Page 1

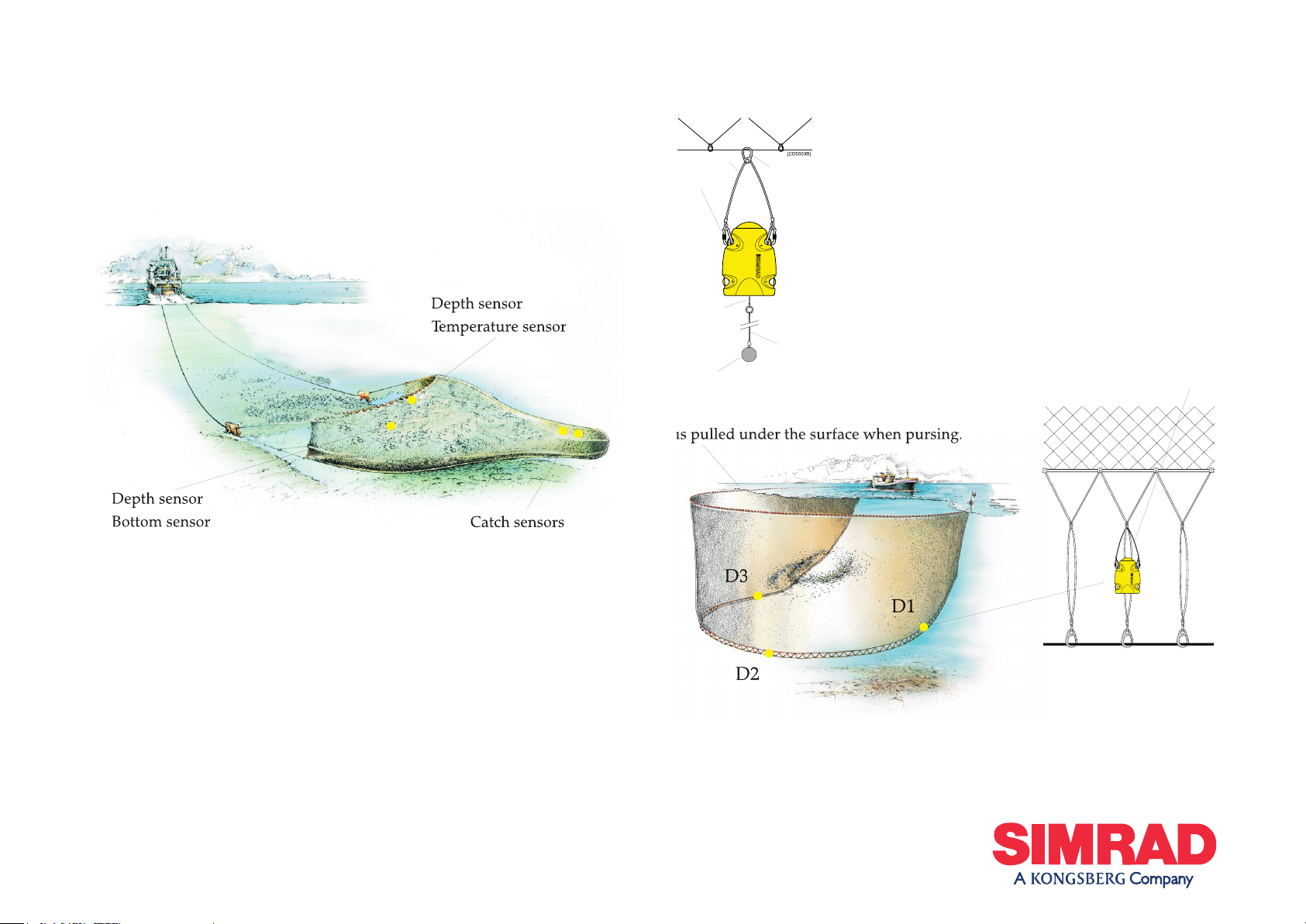

The system below is configured for use with trawls and purse seines. It may

also be employed with Danish purses, pelagic trawls or other types of gear that

require depth, temperature, bottom contact and catch monitoring.

of sensors attached to towed gear should be toward the mother

vessel. Coverage is optimized when the tops of the sensors are oriented toward

the hydrophone mounted on the vessel’s hull.

will normally change status until the quantity of fish caught

is reasonably large. Once the cod-end fills, its natural tendendcy to become “pear

losing or generating unstable communication. This phenomenon is often

experienced just before the next proceeding catch sensor is activated.

Mounting -

and protection of sensors is very important. Sensors attached to

head- or footropes are best protected when sewn in bags designed for that

purpose. Sensors attached to trawling gear should be firmly secured at their

forward ends and drawn aft so that they lay horizontally when towed. Sensors

attached to towed purse seining gear should be allowed to hang as freely as

possible and point vertically when pursing.

of the fishing operation is achieved with three sensors

marked correspondingly with D1, D2 or D3 and attached to the purse seine as

illustrated. Make sure that the attachment locations chosen will not subject the

when sensors pass through the powerblock.

Tuna purse -

attach sen-

to the Instruction manual

for details.

D3

D1

D2

Depth sensor

Temperature sensor

Depth sensor

Bottom sensor

Monitoring

- sensors are preferably attached to the purse

wire with a purse ring or alternatively, as show here, to

the bridle. Sensors must be allowed to hang as freely as

possible so that they point vertically when pursing.

Sensors can be attached to the headwire to warn if it

is pulled under the surface when pursing.

Bottom sensors -

are attached to the purse wire using a

purse ring, wire strop and two karabiners. A weight of

approximately 4.5 kg (or another purse ring) is attached

to the sensors’ detector wire with a flexible, thin rope. The

total length of the strop, sensor, detector wire and rope

thread the weight on the ring needle (but not

around the purse wire) so that the bottom sensor will

be deployed first. The weight must hang freely and sink

clear of other gear so that it may activate the sensor when

bottom contact is made.

Weight

Detector

wire

Rope

Strop

Karabiner

Purse

ring

Page 2

cm in length that will securely hold the bottom sensor in a stable position.

2.) Bend the penetration ring for the detection wire about 30 cm below the footrope as illustrated. Attach

the bottom sensor and check that its detection wire passes through the centre of the penetration ring.

Remove the netting on the inside of the penetration ring.

3.) Attach the rubber strops so that the bottom sensor is held horizontally when towed.

torn off during fishing operations. The sensor’s detection wire must always be allowed to pass freely

through the centre of the penetration ring when it is deployed.

bottom sensors can detect bottom contact with a

precision of just a few centimeters when correct stay and

mance requires that these lengths are configured with regard

to both each other and the gear in use (the standard delivery includes a 63 cm stay and 39 cm detection chain

for use with 14 to 16 inch bobbins or rock hoppers).

the desired bottom detection distance is relative to the diameter of the rock hoppers,

bobbins or other gear in use. This relationship can be determined and precise stay and detection chain

length adjustments made as described below.

- lay the bottom sensor on an elevated surface and observe detection wire movement while simulating

bottom contact by raising the weight. Adjust the detection chain length as necessary. Tilt the weight

approximately 25°(

α

is due to drag through the water) opposite the towed direction and adjust the stay

length so that it begins to be taught. Avoid extra links at the weight ends when shorting chains.

before they transit the drum when hauling to prevent damage.

attach the sensor at the top of the cod-end, closest to where

the catch is to be monitored. As the cod-end fills the net’s mesh will

become taught and activate the catch sensor.

Attachment -

the catch sensor’s orientation toward the mother vessel is

maintained by the steel/nylon attachment rings, strops and karabiners

bent to the net. The number of mesh squares the sensor is supported

between must be restricted to avaoid unnecessary stress on the gear

when the net is filled to maximum capacity. Note that both steel

attachment rings must be located on the same side of the sensor.

is determined by the number of mesh squares separating

the two rubber strops (a larger number increases sensitivity, a smaller

reduces it). Simulate sensor activation by stretching the net’s mesh to

approximate the load generated by a full catch. Experiment accordingly

to determine the correct attachment points and then permanently

mark their locations for future reference.

are subject to heavy loading/wear; they should be

changed at regular intervals and checked before shooting. Strops with

cracks or visible signs of damage should be change immediately.

to a net with an approximate mesh size of 140

mm is illustrated below. The distance between the anchor points for

the attachment rings and rubber strops will vary according to mesh

Vessel

Karibiner and

Nylon

attachment rings,

bent to the netting

attachment rings,

bent to the netting

Rubber strop

Karabiner

Detector wires

Rock hopper,

bobbins, etc.

Attachment ring for the

stay bent securely to the

Karabiners are bent securely to the “top” of the footrope. If the bottom sensor is

attached to the wings, the length of the lashings must be adjusted so that the sensor

points toward the mother vessel when towed.

Penetration ring for

the detection wire.

Weight and stay hang

freely under the trawl.

Touch Down

Detection

wire

Detection

chain

Weight

Stay

Rock hopper

30 cm

Bottom

End link

Note 1

Note 1

Note 1:

The stay can also be attached to the steel spacer between the bobbins/rock

hopper if the footrope is held fairly stable relative to the gear.

Loading...

Loading...