Page 1

INSTRUCTION MANUAL

Robertson AP9 Mk3

Autopilot

20169223

Page 2

Simrad Robertson AS Telephone: +47 51 46 20 00

Nyåskaien Telefax: +47 51 46 20 01

P.O. Box 55

N-4379 Egersund, Norway

NOTE!

Simrad Robertson AS makes every effort to ensure that the information contained

within this document is correct. However, our equipment is continuously being

improved and updated, so we cannot assume liability for any errors which may

occur.

The information contained within this document remains the sole property of Simrad

Robertson AS. No part of this document may be copied or reproduced in any form or

by any means, and the information contained within is not to be passed on to a third

party, without the prior written consent of Simrad Robertson AS.

Warning

The equipment to which this manual applies must only be used for the purpose for

which it was designed. Improper use or maintenance may cause damage to the

equipment or injury to personnel. The user must be familiar with the contents of

the appropriate manuals before attempting to operate or work on the equipment.

Simrad Robertson AS disclaims any responsibility for damage or injury caused by

improper installation, use or maintenance of the equipment.

Page 3

Instruction Manual

20169223D I

Instruction Manual

The manual is intended as a reference guide for operating

and correctly installing the AP9 Mk3 Autopilot.

Great care has been paid to simplify operation and set-up.

However, an autopilot is a complex electronic syste m; it is

affected by sea conditions, speed of the vessel, hull shape

and size.

Please take time to read this manual to get a thorough

understanding of the operation and system components

and their relationship to a complete autopilot system.

Other documentation materials that is provided with your

system include a warranty card. This must be filled in by

the authorized dealer that performed the installation and

mailed in to activate the warranty.

Page 4

Robertson AP9 Mk3 Autopilot

II 20169223D

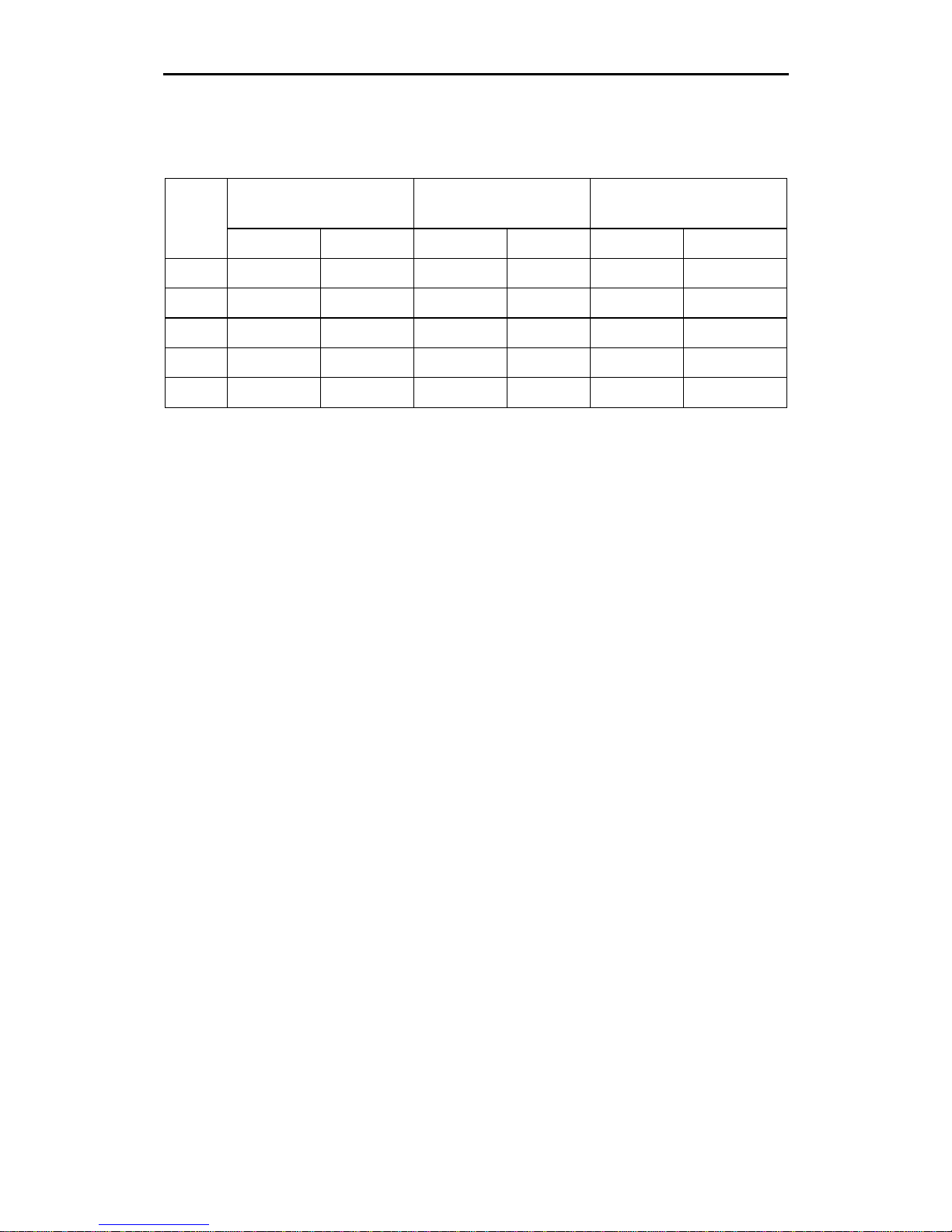

Document revisions

Documentation

department

Hardware/Software

design

Project/Product

Management

Rev Date Sign Date Sign Date Sign

– 10.04.96

N.G.

10.04.96

G.K.

10.04.96

Th.H.

A 30.05.96

N.G.

30.05.96

G.K.

30.05.96

Th.H.

B 12.07.96

N.G.

12.07.96

T.J.

12.07.96

Th.H.

C 3.9.99

N.G.

3.9.99

T.J.

3.9.99

Th.H.

D 07.11.00

N.G.

07.11.00

T.J.

07.11.00

T.R.

Document history

Rev. – First edition

Rev. A Updated table of contents and references throughout the manual

Rev. B Minor corrections in table page 1-6 and fig. 1-5. New dimensional

drawing of control unit, fig. 4.1. Section 5: Due to modified PCBs the

instructions for ferrite core mounting are omitted. New component

layout and set-up procedure for Dual Analogue Board included. Section

8: Updated circuit diagrams included. Section 9: Certificate of Type

Approval included.

Rev. C New layout. Section 2 and 5 revised according to new software version

V1R3. Diagrams updated. Dimensional drawing of RF Standard

Transmission link included. D9X Bus cable connection included. Index

and distributor list included.

Rev. C has not been released.

Rev. D Updated according to software version V1R4.

Page 5

Instruction Manual

20169223D III

TABLE OF CONTENTS

1 INTRODUCTION .........................................................................................................1-1

1.1 General .........................................................................................................1-1

1.2 MK3 System Layout............................................................................................1-1

1.3 Options available with the standard system ..................................................1-1

1.4 AP9 MK3 Standard System, On-Off Valves....................................................1-3

1.5 AP9 MK3 Standard System, Dual analogue output ......................................1-4

1.6 AP9 MK3 with analogue thruster control.......................................................1-5

1.7 Combinations of Heading Sensors...................................................................1-6

GYRO COMPASS................................................................................................1-6

FLUXGATE COMPASS......................................................................................1-8

1.8 Dual Station .........................................................................................................1-9

SERIAL LINES.....................................................................................................1-9

1.9 Connection of steering levers..........................................................................1-11

1.10 Rudder Angle Indicators .................................................................................1-12

1.11 Special Applications.........................................................................................1-13

2 OPERATION .........................................................................................................2-1

2.1 General .........................................................................................................2-1

2.2 Front Panel .........................................................................................................2-1

2.3 Mode selection.....................................................................................................2-2

HELMSMAN (Power ON).................................................................................2-2

AUTOPILOT........................................................................................................2-2

NAV. MODE........................................................................................................2-2

OFF........................................................................................................................2-2

ALARM ................................................................................................................2-3

Thruster/rudder parameters.............................................................................2-3

2.4 Parameter setting ................................................................................................2-3

General..................................................................................................................2-3

Switch ON............................................................................................................2-4

HELMSMAN.......................................................................................................2-5

AUTOPILOT........................................................................................................2-5

INCREASE- and DECREASE-buttons.............................................................2-5

ILLUM ..................................................................................................................2-5

COMPASS SELECT ............................................................................................2-6

RUDDER ..............................................................................................................2-6

WEATHER...........................................................................................................2-7

COUNTER RUDDER..........................................................................................2-8

INFO .....................................................................................................................2-9

2.5 Course selection ................................................................................................2-15

2.6 Navigational steering.......................................................................................2-15

Page 6

Robertson AP9 Mk3 Autopilot

IV 20169223D

General................................................................................................................2-15

Steering by XTE to waypoint...........................................................................2-16

Priority mode (APB sentence).........................................................................2-18

Ecdis mode ( APB sentence)............................................................................2-19

Remote Control .................................................................................................2-19

AP9 MK3 Dual Station.....................................................................................2-20

F200-40 Remote Control...................................................................................2-21

S9 Steering Lever (NFU) ..................................................................................2-22

FOLLOW-UP Steering Levers.........................................................................2-23

2.7 Fault Warnings..................................................................................................2-25

HEADING SENSOR WARNINGS.................................................................2-25

OTHER FAULT WARNINGS.........................................................................2-28

3 DESIGN AND THEORY OF OPERATION..............................................................3-1

3.1 General system description...............................................................................3-1

3.2 AP9 MK3 Control Unit.......................................................................................3-2

3.3 CD109 Course Detector......................................................................................3-4

CD109 Course Detector Principle.....................................................................3-4

3.4 Course Handling.................................................................................................3-4

3.5 RF14XU Rudder Feedback Unit........................................................................3-6

3.6 D90 Series Distribution Unit .............................................................................3-7

POWER SUPPLY BOARD.................................................................................3-7

INTERCONNECTION BOARD........................................................................3-8

THRUSTER INTERFACE BOARD...................................................................3-9

SOLID STATE BOARD ....................................................................................3-10

DUAL ANALOGUE PCB ................................................................................3-13

3.7 F200-40 Remote Control...................................................................................3-15

3.8 FU91/92 Follow-Up Lever ..............................................................................3-16

4 TECHNICAL SPECIFICATIONS ...............................................................................4-1

4.1 AP9 MK3 Control Unit.......................................................................................4-1

4.2 AP9 MK3 Gyro Interface Board........................................................................4-2

4.3 CD109 Course Detector......................................................................................4-2

4.4 RFC35R Rate Compass.......................................................................................4-3

4.5 RFC35NS Fluxgate Compass.............................................................................4-4

4.6 RFC35N NMEA Compass..................................................................................4-4

4.7 Distribution Unit.................................................................................................4-5

4.8 RF14XU Rudder Feedback Unit........................................................................4-7

4.9 RF Standard Transmission Link .......................................................................4-8

4.10 S9 Steering Lever.................................................................................................4-8

4.11 FU91 Steering Lever............................................................................................4-9

4.12 S35 Steering Lever.............................................................................................4-10

Page 7

Instruction Manual

20169223D V

4.13 F1/2 Remote Control........................................................................................4-11

4.14 F200-40 Remote Control...................................................................................4-11

4.15 RI9 Rudder Angle Indicator............................................................................4-12

4.16 IP protection ...................................................................................................4-13

4.17 Specification of messages.................................................................................4-14

CTS steering.......................................................................................................4-14

Bearing steering.................................................................................................4-14

Priority (mixed) steering..................................................................................4-14

Speed correction signal (VTG) ........................................................................4-14

5 INSTALLATION .........................................................................................................5-1

5.1 Unpacking and handling...................................................................................5-1

5.2 General .........................................................................................................5-1

5.3 Control Unit.........................................................................................................5-1

Connector assembly............................................................................................5-2

Screen termination..............................................................................................5-3

5.4 Heading sensors..................................................................................................5-4

General..................................................................................................................5-4

Magnetic compass...............................................................................................5-4

Gyro Compass.....................................................................................................5-7

RFC35NS Fluxgate Compass...........................................................................5-10

RFC35N NMEA Compass................................................................................5-12

5.5 D90/D91/D92/D93/D99 Distribution Unit.................................................5-12

Mounting............................................................................................................5-13

Electrical connections.......................................................................................5-13

Adjustments.......................................................................................................5-15

5.6 RF14XU Rudder Feedback Unit......................................................................5-15

Mechanical mounting.......................................................................................5-15

Electrical installation ........................................................................................5-16

Scaling of rudder angle....................................................................................5-17

Final check..........................................................................................................5-19

5.7 Optional equipment..........................................................................................5-19

AP9 MK3 Dual Station.....................................................................................5-19

5.8 Mode selection (External mode selector).......................................................5-21

F200-40 and Mode Selection............................................................................5-22

Complete Mode Selections ..............................................................................5-22

5.9 F200-40 Remote Control...................................................................................5-23

5.10 S9 Steering Lever...............................................................................................5-23

Mounting............................................................................................................5-23

Electrical connection.........................................................................................5-24

Function..............................................................................................................5-24

5.11 FU9X Follow up Steering Lever......................................................................5-26

Page 8

Robertson AP9 Mk3 Autopilot

VI 20169223D

Mounting............................................................................................................5-26

Electrical connection.........................................................................................5-26

5.12 S35 connection to D9X......................................................................................5-27

S35 alternative connection...............................................................................5-27

5.13 RI9 Rudder Angle Indicator............................................................................5-28

5.14 PANORAMA Mk2 Rudder Angle Indicator ................................................5-28

Installation .........................................................................................................5-28

5.15 Analogue ±10V or 4-20mA control signals...................................................5-29

5.16 Connection to Navigational Receiver ............................................................5-31

5.17 Start-Up and commissioning...........................................................................5-32

Power ON...........................................................................................................5-32

Rudder Feedback Unit Adjustments..............................................................5-32

5.18 Selection of parameter settings .......................................................................5-33

Information and Debug Loops........................................................................5-33

5.19 Dockside Alignment/test................................................................................5-49

General................................................................................................................5-49

RF14XU Feedback unit (ON-OFF valves)......................................................5-49

Rudder Angle Indicators .................................................................................5-50

Analogue signal, Rudder & Thruster.............................................................5-50

Deflection test (Rudder or azimuth thruster propulsion)...........................5-52

Tunnel Thruster function.................................................................................5-57

Gyro Compass selection...................................................................................5-58

Magnetic Compass (CD109) adjustments .....................................................5-60

FOLLOW-UP Levers ........................................................................................5-61

Dual Station Configuration .............................................................................5-61

Mode selectors...................................................................................................5-61

5.20 Sea Trial ...................................................................................................5-62

RFC35NS Fluxgate Compass calibration and alignment............................5-64

RFC35N NMEA and RFC35R Compass calibration and alignment..........5-65

On course steering ............................................................................................5-66

Minimum rudder function ..............................................................................5-66

Course Changes.................................................................................................5-67

Save Parameters ................................................................................................5-69

Navigational Steering test................................................................................5-71

Special feedback arrangement ........................................................................5-72

6 TROUBLE SHOOTING................................................................................................6-1

6.1 Fault warnings.....................................................................................................6-1

6.2 CD109 COURSE DETECTOR............................................................................6-4

6.3 FLUXGATE COMPASS......................................................................................6-4

6.4 MALFUNCTION OF THE D90-91-92..............................................................6-4

6.5 MALFUNCTION OF THE D93/D94 ...............................................................6-5

Page 9

Instruction Manual

20169223D VII

6.6 THRUSTER INTERFACE PCB..........................................................................6-5

7 SPARE PARTS .........................................................................................................7-1

7.1 AP9 MK3 Control Unit.......................................................................................7-1

7.2 Distribution Unit.................................................................................................7-1

7.3 CD109 Course Detector......................................................................................7-3

7.4 RF14XU Rudder Feedback Unit........................................................................7-4

7.5 RF Standard Transmission link.........................................................................7-5

7.6 F200-40 Remote Control.....................................................................................7-6

7.7 S9 Steering Lever.................................................................................................7-7

7.8 FU91 Steering Lever............................................................................................7-7

7.9 S35 NFU Steering Lever.....................................................................................7-7

8 Drawings ........................................................................................................................8-1

9 Index ...............................................................................................................................9-1

10 Appendix ...................................................................................................................10-1

Approvals

Sales and service worldwide (000929)

TABLE OF FIGURES

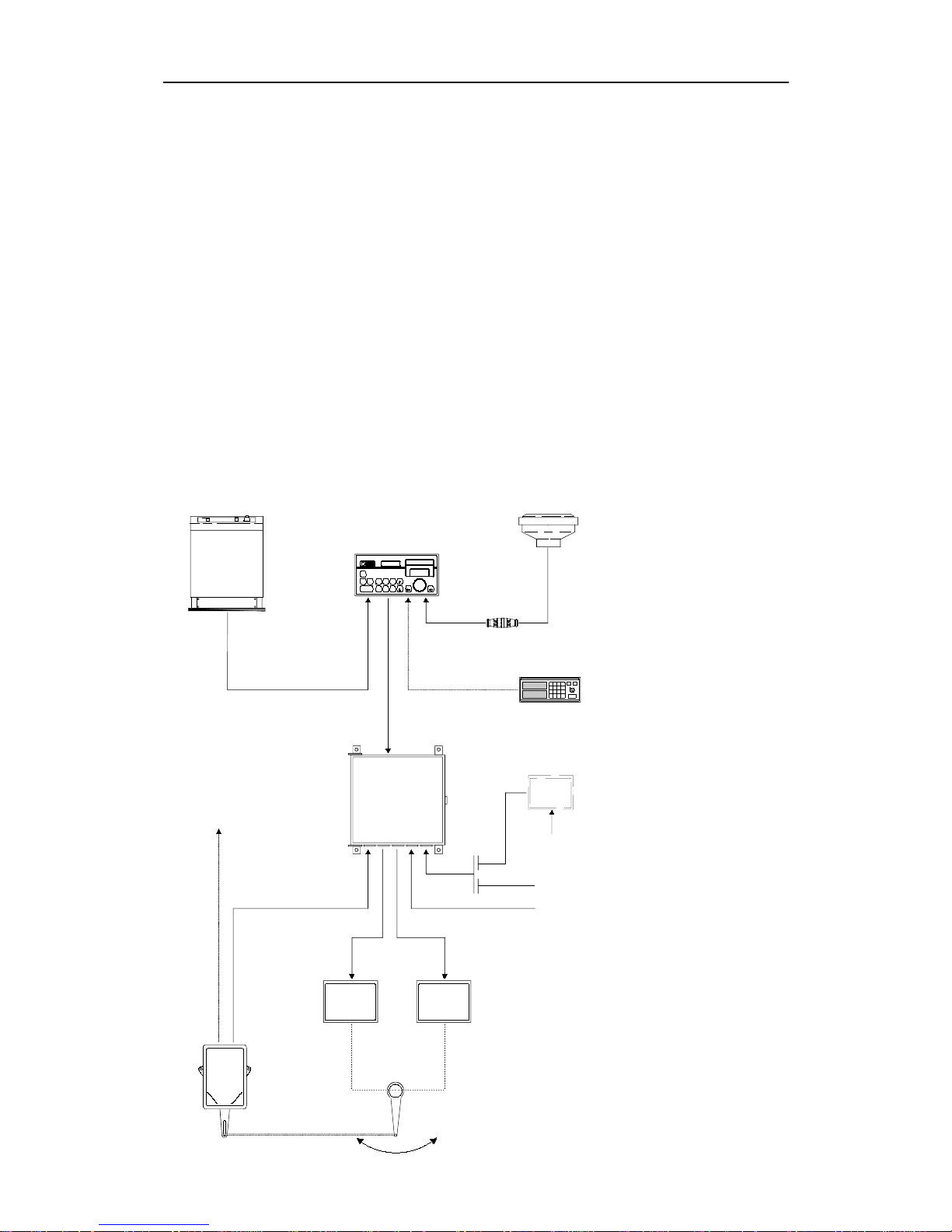

FIG. 1-1 AP9 MK3 SYSTEM LAYOUT..................................................................... 1-2

F

IG. 1-4 THRUSTER CONTROL................................................................................ 1-5

F

IG. 1-5 HEADING SENSORS .................................................................................. 1-7

F

IG. 1-6 SERIAL LINE CONNECTIONS..................................................................... 1-9

F

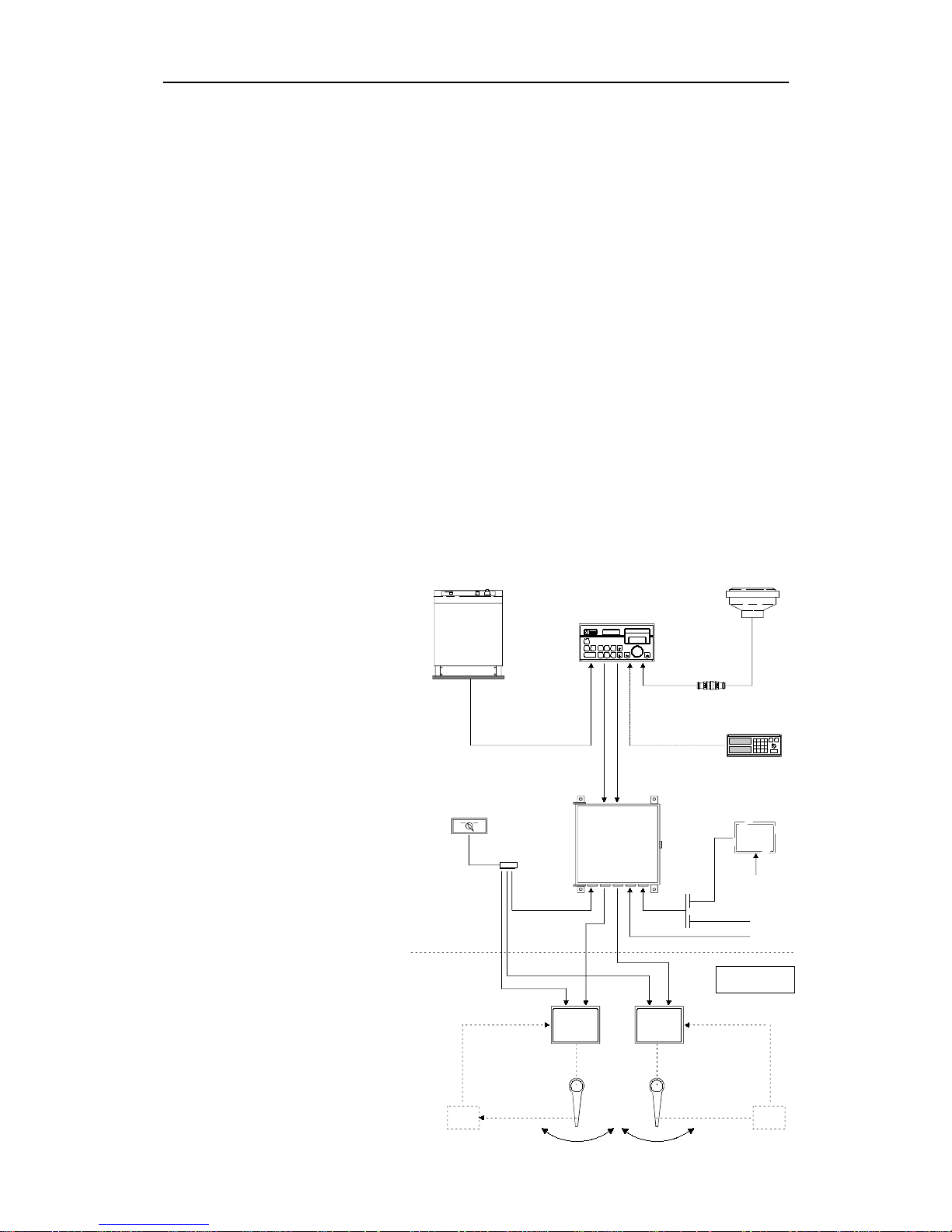

IG. 1-7 DUAL STATION SYSTEM ......................................................................... 1-10

F

IG. 1-8 NFU/FU LEVERS................................................................................... 1-11

F

IG. 1-9 RUDDER ANGLE INDICATORS................................................................ 1-12

F

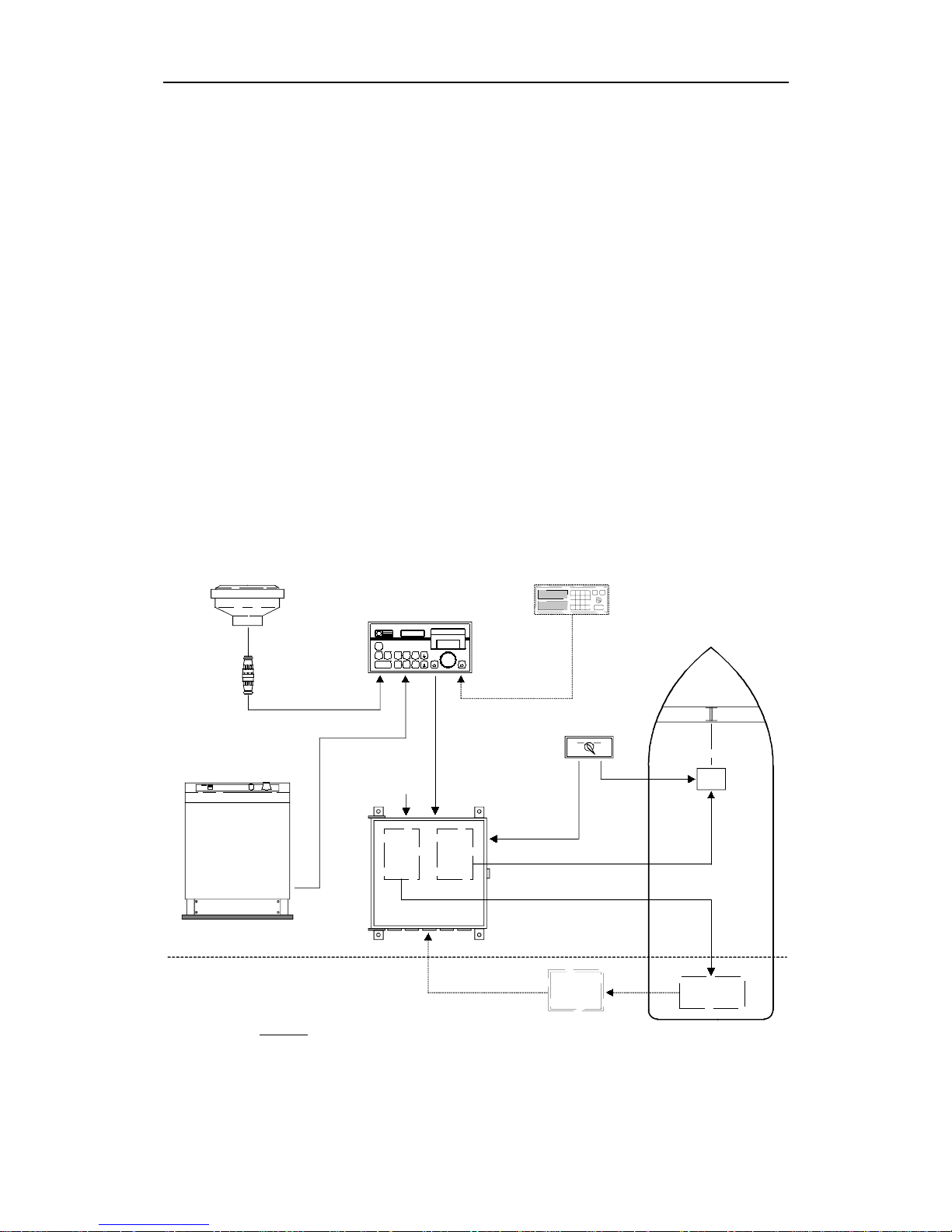

IG. 1-10 SPECIAL APPLICA T IONS, EXAMPLE 1................................................... 1-13

F

IG. 1-11 SPECIAL APPLICA T IONS, EXAMPLE 2................................................... 1-14

F

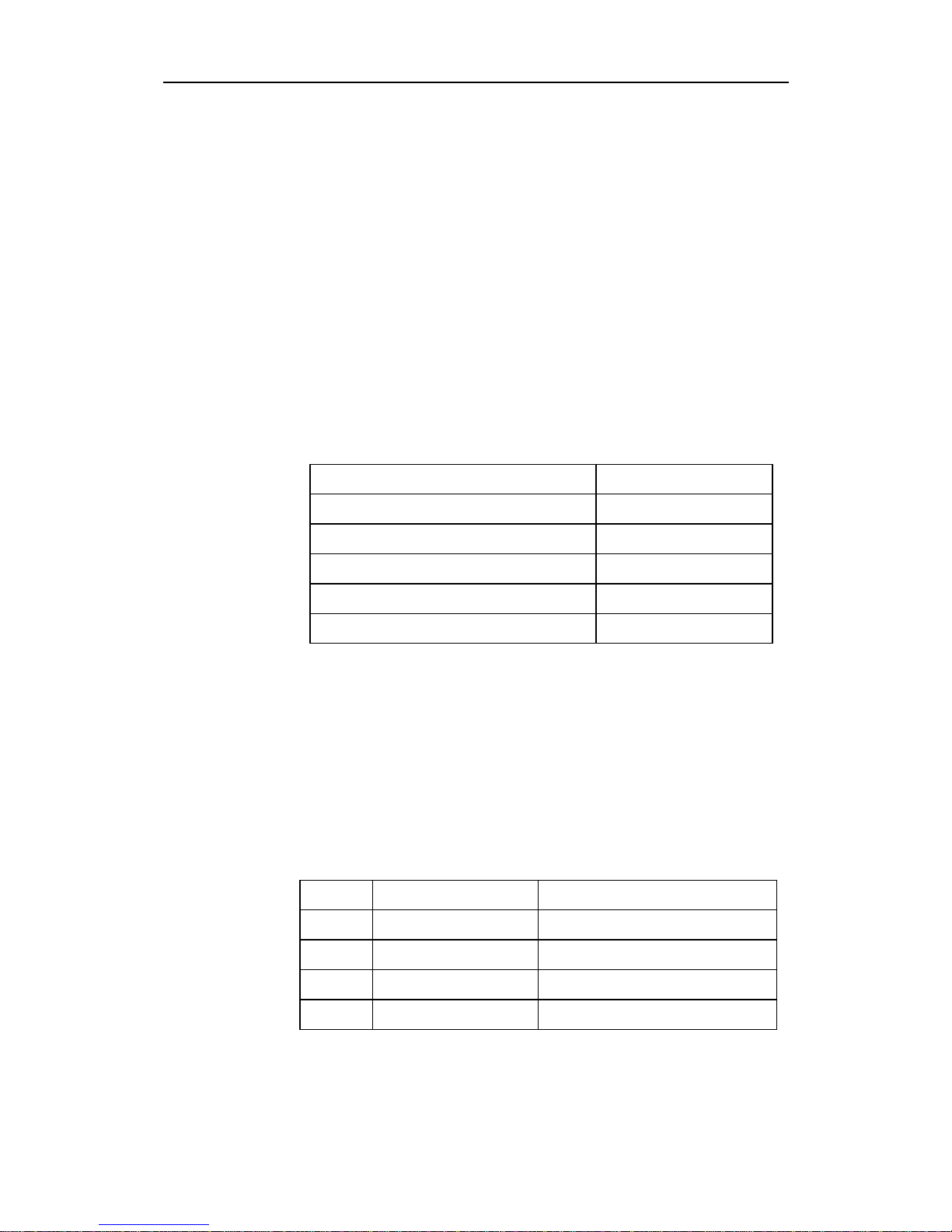

IG. 1-12 SPECIAL APPLICA T ION, EXAMPLE 3..................................................... 1-15

F

IG. 2-1 AP9 MK3 FRONT PANEL......................................................................... 2-1

F

IG. 2-2 RUDDER SETTINGS.................................................................................... 2-7

F

IG. 3-1 AUTOPILOT PRINCIPLE DIAGRAM............................................................ 3-1

F

IG. 3-2 PROCESSOR CONTROLLED AUTOPILOT.................................................... 3-2

F

IG. 3-3 AP9 MK3 ELECTRONIC BOARDS............................................................. 3-3

F

IG. 3-4 COURSE DETECTOR PRINCIPLE ................................................................ 3-4

F

IG. 3-5 AP9 MK3 COURSE HANDLING............................................................... 3-5

F

IG. 3-6 RF14XU PRINCIPLE.................................................................................. 3-6

F

IG. 3-7 D9X PCBS ................................................................................................ 3-7

F

IG. 3-8 POWER SUPPLY PCB - SIMPLIFIED DIAGRAM ..........................................3-8

F

IG. 3-9 INTERCONNECTION PCB - SIMPLIFIED DIAGRAM...................................3-8

F

IG. 3-10 THRUSTER INTERFACE PCB - SIMPLIFIED DIAGRAM ............................ 3-9

F

IG. 3-11 SOLID STATE PCB - SIMPLIFIED DIAGRAM.......................................... 3-10

F

IG. 3-12 SOLID STATE PCB - CONNECTION OF LIMIT SWITCHES.......................3-12

F

IG. 3-13 SOLID STATE PCB - CONNECTION OF SOLENOIDS...............................3-12

F

IG. 3-14 DUAL ANALOGUE PCB - SIMPLIFIED DIAGRAM................................. 3-14

F

IG. 3-15 F200-40 SIMPLIFIED DIAGRAM ............................................................ 3-15

Page 10

Robertson AP9 Mk3 Autopilot

VIII 20169223D

FIG. 3-16 FU91/92 SIMPLIFIED DIAGRAM .......................................................... 3-16

F

IG. 4-1 AP9 MK3 CONTROL UNIT, DIMENSIONS.............................................. 4-1

F

IG. 4-2 CD109 COURSE DETECTOR, DIMENSIONS .............................................. 4-2

F

IG. 4-3 RFC35R RATE COMPASS, DIMENSIONS................................................. 4-3

F

IG. 4-4 D9X DISTRIBUTION UNIT, DIMENSIONS................................................. 4-6

F

IG. 4-5 RF14XU RUDDER FEEDBACK UNIT DIMENSIONS .................................. 4-7

F

IG. 4-6 RF STANDARD TRANSMISSION LINK - DIMENSIONS............................... 4-8

F

IG. 4-7 S9 STEERING LEVER - DIMENSIONS......................................................... 4-8

F

IG. 4-8 FU91 STEERING LEVER - DIMENSIONS.................................................... 4-9

F

IG. 4-9 S35 STEERING LEVER - DIMENSIONS..................................................... 4-10

F

IG. 4-10 F1/2 REMOTE CONTROL - DIMENSIONS............................................. 4-11

F

IG. 4-11 F200-40 REMOTE CONTROL DIMENSIONS ........................................... 4-11

F

IG. 4-12 RI9 RUDDER ANGLE INDICATOR - DIMENSIONS............................... 4-12

F

IG. 5-1 CONTROL UNIT - PANEL MOUNT............................................................. 5-1

F

IG. 5-2 CONTROL UNIT - BRACKET MOUNTING................................................... 5-2

F

IG. 5-3 CONNECTOR ASSEMBLE ........................................................................... 5-2

F

IG. 5-4 CONTROL UNIT - CONNECTOR MOUNTING............................................. 5-3

F

IG. 5-5 SERIAL LINE CONNECTIONS..................................................................... 5-4

F

IG. 5-6 CD109 COURSE DETECTOR MOUNTING.................................................. 5-6

F

IG. 5-7 SYNCHRO SIGNAL CONNECTION .............................................................5-8

F

IG. 5-8 STEP SIGNAL CONNECTION...................................................................... 5-8

F

IG. 5-9 STEP SIGNAL, ALTERNATIVE CONNECTION ............................................. 5-8

F

IG. 5-10 SINE/COSINE CONNECTION...................................................................5-9

F

IG. 5-11 SERIAL LINE CONNECTION..................................................................... 5-9

F

IG. 5-12 RGC12 SERIAL LINE CONNECTION ....................................................... 5-9

F

IG. 5-13 RFC35 MOUNTING.............................................................................. 5-10

F

IG. 5-14 RFC35NS WIRING TO AP9 MK3........................................................5-11

F

IG. 5-15 RFC35N NMEA COMPASS WIRING TO AP9 MK3............................ 5-12

F

IG. 5-16 BUS CABLE (P/N 23602857) CONNECTION........................................ 5-14

F

IG. 5-17 AP9 MK3 / D93 (DUAL ANALOGUE PCB) INTERCONNECTION...... 5-15

F

IG. 5-18 RF14XU - MOUNTING......................................................................... 5-16

F

IG. 5-19 SCREEN TERMINATION......................................................................... 5-17

F

IG. 5-20 RF14XU INTERNAL WIRING................................................................ 5-18

F

IG. 5-21 DUAL STATION WIRING DIAGRAM....................................................... 5-20

F

IG. 5-22 MODE SELECTOR CONNECTION........................................................... 5-21

F

IG. 5-23 F200-40 AS MODE SELECTOR .............................................................. 5-22

F

IG. 5-24 COMPLETE MODE SELECTION............................................................... 5-22

F

IG. 5-25 F200 REMOTE CONTROL, CONNECTION............................................. 5-23

F

IG. 5-26 S9 STEERING LEVER, BULKHEAD MOUNTING ..................................... 5-23

F

IG. 5-27 S9 STEERING LEVER, PANEL MOUNTING............................................. 5-24

F

IG. 5-28 S9 STEERING LEVER, INTERNAL WIRING............................................. 5-24

F

IG. 5-29 PRIORITY NFU CONTROL BY S9 DIRECTLY TO VALVES....................... 5-24

F

IG. 5-30 NON-PRIORITY NFU CONTROL BY S9, NO VALVE LOAD TO S9..........5-25

F

IG. 5-31 FU9X STEERING LEVER, BULKHEAD MOUNTING................................ 5-26

F

IG. 5-32 FU9X CONNECTION TO D9X............................................................... 5-26

F

IG. 5-33 S35 AND F1/2 CONNECTION TO D9X ................................................... 5-27

F

IG. 5-34 S35 AND F1/2 ALTERNATIVE CONNECTION TO AP9 MK3................ 5-27

F

IG. 5-35 RI9 CONNECTION................................................................................. 5-28

F

IG. 5-36 PANORAMA CONNECTION................................................................... 5-29

F

IG. 5-37 AP9MK3 /THRUSTER INTERCONNECTION........................................ 5-30

F

IG. 5-38 NAVIGATIONAL RECEIVER CONNECTION............................................ 5-31

F

IG. 5-39 INFO LOOP 1..........................................................................................5-34

F

IG. 5-40 INFO LOOP 2.........................................................................................5-39

F

IG. 5-41 “HIDDEN” BUTTON LOCATION............................................................ 5-44

F

IG. 5-42 RF14XU INTERNAL WIRING ............................................................... 5-49

Page 11

Instruction Manual

20169223D IX

FIG. 5-43 D9X DUAL ANALOGUE BOARD, COMPONENT LAYOUT (REV. - C ). 5-53

F

IG. 5-44 D9X DUAL ANALOGUE BOARD, COMPONENT LAYOUT (REV. D - ).. 5-54

F

IG. 5-45 D9X SOLID STATE BOARD, COMPONENT LAYOUT.............................. 5-55

F

IG. 5-46 D9X THRUSTER INTERFACE BOARD, COMPONENT LAYOUT............... 5-56

F

IG. 5-47 GYRO INTERFACE BOARD, SWITCHES .................................................. 5-58

F

IG. 5-48 RUDDER/COUNTER RUDDER - COURSE RELATIONSHIP .....................5-66

F

IG. 5-49 SPECIAL FEEDBACK ARRANGEMENT.................................................... 5-72

F

IG. 7-1 AP9 MK3 CONTROL UNIT, SPARE PARTS.............................................. 7-2

F

IG. 7-2 CD109 - SPARE PARTS.............................................................................. 7-3

F

IG. 7-3 RF14XU - SPARE PARTS........................................................................... 7-4

F

IG. 7-4 RF STANDARD TRANSMISSION LINK....................................................... 7-5

F

IG. 7-5 F200-40 COMPONENT REFERENCE.......................................................... 7-6

F

IG. 8-1 J1 - INPUT/OUTPUT SIGNAL REFERENCES............................................... 8-2

F

IG. 8-2 J2 - INPUT/OUTPUT SIGNAL REFERENCES............................................... 8-3

F

IG. 8-3 J3 - INPUT/OUTPUT SIGNAL REFERENCES............................................... 8-4

F

IG. 8-4 J4 - INPUT/OUTPUT SIGNAL REFERENCES............................................... 8-5

F

IG. 8-5 J5 - INPUT/OUTPUT SIGNAL REFERENCES............................................... 8-6

F

IG. 8-6 SCREEN TERMINATION ............................................................................ 8-7

F

IG. 8-7 D9X/S SERIES DISTRIBUTION UNITS (OPTIONAL VERSION)..................8-8

F

IG. 8-8 FU9X - CIRCUIT DIAGRAM (N3-360308C)............................................ 8-9

F

IG. 8-9 D9X POWER SUPPLY - CIRCUIT DIAGRAM (DRW. NO. N3-012812G)8-10

F

IG. 8-10 D9X INTERCONNECTION BOARD – CIRCUIT DIAGRAM

(DRW. NO. N3-012813B)............................................................................ 8-11

F

IG. 8-11 D9X SOLID STATE BOARD, UNIVERSAL TYPE – CIRCUIT DIAGRAM

DRW. NO. N1-012815D.............................................................................. 8-12

F

IG. 8-12 D9X DUAL ANALOGUE BOARD – CIRCUIT DIAGRAM

(DRW. NO. N1-012816E)............................................................................ 8-13

F

IG. 8-13 D9X THRUSTER INTERFACE BOARD – CIRCUIT DIAGRAM

(DRW. NO. N1-012818C) ........................................................................... 8-14

E

XTERNAL CABLING DIAGRAM..................................................DRW. NO. 3-017111

E

XTERNAL WIRING DIAGRAM....................................................DRW. NO. 1-017115

Page 12

Robertson AP9 Mk3 Autopilot

X 20169223D

This page is intentionally left blank

Page 13

Introduction

20169223D 1-1

1 INTRODUCTION

1.1 General

To day Simrad manufacture a complete range of autopilots for all

types of vessels, from leisure boats up to advanced steering systems

for merchant marine vessels. Our factory for these products –

branded Robertson – is located in Egersund, on the south-west coast

of Norway. The company's involvement in autopilots began in 1953

with equipment for the North Sea fishing fleet.

The AP9 MK3 autopilot described in this document is based on

predecessor, the AP9 MkII. The major changes are on the hardware

to comply with IMO resolution 694 (17) and the Marine Directive

(Wheelmark). The hardware changes are compatible with the AP9

MkII.

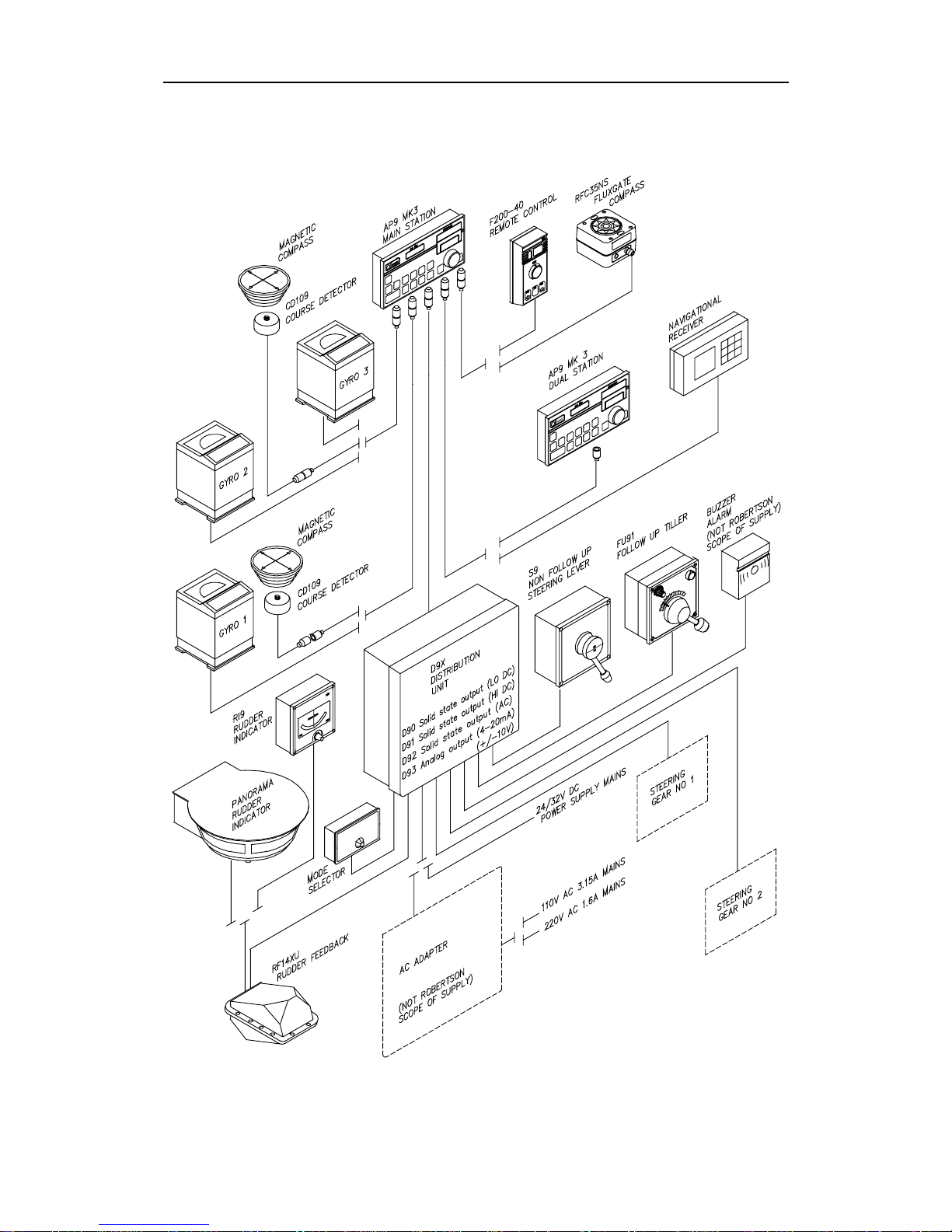

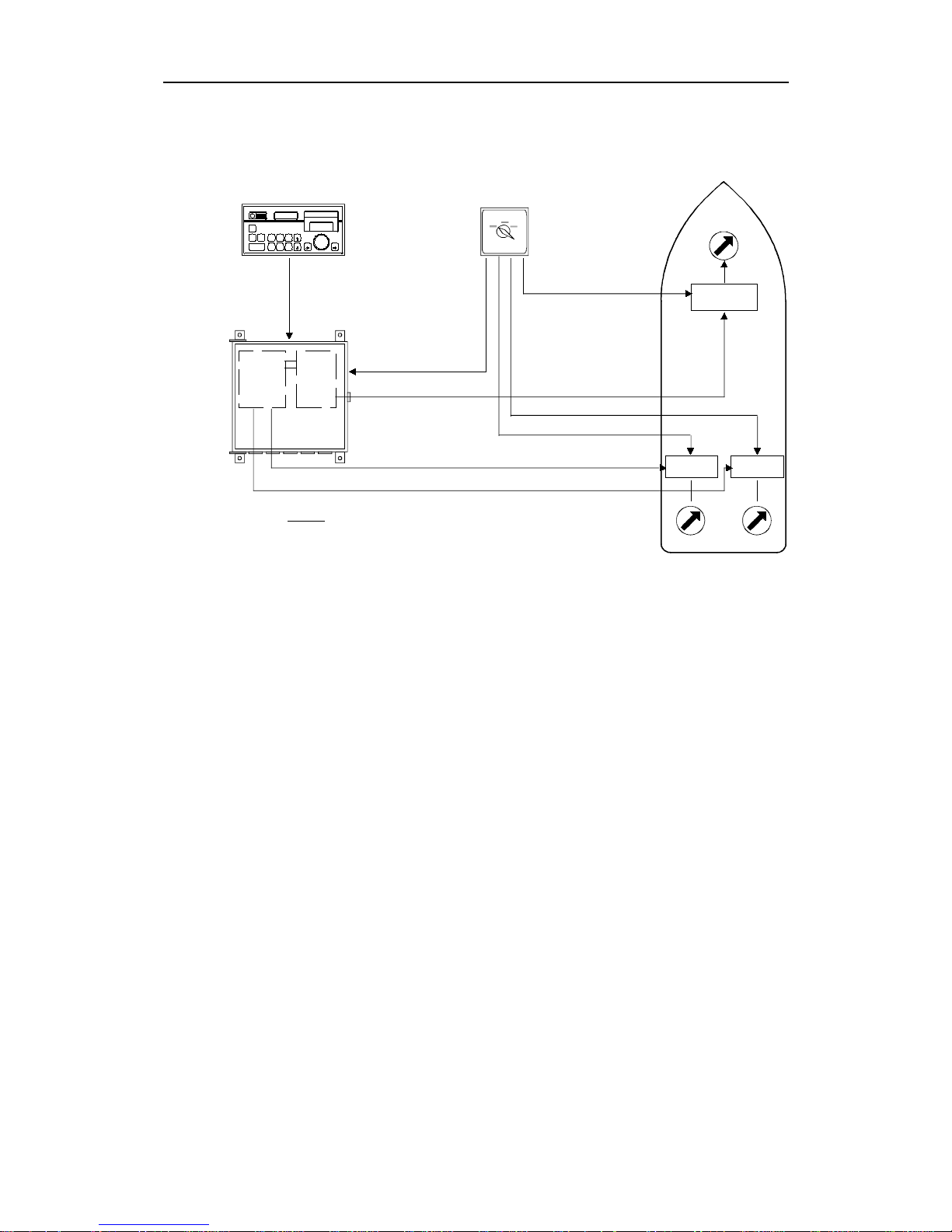

1.2 MK3 System Layout

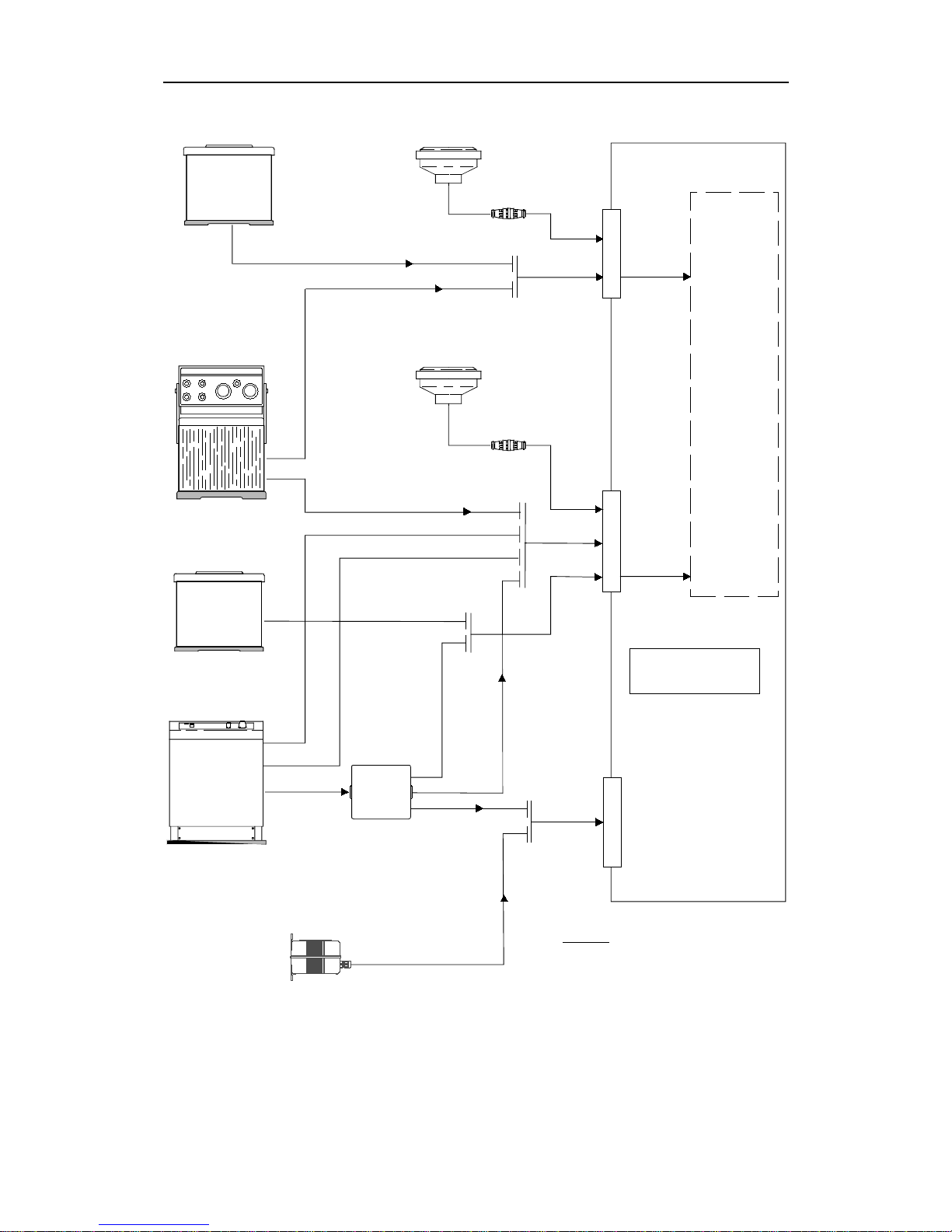

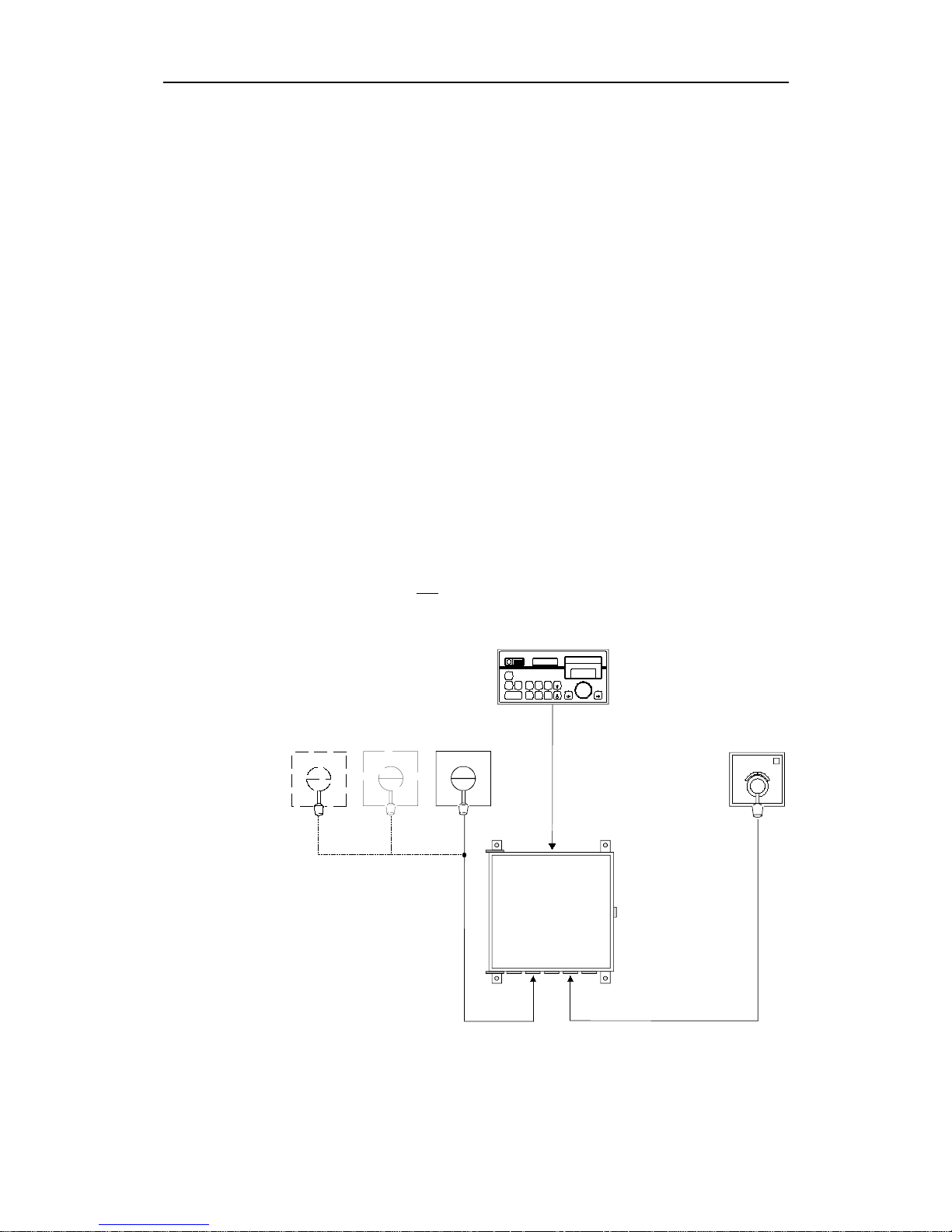

The complete AP9 MK3 system layout is shown in Fig. 1-1

A number of configurations can be made from the complete system

layout, and certain standard systems are shown in separate figures.

The relationship between control signals, mode signals and the

different versions of distribution unit are shown in the standard

system drawings.

The combinations of heading sensors are shown in Fig. 1-5.

1.3 Options available with the standard system

The AP9 MK3 system has a series of options that can be specified,

allowing the autopilot system to be configured to suit virtually any

particular vessel.

Optional equipment:

• Dual station

This is a second control unit for remote control of the main station

functions

• Non Follow Up (NFU) steering lever with mode selector and lock

mechanism

• Follow up (FU) steering lever with mode selection

• Rudder angle indicators

• Watch alarm

• Thruster control/second parameter set; i.e. the ability to control

either a thruster or both the rudder and thruster simultaneously.

This option requires a special interface board in the Distribution

Unit.

Page 14

Robertson AP9 MK3 Autopilot

1-2 20169223D

For operation, technical specifications, installation and spare parts,

see the respective sections of this manual.

Fig. 1-1

AP9 MK3 System layout

Page 15

Introduction

20169223D 1-3

1.4 AP9 MK3 Standard System, On-Off Valves

Ref. Fig. 1-2.

The standard AP9 MK3 system consist of the following units:

• AP9 MK3 Control Unit P/N 20169199

Optional Gyro interface PCB P/N 20168316

• CD109 Magnetic Course Detector

(with tripod holder) P/N 20120861

• RF14XU Feedback Unit (with transm. link) P/N 22501647

• D9X Distribution Units:

Version D90 (19-40V DC, 3A solenoids) P/N 20125001

(Extra S.S.B. P/N 20125043)

Version D91 (110V DC, 1A solenoids) P/N 20125407

(Extra S.S.B. P/N 20125423)

Version D92 (110/220V AC, 1A solenoids) P/N 20125704

(Extra S.S.B. P/N 20125720)

Note that the standard

mains supply is 24V DC.

If AC mains is used, the

system must also include

an AC Power Adapter

(Not supplied by Simrad

Robertson AS)

Where the system shall

operate two sets of

solenoid valves, one

extra Solid State PCB

(S.S.B.) must be mounted

in the D9X Distribution

Unit (see above).

Interface to navigational

receiver is incorporated.

Fig. 1-2

Standard system with ON-OFF

valves

AP9MKII AUTOPILOT

NAV.RECEIVER

AP9 MK3

MAGNETIC COMPASS

CD109

GYRO-COMPASS

D9X

DISTRIBUTION

(D90/91/92)

AC

ADAPTER

24V DC MAINS

24V DC ALARM

"ON-OFF""ON-OFF"

TO INDICATORS

(VOLTAGE)

RF14XU

RUDDER

TRANSMISSION LINK

SOL.

VALVE

PUMP 1

SOL.

VALVE

PUMP 2

AUTOPILOT F.B.

FOR TWO PUMPS,

ADD EXTRA

SOLID STATE PCB.

110/220V AC

50/60Hz

(FREQUENCY)

Page 16

Robertson AP9 MK3 Autopilot

1-4 20169223D

1.5 AP9 MK3 Standard System, Dual analogue output

The dual analogue system consist of the following units (Ref. Fig.

1-3.):

• AP9 MK3 Control Unit P/N 20169199

• Gyro Interface Board (Optional) P/N 20168316

• CD109 Magnetic Course Detector P/N 20120861

(with tripod holder)

• D93 Distribution Unit: P/N 20126009

Provides two galvanic isolated ±10V (adjustable)

or 4-20mA output signals

Note ! No autopilot feedback unit is required.

It is recommended to use a separate mode selector to provide changeover (c/o) signals to the respective steering gear electronic units. Th e

following functions can be included:

A: MANUAL - AUTO

B: MANUAL - PORT - STBD - BOTH

(Function to be specified when ordering)

Fig. 1-3

Standard system, ±10V

Dual Analogue

AP9MKII

AUTO PILOT

STEERING

GEAR

EL. 1

STEERING

GEAR

EL. 2

RUDDER RUDDER

FEEDBA C K FEEDBA C K

EXT. MODE SELECTOR

(OPTIONAL)

D9X

DISTRIBUTION UNIT

D93

POWER

ADAPTER

110/220V AC

50/60Hz

24V DC MAINS

24V DC ALARM

NAV. RECEIVER

MAGNETIC COMPASS

AP9 MK3

GYRO-COMPASS

CD109

T.B.

C/O

C/O

+/-10V

ANALOG

+/-10V

ANALOG

MODE

**

NOT ROBERTSO N

SUPPLY

*

Page 17

Introduction

20169223D 1-5

1.6 AP9 MK3 with analogue thruster control

Ref. Fig. 1-4.

The system consists of the following units:

• AP9 MK3 Control Unit P/N 20169199

Optional Gyro Interface Board P/N 20168316

• CD109 Magnetic Course Detector

(with tripod holder) P/N 20120861

• D9X Distribution Unit P/N 20126306

(Includes S.S.B.(s) or Dual Analogue PCB P/N as per D9X

depending on steering gear interface)

• Thruster Interface PCB P/N 20126017

(Replaces Interconnection PCB P/N 20125027

in D9X Distribution Unit)

• Thruster switch (RUDDER - THRUSTER) P/N 20168605

• RF14XU Feedback Unit P/N 22501647

(When connected to solenoid valves)

AP9M KII

AUTOPILOT

MAGNETIC COMPASS

AP9 MK3

NAV. RECEIVER

THRUSTER SWITCH

GYRO COMPASS

D9X

DISTRIBUTION

UNIT

FEED-

BACK

STEERING

GEAR

EL.

NOTE:

STEERING SYSTEM EITHER ON-OFF OR ANALOGUE.

FOR ANALOGUE, NO FEEDBACK IS REQUIRED FOR AUT OPILOT .

THR.

INT.

PCB

CD109

MODE

+/-10V ANALOG

NOTE

24VDC

MAINS

Fig. 1-4

Thruster control

Page 18

Robertson AP9 MK3 Autopilot

1-6 20169223D

1.7 Combinations of Heading Sensors

Ref. Fig. 1-5.

The AP9 MK3 Control Unit is designed to accept several types of

heading sensors. The sensors can be divided in three groups:

1. Gyro Compass

2. Fluxgate Compass (Recommended as monitor compass only)

3. Magnetic Compass (Recommended as monitor compass only)

GYRO COMPASS

To interface to SYNCHRO, GYRO EXCITED, A/P EXCITED or STEP

type gyro, the AP9 MK3 Control Unit must be equipped with the

Gyro Interface Board P/N 20168316.

Signal type Option al ha rdware

Synchro 11,8V l-l 400Hz Gyro Interface PCB

Synchro 20-115V l-l 50-60Hz, 400Hz Gyro Interface PCB

Step 6 step/degree Gyro Interface PCB

Sin/cos Not required

Serial Not required

Note ! Two SYNCHRO or two STEP signals can not be connected at the same

time. When using two gyrocompasses, one gyro must provide SYNCHRO

signal and the other gyro must provide STEP signal.

When using gyro with serial signal, no Gyro Interface Board is

required.

Notice that dual station system communication can not be made

when UART or NMEA serial line is used.

The Robertson RGC gyros can be connected according to the following

table:

Direct connection RGC Interface connection

RGC10 Synchro Serial, sin/cos, 6 step/degree

RGC11 RS422 Tokimec spes. Serial, sin/cos, 6 step/degree

RGC50 Synchro Serial, sin/cos, 6 step/degree

RGC12 Serial Serial, sin/cos, 6 step/degree

For details of gyro selection see page 5-58.

Page 19

Introduction

20169223D 1-7

SKR-82 GYRO

GYRO-COMPA SS

RGC GYRO

RGC

INT. FACE

ROBERTSON

RFC35NS

J2

SYNCHRO

MAGN.

GYRO

INTERFACE

BOARD

SYNCHRO

1:1

90:1

360:1

STEP

6 STEP/DEGREE

SERIAL

MAGN.

STEP

SIN/COS

(FLUXGATE)

J3

J5

AP9 MK3

CONTROL UNIT

SERIAL UART

SERIAL

UART

SIN/COS

GYRO-COMPA SS

SIN/

COS

1:1 SYNCHRO

110V 400Hz

(ONLY RGC10

AND RGC50)

MAGNETIC COMPASS

CD109

MAGNETIC COMPASS

CD109

SYNCHRO

SYNCHRO

NOTE:

THE GYRO INTERFACE

BOARD CAN NOT ACCEPT

TWO SYNCHRO OR

TWO STEP SIGNALS

SIMULTANEOUSLY,

ONLY ONE OF EACH.

STEP

STEP

SERIAL TOKIM EC

NMEA

Fig. 1-5

Heading Sensors

Page 20

Robertson AP9 MK3 Autopilot

1-8 20169223D

RGC Gyro with RGC Signal Interface Unit

When using an RGC gyro together with the RGC Signal Interface,

four options of connections are possible:

1. UART serial line, 20mA. (Identical to the SKR 82 serial line)

2. NMEA serial signal

3. Fluxgate sin/cos signal, identical to the Robertson fluxgate signal.

4. Step signal, 24V – 6 step/degree.

When using the fluxgate signal, select FLUXGATE compass.

When using step signal, select STEP SIGNAL.

See page 2-6 for compass selection.

RGC12 Gyrocompass

The RGC12 RS422 Tokimec special protocol or NMEA can be

connected directly to the AP9 MK3 without any Gyro Interface PCB.

FLUXGATE COMPASS

The AP9 MK3 is designed to accept fluxgate compass sin/cos signals,

using 2.5V DC as reference.

The Robertson type of Fluxgate Compasses, such as the RFC35NS

therefore interfaces directly to the AP9 MK3.

Note ! A fluxgate compass should only be used as a Monitor Compass.

Gyrocompass is always recommended as Main Compass.

For details, refer to page 5-10.

Page 21

Introduction

20169223D 1-9

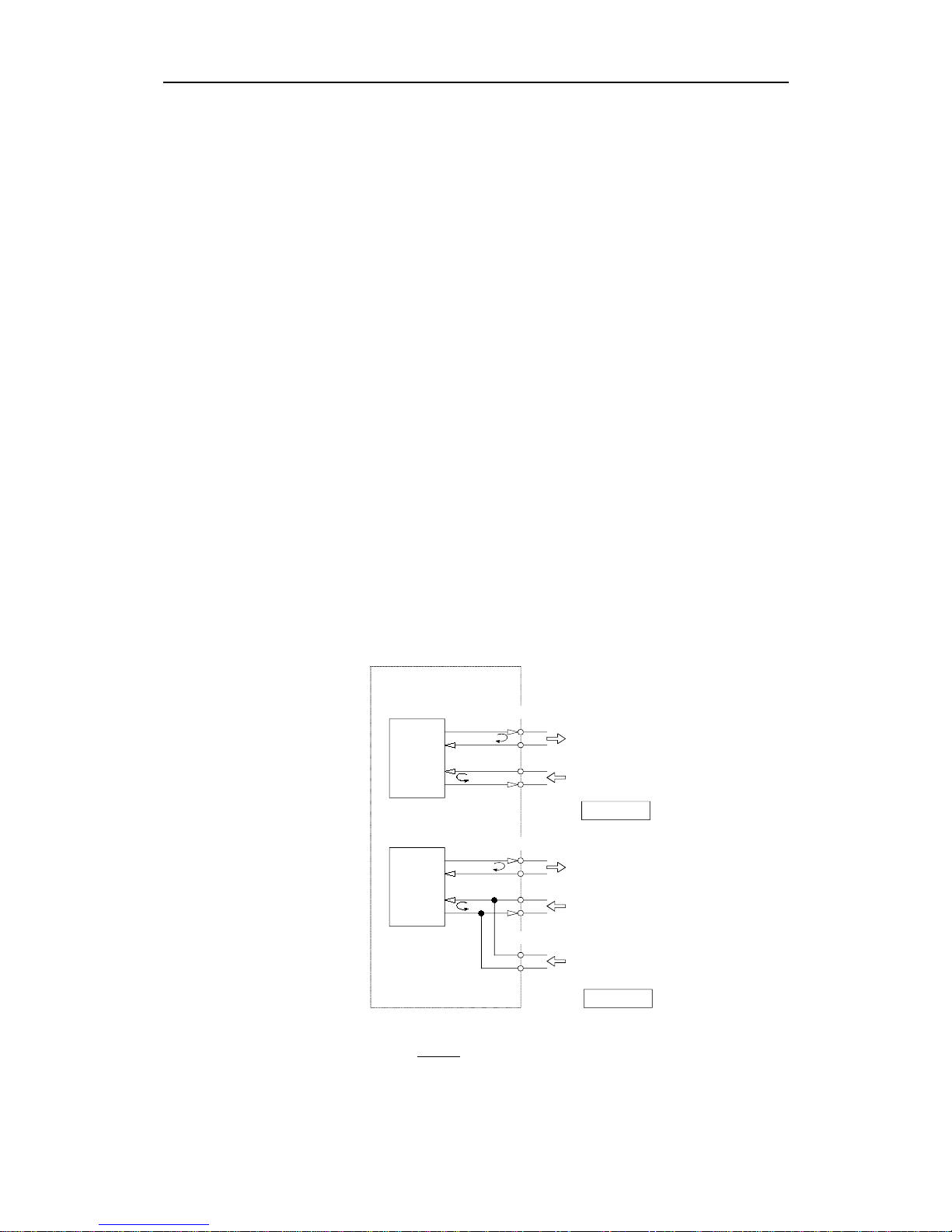

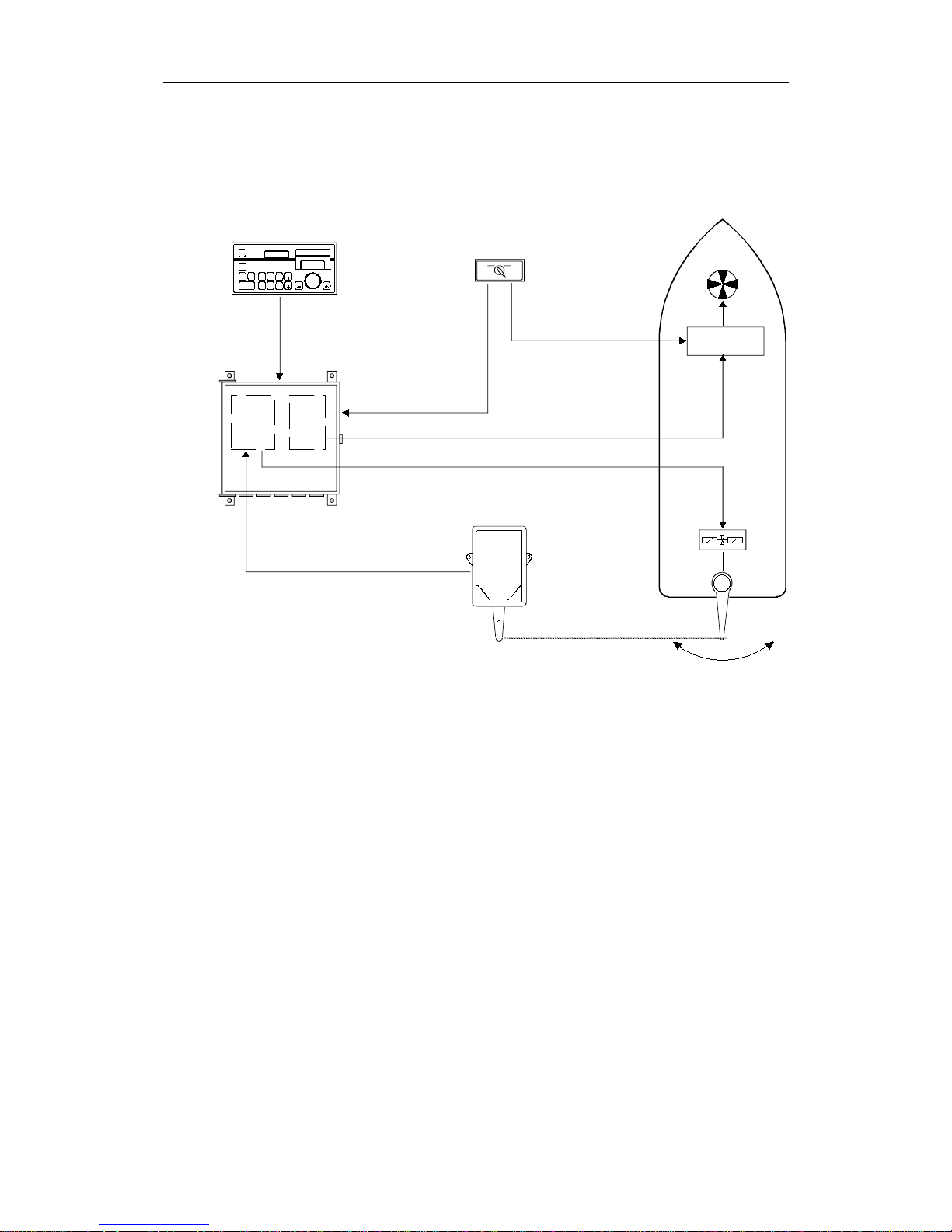

1.8 Dual Station

See Fig. 1-7

The AP9 MK3 Control Unit can also be used as a remote station,

communicating with the main station by serial lines.

The dual station system is designed to enable individual connections

of NFU levers, F200-40 remote controls and mode selectors. This

makes it possible to select mode and change parameters from the two

stations individually. FU levers can only be connected to the main

Control Unit via D9X.

Note ! Change of parameters except the selection of compass on one unit, will

change the same parameters on the other unit.

Parameter 2 option (Thruster function) can be selected individually

on the two units, but adjustment of parameters on one unit will

automatically change the same parameters on the other unit.

When a F200-40 Remote Control is connected, a mode selector must

have an "OFF" position to allow proper function of the F200-40.

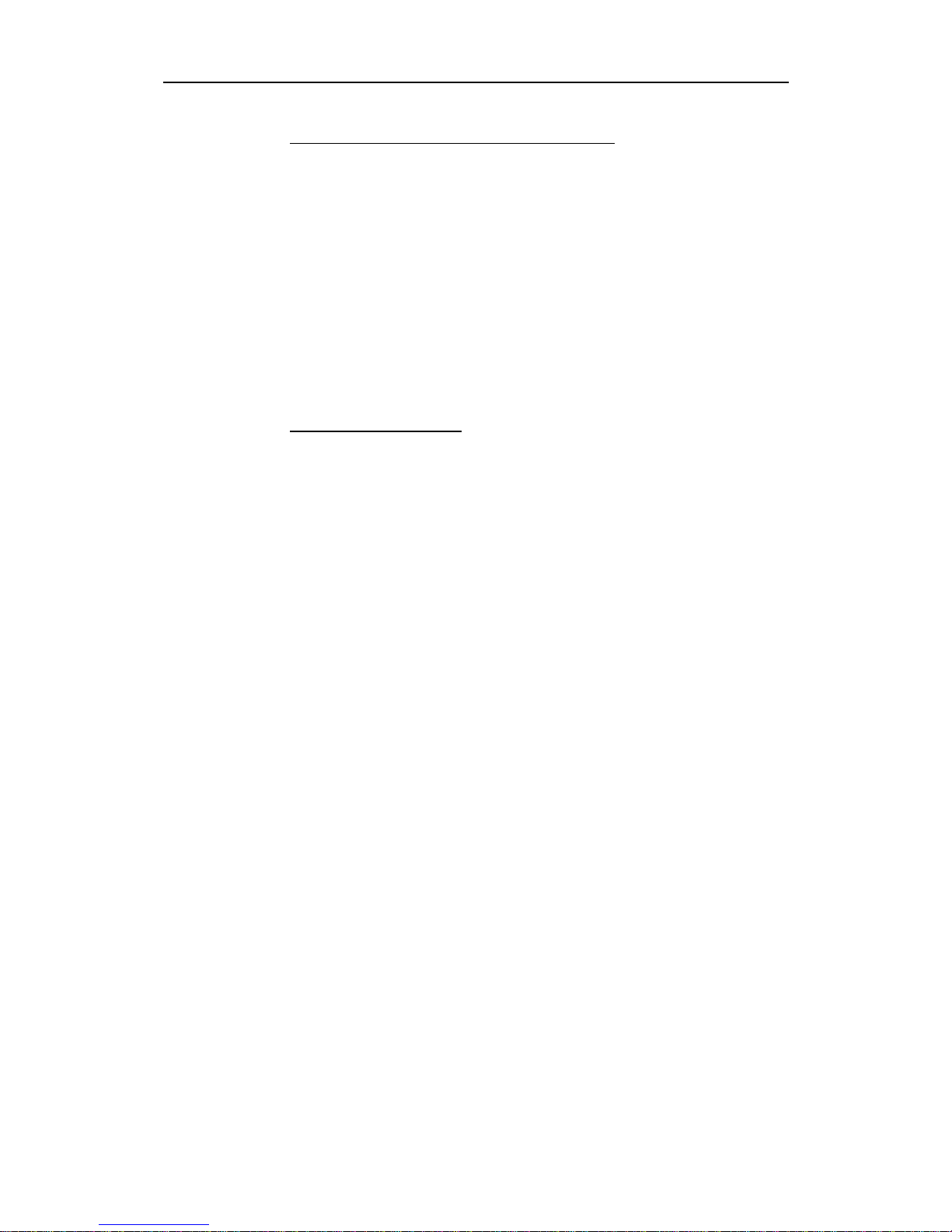

SERIAL LINES

The AP9 MK3 has several serial line connections.

As shown in Fig. 1-6, two input lines are in parallel, the "COMM.

LINE" and the "SERIAL HDG. DATA". This excludes the interface to

serial heading data when a dual station is used.

3

6

9

10

8

6

1

2

1

2

H

H

L

L

OUT

IN

B

OUT

IN

IN

SERIAL HEADING DATA

COMM. LINE

(DUAL ST./RMP)

COMM. LINE

(DUAL ST./RMP)

HEADING

NMEA (HDT/HDM)

NAV. RECEIVER

(NMEA)

AP9 MK3

CHANNEL A

CHANNEL B

NOTE: In Dual Station configuration, serial heading data

can not be connected to J3, 1-2.

H

H

L

L

OUT

IN

A

OUT

IN

J4

J4

J3

Fig. 1-6

Serial line connections

Page 22

Robertson AP9 MK3 Autopilot

1-10 20169223D

AP9MKII AUTOPILOT

AP9MKII A UTOPILOT

S9

NFU LEVER

AP9 MK3

REMOTE STATION

EXT. MODE SELECTOR

(OPTION)

F200-40

SEE N O TE

COMMUNICATION LI NES

D9X

DISTRIBUTIO N

UNIT

F200-40

SEE N O TE

EXT. MODE SELECTOR

(OPTION)

S9

NFU LEVER

FU9X

FOLLOW -UP

LEVER

AP9 MK3

MAIN STATION

PWR

NOTE:

WHEN A F200-40 IS

CONNECTED, T HE

MODE SELECTO R(S)

MUST INCLUDE AN

"OFF" POSITION.

Fig. 1-7

Dual Station System

Page 23

Introduction

20169223D 1-11

1.9 Connection of steering levers

As shown on Fig. 1-8., a number of NFU levers and a single FU lever

can be connected to the AP9 MK3 autopilot system.

The S9 NFU lever combines an "IN - OUT" function with the normal

PORT - STBD operation. The "IN - OUT" function can be combined

with the external mode-selection of the autopilot and this

automatically brings the autopilot to NFU mode when the S9 lever is

pulled out. The mode change has two alternatives:

A. Sets the autopilot to NFU mode when the S9 is pulled out. NFU

mode will remain when S9 is pushed in again. AUTOMATIC or

NAV to be selected on the control unit. For this alternative refer to

page 5-24.

B. Sets the autopilot to NFU-mode when the S9 is pulled out. Mode

will change back to AUTOMATIC or NAV when the S9 lever is

pushed in again. To obtain this function, the closing contacts if S9

no. A5-A6 is used to control the mode. Refer to page 5-21.

An unlimited number of S9’s can be connected in parallel.

Note ! It is also possible to add several FU-levers to an AP9 MK3 system by using

the FUA9X Follow-Up Amplifier instead of the D9X Distribution Unit.

Note ! NFU levers should not be used for analogue steering(

±

10V output).

AP9MKII AUTOPILOT

AP9 MK3

S9 S9

S9

(NFU)

FU9X

D9X

DISTRIBUTION

UNIT

ONE OFF

Fig. 1-8

NFU/FU Levers

Page 24

Robertson AP9 MK3 Autopilot

1-12 20169223D

1.10 Rudder Angle Indicators

RI9

RUDDER

PANORAMA

NO.1

NO.2

NO.3

NO.4

24V DC

INDICATOR

SUPPLY

24V DC

INDICATOR

SUPPLY

FEEDBACK

TO AUTOPILOT

RF14XU

+/-45/60/70/90 DEGREE

FREQ.

3400Hz +/-20Hz/DEGREE

RI9

RI9

RI9

Fig. 1-9

Rudder Angle Indicators

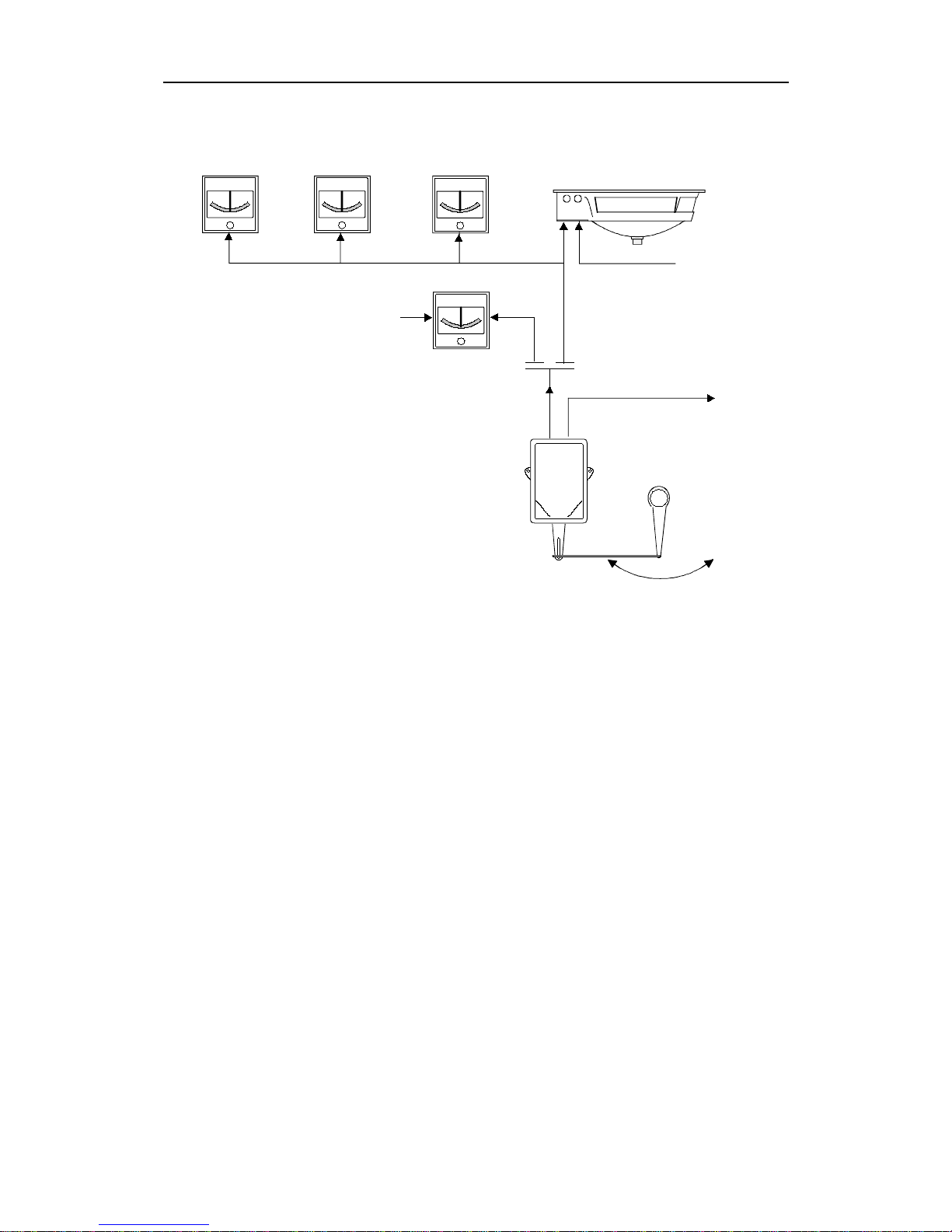

Fig. 1-9 shows a typical Rudder Angle configuration. Number and

type of indicators varies from ship to ship.

The indicators must be of the "voltage" type, such as Panorama, RI40

and RI9. Installation instructions are supplied with the indicators.

Page 25

Introduction

20169223D 1-13

1.11 Special Applications

Example I:

AP9MKII

AUTOPILOT

THR.

INT.

PCB

SOL.

STATE

PCB

AP9 MK3

THRUSTER SELECTOR

SWICH

D9X

DISTRIBUTION

UNIT

RF14XU

RUDDER

SOLENOID

VALVES

MODE

+/-10V ANALOG

(VIA THR.INT.)

C/O SIGNAL

SOLENOID (ON/OFF) SIGNALS

THRUSTER

ELECTRONICS

Fig. 1-10

Special applications, Example 1

In this example the autopilot is interfaced both to a conventional

rudder system, using ON - OFF solenoid valves, and an azimuthing

bow thruster with ±10V as control signal.

The AP9 MK3 can provide different parameters f or the thruster and

the rudder control respectively, and the combination is determined

under the INFO loop 2 (Ref. page 2-9).

The combination shown above requires a Thruster Interface PCB to

provide the single ±10V analogue output, and a Thruster Selector

Switch to provide the change-over (C/O) signal to the thruster

combined with the mode control to the autopilot. The Thruster

Interface PCB, part no. 20126017 is mounted in the Distribution Unit,

and the solid state PCB must be specified according to the switching

voltage. (Ref. Standard System).

Page 26

Robertson AP9 MK3 Autopilot

1-14 20169223D

Example 2:

AP9MKII AUTOPILOT

AP9 MK3

THRUSTER SWITCH

SERVO

POT.

D9X

DISTRIBUTION

UNIT

U/X

CONV.

THR.

INT.

PCB

SOL.

ST.

PCB

C/O SIGNAL

C/O SIGNAL

ON-OFF SIG NAL

MODE

FEEDBACK

+/-10V SIGN.

FREQ. (X)

(U)

SOLENOID

VALVES

THRUSTER

ELECTRONICS

Fig. 1-11

Special applications, Example 2

The AP9 MK3 autopilot is also designed to operate a tunnel bow

thruster, with possibility to set deadband and thruster power in the

second parameter set.

The control signal is the ±10V analogue, generated via the Thruster

Interface PCB.

The shown configuration also includes a main propulsion azimuth

thruster, operated by ordinary ON-OFF solenoid valves.

A special feedback arrangement is required to replace the standard

RF14XU. It consists of a servo potentiometer and a voltage-tofrequency converter, to facilitate the installation of the mechanical

and electrical part of the feedback system. Contact Simrad for further

information

Page 27

Introduction

20169223D 1-15

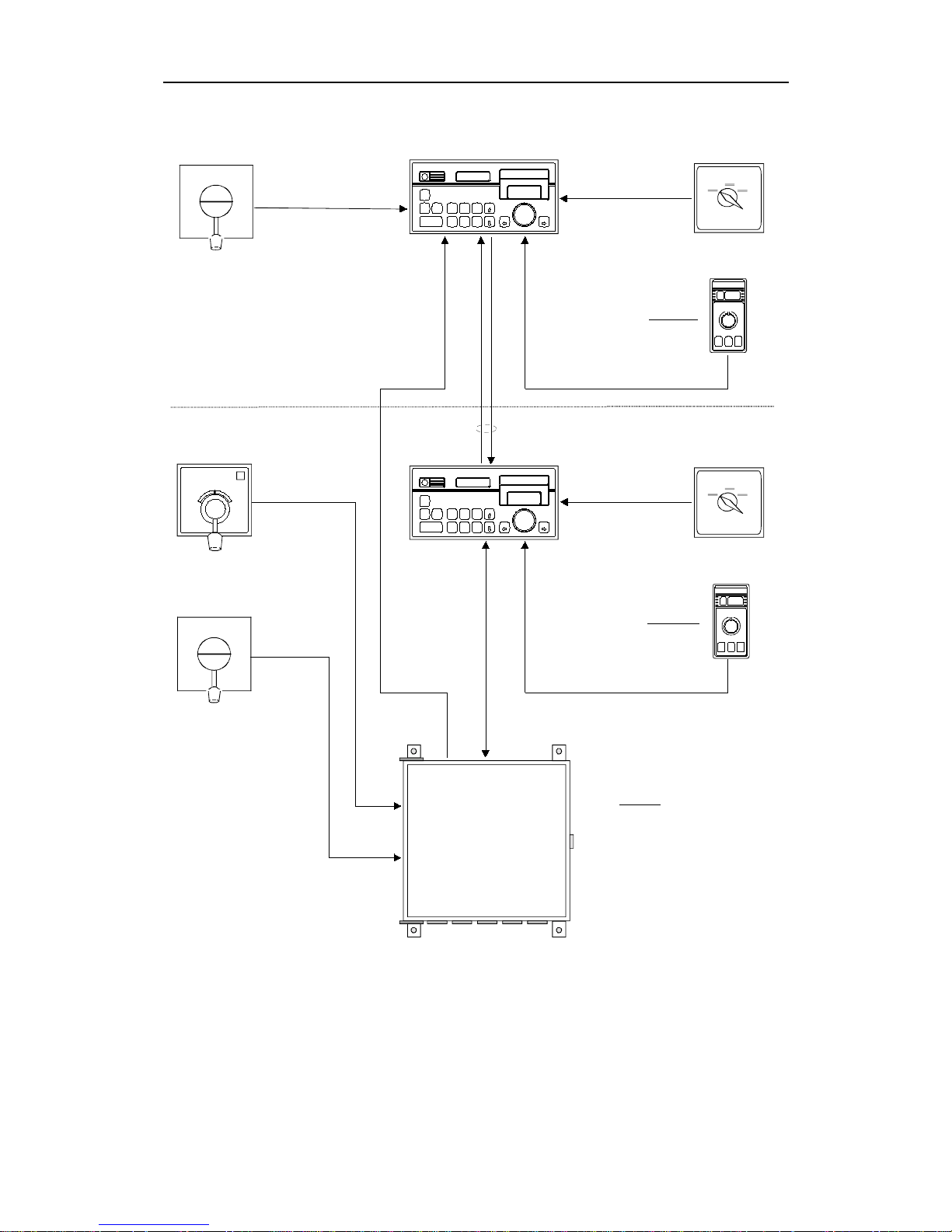

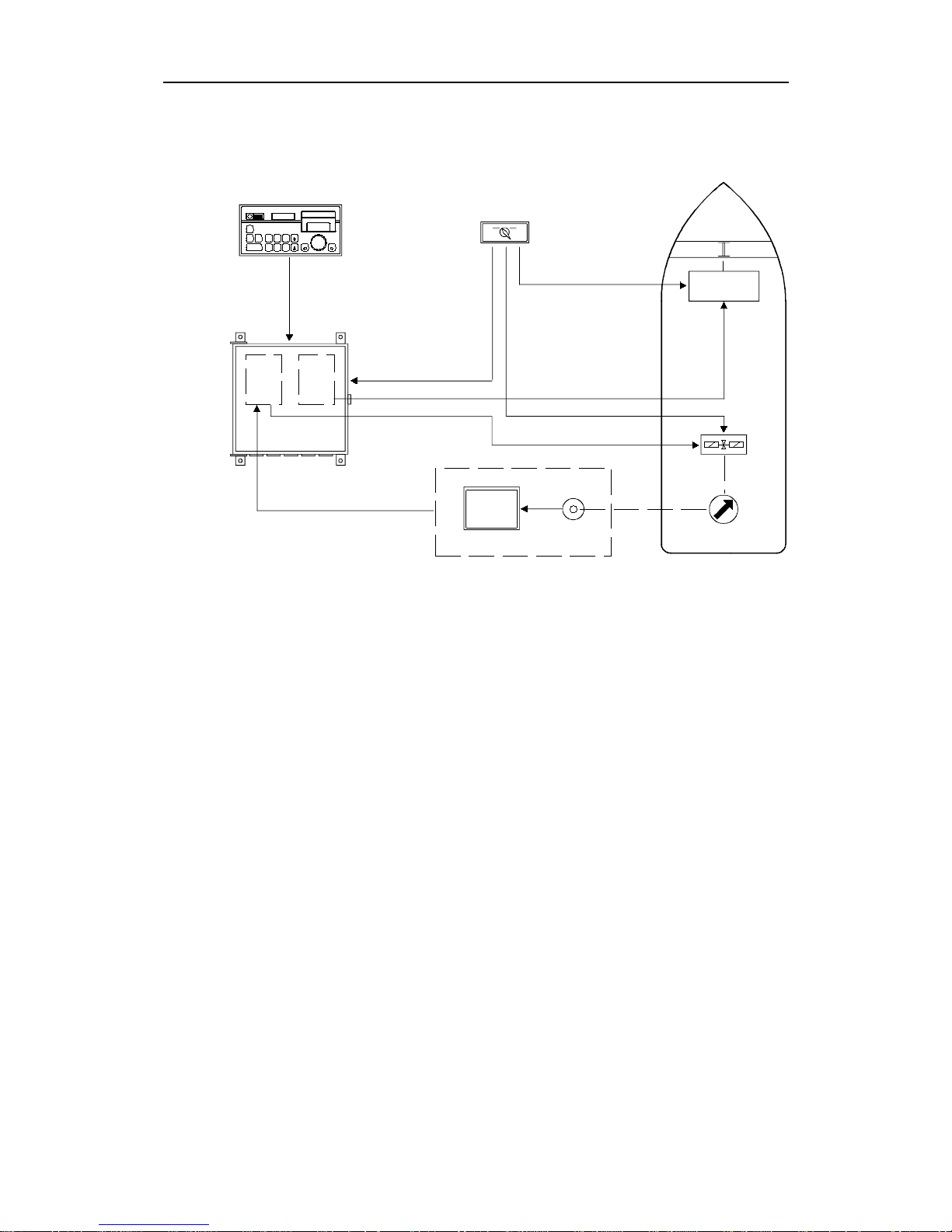

Example 3:

NOTE:

THE D94 CONTAINS ONE THRUSTER INTERFACE

BOARD AND ONE DUAL ANALOG PCB.

AP9MKII AUTOPIL OT

AP9 MK3

THRUSTER SELECTOR

(SPECIAL)

D94

DISTRIBUTION

UNIT

DUAL

ANALOG

PCB

THR.

INT.

PCB

BOW

THRUSTE R

AFT THRUSTERS

+/-10V

+/-10V

C/O SIGNAL

C/O SIGNAL

+/-10V

MODE

P

S

C/O SIGNAL

THRUSTER

ELECTRONICS

THRUSTER

ELECTRONICS

THRUSTER

ELECTRONICS

Fig. 1-12

Special application, Example 3

The AP9 MK3 autopilot system can provide three galvanic isolated

±10V outputs and be configured as shown in Fig. 1-12.

In this example the Distribution Unit is equipped with one Thruster

Interface board to control the bow thruster, and one Dual Analogue

PCB to control the two aft thrusters.

The Thruster Selector Switch is normally custom-made for each

individual system, and provides the change-over signals for the

thrusters, and the mode for the autopilot.

No Feedback Unit is required!

Thruster Selector Positions:

• MANUAL

• AUTO AFT (Aft Thruster)

• AUTO BOW (Bow Thruster)

FEATURES: First parameter set for synchronized operation of the

aft thrusters.

Second parameter set for the operation of the bow

thruster.

Page 28

Robertson AP9 MK3 Autopilot

1-16 20169223D

This page is intentionally left blank.

Page 29

Operation

20169223D 2-1

2 OPERATION

* * * * * * *

NAV

HELMS-

MAN

AUTO COMPASS

SELECT

ILLUM

COUNTER

RUDDER

RUDDER

INFO

WEATHER

OFF

INCREASE

DECREASE

PORT

STBD

AUTOPILOT

AP9 MK3

ALARM

RESET

R

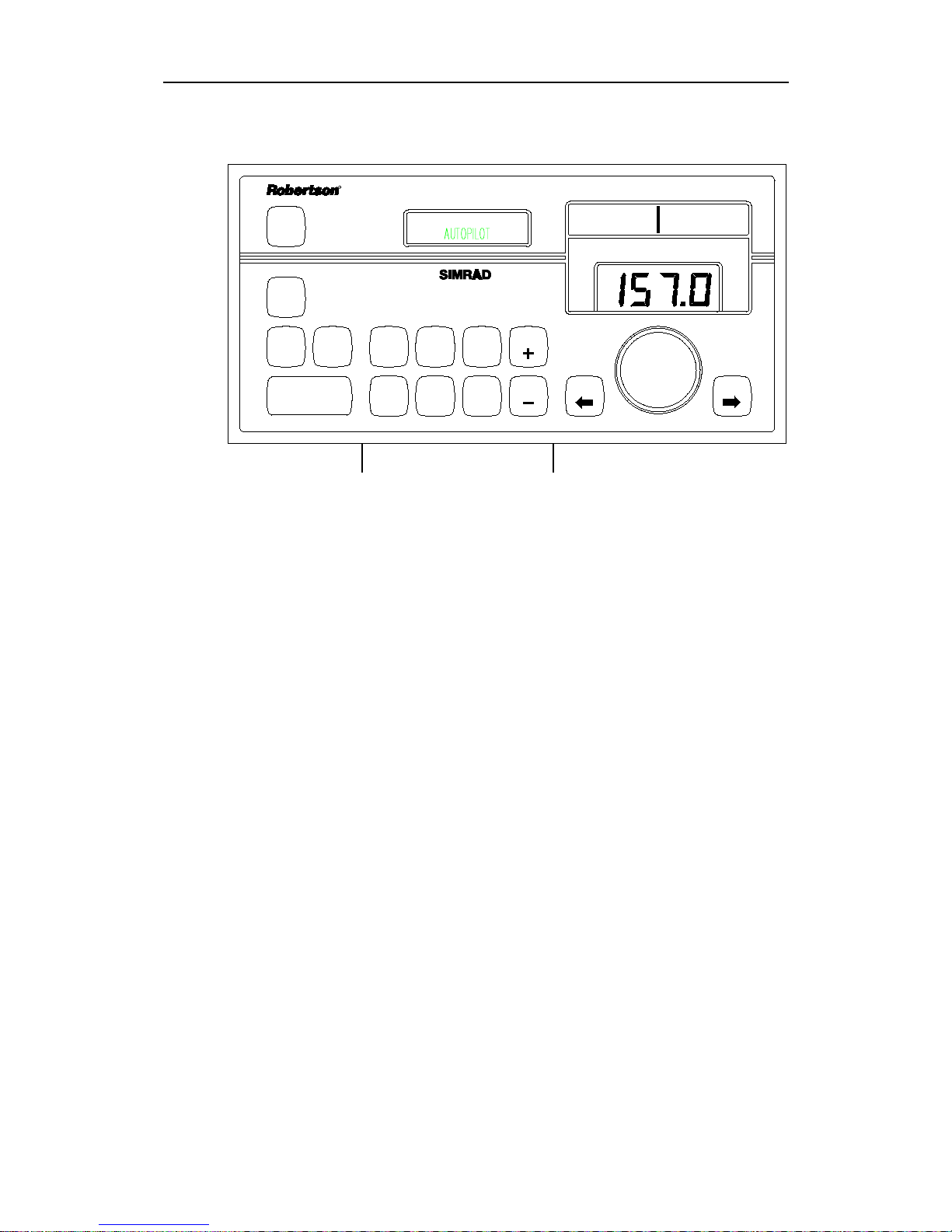

Mode selection Parameter setting Course selection

Fig. 2-1

AP9 MK3 Front panel

2.1 General

AP9 MK3 autopilot is operated by means of keypad push buttons on

the front panel. The buttons are back lighted, activated buttons being

brighter than the others.

Course selection is made by the rotary Course Selector Knob. Course

adjustments in steps of one degree can be achieved by the port or

starboard push buttons.

The front panel has three LCD displays, referred to as the

information display (left side), bargraph display (upper right) and

the course display. An alarm buzzer and an alarm reset button is also

on the front panel.

A few simple operations like pressing a button and/or turning the

Course Selector Knob is required in ordinary use of the autopilot. All

other instructions and data required for the operation are stored in

the autopilot upon delivery.

2.2 Front Panel

The front panel is divided into three sections: Mode selection,

Parameter setting and Course selection (Fig. 2-1).

Page 30

Robertson AP9 MK3 Autopilot

2-2 20169223D

2.3 Mode selection

Together with the OFF-button and the 3 mode buttons, this section

also contains an alarm buzzer and ALARM RESET-button.

HELMSMAN (Power ON)

The HELMSMAN button serves two purposes. It switches on the

autopilot and selects manual steering mode. In this mode the course

display gives a digital read-out of compass heading, while the vessel

can be steered manually by helm or steering lever(s).

AUTOPILOT

The AUTOPILOT-mode is used under normal conditions when the

boat is steered automatically on a pre-set course.

When the AUTOPILOT-button is pressed, the autopilot selects the

current vessel heading as "course to steer".

Any difference between course to steer and the vessel's actual

heading will then be shown as a bargraph in the bargraph display.

One bar equals one degree.

The autopilot uses the activated heading sensor unit, selected from

the COMPASS SELECT button to calculate the difference between

course to steer and actual ships heading. Rudder command signals

are then based on steering parameter settings.

Rudder commands are indicated by an arrow to left or right in the

bargraph display depending upon which direction the autopilot

commands the rudder to move. These arrows do not appear when

the autopilot output signal is analogue voltage. The “Debug” rudder

angle may show a random number as no rudder feedback is

connected.

For the ±10V analogue control signal, a separate rudder control

system moves the rudder to match the rudder angle command.

NAV. MODE

NAV.-mode is used when a navigation receiver is connected to the

autopilot for automatic "waypoint" steering.

When the NAV-mode is selected, the AP9 MK3 automatically

monitors the signals from the navigation system. If the signals are

absent or in a wrong data format, an alarm will be given to alert the

operator. See page 2-15: Navigational Steering.

OFF

The autopilot is switched off by pressing the OFF-button for 2

seconds, during which time the alarm will sound. The alarm ceases

Page 31

Operation

20169223D 2-3

when the AP9 MK3 is switched off. If the OFF-button is released

before two seconds have elapsed, the autopilot will continue to

operate as before and the alarm signal is automatically reset.

Rudder commands will stop as long as the OFF-button is pressed. All

pre-set parameters in the autopilot are stored while the unit is

switched off.

ALARM

The acoustic alarm is reset by pressing the alarm reset button.

Alarm messages shown on the information display are described on

page 2-25. Fault Warnings.

Thruster/rudder parameters

When the autopilot is connected to a thruster in addition to the

rudder, a separate Thruster Switch will enable a second set of

parameters to control the thruster. Whenever the Thruster Mode is

selected, all parameters can be individually set for optimal

performance from the thruster, while the parameters used for

Rudder-steering are saved and resumed when the Thruster Switch is

set to "RUDDER".

2.4 Parameter setting

Note ! When the "RUDDER" and "WEATHER" buttons are pressed

simultaneously, IDEAL parameters are recalled, provided the parameters

have been stored earlier (during sea-trial). See installation section, page 5-

69.

General

The middle section of the AP9 MK3 control unit contains 8 push

buttons and an information display. The display shows selected

mode, deviation from set course, parameter settings and other user

information. The text in the information display can be shown in one

of four selectable languages: English, French, Spanish or Norwegian

(see page 5-40).

When RUDDER, COUNTER RUDDER, WEATHER or ILLUM

buttons are pressed, the display shows which button has been

activated and to what level the value has been set by the number of

bars as well as in plain figures. The displa y returns to normal readout, showing the selected mode one minute after the last press on one

of the buttons.

The ability of the autopilot to steer a vessel is not only dependent

upon the control logic used, but also the hull shape of the vessel, the

steering gear and the weather conditions. The AP9 MK3 can be set up

to steer almost any vessel. During normal day to day operation

Page 32

Robertson AP9 MK3 Autopilot

2-4 20169223D

RUDDER, COUNTER RUDDER and WEATHER can be easily

adjusted from the front panel. In addition the autotrim can also be

adjusted, but should be permanently set during initial sea trials. The

autotrim parameter is accessed using the INFO button.

Switch ON

The autopilot is switched on by pushing the HELMSMAN button

(The switch can be sensed by the finger!)

The autopilot will acknowledge with a short audible "blip" and

confirms initialisation by showing:

SOFTWARE: mk3 V1R4

INITIATING

or

SOFTWARE: mk3 V1R4

CHECKING COMPASS

If the serial compass switch is ON the text ‘CHECKING COMPASS’

is displayed while type of serial compass is detected.

If serial compass data is not connected the alarm text ‘SERIAL COMP

FAIL’ is displayed and serial compass is removed from sensor setup.

If serial data has wrong polarity or has UART format, then the text

‘Uart OK’ or ‘Chg HiLo’ (Change Hi-Lo) is displayed.

After a few seconds Helmsman will be shown in the information

display:

* * * * * * *

HELMSMAN

If the autopilot is connected to a gyrocompass where the gyro

heading needs to be set, the display will show at switch on:

GYROADJUST

PRESS INC / DEC

Press the INCREASE or DECREASE button until the autopilot

display shows the same heading as the gyrocompass.

Then press the HELMSMAN button and the display will show:

* * * * * * *

HELMSMAN

Note ! If another language is preselected, the display may show:

TIMONEL (Spanish), MANUEL (French) or RORMANN

(Norwegian)

To change the language, do the following:

Page 33

Operation

20169223D 2-5

• Press INFO and keep it pressed.

• Press WEATHER

• Release WEATHER

• Release INFO.

The INFO display will show one of the following:

ENGLISH, ESPANOL (Spanish), FRANCAIS (French) or NORSK

(Norwegian)

The language can now be selected and stored by pressing either

INCREASE or DECREASE. The INFO display will fall back to

HELMSMAN approx. 1 minute after the last operation of

INCREASE/ DECREASE, or immediately by pressing HELMSMAN.

HELMSMAN

This is the "stand-by" mode for the autopilot. When this mode is

selected, the autopilot is passive and manual rudder operation, either

by steering wheel or Non Follow Up (NFU) levers, is made.

The Heading Display will show the actual course with resolution of

one tenth of a degree, operating as a heading repeater. The Bargraph

Display will show one single vertical line, indicating zero heading

error.

AUTOPILOT

When clear of obstacles and in open waters, steer the vessel on course

and press the AUTOPILOT button.

The display will now show:

* * * * * * *

AUTOPILOT

and the autopilot will automatically keep the vessel on course.

INCREASE- and DECREASE-buttons

These buttons are used to alter various settings. Each time one button

is pressed, the value shown on the information display, will increase

or decrease by one unit. The value is also shown as a graphical bar. If

the button is kept pressed for more than two seconds, the value will

automatically count up or down until the button is released.

ILLUM

The ILLUM button is used to adjust the illumination of buttons and

displays. .

Page 34

Robertson AP9 MK3 Autopilot

2-6 20169223D

• To adjust the illumination, first press the DIMMER button, than

the INCREASE or DECREASE button. In the information display a

number and a bargraph represent the brightness level.

COMPASS SELECT

The autopilot is capable of reading two heading sensors

simultaneously: Main (steering) compass and monitor (comp.

difference) compass.

If only one compass is connected, this will always be the main

compass. The autopilot shows the main compass heading in

HELMSMAN-mode and selects this heading as set course in

AUTOPILOT mode. The difference between the set course on the

autopilot and the main compass heading is known as the off course

deviation.

The autopilot monitors the off course deviation and if it exceeds the

selected off course limit, an off course alarm will sound. (See page 536 for selection of off course limit).

If more than one compass is connected, one is selected as main

compass and one as monitor compass. The autopilot now monitors

the heading difference between the main compass and the monitor

compass. The heading difference alarm is given when the differen ce

exceeds the off course limit and thus the heading difference alarm

also acts as an additional off-course alarm.

Press the COMPASS SELECT button once and the information

display shows the selected main compass. By then pressing the

INCREASE or DECREASE button another compass can be selected as

main compass from one of the compasses connected to the autopilot.

Press the COMPASS SELECT button a second time and the

information display shows the selected monitor compass. Another

monitor compass can be selected (not the one selected as main

compass) by using the INCREASE or DECREASE buttons. The

monitor compass can also be switched off by the same buttons.

RUDDER

When the RUDDER button is pressed, the Information Display

shows selected RUDDER value. The RUDDER value sets the ratio

between rudder angle and heading error (p-factor).

Example: If RUDDER is set to 1.0 and there is a heading error of 2

degrees, the rudder angle will be 2 degrees. (Heading error x

RUDDER value = rudder angle).

The correct RUDDER setting is dependent upon the size and speed of

the vessel. The RUDDER value should increase with decreasing

speed.

Page 35

Operation

20169223D 2-7

Examples of incorrect RUDDER settings:

Fig. 2-2

Rudder settings

A value which is too low gives relatively large and slow oscillations

(s-ing) around set course, and several rudder commands are given in

the same direction before the vessel is back on course.

A value which is too high will give quick and increasing oscillations

(s-ing) around set course.

The correct setting of RUDDER will be approximately in the middle

of the settings described in Fig. 2-2

Press RUDDER, thereafter INCREASE or DECREASE for required

amount of rudder.

Range: 0.1 - 3.3.

Recommended start value: 0.6 - 1.5.

WEATHER

The WEATHER setting determines the number of degrees the vessel

may fall off the set course before any response is given to the rudder.

In calm weather it should be set to OFF which means that

theoretically the autopilot allows no deviation from set course. The

WEATHER value should be increased with increasing sea state. This

will cause the sensitivity to be decreased such that the vessel has to

fall off course with the number of degrees selected by the Weather

setting before a rudder command is given. The amount of rudder is

calculated by the heading error exceeding the set limit, multiplied

with the p-factor. This will prevent big rudder amounts and reduce

rudder activity.

In conditions where active steering is required, (e.g. following sea

condition), the value should be reduced.

Press WEATHER, thereafter INCREASE or DECREASE for required

sensitivity.

Range: OFF - 8°. (OFF is max. sensitivity).

Recommended start value: OFF - 3°.

Too little rudder

Too much rudder

Course to steer

Course to steer

Page 36

Robertson AP9 MK3 Autopilot

2-8 20169223D

COUNTER RUDDER

The COUNTER RUDDER

serves two purposes, firstly

to give a smooth transition

to a new heading after a

major course change has

been made, and secondly

to enable the autopilot to

stabilize the vessel on a

straight course. The

steering characteristic of

the autopilot is determined

by the RUDDER and the

COUNTER RUDDER

adjustment.

The effect of the Counter

Rudder is partly determined by the selected Turn

Rate, hence tuning the

Counter Rudder effect also

involves the Rudder

Control.

A too low value results in an overshoot past the new heading and it

takes a long time before the new heading is stabilized.

A value that is too high results in an over correction followed by a

small overshoot past the new heading, and the vessel then tends to

oscillate around the new heading. A typically symptom here is an

over active-rudder.

Range: 0 – 8.0

Recommended start value: 0.6

Page 37

Operation

20169223D 2-9

INFO

The INFO button is used to call up a number of parameters and oth er

information.

The INFO loops can be entered in any autopilot mode. No change

will be made unless the INCREASE or DECREASE button is pressed.

The parameters are divided in two loops, one for the often used

parameters and one for seldom used parameters. The two loops are

entered differently and Loop 2 is mainly for installation set-up.

For detailed description of functions, see page 5-33. Information and

Debug loops.

INFO loop 1:

INFO loop 2:

• Rate of turn or Radius steering • Language

• Turn Rate/Radius • Deadband

• Rudder Limit • Minimum Rudder

• Off course • Serv. speed

• Autotrim • Speed sens.

- Nav. Filter *

• Minimum radius

- Nav. Gain *

• Thruster function

- Nav. Trim * - Only Thruster

• Gyro adjust **

- Only Rudder

• Comp. diff. ***

- Rudder + Thruster

- Thruster deadband

- Minimum thrust

• FU/A Scale

• Maximum rudder limit

• Navigational Mode

- Ecdis

- Priority

- XTE

- CTS

• 1/sec. out

- 5/sec out

• Software version/Runtime

* Only when Nav. Steering is selected.

** Only when step gyro or synchro is selected, not 1:1.

*** Only when two compasses are connected.

To escape from the INFO loops, press any mode or parameter button.

Note ! The INFO display will fall back to show the autopilot mode approximately 1

minute after the last entry of any parameter.

Page 38

Robertson AP9 MK3 Autopilot

2-10 20169223D

Operation, INFO loop 1

Press the INFO button. For adjustment of each parameter use

INCREASE or DECREASE button.

IIIIIIIIIIIIIII

AUTOTRIM 0.5

Press

INFO

III

TURNRATE 40°/m

III

RADIUS nm. 0.15

Press

RATE oT STEERING

CHANGE? INC/DEC

RADIUS STEERING

CHANGE? INC/DEC

Press

IIIIIIIIIIII

OFFCOURSE. L 10°

IIIIIIIIIIIIIIIIIIIIIII

RUDDER LIM. 15°

Press

Range: 1°/min - 360°/min.

Note: The range is limited by "min

radius" val ue in INF O LOO P 2.

Recommended: 40°/min

Range: 0,01 nm - 10 nm

Note: The range is limited by "min

radius" val ue in INF O LOO P 2.

Recommended: 0,1 nm

Press INC or DEC to alter between

ROT and Radi us st eer ing .

This rudder limitation setting is only

active during autosteering on straight

courses, NOT course changes.

Range: 1° - 85°

Recomme nd ed : 15°

Range: 3° - 35°

Recomme nd ed : 10°

(First display rea dout depends on what has been selected by

"Rate of turn (RATEoT) steering /Radius steering", see next parameter.)

Press

Range: OFF - 3,2

Recomme nd ed: 0,5

INFO

INFO

INFO

INFO

Page 39

Operation

20169223D 2-11

COMP. DIFF. 5°

PRESS INC.

IIIIIIIIIIIIIII

NAV. FILTER 1.1

IIIIIIIIIIIIIII

NAV. GAIN 1.0

IIIIIIIIIIIIIII

NAV. TRIM 180s

Press

INFO

INFO

INFO

Press

Press

Only if NAV is selected

and CTS is NOT selected

Range: 1. 1 - 2.5

Recommended: 1.1

Range: OFF - 3,2

Recommended: 1.0

Range: 100s - 1600s

Recomme nded: 180s

Press INC to zero-set the relative

difference between the two

compasses. The a ct ual difference i s

then show n in the di splay.

INFO

Press

Next press repeats the INFO loop 1

INFO loop 2

(For detailed description, see Sea Trial, page 5-62)

To enter this loop, do as follows:

• Press the INFO button and keep it pressed

• Press and release WEATHER button

• Release the INFO button

The display will now show:

* * * * * * *

ENGLISH

This is the language parameter. Use INCREASE/DECREASE to select

the required language. The different options are:

ENGLISH – FRANCAIS – ESPANOL – NORSK

Page 40

Robertson AP9 MK3 Autopilot

2-12 20169223D

IIIIIIIIIIIIIII

SERV. SP 18 Kn

Press

Press

Determ i nes the de adband fo r t h e

feedback loop (rudder hunting)

and also the heading sensitivity

of the autopilot.

Range: 0,2° - 3,4°

Recomme nded: 0,6°

Range: OFF - 10°

Recommended: OFF - 2°

Press

Range: 3 kn - 70 kn

Recommended setting: Ship's cruising

speed.

Press

INFO

INFO

INFO

III

MIN. RUDD 1.5

III

DEADBAND 0.6

Sets the autopilot speed re fe r ence

to the ship's service speed.

Determines the minimum amount

of rudde r as first comm and.

IIIIIIIIIIIIIII

SPEED SENS 0.33

Range: OFF - 1.92

Recomme nded: 0.36

INFO

This se tting scal es the amount of

rudder for speed change (lower

speed, more rudder!)

Press

IIIIIIIIIIIIIII

MIN RADIUS 0.05

Range: 0.01 - 1.10 nm.

Recomm e nd ed : Sh i p de pendent

INFO

This parameter limits the maximum

allowed turnrate setting or the minimum

allowed turn radius that can be set by the

Rate of Turn or Radius steering, selected

in Info loop 1. The setting also depends

on the service speed of the vessel. The

lower speed, the higher turn rate can be

set.

THRUSTER FUNC.

RUDDER+THRUST

IIIIIIIIII

FU/A SCALE: 45°

Range: 45° - 60° - 70° - 90°

Recommended: Set to relevant rudder

scale.

Determines the scaling of the

follow up function.

IIIIIIIIII

MAX RUDDLIM: 44°

Range: 26° - 90°

Recommended: Appr. 5° le ss than

max rudder tr avel.

Sets the absolute maximum

rudder deflection.

Press

INFO

Press

INFO

The thrus ter param eters only appear

if J4, 11-13 "Thruster Ident" on the

control unit are connected (via a switch).

See separate de sc ription .

Page 41

Operation

20169223D 2-13

NAVMODE=PRIORITY

CHANGE? INC/DEC

Range: Priority-XTE-CTS-ECDIS

Recommended: Priority (unless

ECDIS is used)

Selects the Nav. mode function

Press

INFO

1/SEC OUT FREQ.

CHANGE? INC/DEC

Range: 1/sec - 5/sec

Recommended: Refer to equipment

to be interfaced.

Determines the NMEA output rate.

Press

INFO

OFFSET = XXX°

FLUXGATE COMP

Only shown if signal is present on sin/co

s

input or at serial HDM input.

Used when fluxgate compass is

selected as steering compass.

Press

INFO

The next press repeates the

loop, starting with language.

SW ver. mk3 V1R4

RUN: 2d 2h