Page 1

INSTALLATION MANUAL

Robertson RGC12

Gyro Compass

20220737

Page 2

NOTE!

Simrad Robertson AS makes every effort to ensure that the information

contained within this document is correct. However, our equipment is

continuously being improved and updated, so we cannot assume liability

for any errors which may occur.

The information contained within this document remains the sole property

of Simrad Robertson AS. No part of this document may be copied or

reproduced in any form or by any means, and the information contained

within is not to be passed on to a third party, without the prior written

consent of Simrad Robertson AS.

Warning

The equipment to which this manual applies must only be used for

the purpose for which it was designed. Improper us e or

maintenance may cause dama ge to the equipment or injury to

personnel. The user must be familiar with the contents of the

appropriate manuals before attempt ing to operate or work on the

equipment.

Simrad Robertson AS disclaims any responsibility for damage or

injury caused by improper installation, use or ma intenance of the

equipment.

Simrad Robertson AS Telephone: +47 51 46 20 00

Nyåskaien Telefax: +47 51 46 20 01

P.O. Box 55

N-4379 Egersund, Norway

Page 3

Installation Manual

Installation Manual

RGC12 Gyro Compass

This document describes the ins tall ation o f the S imr ad

Robertson RGC12 Gyro Compass and optional

equipment.

20220737B

1

Page 4

Robertson RGC12 Gyro Compass

Document revisions

Rev Date Written by Checked by Approved by

A

B

C

D

04.01.2000 NG VP ThH

04.10.2000 NG TR

Document history

Rev. A This is the first issue

Rev. B Section 5 Optional Equipment included. RGC12 External Wiring Diagram

included.

2

20220737B

Page 5

Installation Manual

Contents

1 INTRODUCTION...........................................................................................................5

2 SPECIFICATIONS ..........................................................................................................6

2.1 RGC12 Master Compass........................................................................................6

Physical Dimensions..............................................................................................6

Power.......................................................................................................................6

Accuracy..................................................................................................................6

Environmental specifications................................................................................6

2.2 RGC12 Control Box................................................................................................7

Physical Dimensions..............................................................................................7

Power.......................................................................................................................7

General specifications............................................................................................7

Special specifications (option) ............................................................................10

Environmental specifications..............................................................................10

2.3 Cables.....................................................................................................................11

3 INSTALLATION........................................................................................................... 12

3.1 General information.............................................................................................12

3.2 Precaution before installation.............................................................................12

3.3 Logistics.................................................................................................................13

3.4 Terminal connector tool...................................................................................... 13

3.5 Caution in Installation.........................................................................................13

3.6 100/110V AC Mains ..............................................................................................15

3.7 Spare parts.............................................................................................................16

4 INSTALLATION DRAWINGS...................................................................................17

5 OPTIONAL EQUIPMENT...........................................................................................23

5.1 DR75 Digital Repeater (NMEA)..........................................................................23

Introduction..........................................................................................................23

Specifications........................................................................................................23

Installation.............................................................................................................24

Controls.................................................................................................................26

Indicators............................................................................................................... 27

Modes.....................................................................................................................27

Flashing LCD display ..........................................................................................27

5.2 RSR68 Steering Repeater (Step)..........................................................................28

20220737B

3

Page 6

Robertson RGC12 Gyro Compass

Introduction..........................................................................................................28

Specifications........................................................................................................28

Installation.............................................................................................................29

5.3 RSR77 Steering Repeater (Step)..........................................................................31

Introduction..........................................................................................................31

Specifications........................................................................................................31

Installation.............................................................................................................32

5.4 RP-41-1 Bearing Repeater....................................................................................34

Specifications........................................................................................................34

MB Repeater Holder............................................................................................35

BH Repeater Stand...............................................................................................36

Bearing Repeate r Connection.............................................................................37

5.5 Change Over Unit................................................................................................ 38

Specifications........................................................................................................38

4

20220737B

Page 7

1 INTRODUCTION

This document describes the installation of the Robertson

RGC12 Gyro Compass.

The compass consists of the Master Compass with Sensitive

Element and Control Box.

The gyrocompass RGC12 is a system to detect and display true

heading necessary for navigation and output data to external

equipment. It has been designed for medium and large vessels

and provides high accuracy and reliability on the basis of the

TG-5000 series gyrocompass which has been installed on more

than 5000 vessels.

The Control Box contains all interfaces to external equipment, as

well as connection to the Master Compass. Power for the gyro

system is also terminated in the unit.

Installation Manual

Note ! The guidelines for installation presented here must be regarded as a

base for detailed plans prepared by the installation shipyard. These

plans must include drawings, instructions and procedures specific to

the ship in which the equipment is to be installed . These drawings must

be approved by the local maritime classification society.

Simrad Robertson AS accepts no responsibility for any damage

or injury to the system, ship or personnel caused by drawings,

instructions or procedures not prepared by Simrad Robertson

AS.

20220737B

5

Page 8

Robertson RGC12 Gyro Compass

2 SPECIFICATIONS

2.1 RGC12 Master Compass

Physical Dimensions

Height:.........................................................................432 mm (17,0”)

Width:..........................................................................360 mm (14,2”)

Depth:..........................................................................358 mm (14,1”)

Weight:........................................................................... 25 kg (55 lbs)

Power

Voltage input:........................................Supplied from Control Box

Accuracy

Settling time:..Within 4 hours

(at lat. 35° when starting from deviation angle of

within 30°)

Within 2 hours

(at lat. 35° when starting from deviation angle of

within 5°)

Settle point error:.............................................. ±0.3º x sec. latitude

Standard deviation:..............................................0.1º x sec. latitude

Repeatability:.±0.2°x sec. latitude

Roll and pitch error:..........................................±0.5° x sec. latitude

Accuracy for environmental change:..............±0.5° x sec. latitude

Speed error correction accuracy.......................±0.2 x sec. latitude

Environmental specifications

Enclosure material:..........................................................Aluminium

Enclosure protection:.................................................................. IP22

Operational temperature range:.................................–10°C to 50°C

Storage temperature range:.........................................–25°C to 70°C

Maximum storage period: (recommended temp. +5 - +35°C) 1 year

With reference to the Kongsberg Simrad Environmental

Specification, the following exceptions and additions comply:

IEC Publication: 68-2-1 ref. EN 60945

6

20220737B

Page 9

Installation Manual

68-2-2 ref. EN 60945

68-2-6 ref. EN 60945

68-2-27 Not tested.

68-2-30 ref. EN 60945

68-2-32 Not applicable ref. EN 60945

68-2-52 ref. EN 60945

157-1 Not tested

Note ! The equipment is approved according to the European Marine

Directive 96/98/EC (Wheel mark) which incorporates the European

Norm EN 60945 (IEC 945 3rd revision).

2.2 RGC12 Control Box

Physical Dimensions

Height:.........................................................................570 mm (22,4”)

Width:..........................................................................334 mm (13,1”)

Depth:............................................................................182 mm (7,2”)

Weight:......................................................................16,5 kg (36,3 lbs)

Power

Voltage input:.................100/110/220 VAC, single phase, 50/60 Hz

Power consumption:.............................................140 VA (Starting)

70 VA (Running)

Emergency power supply:....................................................24 VDC

140 W (Starting)

70 W (Running)

General specifications

Repeater type:.................. Step-motor type (24VDC 1 step = 1/6°)

Number of repeater ports:................................................................9

(also possible to connect load of max

24V DC 8.5A)

20220737B

Follow up rate (master compass):..................30°/sec. (360°/12 sec.)

Angular freedom of gimbal:........................±45° for roll and pitch

Latitude error correction:....................................Automatic 0° ∼ 70°

7

Page 10

Robertson RGC12 Gyro Compass

Speed error correction: .............. Automatic

Speed input signal: .......................................................Pulse signal

Digital output - 1

Serial signal ports:..............................................................................8

Electrical specification:........................................ RS422/NMEA0183

Baud rate:....... ..........................................................4800 bits/second

Data length:... .............................................................................8 bits

Parity:............. ............................................................................None

(200 pulse/mile is input)

(GPS input)

or manual

0 ~ 50 Knots settable

Only the repeater compasses

are corrected

(200 pulses/nm dry contact point) or GPS.

Stop bit:.......... ...............................................................................1 bit

Transmission rate:..........................................................1x/5x second

Output format:

$HEHDT, xxx. x, T*hh<CR><LF>

True heading (degree)

$HEROT, –xxx. x, A*hh<CR><LF>

Turning rate

Turning direction: CW (space), CCW (–)

$PTKM, HEALM, xxx. x, *hh<CR><LF>

Alarm group

Appears every 2 seconds.

Digital output - 2

Serial signal ports:..............................................................................4

Electrical specification:....................RS422 (Tokimec specification)

Baud rate:....... ..........................................................9600 bits/second

Data length:... .............................................................................8 bits

Parity:............. ............................................................................None

Stop bit:.......... ...............................................................................1 bit

8

20220737B

Page 11

Installation Manual

Transmission rate:........................................... 50 msec (20x/second)

Output format:

STXKxxx. x, Lxx. x

, R–xxx. xETX

True rate

Turning direction: CW (space)

CCW (–)

Speed L=Log

P=GPS

M=Manual

True heading

$PTKM, HEALM, XYYY, Z*hh

<or><LF> (every 2 sec.)

Checksum

Alarm group

Analogue signal – 1

Turn rate ports:..................................................................................3

–5 to +5 V (±30°/min) + --- CW turn

– --- CCW turn

Analogue signal – 2

Turn rate scale-over ports:................................................................3

±30°/min or more ±5 V + --- CW turn

– --- CCW turn

GPS input signal (for latitude, speed signals)

Serial signal port:...............................................................................1

Electrical specification:.........................RS422/NMEA0183

The Tokimec specifications are as follows:

Baud rate:..................................................4800 bits/second

Data length:..................................................................8 bits

Parity:...........................................................................None

Stop bit: ...........................................................................1 bit

Transmission rate:........................................................1 sec

20220737B

9

Page 12

Robertson RGC12 Gyro Compass

Input format:

$GPGLL, xxxx.xx, Nxxxxx.xx, E*hh<CR><LF>

$GPVTG, xxx, T, xxx, M, xx.x,N,*hh<CR><LF>

Special specifications (option)

Repeater backup signal

24 VDC 1/6° step

3 circuits max. 2.5 A.

Optional output signals

ADD PCB

Additional 6 ports 24V DC stepper output

OPS PCB

Latitude Longitude

Heading (COG), Speed (SOG)

Additional 2 ports 35 VDC stepper output

(OPS PCB can not be installed if an ADD PCB is installed.)

Environmental specifications

Enclosure material:..........................................................Aluminium

Enclosure protection:.................................................................. IP22

Operational temperature range:.................................–10°C to 50°C

Storage temperature range:.........................................–25°C to 70°C

With reference to the Kongsberg Simrad Environmental

Specification, the following exceptions and additions comply:

IEC Publication: 68-2-1 ref. EN 60945

68-2-3 ref. EN 60945

68-2-6 ref. EN 60945

68-2-28 Not tested.

68-2-30 ref. EN 60945

68-2-33 Not applicable ref. EN 60945

68-2-53 ref. EN 60945

157-1 Not tested

Note ! The equipment is approved according to the European Marine

Directive 96/98/EC (Wheel mark) which incorporates the European

Norm EN 60945 (IEC 945 3

10

rd

revision).

20220737B

Page 13

2.3 Cables

No cables are included with the RGC12 delivery.

See Figure 4-5 for cable connections.

Note ! Check with supplied cable drawings.

Installation Manual

Cable

no.

Minimum conductor

requirement - mm

2

or equivalent

Type of cable

Maximum

cable length

Remarks

12 x 1.5 + E AWG15 RCOP -

22 x 1.5 AWG15 RCOP - Shielded

32 x 0.5 AWG20 RCOP 1 km Shielded

42 x 1.5 AWG15 RCOP 13 m Shielded

53 x 0.5 AWG20 RCOP 13 m Shielded

64 x 0.5 AWG20 RCOP 13 m Shielded

Cable Specification List (Ref. Figure 4-5)

20220737B

11

Page 14

Robertson RGC12 Gyro Compass

3 INSTALLATION

3.1 General information

The RGC12 Gyro Compass, part no. 44166585, is shipped in a

cardboard container that includes the following parts:

• RGC12 Master Compass P/N 44174001

• RGC12 Master Compass Sensitive Element P/N 44174019

• RGC12 Control Box P/N 44174027

• Spare Part and Tool Box

• RGC12 Instruction Manual P/N 20220679

• RGC12 Installation Manual P/N 20220737

• Warranty Card

If optional PCBs have been ordered, they are mounted in the

RGC12 Master Compass before shipment. (Refer to Packing

List).

3.2 Precaution before installation

For details of equipment dimensions and layout, see Figure 4-1 Figure 4-4.

The Sensitive Element is packed in foaming styrol, for

protection against vibration and shock, in a separate package.

Caution ! Only people authorized by Simrad or Kongsberg Simrad should

mount the Sensitive Element in the Master Compass.

Make sure that the delivered equipment is free from damage

before starting the installation. Check:

1. Model of equipment

2. Ship’s power supply

12

20220737B

Page 15

3.3 Logistics

Safety: Refer to general safety procedures

Personal qualifications : Trained mechanical workers

Minimum number of personnel: 1

Ship location: No recommendations

Special tools required: Terminal connector tool supplied

with equipment

3.4 Terminal connector tool

All terminal connections are by self locking crimp terminals.

A special connector tool is located in a plastic bag inside the

Control Box.

Insert the tool such that the hook enters the slot above the cable

entry. Press down the shaft to open the wire lock mechanism

and insert the wire. Release the pressure and lift out the tool.

The wire is now locked and secured.

Installation Manual

3.5 Caution in Installation

1. Install the RGC12 Master Compass so that horizontal base

datum lines coincides with the ship’s fore and aft line. See

Figure 4-1, page 17.

2. Ensure that the service space shown in the installation

drawing is provided. See Figure 4-2, page 18.

3. Install the RGC12 Control Box at a convenient place easy

to operate and easy to access for inspection and service.

4. Since the spring-pressure type terminal boards are

applied in the Control Box for cable connections, do not

connect several wires to one terminal.

20220737B

13

Page 16

Robertson RGC12 Gyro Compass

5. The safe distance for magnetic compass is clearly shown

on each unit. Install units in accordance with these safe

distances.

6. Be sure to install the recommended cables separated

according to the function of each cable, as shown by

separate cable list or inter unit wiring diagram (see Figure

4-5, page 21).

7. Be sure to install all the equipment cable more than 5 m

away from radio equipment feeders if possible.

8. Connect terminals marked with

to the ground

terminals of the ship. Shield end of shield cable is to be

finished close to the terminal board and connect to the

ground terminals of the ship.

9. Armour of cable end for the master compass should be

finished 20~30 mm before the cable entrance for easy

connecting to terminals.

10. Since semiconductor elements are used in the equipment.

do not use a megger for any test.

11. Any shipyard that installs this equipment for the first

time should be given instructions by Simrad or

Kongsberg Simrad service engineers.

14

20220737B

Page 17

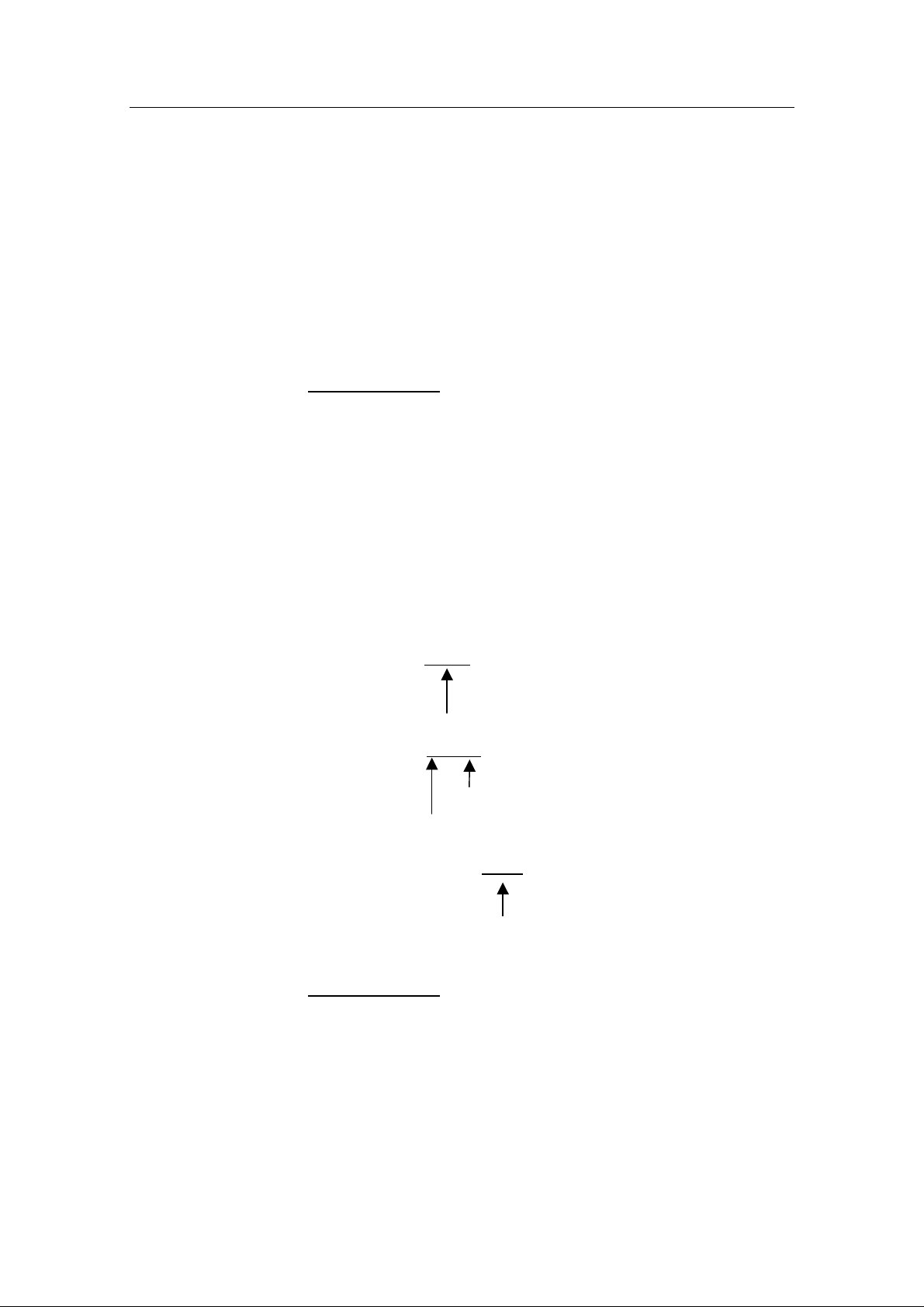

3.6 100/110V AC Mains

The Gyrocompass is pre-wired for connection to 220V AC

Mains. If the Gyrocompass is connected to 100/110V AC Mains

the following jumpers must be connected in the Control Box.

Refer to Figure 3-1.

1. On the Power PCB connect the Jump er J1.

2. On the Term PCB connect the Jumper J3.

Installation Manual

CONTROL BOX

POWER PCB

J1

TERM PCB

J3

OPT PCB

Make a jumper at

J1 and J3 when

connecting to

100/110V AC

Figure 3-1 Jumper connection for 100/110V AC Mains supply

20220737B

15

Page 18

Robertson RGC12 Gyro Compass

3.7 Spare parts

The Spare Part and Tool Box contains the following:

Item no. Name of part Quantity

For Master Compass

1

2 Fuse 125V, 20A (32x6mm) 2

3 Fuse 250V, 6,3A (32x6mm) 2

4 Fuse 125V, 1A (20x5mm) 18

5 Terminal connector tool 1

6 Fuse 125V, 1A (20x5mm) 12

Fuse 250V, 15A (32x6mm)

For Control Box

For Control Box, Optional Board

2

16

20220737B

Page 19

4 INSTALLATION DRAWINGS

Top view

m

m

8

5

3

360 mm

Installation Manual

Front view

328 mm

Right side

m

m

2

3

4

20220737B

Aft datum line

Figure 4-1 Master Compass Dimensions

17

Page 20

Robertson RGC12 Gyro Compass

18

Figure 4-2 Master Compass Installation outline

20220737B

Page 21

Installation Manual

m

m

0

7

5

334 mm

182 mm

Figure 4-3 Control Box Dimensions

20220737B

19

Page 22

Robertson RGC12 Gyro Compass

20

Figure 4-4 Control Box Installation outline

20220737B

Page 23

Installation Manual

20220737B

Figure 4-5 RGC12 Inter Unit Wirin g Diagram (N3-082190)

21

Page 24

Robertson RGC12 Gyro Compass

22

Figure 4-6 RGC12 External Wirin g Diagram (N3-082093C)

20220737B

Page 25

5 OPTIONAL EQUIPMENT

5.1 DR75 Digital Repeater (NME A)

Introduction

DR75 is a four digit, digital heading repeater. It is pow ered from

24 VDC, which is derived from the ships supply. Power

consumption is low typically 10 watts.

The display gives a resolution and an accuracy to one tenth of a

degree. The display is visible to three meters over an arc of

ninety degrees from its centre.

The repeater can either be console mounted or bulkhead

mounted with its supplied trunnion bracket.

The internal components are housed in a robust splashproof

aluminium enclosure.

Installation Manual

In addition to the heading display this repeater has an

additional display which can be used to indicate rate of turn or

to indicate the desired course to be steered. These features are

selectable by buttons on the front.

Specifications

Overall Dimensions

Height:.......................................................................................97 mm

With:........................................................................................192 mm

Depth: …37 mm (110 mm allowing for plug and cable clearance)

Weight (nominal):......................................................................1.2 kg

Mounting options:...............................................Panel or Bulkhead

Finish:............................... Light Weather-work Grey (BS3816-676)

Construction:.............................................Aluminium splash proof

Compass safe distance:.................................................................2 m

Electrical

20220737B

Power supply:.........................................................24 VDC 10 watts

Data input:.........................................$HEHDTXXX.X<CR><LF>

23

Page 26

Robertson RGC12 Gyro Compass

Operational Features

Dynamic performance:

The Display has a resolution of one tenth of a degree and will

retain alignment for rates in excess of 12 degrees per second.

Environmental specifications

Splash proof to:............................................................................ IP33

Temperature:.................................................................-15°C to 45°C

Humidity:..............................................................0% to 95% at 40°C

Vibration:..............................................................1-12.5 Hz ±1.6 mm

Magnetic Permeability:….Cat. A (Acceptable for embarkation

12.5 – 25 Hz ±0.38 mm

25HZ – 50 Hz ±0.1 mm

within volumetric allowances.

Installation

General Information

Upon receipt, carefully inspect the packaging for any signs of

damage. Record any damage if evident for future reference or

action.

Carefully unpack and examine all enclosed items as listed in the

accompanying shipping note. Retain the packaging materials

for possible future use.

Mounting Instructions

Visually inspect the installation site for the following (Refer to

Figure 5-2 DR75 Digital Repeater - Dimensions, page 26):

• There is adequate shock clearance around the position

where the repeater is to be sited.

• The mounting arrangement is such that the repeater is at a

convenient level for viewing and or operating purposes.

• Sufficient accessibility must be provided to enable the

repeater to be removed from the mounting position for

servicing purpose.

24

• Adequate space for removal of the plug exists when the

repeater is permanently mounted and to facilitate the

routing of the power and data cable.

• Fix the repeater mechanically in to position ready for

electrical connection.

20220737B

Page 27

Installation Manual

Electrical Installation

Caution ! Application of any voltage supplies other than those stipulated in

the product specific ation may cause damage to the rep eater.

DR75 are connected to the ships cabling by a supplied prewired D-type connector and a 2.5 m (8’) six core screened cable.

The D-type connector plugs directly into the repeater to make

maintenance and servicing easier. The cable is connected to the

Ship’s Data Cable. It is recommended that a suitable junction

box (not supplied), is used for this purpose.

Connect ships core to repeater cores according to the diagram

below.

Figure 5-1 DR75 connection diagram

20220737B

25

Page 28

Robertson RGC12 Gyro Compass

26

Figure 5-2 DR75 Digital Repeater - Dimensions

(Drw. N4-710311B)

Controls

The DR75 has three button controls. The first two are used to

Dim the horizontal LED bar graph display and control the back

lighting to the LCD display.

The third switch is used to mark or ‘SET’ a course that is to be

steered to. This is depressed when the desired heading to be

steered to is reached. When the correct course is being steered

all the indicators are unlit. With each degree steered off-course

the appropriate left or right LED is lit until this ship is on-course

and all LED’s are unlit.

20220737B

Page 29

Installation Manual

Indicators

The DR75 has two indicators. One is a four digit liquid crystal

display which displays input heading received from the

transmitting device e.g. Gyro. The second is a horizontal LED

bar graph display that is used either as a rate of turn indictor or

as a steering indicator to show how far of a set course the v essel

is.

Modes

The repeater’s LED bar graph display has three modes of

operation. Modes are selected by depressing both the set switch

and the Dim bar digit simultaneously and is cycled until you

release both switches when the desired mode of operation is

indicated on the LCD display (0, 1 and 2).

The first two modes (0 and 1) are used to select the bargraph

display to act as a rate of turn indicator with a cou rse and fine

setting. This is particularly useful when docking manoeuvres

are taking place.

The third mode of operation selects the bargraph display to act

as a set steering display. The set switch is depressed w hen the

desired heading to be steered to is reached. When the correct

course is being steered all the indicators are unlit. With each

degree steered off-course the appropriate left or right LED is lit.

The further off the desired course more LED’s are lit until this

ship is on-course and all LED’s are unlit.

Flashing LCD display

If for any reason the heading display starts to flash this indicates

that the data signal which is being sent by the transmitting

device is either not present or not correct. This must be

investigated further.

If the repeater is presented with a correct NMEA 0183 sentence

but not being true heading (HDT), the display will still flash. If a

magnetic heading is presented (HDM), the repeater will display

the heading, but will still flash and respond slowly. The LED bar

graph will not respond.

20220737B

27

Page 30

Robertson RGC12 Gyro Compass

5.2 RSR68 Steering Repeater (Step)

Introduction

The RSR steering repeater satisfy a number of applications

where accurate repetition of ships heading is displayed for

pilotage or navigation purpose.

The display consists of an electro-mechanically driven compass

card graduated in degrees. A lubber line is provided at the 000

degree mark

Interface between the display and the ships system is through a

cable, which may be terminated via a suitable junction box.

Alignment and dimming facilities are provided through a

membrane keypad on the front of the steering repeaters.

Specifications

Overall dimensions:.................................................... 215 x 215 mm

Card diameter:.......................................................................165 mm

Depth: .................................. 125 mm allowing for cable clearance)

Weight (nominal):......................................................................2.8 kg

Mounting options:.............................. Trunnion or Panel mounted

Finish:.............................................................Satin black (RAL 9005)

Compass safe distance:.................................................................2 m

Electrical

Power supply:.....................From gyro supply 24V, 35V, 50V, 70V

positive or negative common.

Overvolt protection:..... Continuous 25%. Transient (100ms) 35%

Data input:........................... 6 steps per degree24V, 35V, 50V, 70V

positive or negative common.

Data line current:......................................................................20 mA

Power line current:.................................................................500 mA

Operation

Display alignment: Continuous speed; one revolution

(360°); per 20 seconds.

Display illumination: Push button operated providing 70

degrees back illumination to compass

card and lubber line.

28 20220844B

Page 31

Installation Manual

Dynamic limits: Alignment is retained with heading

change rates of up to 12 degrees per

second.

Performance accuracy: Indicates the transmitted heading in 1

degree scale graduations in steps of 1/6

degree resolution.

Environmental specifications

Protection:..................................................................................... IP54

Temperature:.............................................................–20°C to +60°C

Humidity:..............................................................0% to 95% at 40°C

Noise:...........................................................Not greater than 65 dbA

Installation

General Information

Upon receipt, carefully inspect the packaging for any signs of

damage. Record any damage if evident for future reference or

action.

Carefully unpack and examine all enclosed items as listed on

the accompanying shipping note. Retain the packaging

materials for possible future use.

Mounting Instructions

Install the Repeater as follows (Refer to Figure 5-3 RSR68

Steering Repeater - Dimensions):

• Site the RSR68 at the position selected for installation.

Ensure suitable shock clearance.

• Prepare for trunnion or panel mounting.

Electrical Installation

Wire the repeater as follows:

• Ensure that all supplies to the ships data cable are isolated

before continuing.

• Using suitable crimp terminals. Terminate the repeater to

the ships cable via junction box.

20220844B 29

Page 32

Robertson RGC12 Gyro Compass

• For common negative steps connect polarity to –Vdc. For

common positive steps connect polarity to +Vdc.

RED: +24, 35, 50 or 70VDC

BLACK: –VDC

GREEN: L1

BLUE: L2

WHITE: L3

VIOLET: Polarity

GRN/YELL: Chassis

Figure 5-3 RSR68 Steering Repeater - Dimensions

(Drw. N4-710300)

30 20220844B

Page 33

5.3 RSR77 Steering Repeater (Step)

Introduction

The RSR steering repeater satisfy a number of applications

where accurate repetition of ships heading is displayed for

pilotage or navigation purpose.

The display consists of an electro-mechanically driven compass

card graduated in degrees. A lubber line is provided at the 000

degree mark

Interface between the display and the ships system is through a

cable, which may be terminated through a suitable junction box.

Alignment and dimming facilities are provided through a

membrane keypad on the front of the steering repeaters.

Specifications

Overall dimensions:.................................................... 196 x 196 mm

Installation Manual

Card diameter:.......................................................................120 mm

Depth: ………...................... 125 mm allowing for cable clearance)

Weight (nominal):......................................................................2.2 kg

Mounting options:.............................. Trunnion or Panel mounted

Finish:.............................................................Satin black (RAL 9005)

Compass safe distance...................................................................2 m

Electrical

Power supply:.....................From gyro supply 24V, 35V, 50V, 70V

positive or negative common.

Overvoltage protection: Continuous 25%. Transient (100ms) 35%

Data input:........................... 6 steps per degree24V, 35V, 50V, 70V

positive or negative common.

Data line current:......................................................................20 mA

Power line current:.................................................................500 mA

Operation

Display alignment: Continuous speed; one revolution

(360°); per 20 seconds.

Display illumination: Push button operated providing 70

degrees back illumination to compass

card and lubber line.

20220844B 31

Page 34

Robertson RGC12 Gyro Compass

Dynamic limits: Alignment is retained with heading

Performance accuracy: Indicates the transmitted heading in 1

Environmental specifications

Protection:..........................................................................Front: IP66

Back: IP54

Temperature:.............................................................–20°C to +60°C

Humidity:..............................................................0% to 95% at 40°C

Noise:...........................................................Not greater than 65 dbA

Installation

change rates of up to 12 degrees per

second.

degree scale graduations in steps of 1/6

degree resolution.

General Information

Upon receipt, carefully inspect the packaging for any signs of

damage. Record any damage if evident for future reference or

action.

Carefully unpack and examine all enclosed items as listed on

the accompanying shipping note. Retain the packaging

materials for possible future use.

Mounting Instructions

Install the Repeater as follows (Refer to Figure 5-4 RSR77

Steering Repeater - Dimensions):

• Site the RSR77 at the position selected for installation.

Ensure suitable shock clearance.

• Prepare for trunnion or panel mounting.

Electrical Installation

Wire the repeater as follows:

• Ensure that all supplies to the ships data cable are isolated

before continuing.

• Using suitable crimp terminals. Terminate the repeater to

the ships cable via junction box.

• For common negative steps connect polarity to –VDC. For

common positive steps connect polarity to +VDC.

RED: +24, 35, 50 or 70VDC

BLACK: VDC

GREEN: L1

BLUE: L2

32 20220844B

Page 35

WHITE: L3

VIOLET: Polarity

GRN/YELL: Chassis

Installation Manual

Figure 5-4 RSR77 Steering Repeater - Dimensions

(Drw. N4-710292)

20220844B 33

Page 36

Robertson RGC12 Gyro Compass

5.4 RP-41-1 Bearing Repeater

Specifications

Weight:........................................................................................4.5 kg

Input voltage:.......................................................................... 24VDC

Step voltage:............................24VDC 0.3A/phase (6 steps/degree)

Illumination:....................................................................24VDC 0.1A

Compass safe distance:..............................................................0.5 m

Figure 5-5 RP-41-1 Bearing Repeater - Dimensions

(Drw. N4-710302A)

34 20220844B

Page 37

MB Repeater Holder

Installation Manual

Weght: 3.1 kg

Figure 5-6 MB Repeater Holder – Dimensions

(Drw. N4-710304)

20220844B 35

Page 38

Robertson RGC12 Gyro Compass

BH Repeater Stand

Figure 5-7 BH Repeater Stand - Dimensions

(Drw. N4-710292)

36 20220844B

Page 39

Bearing Repeater Connection

Installation Manual

Figure 5-8 Bearing Repeater Connection Diagram

(Drw. N4-710305A)

20220844B 37

Page 40

Robertson RGC12 Gyro Compass

5.5 Change Over Unit

Specifications

1. Main power supply: ................................................100/220VAC 1Φ 50/60 Hz, 16.5VA

2. Emergency power supply: .........................................................................24VDC, 13.5W

3. Output: ..........................................Real load repeater 1/6° 24VDC 9 circuits 8.5A max.

Digital: 1) Tokimec proprietary/RS422

(True bearing/Speed/Rate of turn)............................................x 4 ports

2) NMEA0183/RS422 (True bearing/Rate of turn)......................x 8 ports

Analogue 1) Rate of turn -5 through +5V (30°/min)......................................x 3 ports

Scaleover Greater than ±30°/min ±5V......................................x 3 ports

2) Rate of turn -10 through +10V (120°/min)................................x 3 ports

Scaleover Greater than ±120°/min ±5V....................................x 3 ports

(Analogue (2) is since SCU Ver. 1. 18. )

Note ! Analogue output (1) and (2) cannot be output simultaneously.

Repeater backup 1/6° 24VDC 3 circuits 2.5A max.

4. Indication 7 segments: No. 1 True bearing / No. 2 True bearing / Deviation /

Deviation alarm setting / No. Alarm / No. 2 Alarm

5. Power supply specifications:

Model No. Manufacturer Primary (input) Secondary (output)

PS101 WRB24SK ETA

PS102 VTM-01C-24 ETA 19-32VDC +5VDC±0.3V

PS103 VTM-01C-24 ETA 19-32VDC +5VDC±0.3V

6. Input : The following input signal must be applied to each gyro-compass of

No. 1 and No. 2.

85-264VAC 1Φ

47-440 Hz

24VDC±1V

+12VDC±0.5V

-12VDC±0.5V

+12VDC±0.5V

-12VDC±0.5V

Analogue signal 200 pulse/nm dry contact......................................................x 1 port

Digital signal (GPS) RS422/NMEA0183 (Latitude/Longitude/Speed) .......x 1 port

38 20220844B

Page 41

Installation Manual

Figure 5-9 Change Over Unit (Bulkhead Type) Outline

20220737B 39

Page 42

Robertson RGC12 Gyro Compass

Figure 5-10 Change Over Unit (Flush type) Outline

40 20220737B

Page 43

Installation Manual

Figure 5-11 Change Over Unit - Wiring Diagram

(N3-082462A)

20220737B 41

Page 44

Robertson RGC12 Gyro Compass

42 20220737B

Loading...

Loading...