141

Catchmonitoringinterfacesetupandtest...................................................142

Radiobuoysysteminterfacesetupandtest.................................................143

Currentmeterinterfacesetupandtest.........................................................143

FINALTESTSANDMEASUREMENTS..............................145

Noise/speedcurvemeasurements.........................................................................146

Preparations.............................................................................................146

Testprocedure..........................................................................................146

Problemswithownoise..........................................................................147

Noise/speedtestresults.............................................................................147

ProcessorUnitbackupandrestore.......................................................................150

HowtocreateabackupDVD....................................................................150

HowtorestorefromabackupDVD...........................................................150

HowtoreactivatetheWindowslicence......................................................151

TECHNICALSPECIFICATIONS.....................................157

Powerspecications...........................................................................................157

Weightsandoutlinedimensions.........................................................................158

Environmentalspecications.............................................................................160

Performancespecications.................................................................................161

6

323776/A

Page 9

Installationmanual

DRAWINGFILE.............................................................163

TransceiverUnitdimensions................................................................................164

Forwardview...........................................................................................164

Sideview.................................................................................................165

Topview..................................................................................................166

PowerSupplyUnitdimensions............................................................................167

Forwardview...........................................................................................167

Sideview.................................................................................................168

ProcessorUnitdimensions...................................................................................169

OperatingPaneldimensions.................................................................................170

SH90Hullunitdimensions..................................................................................171

SH90Sonartrunkdimensions..............................................................................172

SH90Sonartrunkproduction...............................................................................173

Sideview.................................................................................................173

Topview..................................................................................................174

SH90Blindcoverdimensions..............................................................................175

AGENERALSAFETYRULES...............................................176

BEQUIPMENTHANDLING................................................177

Transportation.......................................................................................................177

Lifting...................................................................................................................177

Storagepriortoinstallationoruse.......................................................................178

Inspection.............................................................................................................179

Unpacking............................................................................................................180

Generalunpackingprocedure....................................................................180

Unpackingelectronicandelectromechanicalunits......................................181

Unpackingmechanicalunits......................................................................181

Unpackingtransducers..............................................................................181

Storageafterunpacking........................................................................................182

Storageafteruse...................................................................................................182

Cleaningcabinets......................................................................................182

Mechanicalunits.......................................................................................183

Cables......................................................................................................183

Internalbatteries.......................................................................................183

Dehumidier............................................................................................184

Coatings...................................................................................................184

Re-packaging........................................................................................................184

Temperatureprotection.........................................................................................184

Circuitboardhandlingandpackaging..................................................................185

Returningacircuitboard...........................................................................186

Electro-StaticDischarge(ESD)............................................................................186

CSH90CABLEDETAILS...................................................188

323776/A

7

Page 10

SimradSH90

Cablingprinciples.................................................................................................188

Cablestoperipheraldevices.................................................................................189

Positioningsysteminterface......................................................................189

Echosoundersysteminterface...................................................................190

Trawlsonarinterface.................................................................................190

Catchmonitoringsysteminterface.............................................................191

Currentmeterinterface..............................................................................191

Radiobuoysconnectioninterface...............................................................191

Cabledrawings.....................................................................................................193

MoxaCP-134U-Iserialadapter.................................................................194

Vesselground...........................................................................................196

ACmains(IEC60320)..............................................................................197

ACmainstoMotorControlUnit................................................................198

ACmainswithIEC320/C7.......................................................................199

DCpowersupply.....................................................................................200

DCpowerfromPowerSupplyUnittoTransceiverUnit.............................201

RJ45Ethernet,straight..............................................................................202

RJ45Ethernetwithnoisesuppressor..........................................................203

VGA/SVGADisplay.................................................................................204

UniversalSerialBus(USB).......................................................................205

DVI–IDisplay..........................................................................................206

OperatingPanel“Dual”............................................................................208

DBASICCABLEREQUIREMENTS......................................209

Cabletrays............................................................................................................209

RadioFrequencyinterference..............................................................................210

Physicalprotection...............................................................................................210

Grounding.............................................................................................................211

Cableconnections.................................................................................................211

Cableterminations................................................................................................211

Cableidentication...............................................................................................212

ETELEGRAMFORMATS....................................................213

AboutNMEAtelegramformats...........................................................................213

TelegramsreceivedandsentbytheSH90............................................................214

Coursegyrotelegrams...............................................................................214

Speedlogtelegrams..................................................................................215

GPStelegrams..........................................................................................215

ITIandtrawlsystemtelegrams..................................................................215

Echosoundertelegrams.............................................................................216

Windsensortelegrams..............................................................................217

Seacurrenttelegrams................................................................................217

Catchmonitoringsystemtelegrams............................................................217

Buoytelegrams.........................................................................................217

8

323776/A

Page 11

Installationmanual

Targetoutputtelegrams.............................................................................218

SpecicationofNMEAtelegrams.......................................................................218

DBSDepthbelowsurface.........................................................................218

DBTDepthbelowtransducer.....................................................................218

DPTDepth...............................................................................................219

GGAGlobalpositioningsystemxdata.....................................................219

GLLGeographicalpositionlatitude/longitude............................................220

HDGHeading,deviationandvariation.......................................................220

HDMHeading,magnetic...........................................................................221

HDTHeading,true...................................................................................221

MWDWinddirectionandspeed................................................................222

MWVWindspeedandangle.....................................................................222

RMCRecommendedminimumspecicGNSSdata....................................222

VBWDualgroundandwaterspeed...........................................................223

VHWWaterspeedandheading.................................................................224

VTGCourseoverground&groundspeed..................................................224

VWRRelative(apparent)windspeedandangle..........................................224

ZDATimeanddate..................................................................................225

SpecicationofproprietarySimradtelegrams.....................................................225

DBSDepthoftrawlbelowsurface.............................................................225

FS3300Binarydepth................................................................................226

GLLTrawlposition..................................................................................226

HFBTrawlheadropetofootropeandbottom..............................................226

MDSMeasureddatashoal.........................................................................227

MTWWatertemperatureatthetrawl.........................................................228

PSIMP-FPISensordenition....................................................................228

PSIMP-DPISensordata...........................................................................229

TDSTrawldoorspread.............................................................................230

TFITrawllling.......................................................................................230

TPCTrawlpositionincartesiancoordinates...............................................231

TPPTrackedtargetpositionormarker.......................................................231

TPTTrawlpositiontruevessel..................................................................232

TS2Trawlspread2...................................................................................232

TTSTrawltoshoaldistance......................................................................232

Specicationofproprietarythirdpartytelegrams................................................233

VDVCDV ectorcurrentdirection...............................................................233

FurunoCIF...............................................................................................233

SerpeBSCBuoyinput..............................................................................236

RyokoseiRBYBuoyinput........................................................................237

FINSTALLATIONREMARKS.............................................238

323776/A

9

Page 12

SimradSH90

10

323776/A

Page 13

ABOUTTHISMANUAL

Aboutthismanual

Purpose

Thepurposeofthismanualistoprovidetheinformationand

basicdrawingsrequiredforinstallationoftheSimradSH90.

Formoredetailedinformationaboutthepracticaluseofthe

product,refertotheSimradSH90Operatormanualorthe

SimradSH90Referencemanual.

Aboutthetechnicaldescriptionsandthetarget

audience

ThismanualdescribestheinstallationoftheSimradSH90.

Themanualisintendedfortechnicalpersonnel;qualied

maintenanceengineersandtechnicians.Itisassumedthatthe

personnelisconversantwiththegeneralprinciplesofmaritime

electronicequipment,inparticularsonar,echosounderandcatch

monitoringsystems.Thepersonnelmustalsobefamiliarwith

computerhardware,signalprocessing,interfacetechnology

andtraditionaltroubleshootingonelectronicandmechanical

products.

Theinstructionsmustbefollowedcarefullytoensureoptimal

performance.Asaguide,installationproceduresarepresented

intheordertheyaretobeperformed.Successfulcompletion

ofeachprocedureistobeconrmedbycheckingoffthe

correspondingbox.

Note

Theinstallationinstructionsgiveninthisdocumentmustbe

adheredto.Failuretodosomayrendertheguaranteevoid.

KongsbergMaritimeASwillacceptnoresponsibilityforany

damageorinjurytothesystem,vesselorpersonnelcausedby

equipmentthathasbeenincorrectlyinstalledormaintained,

orbydrawings,instructionsorproceduresthathavenotbeen

preparedbyus.

Theequipmentdescribedinthismanualincludesthecomplete

systemwithassociatedcabinets,butnotsystemunitsprovided

locallybythecustomer,installationshipyardorlocaldealer.The

manualalsodenestheequipmentresponsibility,andprovides

instructionsforunpackingandstorage.

Afterinstallation,thisdocumentmustbestoredonboard

thevesselforlaterreferencewhenupdatingorservicingthe

equipment.

323776/A

11

Page 14

SimradSH90

Installationdrawings

Detailedvesselspecicmechanicaldrawingsfortheinstallation

mustbeprovidedbythecustomer,oranyshipyardcontractedto

performtheinstallation.

KongsbergMaritimeASmay,onspecialorder,provideassistance

tothesedrawings.Drawingsmustbeapprovedbytheappropriate

vesselcerticationauthoritypriortoinstallationofthesystem.

Applicableoutlinedimensionandproductionsdrawings

areprovidedintheDrawinglechapter.Drawingsmay

alsobedownloadedinPDFand/orDWGformatsfrom

t t p : / / w w w . s i m r a d . c o m .

h

References

ThefollowingusermanualshavebeenprovidedfortheSimrad

SH90.EnglishmanualsareprovidedwiththeSH90whenitis

shipped.Whenavailable,manualsinotherlanguagesmaybe

downloadedfromh

t t p : / / w w w . s i m r a d . c o m .

•SimradSH90InstallationManual,English[323776]

•SimradSH90OperatorManual,English[323773]

•SimradSH90ReferenceManual,English[323775]

12

323776/A

Page 15

SIMRADSH90

SimradSH90

StudythischaptertofamiliarizeyourselfwiththeSimradSH90.

Topics

•Basicinformationonpage13

•Mainunitsonpage14

•Systemdiagramonpage17

•Installationprocedureonpage18

•Scopeofsupplyonpage20

•Additionalrequireditemsonpage20

•Additionaloptionalitemsonpage22

•Generalsupplyconditionsonpage24

•Generalinstallationrequirementsonpage25

•Supportinformationonpage27

Relatedtopics

•Generalsafetyrulesonpage176

•Equipmenthandlingonpage177

•Basiccablerequirementsonpage209

Basicinformation

TheSimradSH90isanomnidirectionalhighfrequencysonar.

Itisdesignedforallsizedshingvessels,bothpurseseiners

andtrawlers.

Theoperationalfrequencyis114kHz.Thecylindrical

multi-elementtransducerallowstheomnidirectionalsonarbeam

tobetiltedelectronicallyfrom+10to–60degrees.Thisallows

youtoautomaticallytrackschoolsofsh,andtoobservethe

wholewatervolumearoundthevessel.Astabilisingsystemis

includedforelectronicpitchandrollcompensation.

Greatemphasishasbeenplacedongivingthebestpossible

presentationsonahighresolutioncolourdisplay.

TheSH90ProcessorUnitiscontrolledbyMicrosoft’sWindows

®

XP

operatingsystem,whichresultinaexiblechoiceofdisplay

modesforalargerangeofuserapplications.

Thesignalprocessingandbeamformingisperformedinafast

digitalsignalprocessingsystemusingthefulldynamicrange

ofthesignals.

Inadditiontothetraditionalsinglefrequencytransceiversystem,

theSimradSH90containsanadvancedfrequencymodulated

ltersystem(FM).

323776/A

13

Page 16

SimradSH90

Mainunits

TheSimradSH90comprisesthefollowingunits:

Normallyinstalledinthewheelhouse:

•DisplayUnit

•OperatingPanel

•ProcessorUnit

•OperatingPanelpowersupply

Normallyinstalledinthesonarroom:

•TransceiverUnit

•PowerSupplyUnit

•HullUnit

Wheelhouseunits

DisplayUnit

Thecolourdisplayisahigh-resolutionmonitor.Inaddition

tothesonarpicture,themonitorwillalsodisplaythemenu

systemfortheinteractiveoperation.Inordertoeasethesituation

comprehension,certaincolourshavebeenchosentobetterthe

distinctionbetweenthevariouselementsinthepresentation.

Thecolourdisplayisnotapartofthesonardelivery ,anditmust

bepurchasedlocally.

OperatingPanel

Figure1OperatingPanel

TheOperatingPanelcontainsallnecessarycontrolfunctionsfor

normaloperationofthesonar.

Thecontrolsarearrangedinlogicalfunctiongroups,thisgivesa

clearandeasyoperation.

Notethatallsonaroperationcanalsobemadeusingthetrackball

ontheOperatingPanelandthemenusystem.Y oucanalsousea

standardcomputermouse.

ProcessorUnit

TheProcessorUnitisamarinecomputerbasedontheMicrosoft

WindowsXP®operatingsystem.Itisdesignedforruggeduse.

14

323776/A

Page 17

SimradSH90

Thecomputerisbasedonacommercialdesign,butthesoftware

andhardwarehasbeenspeciedandassembledbySimradtosuit

theSH90requirements.

ThecomputerholdsaDVDplayerforusewithfuturesoftware

upgrades.

Figure2ProcessorUnit

Thepurposeofthiscomputeristoallowyoutocontrolthesonar.

Thecomputerservesseveralfunctions.

•Itcontrolstheoveralloperationofthesonarfunctions.

•Itprovidesthegraphicpresentationofthesonarmodesand

echoes.

•Itholdsthemenusystem.

•ItcommunicateswiththeOperatingPaneltoreadthebuttons

andtrackballmovements.

•Itperformstheadvancedsignalprocessingandbeamforming

requiredtopresenttheinformationonthedisplay.

•Itcommunicateswithperipheraldevicesandsensorsusing

seriallines.

•ItcommunicateswiththeTransceiverUnit.

OperatingPanelpowersupply

Asmallpowersupplyisimplementedtoprovidestand-bypower

totheOperatingPanel.Thepowersupplyisconnectedtothe

ProcessorUnit.

Sonarroomunits

TransceiverUnit

TheSH90TransceiverUnitislocatedinthesonarroom,closeto

theHullUnit.

Thetransceiverperformsthetransmissionandreceptioncontrol

ofthe480transmittersand480receiverchannels.16identical

transceiverboardsareused.Adedicatedpowersupplyis

providedtosupplytherequiredDCvoltagestothetransceiver.

OneEthernetcableisusedforcommunicationwiththeProcessor

323776/A

15

Page 18

SimradSH90

Unitinthewheelhouse,andasecondEthernetcableisusedto

controlthehullunit.ThethirdEthernetcableconnectstothe

PowerSupplyUnit.

Thetransducercablesfromthehullunitarepluggedintotheside

walloftheTransceiverUnitcabinetusingaspecialplug.

TheTransceiverUnitismountedonthebulkheadusingpowerful

shockabsorbers.Theconnectorsforpowerandinterfaceare

locatedatthebottomofthecabinet.

PowerSupplyUnit

Adedicatedpowersupplycabinetisusedtoprovidethe

TransceiverUnitwithoperationalpower.

WARNING

Thepowersupplycabinetcontainshighvoltages.

DonotopenthecabinetdoorwhiletheSH90is

switchedon.

HullUnit

TheHullUnitisdesignedtolowerthetransducer1.0meters

belowtheship’shull.

Thetransducercanalsobeloweredtoanyselectedmiddle

position.Incaseofvoltagefailure,thetransducercanberaised

orloweredmanuallybymeansofahandcrank.

Thesensorfortheelectronicstabilisationofthesonarbeams

ishousedintheMotorControlUnit,whichismountedonthe

HullUnit.

WARNING

Ifthetransducerhitslargerobjectsorbottom,the

transducershaftmaybebent,or-inworstcaseitcanbebrokenoff.Abrokentransducershaftwill

causewaterleakagethroughthetopoftheshaft.

Insuchcases,d

itsupperposition.

Topreventseriousdamage,youmusthaveawater

pumpandawarningsysteminthesonarroom.

o n o t raisethetransducershaftto

Transducer

ThecylindricalTransducerallowsthesonarbeamtogivefull

360degreescoverageofthewatervolumefrom+10anddown

to-60degrees.

16

323776/A

Page 19

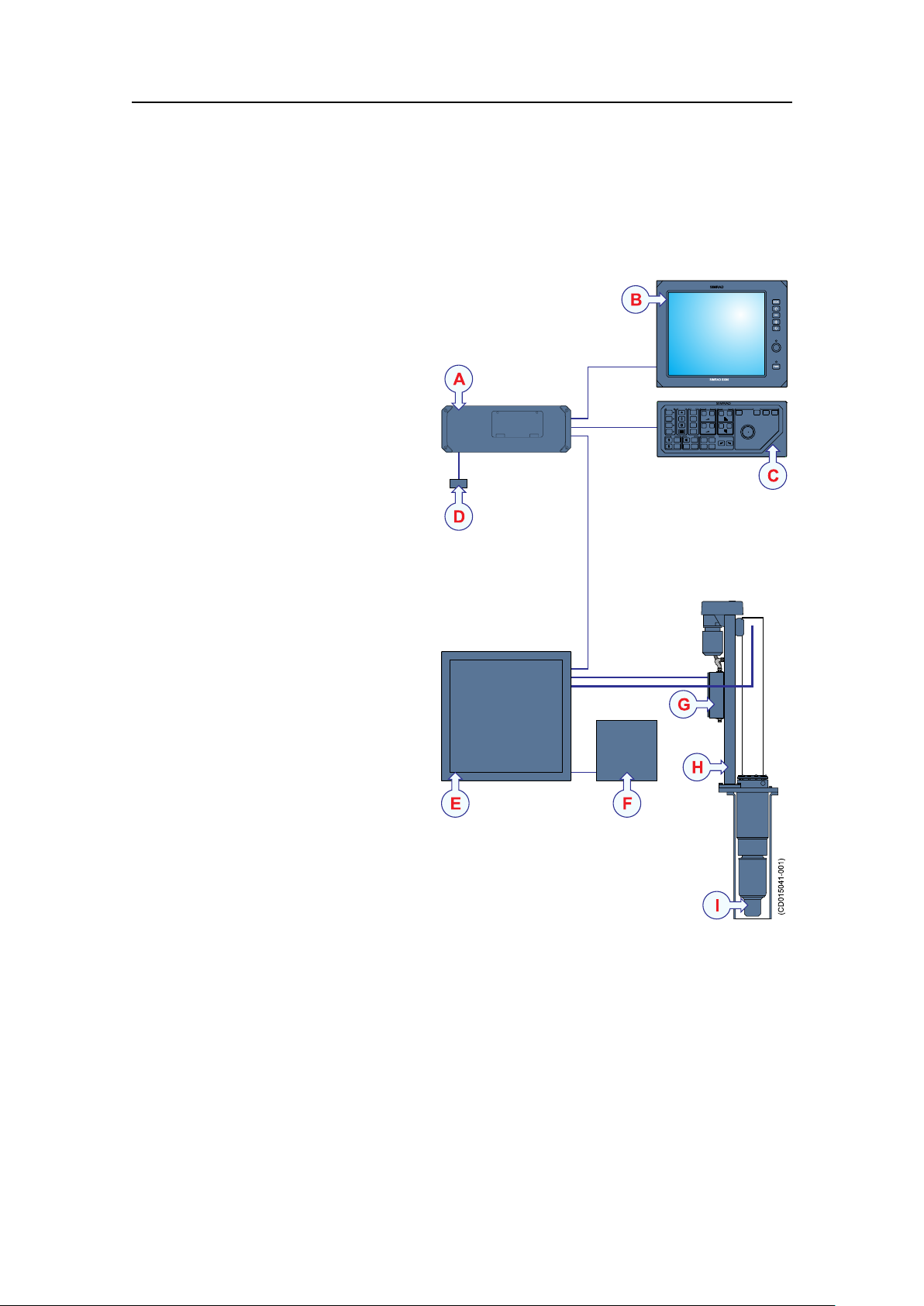

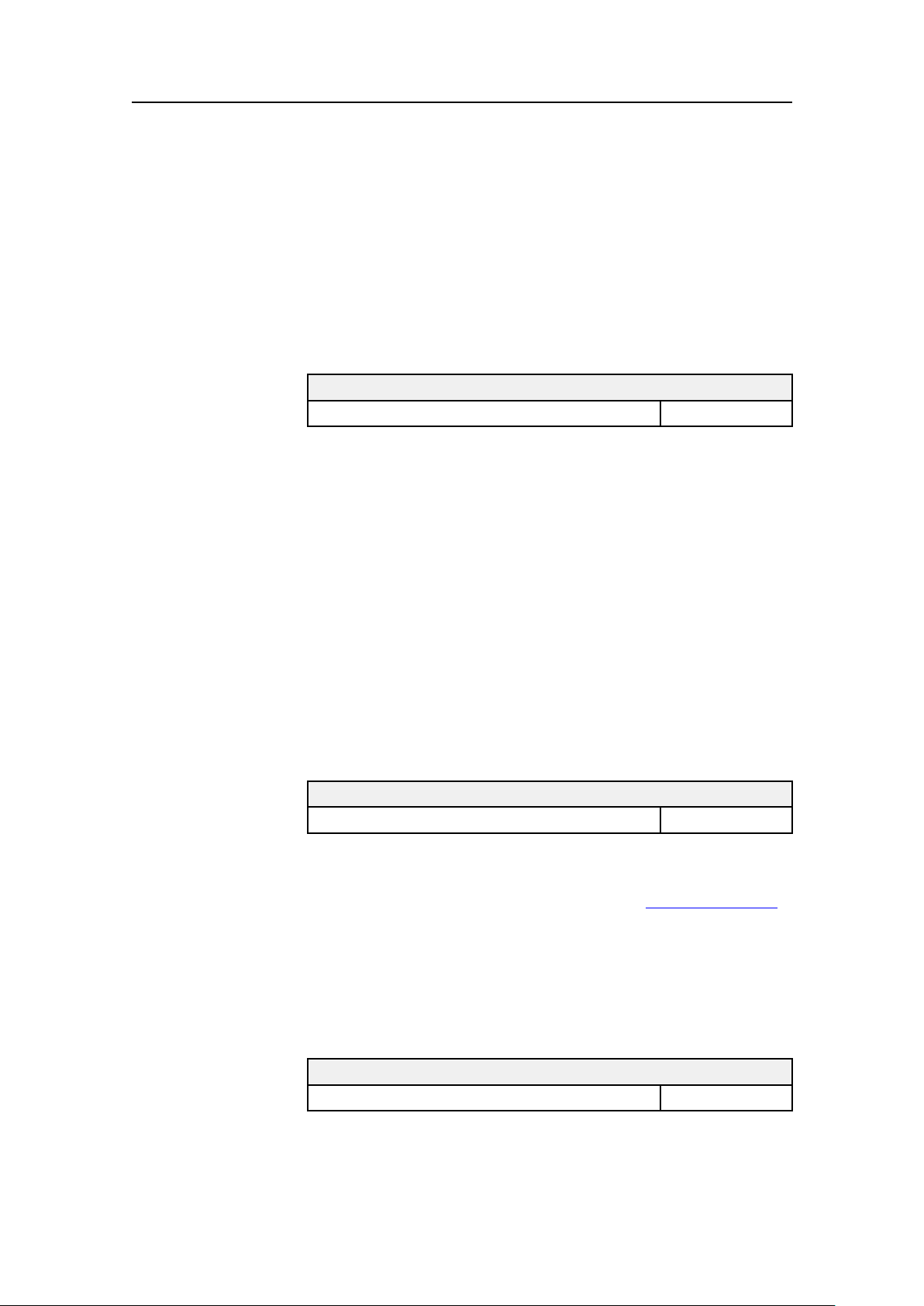

Systemdiagram

SIMRAD

PWR

MENU

SIMRAD

SIMRADSX90

(CD015041-001)

D

B

C

E F

H

G

I

A

Figure3SH90Simpliedsystemdiagram

AProcessorUnit

BDisplayUnit

COperatingPanel

DOperatingPanelpowersupply

ETransceiverUnit

FPowerSupplyUnit

GMotorControlUnit

HHullUnit

ITransducer

SimradSH90

323776/A

17

Page 20

SimradSH90

Installationprocedure

TheSimradSH90isacomplexandadvancedproductfor

professionaluse.

Note

Inordertoobtainmaximumsafetyandperformance,itisvery

importantthattheinstallationproceduresinthismanualare

compliedto,andthatthetasksarecarriedoutinthesuccession

theyaredescribed.Thevesselownermustmakesurethatthe

installationshipyardholdstheapplicablecompetencetoperform

theinstallation,andthattheapplicablemaritimeauthoritiesare

availabletoverifyandcertifytheinstallation.

ObservethebasicrequirementsinGeneralsafetyruleson

page176!

Anoverallinstallationprocedureisprovidedbelow.The

proceduredoesnotdescribeanydetailedtasks,butreferstothe

relevantproceduresinthismanual.

1Basedonthevesseldrawingsandbestpractice,

determinewherethehullunitshallbelocated.Necessary

considerationsmustbetakentoavoidacousticandelectric

disturbances.Makesurethatthesonarroommeetsthe

specicationsprovided.RefertoInstallationplanningon

page28.

2Performthephysicalinstallationofthesonartrunk.The

installationshipyardmustprovideallnecessaryinstallation

drawingsinordertocarryoutthisoperation,andifrequired,

thesedrawingsmustbeapprovedbytheapplicablemaritime

authorities.Thetrunkpenetratesthehull,anditistherefore

acrucialpartofthehullunitassembly.RefertoSonartrunk

installationonpage36.

3Installthehullunit.Duetoitsphysicalsizeandweight,and

thefactthatthetrunkpenetratesthevesselhull,itisvery

importantthatthehullunitisinstalledandsecuredproperly.

RefertoHullunitinstallationonpage42.

4InstalltheTransceiverUnit.RefertoTransceiverunitand

PowerSupplyUnitinstallationonpage49.

5Installthewheelhouseunits.RefertoWheelhouseunits

installationonpage55.

6Performthesystemcabling.Observetheprocedureand

cableplaninsectionCablelayoutandinterconnectionson

page63.Foradditionalinformation,refertoSH90cable

18

323776/A

Page 21

SimradSH90

detailsonpage188.Generalrequirementsforthecabling

areprovidedinBasiccablerequirementsonpage209.

7Performthestart-upproceduresasdetailedinsection

Start-upproceduresonpage93.

Note

Inordertosetupthesonarsysteminasafeandcorrect

manner,thesestart-upproceduresmustbecompliedto!

8Connecttheperipheralunits.Observethesetupandtest

proceduresinsectionInterfacingperipheralequipmenton

page124.Foradditionalinformation,refertoSH90cable

detailsonpage188.Generalrequirementsforthecabling

areprovidedinBasiccablerequirementsonpage209.

9Checkthesourcelevelandreceivingvoltageresponse,

andmakethenoise/speedmeasurements.Observethe

proceduresinsectionFinaltestsandmeasurementson

page145.

10Createabackupofallthesoftwareandinstallationsetup

parametersontheProcessorUnit.SeeProcessorUnit

backupandrestoreonpage150.

11FillinandsigntheInstallationRemarksform,andsenditto

Simrad’ssupportdepartmentasspeciedontheform.See

Installationremarksonpage238.

323776/A

19

Page 22

SimradSH90

Scopeofsupply

Mainunitsincludedwiththestandarddelivery

•OperatingPanel[SH8-203593]

•ProcessorUnit[327202]

•PowerSupplyUnit[327208]

•TransceiverUnit[327203]

•HullUnit[327204]

Additionalrequireditems

Thefollowingadditionalitemsarerequiredforafullyoperational

sonar,buttheyaren

•Colourdisplay

o t i n c l u d e d inthestandarddelivery:

•UninterruptedPowerSupply(UPS)

•Installationtrunk

•Speedlog

•Coursegyro

DisplayUnit

TheSimradSH90requiresaVGAorDVIcolourdisplaywitha

resolutionofatleast1280x1024pixels.

UninterruptedPowerSupply(UPS)

InordertoensurecontinuousoperationoftheSimradSH90

independentofvaryingqualityofthevessel’smainssupply,the

useofuninterruptedpowersupplies(UPS)isrequired.TwoUPS

unitsareused:

•Oneisusedtopowerthewheelhouseunits.

•OneisusedtopowertheTransceiverUnit.

Theuninterruptedpowersupply(UPS)unitsaren

thestandarddelivery.Severalcommercialtypesareavailable.

TochoosethebestUPSforthesonarinstallation,consider

environmentalconditions,spaceavailable,theavailabilityand

durationofthebatteries,andthepowerrequirementsofthesonar

units.

o t includedin

20

323776/A

Page 23

SimradSH90

MinimumUPSpowerspecications

•Inputvoltage:Musttvesselsupplyvoltage

•Outputvoltage:230V ac,50Hz

•Outputpower:

–Wheelhouseunits:600W

–Sonarroomunits:1500W

•Outputrequirement:TheACoutputvoltagemustbeasine

wave

Installationtrunk

Theinstallationtrunkrequiredforthehullunitinstallationisn

includedinthestandarddelivery.

Theinstallationtrunkmaybefabricatedbytheshipyard,or

suppliedbySimradasanoption.Themechanicaldrawingsofthe

trunkandblindcoverareincludedinthismanual.TheSimrad

SH90sonarisdeliveredwithoutadomesystem.

SeealsoInstallationtrunkonpage22.

Speedlog

Inordertooperatecorrectly,theSimradSH90requiresinput

fromaspeedlog.Inmostcasesasuitablesensorisalready

installedonthevessel.Adifferentialglobalpositioningsystem

((D)GPS)canalsobeused.

Speedloginterfaceparameters:

•Serialline:StandardNMEA0183telegramformat

Formoreinformation,seeConnectingthespeedlogonpage136.

Coursegyro

o t

Inordertooperatecorrectly,theSimradSH90requiresinput

fromacoursegyro.Inmostcasesasuitablesensorisalready

installedonthevessel.

Coursegyrointerfaceparameters:

•Serialline:StandardNMEA0183telegramformat

Formoreinformation,seeConnectingthecoursegyroon

page137.

323776/A

21

Page 24

SimradSH90

Additionaloptionalitems

Gyrointerface

Ifthecoursegyroinstalleddoesnotoutputthecorrectserial

interfaceformat,anoptionalgyrointerfaceboxisavailable.It

willconvertthefollowingsynchroandsteppinggyrosignals:

•3-phasesynchrosignal,20to150VL-L,50/60/400Hz,gear

ration1:360or1:180

•3-phasesteppersignal,20to150VL-L,gearration1:360or

1:180

Orderinginformation

LR40Gyrointerface

298-078535

Thefollowingoptionalequipmentandfunctionalitymaybe

orderedatanadditionalchargetoaugmentthestandardSimrad

SH90systemdelivery,orpurchasedlocallybytheinstallation

shipyardorenduser.

•Installationtrunk

•Scienticinterface

•Otherperipheralequipment

Installationtrunk

Theinstallationtrunkmaybefabricatedbytheshipyardor

suppliedbySimrad.

Orderinginformation

SH90Installationtrunk

SD5–112632

Ifyouprefertomanufactureyourowninstallationtrunktotthe

vessel,observethedrawingsintheDrawingleonpage163.The

samedrawingscanalsobedownloadedfromw

w w . s i m r a d . c o m .

Scienticinterface

AspecialsoftwarekeycanbepurchasedtoenableanEthernet

interfaceprovidingsonarbeamdata,sonarsettingsandprocessed

targetdata.Thisfeatureisveryusefulifthesonarisintended

forscienticpurposes.

Orderinginformation

Scienticinterface

22

KIT-203477

323776/A

Page 25

SimradSH90

Otherperipheralequipment

TheSimradSH90providesatotaloffourseriallines.Twoof

theseareusedtointerfacetothespeedlogandcoursegyro.The

remainingseriallinescanbeusedtocommunicatewithother

peripheralequipment.

•DifferentialGlobalPositioningSystem((D)GPS)

•Catchmonitoringsystem

•Trawlsonar

•Currentmetersystem

•Radiobuoysystem

Alltheseperipheralsmaybeconnectedusingtheseriallines.

MostofthemwillcommunicatebymeansofthestandardNMEA

0183format.

Note

Equipmentandsensorsmustbepurchasedlocallybythe

installationshipyardorenduser .

DifferentialGlobalPositioningSystem((D)GPS)

A(D)GPSmaybeinterfacedwiththeSimradSH90sonarto

establishthevessel’spositionandprovidecursorandmarker

latitudeandlongitude.Inadditiontonavigationaldata,the

(D)GPSmayalsobeusedfortheinputofspeedloginformation.

Most(D)GPSareequippedtopresentcourseinformation,but

thisdataisgenerallytooinconsistenttoprovideastablesonar

presentation.

Forcablinginformation,seePositioningsysteminterfaceon

page189.

Catchmonitoringsystem

Toprovidetrawlandpurseseinedepthinformationonthesonar’s

display,thefollowingSimradcatchmonitoringsystemsmay

beconnected:

•SimradPISeriesCatchmonitoringsystems

•SimradITIIntegratedTrawlInstrumentationsystem

Forcablinginformation,seeCatchmonitoringsysteminterface

onpage191.

323776/A

23

Page 26

SimradSH90

Trawlsonar

Toprovidetrawlinformationonthesonar’sdisplay,oneofthe

followingSimradtrawlsystemsmaybeconnected:

•SimradFS903Trawlsonar

•SimradFS3300Trawlsonar

•SimradFS20/25Trawlsonar

•SimradFS70Trawlsonar

Forcablinginformation,seeTrawlsonarinterfaceonpage190.

Currentmetersystem

Acurrentmetersystemmaybeconnectedtothesonartodisplay

thedirectionandspeedoftheseacurrentsonvariousdepths.The

followingcurrentsystemcanbeconnected:

•KaijoDCG-200

Forcablinginformation,seeCurrentmeterinterfaceonpage191.

Generalsupplyconditions

Radiobuoysystem

AGPSbasedradiobuoysystemmaybeconnectedtothesonar

toshowthepositionandbuoydataonthedisplay.Thefollowing

buoysystemscanbeconnected:

•SERPE

•Ariane

•Ryokusei

Forcablinginformation,seeRadiobuoysconnectioninterface

onpage191.

ThefollowingsupplyconditionsareapplicabletothisSimrad

SH90delivery.

Equipmentresponsibility

Theshipyardperformingtheinstallationand/orequipmentdealer

becomesfullyresponsiblefortheequipmentuponreceiptunless

otherwisestatedinthecontract.Thedurationofresponsibility

includes:

•Theperiodoftimetheequipmentisstoredlocallybefore

installation.

•Duringtheentireinstallationprocess.

•Whilecommissioningtheequipment.

•Theperiodoftimebetweencommissioningandthenal

acceptanceoftheequipmentbytheenduser(normallythe

ownerofthevesselwhichtheequipmenthasbeeninstalled).

24

323776/A

Page 27

SimradSH90

Unlessotherarrangementshavebeenmadeinthecontract,the

SimradSH90guaranteeperiod(asspeciedinthecontract)

beginswhentheacceptancedocumentshavebeensigned

Receipt,unpackingandstorage

Uponacceptingshipmentoftheequipment,theshipyardand/or

thedealershouldensurethatthedeliveryiscompleteandinspect

eachshippingcontainerforevidenceofphysicaldamage.If

thisinspectionrevealsanyindicationofcrushing,dropping,

immersioninwateroranyotherformofdamage,therecipient

shouldrequestthatarepresentativefromthecompanyusedto

transporttheequipmentbepresentduringunpacking.

Allequipmentshouldbeinspectedforphysicaldamage,i.e.

brokencontrolsandindicators,dents,scratchesetc.during

unpacking.Ifanydamagetotheequipmentisdiscovered,the

recipientshouldnotifyboththetransportationcompanyand

SimradsothatSimradcanarrangeforreplacementorrepairof

thedamagedequipment.

Generalinstallationrequirements

Onceunpacked,theequipmentmustbestoredinacontrolled

environmentwithanatmospherefreeofcorrosiveagents,

excessivehumidityortemperatureextremes.Theequipment

mustbecoveredtoprotectitfromdustandotherformsof

contaminationwhenstored.

Formoreinformation,seetheappendixrelatedtoequipment

handling.

Thefollowinginstallationrequirementsareapplicabletothis

Simraddelivery.

Approvalbyclassicationsociety

TheSimradSH90transducerinstallationmustbeapprovedby

DetNorskeVeritas(DNV)oranotherclassicationsociety.

Theshipownerandshipyardperformingtheinstallationare

responsibleforobtaininginstallationapproval.

323776/A

25

Page 28

SimradSH90

Supplypower

Thesupplyvoltagetotheequipmentistobekeptwithin±10%of

theinstallation’snominalvoltage.Maximumtransientvoltage

variationsonthemainswitchboard’sbus-barsarenottoexceed

-15%to+20%ofthenominalvoltage(exceptunderfault

conditions).

SimradrecommendsthattheSimradSH90ispoweredusingan

UninterruptablePowerSupply(UPS)withsinewaveoutput.The

UPSmusthavethecapacitytoindependentlymaintainpowerto

thesystemforaminimumof10minutes.Thisensuresthatthe

systemcanbeswitchedoffinacontrolledmannerintheevent

ofapowerfailure.

Compassdeviation

Oncetheinstallationiscomplete,thevesselmustbeswungwith

thesysteminboththeoperativeandinoperativemodes.The

shipownerandcaptainareresponsibleforupdatingthedeviation

tableaccordinglywithregardtothevessel’snationalregistryand

correspondingmaritimeauthority.

Noisesources

Thevessel’shull,rudder(s)andpropeller(s)shouldbethoroughly

inspectedindrydockpriortoinstallation.Roughnessbelow

thewater-linedeformitiesintheshellplatingandprotruding

obstaclescancreateunderwaternoise.Thesesourcesof

turbulencemustbesmoothedorremovedasbestaspossible.Itis

especiallyimportantthatthepropeller(s)isnotpittedordamaged.

Drydocking

Makesurethatampleclearanceunderthesonartrunkand/or

protectionblisterisprovidedwhendrydockingthevessel.Avoid

locatingsupportingblocksorstructuresinthevicinityofthis

equipment.

Note

Thelocationofthetransducerand/orprotectionblistermustbe

notedonthevessel’ sdockingplanforfuturereference.

Powerdownallhydroacousticsystems,andlabeleachsystem

accordinglytopreventaccidentalpoweron.Removecircuit

breakersifnecessary.

Wiring

Allcablesrunningbetweensystemcabinetslocatedindifferent

roomsand/orondifferentdecksmustbesupportedandprotected

alongtheirentirelengthsusingconduitsand/orcabletrays.Note

26

323776/A

Page 29

SimradSH90

thatthecablesmustnotbeinstalledinthevicinityofhigh-power

suppliesandcables,antennacablesorotherpossiblesources

ofinterference.

Note

Wheneverpossible,transducercablesmustberuninsteel

conduits.

Formoredetailedinformationaboutcablesandwiring,referto

thebasiccablerequirements.

→Basiccablerequirementsonpage209

Supportinformation

IfyouneedadditionaltechnicalsupportforyourSimradSH90

youmustcontactyourlocaldealer,oroneofoursupport

departments.

Norway(Mainofce)

•Address:Strandpromenaden50,3190Horten,Norway

•Telephone:+4733034000

•Telefax:+4733042987

•E-mailaddress:s

i m r a d . s u p p o r t @ s i m r a d . c o m

•Website:h t t p : / / w w w . s i m r a d . n o

Spain

•Address:PoligonoPartidaTorres38,03570Villajoyosa,

Spain

•Telephone:+34966810149

•Telefax:+34966852304

•E-mailaddress:s

i m r a d . s p a i n @ s i m r a d . c o m

•Website:h t t p : / / w w w . s i m r a d . e s

USA

•Address:1921033rdAveW,Lynnwood,WA98036,USA

•Telephone:+14257121136

•Telefax:+14257121193

•E-mailaddress:s

i m r a d . u s a @ s i m r a d . c o m

•Website:h t t p : / / w w w . s i m r a d . c o m

323776/A

27

Page 30

SimradSH90

INSTALLATIONPLANNING

Note

Forinstallationinapreviouslyinstalledtrunksystem,rstread

theinformationaboutsonarroomrequirements.Thenproceed

totheHullUnitinstallationdescription.

Thischapterprovidesthemarineengineersresponsibleforthe

installationtheinformationnecessarytoplantheinstallationthe

SimradSH90accordingtoSimrad’srequirements.

CorrectinstallationoftheSH90transducerisvitaltothesystem’s

performance.

Severalvariablesmustbetakenintoconsideration,themost

importantofwhichisthevessel’sconstruction.Thisguidecan

beusedtoselectthebestlocationforthetransducer,andincludes

abriefdescriptionofareastobeavoided.

Aboutinstallationdrawings

Installationdrawingsmustbesuppliedbytheshipyard.

Note

Theinstallationmustbeapprovedbythevessel’ snationalregistry

andcorrespondingmaritimeauthorityand/orclassication

society.Theshipownerandshipyardperformingtheinstallation

areresponsibleforobtainingandpayingforinstallation

approval.

Topics

•Aboutinstallationdrawingsonpage28

•Locationofthehullunitonpage29

•Sonarroomrequirementsonpage31

•Sonarroomarrangementexampleonpage33

Allinstallationdrawingsmustbesuppliedbytheshipyard

performingtheinstallation.

Note

Theinstallationmustbeapprovedbythevessel’ snationalregistry

andcorrespondingmaritimeauthorityand/orclassication

society.Theshipownerandshipyardperformingtheinstallation

areresponsibleforobtainingandpayingforinstallation

approval.

28

323776/A

Page 31

Simradoffersfreeadviceforinstallationplanning.Proposed

arrangementsmaybesentforcommentaryorsuggestions

suppliedbySimrad.Thefollowingdrawingsshouldbesubmitted

shouldassistanceberequested:

•Generalarrangement

•Bodyplananddrawingsofrelevantbottomtanksand

cofferdams

•Linesplan

Locationofthehullunit

Foreandaft

Thehullunitshouldpreferablybelocatedwithin1/3to1/10

ofthevessel’sLengthBetweenPerpendiculars(LBP)fromits

ForwardPerpendicular(FP).Deviationsshouldnotbemade

withoutconsultingSimrad.

Installationplanning

Athwartships

ThehullunitmaybelocatedontheCentreLine(CL)ofthe

vessel,oralongsideitskeel.Iftheinstallationisoffsetfromthe

vessel’scentreline,makesurethattransducertransmissionand

receptionwillnotbeobstructedbythekeel.

323776/A

29

Page 32

SimradSH90

Figure4Locationofthehullunit

AWaterlevelatnormaltrim

BW eldingmarkstoindicatehullunitlocationwhendocking

CLengthBetweenPerpendiculars(LBP)

D1/3to1/10ofLBP

Importantconsiderationsrelatedtonoise

Theinstallationtrunkmustbeinstalledsothatitwillremain

verticalundernormaloperatingconditions.Theprimarysources

ofunderwaterdisturbance(otherthanavessel’smainpropeller

andbow/sternthruster)thataffecttransducerreceptionare:

•Mainorbilgekeels

•Zincanodes

•Coolingelementsprotrudingfromthehull

•Equipmentsuchassonartransducersandpilottubes

•Seachests

•Overboarddischarges

•Dentsinthehull

Allappendagestothehull,indentationsandpipein/outletsare

potentialsourcesofunderwaternoise.Theymayactasresonant

cavitiesamplifyingnoiseatcertainfrequencies,createcavitation

orturbulence.Transducersshouldnotbelocatedinthevicinity

ofsuchobjectsandespeciallynotimmediatelyaftofthem.

30

323776/A

Page 33

Installationplanning

Sonarroomrequirements

Observetheseminimumsonarroomrequirementstoobtain

suitableworkingconditionsforsonarinstallation,useand

maintenance.

Itisstronglyrecommendedtouseadedicatedcompartmentto

housethehullunit,theTransceiverUnitandthePowerSupply

Unit.Theseunitsmustalsobeinstalledrelativelyclosetoeach

otherduetothelimitedlengthofthepowerandtransducercables.

Sizeandaccess

Awelldesignedsonarroomreducestheriskofcorrosionand

simpliesmaintenanceincreasingsystemreliability.

•Thesonarroommustbedimensionedtohousealltherelevant

cabinetsthatcomprisetheSimradSH90.

•ThephysicaldistancebetweentheTransceiverUnitandthe

hullunitislimitedduetothelengthofthetransducercables.

•ThephysicaldistancebetweentheTransceiverUnitandthe

PowerSupplyUnitislimitedduetothelengthofthepower

cable.

•Thesonarroommustnotbeunnecessarilyobstructedby

girders,pipesetc.whichmightcauseinstallationproblemsor

impedemaintenance.

•Thesonarroommustbeaccessibleunderallconditionsat

seaorataberth.

•Alldoorsorhatchesmustbedesignedsothattheequipment

canberemovedwithoutbeingdisassembled.

Heating

Thesonarroommustbeequippedwithheater,dimensionedto

maintaintheequipmentwithinitsenvironmentaltolerances(at

least1000W),installedclosetothedeck.Heatingisalsoan

effectivemethodforreducinghumidity.

Insulation

Bulkheadsmustbeinsulatedandprovidedwithaninteriorwall

tothedeck.Theinsulationshouldbetheminimumequivalent

of50mmofrock-wool.Inaddition,pipingpassingthroughthe

spacepronetocondensationmustbeinsulated.

Ventilation

Thesonarroommustbeconnectedtothevessel’sventilation

system.Ifthisisnotpossible,two3”ventsmustbeprovided

fromthesonarroomtothemaindeck.Intheroom,theairinlet

mustwheneverpossiblebelocatedclosetothedeckandthe

323776/A

31

Page 34

SimradSH90

outletashighaspossible.Afunnelshapeddrip-collectormustbe

mountedbelowtheventpipestodivertmoisturetothebilge.On

themaindeck,thebestventilationisprovidedwhentheoutlet

pipeisatleastfourmetershigherthantheinletpipe.Tokeep

outseawater,rainandspray,theventilationpipesshouldbe

ttedwithgoosenecksortheequivalent.Ifthevesselislikely

tooperateintropicalconditions,asuitableairconditioning

systemmustbeinstalled.Thissystemmustbeabletoprovide

anambienttemperaturenotexceedingthemaximumoperating

temperaturesforthecabinetsinstalledintheroom.

Cableprotection

Ifthecablesbetweenthesonarroomequipmentandothersystem

unitslocatedindifferentcompartmentsonthevesselpass

throughhatchesorareaswheretheymaybedamaged,theymust

berunthroughconduits(minimum2”conduitisrecommended).

Electricalinstallationsandlights

Thesonarroommustbeequippedwithsuitablelightingto

simplifytheinstallationandtoaidfuturemaintenance.A

minimumnumberofelectricaloutletsmustbeprovidedforthe

systemunitsandotherequipment.

Bilgepumpanddecking

Thesonarroommustbeconnectedtothevessel’sbilgepump

system.Ifthisisnotpossible,aseparatebilgepumpforthe

sonarroommustbeinstalled.Oncetheinstallationhasbeen

completed,thesonarroommustbesuitablydeckedwithout

restrictingaccesstotheequipment.

Liftingdevice

Anattachmentpoint,ratedataminimumoftwo-2-tons,for

supportingaliftingdeviceshouldbelocatedabovethehullunit.

Thispermanentlyinstalledxturewillfacilitateinstallation

trunkandhullunitmounting,andalsomaybeusedforfuture

equipmentmaintenanceorreplacement.

32

323776/A

Page 35

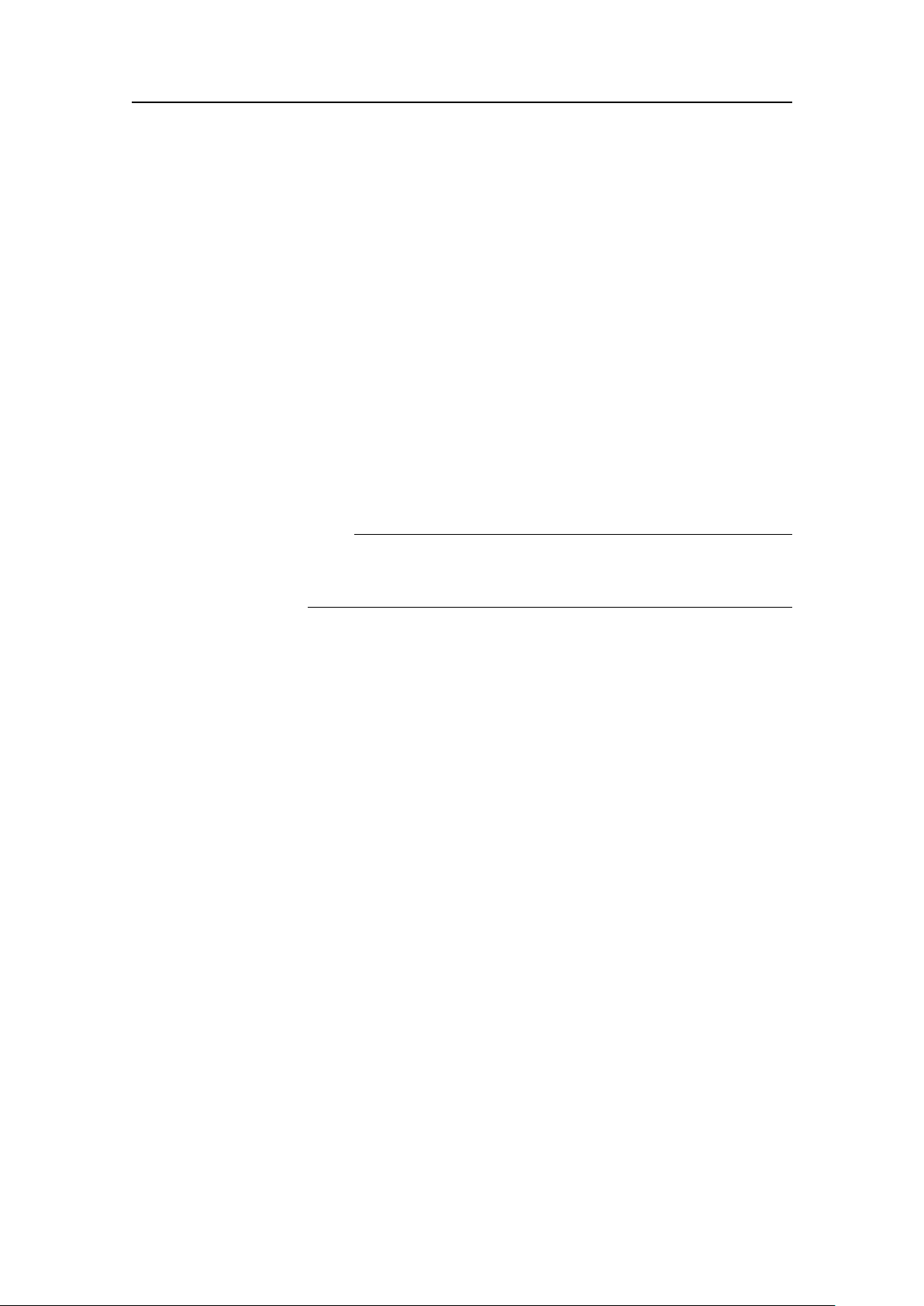

Sonarroomarrangementexample

Thesedrawingsillustrateatypicalsonarroomwithamplespace

forthehullunit,thePowerSupplyUnit,theTransceiverUnit

andpersonnel.

Sonarroomarrangementexample

Figure5Sonarroomarrangementexample:Topview

Installationplanning

323776/A

33

Page 36

SimradSH90

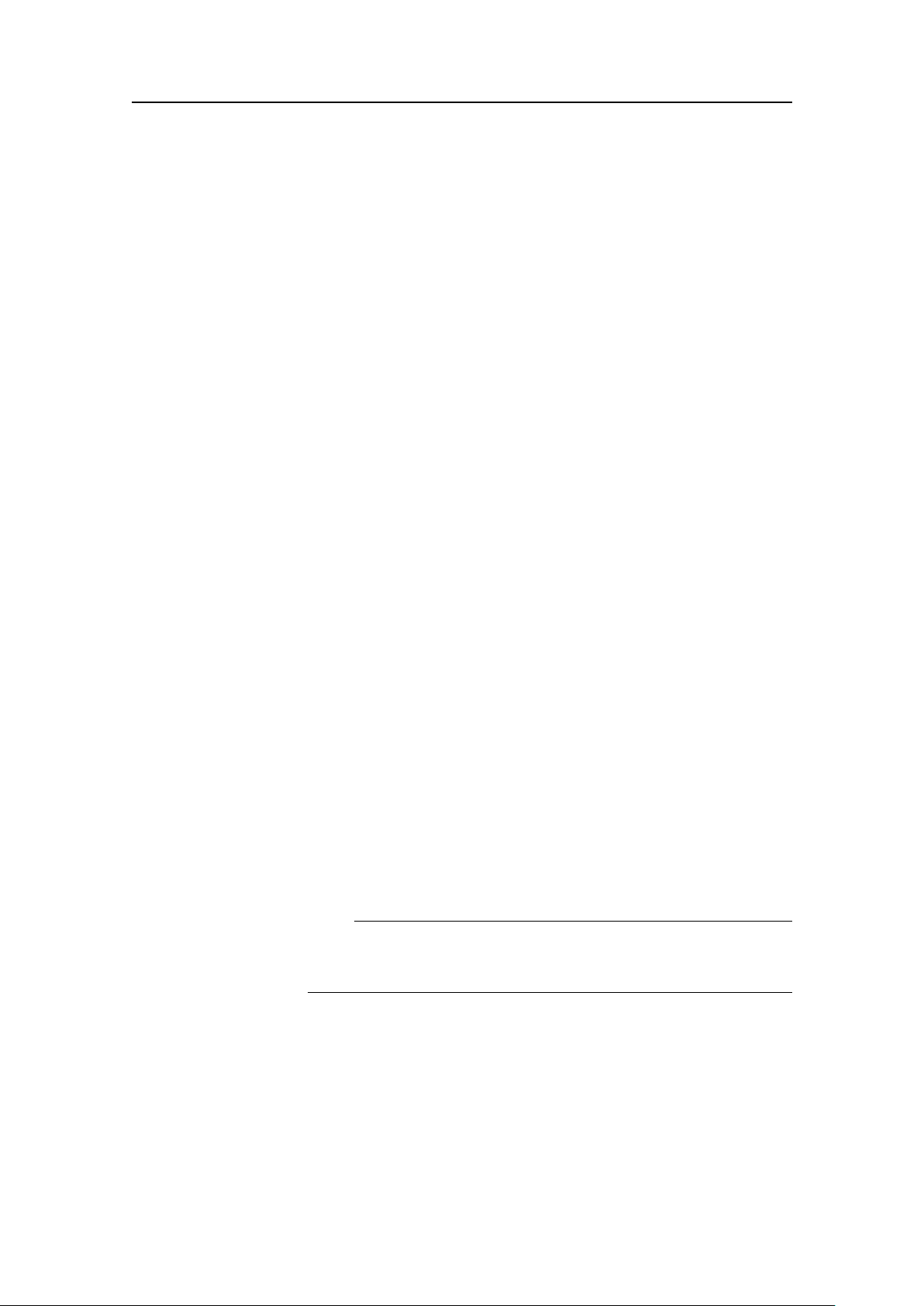

Sonarroomarrangementexample

ThePowerSupplyUnitcanbemounted,over,underorbesides

theTransceiverUnit.

Figure6Sonarroomarrangementexample:Sideview

34

323776/A

Page 37

Installationplanning

(CD015420-003)

BOW

Hullunitorientationexample

Thehullunitshouldnormallybeorientedwiththe

hoisting/loweringmotorpointingaft.Ifthisorientationmakes

theMotorControlUnitattachedtothehullunitdifculttoaccess

formaintenancepurposes,thehullunitmaybeorientedinthe

mostsuitableposition.

ThedistancebetweenthehullunitandtheTransceiverUnitis

limitedbythelengthofthetransducercable.

ThePowerSupplyUnitcanbemountedover,underorbesides

theTransceiverUnit.Thedistancebetweenthetwounitsis

limitedbythelengthofthecables.

Figure7Hullunitorientationexamples

Irrespectiveofthehullunitorientation,thetransducershalln o t

bemechanicallyaligned.

TransduceralignmentisperformedintheSH90ProcessorUnit

byrotatingtheechopresentationonthedisplay.Thisisdescribed

inadedicatedsection.

323776/A

→Alignmentofthesonarpictureonpage121

35

Page 38

SimradSH90

SONARTRUNKINSTALLATION

Thesonartrunkprovidesthephysicalfoundationfortheentire

hullunitgantry.Thetrunkfurtherpenetratesthehull,anditis

thereforeacrucialpartofthehullunitassembly.Inorderto

ensurepropersonaroperation,thelocationofthesonartrunk

mustbecarefullyselected.

Atrunkwithablindcover–approvedbyDetnorskeV eritas

(DnV)–canbeorderedfromSimradasanoptionaldelivery,orit

maybemanufacturedbytheinstallationshipyardbasedonthe

drawingsinthismanualandthepropertiesofthehull.

Note

Theinstallationshipyardmustprovideallnecessaryinstallation

drawings,andifrequired,thesemustbeapprovedbythe

applicableauthorities.See“Installationdrawings”inchapter

About.

→Aboutthismanualonpage11

Topics

•Mountingthesonartrunkonpage37

•Sonartrunkprotectiononpage38

•Sonartrunkinstallationprinciplesonpage38

•Sonartrunkinstallationmeasurementsonpage41

Hullunitoutlinedimensiondrawings

•SH90Hullunitdimensionsonpage171

•SH90Sonartrunkdimensionsonpage172

•SH90Sonartrunkproductiononpage173

•SH90Blindcoverdimensionsonpage175

36

323776/A

Page 39

Mountingthesonartrunk

Thelocationofthesonartrunkmustbecarefullyselected.

Note

Notetheorientationofthecentrelineofthetrunkwithregardto

themountingbolts.

Removethegasketonthetopangeduringwelding.

Figure8Orientationofthesonartrunk

Sonartrunkinstallation

Theheightfromthetopofthetrunkangetotheundersideof

theprotectionblistermustbeselectedasshownintheguresin

sectionSonartrunkinstallationprinciplesonpage38.

Note

Inordertoobtainoptimalsonarperformance,thetotalheight

ofthetrunkmustbeascloseaspossibletoitsstatedminimum

height.

Thetopangemustbeparalleltotheconstructionwaterlinein

boththefore-and-aftandathwartshipdirections.

Theinstallationtrunkmustbeweldedtoadoublingplatewhich

mustbeatleast1.5timesasthickasthesurroundingshellplating.

Thedoublingplate’snaldimensionsaretobegovernedbythe

approvedinstallationdrawingssuppliedbytheshipyard.The

trunkmustalsobestiffenedbyweldingknee-platestoitandthe

doublingplateinboththefore-and-aftandathwartshipdirections.

323776/A

37

Page 40

SimradSH90

Sonartrunkprotection

Blisterprotection

Normally,asteelblisteristtedforprotection.Theblisteris

weldedtotheshellplating.Theblistermaybeanopentype,or

itcanbelledwithoiltopreventcorrosion.Thislastmethod

providesexcellentprotection,andsimpliesmaintenance.See

Sonartrunkinstallationprinciplesonpage38.

Corrosionprotection

Assoonasallinstallation,weldingandgrindinghasbeen

performed,thetrunkandthesurroundingareashouldbeprimed

andpaintedusingaqualityprotectivecoating.

Sonartrunkinstallationprinciples

Observethetwodrawingsprovided.Theseillustratetheprincipal

installationofthesonartrunk.

38

323776/A

Page 41

Figure9Installationofatrunkwithopenblister

Sonartrunkinstallation

323776/A

39

Page 42

SimradSH90

Figure10Installationofatrunkwithoillledblister

40

323776/A

Page 43

Sonartrunkinstallationmeasurements

Sonartrunkinstallation

Forfuturereference,themeasurements“A”,“B”,“C”and“D”

fromthedrawingmustbemadeandnotedinthetablebelow.

Table1Trunkinstallationmeasurements

Millimeters

“A”

“B”

“C”

“D”

Inches

323776/A

41

Page 44

SimradSH90

HULLUNITINSTALLATION

ThischapterdescribesthephysicalinstallationoftheSimrad

SH90HullUnit.

Thehullunitisacrucialpartofthesonarsystem.Duetoits

physicalsizeandweight,andthefactthatthetrunkpenetrates

thevesselhull,itisveryimportantthatthehullunitisinstalled

andsecuredproperly.

Theinstallationshipyardmustprovideallnecessaryinstallation

drawings,andifrequired,thesemustbeapprovedbythe

applicableauthorities.Seethedrawingleformoredetails.

→Aboutthismanualonpage11

→Drawingleonpage163

Note

Toensurethesafetyofthesonarsystemandthevessel,itisvery

importantthatthemechanicalsupportofthehullunitgantryis

satisfactory.Formoreinformation,seetheinformationprovided

aboutmechanicalsupport.

→Mechanicalsupportonpage47

Topics

•Howtounpackthehullunitfromitstransportboxonpage43

•Hullunitmountingonpage45

•Mechanicalsupportonpage47

•Transduceralignmentonpage47

•Hullunitinstallationchecklistonpage48

Relatedtopics

•Hullunitfamiliarizationonpage94

Hullunitoutlinedimensiondrawings

•SH90Hullunitdimensionsonpage171

•SH90Sonartrunkdimensionsonpage172

•SH90Sonartrunkproductiononpage173

•SH90Blindcoverdimensionsonpage175

42

323776/A

Page 45

Hullunitinstallation

Howtounpackthehullunitfromitstransportbox

Note

Thetransducerisprotectedtopreventdamageduringtransport

andhullunitinstallation.Thisprotectionmustremainattached

whilethehullunitisbeingmanoeuvredintothesonarroom.

Figure11Removingthehullunitfromitstransportbox

ALiftingeyeonthehoistingunit

BMountinghardware(woodencradleandsupport

construction)

CTransducerprotection

Procedure

Note

Donotremovethetransducerprotection(C)fromthe

transduceruntiljustbeforethehullunitisloweredontothe

mountingtrunk.

1Removethetopcoverofthewoodenbox.

2PulloutallthenailsmarkedwithIndianink.

3Removethefasteninghardware(B).

4Ifyouwishtoreusetheboxtoholdtheoldhullunit,make

surethatyoukeepallthefasteninghardwareusedtosecure

thehullunitinthewoodenbox.

5Fastentheliftingtackletothetwoliftingeyebolts(A)

onthetopofthehoistingunitandliftthehullunit(with

thetransducerprotection(C)inplace)carefullyoutofthe

transportationbox.

323776/A

43

Page 46

SimradSH90

Figure12Usethecorrectliftingeye!

Therearetwolifting

eyesoneachsideof

thehullunit:one

onthehoistingunit

andoneonthetopof

thetransducershaft.

Makesurethatyouuse

theliftingeyeonthe

hoistingunit(A)when

youliftthehullunitout

ofthetransportation

box!

6Makesurethatyoukeepthetransducercableandconnector

dry.Watchthesecarefullytopreventthemfrombeing

damaged,stuckorhookedontoprotrudingobjectswhile

manoeuvringthehullunitintothesonarroom.

44

323776/A

Page 47

Hullunitinstallation

(CD015420-003)

BOW

Hullunitmounting

Thehullunitshouldnormallybeorientedwiththe

hoisting/loweringmotorpointingaft.Ifthisorientationmakes

theMotorControlUnitattachedtothehullunitdifculttoaccess

formaintenancepurposes,thehullunitmaybeorientedinthe

mostsuitableposition.

Note

TheMotorControlUnitmustneverbephysicallydismounted

fromtheHullUnit.

Figure13Hullunitorientationexamples

Hullunitmountingprocedure

Tomakesurethattheprocedureisfollowedcorrectly,andinthe

rightorder,tickoffeachtaskafterithasbeendone.

1

Useatackletolowerthehullunit(withthetransducer

protectioninplace)intothesonarroom

2

Removetheblindcoverfromthetrunkandcheckthat

thegasketisnotdamaged.

3Storetheblindcoverinthesonarroomforpossible

futureuse.

323776/A

45

Page 48

SimradSH90

4 Removethetransducerprotectionandlowerthehull

unitcarefullyontothetrunk.

5Tightentheangenutswithatorqueofapproximately

140Nm.

6

Keepthetransducercableandconnectordry,and

handlethemwithgreatcaretopreventmechanicaldamage.

46

323776/A

Page 49

Mechanicalsupport

Hullunit

MotorControlUnit

Removablesupportbrackets

(CD015420-004)

Hullunitinstallation

Note

Toensurethesafetyofthesonarsystemandthevessel,itisvery

importantthatthemechanicalsupportofthehullunitgantry

issatisfactory.

Topreventunwantedvortexinducedvibration,thehullunitmust

besecuredtothebulkhead.Usethetwoholesprovidedonthe

gantrytomountsupportbracketsinthefore-and-aftandsideways

direction.Itmustbepossibletoremovethesupportbracketsif

maintenanceisrequired.

Figure14Mechanicalsupport

Transduceralignment

323776/A

Note

Ifyoudonotinstallapropermechanicalsupportforthehullunit

gantry,theguaranteewillbevoid!

Irrespectiveofthehullunitorientation,thetransducershalln

bemechanicallyaligned.

TransduceralignmentisperformedintheSH90ProcessorUnit

byrotatingtheechopresentationonthedisplay.Thisisdescribed

inadedicatedsection.

→Alignmentofthesonarpictureonpage121

o t

47

Page 50

SimradSH90

Hullunitinstallationchecklist

Performaclosevisualinspectionofthesonarroomandthe

physicalinstallationofthehullunit.Refertotheapplicable

requirementsprovidedinsectionSonarroomrequirementson

page31,andllinthetablebelow.

Table2Hullunitinstallationchecklist

Item

Aretheaccesshatchessatisfactory?

Istheheatingsatisfactory?

Istheinsulationsatisfactory?

Istheventilationsatisfactory?

Isabilgepumpinstalled?

Istheroomlightingsatisfactory?

Isthesonarroomsuitablydecked?

Isthemechanicalsupportofthehullunit

satisfactory?

DoyouhavesatisfactoryaccesstotheMotor

ControlUnit?

IftheanswertoanyofthesequestionsisNO,notedownthe

decienciesasinstructedinInstallationremarksonpage238.

YESNO

48

323776/A

Page 51

TransceiverunitandPowerSupplyUnitinstallation

TRANSCEIVERUNITANDPOWERSUPPLY

UNITINSTALLATION

ThischapterexplainshowtoinstalltheSimradSH90Transceiver

UnitandtheSH90PowerSupplyUnit.Thetransceiveris

normallypositionedinthesonarroomclosetothehullunit.

TheSH90PowerSupplyUnitmustbeinstalledclosetothe

TransceiverUnit.Thedistancebetweenthetwocabinetsis

limitedbythelengthofthepowercablebetweenthem.

Topics

•TransceiverUnitpreparationsonpage49

•PowerSupplyUnitpreparationsonpage50

•TransceiverUnitinstallationprocedureonpage50

•PowerSupplyUnitinstallationprocedureonpage54

TransceiverUnitpreparations

Relatedtopics

•Sonarroomrequirementsonpage31

Cabinetoutlinedimensiondrawings

•TransceiverUnitdimensionsonpage164

•PowerSupplyUnitdimensionsonpage167

•ProcessorUnitdimensionsonpage169

•OperatingPaneldimensionsonpage170

FreebulkheadspaceisrequiredtomounttheTransceiverUnit

cabinet.

Provideamplespacearoundthecabinettoallowforinspection,

maintenanceandpartsreplacement.Makesurethatthecabinet

doorcanbefullydismountedforunobstructedaccesstoits

internalparts.

Note

Thecabinetmustbemountedasacompleteunit.Thedoormust

notbeopeneduntiltheunitissecurelyfastenedtothebulkhead.

B e f o r e youmounttheTransceiverUnit,observe:

•ThedistancebetweentheHullUnitandtheTransceiverUnit

isrestrictedbytheexibletransducercablejoiningthetwo.

Remembertotakeintoconsiderationtheslacknecessaryto

lowerthetransducer.

323776/A

49

Page 52

SimradSH90

PowerSupplyUnitpreparations

•ThedistancebetweenthePowerSupplyUnitandthe

TransceiverUnitisrestrictedbythelengthofthepowercable

joiningthetwo.

o n o t fastenthetransducercabletotheTransceiverUnituntil

D

describedlaterinthestart-upprocedure.

Note

Theinstallationshipyardmustprovideallnecessaryinstallation

drawings,andifrequired,thesemustbeapprovedbythe

applicableauthorities.

Observethegeneralsonarroomrequirementsprovidedinsection

Sonarroomrequirementsonpage31.

FreebulkheadspaceisrequiredtomountthePowerSupplyUnit

cabinet.W erecommendthatitismountedover,beloworbesides

theTransceiverUnit.

Provideamplespacearoundthecabinettoallowforinspection,

maintenanceandpartsreplacement.Makesurethatthecabinet

doorcanbefullyopenedforunobstructedaccesstoitsinternal

parts.

Note

Thecabinetmustbemountedasacompleteunit.Thedoormust

notbeopeneduntiltheunitissecurelyfastenedtothebulkhead.

BeforeyoumountthePowerSupplyUnit,observethatthe

distancebetweenthePowerSupplyUnitandtheTransceiver

Unitisrestrictedbythepowercablejoiningthetwo.

Note

Theinstallationshipyardmustprovideallnecessaryinstallation

drawings,andifrequired,thesemustbeapprovedbythe

applicableauthorities.

TransceiverUnitinstallationprocedure

Tomakesurethattheprocedureisfollowedcorrectly,andinthe

rightorder,tickoffeachtaskafterithasbeendone.

1

2

50

Removethetwomountingbracketswhicharefastened