Page 1

Instruction manual

Simrad ITI Trawl System

Serial data communication and

NMEA 0183 message description

111110 10 00101 0101 010

010101001 00010100011

010101010 00101010100

10101001100001111.................

Page 2

Page 3

Simrad ITI Trawl system

Serial data communication and

NMEA 0183 message description

Instruction manual

857--164777 / Rev.A

Page 4

Note

Simrad AS makes every effort to ensure that the information contained within this

document is correct. However, our equipment is continuously being improved and

updated, so we cannot assume liability for any errors which may occur.

Warning

The equipment to which this manual applies must only be used for the purpose for which

it was designed. Improper use or maintenance may cause damage to the equipment or

injury to personnel. The user must be familiar with the contents of the appropriate manuals

before attempting to operate or work on the equipment.

Simrad AS disclaims any responsibility for damage or injury caused by improper

installation, use or maintenance of the equipment.

Copyright

E 2003 Simrad AS

ISBN 82-8066-013-5

The information contained within this document remains the sole property of Simrad AS.

No part of this document may be copied or reproduced in any form or by any means, and

the information contained within is not to be communicated to a third party, without the

prior written consent of Simrad AS.

Support

For support on your Simrad equipment, consult your local dealer, visit www.simrad.com,

or contact us directly at support.fish@simrad.com.

Simrad AS

Strandpromenaden 50

Box 111

N-3191 Horten

Telephone: +47 33 03 40 00

Facsimile: +47 33 04 29 87

A L W A Y S A T T H E F O R E F R O N T O F T E C H N O L O G Y

Page 5

Sections

This book is the Instruction manual manual for the ITI system.

1INTRODUCTION

Instruction manual

2

3

ITI TRAWL SYSTEM, BASIC PRINCIPLE

ITI GEOMETRY FOR TWIN RIG

4 RESPONSIBILITY

5 SERIAL LINES

6 NMEA 0183 MESSAGES, DEFINITIONS

7NMEA–

ABBREVIATIONS, ITI AUX MENU SELECTIONS

(Cd6911)

M/S simrad Echo, our research and demonstration vessel

857-164777 / A

I

Page 6

Simrad ITI

Remarks

References

Further information about the ITI system supplied may befound in the following manual s:

• ITI Installation manual

• ITI Trawl Eye Instruction manual

II

857-164777 / A

Page 7

Instruction manual

Contents

1INTRODUCTION 1..........................................

2 ITI TRAWL SYSTEM, BASIC PRINCIPLE 2................

3ITIGEOMETRYFORTWINRIG 3..........................

4 RESPONSIBILITY 5........................................

5 SERIAL LINES 6............................................

Transmitted messages 6..........................................

Received message 8.............................................

Serial line configuration and pin allocations 9.........................

Serial port pin assignments 10......................................

6 NMEA 0183 MESSAGES, DEFINITIONS 11.................

Message description 11............................................

NMEA output from ITI 12.........................................

NMEA Input to ITI 23.............................................

Telegram from Winch Syncro 2020 25...........................

7 NMEA – ABBREVIATIONS, ITI AUX MENU SELECTIONS 26

857-164777 / A

III

Page 8

Simrad ITI

Document logistics

Rev Date Written Checked A pproved

A 23.09.03 GM KRA KRA

B

C

D

(The original signatures are recorded in the company’s logistic database.)

Rev Comments

A Original issue.

B

C

D

To assist us i n making improvements to the product and to this manual, we would welcome

comments and constructive criticism. Please send all such - in writing or by e-mail - to:

Simrad AS

Documentation Department

P.O.Box 111

N-3191 Horten

Norway

IV

or e-mail:

simrad.documentation@simrad.com

857-164777 / A

Page 9

Instruction manual

1INTRODUCTION

Note This document is intended for software engeneers. It is to be used

for writing codes in order to communicate with the ITI system.

With the rapid development of marine electronic devices, it has

become necessary to develop a standardised interface protocol for

exchanging data between devices regardless of the device

manufacturer. The NMEA 0183 standard protocol for interfacing

electronicmarinedeviceshas been implementedin the ITIsystem.

The most common way of connecting electronic equipment is to

use serial lines.

A more powerful way of integrating, is the Ethernet standard with

highersignalling capacity. The softwarerequired to communicate

over the Ethernet is includedi n the ITI system, however a standard

ITI does not include the hardware required.

A dedicated interface/display board containing the Ethernet

hardwa re must be installed.

→ Please refer to the Simrad ITI Installation Manual, Appendix 1

page 3 – 17 for more details.

The ITI system has four serial lines available for external

equipment connection.

→ Please refer to page 6 for more details.

857-164777 / A

1

Page 10

Simrad ITI

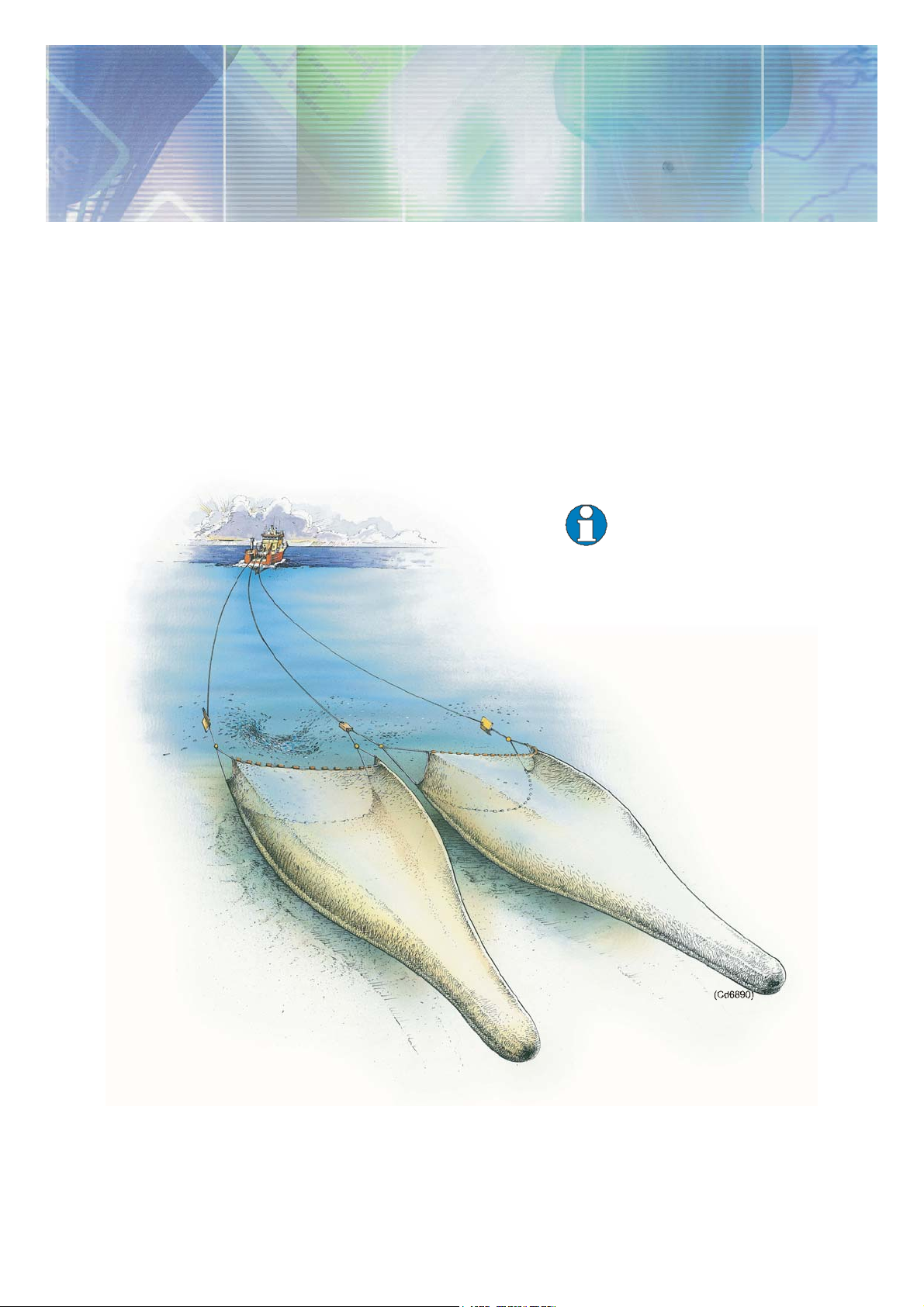

2 ITI TRAWL SYSTEM, BASIC PRINCIPLE

The Simrad ITI wireless trawl positioning and monitoring system

is designedto improvecontrol andefficiency inpelagic andbottom

trawling. Small robust battery powered sensors mounted on the

trawl, transmit important information to the vessel on request.

• The ITI provides the skipper with exact position of the gear and

what is happening in and around the trawl. It also provides all

crucial information for an effective, profitable and responsible

fishing.

• The ITI is a modular system. From a basic unit of one sensor,

the ITI system can be extended to a complete and advanced

instrument package according to the customers requirements.

Trawl Eye

Distance and

Speed sensor

Depth and

Temperature Sensor

Catch Sensor

Simrad’s philosophy is to reduce integration costs and increase the

benefit of our products to let data from the ITI be available for

integration with external equipment like chart plotters, winch

control systems etc.

2

857-164777 / A

Page 11

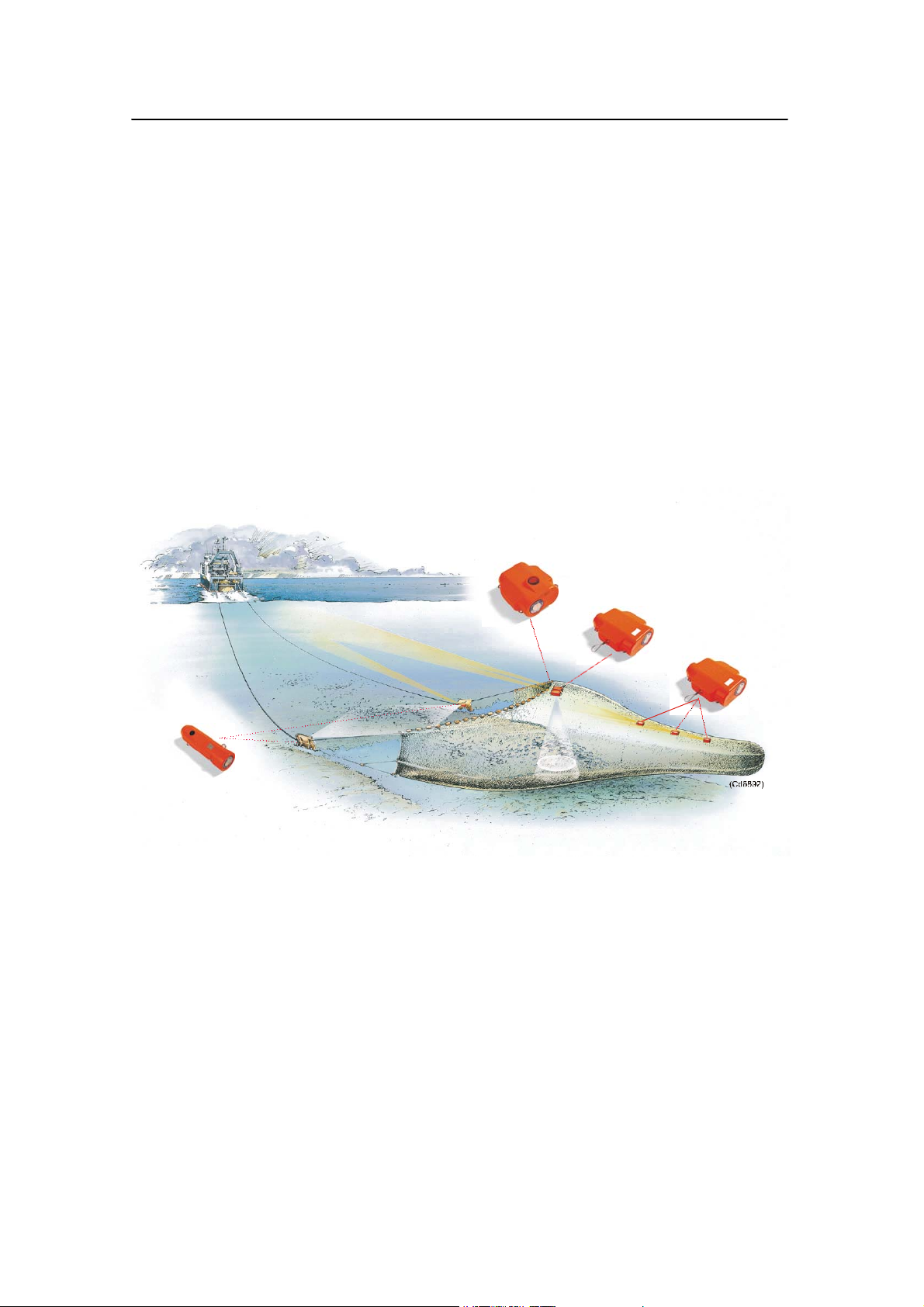

3 ITI GEOMETRY FOR TWIN RIG

Settingup a three wire Twin Rig system is a questionof findingthe

balance point between a number of forces. The adjustment of the

centre warp is very critical. This is one of the reason for the

positioning of the clum p, and hence the balance of forces between

the doors and the warp and sweeps being so critical to get a square

tow.

• The ITI Geometry System provides the skipper with crucial

informationto adjustthe Twin Rig correctlyand henceoptimise

the efficiency of both trawls during the tow.

The ITI Geometry System is based on measurements of the

distance from the vessel to both trawl doors and to the clump. In

addition, the distances between each door and the clump are

measured based on transponders attached to the clump. Based on

these range measurements, the geometry of the Twin Rig is

calculated with high accuracy since all measurementsare relative

to each other.

Instruction manual

310 307 309

28

1.3

30

(Cd6891)

Theclump positionrelative to a straightline betweenthedoorswil l

affect the geometry of the trawl.Toget a square tow, the deviation

from the straight line position should be close to zero.

This is a focus point for the ITI Geometry System. In addition, the

angle between the true course over ground (VTG) and the straight

line between the doors are calculated and displayed.

857-164777 / A

3

Page 12

Simrad ITI

The figure above shows tha t the trawl is 3_ off port side. The doors

and the clump are not lined up correctly with door/clump distances

of 28 and 30 meter. The distances to the trawl doors are 310 and

309 meter and distance to the clump is 307 meters. In order to

obtain maximum door spread and a square tow, the middle wire

should be paid out 1.3 meter.

Note The trawl geometry is comparedto the course over ground showing

_

with 90_being optimum.

94

Both trawl heights are 3,2 meter and the Trawl Eye echogram

shows that the port trawl has good bottom contact but for the

moment , with a few fishes in the opening. One Catch Sensor is

mounted on the port cod end. The trawl is 6:20 min. behind the

vessel, the clump has a light bottom contact ascending 0,4 m/min.

Depth below the vessel is 120 meter and the temperature at the

trawl is 5,8_ C. In addition, heading, speed and Lat./Long. are

displayed.

The ITI Geometry for Twin Rig will be implemented in the ITI

topside software, ve rsion 5.20 or above.

(Cd6 893)

The picture shows a Twin Rig trawl with the Trawl Eye echogram

showing the trawl opening.

4

857-164777 / A

Page 13

4 RESPONSIBILITY

Simrad’s philosophy is to let data from our ITI Trawl System be

available for integration with external equipment like chart

plotters, winch control systems etc. Weare convinced that thiswill

increase the benefit of the product and lead to reduced integration

costs.

The quality of the transmission data depends on:

• sea condition

• dept h

• temperature layers

• multipath

• most important - the noise level from the propeller becauseyou

are receiving the signals from astern.

Compared to serial line data communication channel, the

hydroacoustic transmission channel is far more unstable with data

errors and intermittent interruption of the data transmission as a

result.

Instruction manual

Theappropriatefilteringanddisplayalgorithm usedby Simradfor

displaying the data on a CRT, might not be the optimum for

applic ations, which are using the data as part of input parameters

for controlling or regulating winches etc.

Simrad will therefore emphasise, to any one who are using the ITI

data, to design an application specific filtering and adding

”artificial intelligence” to the use of- and interpreting the data

received.

We will not involve ourselves in applications using our data but

any user will have access to the data from the ITI as described in

this manual. If special agreements are made,Simradcan supply log

files recorded during actual towings for test and simulation

purposes.Beyond that, Simrad have limitedcapacity to assist users

of the ITI data in their application.

The use of the ITI data is t he users responsibility and Simrad

disclai m responsibility for any consequences of using data from

the ITI.

857-164777 / A

5

Page 14

Simrad ITI

5 SERIAL LINES

The ITI system has four (female) serial ports, A, B C and D. All

message transferred via these serial lines are basedon the NMEA

0183 format protocol.

ETHERNE T REMOTE CONTROL MONITO R

B

(Cd4346)

C

D

TD-L TD-R

A

230 V mains supply

CE NTRO NIX

Gyro-compass,

l og, etc.

Port A, C and D have the following dedicated functions:

• Port A for connection to an echo sounder

• Port C to a sonar

• Port D to a navigator.

Port B is dedicated for:

• Auxiliaryequipment like Winch control system, Track plotter,

data l ogger etc.

If port C is not used by the sonar the port might be used for optional

output of the Trawl position (GLL) to an auxiliary plotter. PortA,

B and C have two-way communication while port Donl y has input

data. All four serial lines can receive telegrams without being

activated from the menu.

Ports A, B and C must be activated from the menu before any

messages being transmitted.

Transmitted messages

A NMEA telegram will be transmitted when its data has been

updated. Each individual parameter available on the serial line B

(AUX) can be turned ON or OFF from the menu.

Individual param eters can not be set ON or OFF on serial lines A

and C. These two serial lines have been allocated for interfacing

to Echo sounder and Sonar respectively, and al l parameters on any

of these two lines are either activated or not activated.

No parameters are transmitted out on serial port D.

6

857-164777 / A

Page 15

Instruction manual

Serial line D

Navigator

Serial line A

Echosounder

$IIDBS

@IIHFB

@IIHB2

$IIZDL

Serial line B

Aux

@IITDS

@IITS2

@IIHFB

$IIMTW

@IITFI

@IITPT

@IITPC

@IITTS

$IIGLL

$IIVTG

$SDDBS

$IIDBS

@IIHB2

@IIDAD

$PSIMT

$PSIMTH

$PSIMMW

$PSIMS1

$PSIMS2

$IIZDA

$PSIMH1

$PSIMH2

$PSIMG1

$PSIMG2

$PSIMCA

$PSIMDE

$PSIMTM

Serial line C

Sonar

@IITDS

@IITS2

@IIHFB

$IIMTW

@IITFI

@IITPT

@IITPR

$IIDBS

@IIDAD

@IIHB2

Ethernet

Aux

@IITDS

@IITS2

@IIHFB

$IIMTW

@IITFI

@IITPT

$IIGLL

@IIDAD

@IIHB2

@IITPC

857-164777 / A

Table 1 Transmitted messages

Table 1 shows the different parameters that can be transmitted by

ITI when activated in the menu.In addition,all messagesreceived

on serial line B can be transferred out on Ethernet.

This transfer facility is activated from the command:

NMEA TRANSFER.

Optiona lly $IIGLL (trawl posit ion) is available on Port C. This

require the parameter TEST2 to be set to 8 (Menu /

SYSTEMSETUP / TRAWL EYE), and is then independent on

whether SONAR OUTPUT has been activated.

7

Page 16

Simrad ITI

Received message

All messages listed in table 2 can be received at any time without

acti vating them from the menu. As described above, by settingthe

NMEA TRANSFER command to ON, all messages received on

Ethernet will be transmitted out on serial port B, and vice versa.“-

-” means any character will be accepted.

Serial line D

Navigator

$----GLL

$----VTG

$----ZDA

Serial line A

Echosounder

$SDDBS

$----DBT

Serial line B

Aux

$----GLL

$----VTG

$SDDBS

$----DBT

$----HDT

$----HDM

$----HDG

$----ZDA

@SSTPP

@TAWWL

@TAWWT

$WMSYN

Serial line C

Sonar

$----HDT

$----HDM

$----HDG

@SSTPP

Table 2 Received messages

Ethernet

Aux

$----GLL

$----VTG

$SDDBS

$----DBT

$----HDT

$----HDM

$----HDG

$----ZDA

@SSTPP

@TAWWL

@TAWWT

$WMSYN

8

857-164777 / A

Page 17

Instruction manual

Serial line configuration and pin allocations

→ Refer to drawing no. 824-108590, ITI Installation manual.

The four seri al port (fe male) connectors are found on the

transceiver unit plug panel, located in the bottom of the cabinet.

The serial lines can be configured electrically as follows:

• Port A can be configured as RS-232 or RS-422.

• Ports B and C are standard RS-232 serial lines only.

• Port D can be configured as RS-232, RS-422 or current loop.

Table 3 gives an overview of the different ways of configuring the

serial lines electrically, and the dedicated use of each line.

Port

Possible

ITI port allocation Format

configurations

A RS-232 Echo sounder NMEA 0183

B RS-422 - Winch control

NMEA 0183

- Track plotte r

- Data logge r

C RS-232 Sonar NMEA 0183

D - RS-232

-- RS-422

-- 20 mA Current loop

Navigator NMEA 0183

Table 3 Possible serial port configurations and allocations

→ Refer to the ITI installation manual for further information

regarding configuration port A and D.

857-164777 / A

9

Page 18

Simrad ITI

Serial port pin assignments

The ITI system is designed to communicate over serial interfaces

where control signals are not required. The connectors in the

cabinetare femaleand requirea maleconnectorfor the serialcable.

Table 4 shows the pin assignments for port B (and C) available on

the ITI transceiver cabinet.

Pin

Name Description

1

2

3

RX DA2

TX DA2

Receive data RS-232 NMEA RX A

Transmit data RS-232 NMEA TX A

4

5

GND

Signal ground RS-232 NMEA RX/TX B

6

7

8

RT SA2

CT SA2

Request to send RS-232

Clear to send RS-232

9

Table 4 Pin assignments - ports B and C

Note The RS-232 inputs of port A-D do not meet the optoisolation

requirements of the NMEA standard and precautions should be

taken thereafter.

→ Refer to the ITI Installation manual for pin assignments of port A

and D.

10

857-164777 / A

Page 19

Instruction manual

6 NMEA 0183 MESSAGES, DEFINITIONS

Messages transmitted and received on serial lines or Ethernet are

all base d on the NMEA 0183 data format protocol.

The main characteristics are as follows:

• RS-422A asynchronous serial line

• 4800 baud

• 8 data bits

• No parity

• One or more stop bits

• All data coded in ASCII code

• Optional ”X-OR” checksum

All messages start with either; “$” or “@”.

Telegram s starting with “$” do fully comply with the NMEA 0183

data form at protocol.

• All other telegrams are in accordance with an old proprietary

“Simrad standard.” They start with @, but otherwise they

follow the main characteristics listed below.

• The next two letters (Talker identifier) indicate which system

is transmitting the messages. Simrad ITI System uses II as a

talker identifier.

• The next three lettersindicate the type of message. The telegram

may consist of many data fields separated by commas. A field

may be empty, and then only the separating commas are

transmitted, also called nullfields.

• Each message ends with <cr>(Carriage Return) and <lf> (Line

Feed). For all message starting with ”$” the checksum *hh is

included in compliance with version 2.20 of the NMEA 0183

standard, - no checksum on ”@” sentences.

Throughout this document, all telegrams with II as the Talker

identifier, and telegrams with the proprietary code PSIM,are

originated by ITI and transmitted to other equipment. All

telegrams with other Talker identifiers are received by ITI from

external equipment.

Message description

Below you will find the message description for IT I topside

software version 5.30 or above. The different types of telegrams

are not listed in consecutive order.

Note The *hh check sum, <cr> carriage return and <lf> line feed are

not described for each sentence.

857-164777 / A

11

Page 20

Simrad ITI

NMEA output from ITI

$IIVTG,,,xxx,M,yy.y,N,,*hh<cr><lf>Ve ssel course and speed

→ requires input from a nav. Receiver.

VTG represents the Vessel Track over t he Ground.

xxx,M is the track be aring, in degre es magnetic.

yy.y,N is the speed i n knots relative to ground.

$IIZDA,hhmmss.ss,dd,MM,yyyy,xx,xx*hh<cr><lf> Time & Date of ITI

→ equals UTC±5 seconds if GPS connected.

hh is the hours

mm is the minutes

ss.ss is the seconds and par ts of seconds

dd is the day’s date

MM is the month

yyyy is the year

xx,xx is the local time zone (hh,mm)positive offset east ofGreenwich.

@IITPT,xxxx,M,y,P,zzzz.z,M<cr><lf> Trawl Position True vessel

TPT represents the True Trawl Position relative to the vessel.

xxxx,M is the horizonta l range in metres to the target (0 - 4000 m).

- requires an active depth sensor on the trawl or manual set

depth, if not the slant range will be presented.

yyy,P Is the true bearing to the target (i.e. relative to north).

(Resolution 1°.)

- requires gyro input for reliable data.

zzzz.z,M is the depth in metres of trawl below the surface (0 - 2000 m).

- requires an active depth sensor on the trawl or manual set

depth, if not the depth field will be empty.

12

857-164777 / A

Page 21

Instruction manual

@IITPC,x,M,y,M,z,M<c r><lf>Trawl Position in Cartesian co-ordinates

TPC represents the Trawl Position in Cartesian co-ordinates.

x,M isthe horizontal distancein metresfrom vesselcentre line.Value

is positive if trawl is on starboard side, negative if on port side.

- requires an active depth sensor on the trawl or manual set

depth, if not the slant range will be presented.

y,M is the horizontal distance in metres from the transducer to the

trawl along the vessel’s centre line. The value will normally be

positive as the trawl is usually behind the vessel.

- requires an active depth sensor on the trawl or manual set

depth, if not the slant range will be presented.

z,M is the depth of the trawl in metres below the surface. the value is

normally positive.

- requires an active depth sensor on the trawl or manual set

depth, if not the depth field will be empty.

$IIGLL,ddmm.hhh,N,dddmm.hhh,W ,hhmmss.ss,A*hh<cr><lf>

Trawl Position in Latitude and Longitude

GLL represents the trawls Geographical Latitude and Longitude.

- requires GLL input from a nav. Receiver.

ddmm.hhh,N is t he Latitude, Deg.Min.Hundredths, N=North, S=South.

dddmm.hhh,W is the longitude, Deg.Min.Hundredths, W=West, E=East.

hhmmss.ss UTC of position (time stamp, fraction of seconds void).

- requires ZDA input from GPS for accurate timestamp.

A valid

- never invalid, terminates output after one minute without

GLL input from a nav. Receiver.

$IIDBS,,,xxxx.x,M,,*hh<cr><lf>Depth of trawl Below Surface

DBS represents Depth of the trawl Below the Surface.

857-164777 / A

xxxx.x,M i s the depth in metres (0 - 2000). The fields for depth in feet and

fathoms are empty.

- requires an a ctive depth sensor on the trawl.

13

Page 22

Simrad ITI

$IIMTW,-xx.x,C*hh<cr><lf> Water t emperature at the trawl

MTW represents the Meteorological Temperature in the Water.

xx.x is the water temperature (° C) measured at the trawl.

(Sign prefix only if minus.) Range from -5° Cto+30° C.

C means the value is in ° Celsius.

- requires an a ctive temperature sensor on the trawl.

@IIHFB,x.x,M,y.y,M <cr><lf>

Trawl Headrope to Footrope and Bottom (Trawl Eye/Height sensor 1)

HFB represents the distances from the Headrope to the Footrope and

Bottom.

x.x,M i s the distance in metres from headrope to footrope (0 - 100 m).

y.y,M is the distance in metres from headrope to bottom (0 - 100 m).

@IIHB2,x.x,M,y.y,M<cr><lf>

Trawl Headrope to Footrope and Bottom (Height sensor 2)

HB2 representsthe distances from the Headrope to the Footrope and

Bottom.

x.x,M isthe distance in metres from headrope to footrope (0 -- 100m).

y.y,M is the distance in metres from headrope to bottom (0 -- 100 m).

@IITDS,x.x,M<cr><lf> Trawl Door Spread 1

TDS represents the Trawl Door Spread 1 distance.

x.x,M i s the spread distance in metres (0 - 300 m)

- if invalid, nullfields will be transmitted

- filtered values if sensorfilter is on.

@IITS2,x.x,M<cr><lf> Trawl Door Spread 2

TS2 represents the Trawl Door Spread 2 distance.

x.x,M i s the spread distance in metres (0 -300 m)

- if invalid, nullfields will be transmitted

- filtered values if sensorfilter is on.

14

857-164777 / A

Page 23

Instruction manual

$PSIMTH,x.x,M,y.y,M*hh<cr><lf>

Trawl Headrope to Footrope and Bottom (Trawl Eye/Height sensor 1)

TH represents the distances from the Headrope to the Footrope and

Bottom.

x.x,M i s the distance in metres from headrope to footrope (0 - 100 m).

y.y,M is the distance in metres from headrope to bottom (0 - 100 m).

$PSIMTE,xx%y,xx%y,xx%y,xx%y,xx%y,xx%y,xx%y,xx%y,xx%y,xx%y,a,x.x,M,

Gx,gx,Vx.x *hh<cr><lf> Trawl Eye, Echo telegram, fish detection

TE carries the echo readings from fish detection and the sensor set

up parame ters (type of trawl, range gain etc).

x.x% per cent of samples above threshold for the 10 echo cells.

y average level (1-7) of the xx %. Data skipped if cell is empty or

not avai lable.

a B/P Bottom/Pelagic 10 cells. b/p: bottom/pelagic 5 cells.

x.x,M total range, 2,5 – 50 m of fish detection range.

Gx Gain setting, coarse.

gx g1 – g7 gain setting fine.

Vx.x Version of Trawl Eye Sensor software.

857-164777 / A

15

Page 24

Simrad ITI

$PSIMSn,xxxx,M,xxxx,M,yyy.y,T,xxx.x,M,hhmmss*hh<cr><lf>

nn=1Spread1 (port trawl door when Twin Rig)

n=2 Spread2 (starboard trawl door when Twin Rig)

xxx,M slant range in m etres to sensor

- filtered values

- decimals not used.

xxx,M horizontal range in metres to sensor

- unfiltered values

- nullfields if depth-sensor not activated (will calculate

horizontal range with manual set de pth)

- decimals not used.

yyy.y,T true bearing (deg.rel.north) to sensor

- requires gyro input for reliable data.

xxx.x,M spread measurement in metres (door to door or door to middle

weight)

- if invalid values nullfields will be transmitted

- filtered values if sensorfilter is on.

hhmmss time of transmission (time of Spread interrogation)

- requires ZDA input from GPS for accurate timestam.

$PSIMHn,xxxx,M,xxxx,M,yyy.y,T,zz.z,M,zz.z,M,hhmmss*hh<CR> <LF>

n -n=1height 1 sensor or trawl eye

-n=2height 2 sensor

xxxx,M Slant range in meters to sensor

- filtered values

- decimals not used.

xxxx,M horizontal range in m etres to sensor

- unfiltered values

- nullfields if depth-sensor not activated (will calculate

horizonta l range with manual set depth

- decimals not used.

yyy.y,T true bearing (deg.re l.north) to sensor

16

- requires gyro input for reliable data.

zz.z,M height in metres from headrope to footrope, 0 - 50 m.

zz.z,M height in metres from headrope to bottom, 0 - 100 m

- if invalid values nullfields will be transmitted.

857-164777 / A

Page 25

$PSIMGn,xxxx,M,xxxx,M,yyy.y,T,yz.z,D,hhmmss*hh<CR><LF>

n n=1 grid 1 sensor

n=2 grid 2 sensor

xxxx,M slant range in metres to sensor

- filtered values

- decimals not used.

xxxx,M horizontal range in m etres to sensor

- unfiltered values

- nullfields if depth-sensor not activated (will calculate

horizonta l range with manual set depth

- decimals not used.

yyy.y,T true bearing (deg.re l.north) to sensor

- requires gyro input for reliable data.

Instruction manual

zz.z,D angle of grid, 0-90 degrees

- if invalid values nullfields will be transmitted.

$PSIMCA,xxxx,M,xxxx,M,yyy.y,T,x,y,z ,hhmmss*hh<CR><LF>

CA catch sensor (bearing and range only to activated sensor with

lowest number).

xxxx,M slant range in m etres to sensor

- filtered values

- decimals not used.

xxxx,M horizontal range in metres to sensor

- unfiltered values

- nullfields if depth-sensor not activated (will calculate

horizonta l range with manual set depth

- decimals not used.

yyy.y,T true bearing (deg.rel.north) to sensor

- requires gyro input for reliable data.

x catch1 sensor: 0=off, 1=on, 2=not a ctivated/no answer.

857-164777 / A

y catch2 sensor: 0=off, 1=on, 2=not a ctivated/no answer.

z catch3 sensor: 0=off, 1=on, 2=not activated/no answer.

17

Page 26

Simrad ITI

$PSIMDE,xxxx,M,xxxx,M,yyy.y,T,zzzz.z,M,a,hhmmss*hh<CR> <LF>

DE depth sensor

x.x,M slant range in m etres to sensor

- filtered values

- decimals not used.

x.x,M horizontal range in metres to sensor

- unfiltered values

- nullfields if depth-sensor not activated (will calculate

horizonta l range with manual set depth

- decimals not used.

y.y,T true bearing (deg.rel.north) to sensor

- requires gyro input for reliable data.

zzzz.z,M water depth in metres, 0-2000 metres

- if invalid values nullfields will be transmitted.

a Indicate the menu selected position of the sensor

a=p port , a=c centre, a=s starboard.

$PSIMTM,xxxx,M,xxxx,M,yyy.y,T,zz.z,C,a,hhmmss*hh<CR><LF>

TM temperature sensor

xxxx,M slant range in m etres to sensor

- filtered values

- decimals not used.

xxxx,M horizontal range in metres to sensor

- unfiltered values

- nullfields if depthsensor not activated(will calculate

horizonta l range with manual set depth

- decimals not used.

yyy.y,T true bearing (deg.rel.north) to sensor

- requires gyro input for reliable data.

zz.z,C water temperature in -5 to 30 degrees Celsius

- if invalid values nullfields will be transmitted.

18

a Indicate the menu selected position of the sensor

a=p port, a=c centre, a=s starboard.

Ac ombi sensor (depth/temperature) will generate boththe DE and

TM sentences. The temperature, depth or combi sensor must be

used to show the range t o the remote spread sensor if the geometry

of the trawl system shall be calculated.

857-164777 / A

Page 27

Instruction manual

$PSIMMW,xxxx.x,M,xxxx.x,M,yyy.y,T,z.z,M,y.y,D,c,hhmmss*hh<cr><lf>

xxxx.x,M slant range in m etres to middle weight (clump)

- filtered values.

xxxx.x,M horizontal range in metres to middle weight

- unfiltered values

- nullfields if depth-sensor not activated (will calculate

horizonta l range with manual set depth).

yyy.y,T true bearing (deg.rel.north) to middle weight

- requires gyro input for reliable data.

z.z,M signed deviation in metres (if deviation positive, then middle

weight further out than door-door line)

- an offset to the deviation may be set in the trawlsetup in order

toget the deviationnearzero whenthetrawlgeometryis ideal.

A positive offset will shorten the mid weight wire

- a mid weight filter, filtering the signed deviation, is found in

the trawl setup.

About the mid weight filter:

- the mw filter calculates from unfiltered horizontal ranges for

mw filter setting of 1 to 5 and if active depth sensor on trawl

- the mw filter calculates from filtered horizontal ranges for

mw filter setting of 6 to 10 and active depth sensor on trawl

- the mw filter calculates from filtered slant ranges if no active

depth sensor on trawl.

y.y,D “starboard angle” between true GPS course (or heading if no

GPS) and the “Door-Door Line” of the trawl (0° < y.y < 180°).

c status of data, primarily middle weight deviation status

A: OK

B: OK but ambiguous

(± on deviation, presented range complies with positive

deviation, i.e. the larger range possibility)

C: Uncertain (angle based calculations)

D: Uncertain and ambiguous

E: Invalid data, require d sensors not active

V: Invalid data, throw away

857-164777 / A

W: Invalid and ambiguous.

hhmmss time of transmission

(time of Middle weight deviation calculations)

- requires ZDA input from GPS for accurate timestamP.

19

Page 28

Simrad ITI

Note $PSIMMW will be sent when clumppositionundated, only.Update

of the new angle parameter due only to change of course, is not

supported!

@IITFI,x,y,z<cr><lf> Trawl Filling

TFI represents Trawl Filling.

x,y,z are the catch 1, 2 and 3 messages

(off = 0, on = 1, no answer = 2).

@IITTS,x,M,y,P,z,M<cr><lf> Trawl To Shoal distance

TTS represents the Trawl To Shoal distance.

x,M is the horizontal distance i n metres from the trawl to the shoal in

a direction normal to the vessel’s centre line. The value will be

positive if the shoal is on the starboard side of the trawl,

otherwise negative.

y,M is the horizontal distance in metres from the trawl to the shoal is

thedirectionof the vessel’s centre line. The value willbepositive

if the shoal is ahead of the trawl, negative if the shoal is behind

the trawl.

z,M is the vertical distance in metres from the tra wl to the shoal. The

value will be positive if the trawl is above the shoal, negative if

the tra wl is below the shoal. The sign will be shown only if the

value is negative.

Note This sentence requires the @SSTPP sente n ce from a scanning

sonar, an active depth sensor on the trawl and gyro input on both

sonar and ITI.

$SDDBS,x.x,f,y.y,M,z.z,F*hh<cr><lf> Sounder Depth Below Surface

SD represents Sounder Depth.

DBS represents Depth of water Below Surface.

x.x,f is the depth in feet.

y.y,M is the depth in metres.

20

z.z,F is the depth in fathoms

- only depth in meters will be transmitted

- this is a filtered copy of external echosounders depth.

857-164777 / A

Page 29

Instruction manual

@IIDAD,x.x,M,x.x,M<cr><lf> Depth of trawl Ascend/Descend

DAD represents Depth Ascend Descend.

x.x,M represents Depth of trawl in metres.

x.x,M represents change of depth in metres per minute, negative

number if a scending.

Note This sentence requires an active depth sensor on the trawl.

$IIZDL,hhmmss.ss,x.x,a*hh<cr><lf> Time and Distance to Variable Point

→ The point is here the position sensor on the trawl which normally

is the mid weight sensor on double traw l.

hhmmss.ss Time t o point, 00 to 99 hours minutes and seconds.

x.x distance to point in nautical miles.

a type of point.

C: Collision

T: Turning point

R: Reference/general -usedbyITI

W: Wheelover

857-164777 / A

21

Page 30

Simrad ITI

An example of NMEA output from port B:

@IITPT,3089,M,175,P,0375.5,M

@IITPC,00162,M,3085,M,0375,M

@IIHFB,007.6,M,012.0,M

$PSIMTH,007.6,M,012.0,M*19

$IIGLL,5924.462,N,01030.048,E,062216,A*38

@IITTS,-0154,M,03256,M,-0121,M

$IIVTG,,,358,M,03.7,N,,*62

$IIZDA,062216.00,02,01,1999,01,00*7B

@IIHB2,008.7,M,008.8,M

@IITDS,105.5,M

$PSIMS1,3021,M,2998,M,177.0,T,105.5,M,062217*5A

@IITS2,118.9,M

$PSIMS2,3021,M,2998,M,172.6,T,118.9,M,062218*55

@IITFI,1,1,0

@IIDAD,0375.6,M,-001.9,M

$IIMTW,03.5,C*15

$PSIMMW,3018.3,M,2996.3,M,174.9,T,0000.8,M,A,062220*7C

$SDDBS,,,0187.5,M,,*1A

$IIDBS,,,0375.6,M,,*01

$PSIMTE,,29%4,60%3,98%7,97%7,,97%6,97%4,97%2,46%1,B,8.0,M,G1,g7,V3.08*52

$PSIMH1,1557,M,1512,M,189.9,T,008.1,M,015.0,M,143842*25

$PSIMH2,1557,M,1512,M,189.9,T,007.0,M,015.0,M,143843*29

$PSIMS1,1556,M,1511,M,193.1,T,090.2,M,143844*5C

$PSIMDE,1557,M,1512,M,189.9,T,0372.0,M,c,143847*4F

$PSIMTM,1558,M,1513,M,189.9,T,03.9,C,s,143849*45

22

857-164777 / A

Page 31

Instruction manual

NMEA Input to ITI

$SDDBS,x.x,f,y.y,M,z.z,F*hh<cr><lf> Sounder Depth Below Surface

SD represents Sounder Depth.

DBS represents Depth of water Below Surface.

x.x,f is the depth in feet.

y.y,M is the depth in metres.

z.z,F is the depth in fathoms.

Note Only one of the depth values is required.

$--DBT,,,y.y,M,,*hh<cr><lf> Sounder Depth Below Transducer

-- Means: accept any combination.

DBT represents the Depth of water Below the Transducer.

x.x,M is the depth in metres.

@SSTPP,x,M,y,P,z,M,nn*hh<cr><lf> Position of target or marker

SS represents Receive from Scanning Sonar.

TPP represents Target Position in Polar co-ordinates.

x,M is the horizontal range in metres to the target.

y,P is the bearing to the target relative to the vessel’s heading

- requires gyro input on both Sonar and ITI for reliable data.

z,M is the target’s depth in metres below the surface.

nn is the target identificationcode: 0 means echo target tracked, 10

means position tracked.

$--GLL,ddmm.hh,N,dddmm.hh,W*hh<cr><lf> Geographical position

-- is the code for the type of system used. -- will be OM if Omega,

LC if Loran-C, GP if GPS, DE if decca etc.

GLL represents Geographical Lat itude, Longitude.ddmm.hh,N is the

latitude position in Deg.Min.Hundredths, N=North, S=South.

dddmm.hh,W is the longitude position, Deg.Min.Hundredths, W=West,

E=East.

Note The ITI system will only use the ZDA sentence for time input.

857-164777 / A

23

Page 32

Simrad ITI

$--VTG,,,x.x,M,y.y,N,,*hh<cr><lf> Vessel course and speed

-- is the code for the type of system used. -- will be OM if Omega,

LC if Loran-C etc.

VTG is the abbreviation for Vessel Track Ground.

x.x,M is the track be aring, in degre es magnetic.

y.y,N is the speed, with resolution 0.1 knots.

@TAWWL,x,M,y,M<cr> <lf> Winch Wire Length

TA is the identification code.

WWL represents Winch Wire Length.

x,M is the wire lengt h to starboard trawl door, resolution 1 m.

y,M is the wire length to the port trawl door, resolution 1 m.

@TAWWT,x.x,T,y.y,T<cr><lf> Winch Wire Tension

TA is the identification code.

WWT represents Winch Wire Tension.

x.x,T is the starboard wire tension, resolution 0.1 ton.

y.y,T is the port wire tension, resolution 0.1 ton.

$--ZDA,hhmmss.ss,dd,MM,yyyy,xx,xx*hh<cr><lf>Time & Date

hh is the hours.

mm is the minutes.

ss is the se conds and parts of seconds.

dd is the day’s date.

MM is the month.

yyyy is the year.

xx is the local time zone etc. (not used by ITI).

Note The ITI system will not use other sentences than the ZDA sentence

for time input.

$--HDM,x.x,M*hh<cr><lf> Heading, Magnetic

x.x,M is the heading i n degrees magne tic.

24

857-164777 / A

Page 33

Instruction manual

$--HDT,x.x,T*hh<cr><lf> Heading, True

x.x,T is the hea ding in degrees relative to true north.

$--HDG,x.x,,,,*hh<cr><lf> Heading, Deviation & Variation

x.x this is the magnetic sensor hea ding, in degrees.

Telegram from Winch Syncro 2020

This telegram carries the length of trawl wires as measured at the

winches.

Though the sentence is not an approved NMEA 0183 sentence, its

format complies with most of the “NMEA rules”.

$WMSYN,xxx.x,c,xxx.x,c,xxx.x,c,xx.x,T,xx.x,T,xx.x,T*hh<cr><lf>

Port Wire Tension [tons]

Mid Wire Tension [tons]

Starboard Wire Tension

[tons]

m - meter, F - Fathom, f - feet

Port Wire Length

Mid Wire Length

Starboard Wire Length

(Cd6887 )

Sentence identifier

Note The ITI will not present the mid wire tension and mid wire length

References:

National Marine Electronic Association NMEA0183.

Standard for interfacing marine electronic devices.

Version 2.20, January 1, 1997.

857-164777 / A

25

Page 34

Simrad ITI

7 NMEA – ABBREVIATIONS, ITI AUX MENU

SELECTIONS

In the AUX menu sel ections only the NMEA start code are

indicated.

The different codes with comments are as follows:

IIZDA

IIGLL Geographical position of trawl

IITPT Trawl position true vessel

IIMTV Water temperature at the trawl

IIHFB Distance trawl headrope to footrope and bottom,

PSIMTH Distance tr awl headrope to footrope and bottom, Trawl Eye,

IIHB2 Height 2

IITDS +IITS2 Trawl door spread Sensor1 and Sensor2

PSIMS1 +

PSIMS2

IITFI Trawl filling

IITPC Trawl position in Cartesian coordinates

IITTS Trawl to shoal distance

IIVTG Vessel course over ground and speed

Time & date of ITI system

Height Sensor 2

Height Sensor 1

Range, bearing and distance Spread 1 and Spread 2

IIDBS Depth of trawl below surface

IIDAD Depth Ascend / Descend

SDDBS Sounder depth below surface

PSIMTE Trawl Eye, echo readings and sensor setup

PSIMMV Range, bearing, signed deviation and status Middle weight

26

857-164777 / A

Page 35

Page 36

E 2003 Simrad AS

ISBN 82-8066-013-5

Simrad AS

Strandpromenaden 50

Box 111

N-3191 Horten

Telephone: +47 33 03 40 00

Facsimile: +47 33 04 29 87

A L W A Y S A T T H E F O R E F R O N T O F T E C H N O L O G Y

Loading...

Loading...